Dynamic Propagation and Electro-Mechanical Characteristics of New Microcracks in Notched Coal Samples Studied by the Three-Point Bending Test System and AFM

Abstract

:1. Introduction

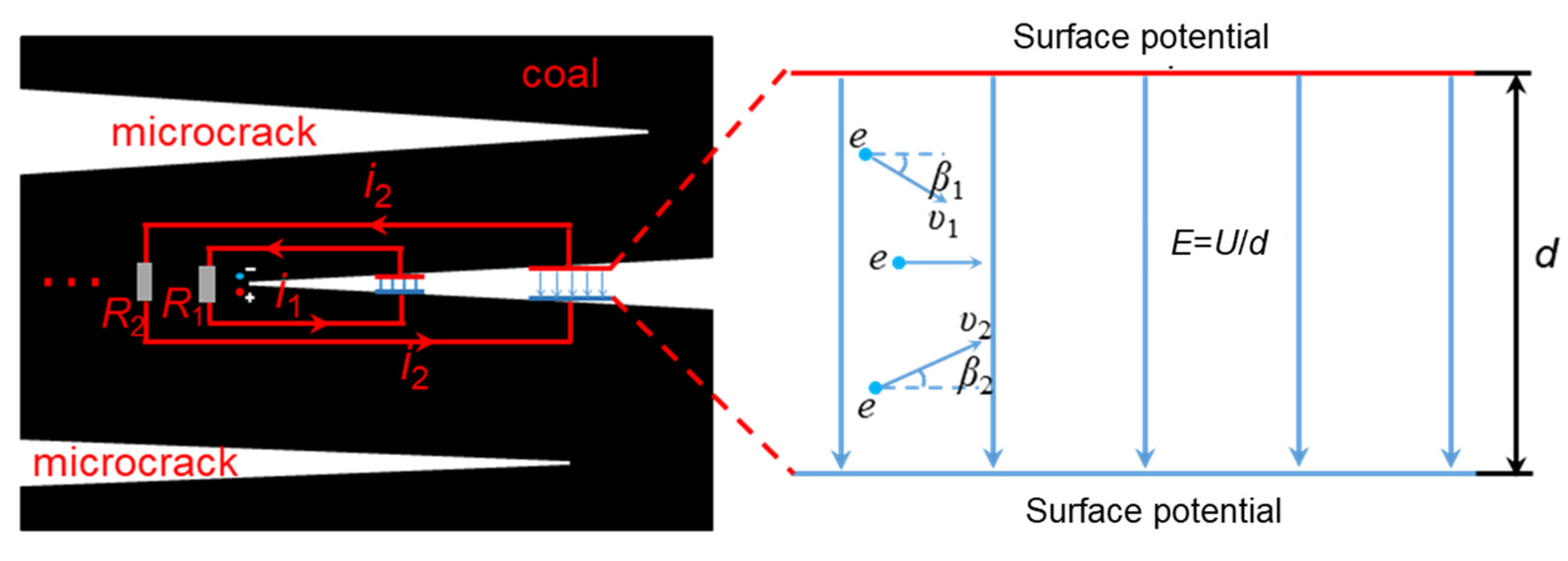

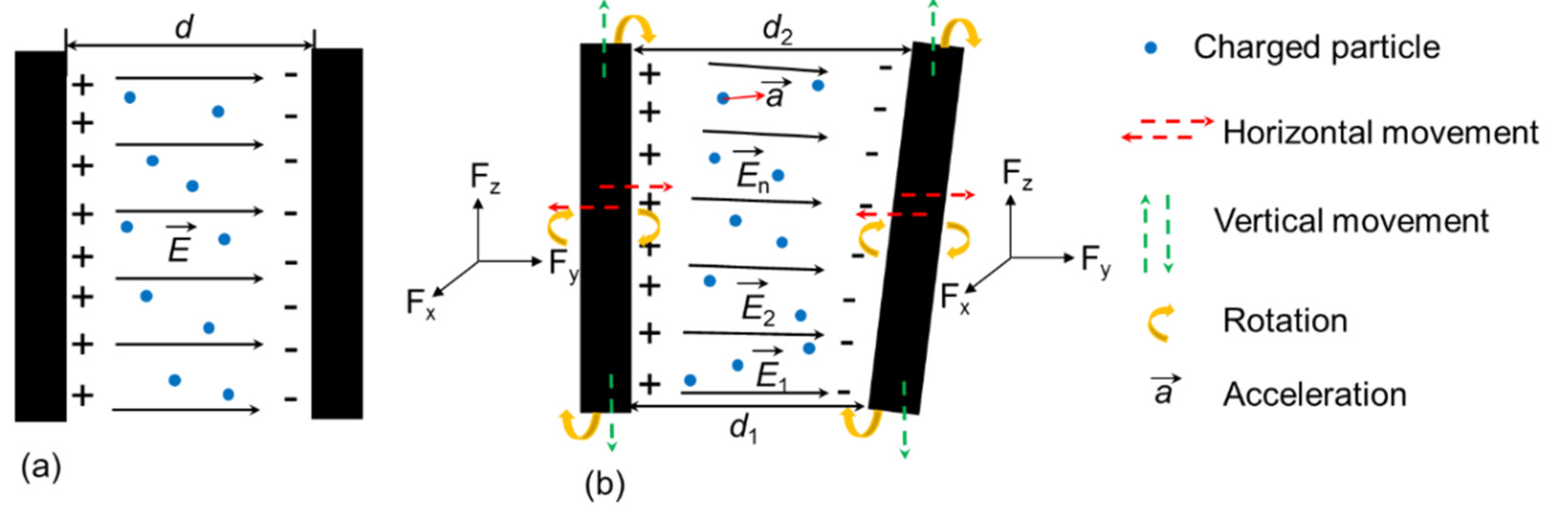

2. Theory of EMR

3. Materials and Methods

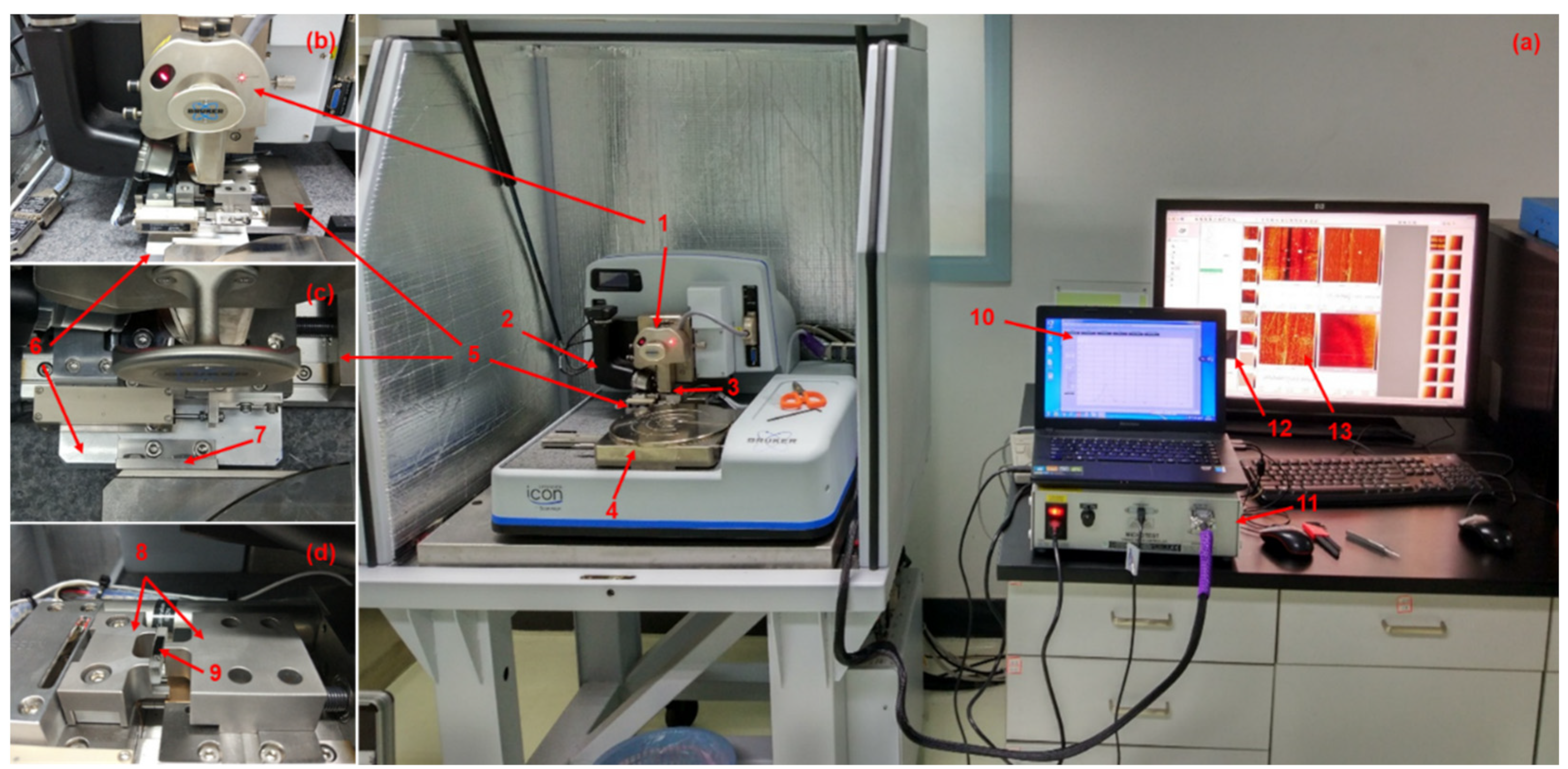

3.1. Construction of the Microdynamic Loading Test System

