Abstract

Hydrometallurgical methods for NdFeB recycling typically consist of several unit operations and require the extensive use of energy, water and chemicals which may negatively affect the applicability of these methods on an industrial scale. Based on the data from our previous studies, a simplified process of rare earth elements (REE) recovery from spent NdFeB magnets was developed further. The possibility of regenerating the leaching agent, as well as water recovery, in the process was investigated. This study also investigates a possibility of scaling up the recycling process developed on a laboratory scale. The leaching and precipitation stages were tested on a larger scale, where about 1 kg of end-of-life magnets was used as feed to the leaching step. In this study, end-of-life magnets were obtained from the manual disassembly of computer hard disc drives. After disassembly, the magnets were demagnetized, broken into pieces and fed to the leaching process. In the following step, rare earths were precipitated in the form of oxalates. The rare earths’ precipitation efficiency reached a maximum of 95.6%. The results showed that the co-precipitation of Fe highly depends on the amount of oxalic acid used as the precipitant. Smaller losses of Fe were achieved while using a stoichiometric amount of oxalic acid in relation to the REE present in the solution. At the end of the investigated process, rare earth oxalates were calcinated to oxides and their purity was investigated. The recirculation of a solution after oxalate precipitation and acid regeneration was tested with hydrochloric and sulfuric acids used as leaching agents. Solution recirculation was found to be possible only in the case of hydrochloric acid.

1. Introduction

Rare earth elements (REEs) are essential for very strong permanent magnets and high-temperature superconducting (HTS) materials used in magnets, wires and cables [1]. NdFeB magnets are one of the most common types of magnets used in electrical motors, generators, speakers and hard disc drives (HDDs) [2]. Permanent magnets play an essential role in green energy production and low carbon emissions [3]. Therefore, rare earths have been identified by the European Commission as critical raw materials with the highest supply risk [4].

The development of recycling technologies for the efficient recovery of rare earths is of high importance. Ganguli and Cook [2] described that of all REE applications, magnets show the highest potential for recycling. In the last 20 years, great efforts have been made to develop an efficient end-of-life magnet recycling process. The investigated methods have been described in recent review papers [5,6,7,8].

It has been reported in the literature that there are only a few magnet recycling technologies applied in the industry. Hitachi has reported the development of magnet recovery machines designed for specific end-of-life products, i.e., electric motors and air conditioner compressors [9]. According to Hitachi, their machinery is custom made and aims to address the challenges of recycling. Urban Mining Company (UMC) has patented a process known as magnet-to-magnet, which allows for the reprocessing of scrap magnets into new superior magnets [10]. Magnet-to-magnet technology has been receiving great attention for more than 20 years. One of the first studies was published by McGuiness et al. [11] where a combination of hydrogen decrepitation and jet milling was described. In the papers published by Zakotnik et al. [10,12,13,14], the use of hydrogen in the direct recycling process was further investigated and different options for magnets re-sintering were described. In 2022, Urban Mining Company rebranded as Noveon Magnetics Inc. and they have reported the development of magnet production through a process involving the recycling of waste and removal of hazardous products. However, it was not reported in the literature what the recycling process used was [15], but it can be assumed that the previously developed method of magnet-to-magnet is continuing to be applied.

Despite the great efforts in applying REE recycling technologies on an industrial scale, the REE recycling rates remain very low, lower than 1% [2]. As the REEs remain critical for the technology and economy of Europe, it is necessary to develop more recycling technologies applicable on an industrial scale.

The hydrometallurgical methods for REE recycling are of high interest because of their advantages. Opposite to magnet-to-magnet recycling, hydrometallurgical methods allow the recovery of REEs in the form of pure oxides suitable for any applications [16]. The main operations in the hydrometallurgical process involve the leaching of magnets followed by the separation of individual REEs. The literature describes many new separation techniques that involve novel solvent extraction methods, the use of ionic liquids and ion exchange resins [6,17]. The great advantage of hydrometallurgical treatment is the fact that it can be applied in the recycling of multiple mixtures of different magnets. The hydrometallurgical approach is typically characterized by a high capacity, a relatively high recovery of REEs and a high purity of the final product [18]. However, hydrometallurgical technologies require the use of many operations, a large amount of water and chemicals; moreover, large amounts of waste solutions are produced and require special treatment [16,18]. In the recent study of Zhu et al. [18], a mechanical activation method, as pretreatment technique for NdFeB magnet recycling, was introduced. In this method, waste NdFeB magnets were demagnetized by heating above Curie temperature, crushed and ground and additionally roasted in order to transform the NdFeB alloy into the corresponding oxides. After roasting, the mechanical activation was performed in a ball mill followed by leaching in hydrochloric acid. The authors reported that the mechanical activation significantly increased the leaching efficiency and tripled the leaching speed [18]. Even though the pretreatment method seems helpful in achieving higher efficiencies of REEs recovery, it should be noted that all of the pretreatment operations such as demagnetization, crushing, roasting and milling require an extensive use of energy; thus, the approach brings another challenge for implementing the recycling process on an industrial scale.

In our previous study, the possibility of simplifying the NdFeb magnet recycling process by excluding the grinding, milling and roasting steps was investigated. Demagnetized and broken magnets were leached with hydrochloric and sulfuric acids. It was shown that the application of a higher temperature of 40 °C allowed the shortening of the leaching time [19]. After the leaching, a separation method of rare earths from the solution was investigated. Based on the conducted experiments, it was indicated that it is possible to selectively precipitate rare earth oxalates from leaching solutions without the co-precipitation of iron or other elements present in the solution [20]. The aim of the current study is to investigate the possibility of regenerating the leaching agents as well as water recovery in the proposed process. The novelty of this study also lies in the investigation of a possibility of scaling up the hydrometallurgical recycling process. The leaching and precipitation stages were tested on a larger scale, where about 1 kg of waste magnets was used as an input stream in the first leaching cycle, and, in total, about 4 kg of magnets was processed through a semicontinuous recycling process. In the study, REEs are recovered together in the form of a mixture of REE oxalates; thus, the separation of individual rare earths from that mixture is not the aim of the current work.

2. Materials and Methods

2.1. Methodology Background

In our previously published studies [19,20], the NdFeB magnet recycling process based on leaching in hydrochloric and sulfuric acids followed by the selective precipitation of rare earth oxalates was investigated. The leaching process with the use of hydrochloric and sulfuric acids allowed for the dissolution of REEs and Fe whereas the metallic nickel layer, which covers the magnets, was left in the solid state. It was also discovered that the efficiency of leaching can be improved by demagnetization and by breaking the magnets before leaching [19]. After the leaching, the concentrations of REEs and Fe were approximately 20 and 35 g L−1, respectively. Directly after leaching, the solution was characterized with a pH of about 1.0 and iron was present in the form of Fe2+. In the following step, the REEs were precipitated from the solution as oxalates. The selective separation of rare earths from iron was possible based on the difference between the solubility of rare earths and iron oxalates. In the precipitation process, oxalic acid was used as a precipitant. The use of oxalic acid in a 20% excess compared to its stoichiometric amount allowed the achievement of a higher precipitation efficiency of rare earths [20]. An even higher rare earths precipitation efficiency, about 99%, was also possible but required the use of a bigger excess of oxalic acid and involved the co-precipitation of iron oxalate.

