Research on Engineering Practice and Effect Evaluation Method of Pressure Relief in Deep Rock Burst Danger Area of Coal Mine

Abstract

:1. Introduction

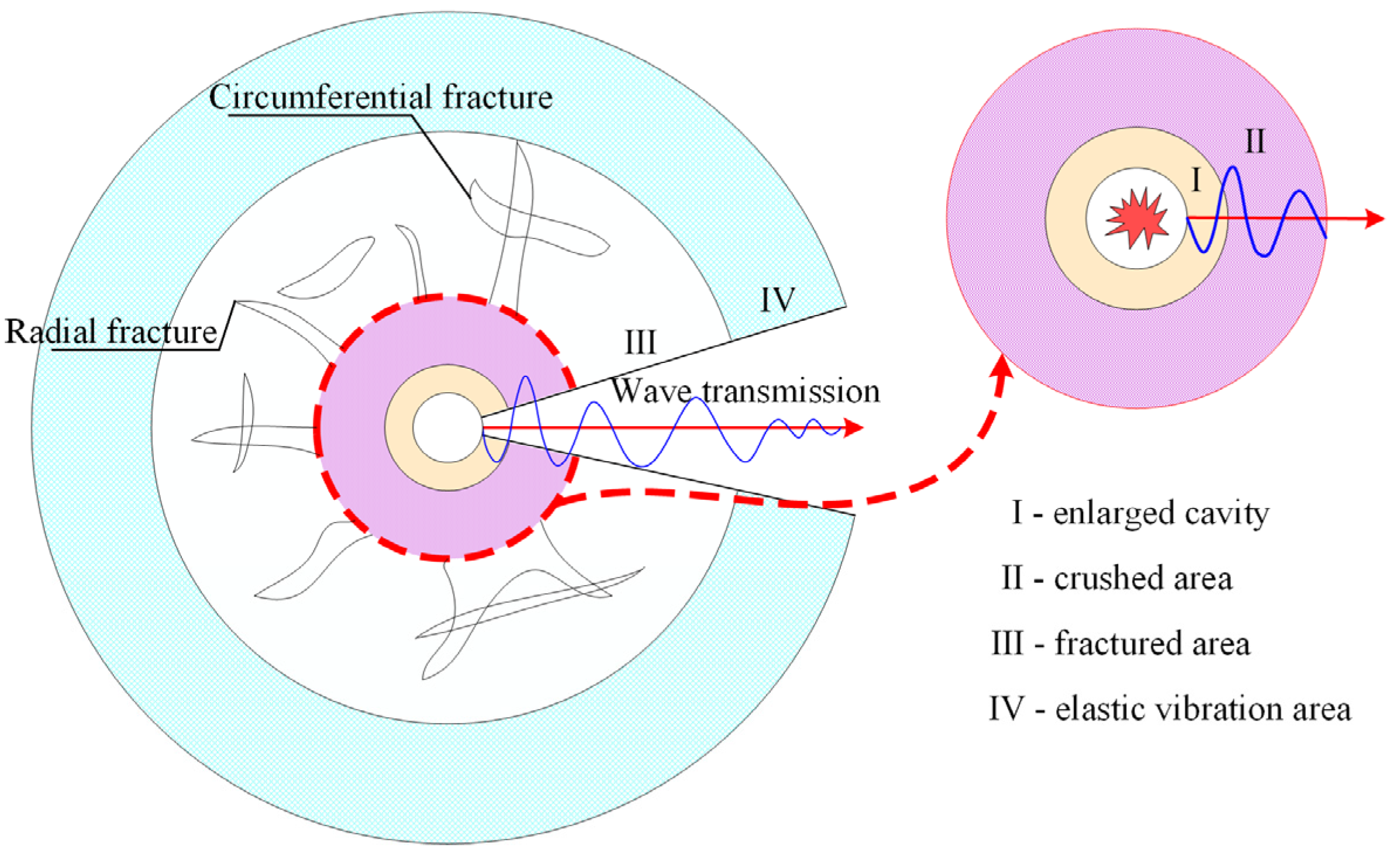

2. Mechanism of On-Site Multi-Dimensional Pressure Relief Prevention and Control Technology

2.1. Mechanism of Pressure Relief by Large-Diameter Drillhole in Coal Seam

