Extraction of REEs from Blast Furnace Slag by Gluconobacter oxydans

Abstract

:1. Introduction

2. Materials and Methods

2.1. Blast Furnace Slag

2.2. Growth Characteristics of Gluconobacter oxydans and Adaptation

2.3. Bioleaching Experiments

3. Results

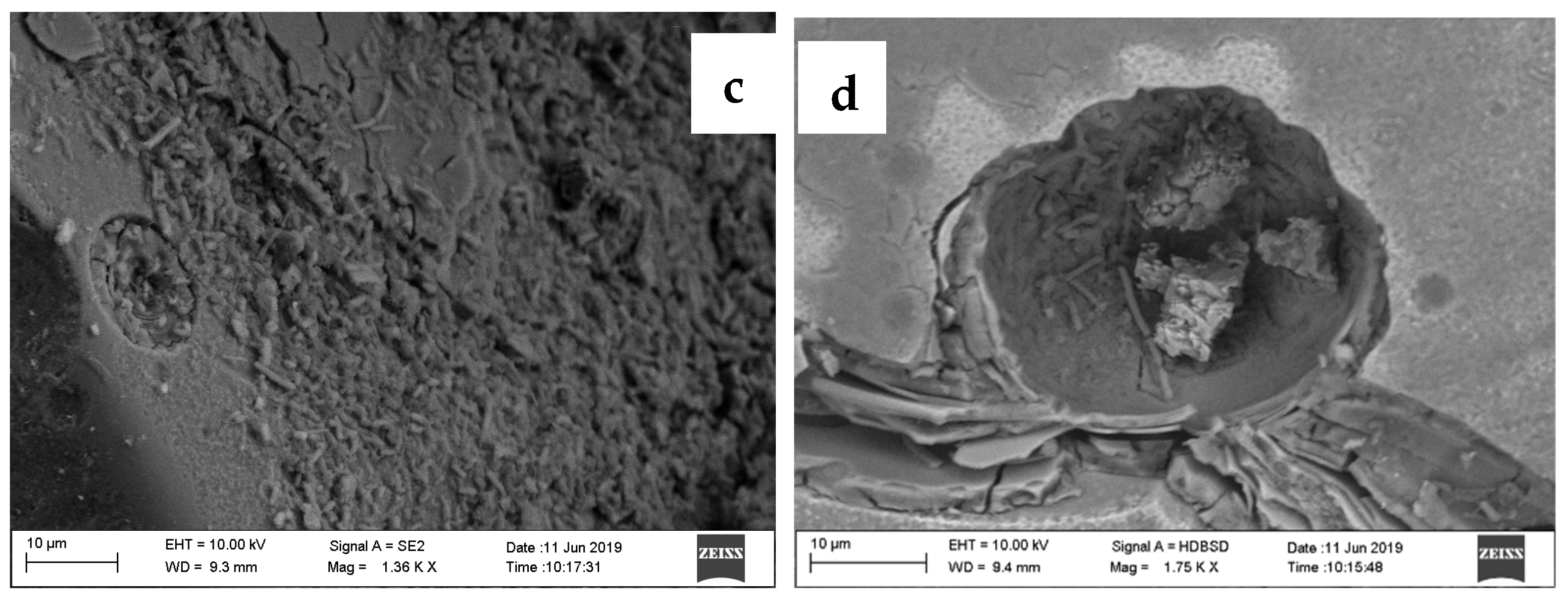

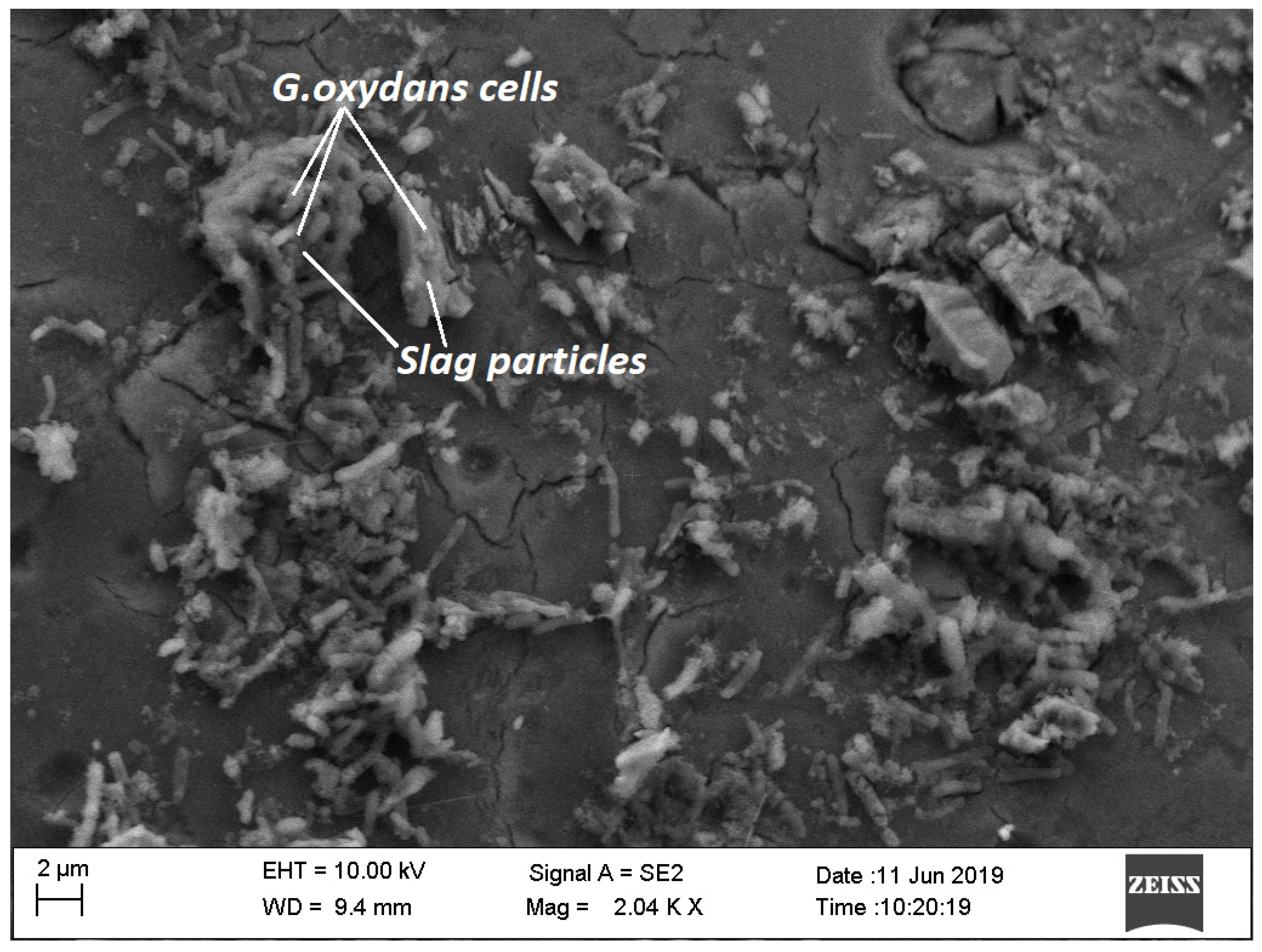

3.1. GGBFS Characterization

3.2. Growth Kinetics and Gluconic Acid Production by G. oxydans

