Aeschynite Group Minerals Are a Potential Recovery Target for Niobium Resources at the Giant Bayan Obo Nb–REE–Fe Deposit in China

Abstract

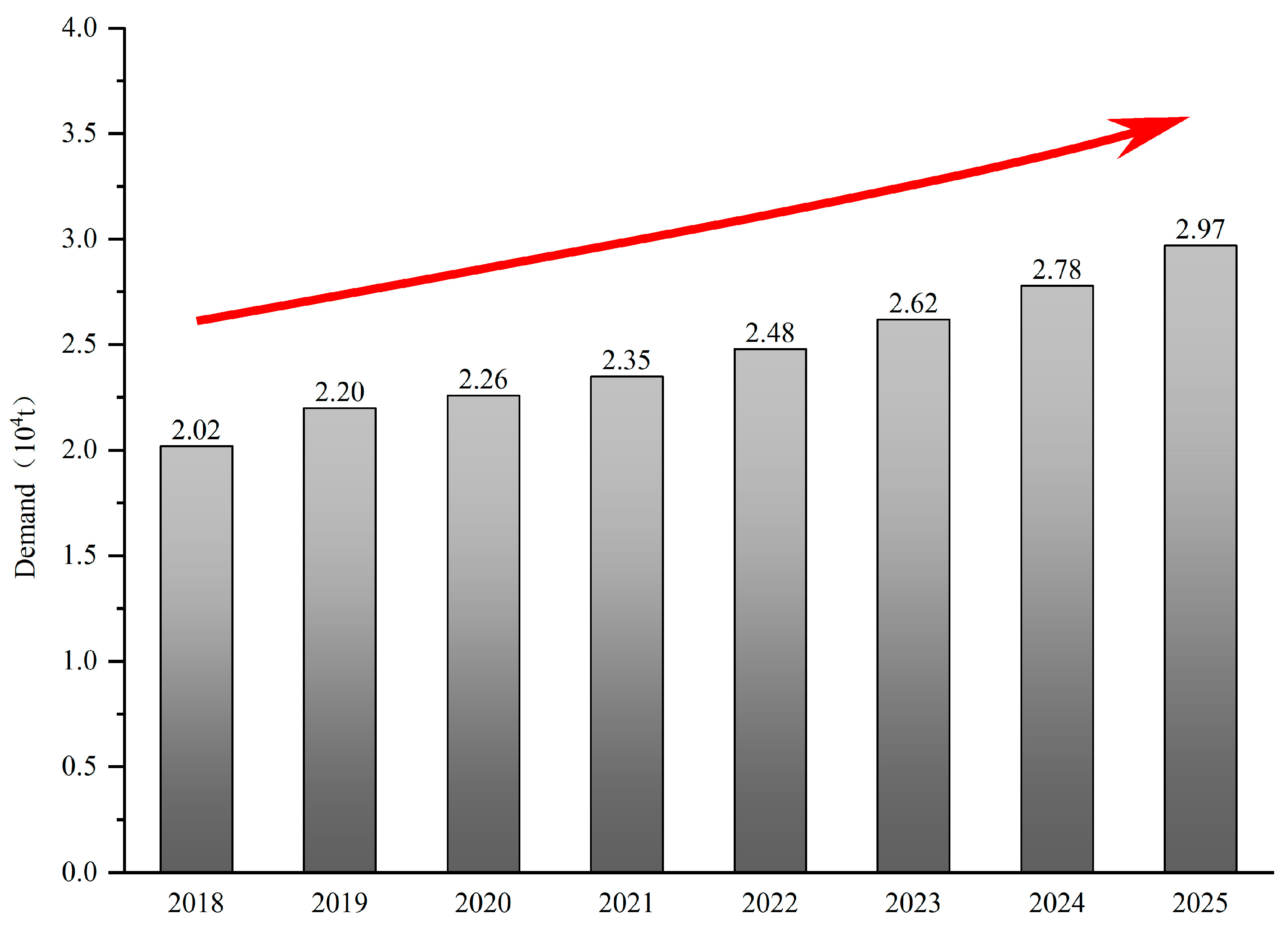

:1. Introduction

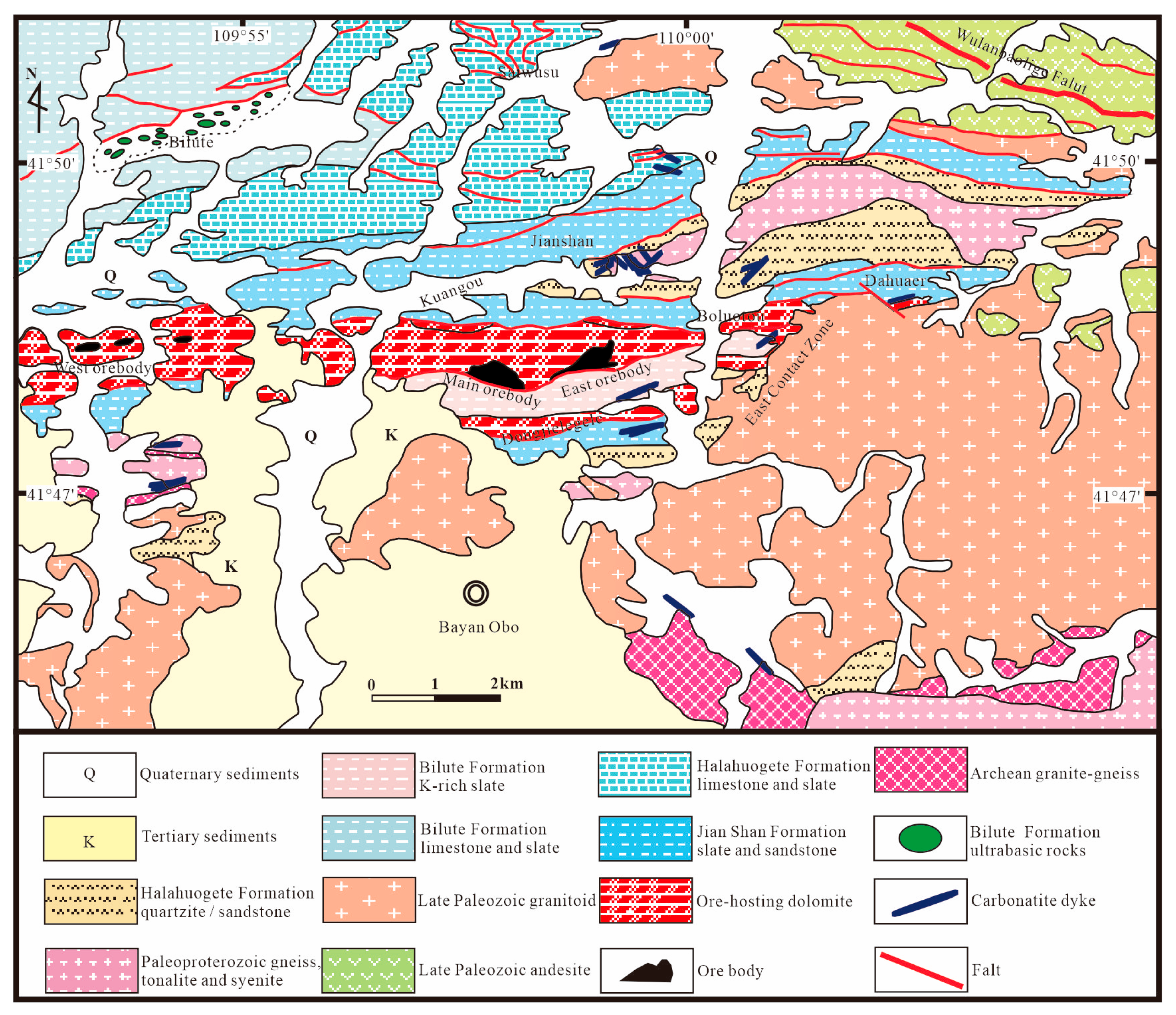

2. Geological Background

3. Samples and Analytical Methods

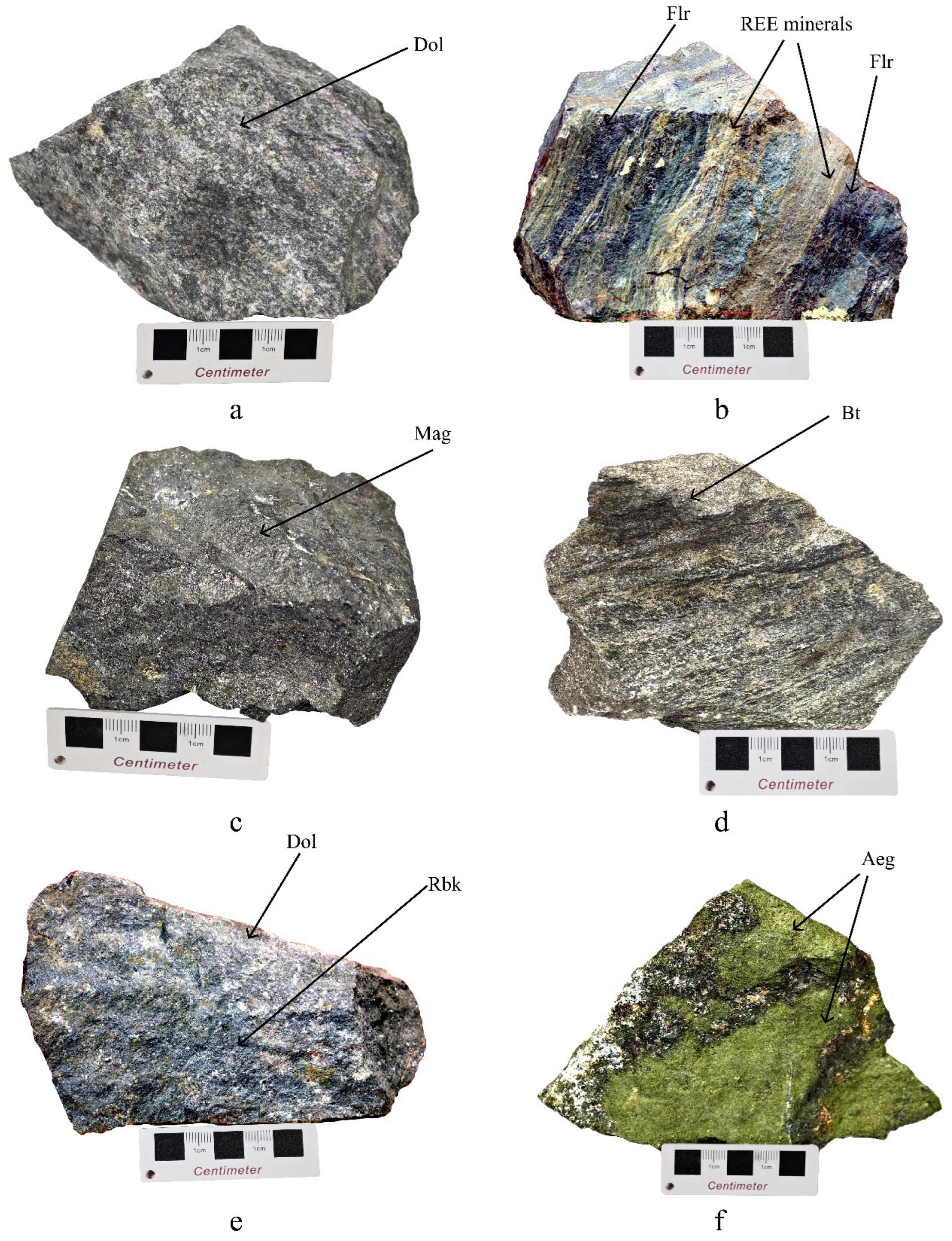

3.1. Sample Description

