Characteristics and Factors Influencing Pore Structure in Shale Oil Reservoirs of Different Lithologies in the Jurassic Lianggaoshan Formation of the Yingshan Gas Field in Central Sichuan Basin

Abstract

:1. Introduction

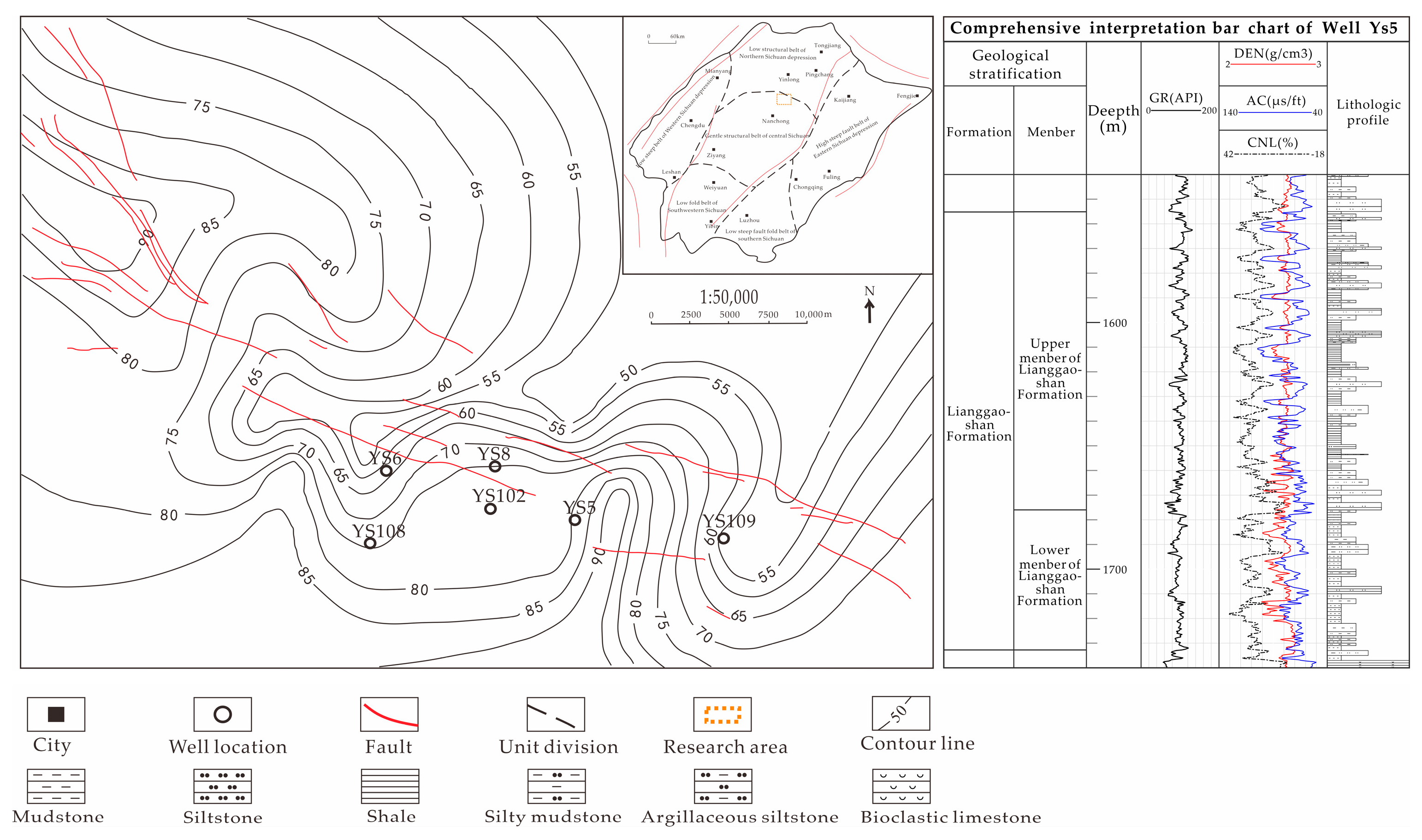

2. Geological Overview

3. Materials and Methods

3.1. Sample Selection

3.2. Experimental Methods

- Xi is he percentage content of mineral i, expressed as a percentage;

- Ii is the diffraction peak intensity of mineral i; and

- Ki is the reference strength of mineral i.