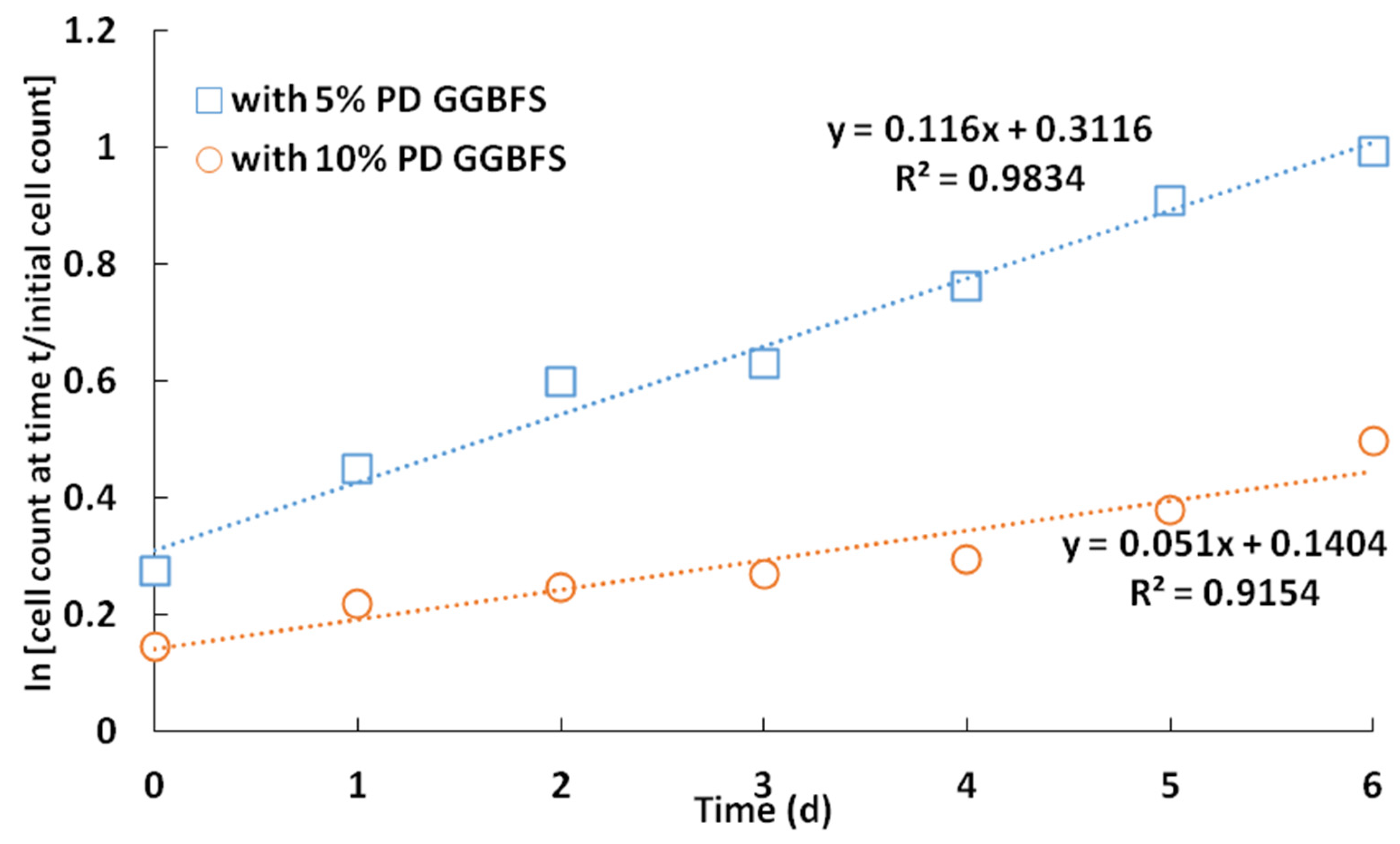

3.3. Adaptation of G. oxydans on 5%–10% (w/v) GGBFS

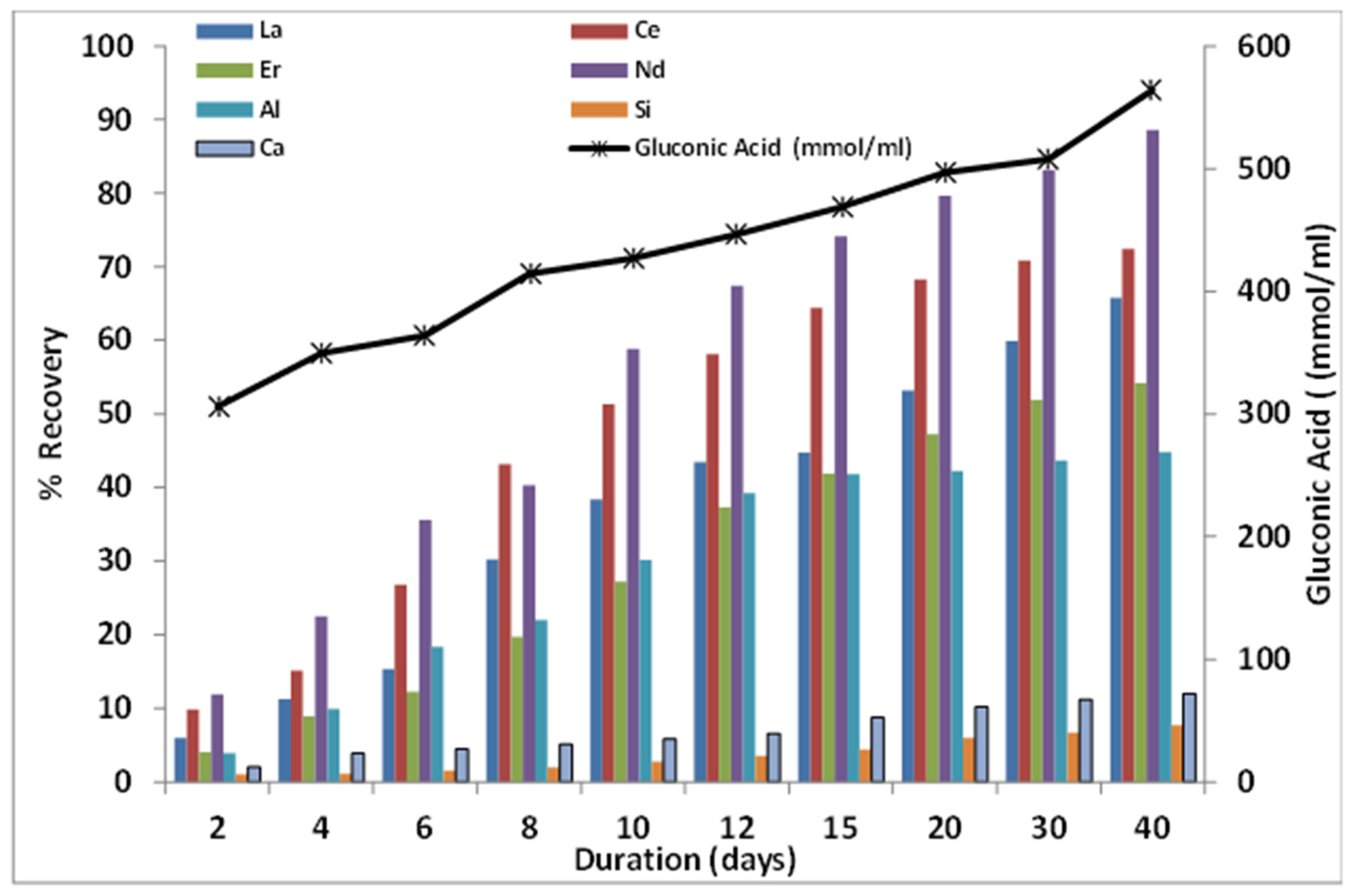

3.4. Bioleaching Studies for Extraction of REE from GGBFS

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Zheng, B. What Happens after the Rare Earth Crisis: A Systematic Literature Review. Sustainability 2019, 11, 1288. [Google Scholar] [CrossRef] [Green Version]