2.2. Mechanism of Pressure Relief by Roof Blasting and Destress Blasting in Coal Seam

3. Engineering Background and Practice of Pressure Relief in Deep Rock Burst Danger Areas of Coal Mine

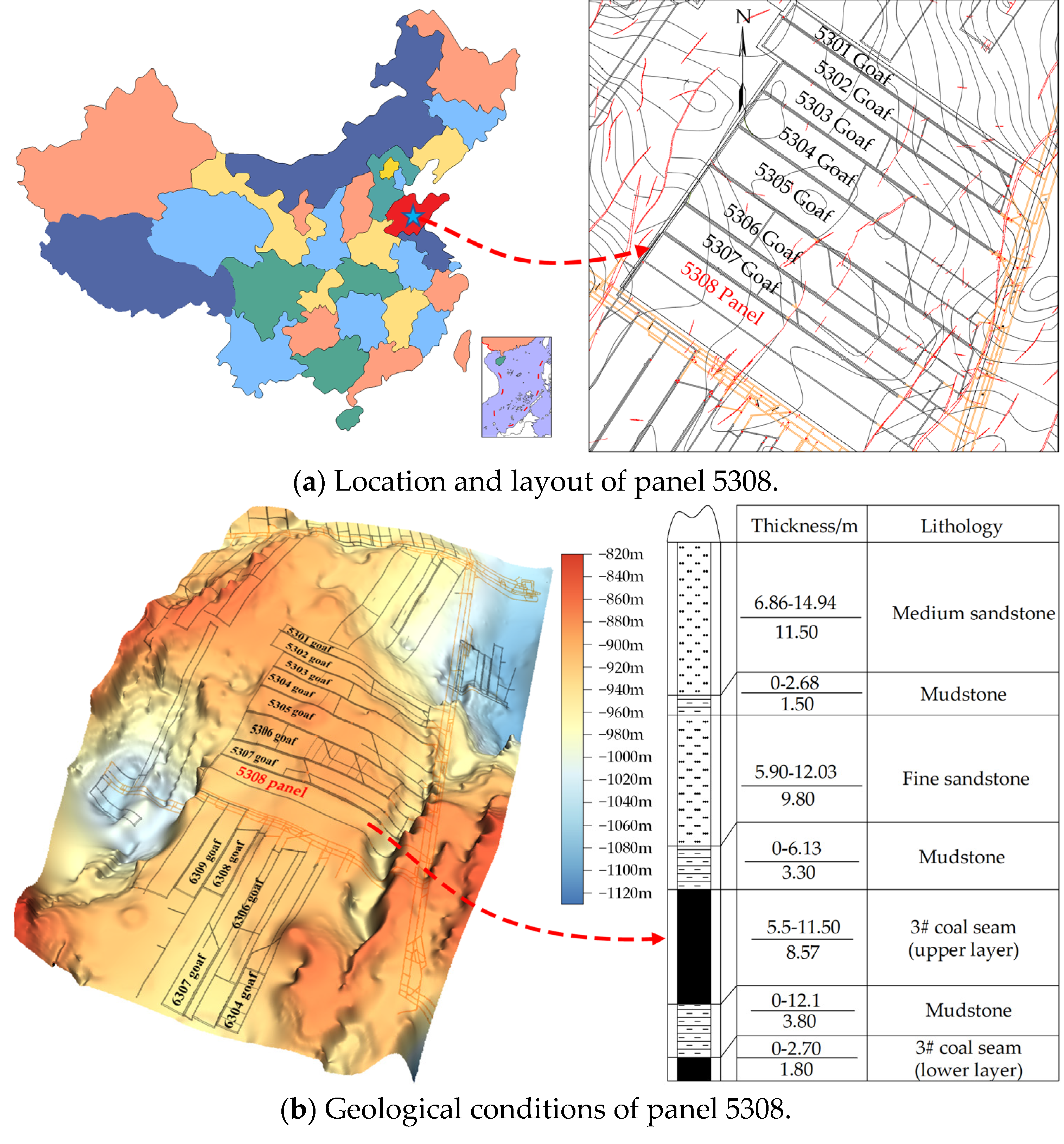

3.1. Engineering Background

3.1.1. Engineering Geological Conditions

3.1.2. Comprehensive Evaluation of Geological Conditions

- Geological structure.

- 2.

- Coal rock structure.

- 3.