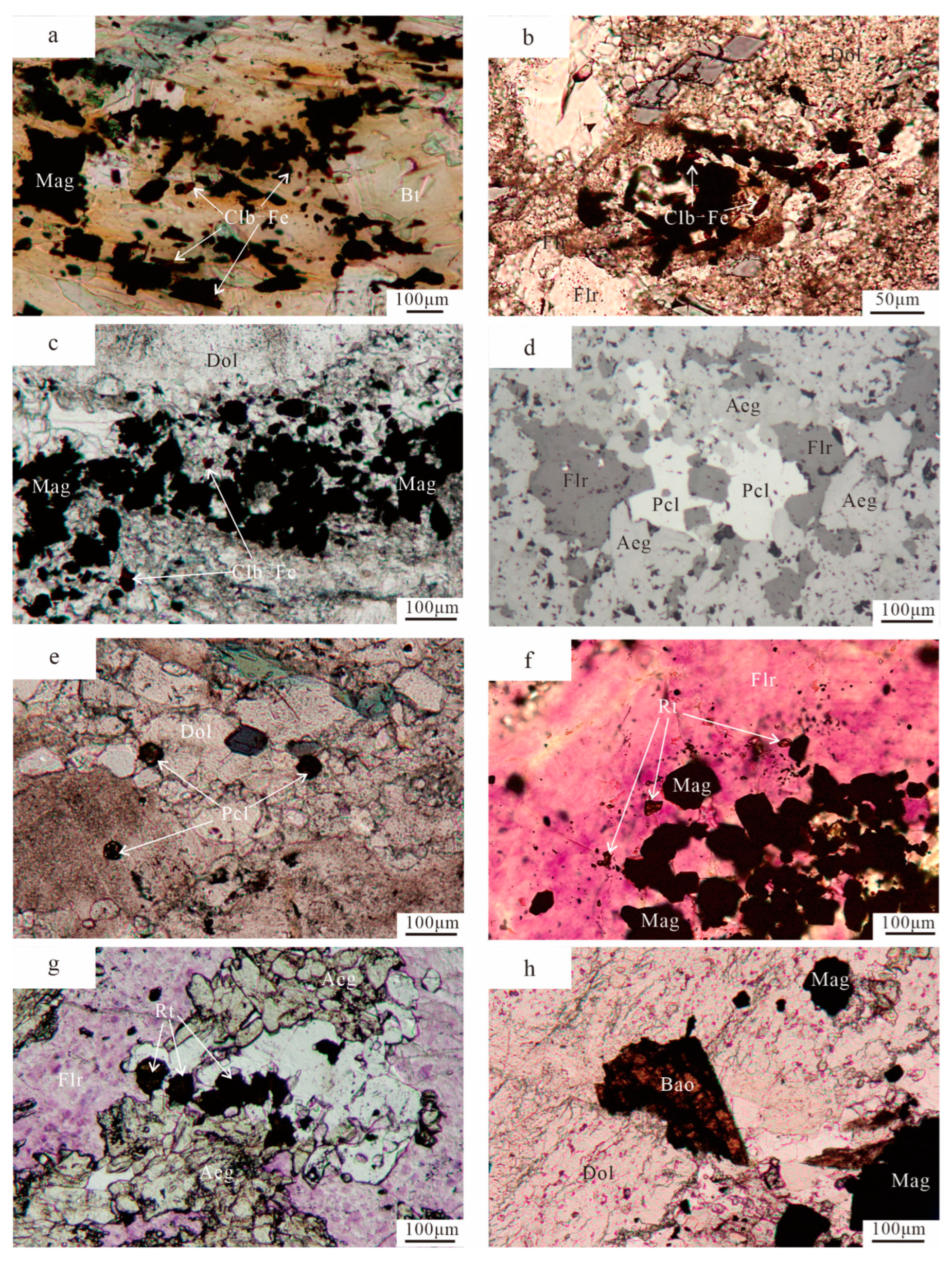

3.2. Petrographic Observation

3.3. Major and Trace Element Compositions of Niobium Minerals

4. Results

4.1. Petrography and Mineralogy of Nb Minerals in the Ores

4.1.1. Aeschynite Group Minerals

4.1.2. Columbite–(Fe)

4.1.3. Fluorcalciopyrochlore

4.1.4. Nb–Bearing Rutile

4.1.5. Baotite, Fergusonite–(Y), Fersmite, and Samarskite–(Y)