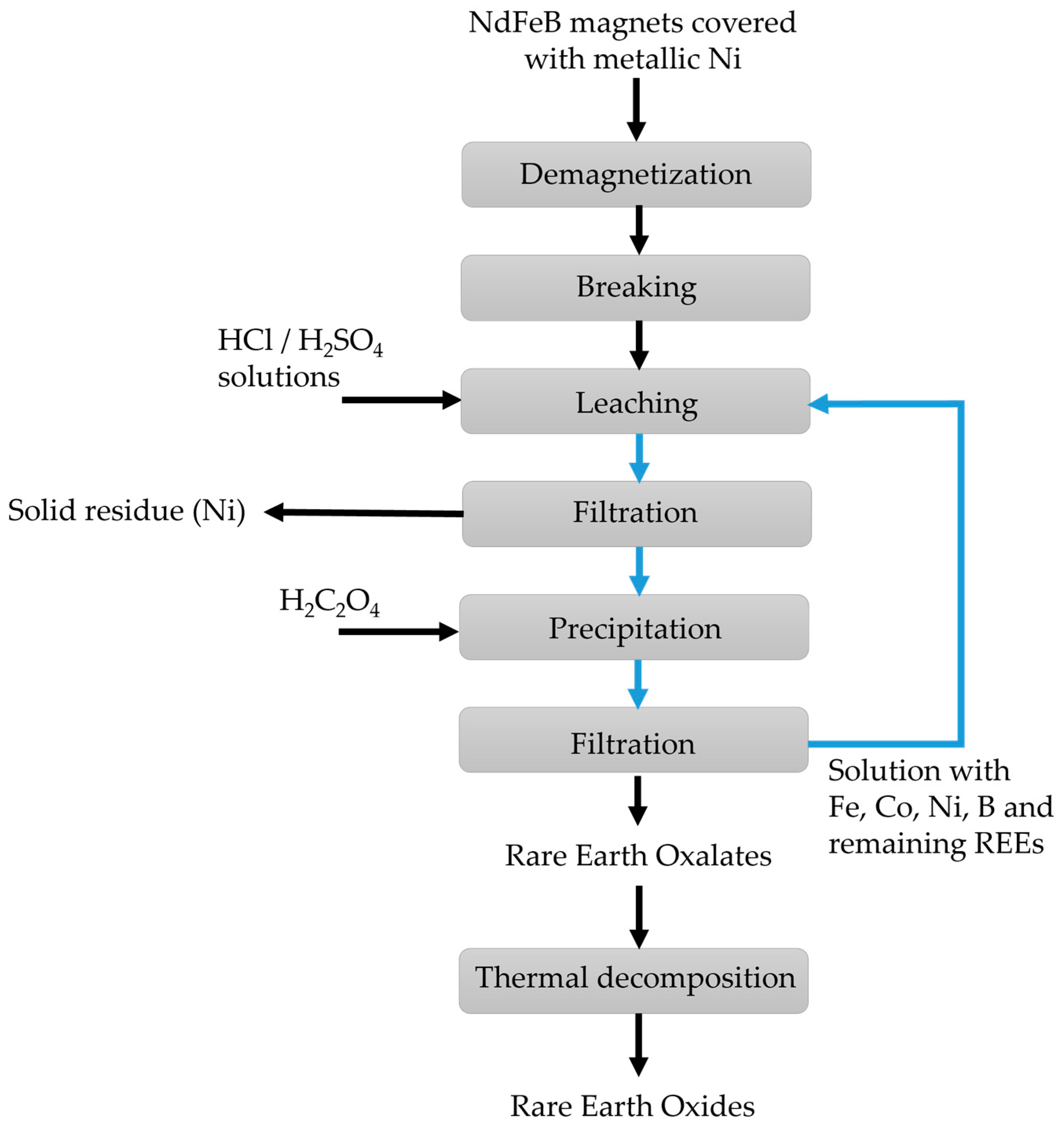

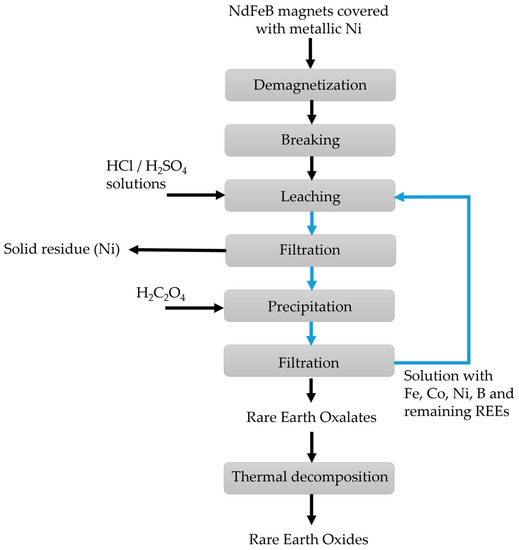

The use of oxalic acid as a precipitating agent does not introduce additional metal ions into the solution. The concentration of iron ions in the solutions after lanthanide oxalate precipitation was between 30 and 35 g L−1, which is much lower than the concentrations of iron ions in saturated solutions of FeCl2 or FeSO4, which are 175 g·L−1 and 295 g·L−1 (at 25 °C), respectively [21]. Additionally, after the use of oxalic acid for the precipitation of rare earths, the remaining solution contained a high concentration of H+ ions and could be potentially reused in the leaching process. Based on this knowledge, it should be possible to reuse solutions obtained after the precipitation of REE oxalates. In this work, the possibility of solution recirculation back to the leaching process was tested on a laboratory scale followed by a test performed on a larger laboratory scale. The recycling process tested in this work is presented in Figure 1. The final products of the previously proposed NdFeB magnet recycling process were rare earth oxalates. According to the literature [22], the rare earth oxalates can be further calcinated to rare earth oxides. Therefore, the rare earth oxalates obtained after leaching and precipitations on a large scale were subjected to thermal decomposition at the end of this study.

Figure 1.

The NdFeB magnet recycling process proposed based on previous studies of the authors [19,20]. The blue arrows represent the solution recirculation studied in this work.

2.2. Materials

The NdFeB magnets used in the study came from end-of-life hard disk drives (HDDs) obtained from different types of desktop PCs (3.5″ HDDs) and notebooks (2.5″ HDDs). All the HDDs were disassembled manually. After disassembly, the magnets were demagnetized at 350 °C in a muffle furnace for 30 min to separate them from the carrier iron plates. The characteristics of the NdFeB magnets and the other main HDD components can be found in our previous work [23]. It was shown that magnets are highly heterogenous, as their chemical composition varies in a wide range (24–29 wt% of Nd, 2–13 wt% of Pr, 0.08–1.42 wt% of Dy, 53–62 wt% of Fe, 3.4–6.4 wt% of Ni, 0.85–0.96 wt% of B, 0.54–3.6 wt% of Co). In the leaching experiments, demagnetized magnets broken into pieces, presented in Figure 2, were used as feed material. Solutions of hydrochloric and sulfuric acids were used as leaching agents. All chemicals used in the experiments are listed in Table 1.

Figure 2.

Broken magnets after demagnetization used as a feed in the leaching process.

Table 1.

Chemicals used in the experiments.

2.3. Leaching and Precipitation Procedure

Due to the physical form of the magnets (big pieces), leaching could not be performed in a typical reactor with a mechanical stirrer. Therefore, the leaching experiments on a laboratory scale were performed in a rotary reactor driven by an evaporator (Rotavapor R-210/215, Büchi, Flawil, Switzerland).

Four cycles of leaching of NdFeB magnets with hydrochloric acid and two cycles of leaching with sulfuric acid followed by the precipitation of rare earth oxalates were conducted. In the first leaching cycle, an acid solution with a concentration of 2 mol·L−1 and a volume of 200 mL in the case of hydrochloric acid and 100 mL in the case of sulfuric acid was used as the leaching agent. In subsequent leaching experiments, solutions after the precipitation of rare earth oxalates and after the correction of acid concentration to a value of 2 mol·L−1 (by the addition of concentrated hydrochloric or sulfuric acid) were used.

The volumes of the leaching solutions were 200 mL and 100 mL each time in the cases of hydrochloric and sulfuric acid solutions, respectively. All leaching experiments were carried out under identical conditions: reactor speed 40 rpm, temperature 40 °C, atmospheric pressure. The feed was demagnetized and broken magnets had a weight of 25.5 g ± 1.0 g. The chemical reactions occurring during leaching in hydrochloric and sulfuric acids can be described by the following Equations (1) and (2):

where Re represents a rare earth element.

During the leaching, samples of the solution were taken at specified intervals to analyze the acid concentration and thus control the leaching progress. The concentration of the acid during leaching was analyzed via a potentiometric titration of samples of leaching solutions with NaOH. This method was described in detail in our previous study [19].

After the leaching process, the solid residue (mainly nickel) was separated from the solution by filtration. In the following step, the rare earths were separated from the leaching solution by precipitation with the use of oxalic acid. The oxalic acid was added in an amount of approximately 1.4 times the stoichiometric amount necessary to precipitate rare earth oxalates, according to Equation (3):

After the separation of the precipitated oxalates, the concentration of hydrochloric acid in the solution was adjusted to the value of 2 mol·L−1, and then the solution was used for the next leaching, as described above.

