Abstract

Grinding iron ores in conventional ball mills involve a considerably high consumption of metallic media, resulting in high operating costs. In the case of compact itabirites, the high silica content increases such consumption, potentially exceeding the costs associated with electric power consumption in industrial operations. This paper presents research conducted to assess the use of compact itabirite samples obtained from an industrial crushing plant as grinding media to assist conventional ball grinding in the same installation. In this case, the mill charge included both coarse ore fragments and steel balls. Two ore samples were characterized, and bench-scale grinding tests were carried out in laboratory mills 30 and 58 cm in diameter. The results indicated that coarse compact itabirite ore (pebbles) can be used as grinding media. Grinding tests have shown that replacing 25% of the steel balls with pebbles offered promising results. Their use as mixed grinding media results in a relatively minor increase in power consumption and low pebble wear.

1. Introduction

The world mining industry has seen a clear downward trend in ore grade in operating mines [1,2]. The Brazilian Iron Quadrangle, a region of great mineral wealth in the state of Minas Gerais, has undergone changes in ore quality over the years [3]. In the mid-1940s, iron ore processing comprised only crushing and screening. Currently, some processing plants also perform grinding and concentration steps (such as flotation). Ore processing plants that used to process richer ores, such as compact and friable hematite, had to increase the feed mass flow rate to ensure the same level of production when they started processing lower grade ores, such as friable and compact itabirite, materials that are the focus of this study. In addition, compact itabirite has led to a significant increase in grinding media consumption when compared with friable itabirite ore [4,5].

Grinding usually accounts for most of the energy consumption in ore processing plants [6]. The plant’s energy consumption increases as the grind size becomes smaller; that is, the smaller the required particle size of product, the greater the energy consumption in the comminution stage [7].

In addition to the direct consumption of energy from grinding, steel balls have an embodied energy (mining, smelting, and transport), which may increase the circuit’s specific energy by 3.4 kWh/t, adding to the consumption during the grinding itself because of wear [8]. Some ore processing plants have a high grinding media consumption, as is the case in the mill studied herein, which currently consumes around 13 kt per year of steel balls to process itabirite ores, with an average flow of 1433 t/h in two parallel lines of primary and secondary ball mills. The ore feed consists of around 70% friable itabirite and 30% compact itabirite, with an expected increase in the percentage of the latter in the future.

The grinding circuit’s idle capacity in the present case study was one reason for evaluating the use of pebbles as a replacement for a portion of the steel balls in the grinding charge. The use of pebbles as grinding media is a known practice throughout the world [9,10,11,12] and stands out for its low operating cost when using processed ore as grinding media, thus eliminating the operating cost of grinding media (such as balls or rods) [6,13]. Pebbles can come from previous processing steps, such as autogenous or semi-autogenous primary crushing and/or grinding, or from external sources, such as gravel pebbles or ceramic balls [13]. In Scandinavia, a common use of this grinding approach is found in the AG–Pebbles circuit, where the primary grinding is carried out by an AG mill, and the secondary grinding by a pebble mill using pebbles generated in the autogenous primary mill as grinding media. It has found application in both older plants, such as the LKAB iron mine in Sweden [12], and newer plants, such as the expansion project of the copper processing plant at the Boliden AITIK mine, also in Sweden [14].

Certain studies have analyzed the partial replacement of steel balls by pebbles, resulting in a mixed load, as in the case of the present study [15,16,17,18]. Loveday [17] analyzed, on a laboratory scale, the use of small pebbles of 7 to 25 mm to fill the interstices of 40 mm steel balls, studying the grinding with a mixed load. The results were encouraging, and the best condition considered 75% steel balls and 25% small pebbles. The product contained the same quantity of fines, and the energy savings were around 12%, in addition to the implied savings of 25% lower steel ball consumption. Nkwanyana and Loveday [15] continued this study, conducting tests on a pilot scale with the same size distribution of the grinding media as in the first study. The results indicated high consumption of pebbles. New tests were conducted with pebbles of between 19 and 75 mm, 37.5 mm balls, and the replacement percentage of steel balls at 25%. In this case, the results showed energy consumption of 45.88 to 39.72 kWh/t of new fines, without impacting productivity. Nkwanyana and Loveday [16] used SABC grinding parameters on a pilot scale trial with 75 mm balls and pebbles between 19 and 75 mm. The mill throughput dropped with this condition. By changing the substitution to pebbles in smaller sizes, it was possible to keep the same feed rate as the base case, with the additional savings in grinding media and energy consumption. Despite the similar objectives of the present work and the studies carried out by Nkwanyana and Loveday, there is an important parameter that differs between the projects: the shape of the grinding media. Pebbles from autogenous and semi-autogenous grinding have a rounded shape. The present work included the use of pebbles from the secondary and/or tertiary crushing stage, without the rounding stage. Therefore, particles tended to have a more angular and irregular shape, which can result in potentially significant changes in grinding efficiency [19].

The purpose of this paper is to evaluate the effects and the possibility of replacing part of the steel grinding media with pebbles formed by the coarse fraction from the secondary and/or tertiary crushing.