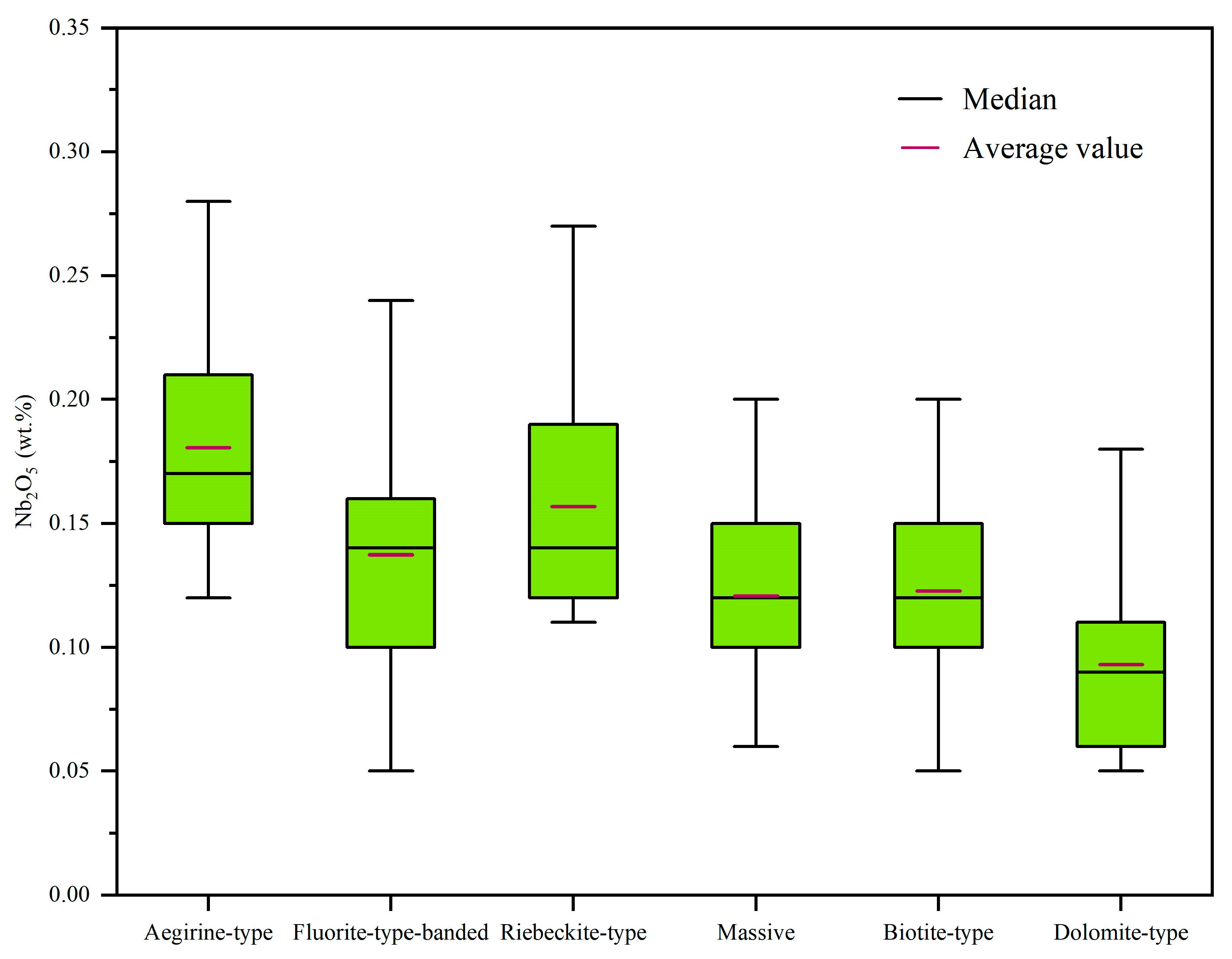

4.2. Chemical Compositions of Ores

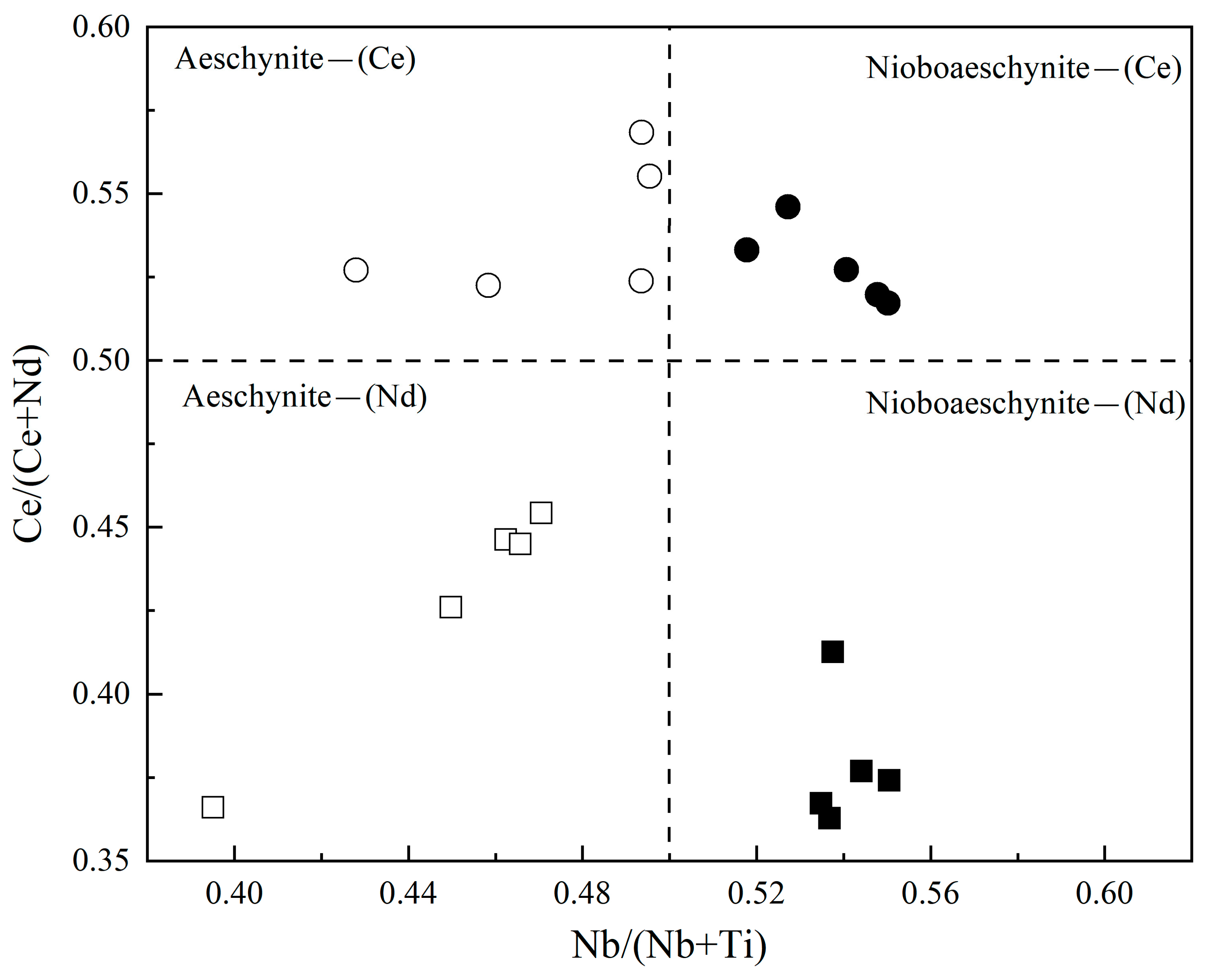

4.3. Major Elements of Aeschynite Group Minerals

- (Nd0.39Ce0.29Th0.10Ca0.06Pr0.05Sm0.04Fe0.04La0.02Y0.01Gd0.01Ba0.01)Σ1.02(Ti1.10Nb0.90)Σ2.00O6.00 for aeschynite–(Nd),

- (Nd0.33Ce0.20Th0.07Ca0.10Pr0.03Sm0.05Fe0.07La0.01Y0.07Gd0.02Dy0.01Er0.01Lu0.01)Σ0.98(Nb1.09Ti0.93)Σ2.02O6.00 for nioboaeschynite–(Nd),

- (Ce0.37Nd0.32Th0.01Ca0.12Pr0.04Sm0.02Fe0.03La0.04Y0.03Gd0.01Lu0.01)Σ1.00(Ti1.07Nb0.96)Σ2.03O6.00 for aeschynite–(Ce), and

- (Ce0.36Nd0.32Th0.01Ca0.14Pr0.04Sm0.04Fe0.03La0.04Y0.03Gd0.01)Σ1.02(Nb1.07Ti0.92)Σ1.99(O5.96F0.04)Σ6.00 for nioboaeschynite–(Ce), respectively (Table S2).

