1. Introduction

In recent years, the resources in shallow areas have been gradually depleted, leading to the resources in deeper areas being exploited [

1]. Although current mining technology has been greatly improved, a series of mining disasters, such as coal and gas bursts [

2], rock bursts [

3,

4,

5] and water inrush [

6], and other dynamic disasters, more frequently occur as the mining depth increases. The main reason for the dynamic hazards in deep mining is the higher mining intensity, causing stronger mining stress and disturbance stress on the surrounding rocks. Previous studies have shown that the surrounding rock mass is in a state of loading and unloading as the working face advances [

7,

8,

9]. Therefore, the mechanical properties of the rock mass in a loading and unloading state are significant for roadway failure and ground control.

For the dynamic hazards of rocks, energy accumulation and release characteristics related to mining activities are the main reasons [

10,

11,

12,

13,

14]. Most studies focus on the stress–strain curves to obtain the process of energy accumulation and dissipation. The rock damage related to energy accumulation, dissipation, and release has been widely discussed in recent years [

15,

16,

17,

18]. Huang and Li found that the strain energy peak front conversion rate increased with the increase in unloading stress and that the specimens released a large amount of strain energy after reaching the peak strength through cyclic loading and unloading experiments [

19]. Compared to conventional triaxial tests, the dissipated energy used to drive crack extension in stress perturbation tests is relatively large in rock samples. Zhang and Gao found that saturated samples have large irreversible deformation in the pre-peak phase and a small stress drop in the post-peak phase through cyclic loading and unloading experiments. The saturation process reduces the accumulated energy limit by 38.9% but increases the dissipated energy and residual elastic energy density, which greatly reduces the magnitude and rate of energy release [

20]. The water-saturated sample is 3% less efficient in converting the elastic energy in the pre-peak region. In addition, the elastic energy ratio has a smaller range in the post-peak phase, and the saturation process can greatly reduce the risk of dynamic hazards [

21]. Cao et al. analyzed the existence of linear functions of total strain energy, elastic strain energy, and infrared radiation variance during rock loading in different water-bearing states, which led to the discovery of linear energy transport and linear energy storage laws in rocks, and they defined the energy transport infrared radiation coefficient and energy storage infrared radiation. The coefficients of energy transfer and energy storage are defined (the ratio of total strain energy, elastic strain energy, and infrared radiation variance during rock loading, respectively). On this basis, the quantitative analysis index of the energy dissipation IR radiation ratio, i.e., the ratio of dissipated strain energy to IR variance, is proposed, and the index can be used to predict and discriminate the damage of water-bearing rocks [

22].

Previous studies have focused on the strain energy evolution characteristics of unloaded rocks, while the loading and unloading cycling state is seldom considered. In addition, there are many intrinsic pores and microfractures in rocks [

23,

24,

25]. They are all related to the evolution characteristics of strain energy, but many of them are not investigated in depth. With mining disturbances, pores and microfractures will be initiated and cracked to induce macro-fractures, resulting in rock failure [

26,

27]. However, this situation is quite different in experimental and analytical results for the strain energy characteristics of such rocks due to being inhomogeneous with the complex microstructure characteristics. The traditional mechanical and mathematical models in metal are not able to model the constitution characteristics, especially for cyclic loading and unloading rocks. Artificial intelligence modeling is based on the experience of historical data, and the modeling of predictive parameters is realized by using autonomous learning and inference performance [

28,

29,

30,

31,

32,

33]. It is able to handle nonlinear problems in rock fields [

34,

35,

36,

37,

38].

Therefore, this paper analyzes the strain energy characteristics of dry and saturated rocks during cyclic loading and unloading and investigates the quantitative relationship between strain energy and the absolute energy of acoustic emission. Based on this, an artificial intelligence model for predicting the dissipative strain energy under the action of cyclic rock loading and unloading is constructed. The research results can provide an experimental theoretical basis for the monitoring and early warning of rock engineering disasters in slopes, tunnels, and coal mines.

2. Experimental Descriptions

The sandstones used in the experiments were taken from a coal mine in Shandong Province, and the same whole rock was used in the process. The dimensions of the rock samples were 50 × 50 × 100 mm, with an unevenness error of less than 0.05 mm at both ends and a length error of less than 0.3 mm along the two opposite sides of the rock sample height. In total, 14 rock samples were processed and divided equally into two groups, A and B, with 7 rock samples in each group. The samples in group A were dry rock samples, which were baked in the oven for 48 h to obtain a dry state, and group B contained saturated rock samples, which were baked in the oven for 48 h to obtain a dry state, and the weight was recorded; after this, the rock samples were soaked in water for 30 days to achieve a saturated state, the weight was recorded, and the water content was calculated.