2. Materials and Methods

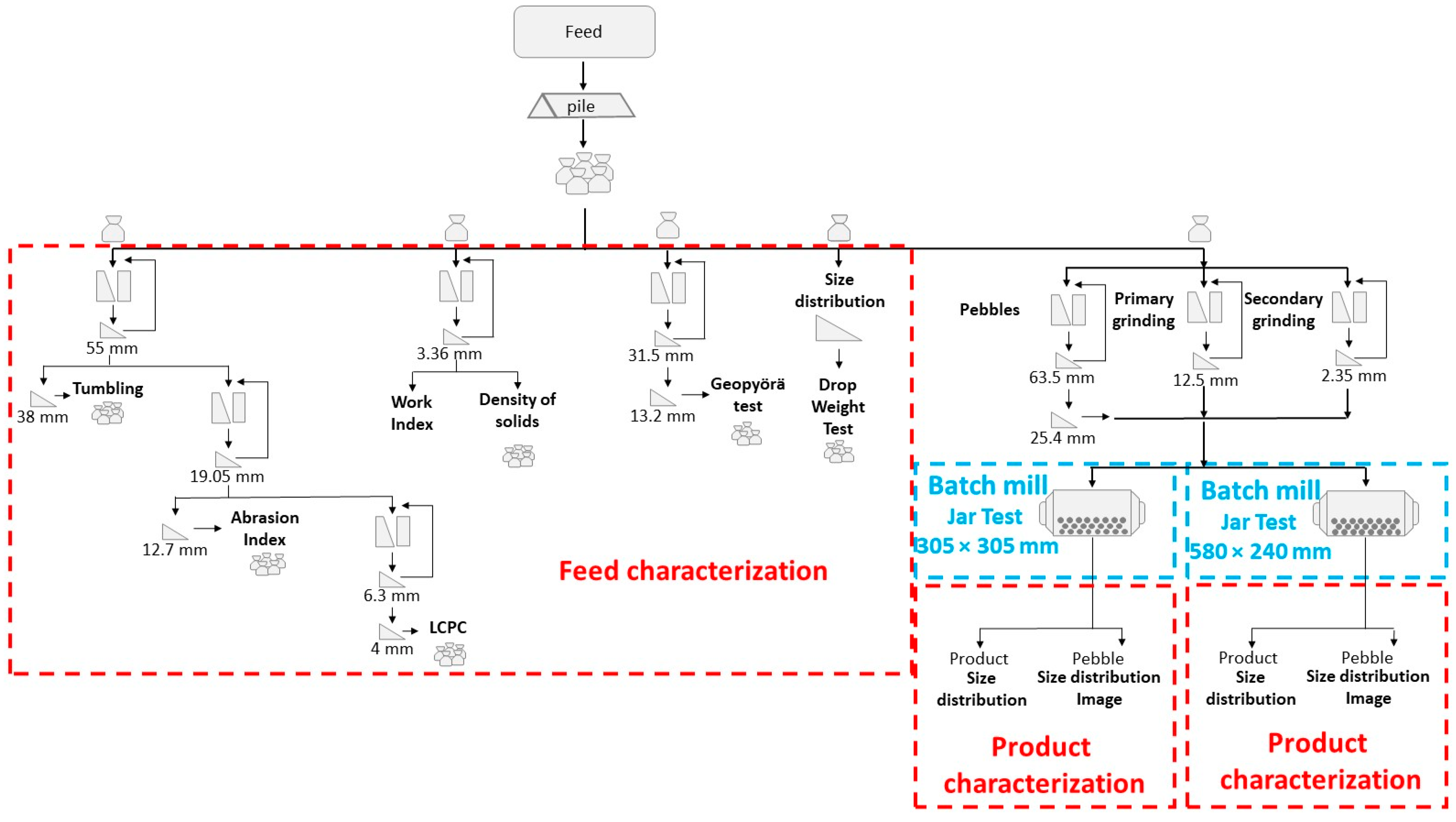

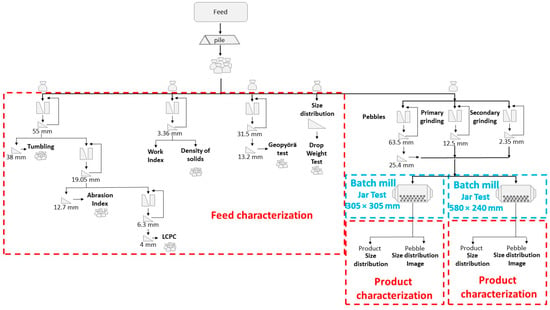

Typical samples of friable and compact itabirite from one iron operation in the Brazilian Iron Quadrangle were selected and forwarded to the Mineral Processing Laboratory at the University of São Paulo for testing. In the first step, homogenized aliquots of these initial samples were prepared (crushed and screened) and characterized using the following tests: determination of the particle size distribution, Bond abrasion index (AI), Bond balls work index (WI), Laboratoire Central des Ponts et Chaussées abrasiveness test (LCPC), helium pycnometry, chemical and mineralogical analysis, Geopyörä breakage test, drop-weight test (DWT), tumbling abrasion test, and a rounding observation grinding test (based on tumbling principles). The tumbling and DWT tests were carried out only on the compact itabirite sample because of the particle size. Figure 1 shows a flowchart of performed tests.

Figure 1.

Test flowchart.

The particle size analysis used a portion of the initial samples and was carried out in two stages: dry screening in a 500 mm × 500 mm square sieve above the 2.36 mm mesh and wet screening using sieving equipment (model EML 450 digital plus, Haver & Boecker®, Oelde, Germany) provided with an ultrasound vibration arrangement below the 2.36 mm mesh. Chemical and mineralogical analyses were made at Vale’s laboratories. The density of the solids was determined at LCT-USP through pycnometry using helium gas as a reference.

The WI test was carried out according to the procedure described by Bond [20], using a 0.150 mm test mesh and a −3.36 mm feed size. For the friable itabirite, the first cycle was adjusted as recommend by McIvor [21], as the fresh feed contained more than 30% of material passing the closing screen aperture. The abrasiveness test was performed according to the procedure proposed by Bond and described by Bergstrom [22]. The LCPC test was carried out with the same objective as Bond’s AI test. It also reproduced the index of abrasiveness measured by the wear of a steel blade using less material and requiring a finer particle size than the Bond AI test.

A simplified method [23] was used to perform the drop-weight test (DWT) solely on compact itabirite. It consisted of dropping a weight from a predetermined height onto a single particle in the −22.4 + 19.0 mm particle size range and then calculating the energy required to break it [24]. Another test, the Geopyörä [25], was carried out with the same objective as the DWT to compare the itabirite samples, yet with different particle size and mass requirements. The test consisted of two wheels rotating in opposite directions, with the resulting compression force breaking the particles passing between the wheels. The force required for breakage was subsequently applied to calculations that resulted in a breakage index [25].