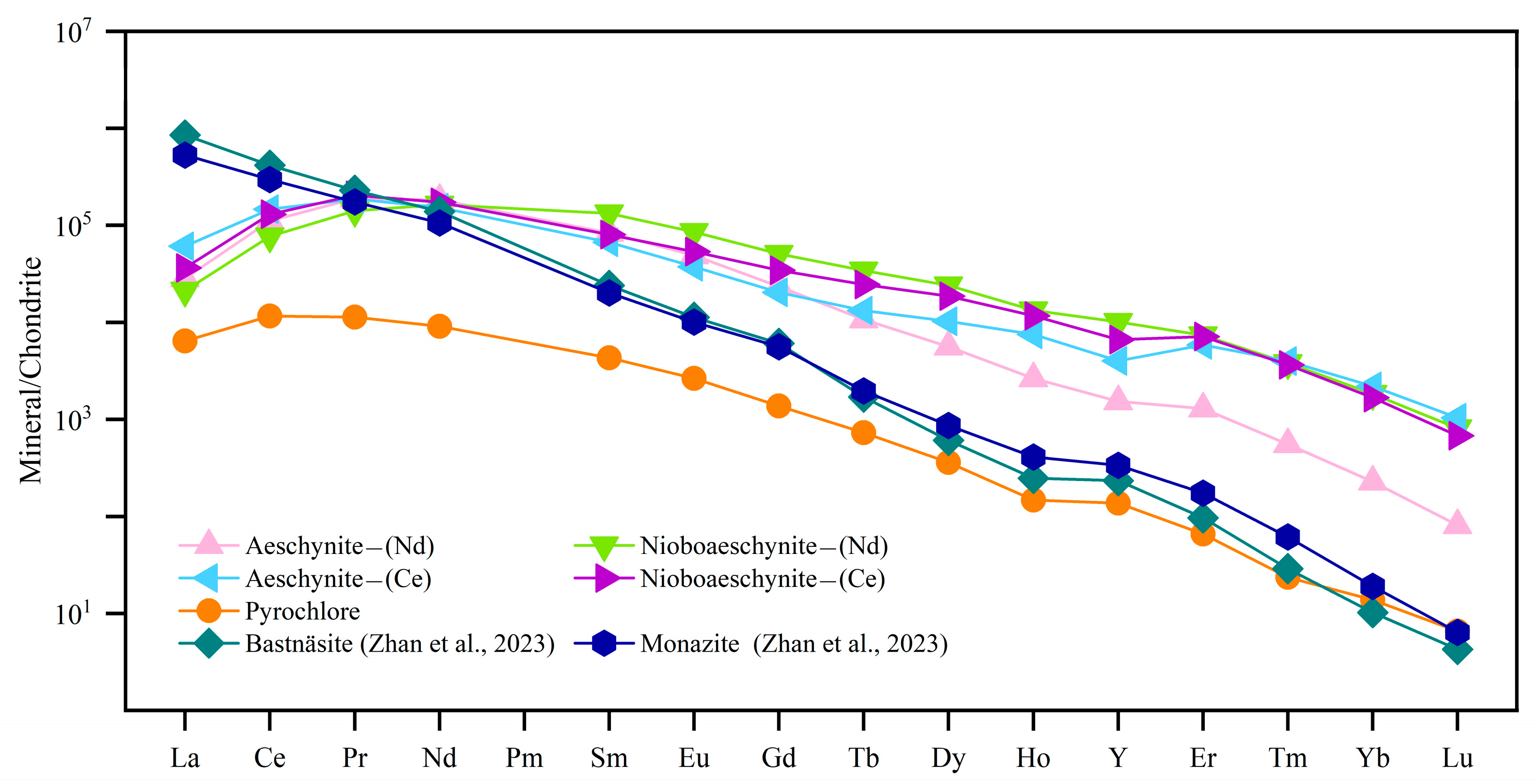

4.4. REE and Trace Elements of Nb Minerals

4.5. Occurrence and Distributions of Nb Minerals in the Raw Ores

5. Discussion

5.1. Aeschynite Group Minerals Are the Major Source of Niobium at Bayan Obo

5.2. Aeschynite Group Minerals Are Also the Major Source of M-HREE at Bayan Obo

5.3. Aegirine-Type Nb–REE–(Fe) Ore Has Important Insights for Mineral Processing and Prospecting

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chakhmouradian, A.R.; Smith, M.P.; Kynicky, J. From “strategic” tungsten to “green” neodymium: A century of critical metals at a glance. Ore Geol. Rev. 2015, 64, 455–458. [Google Scholar] [CrossRef]

- Bartl, A.; Tkaczyk, A.H.; Amato, A.; Beolchini, F.; Lapkovskis, V.; Petranikova, M. Supply and substitution options for selected critical raw materials: Cobalt, niobium, tungsten, yttrium and rare earths elements. Detritus 2018, 3, 37–42. [Google Scholar] [CrossRef]

- McCaffrey, D.M.; Nassar, N.T.; Jowitt, S.M.; Padilla, A.J.; Bird, L.R. Embedded critical material flow: The case of niobium, the United States, and China. Resour. Conserv. Recycl. 2023, 188, 106698. [Google Scholar] [CrossRef]

- Williams-Jones, A.E.; Vasyukova, O.V. Niobium, critical metal, and progeny of the mantle. Econ. Geol. 2023, 118, 837–855. [Google Scholar] [CrossRef]