MTS 816 Systems were used for the experiment as a loading control system, with the specification and model number of the MTS C64.106 electro-hydraulic servo universal testing machine, with a maximum load of 1000 kN. The model number of the acoustic emission monitoring equipment was PCI-2. The press was set to 0.1 mm/min of equal displacement loading. The test method was equal incremental cyclic loading and unloading; the cyclic peak load was increased by 20 kN each time and unloaded to 5 kN, i.e., 0–20 kN–5 kN–40 kN–5 kN–60 kN, etc., until the final damage of the rock. Since the stress area at the loading end of the rock is 0.0025 m

2, the rock loading and unloading stress path are 0–8 MPa–2 MPa-16 MPa–2 MPa–24 MPa, etc. [

20], and

Figure 1 shows the relationship between the rock loading and unloading stress path and the number of cycles. The loading–unloading of the rock is one cycle, and the second cycle of rock loading and unloading was analyzed as an example; the stress path in the loading phase was 2 MPa–16 MPa, and the stress path in the unloading phase was 16 MPa–2 MPa. Then, the maximum stress corresponding to the second cycle of loading and unloading was 16 MPa. As shown in

Figure 1, the maximum stress of rock cyclic loading and unloading increased linearly with the increase in the number of cycles. The maximum stress increased by 8 MPa for each increase of 1 in the number of cycles.

3. Strain Energy Results from Stress–Strain Curves

3.1. Strain Energy Calculation Method

During the cyclic loading and unloading of sandstone, it is obtained from the law of conservation of energy that if there is no heat exchange between the specimen and the external environment during this process, then the following relationship exists:

where

U is the total work exerted on the rock by the external load, i.e., the total strain energy of the rock;

Ud dissipates the strain energy; and

Ue is the elastic strain energy.

From the thermodynamic point of view, it is concluded that the energy dissipated during the cyclic loading and unloading of the specimen is unidirectional, and this process is irreversible.

Figure 2 shows the loading and unloading stress–strain curves of the rock. The area OAB enclosed by the loading stress–strain curve 0 A and the horizontal coordinate is the total strain energy, the area ACB enclosed by the unloading stress–strain curve AC and the horizontal coordinate is the elastic strain energy, and the shaded area consisting of the loading stress–strain curve OA, the unloading stress–strain curve AC, and OC is the dissipated strain energy.

The rock cyclic loading and unloading process is accompanied by energy input, energy accumulation, energy dissipation, and energy release [

39,

40], as shown in

Figure 3. The external energy input is mechanical energy, i.e., the work exerted by the press on the rock (the experimental environment in this paper is normal room temperature, and the energy input by environmental conduction is negligible). Most of the input energy is stored in the rock in the form of elastic strain energy

Ue, which is reversible. The other part is the dissipative strain energy

Ud, which is dissipated in the form of plastic deformation energy and damage energy (including the energy released by rock rupture, such as acoustic emission) and is irreversible. When

Ue is stored to a certain limit, the rock will rupture and destabilize along the main fracture and release energy to the outside world, including elastic strain energy, frictional heat energy, and various types of radiation energy, etc.