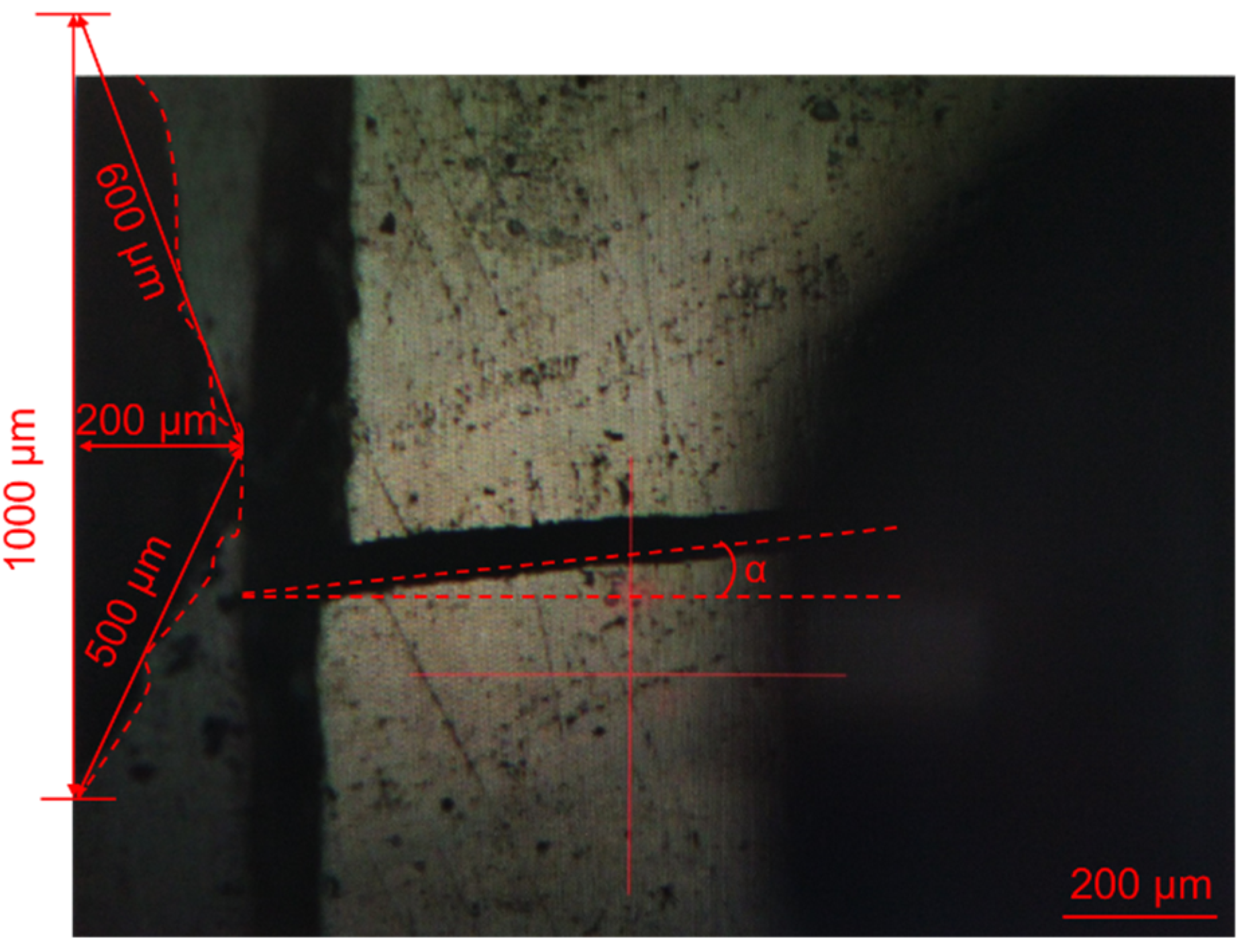

3.2. Sample Preparation

3.3. Experimental Setup and Procedure

4. Results

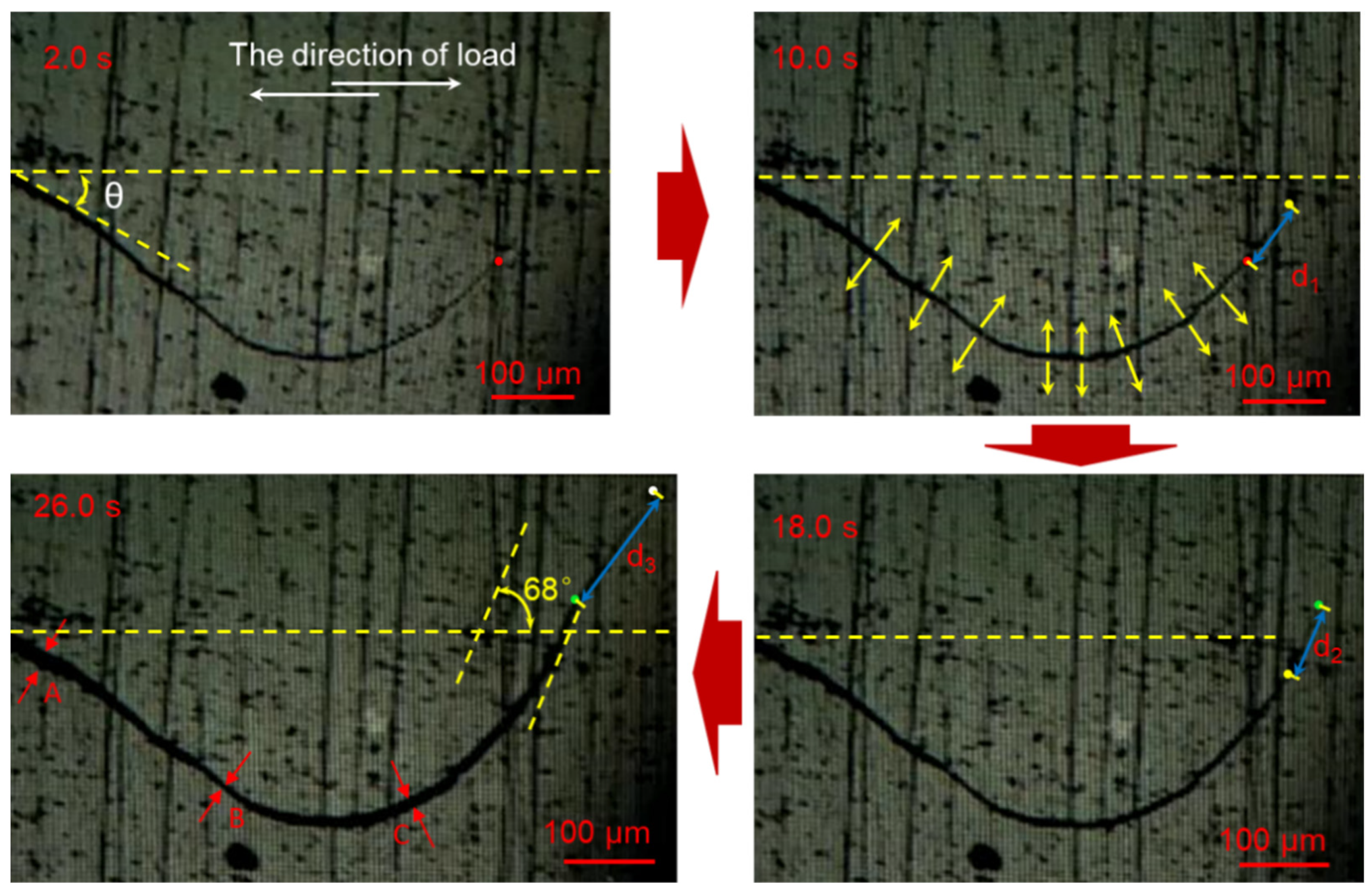

4.1. Characteristics of Microcrack Dynamic Propagation

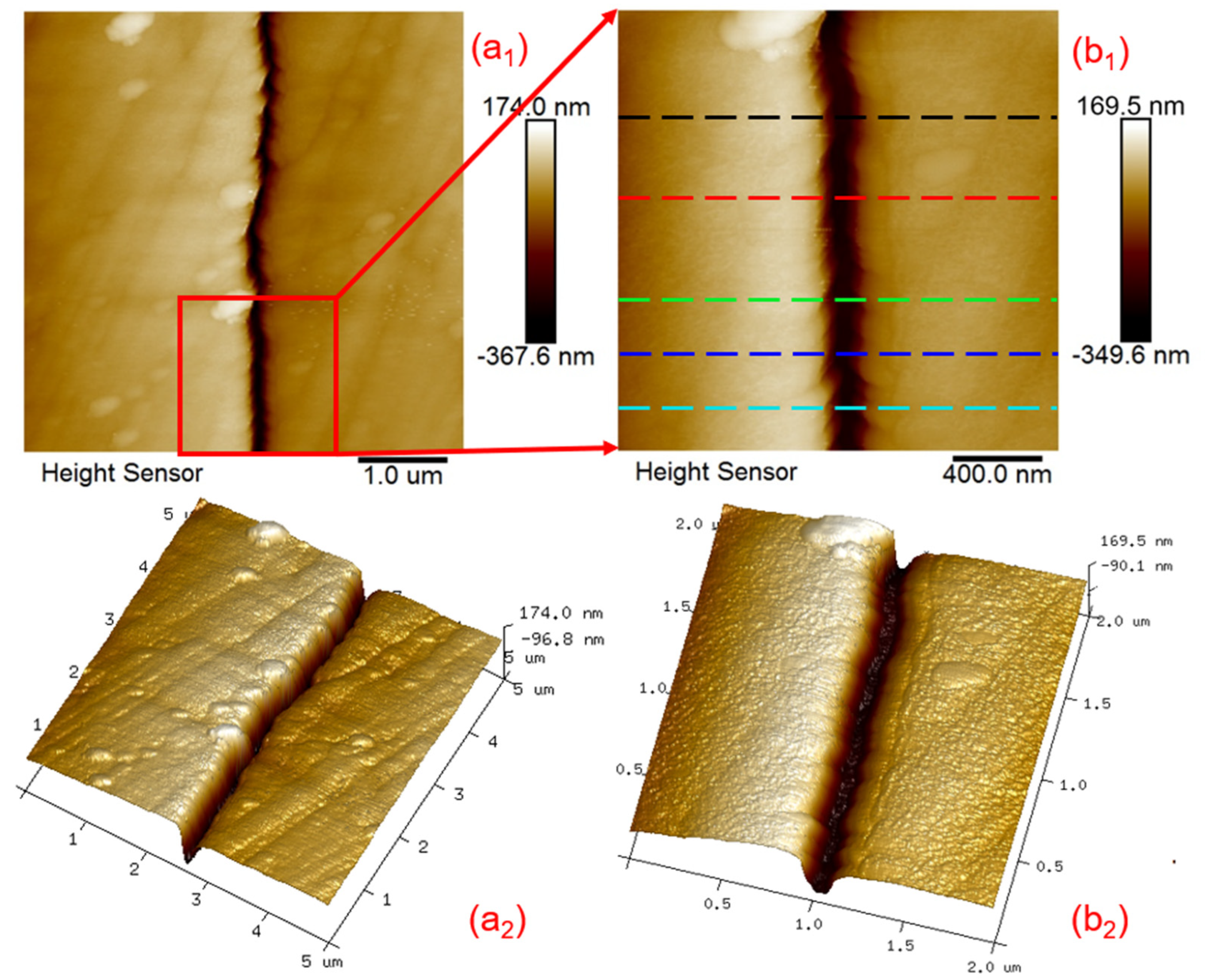

4.2. Characteristics of New Microcracks and Surface Morphology

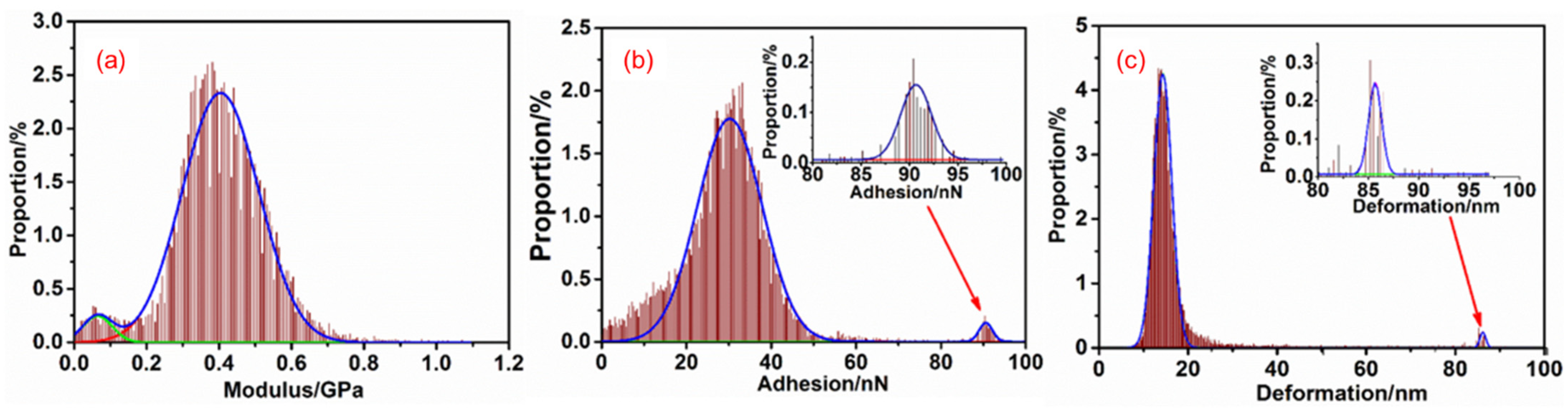

4.3. Micro Mechanical Distribution Characteristics of New Microcracks