- Alves, A.R.; Coutinho, A.D.R. The evolution of the niobium production in Brazil. Mater. Res. 2015, 18, 106–112. [Google Scholar] [CrossRef]

- Bakry, M.; Li, J.; Zeng, X. Evaluation of global niobium flow modeling and its market forecasting. Front. Energy 2022, 17, 286–293. [Google Scholar] [CrossRef]

- Zhai, M.; Hu, R.; Wang, Y.; Jiang, S.; Wang, R.; Li, J.; Chen, H.; Yang, Z.; Lü, Q.; Qi, T.; et al. Mineral Resource Science in China: Review and perspective. Geogr. Sustain. 2021, 2, 107–114. [Google Scholar] [CrossRef]

- Liang, Z.; Geng, Y.; Zhong, C.; Xiao, S.; Wei, W. Tracking the evolution of niobium cycle in China from 2000 to 2021: A dynamic material flow analysis. J. Clean. Prod. 2024, 434, 140455. [Google Scholar] [CrossRef]

- Liu, S.; Ding, L.; Fan, H.R.; Yang, K.F.; Tang, Y.W.; She, H.D.; Hao, M.Z. Hydrothermal genesis of Nb mineralization in the giant Bayan Obo REE-Nb-Fe deposit (China): Implicated by petrography and geochemistry of Nb-bearing minerals. Precambrian Res. 2020, 348, 105864. [Google Scholar] [CrossRef]

- She, H.D.; Fan, H.R.; Yang, K.F.; Li, X.C.; Yang, Z.F.; Wang, Q.W.; Zhang, L.F.; Wang, Z.J. Complex, multi-stage mineralization processes in the giant Bayan Obo REE-Nb-Fe deposit, China. Ore Geol. Rev. 2021, 139, 104461. [Google Scholar] [CrossRef]

- Hou, X.; Yang, Z.; Wang, Z. Occurrence state and distribution regularity of key metal element niobium in Bayan Obo deposit, China. JOM 2023, 75, 2753–2762. [Google Scholar] [CrossRef]

- Li, X.C.; Fan, H.R.; Su, J.H.; Groves, D.I.; Yang, K.F.; Zhao, X.F. Giant REE accumulation related to voluminous, highly evolved carbonatite: A microanalytical study of carbonate minerals from the Bayan Obo deposit, China. Econ. Geol. 2024, 119, 373–393. [Google Scholar] [CrossRef]

- Yu, Y.; Li, Y.; Liu, Y.; Ling, X.X.; Wu, L.G.; Yang, L.; Yang, L.; Yang, B.; Zhao, Y.G.; Li, X.H. Three-stage niobium mineralization at Bayan Obo, China. Natl. Sci. Rev. 2024, 11, nwae063. [Google Scholar] [CrossRef] [PubMed]

- Drew, L.J.; Qingrun, M.; Weijun, S. The Bayan Obo iron-rare-earth-niobium deposits, Inner Mongolia, China. Lithos 1990, 26, 43–65. [Google Scholar] [CrossRef]

- Zhang, Q.F. Analysis on the mineralogical characteristics of niobium-bearing resources in Baiyunebo deposit. Nonferrous Met. Eng. 2005, 2, 111–113, (In Chinese with English Abstract). [Google Scholar]

- Guo, C.S.; Li, M.; Liu, Z.G.; Zhang, D.L.; Gao, K. Present status and new ideas on utilization of Bayan Obo rare earth and niobium resource. Chin. Rare Earths 2014, 35, 96–100, (In Chinese with English Abstract). [Google Scholar]

- Yin, Z.; Gao, L.; Rao, B. Overview of Niobium resources and progress in mineral processing technology in China. Conserv. Util. Miner. Resour. 2024, 44, 115–125, (In Chinese with English Abstract). [Google Scholar]

- Song, W.; Xu, C.; Smith, M.P.; Chakhmouradian, A.R.; Brenna, M.; Kynický, J.; Chen, W.; Yang, Y.; Deng, M.; Tang, H. Genesis of the world’s largest rare earth element deposit, Bayan Obo, China: Protracted mineralization evolution over ∼1 by. Geology 2018, 46, 323–326. [Google Scholar] [CrossRef]

- Weng, Z.; Jowitt, S.M.; Mudd, G.M.; Haque, N. A detailed assessment of global rare earth element resources: Opportunities and challenges. Econ. Geol. 2015, 110, 1925–1952. [Google Scholar] [CrossRef]

- Campbell, L.S.; Compston, W.; Sircombe, K.N.; Wilkinson, C.C. Zircon from the East Orebody of the Bayan Obo Fe–Nb–REE deposit, China, and SHRIMP ages for carbonatite-related magmatism and REE mineralization events. Contrib. Mineral. Petrol. 2014, 168, 1041. [Google Scholar] [CrossRef]

- Yang, K.F.; Fan, H.R.; Pirajno, F.; Liu, X. Magnesium isotope fractionation in differentiation of mafic-alkaline-carbonatitic magma and Fe-P-REE-rich melt at Bayan Obo, China. Ore Geol. Rev. 2023, 157, 105466. [Google Scholar] [CrossRef]

- Li, X.C.; Fan, H.R.; Zeng, X.; Yang, K.F.; Yang, Z.F.; Wang, Q.W.; Li, H.T. Identification of ~1.3 Ga hydrothermal zircon from the giant Bayan Obo REE deposit (China): Implication for dating geologically-complicated REE ore system. Ore Geol. Rev. 2021, 138, 104405. [Google Scholar] [CrossRef]

- Fan, H.R.; Yang, K.F.; Hu, F.F.; Liu, S.; Wang, K.Y. The giant Bayan Obo REE-Nb-Fe deposit, China: Controversy and ore genesis. Geosci. Front. 2016, 7, 335–344. [Google Scholar] [CrossRef]

- Smith, M.P.; Campbell, L.S.; Kynicky, J. A review of the genesis of the world class Bayan Obo Fe–REE–Nb deposits, Inner Mongolia, China: Multistage processes and outstanding questions. Ore Geol. Rev. 2015, 64, 459–476. [Google Scholar] [CrossRef]