3.2. Strain Energy Evolution Characteristics

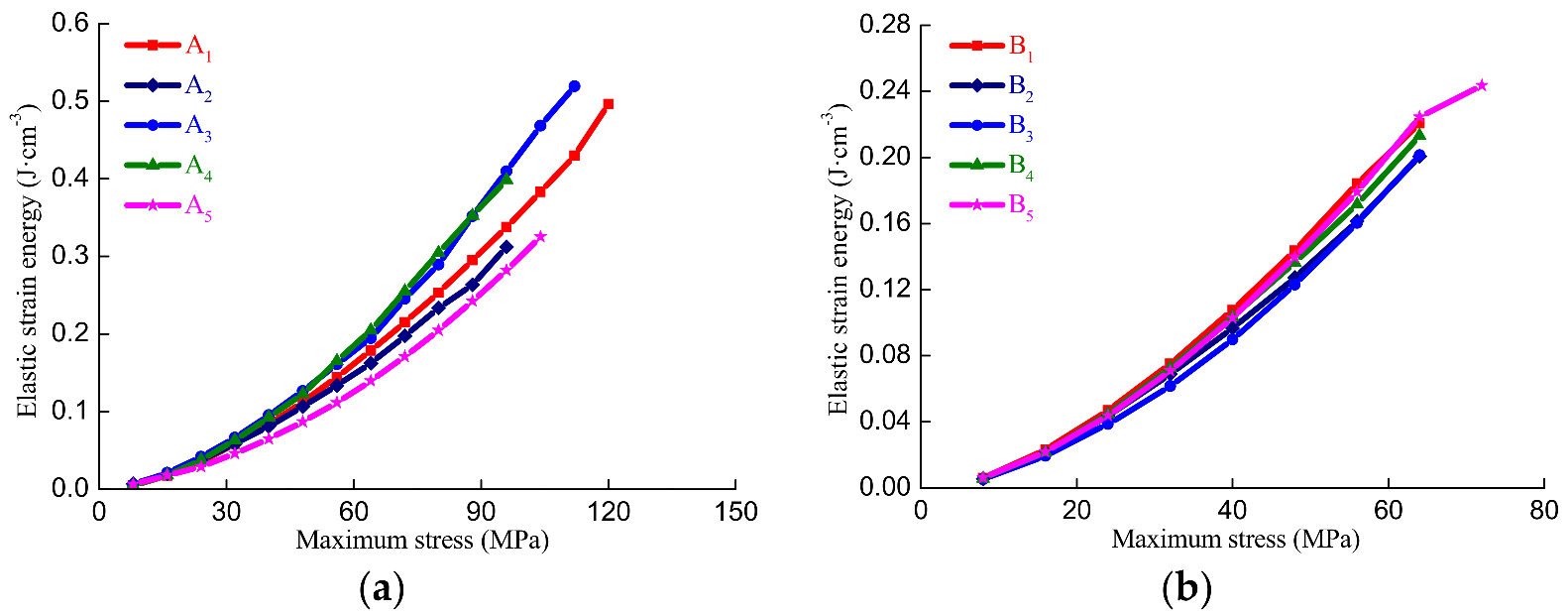

The elastic strain energy and dissipative strain energy of sandstone were plotted with the unloading stress, as shown in

Figure 4. The elastic strain energy evolution curves during the cyclic loading and unloading of dry and saturated rocks were roughly the same, showing a nonlinear growth trend. The elastic strain energy storage limit of saturated rock samples is 0.53 times that of dry rock samples, which indicates that water saturation has a suppressive effect on the storage limit of rock samples, and, in the coal mining face, if the hard roof is water-saturated, it can reduce the released energy of elastic strain energy when the impact dynamic load appears. At the beginning of cyclic loading and unloading, the growth rate of elastic strain energy is small, which corresponds to the compression density stage of the rock, and then slowly increases, and the elastic strain energy curve of the rock shows a nearly linear growth trend, which corresponds to the linear elastic and plastic stage of the rock. When the peak stress of the rock reaches the maximum, it means that the elastic strain energy reaches the maximum and the rock reaches the energy storage limit, which will then cause the rock to be violently damaged. In addition, the elastic strain energy available for release at the time of damage is different for each red sandstone specimen, i.e., each specimen corresponds to a specific energy storage limit, while the specimens used in the test are taken from the same rock with basically the same components and texture, indicating that the internal structure is one of the factors determining the elastic energy storage limit of the rock.

Figure 5 shows the trend of dissipative strain energy with unloading stress for dry and saturated rock samples. As shown in

Figure 5, the dissipated strain energy curves of dry and saturated rocks are more discrete compared to the elastic strain energy of the rock samples during cyclic unloading and loading. At the beginning of cyclic unloading, the difference in the values of the dissipative strain energy of rocks is not significant, and with the continuous damage evolution of rocks, the difference in the values of dissipative strain energy becomes larger and larger. This is because the rupture and damage during the cyclic loading and unloading of the rock are random, and the dissipative strain energy drives the behavior of rupture and crack development within the rock, so the evolution of the dissipative strain energy shows a certain degree of dispersion.

In addition, it can be seen from

Figure 5 that the dissipative strain energy of dry rocks exhibits different characteristics at the late stage of cyclic unloading and loading. For example, rock sample A1 shows a large increase in dissipative strain energy at the last cycle, with an increase of 0.0441 J/cm

3; rock sample A3 shows a nearly linear increase in dissipative strain energy at the late stage of cyclic unloading and an increase of 0.0181 J/cm

3 at the last cycle, while, for rock sample A2, the increase in dissipative strain energy was more obvious during the penultimate cycle of loading and unloading, and the trend of dissipative strain energy leveled off during the last cycle. The dissipation strain energy values of saturated rocks were nearly equal in the first two cycles of loading and unloading, and then the dissipation strain energy values showed dispersion, but the degree of dispersion was much lower than that of dry rocks, with rock samples B1 and B5 showing a larger increase in dissipation strain energy in the last cycle, reaching 0.0241 J/cm