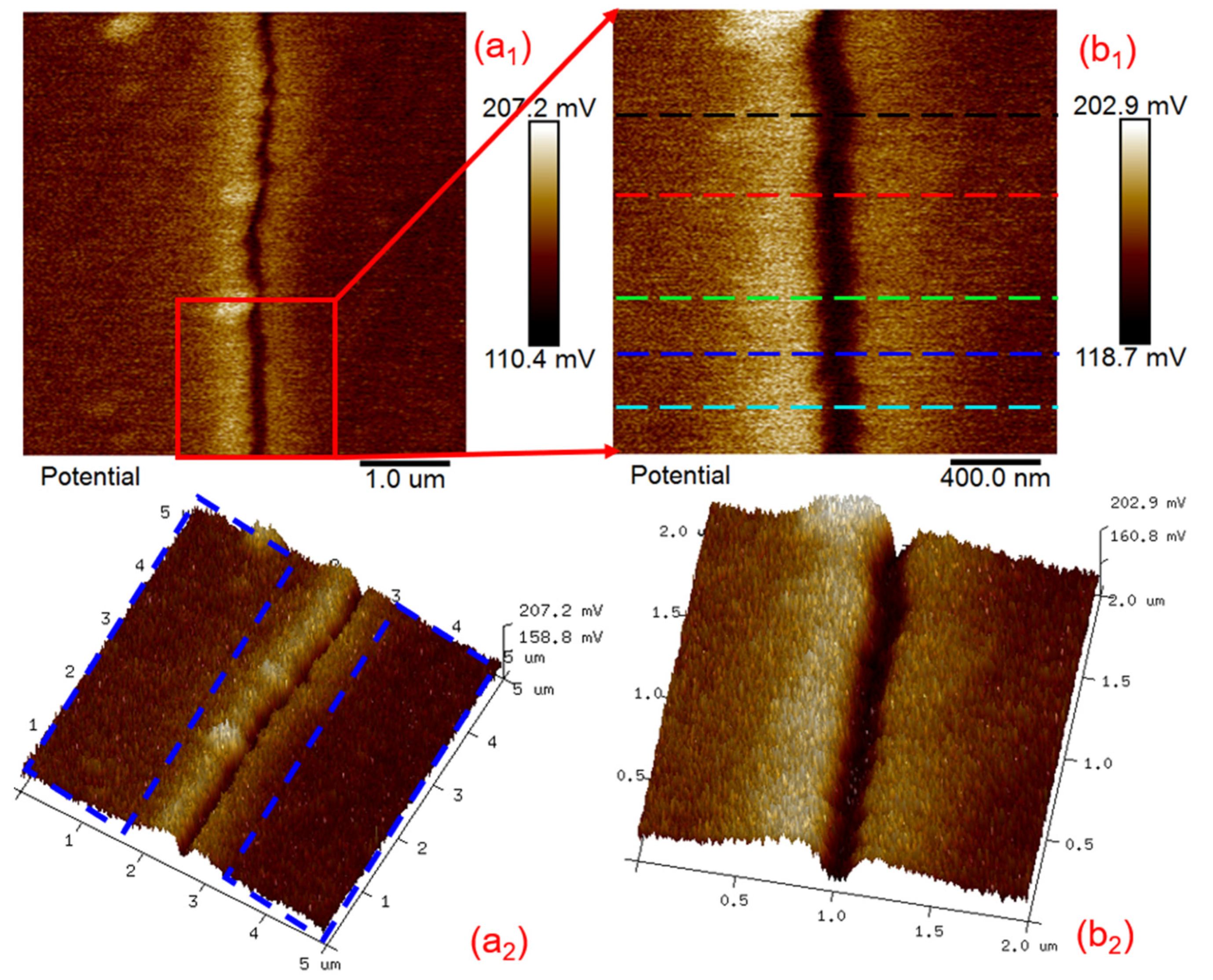

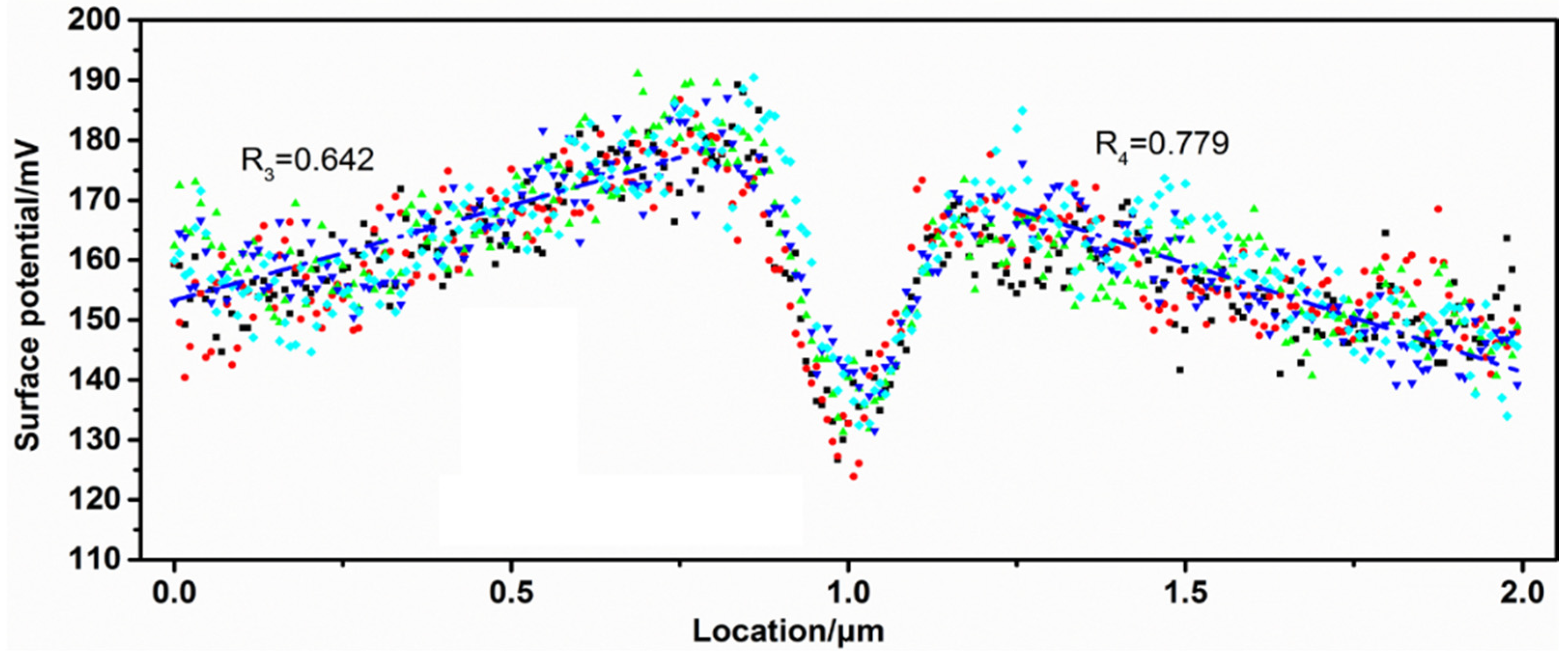

4.4. Surface Potential Distribution Characteristics of New Microcracks

5. Discussion

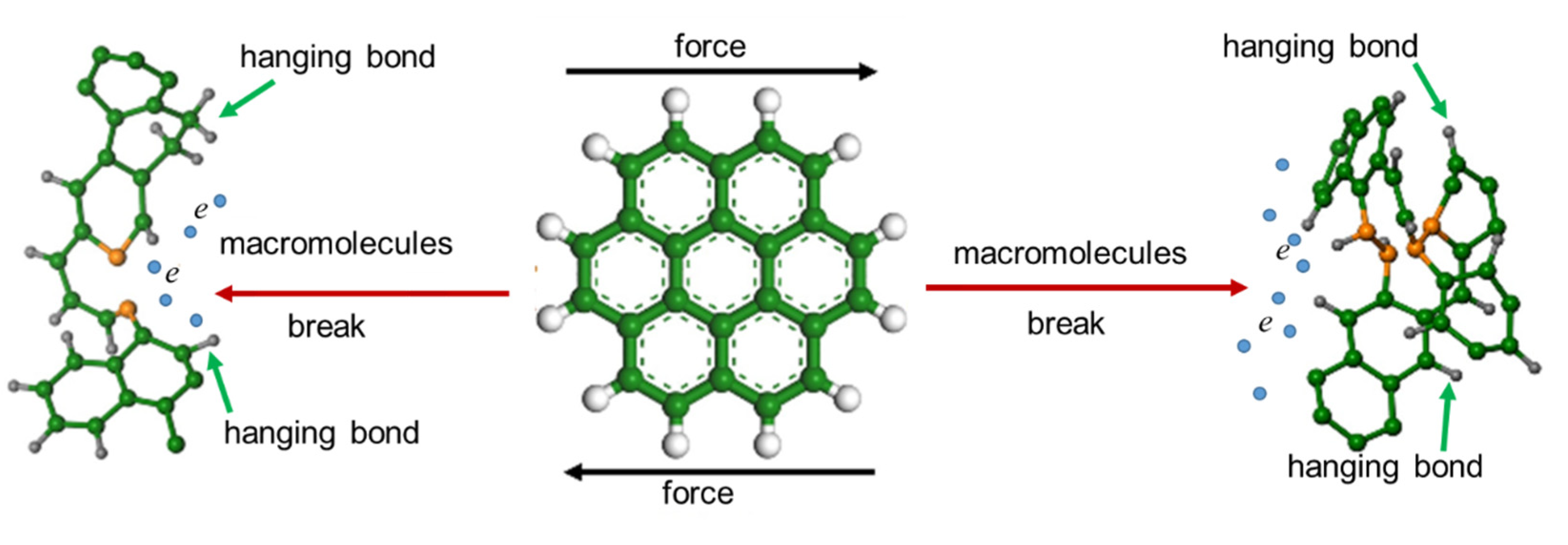

5.1. The Reason for the Changes of Electro-Mechanical Characteristics before and after Fracture

5.2. Effect of Coal Fracture on EMR