- Li, X.C.; Yang, K.F.; Spandler, C.; Fan, H.R.; Zhou, M.F.; Hao, J.L.; Yang, Y.H. The effect of fluid-aided modification on the Sm-Nd and Th-Pb geochronology of monazite and bastnäsite: Implication for resolving complex isotopic age data in REE ore systems. Geochim. Et Cosmochim. Acta 2021, 300, 1–24. [Google Scholar] [CrossRef]

- Institute of Geochemistry, Chinese Academy of Sciences. Geochemistry of Bayan Obo Ore Deposit; Science Press: Beijing, China, 1988. (In Chinese) [Google Scholar]

- Liu, W.; Du, W.; Chen, H.; Zeng, Y.; Peng, H.; Wang, X.; Liu, J. Recovery of niobium from rare earth flotation tailings of Bayan Obo Mine. Mod. Min. 2023, 39, 148–151+155, (In Chinese with English Abstract). [Google Scholar]

- Wu, S.T.; Huang, C.; Xie, L.W.; Yang, Y.H.; Yang, J.H. Iolite based bulk normalization as 100% m/m quantification strategy for reduction of laser ablation-inductively coupled plasma-mass spectrometry transient signal. Chin. J. Anal. Chem. 2018, 46, 1628–1636, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wu, S.; Wörner, G.; Jochum, K.P.; Stoll, B.; Simon, K.; Kronz, A. The preparation and preliminary characterisation of three synthetic andesite reference glass materials (ARM-1, ARM-2, ARM-3) for in situ microanalysis. Geostand. Geoanal. Res. 2019, 43, 567–584. [Google Scholar] [CrossRef]

- Wu, S.; Yang, Y.; Jochum, K.P.; Romer, R.L.; Glodny, J.; Savov, I.P.; Agostini, S.; De Hoog, J.C.M.; Peters, S.T.M.; Kronz, A.; et al. Isotopic Compositions (Li-B-Si-O-Mg-Sr-Nd-Hf-Pb) and Fe2+/ΣFe Ratios of Three Synthetic Andesite Glass Reference Materials (ARM-1, ARM-2, ARM-3). Geostand. Geoanal. Res. 2021, 45, 719–745. [Google Scholar] [CrossRef]

- Griffin, W.L. GLITTER: Data reduction software for laser ablation ICP-MS. In Laser Ablation-ICP-MS in the Earth Sciences: Current Practices and Outstanding Issues (Short Course); Mineralogical Assn of Canada: Quebec City, QC, Canada, 2008; pp. 308–311. [Google Scholar]

- Yang, X.; Lai, X.; Pirajno, F.; Liu, Y.; Ling, M.; Sun, W. Genesis of the Bayan Obo Fe-REE-Nb formation in Inner Mongolia, north China craton: A perspective review. Precambrian Res. 2017, 288, 39–71. [Google Scholar] [CrossRef]

- Liu, Y.L.; Ling, M.X.; Williams, I.S.; Yang, X.Y.; Wang, C.Y.; Sun, W. The formation of the giant Bayan Obo REE-Nb-Fe deposit, North China, Mesoproterozoic carbonatite and overprinted Paleozoic dolomitization. Ore Geol. Rev. 2018, 92, 73–83. [Google Scholar] [CrossRef]

- Le Bas, M.J.; Spiro, B.; Yang, X.Y. Oxygen, carbon and strontium isotope study of the carbonatitic dolomite host of the Bayan Obo Fe-Nb-REE deposit, Inner Mongolia, N China. Mineral. Mag. 1997, 61, 531–541. [Google Scholar] [CrossRef]

- Back, M.E.; Mandarino, J.A. Fleischer’s Glossary of Mineral Species, 10th ed.; The Mineralogical Record: Tucson, AZ, USA, 2008. [Google Scholar]

- Zhan, Y.X.; Li, X.C.; Wu, B.; Yang, K.F.; Fan, H.R.; Li, X.H. The occurrence and genesis of HREE-rich minerals from the giant Bayan Obo deposit, China. Ore Geol. Rev. 2023, 157, 105438. [Google Scholar] [CrossRef]

- Taylor, S.R.; McLennan, S.M. The Continental Crust: Its Composition and Evolution; Blackwell Scientific Publications: Oxford, UK, 1985. [Google Scholar]

- Cordeiro, P.F.d.O.; Brod, J.A.; Palmieri, M.; de Oliveira, C.G.; Barbosa, E.S.R.; Santos, R.V.; Gaspar, J.C.; Assis, L.C. The Catalão I niobium deposit, central Brazil: Resources, geology and pyrochlore chemistry. Ore Geol. Rev. 2011, 41, 112–121. [Google Scholar] [CrossRef]

- Mitchell, R.H. Primary and secondary niobium mineral deposits associated with carbonatites. Ore Geol. Rev. 2015, 64, 626–641. [Google Scholar] [CrossRef]

- Vasyukova, O.V.; Williams-Jones, A.E. A new model for the origin of pyrochlore: Evidence from the St Honoré carbonatite, Canada. Chem. Geol. 2023, 632, 121549. [Google Scholar] [CrossRef]

- Neumann, R.; Medeiros, E.B. Comprehensive mineralogical and technological characterisation of the Araxá (SE Brazil) complex REE (Nb-P) ore, and the fate of its processing. Int. J. Miner. Process. 2015, 144, 1–10. [Google Scholar] [CrossRef]

- Miyawaki, R.; Momma, K.; Matsubara, S.; Sano, T.; Shigeoka, M.; Horiuchi, H. Hydroxykenopyrochlore, (□, Ce, Ba)2 (Nb, Ti)2O6 (OH, F), a new member of the pyrochlore group from Araxá, Minas Gerais, Brazil. Can. Mineral. 2021, 59, 589–601. [Google Scholar] [CrossRef]

- Biondi, J.C.; Braga, J.M., Jr. Main minerals of the Araxá alkali-carbonatite complex, Minas Gerais State, Brazil. J. South Am. Earth Sci. 2024, 134, 104751. [Google Scholar] [CrossRef]

- Tremblay, J.; Bédard, L.P.; Matton, G. A petrographic study of Nb-bearing minerals at the Saint-Honoré niobium deposit. Br. Columbia Geol. Surv. Pap. 2015, 3, 75–81. [Google Scholar]