2.4. Experimental Procedure in the Larger Laboratory Scale

Due to the large amounts of hydrogen released in the process (about 0.5 m3), the leaching of NdFeB magnets with hydrochloric acid solutions on a large laboratory scale was carried out in a laboratory with efficient exhaust ventilation. Leaching was carried out in a plastic tank placed in a steel rotary reactor (concrete mixer) at atmospheric pressure and ambient temperature. The rotational speed of the reactor was constant and amounted to 40 rpm, similarly to the experiments performed on a smaller laboratory scale. In the leaching tests, a solution of hydrochloric acid with a concentration of 2 M and a volume of 16 L was used as the leaching agent. The volume of acid and the mass of the magnets were selected to maintain the same solid/liquid ratio as in the case of smaller laboratory scale leaching. Similarly, as in the smaller scale during leaching, samples of the solution were taken at appropriate intervals to analyze the acid concentration during leaching. After leaching, lanthanides were recovered by the selective precipitation of lanthanide oxalates. Oxalic acid was added to the leaching solution in the stoichiometrically estimated amount necessary to precipitate the lanthanide oxalates present in the solution. The use of excess oxalic acid was abandoned due to the partial co-precipitation of iron(II) oxalate observed on the laboratory scale. The obtained solution was then filtrated, its acid concentration was adjusted to 2 M by adding concentrated hydrochloric acid and it was used in the next leaching. Four cycles of magnet leaching—precipitation of rare earth oxalates were performed. A total of 4 kg of magnets was then broken and used as feed in the leaching process.

2.5. Thermal Decomposition of Rare Earth Oxalates

The thermal decomposition of lanthanide oxalates to lanthanide oxides was performed in a resistance electric furnace (Carbolite RWF Rapid Heating Chamber Furnace). The oxalates were placed in a ceramic crucible and heated to 1000 °C with a heating rate of 5 °C·min−1. Once the temperature reached 1000 °C, the sample was held in the hot zone for 1 h.

2.6. Chemical Analysis of Solutions and Solids

The concentrations of elements in leaching solutions were determined using an optical Jobin Yvon sequential ICP-OES instrument (Jobin Yvon 38S, HORIBA Jobin Yvon SAS, Longjumeau, France). The details of the analytical procedure were presented in our previous work [19].

A qualitative analysis of precipitated solids was conducted using the X-ray diffraction (XRD) technique. Measurements were performed in the symmetric θ/2θ Bragg–Brentano geometry using a Philips X’PERT system with a diffractometer equipped with a CuKα (λ = 0.154 nm) source.

The analysis of the solid residue after the leaching of NdFeB magnets in solutions of sulfuric acid was carried out via a scanning electron microscope–energy dispersive spectrometer (SEM, FEI Quanta 250, FEI, Thermo Fisher Scientific, Waltham, MA, USA) working in backscattered electron mode (BSE).

3. Results and Discussion

3.1. Recirculation of the Solution in the Leaching–Precipitation Cycle

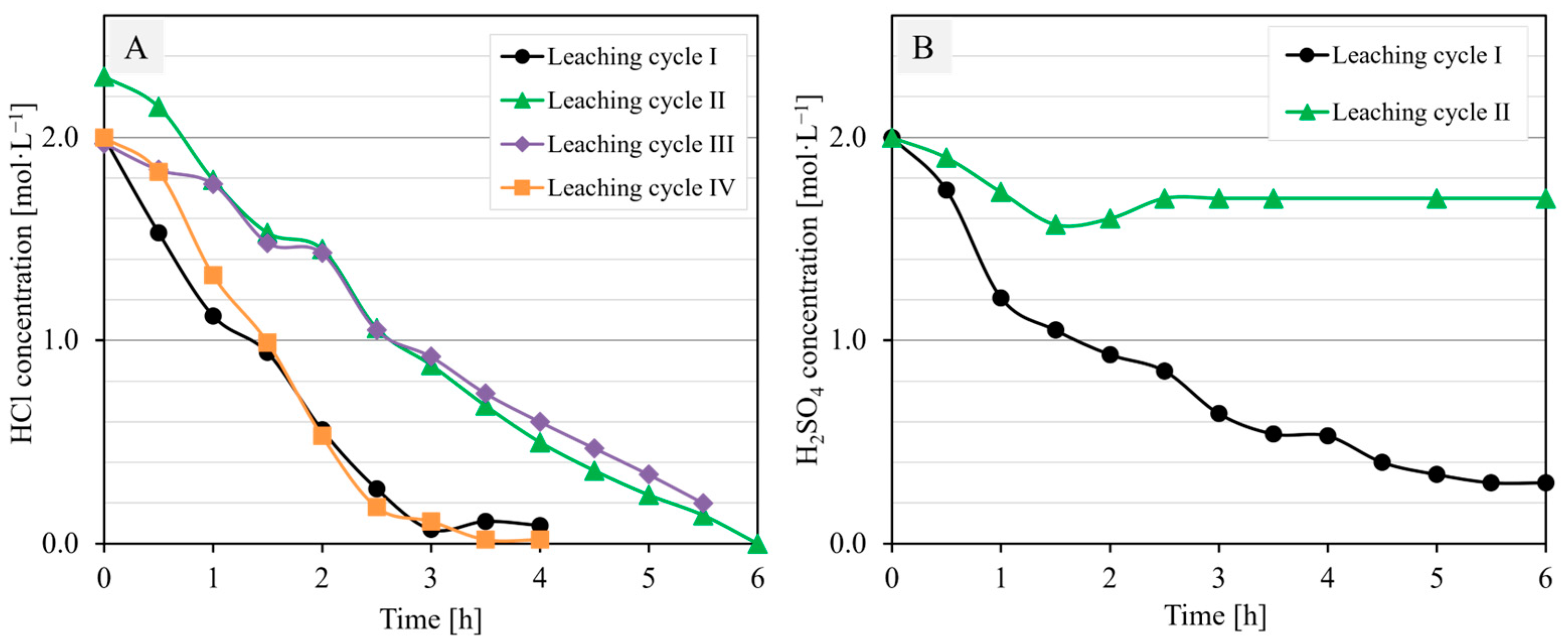

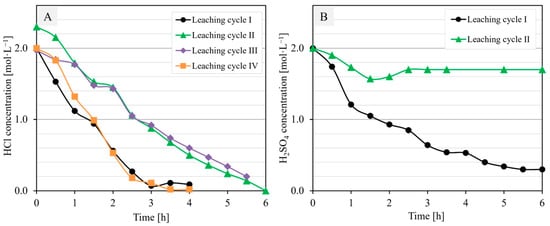

Figure 3 shows the dependence of hydrochloric acid and sulfuric acid concentrations as a function of leaching time in individual leaching cycles. In case of leaching in hydrochloric acid (Figure 3A), it was possible to conduct four leaching–precipitation cycles. The obtained results confirmed the possibility of leaching the new batch of magnets with solutions from the previous leaching after the precipitation of rare earth oxalates and the correction of the acid concentration). Differences in leaching rates may be due to the different surface areas of the magnets available for leaching.

Figure 3.

The dependence between the concentrations of (A)—hydrochloric acid, (B)—sulfuric acid and the leaching time.