- Coal rock burst tendency

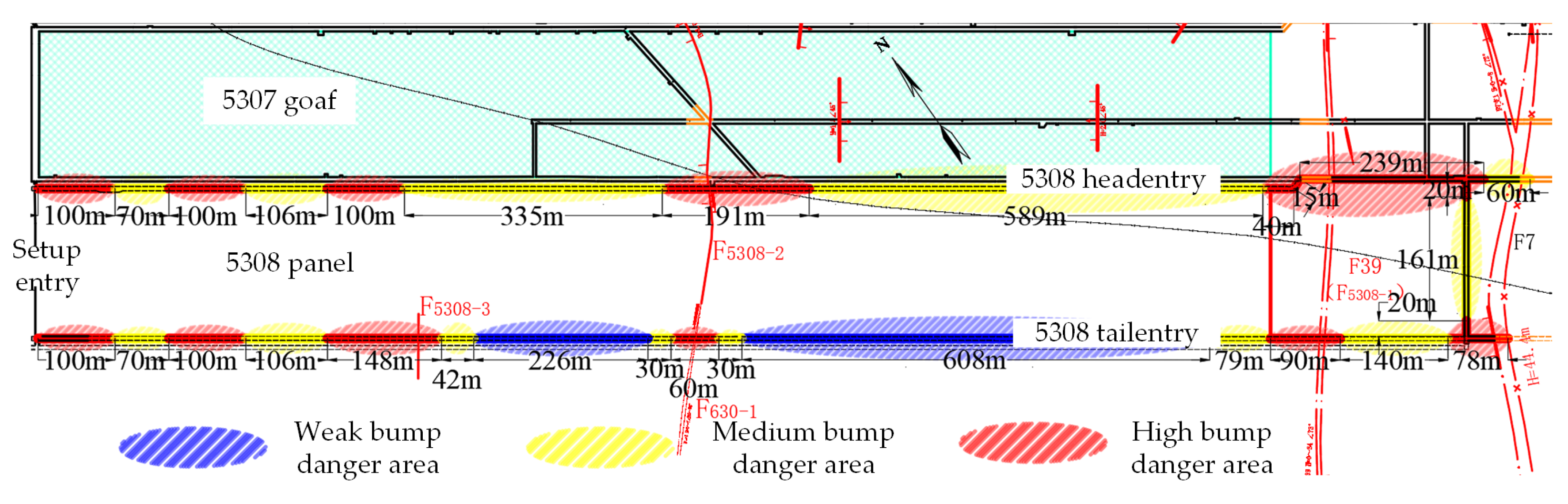

3.1.3. Rock Burst Danger Area Classification

3.2. Engineering Practice of On-Site Multi-Dimensional Pressure Relief

4. Evaluation Method of Pressure Relief Effect in Deep Coal Mine Rock Burst Danger Area

- Construction of comparative scales.

- 2.

- Construction of judgment matrix.

- 3.

- Consistency test.

- 4.

- Determine the weight vector.

- 5.

- Evaluation indicators’ interval index.

- 6.

- Comprehensive evaluation of pressure relief effect.