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, X.; Zhou, C.; Song, D.; Li, Z.; Cao, A.; He, S.; Khan, M. Mechanism and monitoring and early warning technology for rockburst in coal mines. Int. J. Miner. Met. Mater. 2021, 28, 1097–1111. [Google Scholar] [CrossRef]

- He, S.; Song, D.; Li, Z.; He, X.; Chen, J.; Li, D.; Tian, X. Precursor of Spatio-temporal Evolution Law of MS and AE Activities for Rock Burst Warning in Steeply Inclined and Extremely Thick Coal Seams Under Caving Mining Conditions. Rock Mech. Rock Eng. 2019, 52, 2415–2435. [Google Scholar] [CrossRef]

- Bahadori, M.; Amnieh, H.; Khajezadeh, A. A new geometrical-statistical algorithm for predicting two-dimensional distribution of rock fragments caused by blasting. Int. J. Rock Mech. Min. Sci. 2016, 86, 55–64. [Google Scholar] [CrossRef]

- Qiu, L.; Zhu, Y.; Song, D.; He, X.; Wang, W.; Liu, Y.; Xiao, Y.; Wei, M.; Yin, S.; Liu, Q. Study on the Nonlinear Characteristics of EMR and AE during Coal Splitting Tests. Minerals 2022, 12, 108. [Google Scholar] [CrossRef]

- Qiu, L.; Liu, Z.; Wang, E.; He, X.; Feng, J.; Li, B. Early-warning of rock burst in coal mine by low-frequency electromagnetic radiation. Eng. Geol. 2020, 279, 105755. [Google Scholar] [CrossRef]