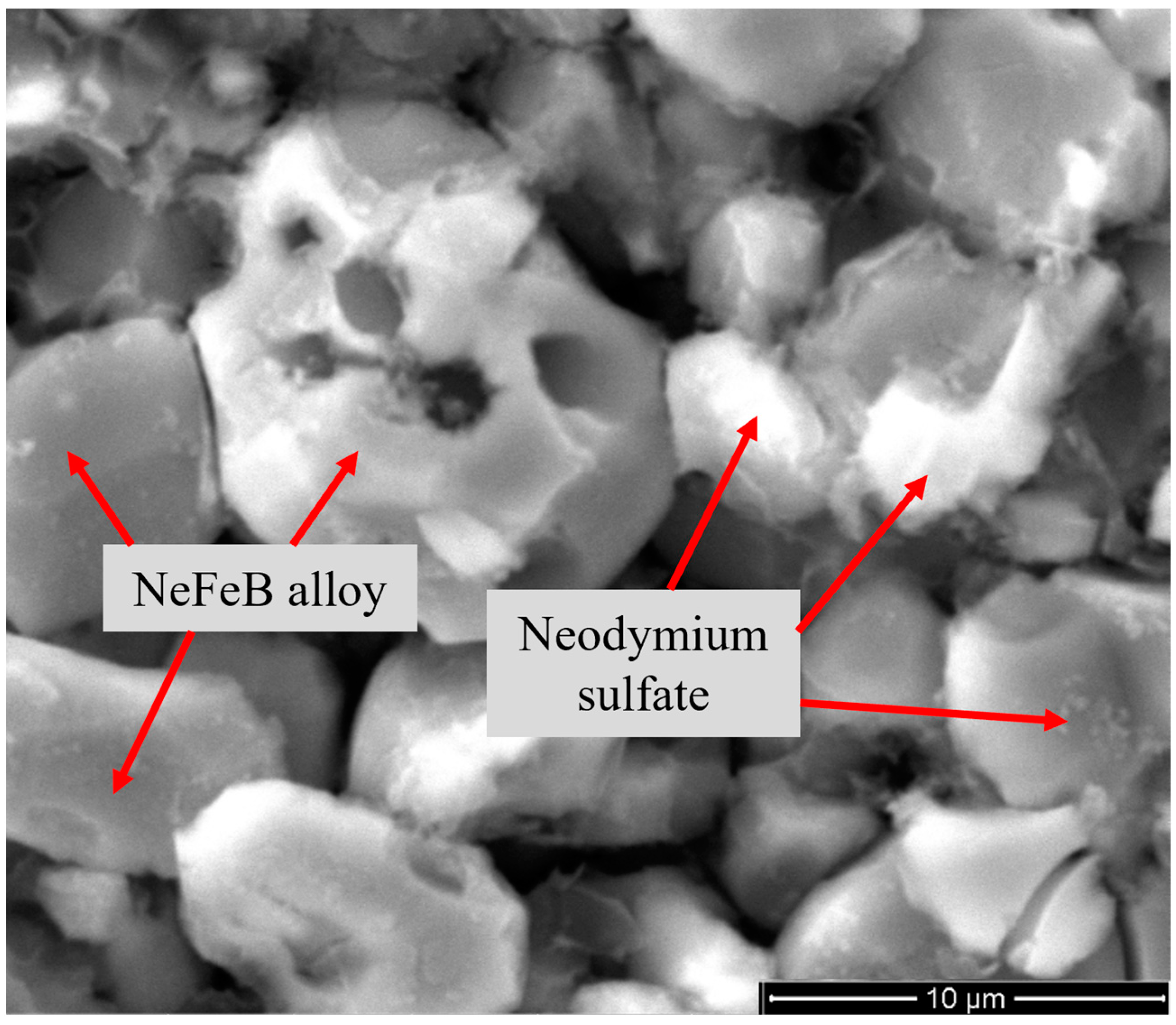

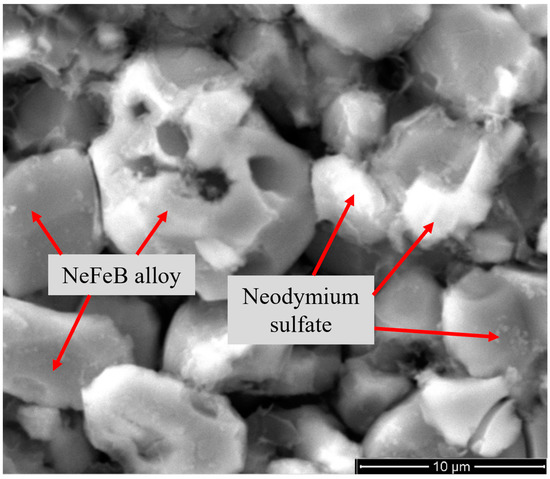

In the case of the experiments with sulfuric acid, it was possible to conduct only two cycles of leaching–precipitation. As seen from Figure 3B, during the second cycle, the leaching stopped after about 1.5 h. The probable cause of stopping the leaching process is too high a concentration of sulfate ions, which resulted in covering the surface of the leached magnets with a layer of rare earth sulfates. After the leaching stopped in the second cycle, the sample of the leaching residue was analyzed using the SEM-EDS technique. Figure 4 shows an example of the SEM image of a sample surface. It was indicated that the NdFeB alloy, visible as grey grains, was covered with a bright color solid phase, the composition of which corresponded to neodymium sulfate. The conducted experiment showed that unlike solutions from leaching with hydrochloric acid, it is impossible to recycle the solution from leaching with sulfuric acid after the precipitation of lanthanide oxalates in the next leaching.

Figure 4.

SEM image of the magnet surface after leaching cycle II with sulfuric acid.