5. Application of the Evaluation Method in Deep Rock Burst Danger Area of Coal Mine

5.1. Pressure Relief Effect Evaluation of Microseismic Data

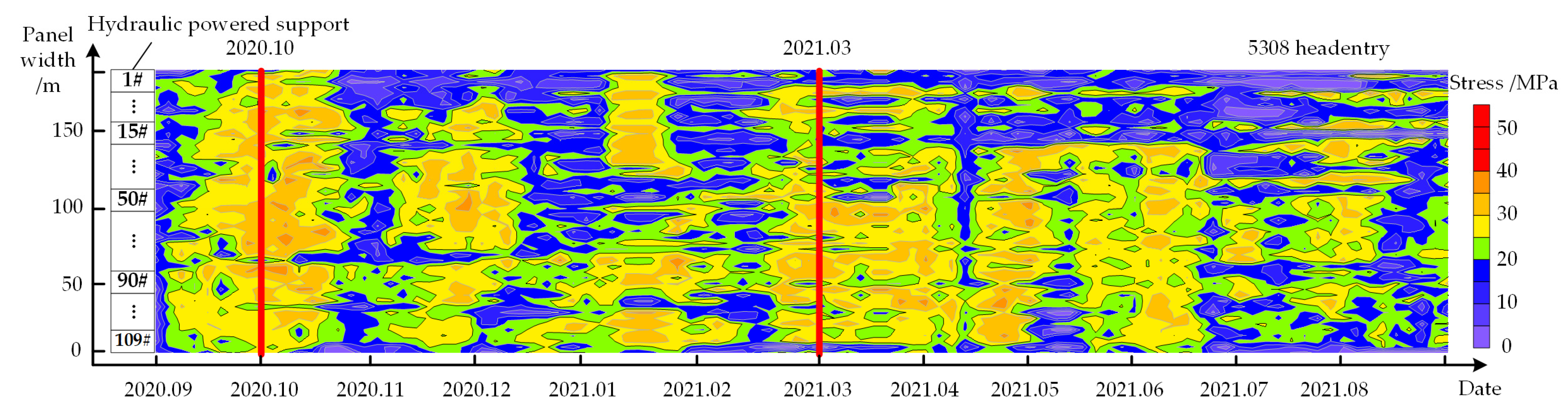

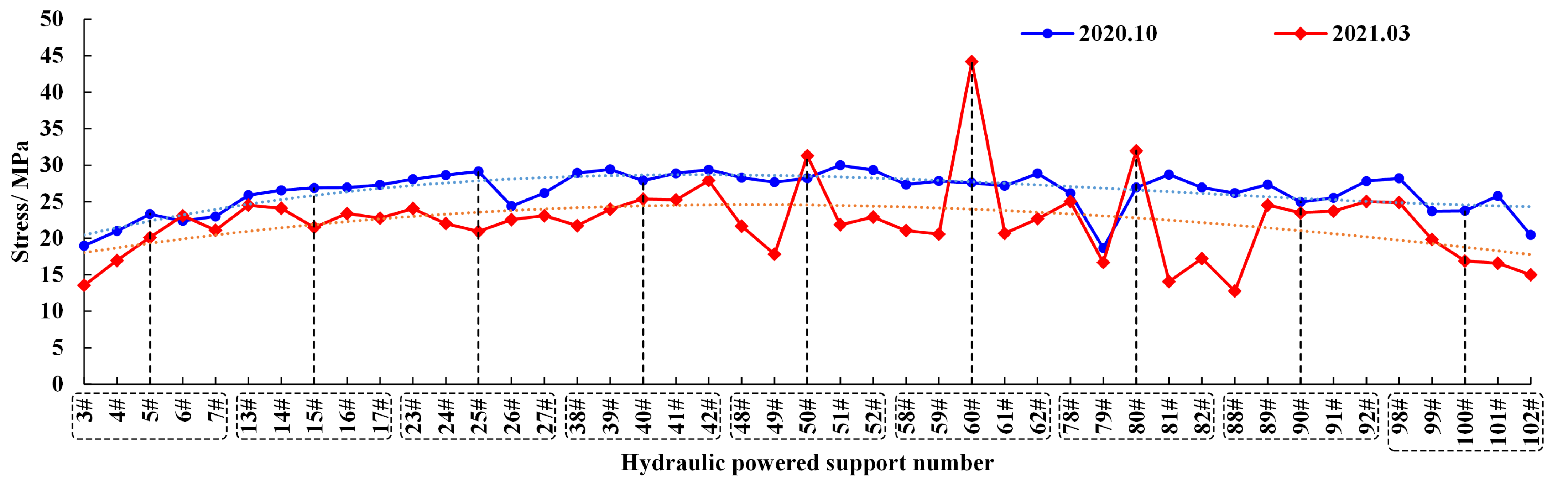

5.2. Pressure Relief Effect Evaluation of Hydraulic-Powered Support Stress Data

5.3. Pressure Relief Effect Evaluation of Bursting Strain Energy

5.4. Evaluation Results of Pressure Relief Effect Based on AHP

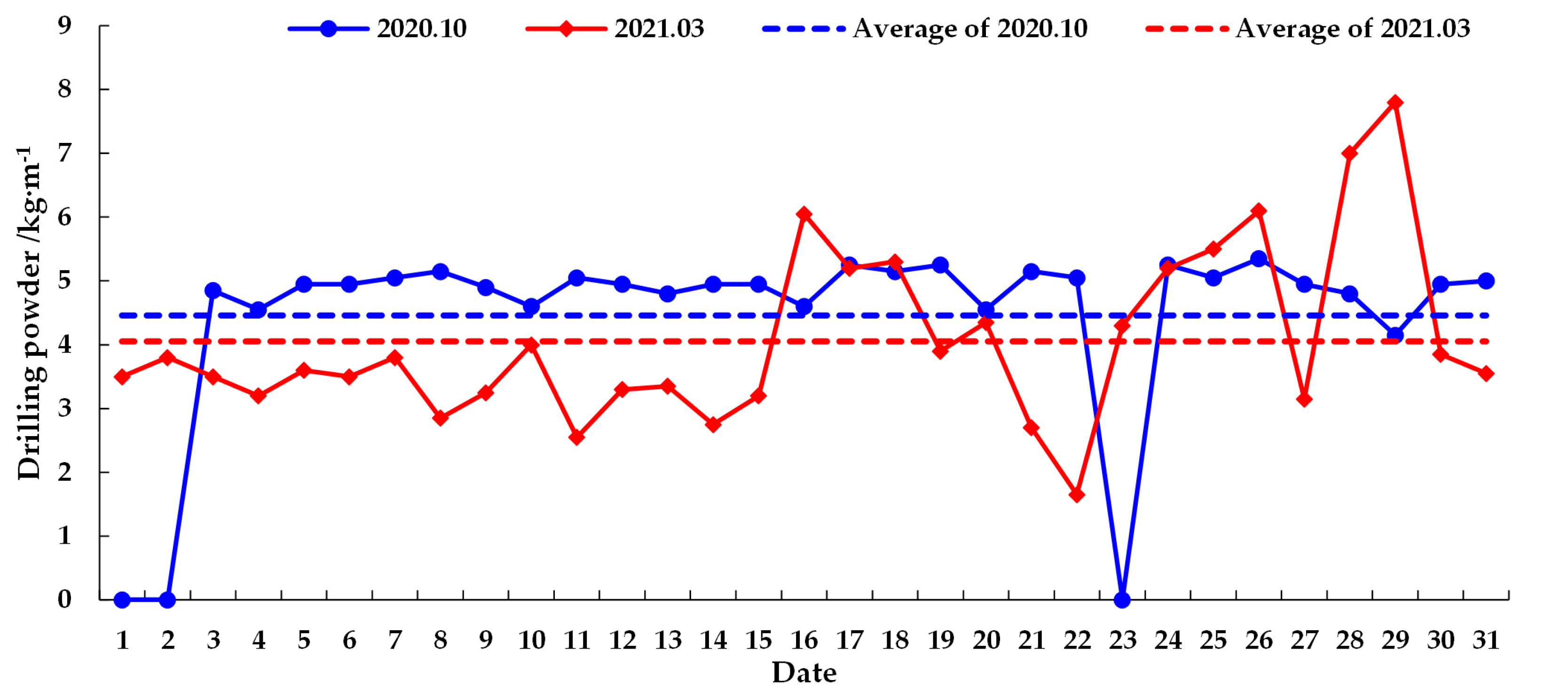

5.5. Validation of Multi-Dimensional Pressure Relief Effect Evaluation System

5.6. Plan for Further Prospective Study

6. Conclusions

- (1)

- Based on the geological and mining technical conditions of panel 5308, the rock burst danger areas were divided. Multi-dimensional pressure relief prevention and control technology was proposed. Zoning and grading pre-pressure relief and danger relief measures were carried out in different rock burst danger areas.

- (2)

- In the practice of pressure relief engineering in deep mines with rock burst danger, when large-diameter boreholes are used for pressure relief, the borehole diameter is recommended to be in the range of 100–200 mm and the length should be adjusted according to the mining thickness. When roof blasting is adopted, the depth of the blasting hole should cover the thick and hard rock layer on the working surface and the diameter of the blasting hole should be designed considering the thickness of the rock layer and the specifications of the explosive.

- (3)

- To establish a multi-dimensional pressure relief effect evaluation system, the evaluation indicators are the change rate of the event frequency in microseismic high-energy intervals, the change rate of the mean value of the hydraulic-powered support stress, and the change rate of the bursting strain energy. Based on the AHP, the weights of the three evaluation indicators were 0.55, 0.27, and 0.18; the pressure relief effect index was calculated by using the interval index and the indicator weights to establish the pressure relief effect classification standard.