- Abhilash; Akcil, A. Critical and Rare Earth Elements: Recovery from Secondary Resources, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Lidelöw, S. Leaching Behavior of Air-Cooled Blast-Furnace Slag under Intermittent and Continuous Wetting. Ph.D. Thesis, Universitetstryckeriet, Lulea, Sweden, 2011. [Google Scholar]

- Brand, A.S.; Fanijo, E.O. A Review of the Influence of Steel Furnace Slag Type on the Properties of Cementitious Composites. Appl. Sci. 2020, 10, 8210. [Google Scholar] [CrossRef]

- Shanmuganathan, N.; Akbar Basha, S.; Sheikibrahim, K.; Mohammed Fahad, A.S. Ground Granulated Blast Furnace Slag (GGBS OR GGBFS) and Fly Ash (FA) in Concrete—A Study Report. Int. J. Civ. Eng. 2018, 5, 13–17. [Google Scholar]

- Binnemans, K.; Tom Jones, P.; Fernández, A.M.; Torres, V.M. Hydrometallurgical Processes for the Recovery of Metals from Steel Industry By-Products: A Critical Review. J. Sustain. Metall. 2020, 6, 505–540. [Google Scholar] [CrossRef]

- Abhilash; Meshram, P.; Sarkar, S.; Venugopalan, T. Exploring blast furnace slag as a secondary resource for extraction of rare earth elements. Miner. Metall. Process. 2017, 34, 178–182. [Google Scholar] [CrossRef]

- Sinha, S.; Abhilash; Meshram, P.; Pandey, B.D. Metallurgical processes for the recovery and recycling of lanthanum from various resources—A review. Hydrometallurgy 2016, 160, 47–59. [Google Scholar] [CrossRef]

- Abaka-Wood, G.B.; Ehrig, K.; Addai-Mensah, J.; Skinner, W. Recovery of Rare Earth Elements Minerals from Iron-Oxide-Silicate-Rich Tailings: Research Review. Eng 2022, 3, 259–275. [Google Scholar] [CrossRef]

- Abhilash; Meshram, P. Recovery of Rare Earth Elements from Metallurgical Wastes. In Sustainable and Economic Waste Management—Resource Recovery Techniques, 1st ed.; Md Anawar, H., Strezov, V., Abhilash, Eds.; CRC Press: Boca Raton, FL, USA, 2019; pp. 247–263. [Google Scholar]

- Abhilash; Hedrich, S.; Schippers, A. Distribution of scandium in red mud and extraction using Gluconobacter oxydans. Hydrometallurgy 2021, 202, 105621. [Google Scholar] [CrossRef]

- Antonick, P.J.; Hu, Z.; Fujita, Y.; Reed, D.W.; Das, G.; Wu, L.; Shivaramaiah, R.; Kim, P.; Eslamimanesh, A.; Lencka, M.M.; et al. Bio- and mineral acid leaching of rare earth elements from synthetic Phosphogypsum. J. Chem. Thermodyn. 2019, 132, 491–496. [Google Scholar] [CrossRef]

- Fathollahzadeh, H.; Becker, T.; Eksteen, J.J.; Kaksonen, A.H. Microbial contact enhances bioleaching of rare earth elements. Bioresour. Technol. Rep. 2018, 3, 102–108. [Google Scholar] [CrossRef]

- Schmitz, A.M.; Pian, B.; Medin, S.; Reid, M.C.; Wu, M.; Gazel, E.; Barstow, B. Generation of a Gluconobacter oxydans knockout collection for improved extraction of rare earth elements. Nat. Commun. 2021, 12, 6693. [Google Scholar] [CrossRef] [PubMed]

- Thompson, V.S.; Gupta, M.; Jin, H.; Vahidi, E.; Jindra, M.A.; Nguyen, V.; Fujita, Y.; Sutherland, J.W.; Jiao, Y.; Reed, D.W.; et al. Techno-economic and life cycle analysis for bioleaching rare-earth elements from waste materials. ACS Sustain. Chem. Eng. 2018, 6, 1602–1609. [Google Scholar] [CrossRef]