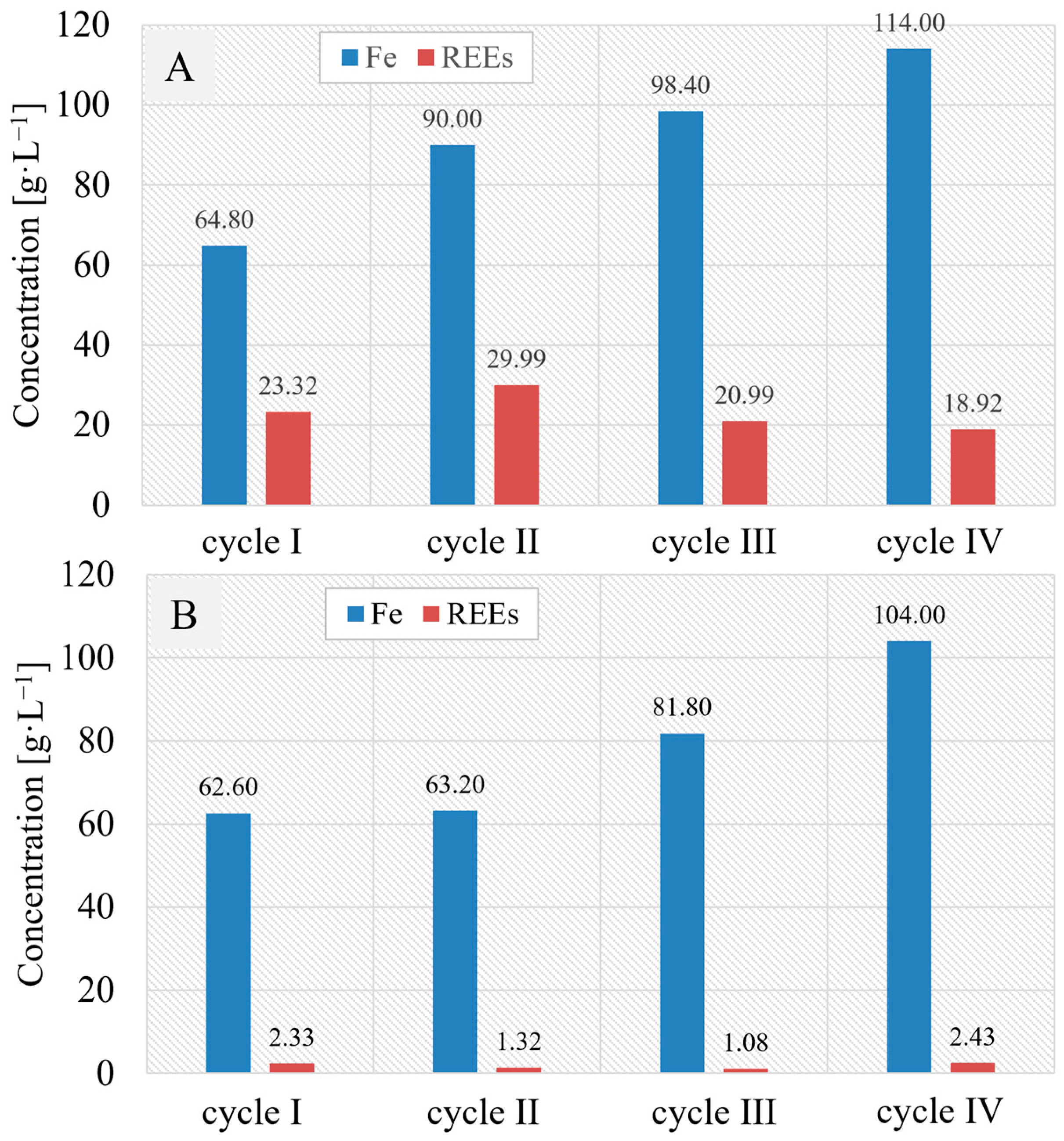

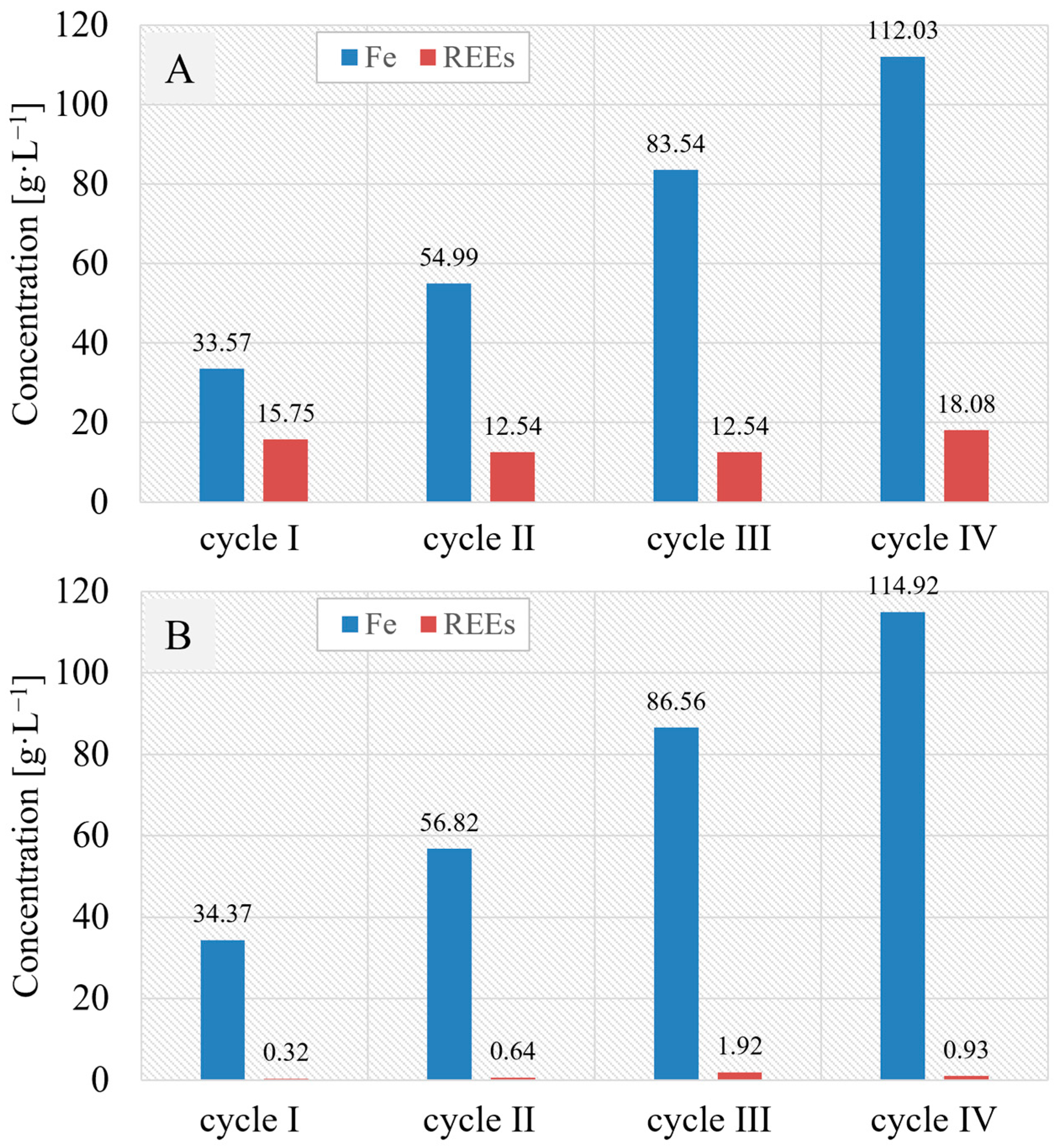

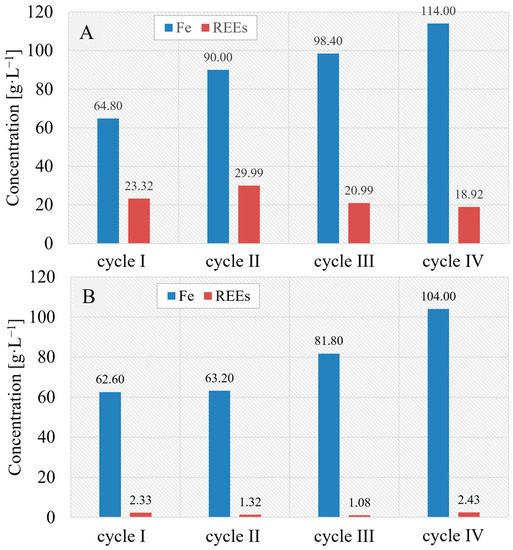

The concentrations of Fe and the total concentration of rare earths in solutions after leaching in hydrochloric acid and after the precipitation of rare earth oxalates are presented in Figure 5. Numerical values for the concentrations of rare earths and Fe in the solutions are presented in Table S1 in the Supplementary Materials. After the first leaching cycle, the Fe concentration was 64.80 g·L−1 and after the fourth leaching cycle it reached 114.00 g·L−1. The total REEs concentration in the leaching solution varied between 18.92 and 29.99 g·L−1, without a clear trend. As can be seen from Figure 5B, the REEs concentration in the solution after oxalate precipitation decreased significantly in comparison to the initial leaching solution. The REEs precipitation efficiency reached 90.0%, 95.6%, 94.9% and 87.2% after the first, second, third and fourth precipitation cycles, respectively. It is worth highlighting that REEs which remain in the solution after precipitation are not lost but are recycled back to the leaching process and are possibly precipitated in the next precipitation cycle. Therefore, it can be stated that the proposed method is efficient for REE recovery. However, the excess of oxalic acid also caused the co-precipitation of iron in amounts from 3% to 30%. Iron co-precipitation is an undesirable process causing the contamination of the obtained rare earth oxalates. Based on this knowledge, the amount of added oxalic acid should be reduced to a stoichiometric amount in relation to the content of rare earths present in the solution.

Figure 5.

Concentration of Fe and total REEs in the solution (A): after leaching in hydrochloric acid, (B): after precipitation of rare earth oxalates.

3.2. Leaching–Precipitation Cycles on the Larger Laboratory Scale

Four cycles of the leaching of magnets–precipitation of lanthanide oxalates were performed on a larger laboratory scale. The mass parameters of the tests carried out are presented in Table 2.

Table 2.

Mass parameters of magnet leaching with hydrochloric acid and lanthanide oxalates precipitation on a large laboratory scale.