- (4)

- The multi-dimensional pressure relief effect evaluation system was used to comprehensively evaluate the pressure relief effect of the indicators monitored in October 2020 and March 2021 at panel 5308; the microseismic indicator was C1 = 3, the hydraulic-powered support stress was C2 = 2, and the bursting strain energy was C3 = 2. The pressure relief effect index was calculated as C = 2.55, indicating good results. Then, the data of the drilling method was used for validating the destress effect. The results show that the average value of the drilling powder decreased by 18% after the pressure relief compared with before and the overall effect was good, which was consistent with the evaluation results of the multi-dimensional pressure relief effect evaluation system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dou, L.M.; Tian, X.Y.; Cao, A.Y.; Gong, S.Y.; He, H.; He, J.; Cai, W.; Li, X.W. Present situation and problems of coal mine rock burst prevention and control in China. J. China Coal Soc. 2022, 47, 152–171. [Google Scholar]

- Jiang, F.X.; Wei, Q.D.; Yao, S.L.; Wang, C.W.; Qu, X.C. Key theory and technical analysis on mine pressure bumping prevention and control. Coal Sci. Technol. 2013, 41, 6–9. [Google Scholar]

- Pan, J.F.; Mao, D.B.; Lan, H.; Wang, S.W.; Qi, Q.X. Study status and prospects of mine pressure bumping control technology in China. Coal Sci. Technol. 2013, 41, 21–25. [Google Scholar]

- Dou, L.M.; Zhou, K.Y.; Song, S.K.; Cao, A.Y.; Cui, H.; Gong, S.Y.; Ma, X.T. Occurrence mechanism, monitoring and prevention technology of rockburst in coal mines. J. Eng. Geol. 2021, 29, 917–932. [Google Scholar]

- Zhang, Z.M. Bored of Pressure Relief Mechanism and a Reasonable Argument. Ph.D. Thesis, Shandong University of Science and Technology, Qingdao, China, 2011. [Google Scholar]

- Bažant, Z.P.; Lin, F.B.; Lippmann, H. Fracture energy release and size effect in borehole breakout. Int. J. Numer. Anal. Methods Geomech. 1993, 17, 1–14. [Google Scholar] [CrossRef]

- Meier, T.; Rybacki, E.; Reinicke, A.; Dresen, G. Influence of borehole diameter on the formation of borehole breakouts in black shale. Int. J. Rock Mech. Min. Sci. 2013, 62, 74–85. [Google Scholar] [CrossRef]

- Lee, H.; Moon, T.; Haimson, B.C. Borehole breakouts induced in arkosic sandstones and a discrete element analysis. Rock Mech. Rock Eng. 2016, 49, 1369–1388. [Google Scholar] [CrossRef]

- Sahara, D.P.; Schoenball, M.; Gerolymatou, E.; Kohl, T. Analysis of borehole breakout development using continuum damage mechanics. Int. J. Rock Mech. Min. Sci. 2017, 97, 134–143. [Google Scholar] [CrossRef]

- Liu, H.J. Drilling pressure relief technology and effect of bilateral goaf island working face. Coal Eng. 2016, 48, 58–61. [Google Scholar]

- Xu, Y.Y. Simulation Study on Distribution and Variation of Coal Water Injection Water Pressure and Porosity and Moisture. Master’s Thesis, Liaoning Technical University, Fuxin, China, 2015. [Google Scholar]

- Li, H.Z. Study of Pre-Cracking Hard Coal by Water Infusion in Sub-Level Caving Mining. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2003. [Google Scholar]

- Chu, H.B.; Yang, X.L.; Liang, W.M.; Yu, Y.Q. Simulation experimental study on the coal blast mechanism. J. China Coal Soc. 2011, 36, 1451–1456. [Google Scholar]

- Brigida, V.S.; Golik, V.I.; Dmitrak, Y.V.; Gabaraev, O.Z. Ensuring stability of undermining inclined drainage holes during intensive development of multiple gas-bearing coal layers. J. Min. Inst. 2019, 239, 497–501. [Google Scholar] [CrossRef]

- Bosikov, I.I.; Klyuev, R.V.; Mayer, A.V. Comprehensive assessment of hydraulic fracturing technology efficiency for well construction during hydrocarbon production. J. Min. Inst. 2022, 258, 1018–1025. [Google Scholar] [CrossRef]

- Zhao, S.K.; Ouyang, Z.H.; Liu, J.; Zhang, G.H.; Wang, Y.R.; Li, X.L. Theory and application of prevention of rock burst by advanced deep hole roof blasting. Chin. J. Rock Mech. Eng. 2013, 32, 3768–3775. [Google Scholar]

- Huang, B.H.; Zhao, X.L.; Chen, S.L.; Liu, J.W. Theory and technology of controlling hard roof with hydraulic fracturing in underground mining. Chin. J. Rock Mech. Eng. 2017, 36, 2954–2970. [Google Scholar]

