Preconcentration of a Medium-Grade Celestine Ore by Dense Medium Cyclone Using a Factorial Design

Abstract

:1. Introduction

2. Materials and Methods

2.1. Montevive Celestine Mineral

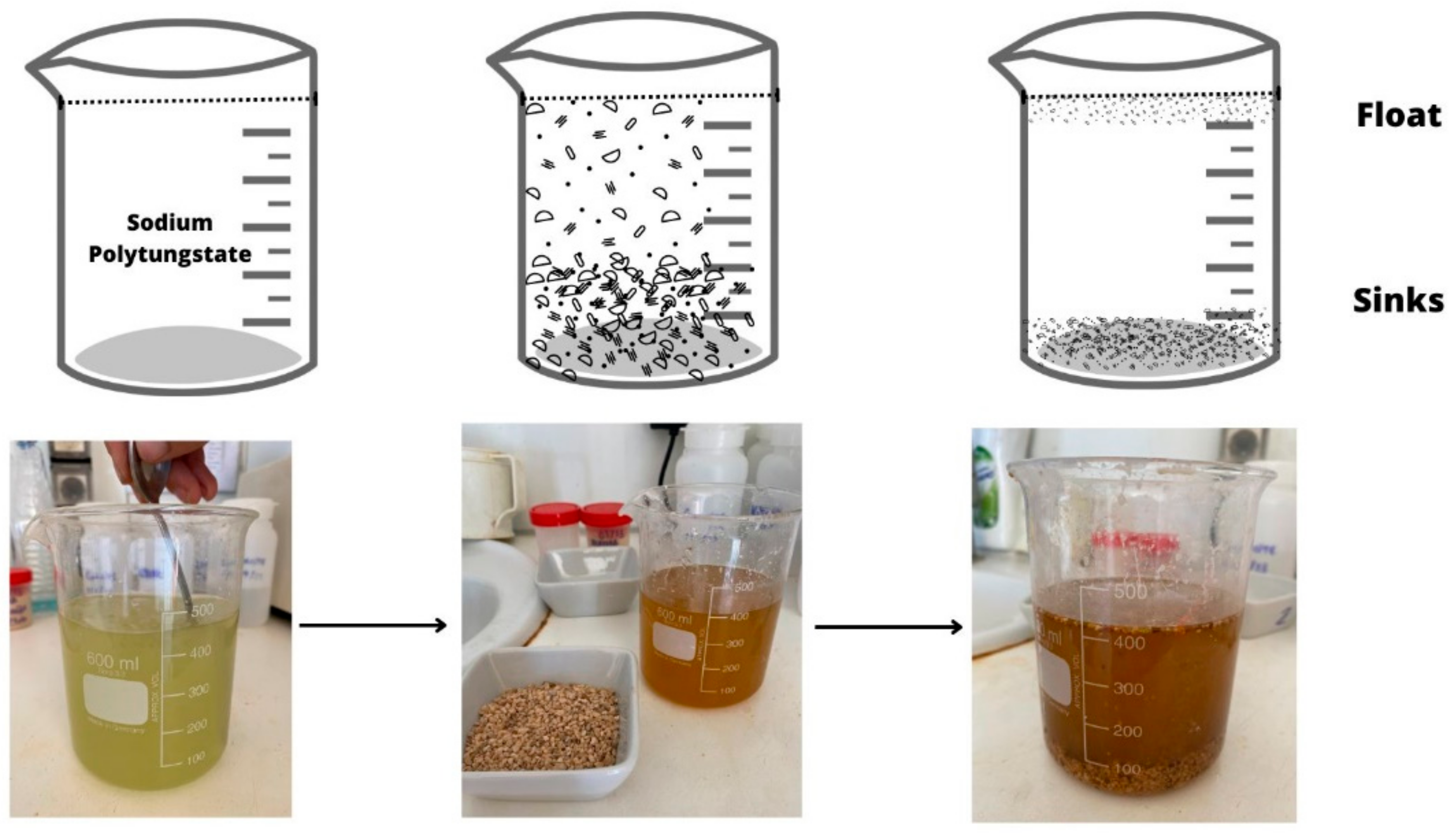

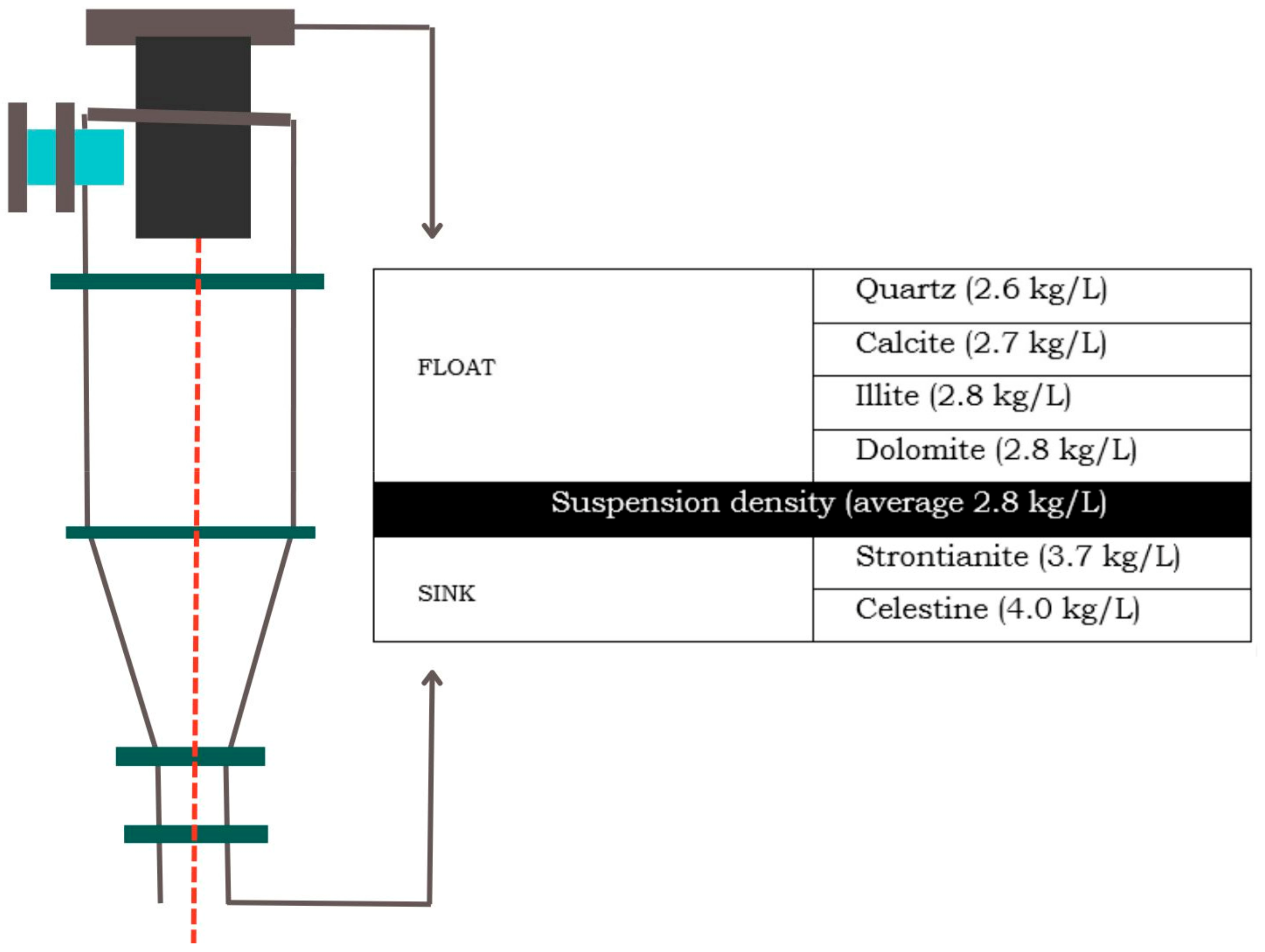

2.2. Float–Sink Tests

2.3. DMC Separation Experiments

| Acronym | Parameter | Equation or Value | |

|---|---|---|---|

| Q | Flow rate | [14] | |

| D | Body diameter | 250 mm | Predefined |