The tumbling test was used to determine the resistance to fragmentation by abrasion, as described in detail in Napier-Munn et al. [24]. It involved tumbling 3 kg of compact itabirite ore in the −55 + 38 mm particle size range within a 305 mm × 305 mm jar. The jar was fitted with lifting bars so that ore particles were projected against each other. The ore was then processed for 10 min at a speed of 53 rpm.

After the characterization, the second stage of the work consisted of conducting grinding tests on a laboratory scale using the method proposed by Donda [26]. An initial exploratory analysis was carried out on a 305 mm long mill, 305 mm in diameter, fitted with a smooth lining and a torque measurement device (model MKDC-50, manufactured by MK Controle e Instrumentação with 0.3% error, São Paulo, Brazil), designated Mill 1 and shown in Figure 2a. Then, additional tests were conducted in a 240 mm long mill, 580 mm in diameter, also equipped with a torque measurement device (model DR-3000, manufactured by Lorenz Messtechnik GmbH with 0.1% error, Alfdorf, Germany), designated Mill 2 and shown in Figure 2b. Tests with Mill 2 were conducted at the Mineral Technology Laboratory of the Federal University of Rio de Janeiro. A greater number of tests were carried out in the smaller mill, since its operation was easier and therefore allowed more grinding variables to be tested. For example, the ball charge used in Mill 1 reached 31 kg, and in Mill 2 it reached 88 kg.

Figure 2.

Test mills. (a) LTM-USP 305 mm × 305 mm mill; (b) LTM-UFRJ 580 mm × 240 mm mill.

The grinding parameters are set out in Table 1. The pulp volume was such to fill the voids in the grinding media charge, which was estimated at 40% in all tests.

Table 1.

Grinding parameters.

The tested ore feed was consistent with the parameters used in the investigated plant; that is, the proportions of friable and compact itabirites for both grindings were 70% and 30%, respectively. The ore top sizes were 12.5 and 2.35 mm for primary and secondary grinding, respectively. The grinding times in Mill 1 were chosen according to a grinding curve for each condition, so that the output size distribution was as close as possible to the desired one, which was 80% passing in 1 mm for the primary grinding and 95% passing in 0.150 mm for the secondary grinding. In Mill 2, the times were chosen according to the energy consumed in Mill 1 for each condition.

The pebbles’ particle sizes ranged from 63.5 to 25.4 mm in all grindings. This range was selected for the primary grinding based on industrial plants that use pebble mills [8], and for the secondary grinding because the mass of pebbles would be closer to the mass of steel balls, which was in line with the literature regarding pebble grinding optimization [6,13]. To calculate the consumption of pebbles, the difference between the initial mass and the final mass of these grinding media for the −63.5 + 24.5 mm particle size was determined, and the percentage that this delta represented of the final mass of ore in the test was calculated. This percentage was the pebble consumption.

The steel ball size distribution was calculated from the mill feed’s particle size (63.5 mm in primary grinding and 50.8 mm in secondary grinding), with the aim of simulating the steady state of a continuous grinding operation [24]. Table 2 shows the ball size distributions. The steel ball density was 7.77 g/cm3, and the pebble density was 3.54 g/cm3.

Table 2.

Steel ball mass distribution.