- Wen, Y.Y.; Guo, Z.G.; Cao, A.Y. Analysis of pressure relief effect of roof deep hole blasting parameters based on micro-seismic data evaluation. Coal Sci. Technol. 2020, 48, 57–63. [Google Scholar]

- Wu, S.S.; Zhou, J.F.; Du, C.B. Study on prevention and control effect of strong rock burst based on rapid stress release of blasting relieving pressure technology. Adv. Eng. Sci. 2018, 50, 22–29. [Google Scholar]

- Kulikova, E.Y. Methods of forming an integral risk assessment in mine and underground construction. Min. Inf. Anal. Bull. 2021, 2, 124–133. [Google Scholar] [CrossRef]

- Jia, C.Y.; Jiang, Y.J.; Zhang, X.P.; Wang, D.; Luan, H.J.; Wang, C.S. Laboratory and numerical experiments on pressure relief mechanism of large-diameter boreholes. Chin. J. Geotech. Eng. 2017, 39, 1115–1122. [Google Scholar]

- Pang, L.N.; Fu, S.J.; Su, B. Research and application of anti rock burst mechanism of large diameter boreholes in coal seam and roof pre-splitting holes. Saf. Coal Mines 2021, 52, 183–189. [Google Scholar]

- Dou, L.M.; Kan, J.L.; Li, X.W.; Qi, Y.J.; Bai, J.Z.; Liu, M.H. Study on prevention technology of rock burst by break-tip blasting and its effect estimation. Coal Sci. Technol. 2020, 48, 24–32. [Google Scholar]

- Chu, H.B.; Yang, X.L.; Liang, W.M.; Yu, Y.Q.; Wang, L.P. Experimental study on the blast damage law of the simulated coal. J. Min. Saf. Eng. 2011, 28, 488–492. [Google Scholar]

- Liu, Z.G.; Cao, A.Y.; Zhu, G.A.; Wang, C.B.; Jing, G.C. Stress relieving effect of non-coupling blasting technique on high stress area. Explos. Shock Waves 2018, 38, 390–396. [Google Scholar]

- Liu, Z.G. Rockburst Mitigating Mechanism of Hard-Roof-Blasting and Its Application in the Working Face with Wide Barrier Coal Pillar of Hujirt Deep Mining Area. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2018. [Google Scholar]

- Xia, H.M.; Wang, J.; Cui, J.S.; Zhang, Y.L.; Wang, B.; Song, J.L. Experiment study on burst tendency of 7# coal seam and roof in Hongyang coal mine. Saf. Coal Mines 2015, 46, 50–57. [Google Scholar]

- Benioff, H. Crustal strain characteristics derived from earthquake sequences. Trans. Am. Geophys. Union 1951, 32, 508–514. [Google Scholar]

- Dieter, W.K.; Roswitha, H. Local seismic hazard assessment in areas of weak to moderate seismicity case study from Eastern Germany. Tectonophysics 2004, 390, 45–55. [Google Scholar]

- Qu, X.C.; Jiang, F.X.; Yu, Z.X.; Ju, H.Y. Rockburst monitoring and precaution technology based on equivalent drilling research and its applications. Chin. J. Rock Mech. Eng. 2011, 30, 2346–2351. [Google Scholar]

- Chen, F.; Pan, Y.S.; Li, Z.H.; Wang, A.W.; Tang, Z.; Xu, L.M. Detection and study of rock burst hazard based on drilling cuttings method. Chin. J. Geol. Hazard Control 2013, 24, 116–119. [Google Scholar]

- Lu, Z.Y.; Dou, L.M.; Xu, X.F.; Zhang, Y.L. New discovery on drilling cuttings method to detect surrounding rock stress of mine roadway and predict mine pressure bumping dangers. Coal Eng. 2011, 1, 72–74. [Google Scholar]

| Divisions | I | II | III | IV |

|---|---|---|---|---|

| Radius | (0–3) rc | (3–7) rc | (120–150) rc | (>150) rc |

| Layer | Lithology | Thickness/m | Tensile Strength/MPa | Compressive Strength/MPa |