3 and 0.0578 J/cm

3, respectively, and rock samples B2, B3, and B4 showing a nearly linear increase in dissipation strain energy in the last cycle. Nearly half of the rock samples used in this study showed an accelerated increase in dissipative strain energy at the last cycle, because the rock needs to consume a large amount of dissipative strain energy for the expansion and penetration of the internal microcracks when the rock is close to damage until the rock is suddenly damaged when the cracks penetrate. In contrast, the other half of the rock samples showed a steady increase in dissipated strain energy at the last cycle. The authors concluded that, compared to uniaxially loaded rocks, during the cyclic loading and unloading of rocks, in addition to the rupture and damage caused by the maximum stress (i.e., the rupture caused by the loading stage exceeding the maximum stress of the last cycle at each cycle), there is also rupture caused by cyclic action (fatigue), and cyclic action has a facilitating effect on rock rupture with the the number and degree of microcracking. When the number and degree of micro-ruptures reach a certain amount, the slow destruction of the rock is triggered, i.e., a smooth increase in the dissipative strain energy of the rock occurs during the last cycle.

3.3. Strain Energy Distribution

Figure 6 and

Figure 7 show the proportional curves of elastic strain energy and dissipative strain energy to the total strain energy, respectively. As can be seen from

Figure 6, the elastic strain energy proportion curve varies nonlinearly with the exhibited nonlinearity and keeps growing until the damage is near, and the growth rate gradually becomes slower. At the initial stage of loading, the proportion increases sharply, and when the unloading stress reaches approximately 30% of the ultimate unloading stress level, the growth starts to slow down and gradually stabilizes. When the loading reaches approximately 60% of the ultimate unloading stress level (the end of the elastic phase), the maximum is reached, and it then decreases significantly near the time of damage. In contrast, the dissipative strain energy ratio curve also shows a nonlinear change and decreases until the damage is near, and the dissipative strain energy ratio of the whole loading process decreases from 0.406 at the beginning of the first cycle to 0.174 at the last cycle. The dissipated strain energy ratio decreases from 0.406 at the beginning of the first cycle loading to 0.174 at the last cycle loading and unloading.

In the initial stage of loading, the amount of external input strain energy converted into elastic strain energy is more than the dissipated strain energy, but the difference is not large, indicating that the initial microcrack closure and frictional slip in the compression density stage consume a lot of strain energy. Entering the elastic stage, the pores in the rock have been compacted, but, due to the stress concentration, there will be microcrack sprouting, expansion, and other behaviors, which still consume a small amount of strain energy, resulting in the elastic stage not being completely linear elastic. The continuity of microcracks and the formation and destabilizing extension of macroscopic cracks near the time of damage consume part of the strain energy, leading to an increase in the proportion of dissipated strain energy in some rock samples.

3.4. Strain Energy Growth Rate

Due to the discrete nature of rock mechanics experiments, it may be inaccurate to use the characteristics of a particular rock sample as the characteristics of the rock when analyzing the strain energy characteristics of the rock.

Figure 8 shows the curves of strain energy with maximum stress for dry and saturated rocks. As shown in

Figure 8, the elastic strain energy of the dry and saturated rock samples increased nonlinearly as a whole, and the elastic strain energy of the dry and saturated rock samples was nearly the same in the first three cycles, after which the elastic strain energy curve of the saturated rock samples was higher than that of the dry rock samples. The dissipative strain energy curves of the dry and saturated rock samples nearly overlapped in the first five cycles, after which the curves diverged, and the difference between the dissipative strain energy values of the saturated and dry rock samples became larger and larger as the maximum stress value of cyclic loading and unloading increased, reaching 0.0797 J/cm

3.

Figure 9 shows the variation curves of the increase in strain energy with maximum stress for each cycle. As shown in

Figure 9, for both dry and saturated rocks, the increase in elastic strain energy tends to increase and then decrease, with the maximum value in the penultimate cycle and a sudden decrease in the increase in elastic strain energy in the last cycle; the curve of the increase in dissipative strain energy shows a process of “rise–fall–gentle rise–rapid rise”.

The increase in dissipative strain energy during the last cycle of unloading (near destruction) was 0.03469 J/cm3 and 0.04539 J/cm3 for dry and saturated rocks, respectively, while the elastic strain energy decreased abruptly, with values of 0.06054 J/cm3 and 0.0092 J/cm3, respectively. However, it suppressed the sudden drop in elastic strain energy. This is because water saturation greatly promotes the development of pore microcracks in the rock, resulting in a higher number of microcracks and fracture development than in dry rocks before rock destruction, which consumes more dissipative strain energy. The extension and penetration of microcracks lead to an increase in the deformation of the rock before the damage, which reduces the bearing capacity of the rock and thus inhibits the accumulation of elastic strain energy.