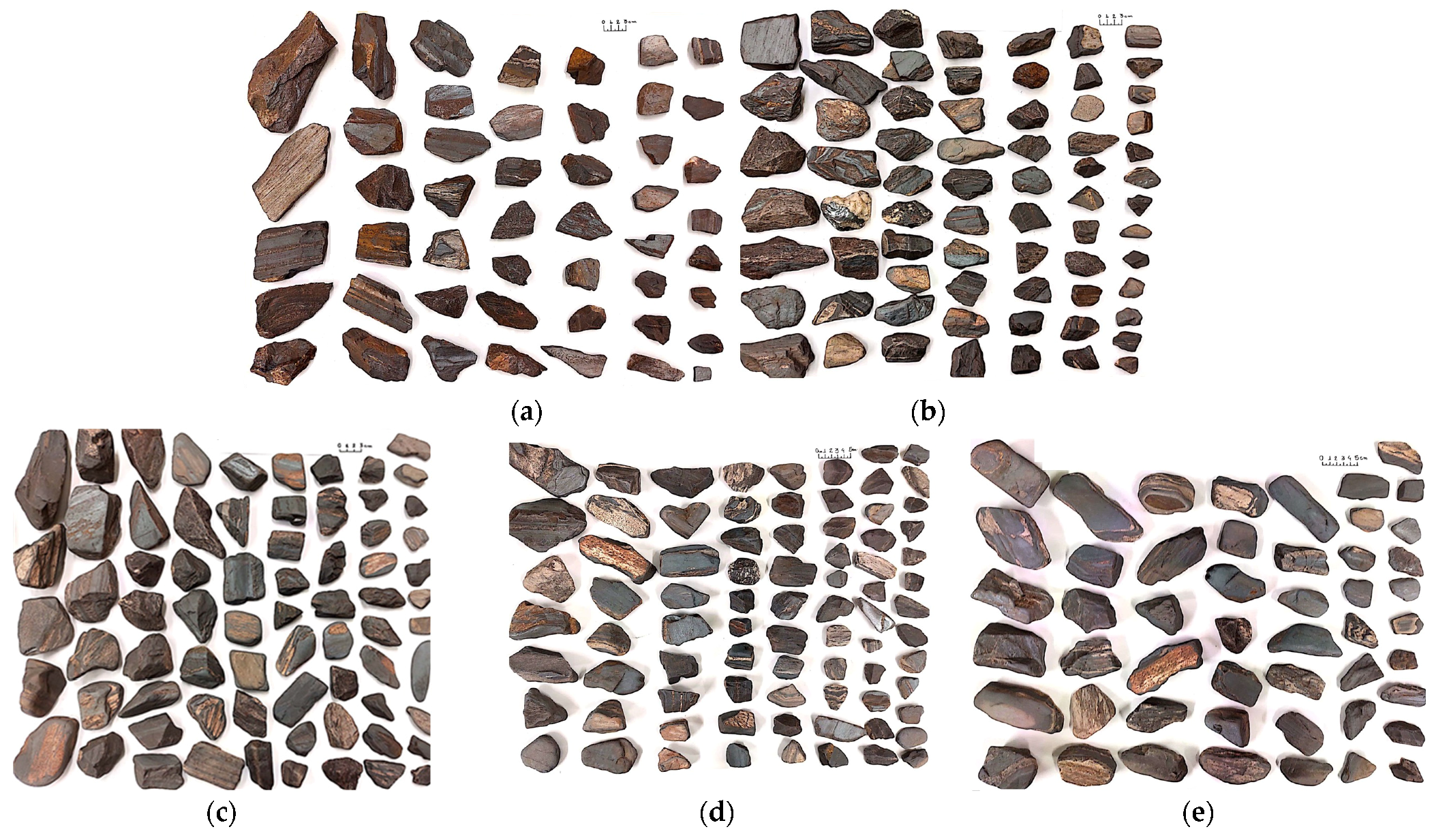

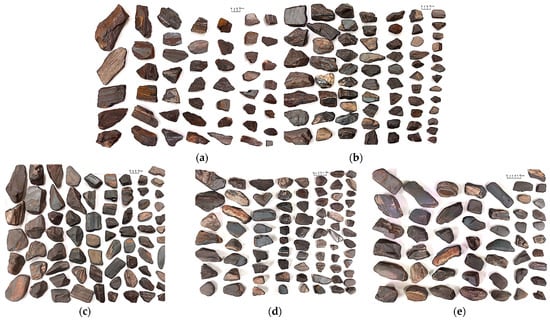

Another test was carried out in Mill 1 to investigate certain conditions that optimized pebble grinding. This grinding test was carried out with 100% pebbles as grinding media, considering two different parameters: higher pulp dilution (from 74% to 69% solids) and higher rotation speed (from 72% to 76% of the critical speed). Both parameters were deemed to optimize pebble grinding, as described in the literature [13]. A final observation test was performed to qualitatively analyze pebble wear and rounding. The tumbling test allowed a quantitative analysis of the rounding, but the qualitative analysis of how the pebbles behaved during the milling was also important in order to understand how the wear of the grinding media was occurring. It was carried out under secondary grinding conditions using 100% pebbles, as will be explained later. The pebbles were dried and screened after every 30 min of testing, and the particles were photographed. After analysis, pebbles of −63.5 + 25.4 mm were reused as grinding media. This procedure was repeated five times in Mill 1 and three times in Mill 2, totaling 150 and 90 min, respectively (the mills are shown in Figure 2).

Equation (1) gives the required electric motor power for each test:

where P is the power consumed by the motor (kW), n is the motor rotation speed (rpm), Tc is the full mill torque (Nm), and Tv is the empty mill torque (Nm). Based on the power value, Equation (2) gives the specific energy value in kWh/t.

where t is the test time (hours) and m is the mass of ore feed (t).

The specific energy per size fraction SSE [27] was calculated according to Equation (3), considering 1 mm for primary grinding and 0.15 mm for secondary grinding.

where SSE is the size-specific energy (kWh/t of fine generated), E is the calculated specific energy (kWh/t), Fn is the percentage of passing feed for particle size n, and Pn is the percentage of passing product for particle size n.

Finally, the −0.038 mm product from each test using Mill 1 was analyzed using the granulometric analysis method of low angle laser scattering (equipment manufactured by Malvern Panalytical, model Hydro 2000MU, Malvern, UK) to determine the generation of slimes, i.e., material below 0.010 mm, which is detrimental to the later stages of mineral processing [28,29].