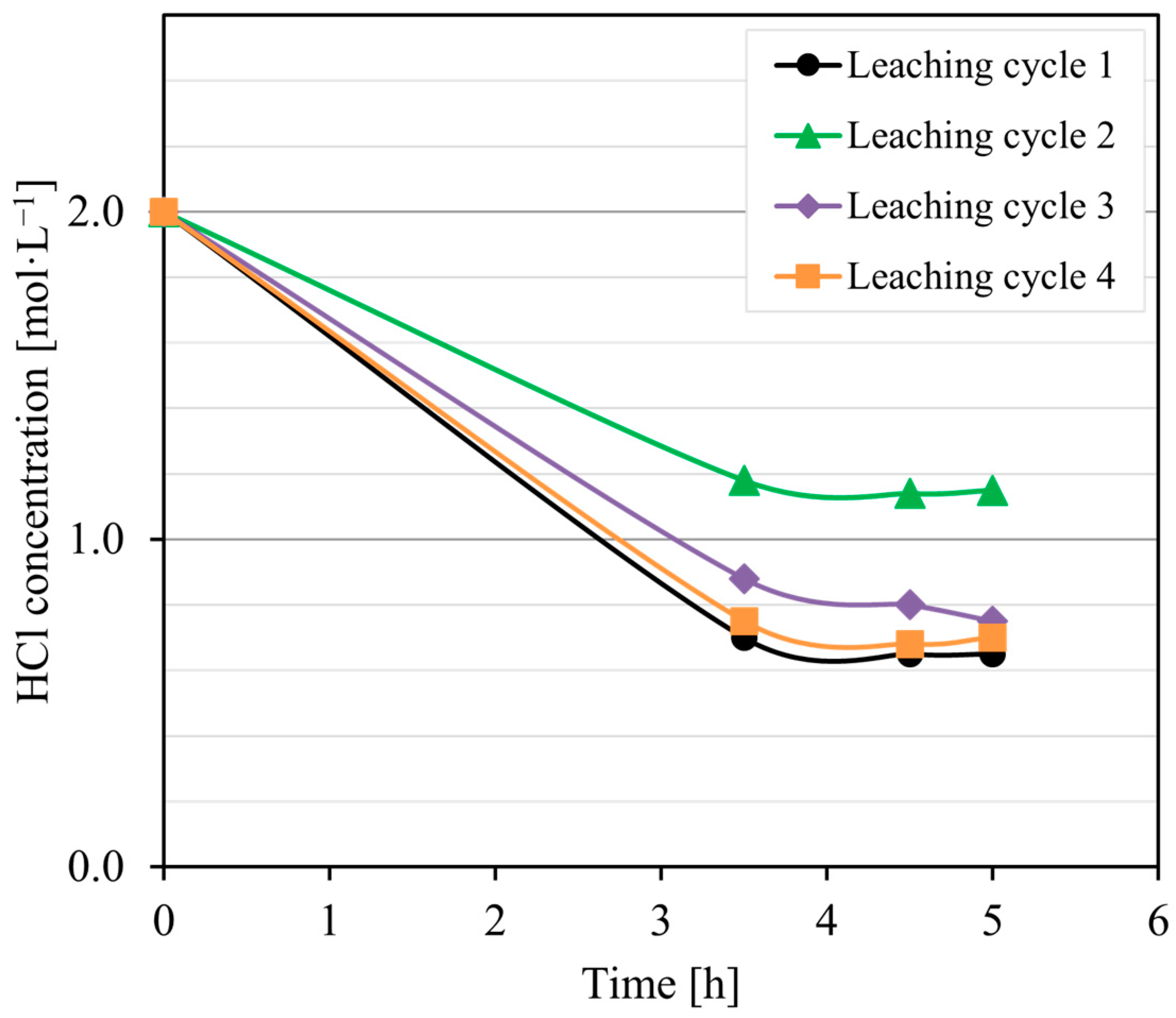

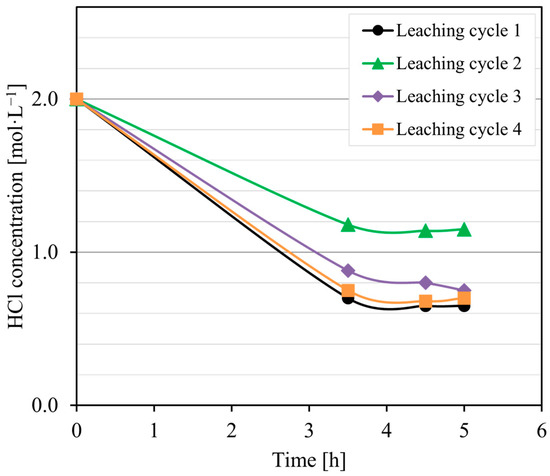

Figure 6 shows the concentration of hydrochloric acid during the first leaching cycle conducted on a larger scale as a function of leaching time. It was indicated that the practical inhibition of the leaching process occurred after 4–5 h, despite the presence of undissolved magnets and an acid concentration at a level of about 0.75 mol·L−1. Therefore, there is no economic justification for extending the leaching time. Undissolved magnets were used as a feed in the subsequent leaching together with the new portion of magnets.

Figure 6.

The dependence between HCl concentration and leaching time during leaching of magnets on larger laboratory scale.

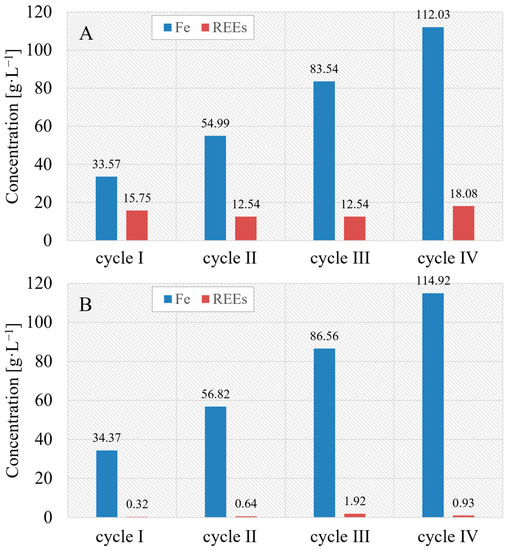

The chemical composition of leaching solutions and solutions after oxalate precipitation was determined using ICP-OES techniques. The concentrations of all elements present in solutions after magnet leaching and after the precipitation of oxalates in different cycles are shown in Tables S2 and S3 in the Supplementary Materials. Figure 7 shows the Fe and REE concentrations in the solution after 5 h of leaching and after precipitation in different cycles. The use of a stoichiometric amount of oxalic acid allowed for the precipitation of 85% to 98% of rare earths present in the leaching solutions. At the same time, all the iron remained in solution. Slightly lower (within error) values of iron concentration in the solutions after leaching compared to the concentration of iron after the precipitation of lanthanide oxalate are most likely related to the matrix effects caused by lanthanides.

Figure 7.

Concentration of Fe and total REEs in the solution (A): after 5 h of leaching in hydrochloric acid on a large laboratory scale, (B): after precipitation of rare earth oxalates.

The concentrations of nickel, boron and cobalt reached values of 0.026, 0.43 and 0.50 g·L−1 in the solution after the first cycle of leaching and increased to 0.062, 1.71 and 2.10 g·L−1 after the fourth leaching cycle. The nickel, boron and cobalt concentrations in the solution obtained after oxalate precipitation remained similar to their concentrations in leaching solutions.

The tests carried out on a large laboratory scale confirmed the possibility of solution recirculation after the precipitation of lanthanide oxalate and after the correction of the concentration of hydrochloric acid for leaching a new portion of magnets. Taking into account that the concentration of iron in a saturated FeCl2 solution is 175 g·L−1 [21], it can be estimated that it is possible to make 5–6 cycles of leaching–precipitation of lanthanide oxalates before the saturation of a solution with iron(II) chloride. After these cycles, iron(II) oxalate can be precipitated and the solution will be ready for cobalt recovery.