|---|---|---|---|---|

| Immediate roof | Mudstone | 3.30 | 1.482 | 4.413 |

| Main roof | Fine sandstone | 9.80 | 3.036 | 50.248 |

| Immediate floor | Mudstone | 3.80 m | 1.541 | 4.783 |

| Coal | 3# coal (upper layer) | 8.57 | 1.046 | 13.467 |

| Evaluation Indicators | Grading | Scoring Criteria |

|---|---|---|

| Geological formations | Level I | Tectonically undeveloped |

| Level II | Tectonic development | |

| Level III | The tectonics are very developed |

| Evaluation Indicators | Grading | Scoring Criteria |

|---|---|---|

| Coal rock structure | Level I | UWQ ≤ 15 |

| Level II | 15 < UWQ ≤ 120 | |

| Level III | UWQ > 120 |

| Evaluation Indicators | Grading | Scoring Criteria |

|---|---|---|

| Coal rock burst tendency | Level I | DT > 500 ms, WET < 2, KE < 1.5, RC < 7 MPa |

| Level II | 50 ms ≤ DT < 500 ms, 2 ≤ WET < 5, 1.5 ≤ KE < 5, 7 MPa < RC < 14 MPa | |

| Level III | DT ≤ 50 ms, WET ≥ 5, KE ≥ 5, RC ≥ 14 MPa |

| Rock Burst Danger Level | Drillhole Depth/m | Drillhole Diameter/mm | Drillhole Spacing/m | Distance Ahead of Working Face/m |

|---|---|---|---|---|

| Strong | 25 | 150 | 1 | 200 |

| Medium | 25 | 150 | 2 | 200 |

| Weak | 25 | 150 | 3 | 200 |

| Measures | Hole Depth/m | Hole Diameter/mm | Hole Spacing/m | Hole Arrangement |

|---|---|---|---|---|

| Large-diameter drillhole in coal seam | ≤25 | ≥150 | ≤1 | The first hole is placed 15 m away from the rock burst danger area and the holes are arranged along the coal seam tendency 1.0–1.5 m away from the floor. |

| Destress blasting in coal seam | ≥14 | 42–100 | ≤5 |

| Evaluation Scale | Definition | Description |

|---|---|---|

| 1 | Equally important | Both factors have equal importance compared to each other |

| 3 | More important | Comparing two factors, the former is more important than the latter |

| 5 | Most important | Comparing two factors, the former is of absolute importance |

| 2, 4 | Intermediate value of two adjacent scales | Importance level between 1 and 3, 3 and 5 |

| Indicator Factors | Microseismic | Hydraulic-Powered Support | Bursting Strain Energy |

|---|---|---|---|

| Microseismic | 1 | 2 | 3 |

| Hydraulic-powered support | 1/2 | 1 | 3/2 |

| Bursting strain energy | 1/3 | 2/3 | 1 |

| Order of Judgment Matrix | RI |

|---|---|

| 1 | 0 |

| 2 | 0 |

| 3 | 0.58 |

| 4 | 0.90 |

| Evaluation Indicators | Indicator interval change | Interval Index Di |

|---|---|---|

| The change rate of event frequency in microseismic high-energy interval, the change rate of mean value of hydraulic-powered support stress, and the change rate of bursting strain energy | Decrease 0–10% | 1 |

| Decrease 10%–30% | 2 | |

| Decrease 30%–60% | 3 | |

| Decrease > 60% | 4 |

| Pressure Relief Effect Index C | Pressure Relief Effect Grade |

|---|---|

| 1–2 | Bad |

| 2–5 | Good |

| 5–8 | Very good |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Liu, S.; Ren, W.; Liu, H.; Li, S.; Yan, K. Research on Engineering Practice and Effect Evaluation Method of Pressure Relief in Deep Rock Burst Danger Area of Coal Mine. Minerals 2023, 13, 570. https://doi.org/10.3390/min13040570

Li J, Liu S, Ren W, Liu H, Li S, Yan K. Research on Engineering Practice and Effect Evaluation Method of Pressure Relief in Deep Rock Burst Danger Area of Coal Mine. Minerals. 2023; 13(4):570. https://doi.org/10.3390/min13040570

Chicago/Turabian StyleLi, Jiazhuo, Shun Liu, Wentao Ren, Hui Liu, Songyue Li, and Kangxing Yan. 2023. "Research on Engineering Practice and Effect Evaluation Method of Pressure Relief in Deep Rock Burst Danger Area of Coal Mine" Minerals 13, no. 4: 570. https://doi.org/10.3390/min13040570

APA StyleLi, J., Liu, S., Ren, W., Liu, H., Li, S., & Yan, K. (2023). Research on Engineering Practice and Effect Evaluation Method of Pressure Relief in Deep Rock Burst Danger Area of Coal Mine. Minerals, 13(4), 570. https://doi.org/10.3390/min13040570