3. Results and Discussion

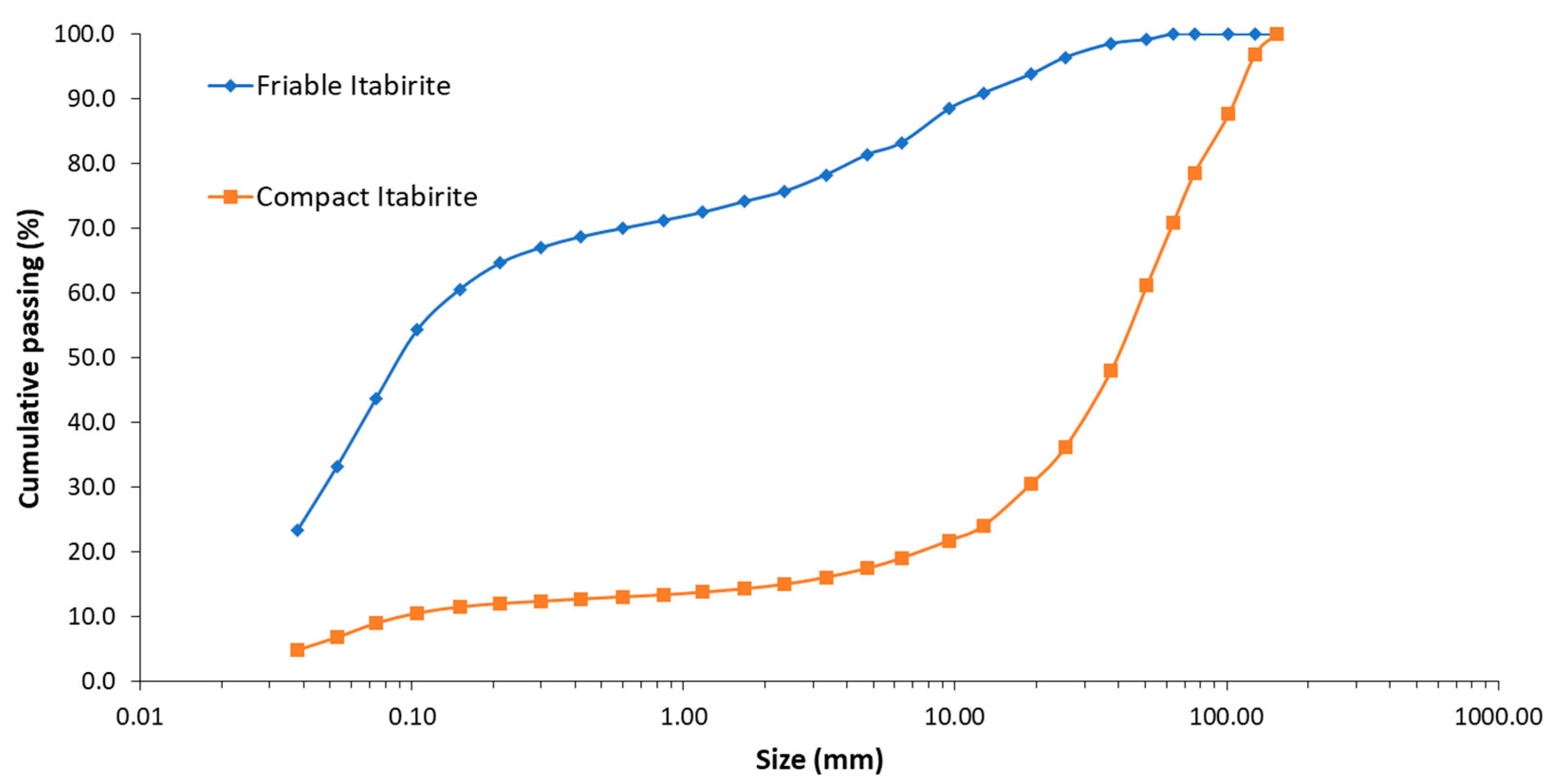

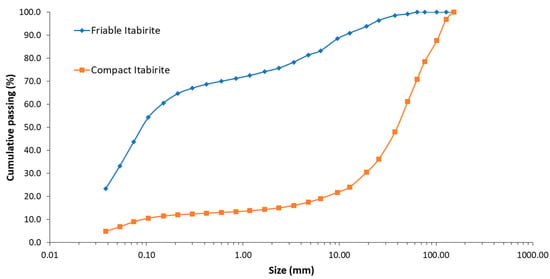

The particle size analysis results for the initial samples are shown in Figure 3. The compact itabirite sample showed a top size of 150 mm, with a significantly coarser particle size than the friable itabirite sample, with a top size of 63.0 mm.

Figure 3.

Particle size distribution in the initial sample.

Table 3 presents the results of the chemical, mineralogical, and helium pycnometry tests.

Table 3.

Chemical and mineralogical analysis results and actual density of solids.

Table 3 indicates that there were no significant differences in the results of the chemical and mineralogical analyses performed on the compact and friable itabirite samples. The same situation was observed in terms of the density of solids.

Results for other characterization tests are shown in Table 4.

Table 4.

Sample characterization results.

One can see from Table 4 that both the Bond AI and LCPC indicated a greater abrasiveness of compact itabirite in relation to the friable itabirite, with the first being classified as highly abrasive and the second as moderately abrasive [30].

The WI value of both materials ranked them as soft [26].

The DWT provided a breaking index of 88, which meant low impact resistance [31], whereas the Geopyörä test results indicated that compact itabirite demanded significantly more energy to break than friable itabirite [25].

The tumbling abrasion test result indicated a ta of 0.48, i.e., the compact itabirite sample featured medium resistance to abrasion [31].

Figure 4 presents photos for analyzing the pebble rounding and consumption during the tests, showing the material before and after two different test periods. A high degree of fragment preservation can be seen after several grinding periods, with noticeable edge rounding. The resilience of fragments that did not degrade and kept their original particle size was suitable for use as a grinding medium.

Figure 4.

Pebbles from rounding grinding: (a) test feed pebbles; (b) pebbles after a 30-min test in Mill 1; (c) pebbles after a 150-min test in Mill 1; (d) pebbles after a 30-min test in Mill 2; (e) pebbles after a 90-min test in Mill 2.

The grinding test results were split into primary grinding and secondary grinding, as shown in Table 5 and Table 6.

Table 5.

Primary grinding test results.

Table 6.

Secondary grinding test results.