3.5. The Effect of Cyclic Loading and Unloading on the Energy of the Rock

Figure 10 shows the strain energy evolution curve of the sandstone under uniaxial loading conditions. In the compacting stage, the increase in the elastic strain energy of sandstone is higher than that of dissipative strain energy, but the compaction of primary pores and microfractures inside the rock sample also consumes part of the dissipative strain energy, as shown in

Figure 10. In the elastic stage, the elastic strain energy accumulates rapidly, while the dissipative strain energy remains almost constant or increases slightly. In the plastic stage, the proportion of plastic deformation in the total deformation increases significantly due to the appearance of a large number of new microscopic cracks in the rock, and the dissipated strain energy increases significantly. Near the peak strength, the elastic strain energy gradually reaches the energy storage limit of the rock, the dissipation strain energy increases significantly, and macroscopic cracks are formed in the specimen at this time. After the peak stress, the dissipative strain energy increases rapidly and the rock strength is gradually lost. Compared with the uniaxial loading state, the sandstone showed more fatigue damage during cyclic loading and unloading, and its elastic strain energy and dissipative strain energy both showed an increasing trend of a nearly quadratic function.

This further indicates that the damage mechanisms of uniaxially loaded rocks and cyclically loaded rocks are different. The damage of cyclically loaded rocks is the result of the combined action of historical maximum stress and cyclic loading, which causes the occurrence of microfractures in rocks, resulting in the continuous development of cracks, which in turn leads to a steady increase in dissipative strain energy, and the release of elastic strain energy when the damage reaches a certain level, destroying the rock. It should be noted that the damage to the rock is the result of both the release of elastic strain energy and the increase in dissipative strain energy. The rapid development of pores and microfractures consumes the dissipative strain energy and contributes to the increase in dissipative strain energy. In turn, the random development of fractures affects the energy storage limit of elastic strain energy. Therefore, the authors concluded that the energy storage limit is a dynamically changing, uncertain quantity, which is related to the distribution state of pores and microcracks, the variation characteristics of dissipative strain energy, and the development of microcracks during the loading process.

To quantify the difference in strain energy between cyclically unloaded sandstone and uniaxially loaded sandstone, the authors subtracted the strain energy during the cyclic unloading of dry and saturated sandstone from the strain energy during uniaxial unloading and obtained the strain energy difference, as shown in

Figure 11 and

Figure 12. The strain energy difference curves of rock samples A2 and A4 showed a rising trend with the increase in cyclic loading and unloading stresses and achieved the maximum value at 96 MPa and 80 MPa, respectively. The rock samples A1, A3, and A5 showed an overall decreasing trend of rising and then decreasing. In addition, the difference in dissipated strain energy minus uniaxial loading dissipated strain energy during the cyclic loading and unloading of the dry rock samples showed an overall decreasing trend with the increase in unloading stress. As shown in

Figure 12, the difference between strain energy and uniaxial loading strain energy during the cyclic loading and unloading of saturated rock samples is different from that of dry sandstone, and the elastic strain energy difference curves of rock samples B3 and B5 show an overall increasing trend of first decreasing and then increasing, while the elastic strain energy difference curves of the rest of the saturated rock samples show a rapid increase. In addition, the dissipative strain energy difference curves of the saturated rock samples all showed a rapidly increasing trend.

From the above analysis, the values of elastic strain energy and dissipative strain energy during the cyclic loading and unloading of dry rock samples were higher in the early stage of uniaxial loading and lower in the late stage of cyclic loading and uniaxial loading. The elastic strain energy and dissipative strain energy during the cyclic loading and unloading of saturated rock samples were higher than those in the uniaxially loaded condition. The authors concluded that this is due to the increase in fatigue-induced strain energy by water saturation. Both elastic strain energy and dissipative strain energy are related to the stress–strain values during rock loading, and since the stresses were controlled to be the same when performing strain energy difference calculations in this study, water saturation increased the strain values during the cyclic loading and unloading of sandstone, which in turn promoted the development of elastic strain energy and dissipative strain energy during cyclic loading and unloading.