- Ma, Y.; Nie, B.; He, X.; Li, X.; Meng, J.; Song, D. Mechanism investigation on coal and gas outburst: An overview. Int. J. Miner. Met. Mater. 2020, 27, 872–887. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, H.; Wang, Z.; Zhang, L.; Kong, L.; Li, S.; Zhang, C. Experimental study on the prediction of rockburst hazards induced by dynamic structural plane shearing in deeply buried hard rock tunnels. Int. J. Rock Mech. Min. Sci. 2016, 86, 210–223. [Google Scholar] [CrossRef]

- Frid, V.; Vozoff, K. Electromagnetic radiation induced by mining rock failure. Int. J. Coal Geol. 2005, 64, 57–65. [Google Scholar] [CrossRef]

- Frid, V. Electromagnetic radiation method for rock and gas outburst forecast. J. Appl. Geophys. 1997, 38, 97–104. [Google Scholar] [CrossRef]

- Nitsan, U. Electromagnetic emission accompanying fracture of quart-bearing rock. Geophys. Res. Lett. 1977, 4, 333–336. [Google Scholar] [CrossRef]

- Cress, G.; Brady, B.; Rowell, G. Sources of electromagnetic radiation from fracture of rock samples in the laboratory. Geophys. Res. Lett. 1987, 14, 331–334. [Google Scholar] [CrossRef]

- Enomoto, Y.; Hashimoto, H. Emission of charged particles from indentation fracture of rocks. Nature 1990, 346, 641–643. [Google Scholar] [CrossRef]

- O’Keefe, S.; Thiel, D. A mechanism for the production of electromagnetic radiation during fracture of brittle materials. Phys. Earth Planet. Inter. 1995, 89, 127–135. [Google Scholar] [CrossRef]

- Kawaguchi, Y. Charged particle emission and luminescence upon bending fracture of granite. Jpn. J. Appl. Phys. 1998, 37, 3495. [Google Scholar] [CrossRef]

- Wang, E.; He, X. An experimental study of the electromagnetic emission during the deformation and fracture of coal or rock. Chin. J. Geophys. 2000, 43, 134–140. [Google Scholar] [CrossRef]

- Rabinovitch, A.; Frid, V.; Bahat, D. Surface oscillations-a possible source of fracture induced electromagnetic radiation. Tectonophysics 2007, 431, 15–21. [Google Scholar] [CrossRef]

- Han, J.; Huang, S.; Zhao, W.; Wang, S. Stress excited electrical dipole model for electromagnetic emission induced in fractured rock. Int. J. Appl. Electromagn. Mech. 2016, 52, 1023–1034. [Google Scholar] [CrossRef]

- Han, J.; Huang, S.; Zhao, W.; Wang, S.; Deng, Y. Study on electromagnetic radiation in crack propagation produced by fracture of rocks. Measurement 2019, 131, 125–131. [Google Scholar] [CrossRef]

- Rabinovitch, A.; Frid, V.; Bahat, D.; Goldbaum, J. Fracture area calculation from electromagnetic radiation and its use in chalk failure analysis. Int. J. Rock Mech. Min. Sci. 2000, 37, 1149–1154. [Google Scholar] [CrossRef]

- Frid, V.; Rabinovitch, A.; Bahat, D. Fracture induced electromagnetic radiation. J. Phys. D: Appl. Phys. 2003, 36, 1620. [Google Scholar] [CrossRef] [Green Version]

- Gade, S.; Sause, M. Measurement and study of electromagnetic emission generated by tensile fracture of polymers and carbon fibres. J. Nondestruct. Eval. 2017, 36, 9. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Liu, X.; Song, D.; Nie, B. Effect of microstructure on electrical property of coal surface. Appl. Surf. Sci. 2019, 483, 713–720. [Google Scholar] [CrossRef]

- Wang, W.; Song, D.; He, X.; Liu, X.; Li, Z.; Tian, X. The heterogeneity and electro-mechanical characteristics of coal at the micro-and nanoscale. J. Geophys. Eng. 2019, 16, 717–728. [Google Scholar] [CrossRef]

- Tian, X.; Song, D.; He, X.; Liu, H.; Wang, W.; Li, Z. Investigation of micro-surface potential of coals with different metamorphism by AFM. Measurement 2021, 172, 108915. [Google Scholar] [CrossRef]

- Pashmforoush, F.; Fotouhi, M.; Ahmadi, M. Damage characterization of glass/epoxy composite under three-point bending test using acoustic emission technique. J. Mater. Eng. Perform. 2012, 21, 1380–1390. [Google Scholar] [CrossRef]

- Kozłowski, M.; Kadela, M.; Kukiełka, A. Fracture energy of foamed concrete based on three-point bending test on notched beams. Procedia Eng. 2015, 108, 349–354. [Google Scholar] [CrossRef] [Green Version]

- Zuo, J.; Xie, H.; Dai, F.; Ju, Y. Three-point bending test investigation of the fracture behavior of siltstone after thermal treatment. Int. J. Rock Mech. Min. Sci. 2014, 70, 133–143. [Google Scholar] [CrossRef]

- Lu, Y.; Li, W.; Wang, L.; Meng, X.; Wang, B.; Zhang, K.; Zhang, X. In-situ microscale visualization experiments on microcracking and microdeformation behaviour around a pre-crack tip in a three-point bending sandstone. Int. J. Rock Mech. Min. Sci. 2019, 114, 175–185. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, G.; Jiang, Y. Experimental and numerical modelling investigation on fracturing in coal under impact loads. Int. J. Fract. 2013, 183, 63–80. [Google Scholar] [CrossRef]

- Tian, X.; Song, D.; He, X.; Liu, H.; Wang, W.; Li, Z. Surface microtopography and micromechanics of various rank coals. Int. J. Miner. Met. Mater. 2019, 26, 1351–1363. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Huang, J.; Cui, X.; Tan, L.; Liu, Q.; Zeng, H. Heterogeneous distribution of adsorbed bitumen on fine solids from solvent-based extraction of oil sands probed by AFM. Energy Fuels 2017, 31, 8833–8842. [Google Scholar] [CrossRef]