4. Characteristics of the Reservoir Space of the Lianggaoshan Formation

4.1. Lithological Characteristics

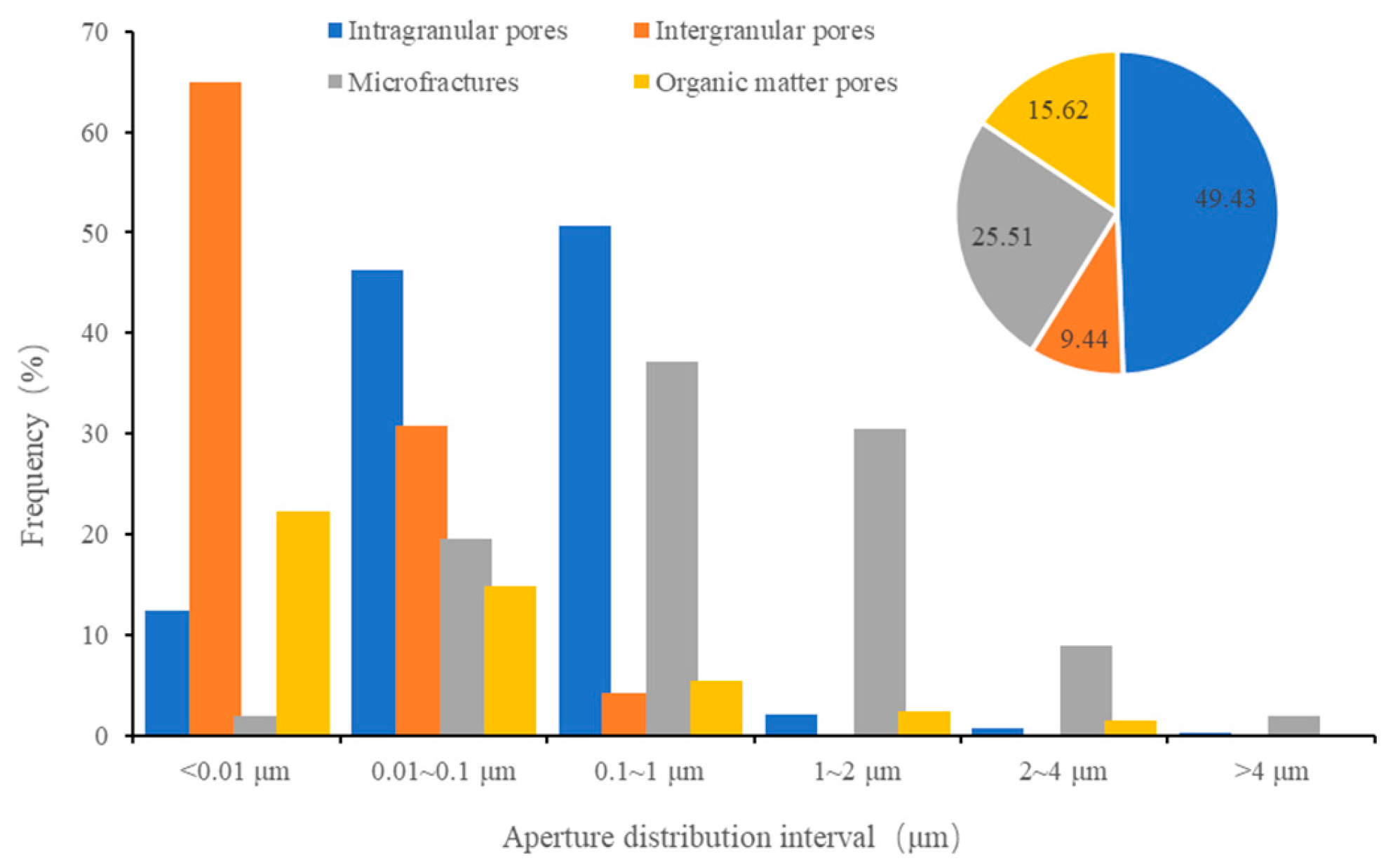

4.2. Storage Space Type and Distribution Characteristics

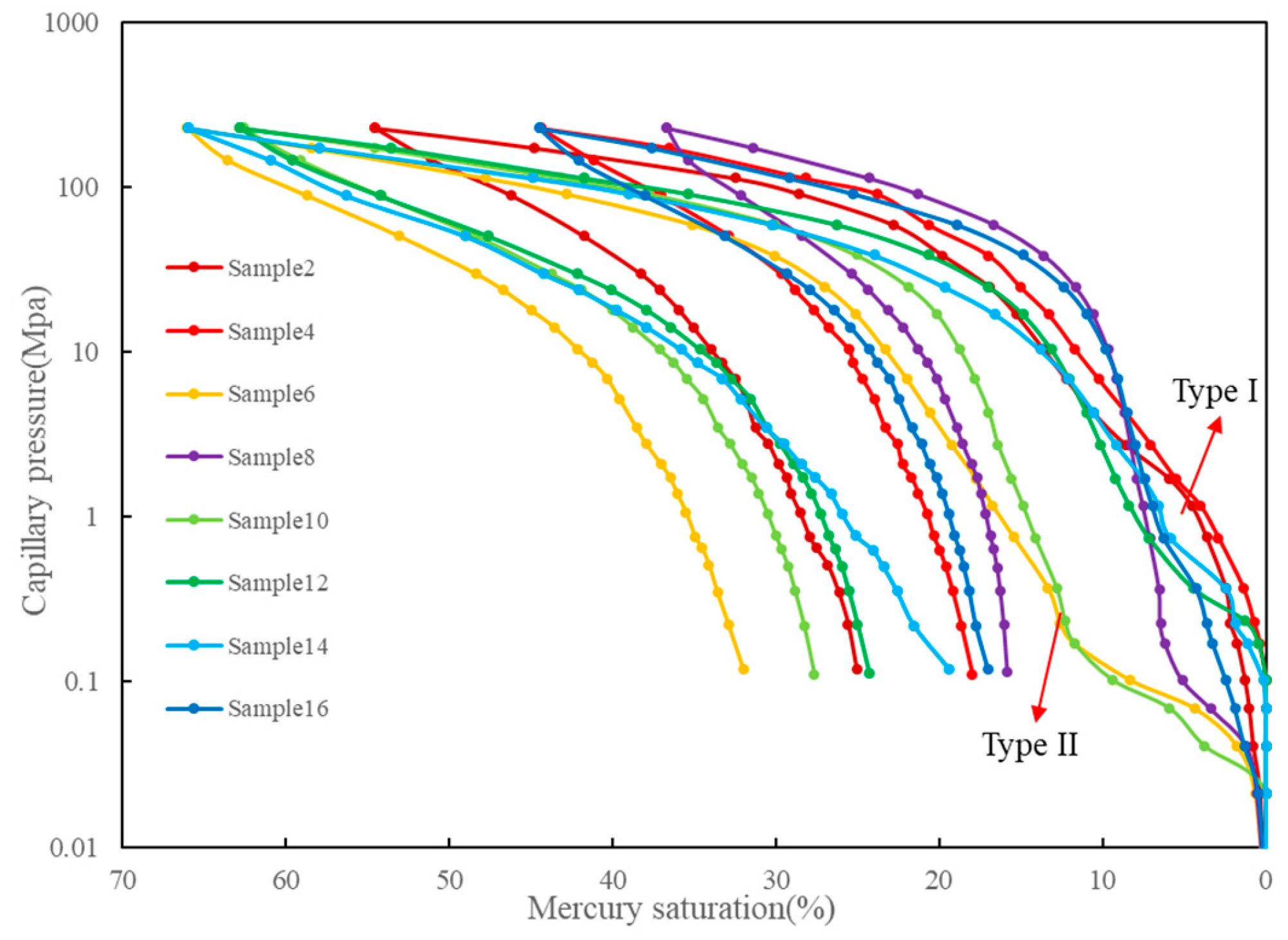

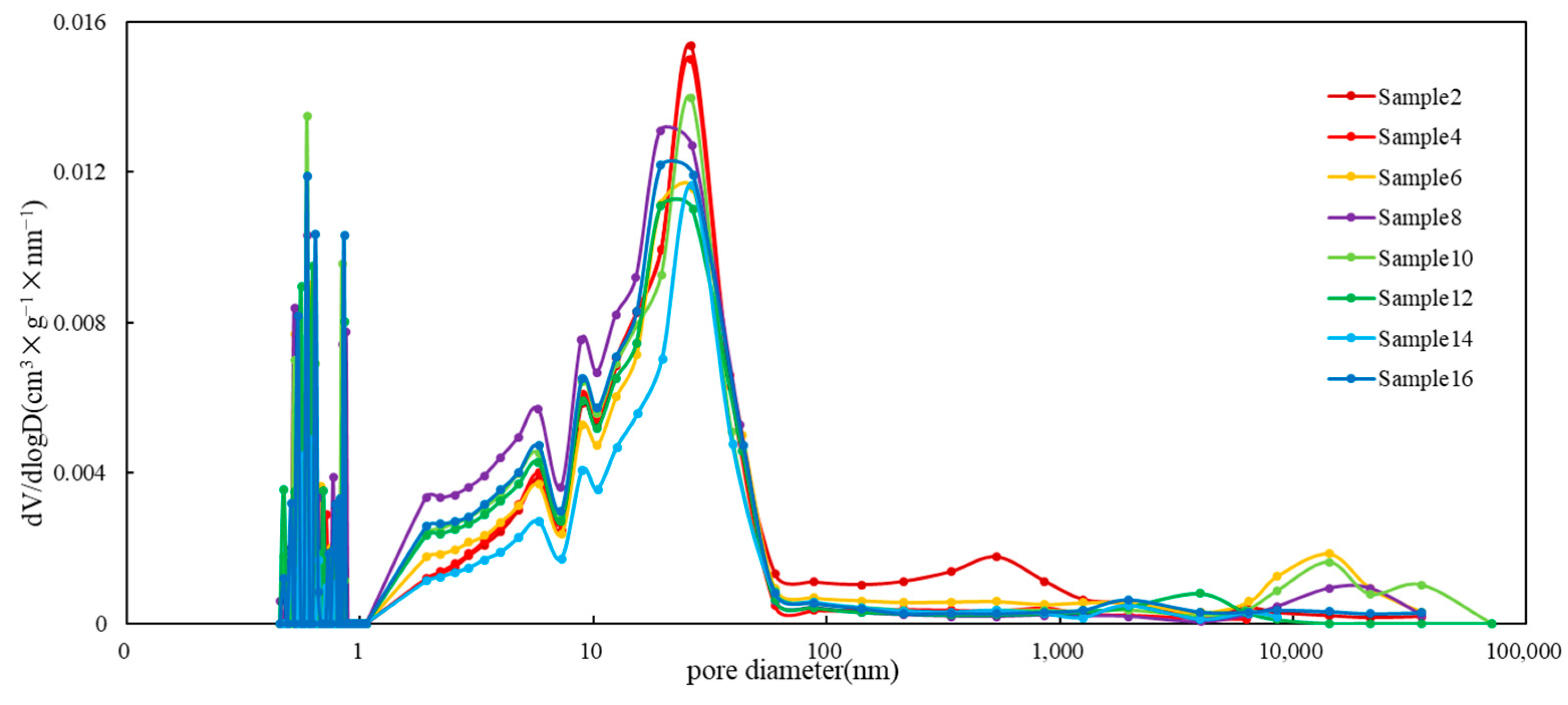

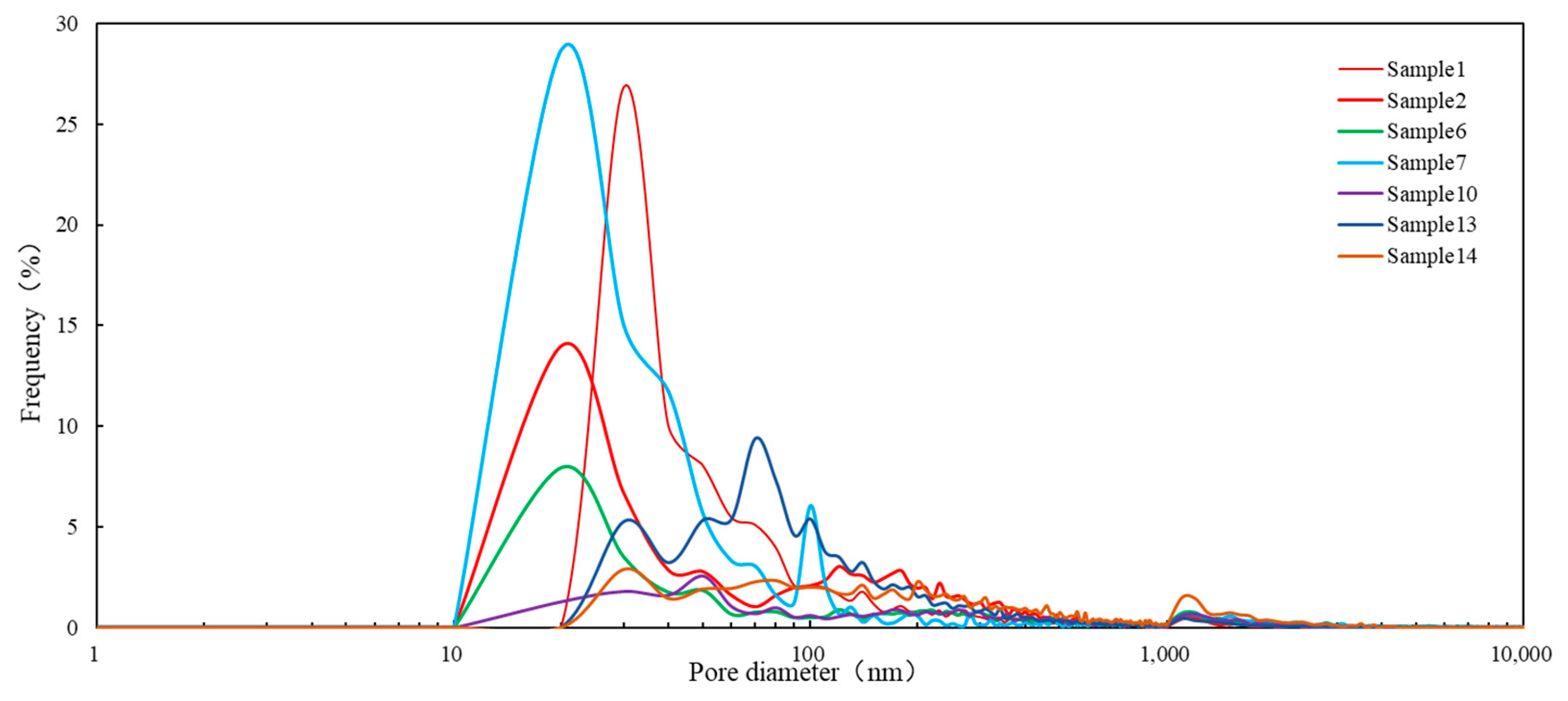

4.3. Pore Structure Distribution Characteristics

5. Factors Influencing the Development of the Pore Structure

5.1. Comparison of Pore Structure Characteristics of Different Lithologies

5.2. Factors Influencing Pore Structure Development

6. Conclusions

Recommendations for Hydraulic Fracturing Modifications based on In Situ Stress Magnitude Evaluation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, W.; Bai, X.; Meng, Q.; Li, J.; Zhang, D.; Wang, Y. Accumulation geological characteristics and major discoveries of lacustrine shale oil in Sichuan Basin. Acta Pet. Sin. 2022, 43, 885–898. [Google Scholar]