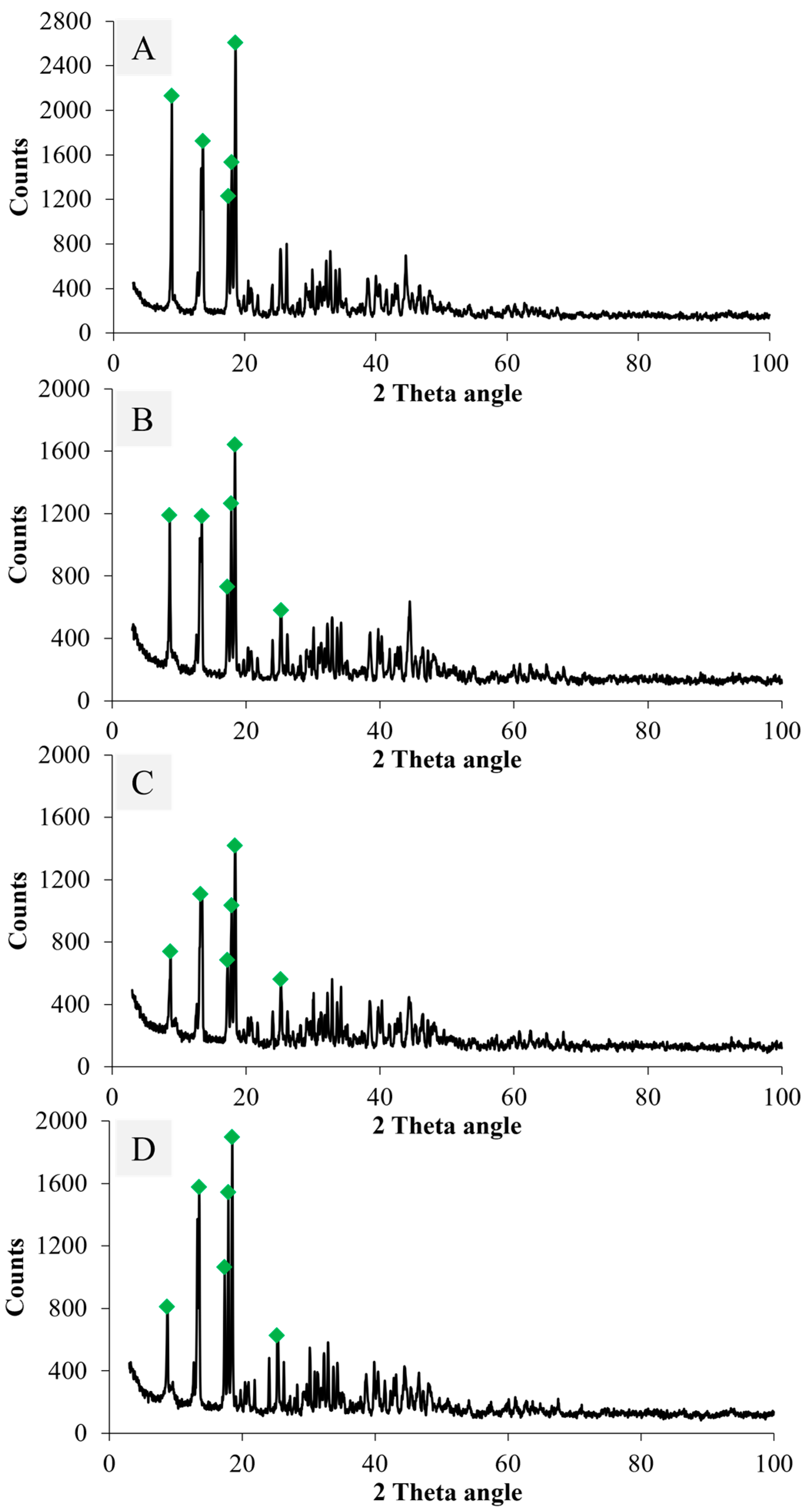

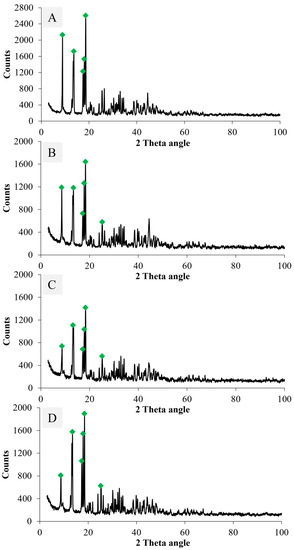

The precipitates of lanthanide oxalates were washed with distilled water, dried at 50 °C and then analyzed via XRD (Figure 8). An analysis of these diffraction patterns confirmed the presence of hydrated neodymium oxalate in all sediments. The positions of the reflexes (2θ = 8.8355°; 13.4044°; 17.4775°; 18.5469°; 25.4275°) on the obtained diffraction patterns are in good agreement with the data for the standard (standard card 18-0858).

Figure 8.

XRD diffractograms of precipitated rare earth oxalates from solutions after magnet leaching with HCl on a large laboratory scale: (A)—cycle I, (B)—cycle II, (C)—cycle III, (D)—cycle IV. Green diamond icons indicate peaks corresponding to Nd2(C2O4)3·10H2O.

3.3. Thermal Decomposition of Rare Earth Oxalates

The obtained lanthanide oxalates were subjected to thermal decomposition to oxides by calcination at a temperature of 1000 °C. The obtained results are presented in Table 3. In the conducted large laboratory tests, the mass of leached magnets was in total 3390 g (Table 2) and the total mass of the obtained rare earth oxides was 1100 g. This corresponds to a mass of metallic rare earths of about 950 g, which in relation to the mass of the magnets used is about 28% and it corresponds to the content of metallic rare earth in the magnet alloy (of about 28%–29%). Such a result confirms the practically 100% effectiveness of the proposed method of processing using neodymium magnets.

Table 3.

Results of thermal decomposition of lanthanide oxalates obtained in large laboratory leaching tests with hydrochloric acid solutions.

Samples of the obtained lanthanide oxides were dissolved in concentrated hydrochloric acid. The obtained solutions were diluted and the concentration of iron ions present in them was analyzed via the ICP-EOS technique. The obtained Fe content in the rare earth oxides mixture, presented in Table 3, ranges from 0.4 to 1.5%. This content could be lowered by washing the resulting oxalate precipitates several times.

3.4. Further Considerations

The proposed process of REE recovery from waste NdFeB seems to be efficient and applicable on a large scale. Although the results are promising, some aspects must be further considered and additional investigations are recommended.

During the leaching process, the hydrogen is released. Hydrogen is a highly flammable gas that ignites and burns more easily than other fuels. Moreover, in the indoor environment, it may displace oxygen leading to asphyxiation. Therefore, before the implementation of the process on a large scale, the methods of capturing the hydrogen should be tested. As the demand for hydrogen has been significantly increasing over the last few years, more technologies for capturing hydrogen industrial gases are being developed, some of which were reviewed by Benson and Celin [24].

In the proposed process, the solution obtained after rare earth oxalate precipitation is recirculated back to the leaching process. As shown in Figure 5 and Figure 7, iron is accumulating in the solution. It has been reported in the literature that the large amount of iron ions in the leach solution brings a great challenge [25]. Based on our results, it is recommended to remove iron from the solution after 5–6 leaching cycles. Some of the possible methods have been presented in the literature. Yang et al. [26] effectively recovered iron from the leach solution of red mud in the form of Fe(C2O4)3−3. In their study, Fe was precipitated using oxalic acid and adjusting the pH to 3.51 with calcium carbonate. In another work, Pietrantoni et al. [27], alkali solutions, NaOH and NH3·H2O were used to precipitate Fe in the form of Fe(OH)3. The precipitate had a high purity grade of 98%. Another option for the selective recovery of iron could be solvent extraction. In the study of Mystrioti et al. [28], solvent extraction was applied for the selective recovery of Fe from Ni-laterite leach solution. The investigated technique was based on the use of Di-2-ethylhexyl phosphoric acid (D2EHPA) and Tri-butyl phosphate (TBP) extractants and the most efficient separation was achieved when the pH was regulated to 1.4. Based on the literature findings, there are possible options for the effective recovery of iron from leaching solutions.

The solution recirculation in the REEs recovery process gives a great opportunity to decrease the water consumption, which is one of the biggest challenges of hydrometallurgical methods. However, it is worth highlighting that the consumption of water as well as hydrochloric and oxalic acids in the proposed process should be estimated and compared with other processes. A comparison of the current study with previously reported leaching–precipitation studies requires a thorough life cycle analysis (LCA), which should be the subject of further studies.

4. Summary and Conclusions

The process of rare earths’ recovery from NdFeB permanent magnets developed in this work is fundamentally different from the methods described in the literature. Its advantage is the elimination of many unit operations, which have greatly simplified the recycling process. The grinding and oxidation of magnets have been eliminated from the recycling process. In the developed method, the magnets, after demagnetization and breaking, are directed to the process of leaching with hydrochloric acid. Leaching can be carried out at ambient temperature. The leaching residues (undissolved magnets and nickel) can be recycled to the subsequent leaching process. Rare earths are precipitated in the form of oxalates from the leaching solution. After precipitation, the solution can be recycled for the next leaching cycle after the correction of the acid concentration. In the case of chloride solutions obtained as a result of leaching magnets with hydrochloric acid solution, it is possible to return the final solution several times for repeated leaching (after correcting the acid concentration). This allows us to reduce the losses of rare earths caused by incomplete precipitation, which consequently reduces the volume of waste solutions. Rare earth oxalates, after washing with water, undergo thermal decomposition to oxides. The tests carried out on a large laboratory scale (kilogram) confirmed the results obtained on a laboratory scale. The developed method can be used on an industrial scale. The use of recirculated solutions allows for achieving efficiencies close to 100% for both the leaching process and the precipitation of lanthanide oxalate.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/min13070862/s1, Table S1: Concentration of Dy, Nd, Pr, Tb and Fe in solutions after leaching of magnets with HCl solution and in solutions after precipitation of rare earth oxalates; Table S2: Concentration of Dy, Nd, Pr and Tb in solutions after leaching and after precipitation of lanthanide oxalates in a larger laboratory scale. Three samples from each solution were analyzed using the ICP-OES technique. The numbers in the table represent the average concentrations; Table S3: Concentration of B, Co, Fe and Ni in solutions after leaching and after precipitation of lanthanide oxalates in a larger laboratory scale. Three samples from each solution were analyzed using the ICP-OES technique. The numbers in the table represent the average concentrations.

Author Contributions

Conceptualization, A.K., Z.A. and L.R.; methodology, A.K., Z.A. and L.R.; software, A.K. and A.L.; validation, A.K., A.L., Z.A. and L.R.; formal analysis, A.K. and A.L.; investigation, A.K. and A.L; resources, A.L., Z.A. and L.R.; data curation, A.K. and L.R.; writing—original draft preparation, A.K. and L.R.; writing—review and editing, A.L. and L.R.; visualization, A.K.; supervision, Z.A. and L.R.; project administration, L.R.; funding acquisition, L.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Wroclaw Research Center EIT+ within the project ‘The Application of Nanotechnology in Advanced Materials–NanoMat’ (POIG 01.01.02-02-002/08).