- Li, T.; Zeng, K. Nanoscale elasticity mappings of micro-constituents of abalone shell by band excitation-contact resonance force microscopy. Nanoscale 2014, 6, 2177–2185. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Fang, H.; Chen, M. Experiment on surface charge distribution of fine sediment. Sci. China Technol. Sci. 2012, 55, 1146–1152. [Google Scholar] [CrossRef]

- Yan, L.; Englert, A.; Masliyah, J.; Xu, Z. Determination of anisotropic surface characteristics of different phyllosilicates by direct force measurements. Langmuir 2011, 27, 12996–13007. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Hu, Y.; Sun, W.; Drelich, J. Surface-charge anisotropy of scheelite crystals. Langmuir 2016, 32, 6282–6288. [Google Scholar] [CrossRef] [PubMed]

- Heald, M.; Marion, J. Classical Electromagnetic Radiation, 3rd ed.; Dover Publications, Inc.: New York, NY, USA, 2012. [Google Scholar]

- Casal, M.; Vega, M.; Diaz-Faes, E.; Barriocanal, C. The influence of chemical structure on the kinetics of coal pyrolysis. Int. J. Coal Geol. 2018, 195, 415–422. [Google Scholar] [CrossRef]

- Liu, X.; Song, D.; He, X.; Nie, B.; Wang, Q.; Sun, R.; Sun, D. Coal macromolecular structural characteristic and its influence on coalbed methane adsorption. Fuel 2018, 222, 687–694. [Google Scholar] [CrossRef]

- He, X.; Liu, X.; Nie, B.; Song, D. FTIR and Raman spectroscopy characterization of functional groups in various rank coals. Fuel 2017, 206, 555–563. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, Y.; Wang, J.; Xue, S.; Wu, J.; Chang, L. Study on the relationship between microscopic functional group and coal mass changes during low-temperature oxidation of coal. Int. J. Coal Geol. 2017, 171, 212–222. [Google Scholar] [CrossRef]

- Liu, X.; Song, D.; He, X.; Nie, B.; Wang, L. Insight into the macromolecular structural differences between hard coal and deformed soft coal. Fuel 2019, 245, 188–197. [Google Scholar] [CrossRef]

- Huheey, J. The electronegativity of groups. J. Phys. Chem. A. 1965, 69, 3284–3291. [Google Scholar] [CrossRef]

- Epstein, L.; Shubina, E. New types of hydrogen bonding in organometallic chemistry. Coord. Chem. Rev. 2002, 231, 165–181. [Google Scholar] [CrossRef]

- Krzesińska, M.; Szeluga, U.; Smędowski, Ł.; Majewska, J.; Pusz, S.; Czajkowska, S.; Kwiecińska, B. TGA and DMA studies of blends from very good coking Zofiówka coal and various carbon additives: Weakly coking coals, industrial coke and carbonized plants. Int. J. Coal Geol. 2010, 81, 293–300. [Google Scholar] [CrossRef]

- Liu, J.; Holuszko, M.; Mastalerz, M. Applications of micro-FTIR technique in studying hydrophobicity of coal. Int. J. Coal Geol. 2017, 178, 74–83. [Google Scholar] [CrossRef]

- Keiluweit, M.; Kleber, M. Molecular-level interactions in soils and sediments: The role of aromatic π-systems. Environ. Sci. Technol. 2009, 43, 3421–3429. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Sun, H.; Zhang, Y.; Zhou, T.; Li, K.; Guo, J. Characteristics of infrared radiation of coal specimens under uniaxial loading. Rock Mech. Rock Eng. 2016, 49, 1567–1572. [Google Scholar] [CrossRef]

- Sun, H.; Ma, L.; Adeleke, N.; Zhang, Y. Background thermal noise correction methodology for average infrared radiation temperature of coal under uniaxial loading. Infrared Phys. Technol. 2017, 81, 157–165. [Google Scholar] [CrossRef]

- Ogawa, T.; Oike, K.; Miura, T. Electromagnetic radiations from rocks. J. Geophys. Res. Earth Surf. 1985, 90, 6245–6249. [Google Scholar] [CrossRef]

| Proximate Analysis wt (%) | Ultimate Analysis wt (%, Daf) | R0 (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vdaf | FCad | C | H | O | N | S | 2.7 |

| 3.07 | 7.13 | 6.58 | 83.22 | 87.49 | 3.50 | 5.92 | 2.46 | 0.63 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Song, D.; He, X.; Liu, Q.; Li, Z.; Qiu, L.; Mei, G. Dynamic Propagation and Electro-Mechanical Characteristics of New Microcracks in Notched Coal Samples Studied by the Three-Point Bending Test System and AFM. Minerals 2022, 12, 582. https://doi.org/10.3390/min12050582

Wang W, Song D, He X, Liu Q, Li Z, Qiu L, Mei G. Dynamic Propagation and Electro-Mechanical Characteristics of New Microcracks in Notched Coal Samples Studied by the Three-Point Bending Test System and AFM. Minerals. 2022; 12(5):582. https://doi.org/10.3390/min12050582

Chicago/Turabian StyleWang, Weixiang, Dazhao Song, Xueqiu He, Qingxia Liu, Zhenlei Li, Liming Qiu, and Guodong Mei. 2022. "Dynamic Propagation and Electro-Mechanical Characteristics of New Microcracks in Notched Coal Samples Studied by the Three-Point Bending Test System and AFM" Minerals 12, no. 5: 582. https://doi.org/10.3390/min12050582

APA StyleWang, W., Song, D., He, X., Liu, Q., Li, Z., Qiu, L., & Mei, G. (2022). Dynamic Propagation and Electro-Mechanical Characteristics of New Microcracks in Notched Coal Samples Studied by the Three-Point Bending Test System and AFM. Minerals, 12(5), 582. https://doi.org/10.3390/min12050582