- Li, G.; Lei, Z.; Dong, W.; Wang, H.; Zheng, X.; Tan, J. Progress, challenges and prospects of unconventional oil and gas development of CNPC. China Pet. Explor. 2022, 27, 1–11. [Google Scholar]

- Wang, Q.; Tao, S.; Guan, P. Progress in research and exploration & development of shale oil in continental basins in China. Nat. Gas Geosci. 2020, 31, 417–427. [Google Scholar]

- Cao, Q.; Qi, M.; Li, X.; Wang, D.; Deng, Y.; Wu, C. Study on Organic Matter Enrichment and Reservoir Characteristics of Permian Longtan Formation Shale in Southeast Sichuan. Front. Earth Sci. 2022, 10, 895941. [Google Scholar] [CrossRef]

- Cao, Q.; Jiang, K.; Wen, Z.; Wang, X.; Qi, M.; Yin, Z. Characteristics of Organic Matter Pores and the Relationship with Current Pressure System of Lower Silurian Longmaxi Shales in Dingshan Field, Southern Sichuan, China. Geofluids 2021, 2021, 9967479. [Google Scholar] [CrossRef]

- Cao, Q.; Zhou, W.; Deng, H.; Chen, W. Classification and Controlling Factors of Organic Pores in Continental Shale Gas Reservoir based on Laboratory Experimental Results. J. Nat. Gas Sci. Eng. 2015, 27, 1381–1388. [Google Scholar] [CrossRef]

- He, W.; He, H.; Wang, Y.; Cui, B.; Meng, Q.; Guo, X.; Bai, X.; Wang, Y. Major breakthrough and significance of shale oil of the Jurassic Lianggaoshan Formation in Well Ping’an 1 in northeastern Sichuan Basin. China Pet. Explor. 2022, 27, 40–49. [Google Scholar]

- Yang, Y.; Yang, J.; Yang, G.; Tao, S.; Ni, C.; Zhang, B.; He, X.; Lin, J.; Huang, D.; Liu, M.; et al. New research progress of Jurassic tight oil in central Sichuan Basin. Pet. Explor. Dev. 2016, 43, 873–882. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.; Chalmers, G.; He, L.; Melnichenko, Y.B.; Radlinski, A.P.; Blach, T.P. Pore structure characterization of North American shale gas reservoirs usingUSANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Labani, M.M.; Rezaee, R.; Saeedi, A.; Hinai, A.A. Evaluation of pore size spectrum of gas shale reservusing low pressure nitrogen adsorption, gas expansion and mercury porosimetry: A case sfrom the Perth and Canning Basins, Western Australia. J. Pet. Sci. Eng. 2013, 112, 7–16. [Google Scholar] [CrossRef]

- Zhou, K.; Li, J.; Xu, Y.; Zhang, Y. Measurement of rock pore structure based on NMR technology. J. Cent. South Univ. (Sci. Technol.) 2012, 43, 4776–4800. [Google Scholar]

- Yang, F.; Ning, Z.; Hu, C.; Wang, B.; Peng, K.; Liu, H. Characterization of microscopic pore structures in shale reservoirs. Acta Pet. Sin. 2013, 34, 301–311. [Google Scholar]