- Zhang, P.S.; Tao, K.J. Bayan Obo Mineralogy; Science Press: Beijing, China, 1986. (In Chinese) [Google Scholar]

- Ren, Y.S.; Yang, X.Y.; Wang, X.X. Occurrence of niobium in biotite-type Fe-REE-Nb ore in the Bayan Obo deposit. Solid Earth Sci. 2023, 8, 25–28. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, D.; Li, Y.; Ke, C.; Yu, H.; Chen, Z.; She, H.; Wang, R.; Hu, H.; Zhao, Y.; et al. Detail mineralogical study and ge-ochronological framework of Bayan Obo (China) Nb mineralization recorded by in situ U-Pb dating of columbite. Ore Geol. Rev. 2024, 165, 105874. [Google Scholar] [CrossRef]

- Smith, M.; Spratt, J. The chemistry of niobium mineralization at Bayan Obo, Inner Mongolia, China: Constraints on the hydrothermal precipitation and alteration of Nb-minerals. Acta Geol. Sin. 2012, 86, 700–722. [Google Scholar]

| Particle Size (μm) | Weight (g) | Weight Distribution (%) | Nb2O5 Grade (%) | Nb2O5 Distribution Rate (%) |

|---|---|---|---|---|

| >74 | 21.0 | 14.14 | 0.12 | 11.96 |

| 45~74 | 30.9 | 20.81 | 0.12 | 19.21 |

| 32~45 | 4.5 | 3.03 | 0.08 | 2.56 |

| 25~32 | 12.8 | 8.62 | 0.15 | 4.64 |

| <25 | 79.3 | 53.40 | 0.13 | 61.62 |

| Total | 148.5 | 100 | 0.13 | 100 |

| Deposit | Main Niobium and Niobium–Bearing Minerals | References |

|---|---|---|

| Araxá | pyrochlore group minerals | [42,43] |

| Catalão I | pyrochlore group minerals | [38] |

| Saint-Honoré | pyrochlore group minerals, columbite–(Fe), phosphorite, magnetite, phlogopite | [39,44] |

| Bayan Obo | aeschynite–(Nd), nioboaeschynite–(Nd), aeschynite–(Ce), nioboaeschynite–(Ce), pyrochlore group minerals, Nb–bearing rutile, columbite–(Fe), samarskite–(Y), columbite–(Mn), fersmite, fergusonite–(Ce), fergusonite–(Ce)–β, fergusonite–(Nd), fergusonite–(Nd)–β, fergusonite–(Y), baotite, niobobaotite, nioboixiolite–(□), chevkinite–(Ce), titanite, bafertisite | [13,23,45,46,47] |

| Ore | Aeschynite Group Minerals | Columbite–(Fe) | Pyrochlore Group Minerals | Nb–Bearing Rutile | Baotite, Fergusonite–(Y), Samarskite–(Y), Fersmite, etc. | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Volume Content | Grain Size (μm) | Volume Content | Grain Size (μm) | Volume Content | Grain Size (μm) | Volume Content | Grain Size (μm) | Volume Content | Grain Size (μm) | |

| Aegirine-type Nb–REE–(Fe) ore | ~50% | 100~400 | ~10% | 10~50 | ~20% | 50~200 | ~10% | 10~30 | ~10% | 10~30 |

| Riebeckite-type Nb–REE–Fe ore | ~40% | 100~200 | ~15% | 10~50 | ~10% | 20~100 | ~25% | 10~30 | ~10% | 10~30 |

| Dolomite-type Nb–REE–(Fe) ore | ~30% | 20~100 | ~15% | 10~20 | ~20% | 20~100 | ~25% | 10~30 | ~10% | 10~30 |

| Massive Nb–REE–Fe ore | ~30% | 20~100 | ~15% | 10~20 | ~15% | 20~100 | ~25% | 10~50 | ~15% | 10~30 |

| Fluorite-type-banded Nb–REE–Fe ore | ~15% | 30~50 | ~5% | 10~30 | ~10% | 30~50 | ~60% | 10~50 | ~10% | 10~30 |

| Biotite-type Nb–REE–Fe ore | ~25% | 10~50 | ~30% | 20~50 | ~15% | 10~50 | ~20% | 10~30 | ~10% | 10~30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Yang, L.; Zhao, Y.-G.; Yan, G.-Y.; Liu, J.-Y.; Meng, W.-X.; Yu, J.-F.; Chen, L.; Li, X.-C.; Li, X.-H. Aeschynite Group Minerals Are a Potential Recovery Target for Niobium Resources at the Giant Bayan Obo Nb–REE–Fe Deposit in China. Minerals 2024, 14, 1029. https://doi.org/10.3390/min14101029

Yang B, Yang L, Zhao Y-G, Yan G-Y, Liu J-Y, Meng W-X, Yu J-F, Chen L, Li X-C, Li X-H. Aeschynite Group Minerals Are a Potential Recovery Target for Niobium Resources at the Giant Bayan Obo Nb–REE–Fe Deposit in China. Minerals. 2024; 14(10):1029. https://doi.org/10.3390/min14101029

Chicago/Turabian StyleYang, Bo, Li Yang, Yong-Gang Zhao, Guo-Ying Yan, Jian-Yong Liu, Wen-Xiang Meng, Jun-Fang Yu, Lei Chen, Xiao-Chun Li, and Xian-Hua Li. 2024. "Aeschynite Group Minerals Are a Potential Recovery Target for Niobium Resources at the Giant Bayan Obo Nb–REE–Fe Deposit in China" Minerals 14, no. 10: 1029. https://doi.org/10.3390/min14101029

APA StyleYang, B., Yang, L., Zhao, Y.-G., Yan, G.-Y., Liu, J.-Y., Meng, W.-X., Yu, J.-F., Chen, L., Li, X.-C., & Li, X.-H. (2024). Aeschynite Group Minerals Are a Potential Recovery Target for Niobium Resources at the Giant Bayan Obo Nb–REE–Fe Deposit in China. Minerals, 14(10), 1029. https://doi.org/10.3390/min14101029