3.6. Dynamic Adjustment Factor of Dissipative Strain Energy

The dissipative strain energy is the driving energy of rock deformation and damage, and the dissipative strain energy is closely related to the stress value at unloading; as can be seen from

Figure 12, the dissipative strain energy increases with the increase in the unloading stress value, and the dissipative strain energy of some rock samples has a nearly linear relationship with the stress value at unloading, while the rest have a nonlinear growth characteristic of nearly quadratic function—that is, the dissipative strain energy of different rock samples is related to the unloading stress value as a function of the relationship between the dissipative strain energy and unloading stress value, which is different for different rock samples. Assuming that the dissipative strain energy grows nearly linearly concerning the unloading stress when the unloading stress changes are small, the following equation is used:

where σ is the unloading stress value, and

a is the dynamic adjustment factor of dissipative strain energy, the value of which may vary with the unloading stress value.

The physical meaning of the dynamic adjustment coefficient of dissipative strain energy is the increment in dissipative strain energy per unit unloading stress. In coal mining work, the dissipative strain energy is more difficult to measure than the unloading stress, and the dissipative strain energy can be calculated from the unloading stress as long as the dynamic adjustment coefficient during the unloading of sandstone is determined.

Figure 13 shows the trend of the dynamic adjustment coefficient of dissipative strain energy with unloading stress during the uniaxial cyclic loading and unloading of dry and saturated rock samples. As shown in

Figure 13, the dynamic adjustment coefficients of dry and saturated rock samples show a certain dispersion with the increase in unloading stress; for example, the dynamic adjustment coefficient of rock sample A1 shows a trend of “fast rise–smooth–slow rise” with the increase in unloading stress, and the dynamic adjustment coefficients of rock samples B1 and B4 show the trend of “fast rising–slow falling–slow rising”, while the dynamic adjustment coefficient of rock sample A4 shows the trend of “fast rising–slow falling–slow rising”. The dispersion of the dynamic adjustment coefficients of different rock samples is closely related to the microstructure, mechanical parameters, and strain energy evolution characteristics of sandstone during cyclic loading and unloading, and its variation mechanism needs to be explored in depth in future studies.

This further indicates that the damage mechanisms of uniaxially loaded rocks and cyclically loaded rocks are different. The damage of cyclically loaded rocks is the result of the combined action of historical maximum stress and cyclic loading, which causes the occurrence of microfractures in rocks, resulting in the continuous development of cracks, which in turn leads to a steady increase in dissipative strain energy and the release of elastic strain energy when the damage reaches a certain level, destroying the rock. It should be noted that the damage to the rock is the result of both the release of elastic strain energy and the increase in dissipative strain energy. The rapid development of pores and microfractures consumes the dissipative strain energy and contributes to the increase in dissipative strain energy. In turn, the random development of fractures affects the energy storage limit of elastic strain energy. Therefore, the authors concluded that the energy storage limit is a dynamically changing, uncertain quantity, which is related to the distribution state of pores and microcracks, the variation characteristics of dissipative strain energy, and the development of microcracks during the loading process.

4. Acoustic Emission Characteristics

The dissipative strain energy during the cyclic loading and unloading of sandstone promotes the sprouting, development, expansion, and penetration of its internal primary pores and microfractures, which eventually leads to the brittle damage of sandstone. At the same time, the expansion and development of internal pores and microfractures in sandstone will trigger the response of acoustic emission signals.

Figure 14 shows the stress and acoustic emission absolute energy evolution curves during the cyclic loading and unloading of sandstone, and the absolute energy can characterize the rupture damage of the internal microstructure of sandstone. Since the absolute energy trends of dry and water-saturated rock samples do not show obvious differences, only dry rock samples are selected for analysis in this paper. As shown in

Figure 14, the absolute energy of the sandstone showed a large abrupt change during the first cyclic unloading, which was due to the compression density effect of the primary pores and microfractures inside the sandstone during the initial loading. After this, the absolute energy of the sandstone during cyclic loading and unloading showed some dispersion. In the second and third cyclic loading and unloading of rock sample A1, a large, abrupt change in absolute energy was observed when the stress exceeded the maximum stress of the previous loading. During the subsequent cycles of loading and unloading, the absolute energy of rock sample A1 showed a small, abrupt change when the stress exceeded the maximum stress of the previous loading. In the last two cycles of loading and unloading, the absolute energy of rock sample A1 showed a large, abrupt change when the stress exceeded the maximum stress of the previous loading, and the absolute energy of acoustic emission entered the active period, indicating that the unstable expansion of cracks appeared inside the sandstone at this time, and gradually penetrated to form macroscopic cracks. Rock sample A1 showed a large, abrupt change in absolute energy at the last cyclic loading, and sudden damage occurred, accompanied by a violent ringing sound. In the sixth cycle of loading and unloading, a large, abrupt change in absolute energy occurred when the stress exceeded the maximum stress of the previous loading. After this, in the last two cycles of loading and unloading, when the stress exceeded the maximum stress of the previous loading, the absolute energy of rock sample A2 showed a large, abrupt change, and the rock was damaged in the last loading, accompanied by a violent sound. In the penultimate cycle of loading and unloading, there was no sudden change in the absolute energy of rock sample A3, which was in a calm period. During the last cycle of loading and unloading, there was a large, abrupt change in absolute energy when the stress exceeded the maximum stress of the last loading, and a large abrupt change in absolute energy during the last cycle of loading, and rock sample was suddenly damaged. After the fourth cyclic loading and unloading of rock sample A3, when the stress exceeded the maximum stress of the last loading, the absolute energy showed a large, abrupt change, and the absolute energy showed an intensive, abrupt change at the last cyclic loading and unloading, and the rock sample was suddenly damaged at the last loading.