- Guo, X.; Li, Y.; Liu, R.; Wang, Q. Characteristics and controlling factors of micro-pore structures of Longmaxi Shale Play in the Jiaoshiba area, Sichuan Basin. Nat. Gas Ind. 2014, 34, 9–16. [Google Scholar]

- Wang, P.; Nie, H.; Liu, Z.; Sun, C.; Cao, Z.; Wang, R.; Li, P. Differences in Pore Type and Pore Structure between Silurian Longmaxi Marine Shale and Jurassic Dongyuemiao Lacustrine Shale and Their Influence on Shale-Gas Enrichment. Minerals 2023, 13, 190. [Google Scholar] [CrossRef]

- Qing, Y. Formation Mechanism of Tight Oil Reservoirs in Liangshang Member and Shayi Member of Jurassic, Central Sichuan Basin. Ph.D. Thesis, Chengdu University of Technology, Chengdu, China, 2020. [Google Scholar]

- Liu, A.; Tian, J.; Zhang, S.; Chen, S.; Yi, J.; Luo, X.; Luo, N.; Cai, L.; Yang, T. Characteristics and controlling factors of tight sandstone reservoirs of the Jurassic Lianggaoshan Formation in the eastern Sichuan Basin. Mineral. Petrol. 2023, 43, 144–155. [Google Scholar]

- Feng, Y. Geological characteristics and exploration direction of continental shale gas in Jurassic Da ‘anzhai Member, Sichuan Basin. Pet. Geol. Exp. 2022, 44, 219–230. [Google Scholar]

- Yang, R.; Wang, F.; Yun, N.; Zeng, H.; Han, Y.; Hu, X.; Diao, N. Pore Structure Characteristics and Permeability Stress Sensitivity of Jurassic Continental Shale of Dongyuemiao Member of Ziliujing Formation, Fuxing Area, Eastern Sichuan Basin. Minerals 2022, 12, 1492. [Google Scholar]

- Curtis, M.E.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.S. Development of organic porosity in the Woodford shale with increasing thermal maturity. Int. J. Coal Geol. 2012, 26, 26–30. [Google Scholar] [CrossRef]

- Keller, L.M.; Schuetz, P.; Erni, R.; Rossell, M.D.; Lucas, F.; Gasser, P.; Holzer, L. Characterization of multi-scale microstructural features in Opalinus Clay. Microporous Mesoporous Mater. 2013, 83, 84–90. [Google Scholar] [CrossRef]

- Deng, H.; Hu, X.; Li, H.A.; Luo, B.; Wang, W. Improved pore-structure characterization in shale formations with FESEM technique. J. Nat. Gas Sci. Eng. 2016, 35, 309–319. [Google Scholar]

- Zou, J.; Lei, Y.; Jin, T.; Li, X.; Li, X.; Wei, T. Genesis and Sweet Spot Prediction of Jurassic Tight Sandstone Reservoir in Central Sichuan Basin. Xinjiang Pet. Geol. 2018, 39, 555–560. [Google Scholar]

- Li, N.; Hong, H.; Li, G.; Zhou, H.; Jia, M.; Kang, J. Geological characteristics of shale oil and gas of Lianggaoshan Formation in high-steep structural zone, Sichuan Basin. Nat. Gas Explor. Dev. 2022, 45, 86–95. [Google Scholar]

- Li, J. Reservoir Characteristics of Longmaxi Shale in the Southeast of Chongqing. Master’s Thesis, China University of Geosciences (Beijing), Beijing, China, 2013. [Google Scholar]

- Liao, Q.; Hu, H.; Lin, J.; Liu, Z.; Mu, X. Petroleum exploration prospect of the Jurassic tight reservoirs in central Sichuan Basin. Oil Gas Geol. 2011, 32, 815–822+838. [Google Scholar]

- Chen, S.; Gao, X.; Wang, L.; Lu, J.; Liu, C.; Tang, H.; Zhang, H.; Huang, M.; Ni, S. Factors controlling oiliness of Jurassic Lianggaoshan tight sands in central Sichuan Basin, SW China. Pet. Explor. Dev. 2014, 41, 421–427. [Google Scholar] [CrossRef]

- Hong, H.; Zhang, S.; Zhang, R.; Guan, X. Establishment of Sequence Stratigraphic Framework and Optimization of Favorable Exploration Areas of Lianggaoshan Formation, Sichuan Basin. J/OL. Spec. Oil Gas Reserv. 2023, 30, 58–64. [Google Scholar]

- Yi, J.; Zhang, S.; Cai, L.; Chen, S.; Luo, X.; Yu, J.; Luo, N.; Yang, T. Strata and Sedimentary Filling Characteristics of the Lower Jurassic Lianggaoshan Formation and Its Hydrocarbon Exploration in Eastern Sichuan Basin. J. Jilin Univ. (Earth Sci. Ed.) 2022, 52, 795–815. [Google Scholar]