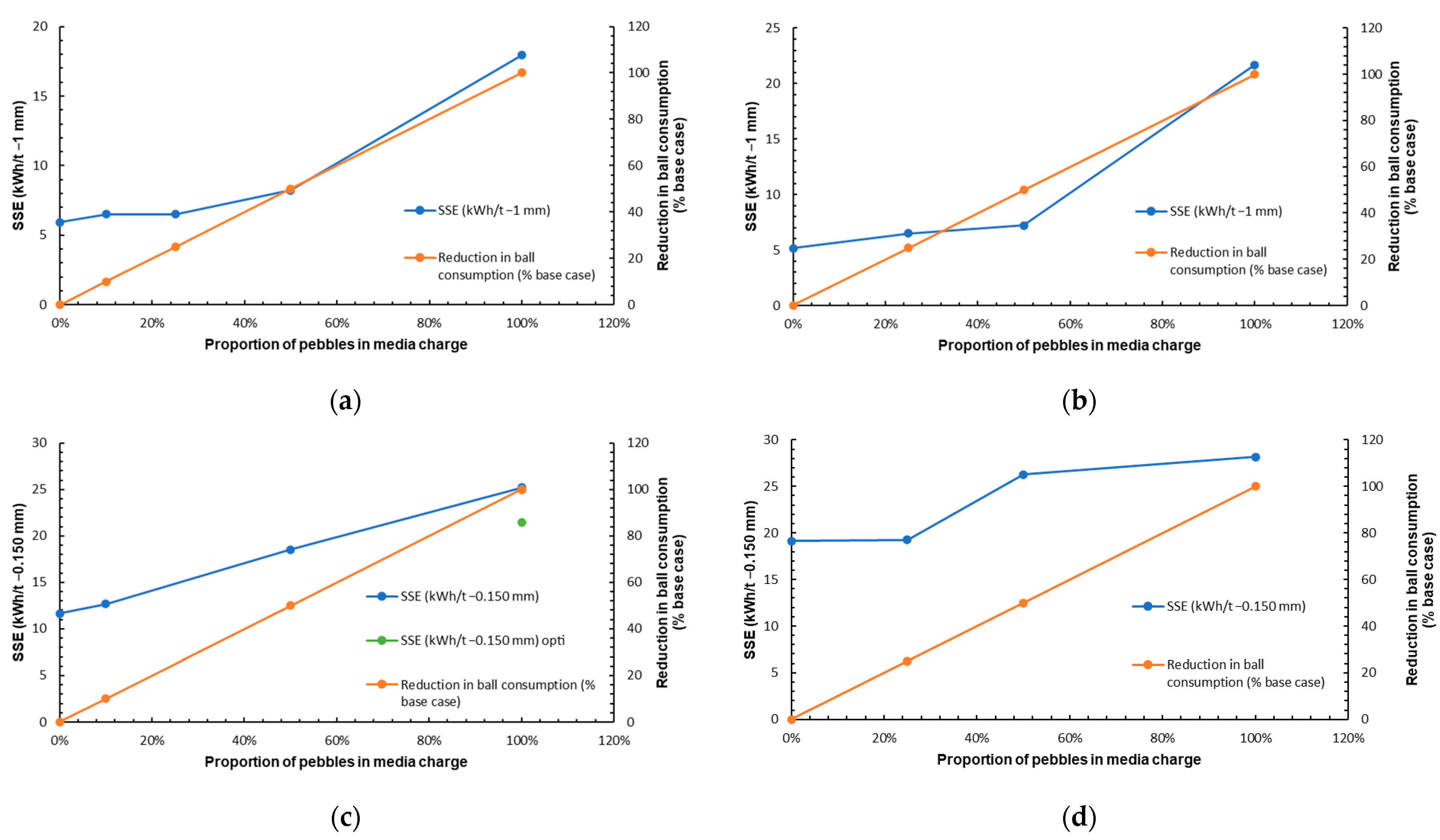

It was seen in all grinding conditions in both laboratory mills that the higher the proportion of pebbles as replacement for steel balls, the progressively higher the pebble consumption, specific energy, and specific energy per size. Figure 5 presents the SSE data and the reduction in ball consumption according to each replacement condition of each of the mills.

Figure 5.

SSEs and reduction in ball consumption. (a) Primary grinding—Mill 1; (b) primary grinding—Mill 2; (c) secondary grinding—Mill 1; (d) secondary grinding—Mill 2.

The data of the primary grinding presented in Table 5 and Figure 5a,b indicate that, with the progressive increase in pebble substitution, the most significant increase in energy consumption happened when 100% of the steel balls were replaced with pebbles. In the case of tests conducted in Mill 1, the results for 50% replacement of steel balls with pebbles showed a 49% rise in specific energy, and the option considering 100% replacement of steel balls with pebbles pointed to a 268% rise in this parameter. SSE, in turn, grew 39% and 202% for these two conditions, respectively. Similarly in the case of Mill 2, a significant increase in energy consumption can also be seen when replacing steel balls with pebbles: from 0% to 50% replacement, the specific energy and SSE rose 6% and 26%, respectively, and from 0% to 100% replacement, these increases amounted to almost 271% in specific energy and almost 320% in SSE. The slime generation did not change much with the different grinding conditions, and again indicated the 25% replacement condition as the most advantageous, with only 0.35% more slurry than the base case.

In the secondary grinding, it was possible to see that the conditions with 10% and 25% substitution were the ones with smaller energy additions in relation to the base case, as well as in the primary grinding; results are shown in Table 6 and Figure 5c,d. Considering Mill 1, the condition with 10% replacement stood out from the others, with an increase of only 12% in specific energy and 9% in SSE; the closest condition (50% replacement) had respective increases of 146% and 116%. Figure 5d shows that the 25% substitution condition had an almost negligible increase in energy for a 25% reduction in ball consumption. Another important factor was the grinding with 100% pebbles with optimizing conditions, which led to 12% less energy consumption, changing only the pulp dilution and the mill speed. This confirmed that there were important factors to be observed for the optimization of grinding using pebbles as grinding media. In Mill 2, the increase in specific energy in the condition of 25% replacement was only 0.7%, with 25% savings in grinding media. The slime generation was very close in all the conditions, making it clear that, for the secondary grinding in Mill 1, this variable was not impacted.

Such results suggested that partial replacements were more promising than the total replacement of steel balls with pebbles. In this respect, the most promising case in terms of energy consumption in both primary and secondary grinding consisted of replacing 25% of the metallic charge with pebbles, since these results saw a lower impact on the specific energy consumption, but with a 25% reduction of steel balls.

The increasing energy consumption as a result of progressive replacement of steel balls with pebbles can be attributed to the shape and lower density of the latter in relation to the former [12,24]. It is also interesting to note that the increments of grinding energy were significantly lower for secondary grinding compared to primary grinding, as illustrated in Table 6. In this case, the pebble’s abrasive wear may have favored the generation of fine fractions in the product, according to the secondary grinding product size.