- Warwick, P.; Evans, N.; Vines, S. Studies on metal gluconic acid complexes. MRS Online Proc. Libr. 2006, 932, 959–966. [Google Scholar] [CrossRef] [Green Version]

| Metals | Concentration | Metals | Concentration |

|---|---|---|---|

| CaO | 33.62 wt% | K2O | 0.48 wt% |

| SiO2 | 32.82 wt% | Na2O | 0.15 wt% |

| Al2O3 | 18.26 wt% | MnO | 0.064 wt% |

| MgO | 10.12 wt% | P2O5 | 0.03 wt% |

| SO3 | 1.23 wt% | Ce | 157 ppm |

| TiO2 | 0.91 wt% | La | 90 ppm |

| Fe2O3 | 0.63 wt% | Nd | 71 ppm |

| K2O | 0.48 wt% | Er | 40 ppm |

| Culture Type | % Metal Recovery | ||||||

|---|---|---|---|---|---|---|---|

| La | Ce | Er | Nd | Al | Si | Ca | |

| 5% PD with non-adapted G. oxydans | 13 | 19.4 | 11.2 | 18.6 | 25.7 | 8.1 | 17.9 |

| 10% PD with non-adapted G. oxydans | 11.4 | 18.7 | 10.6 | 16.2 | 20.1 | 2.2 | 16.6 |

| 5% PD with adapted G. oxydans | 43.4 | 58.1 | 37.3 | 67.4 | 25.5 | 3.6 | 6.6 |

| 10% PD with adapted G. oxydans | 42.1 | 56.2 | 34.1 | 65 | 24.8 | 3.2 | 6.5 |

| Days | Gluconic Acid Concentration (mM) | |||

|---|---|---|---|---|

| 5% PD with Non-Adapted G. oxydans | 10% PD with Non-Adapted G. oxydans | 5% PD with Adapted G. oxydans | 10% PD with Adapted G. oxydans | |

| 2 | 62.8 | 125.6 | 316.4 | 233.6 |

| 4 | 84.7 | 169.4 | 377.8 | 277.4 |

| 6 | 91.9 | 183.8 | 395.6 | 291.8 |

| 8 | 117.2 | 234.4 | 402.4 | 342.4 |

| 10 | 123.4 | 246.8 | 417.4 | 354.8 |

| 12 | 133.2 | 266.4 | 446.3 | 374.4 |

| 15 | 144.4 | 288.8 | 498.2 | 396.8 |

| 20 | 158.4 | 316.8 | 516.4 | 432.8 |

| 30 | 163.9 | 327.8 | 527.6 | 451.8 |

| 40 | 172.2 | 343.2 | 564.2 | 457.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abhilash; Hedrich, S.; Meshram, P.; Schippers, A.; Gupta, A.; Sen, S. Extraction of REEs from Blast Furnace Slag by Gluconobacter oxydans. Minerals 2022, 12, 701. https://doi.org/10.3390/min12060701

Abhilash, Hedrich S, Meshram P, Schippers A, Gupta A, Sen S. Extraction of REEs from Blast Furnace Slag by Gluconobacter oxydans. Minerals. 2022; 12(6):701. https://doi.org/10.3390/min12060701

Chicago/Turabian StyleAbhilash, Sabrina Hedrich, Pratima Meshram, Axel Schippers, Ajay Gupta, and Subhadra Sen. 2022. "Extraction of REEs from Blast Furnace Slag by Gluconobacter oxydans" Minerals 12, no. 6: 701. https://doi.org/10.3390/min12060701

APA StyleAbhilash, Hedrich, S., Meshram, P., Schippers, A., Gupta, A., & Sen, S. (2022). Extraction of REEs from Blast Furnace Slag by Gluconobacter oxydans. Minerals, 12(6), 701. https://doi.org/10.3390/min12060701