- Cheng, D.; Zhang, Z.; Hong, H.; Zhang, S.; Qin, C.; Yuan, X.; Zhang, B.; Zhou, C.; Deng, Q. Sequence structure, sedimentary evolution and their controlling factors of the Jurassic Lianggaoshan Formation in the East Sichuan Basin, SW China. Pet. Explor. Dev. 2023, 50, 262–272. [Google Scholar] [CrossRef]

- Erik, N.Y.; Ay, F. Use of petrological and organic geochemical data in determining hydrocarbon generation potential of coals: Miocene coals of Malatya Basin (Eastern Anatolia-Turkey). Int. J. Coal Sci. Technol. 2021, 8, 510–533. [Google Scholar]

- Corrado, S.; Schito, A.; Romano, C.; Grigo, D.; Poe, B.T.; Aldega, L.; Caricchi, C.; Di Paolo, L.; Zattin, M. An integrated platform for thermal maturity assessment of polyphase, long-lasting sedimentary basins, from classical to brand-new thermal parameters and models: An example from the on-shore Baltic Basin (Poland). Mar. Pet. Geol. 2020, 122, 104547. [Google Scholar]

- Caricchi, C.; Corrado, S.; Di Paolo, L.; Aldega, L.; Grigo, D. Thermal maturity of Silurian deposits in the Baltic Syneclise (on-shore Polish Baltic Basin): Contribution to unconventional resources assessment. Ital. J. Geosci. 2016, 135, 383–393. [Google Scholar] [CrossRef]

- Stach, E. Stach’s Textbook of Coal Petrology, 3rd ed.; Gerbrüder Barntraeger: Berlin, Germany, 1982. [Google Scholar]

- Yu, J.; Liu, H.; Wang, Y.; Liu, H.; Yang, K.; Lin, J. Characteristics and Influencing Factors of Micropore Structures in Jurassic Lianggaoshan Formation in Central Sichuan Basin. Well Logging Technol. 2019, 43, 612–619. [Google Scholar]

- Huang, Y.; Zhang, J.; Zhang, P.; Tang, X.; Su, H. Microscopic Characteristics and Main Controlling Factors of Shale Reservoir Space of Es3 Formation, Northern Dongpu Depression. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2016, 35, 8–16. [Google Scholar]

- Ge, M.; Ren, S.; Bao, S.; Wang, S.; Guo, T. Continental shale gas-bearing analysis and exploration prospect:a case study of K1q1 formation of southern Songliao basin. China Min. Mag. 2019, 28, 162–168. [Google Scholar]

- Zou, G.; She, J.; Peng, S.; Yin, Q.; Liu, H.; Che, Y. Two-dimensional SEM image-based analysis of coal porosity and its pore structure. Int. J. Coal Sci. Technol. 2020, 7, 350–361. [Google Scholar] [CrossRef] [Green Version]

- Fu, D.; Xu, G.; Ma, L.; Yang, F.; He, D.; Duan, Z.; Ma, Y. Gas generation from coal: Taking Jurassic coal in the Minhe Basin as an example. Int. J. Coal Sci. Technol. 2020, 7, 611–622. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, Q.; Ye, X.; Dong, L. Adsorption Characteristics and Pore Structure of Organic-Rich Shale with Different Moisture Contents. Front. Earth Sci. 2022, 10, 863691. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Kong, D.; Liu, H. Pore Structure of Shales from High Pressure Mercury Injection and Nitrogen Adsorption Method. Nat. Gas Geosci. 2013, 24, 450–455. [Google Scholar]

- Chen, S.; Zhang, C.; Li, X.; Zhang, Y.; Wang, X. Simulation of methane adsorption in diverse organic pores in shale reservoirs with multi-period geological evolution. Int. J. Coal Sci. Technol. 2021, 8, 844–855. [Google Scholar] [CrossRef]

- Liu, A.; Liu, S.; Liu, P.; Wang, K. Water sorption on coal: Effects of oxygen-containing function groups and pore structure. Int. J. Coal Sci. Technol. 2021, 8, 983–1002. [Google Scholar]

- Tan, R.; Wang, R.; Huang, Y.; Yang, R.; Li, H.; Lu, K. Mechanism of the Enrichment and Loss Progress of Deep Shale Gas: Evidence from Fracture Veins of the Wufeng–Longmaxi Formations in the Southern Sichuan Basin. Minerals 2022, 12, 897. [Google Scholar] [CrossRef]

- Cao, Q. Characterization and Techniques of Micropores in Organic-Richshale of Chang 7th of Yanchang Formation, Ordos Basin. Ph.D. Thesis, Chengdu University of Technology, Chengdu, China, 2016. [Google Scholar]