Regarding the consumption of pebbles as grinding media, according to Crocker [13], when using 100% pebbles as grinding media, the pebble consumption in relation to the product ranges from 2.6% to 6% for hard ores. Nkwanyana and Loveday [15,16] carried out tests with a mixed grinding charge (pebbles and balls) and obtained pebble consumption results in the range of 6% to 16% using a mill similar in size to Mill 2 of the present study. Based on these results and the data in Table 5 and Table 6, a 10% pebble consumption rate was deemed satisfactory. In both primary and secondary grinding, this condition was achieved with between 10% and 25% of pebbles in the charge in both Mill 1 and Mill 2. Another fact worthy of mention is the similar grinding behavior for both laboratory mills. Moreover, a lower consumption of itabirite grinding media was recorded in the secondary grinding in Mill 2, with the largest diameter. Another consideration involves the processing of pebbles industrially. In the case of the plant studied in this paper, an alternative would be the partial or total deviation of the oversizing of some of the crushing stages to a stock pile in order to be used as grinding media.

It should be emphasized that in considering the option of 25% pebbles in the charge, an increase in energy consumption between 0.7% and 14.4% in the grinding stage led to a 25% decrease in steel ball consumption, thus allowing a significant reduction in operating costs. Therefore, the analyses indicated that the 25% replacement condition was the most promising scenario among the studied conditions and confirmed the literature data for similar applications [18].

As an aid to the analysis of this study, we suggest larger scale tests, such as pilot plant trials [15,16], and the evaluation of different conditions using simulations [12,32]. In the economic analysis of this alternative, it is also important to consider the additional workload on site of pebble handling owing to the high consumption of pebbles compared to steel balls.

4. Conclusions

The present study evaluated the possibility of partially replacing steel balls in a conventional ball mill with pebbles from the crushing stage. Characterization tests showed that the properties of compact itabirite favor its use as a grinding medium. In addition, tests showed that the compact itabirite, whose percentage is expected to increase in the processing at the plant, has a much higher abrasiveness than friable itabirite, a material that tends to be less processed. This characteristic may cause the problem of grinding media consumption in the future, reinforcing the importance of studies such as this one. The results of the tumbling tests were in line with the rounding test based on visual analysis, thus corroborating the promising properties of compact itabirite as a grinding medium.

Grinding tests determined that a partial replacement of steels balls with 25% pebbles can achieve positive results when compared to using only balls or only pebbles as grinding media. Furthermore, tests with a larger diameter laboratory mill did not indicate greater wear of the pebbles as grinding media, which supported the conclusion on the use of mixed grinding media. The energy consumption during the tests showed that partial substitutions of 10% and 25% presented energy consumption figures very close to the base case of 100% steel balls. Therefore, these substitution ratios should raise interest in economic studies on reducing the steel ball consumption in itabirite ore-grinding circuits.

Author Contributions

Conceptualization, J.G.S. and M.G.B.; methodology, J.G.S. and M.G.B.; software, J.G.S.; validation, J.G.S., M.G.B. and N.L.; formal analysis, J.G.S., M.G.B. and H.D.J.; investigation, J.G.S., M.G.B. and H.D.J.; resources, M.G.B.; data curation, J.G.S., M.G.B. and H.D.J.; writing—original draft, J.G.S.; writing—review and editing, J.G.S., M.G.B., H.D.J. and N.L.; visualization, M.G.B., H.D.J. and N.L.; supervision, J.G.S., M.G.B. and H.D.J.; project administration, J.G.S. and M.G.B.; funding acquisition, M.G.B. and N.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior) for funding for DS edict process #88887.606604/2021-00, CNPq (Brazilian Technological and Scientific Development Council) for productivity grant under processes #313411/2019 and post-doctoral grant under process #200298/2022-4, Sao Paulo Research Foundation (Fapesp) for the BPE grant under process #2021/11923-9 and the Thematic Project under process #2019/11866-5.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the company Vale SA, the LTM COPPE/UFRJ, Luis Marcelo Tavares, Victor Rodriguez, and Arthur Pinto Chaves in the development of this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Norgate, T.; Jahanshahi, S. Reducing the Greenhouse Gas Footprint of Primary Metal Production: Where Should the Focus Be? Miner. Eng. 2011, 24, 1563–1570. [Google Scholar] [CrossRef]

- Bearman, R.A. Step Change in the Context of Comminution. Miner. Eng. 2013, 43–44, 2–11. [Google Scholar] [CrossRef]

- ANM. Informe Mineral—2° Semestre; Agência Nacional de Mineração: Brasília, Brazil, 2019. [Google Scholar]

- Pinto, P.F.; Delboni, H., Jr. Comminution Circuits for Compact Itabirites. REM Int. Eng. J. 2016, 69, 355–359. [Google Scholar] [CrossRef]

- Dorr, J.V.N. Physiographic, Stratigraphic and Structural Development of the Quadrilatero Ferrifero Minas Gerais, Brazil; United States Government Printing Office: Washington, DC, USA, 1969.

- Rowland, C.A. Selection Of Rod Mills, Ball Mills, Pebble Mills and Regrind Mills. In Desingn and Installation of Comminution Circuits; Mular, A.L., Jergensen, G.V., II, Eds.; The American Institute of Mining, Metallurgical, and Petroleum Engineers: New York, NY, USA, 1982; pp. 239–439. ISBN 0-89520-401-0. [Google Scholar]

- Rowland, C.A. Selection of Rod Mills, Ball Mills and Regrind Mills. In Mineral Processing Plant Design, Practice and Control V.1; Mular, A.L., Halbe, D.N., Barratt, D.J., Eds.; Society for Mining, Metallugy, and Exploration, Inc.: Littleton, CO, USA, 2002; pp. 733–735. [Google Scholar]

- Ballantyne, G. Quantifying the Additional Energy Consumed by Ancillary Equipament and Embodied in Grinding Media in Comminution Circuits. In Proceedings of the SAG Conference, Vancouver, BC, Canada, 22–26 September 2019. [Google Scholar]

- Dowling, E.C.; Korpi, P.A.; Mclvor, R.E.; Rose, D.J. Application of High Pressure Grinding Rolls in an Autogenous-Pebble Milling Circuit. In Proceedings of the SAG Conference, Vancouver, BC, Canada, 30 September–3 October 2001; pp. III-194–III-201. [Google Scholar]