During the cyclic loading and unloading of sandstone, repeated loading and unloading (the part of the loading phase not exceeding the last loading maximum stress and unloading phase) and the historical maximum stress (the part of the loading phase exceeding the last loading maximum stress, excluding the unloading phase) will have an effect on the damage rupture process of the rock, and after several cycles of loading and unloading, the microstructure of the rock material changes and the cracks are further extended to a complete fracture, which is the damage caused by repeated unloading and unloading. The historical maximum stress part will induce the expansion of pores and microfractures, causing the frictional rubbing between rock particles to intensify, which causes the internal stress and deformation state of the rock to change, and then causes the rupture and damage of the rock. However, if we can distinguish the effects of repeated unloading and historical maximum stress on rock damage, it will be possible to reveal the damage rupture mechanism of unloaded rocks, prevent the growing damage of rocks or rock masses according to the damage evolution law, and evaluate the stability of rock engineering. The authors studied the damage caused by repeated unloading and historical maximum stress by calculating the ratio of the sum of the absolute energy of the historical maximum stress part during each cycle of unloading and loading to the sum of the total absolute energy of the cycle.

Figure 15 shows the trend of the ratio of the absolute energy of the historical maximum stress fraction in dry and saturated rocks with the number of cyclic loading and unloading steps. As shown in

Figure 15, the ratio of the absolute energy of the maximum stress part of the history of rock sample A1 during the cycle of unloading and cycling from 1 to 12 times tends to decrease with the increase in the number of cycles and is 0.448 in the 12th cycle. The ratio of the absolute energy of the maximum stress part of the acoustic emission during cycles 1–9 showed an overall decreasing trend with the increase in the number of cycles and was 0.151 at the ninth cycle. The ratio of the absolute energy of the maximum stress part in terms of the history increased rapidly during cycles 9–11 and was 0.97 at the 11th cycle. The ratio of the absolute energy of the maximum stress part in terms of the history decreased slightly at the 12th cycle, and its value was 0.756. The ratio of the absolute energy of the maximum stress part in terms of the history in the process of cyclic loading and unloading of rock sample B1 from 1 to 8 times tends to decrease with the increase in the number of cycles, and the ratio of the absolute energy of the maximum stress part in terms of the history is 0.834 at the first time and 0.111 at the eighth time. The ratio of the absolute energy of the maximum stress part in terms of the history during the cyclic unloading of the dry and saturated rock samples was 0.815 at the eight time, after a linear increase from 0.952 to 0.315 at the sixth to eight times. The absolute energy of dry and saturated rock samples in the early and middle stages of cyclic unloading is mainly generated by the historical maximum stress fraction, while, in the later stages of cyclic unloading, the absolute energy is mainly generated by repeated unloading.

At the same time, the development of dissipative strain energy promotes the development of local deformation; that is, the dissipative strain energy contributes to the rupture damage of the rock, and the accumulation of elastic strain energy leads to the enhancement of the damage capacity of the rock. The physical meaning of the ratio of absolute energy as a part of dissipative strain energy to dissipative strain energy is the ratio of energy generated by rock micro-rupture to dissipative energy, and its trend reflects the rupture damage characteristics of rocks to a certain extent, providing new indicators to reveal the damage mechanism of loaded rocks from the energy perspective. The authors accumulated the absolute energy of acoustic emission during each cycle of loading and unloading and compared the absolute energy with the dissipated strain energy during each cycle of loading and unloading.