Data Availability Statement

Data are contained within the article or Supplementary Materials.

Acknowledgments

The authors would like to thank the Wroclaw Research Center EIT+ for the financial support. The work was also co-financed by a statutory activity subsidy from the Polish Ministry of Science and Higher Education for the Faculty of Chemistry of Wroclaw University of Science and Technology.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Bromberg, L.; Hashizume, H.; Ito, S.; Minervini, J.V.; Yanagi, N. Status of high temperature superconducting magnet development. Plasma Sci. Fusion. Cent. MIT 2010, 60, 635–642. Available online: http://dspace.mit.edu/bitstream/handle/1721.1/94387/10ja045_full.pdf;sequence=1 (accessed on 16 May 2023). [CrossRef]

- Ganguli, R.; Cook, D. Rare earths: A review of the landscape. MRS Energy Sustain. 2018, 5, 1–16. [Google Scholar] [CrossRef]

- Uysal, E.; Al, S.; Emil-Kaya, E.; Stopic, S.; Gürmen, S.; Friedrich, B. Hydrometallurgical recycling of waste NdFeB magnets: Design of experiment, optimisation of low concentrations of sulphuric acid leaching and process and analysis. Can. Metall. Q. 2023, 62, 107–118. [Google Scholar] [CrossRef]

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and Committee of Regions Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability; European Commission: Brussel, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474 (accessed on 25 April 2023).

- Firdaus, M.; Rhamdhani, M.A.; Durandet, Y.; Rankin, W.J.; McGregor, K. Review of High-Temperature Recovery of Rare Earth (Nd/Dy) from Magnet Waste. J. Sustain. Metall. 2016, 2, 276–295. [Google Scholar] [CrossRef]

- Yang, Y.; Walton, A.; Sheridan, R.; Gu, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.M.; Van Gerven, T.; Jones, P.T.; et al. REE Recovery from End-of-Life NdFeB Permanent Magnet Scrap: A Critical Review. J. Sustain. Metall. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, F.; Su, Z.; Liu, S.; Anderson, C.; Jiang, T. Hydrometallurgical Recovery of Rare Earth Elements from NdFeB Permanent Magnet Scrap: A Review. Metals 2020, 10, 841. [Google Scholar] [CrossRef]

- Karal, E.; Kucuker, M.A.; Demirel, B.; Copty, N.K.; Kuchta, K. Hydrometallurgical recovery of neodymium from spent hard disk magnets: A life cycle perspective. J. Clean. Prod. 2021, 288, 125087. [Google Scholar] [CrossRef]

- Baba, K.; Hiroshige, Y.; Nemoto, T. Rare-earth Magnet Recycling. Hitachi Rev. 2013, 62, 8. Available online: https://www.hitachi.com/rev/pdf/2013/r2013_08_105.pdf (accessed on 16 May 2023).

- Zakotnik, M.; Afiuny, P.; Dunn, S.; Tudor, C.O. Magnet Recycling to Create Nd–Fe–B Magnets with Improved or Restored Magnetic Performance. U.S. Patent Application Number 20140369881, 18 December 2014. [Google Scholar]

- McGuiness, P.J.; Devlin, E.; Harris, I.R. A study of Nd-Fe-B magnets produced using a combination of hydrogen decrepitation and jet milling. J. Mater. Sci. 1989, 24, 2541–2548. [Google Scholar] [CrossRef]

- Zakotnik, M.; Harris, I.R.; Williams, A.J. Hydrogen decrepitation and recycling of sintered NdFeB-type sintered magnets. In Proceedings of the 19th International Workshop on Rare Earth Permanent Magnets & Their Applications, Beijing, China, 30 August–2 September 2006; pp. 289–295. [Google Scholar]

- Zakotnik, M.; Harris, I.R.; Williams, A.J. Possible methods of recycling NdFeB-type sintered magnets using the HD/degassing process. J. Alloys Compd. 2008, 450, 525–531. [Google Scholar] [CrossRef]

- Zakotnik, M.; Harris, I.R.; Williams, A.J. Multiple recycling of NdFeB-type sintered magnets. J. Alloys Compd. 2009, 469, 314–321. [Google Scholar] [CrossRef]

- Available online: https://noveon.co/our-process (accessed on 16 May 2023).

- Polyakov, E.G.; Sibilev, A. Recycling Rare-Earth-Metal Waste Using Hydrometallurgical Methods. Theor. Found. Chem. Eng. 2016, 50, 607–612. [Google Scholar] [CrossRef]

- Arrachart, G.; Couturier, J.; Dourdain, S.; Levard, C.; Pellet-Rostaing, S. Recovery of Rare Earth Elements (REEs) Using Ionic Solvents. Processes 2021, 9, 1202. [Google Scholar] [CrossRef]

- Zhu, F.M.N.; Zhu, W.; Liu, B.; Wu, P.; Dang, Z. Efficient recovery of rare earth elements from discarded NdFeB magnets by mechanical activation coupled with acid leaching. Environ. Sci. Pollut. Res. 2022, 29, 25532–25543. [Google Scholar] [CrossRef]

- Klemettinen, A.; Żak, A.; Chojnacka, I.; Matuska, S.; Lesniewicz, A.; Wełna, M.; Adamski, Z.; Klemettinen, L.; Rycerz, L. Leaching of Rare Earth Elements from NdFeB Magnets without Mechanical Pretreatment by Sulfuric (H2SO4) and Hydrochloric (HCl) Acids. Minerals 2021, 11, 1374. [Google Scholar] [CrossRef]

- Klemettinen, A.; Adamski, Z.; Chojnacka, I.; Lesniewicz, A.; Rycerz, L. Recovery of Rare Earth Elements from the Leaching Solutions of spent NdFeB Magnets by Selective Precipitation of Rare Earth Oxalates. Minerals 2023, 13, 846. [Google Scholar] [CrossRef]

- Haynes, W.M. Basic constants, Units and Conversion Factors. In CRC Handbook of Chemistry and Physics, 95th ed.; Taylor and Francis Group: Boca Raton, FL, USA, 2013; pp. 5–190. [Google Scholar] [CrossRef]

- Vander Hoogerstraete, T.; Blanpain, B.; Van Gerven, T.; Binnemans, K. From NdFeB magnets towards the rare-earth oxides: A recycling process consuming only oxalic acid. RSC Adv. 2014, 4, 64099–64111. [Google Scholar] [CrossRef]

- Danczak, A.; Chojnacka, I.; Matuska, S.; Marcola, K.; Lesniewicz, A.; Wełna, M.; Żak, A.; Adamski, Z.; Rycerz, L. The recycling-oriented material characterization of hard disk drives with special emphasis on NdFeB magnets. Physicochem. Probl. Miner. Process. 2018, 54, 363–376. [Google Scholar] [CrossRef]

- Benson, J.; Celin, A. Recovering Hydrogen—And Profits—From Hydrogen-Rich Offgas. Reactions and Separations. 2018. Available online: https://www.aiche.org/resources/publications/cep/2018/january/recovering-hydrogen-and-profits-hydrogen-rich-offgas (accessed on 21 June 2023).

- Xiao, F.; Hu, W.; Zhao, J.; Zhu, H. Technologies of Recycling REEs and Iron from NdFeB Scrap. Metals 2023, 13, 779. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, X.; Wang, M.; Wang, H.; Xian, P. Iron recovery from the leached solution of red mud through the application of oxalic acid. Int. J. Miner. Process. 2016, 157, 145–151. [Google Scholar] [CrossRef]

- Pietrantonio, M.; Pucciarmati, S.; Sebastianelli, L.; Forte, F.; Fontana, D. Materials recovery from end-of-life wind turbine magnets. Int. J. Environ. Sci. Technol. 2022, 19, 8019–8026. [Google Scholar] [CrossRef]

- Mystrioti, C.; Papassiopi, N.; Xenidis, A. Selective Recovery of Iron by Solvent Extraction from Ni-Laterite Leach Solutions, as Precursor for the Synthesis of High Added-Value Nanomaterials. Circ. Econ. Sustain. 2022, 2, 1575–1587. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).