- Hahne, R.; Palsson, B.I.; Samskog, P.-O. Abrasion Tests on Iron Ore Evaluated by Multivariate Statistics. In Proceedings of the SAG Conference, Vancouver, BC, Canada, 30 September–3 October 2001; pp. I-326–I-338. [Google Scholar]

- Yahyaei, M.; Limpus, A.; Russell, J.; Toor, P.; Powell, M. Improving Liner Design for Effeciency. In Proceedings of the SAG Conference, Vancouver, BC, Canada, 20–24 September 2015; pp. 1–15. [Google Scholar]

- Powell, M.S.; Benzer, H.; Dundar, H.; Aydogan, N.; Adolfsson, G.; Partapuoli, A.; Wikstrom, P.; Fredriksson, A.; Tano, K. LKAB Autogenous Milling of Magnetite. In Proceedings of the SAG Conference, Vancouver, BC, Canada, 25–28 September 2011; p. 24. [Google Scholar]

- Crocker, B.S. Pebble Mills. In SME Mineral Processing Handbook; Weiss, N.L., Ed.; Society of Mining Engineers: New York, NY, USA, 1985; Volume 1, pp. 3C94–3C107. ISBN 0-89520-433-6. [Google Scholar]

- Markstrom, S. Commissioning and Operation of the AG Mills at the AITIK Expansion Project. In Proceedings of the SAG Conference, Vancouver, BC, Canada, 25–28 September 2011. [Google Scholar]

- Nkwanyana, S.; Loveday, B. Addition of Pebbles to a Ball-Mill to Improve Grinding Efficiency. Miner. Eng. 2017, 103–104, 72–77. [Google Scholar] [CrossRef]

- Nkwanyana, S.; Loveday, B. Addition of Pebbles to a Ball-Mill to Improve Grinding Efficiency—Part 2. Miner. Eng. 2018, 128, 115–122. [Google Scholar] [CrossRef]

- Loveday, B. The Small Pebble Process for Reducing Ball and Power Consumption in Secondary Grinding. In Proceedings of the XXV Internacional Mineral Processing Congress, Brisbane, Australia, 6–10 September 2010; Volume 2, pp. 981–989. [Google Scholar]

- Loveday, B.K. The Use of Small Pebbles for Secondary Grinding. In Proceedings of the SAG Conference, Vancouver, BC, Canada, 25–28 September 2001; pp. 149–158. [Google Scholar]

- Shahbazi, B.; Jafari, M.; Parian, M.; Rosenkranz, J.; Chehreh Chelgani, S. Study on the Impacts of Media Shapes on the Performance of Tumbling Mills–A Review. Miner. Eng. 2020, 157, 106490. [Google Scholar] [CrossRef]

- Bond, F.C. The Third Theory of Comminution. Min. Eng. 1952, 193, 484–494. [Google Scholar]

- McIvor, R.E. Determining the Bond Efficiency of Industrial Grinding Circuits; Global Mining Guidelines Group: Ormstown, QC, Canada, 2015. [Google Scholar]

- Bergstrom, B.H. Abrasiveness. In SME Mineral Processing Handbook; SME Society for Mining, Metallugy, and Exploration: New York, NY, UYA, 1985; pp. 30–70. [Google Scholar]

- Delboni, H., Jr.; Chieregati, A.C.; Bergerman, M.G. Development and Validation of Ore Characterisation Test and Its Use in Variability Campaigns of Comminution Circuits. In Proceedings of the XXV Internacional Mineral Processing Congress, Brisbane, Australia, 6–10 September 2010. [Google Scholar]

- Napier-Munn, T.J.; Morrell, S.; Morrison, R.D.; Kojovic, T. Mineral Comminution Circuits: Their Operation and Optimisation, 1st ed.; Julius Kruttschnitt Mineral Research Centre: Indooroopilly, Australia, 1996; ISBN 064628861X. [Google Scholar]

- Bueno, M.; Torvela, J.; Chandramohan, R.; Chavez, T.; Liedes, T.; Powell, M. The Double Wheel Breakage Test. Miner. Eng. 2021, 168, 106905. [Google Scholar] [CrossRef]

- Rosa, A.C.; de Oliveira, P.S.; Donda, J.D. Comparing Ball and Vertical Mills Performance: An Industrial Case Study. In Proceedings of the XXVII International Mineral Processing Congress, Santiago, Chile, 20–24 October 2014; pp. 44–52. [Google Scholar]

- Ballantyne, G. Assessing Comminution Energy Efficiency with the Size Specific Energy (SSE) Approach. In Proceedings of the 16th European Symposium on Comminution & Classification, Leeds, UK, 2–4 September 2019; pp. 29–30. [Google Scholar]

- Pereira Lima, N.; Valadão, G.E.S.; Peres, A.E.C. Effect of Particles Size Range on Iron Ore Flotation. Rem Rev. Esc. Minas 2013, 66, 251–256. [Google Scholar] [CrossRef]

- Lima, N.P.; de Souza Pinto, T.C.; Tavares, A.C.; Sweet, J. The Entrainment Effect on the Performance of Iron Ore Reverse Flotation. Miner. Eng. 2016, 96–97, 53–58. [Google Scholar] [CrossRef]

- Norgaard, S. Laboratory Test Work and Equipament. In SME Mineral Processing and Extractive Metallurgy Handbook; Dunne, R.C., Kawatra, S.K., Young, C.A., Eds.; Society for Mining, Metallugy, and Exploration, Inc.: Englewood, CO, USA, 2019; pp. 115–145. ISBN 9780873353854. [Google Scholar]

- Lynch, A.J. Comminution Handbook; Australasian Institute of Mining and Metallurgy: Carlton, Australia, 2015. [Google Scholar]

- Gomes, W.L.; Delboni Júnior, H.; Chieregati, A.C.; Jatobá, T.L.A. Development of Ball Mill Test for Simulation of Industrial Circuit. Rem Rev. Esc. Minas 2016, 69, 91–96. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).