Figure 15 shows the trend of the ratio of absolute energy to dissipated strain energy for dry and saturated rock samples with the increase in the number of cycles of loading and unloading. The ratio of absolute energy to dissipated strain energy of rock sample A1 showed a trend of “decreasing–steady–increasing” with the increase in the number of cycles, while the ratio of absolute energy to dissipated strain energy of rock sample A2 showed a trend of “steady–increasing” with the increase in the number of cycles, and the ratio of absolute energy to dissipated strain energy of rock samples B1 and B2 showed a trend of “steady–increasing” with the increase in the number of cycles. The ratio of absolute energy to dissipated strain energy of rock samples B1 and B2 showed a trend of “overall decrease–sudden increase” with the increase in the number of cycles. By analyzing all rock samples, it was found that the absolute energy to dissipation strain energy ratio of rock samples showed some dispersion with the number of cycles, but the absolute energy to dissipation strain energy ratio of rock samples showed a sudden increase at the last cycle of unloading. The authors suggest that this is related to the unstable development and rapid expansion of internal microcracks when the rock is about to be damaged. The last cyclic unloading is the stage when the rock fractures are fully developed and will undergo violent expansion and deformation. The damage of cyclically unloaded rocks is the result of both fatigue caused by repeated unloading and microfractures caused by maximum stress, which is more complicated than the rupture damage of uniaxially loaded rocks. Rupture occurs when microcracking sets form a local weakness at the macroscopic critical scale, and, finally, a fracture surface is formed. The emergence of macroscopic cracks is a sign of a qualitative change in the evolution of sandstone damage, and multiple ruptures lead to the destabilization of the load-bearing rock when the increase in the volume strain value reaches the maximum value before the damage, and the violent rupture activity leads to a sudden increase in the absolute energy of acoustic emission. Combined with the analysis in

Figure 11, the change in the dissipative strain energy of dry and saturated rocks increased abruptly during the last cycle of loading and unloading, and the abrupt increase reached the maximum value before rock damage, but the abrupt increase was smaller compared to the abrupt increase in absolute energy. Therefore, the ratio of absolute energy to dissipated strain energy increased abruptly during the last cyclic loading and unloading, and this increase can be used as a precursor to the damage of the cyclic unloaded rock. After a sudden increase in the absolute energy to dissipated strain energy ratio, the rock is damaged during the loading phase of the next cycle, either when the stress at the time of damage exceeds the maximum stress value of the last cyclic unloading, as in the case of rock sample A1, or when the maximum stress value of the last cyclic unloading is not reached, as in the case of rock samples A2, B1, and B2.

6. Conclusions and Discussion

In this paper, the strain energy characteristics of dry and saturated rocks during cyclic loading and unloading were assessed to investigate the quantitative relationship between the strain energy and absolute energy of acoustic emission. Based on this, an artificial intelligence model for predicting dissipative strain energy under the action of cyclic rock loading and unloading is constructed. The following results can be obtained:

- (1)

Water saturation promotes an increase in dissipative strain energy during the last cycle of unloading, but suppresses the sudden drop in elastic strain energy. The increase in dissipative strain energy at the last cyclic unloading (near damage) was 0.03469 and 0.04539 for dry and saturated rocks, respectively, while the decrease in elastic strain energy was 0.06054 and 0.0092, respectively.

- (2)

Both repeated unloading and historical maximum stress affect the damage rupture process of rocks. The absolute acoustic emission energy of dry and saturated rock samples in the early and middle stages of cyclic unloading is mainly generated by the historical maximum stress part, while, in the later stages of cyclic unloading, the absolute acoustic emission energy is mainly generated by repeated unloading.

- (3)

The absolute energy ratio index of cyclically unloaded rocks was defined, i.e., the ratio of absolute acoustic emission energy to dissipation energy at each cyclic unloading, and it was found that the absolute energy ratio index of both dry and saturated rock samples showed a sudden increase at the last cyclic unloading, and the sudden increase was taken as a precursor of the damage of cyclically unloaded rocks.

- (4)

The dynamic adjustment coefficient of dissipative strain energy, i.e., the ratio of dissipative strain energy to unloading stress during the cyclic unloading of sandstone, was defined, and the prediction of the dynamic adjustment coefficient of dissipative strain energy was carried out by a recurrent neural network.

However, it is worth mentioning that this study is only based on uniaxial cyclic loading and unloading tests of sandstone. More tests should be conducted on some other types of rocks and even other materials in future studies to validate the artificial intelligence model developed. In addition, the damage precursor characteristics of cyclic unloading rocks proposed in this paper are only for laboratory rock samples; for practical engineering problems, it is necessary to collect and calculate the stress–strain and strain energy data of engineering rocks in the field and establish a new sample library for cyclic neural network training, to establish a dissipative strain energy prediction system for practical engineering.