- Wang, W.; Shi, W.; Fu, X.; Xie, J.; Ni, K. Oil and gas enrichment regularity of continental shale of Lianggaoshan Formation of Middle Jurassic in Fuling area, Sichuan Basin. Nat. Gas Geosci. 2022, 33, 764–774. (In Chinese) [Google Scholar]

| Number | Depth (m) | TOC (%) | Mineral Content (%) | Clay Mineral Content (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | Feldspar | Calcite | Dolomite | Pyrite | Clay Mineral | Illite | Kaolinite | Chlorite | Illite/Montmorillonite Mixed Layers | |||

| 2 | 1611.44–1611.55 | 3.17 | 32.9 | 4.5 | 3.9 | 0 | 0.6 | 58.1 | 23.2 | 9.3 | 17.4 | 8.1 |

| 4 | 1612.57–1612.71 | 3.62 | 28.9 | 2.4 | 19.5 | 1.3 | 3.6 | 44.3 | 14.2 | 10.2 | 11.5 | 8.4 |

| 6 | 1614.69–1614.86 | 1.35 | 30.3 | 2.3 | 19.8 | 1 | 3.1 | 43.5 | 17.0 | 12.2 | 9.1 | 5.2 |

| 8 | 1615.64–1615.79 | 0.64 | 28.9 | 2 | 21.9 | 2.2 | 3.6 | 41.4 | 14.9 | 11.2 | 9.9 | 5.4 |

| 10 | 1647.04–1647.20 | 1.64 | 34.4 | 7.8 | 13 | 0 | 2.4 | 42.4 | 18.7 | 5.5 | 12.7 | 5.5 |

| 12 | 1648.75–1648.96 | 1.22 | 35.2 | 9.2 | 0 | 0 | 2 | 53.6 | 24.1 | 7.0 | 14.5 | 8.0 |

| 14 | 1652.54–1652.67 | 1.46 | 39.7 | 9.1 | 0 | 0 | 1.3 | 49.9 | 19.0 | 5.0 | 9.5 | 16.5 |

| 16 | 1653.09–1653.27 | 1.08 | 38.5 | 12 | 1.7 | 2.8 | 0 | 45 | 13.5 | 6.3 | 9.0 | 16.2 |

| Number | SSA (m2/g) | PV (cm3/g) | Fractal Dimension of Full Aperture Range |

|---|---|---|---|

| 1 | 4.2003 | 0.008694 | |

| 2 | 5.2561 | 0.014928 | 2.7843 |

| 3 | 2.8221 | 0.006958 | |

| 4 | 5.3439 | 0.015185 | 2.7005 |

| 5 | 16.0593 | 0.017826 | |

| 6 | 7.1863 | 0.014279 | 2.7299 |

| 7 | 3.7634 | 0.008465 | |

| 8 | 14.4304 | 0.018242 | 2.7124 |

| 9 | 4.5694 | 0.009177 | |

| 10 | 9.575 | 0.015047 | 2.7568 |

| 11 | 13.7266 | 0.015825 | |

| 12 | 9.27 | 0.014558 | 2.7535 |

| 13 | 6.3728 | 0.011286 | |

| 14 | 4.1966 | 0.011727 | 2.7209 |

| 15 | 10.3870 | 0.015830 | |

| 16 | 10.3587 | 0.015705 | 2.7514 |

| 17 | 9.7045 | 0.013542 | |

| 18 | 10.6579 | 0.013794 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Deng, H.; Wang, Z.; Wang, X.; Cao, Q.; Cheng, D.; Zhu, Y.; Li, A. Characteristics and Factors Influencing Pore Structure in Shale Oil Reservoirs of Different Lithologies in the Jurassic Lianggaoshan Formation of the Yingshan Gas Field in Central Sichuan Basin. Minerals 2023, 13, 958. https://doi.org/10.3390/min13070958

Wang Y, Deng H, Wang Z, Wang X, Cao Q, Cheng D, Zhu Y, Li A. Characteristics and Factors Influencing Pore Structure in Shale Oil Reservoirs of Different Lithologies in the Jurassic Lianggaoshan Formation of the Yingshan Gas Field in Central Sichuan Basin. Minerals. 2023; 13(7):958. https://doi.org/10.3390/min13070958

Chicago/Turabian StyleWang, Youzhi, Hucheng Deng, Zhiguo Wang, Xiandong Wang, Qian Cao, Dean Cheng, Yanping Zhu, and An Li. 2023. "Characteristics and Factors Influencing Pore Structure in Shale Oil Reservoirs of Different Lithologies in the Jurassic Lianggaoshan Formation of the Yingshan Gas Field in Central Sichuan Basin" Minerals 13, no. 7: 958. https://doi.org/10.3390/min13070958