| Di | Feed diameter | [15] | |

| Do | Vortex diameter | [16] | |

| Du | Apex diameter | [17] Bradley Ecuation | |

| Du/Do | Ratio Du/Do | [18] | |

| θ | Angle of conical section | 20° | Predefined |

| Hci | Height of cylindrical section | 200 mm | Predefined |

| Hco | Height of conical section | 600 mm | Predefined |

| P | Operating head | Minimum 9D |

3. Results and Discussion

3.1. Characteristics of Celestine Ore Sample

3.2. Evaluation of Gravity Separation

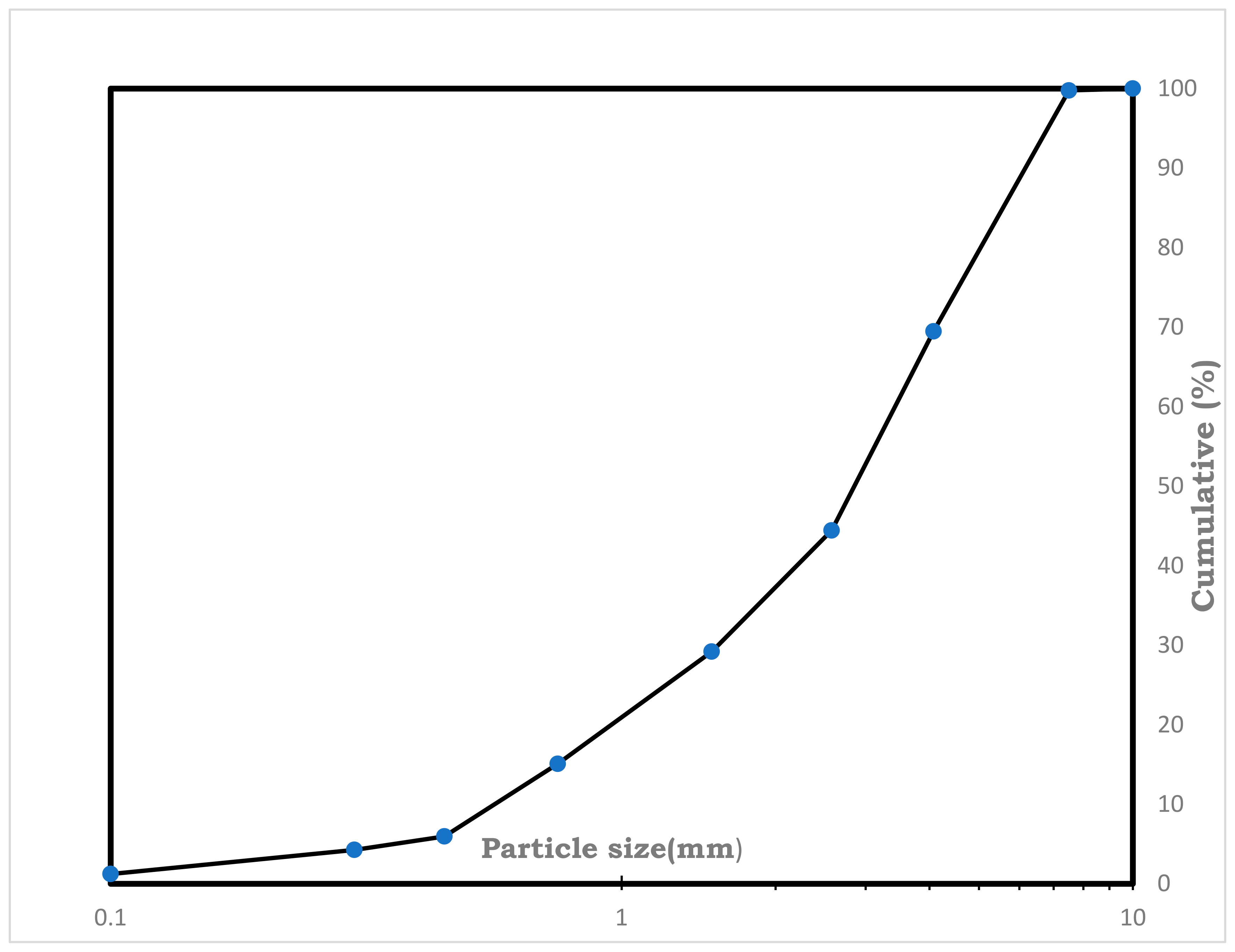

3.2.1. Particle Size Tests

3.2.2. Separation Density Tests

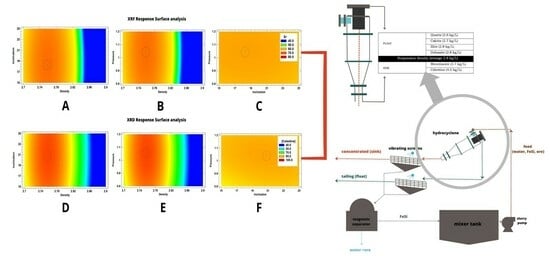

3.3. Separation Performance of DMS

3.3.1. Effect of Separation Density

3.3.2. Effect of Inlet Pressure

3.3.3. Effect of Inclination

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jimeno, C.L.; González, C.M. Las materias primas minerales y la transición energética. Cuad. Estrateg. 2022, 209, 61–174. [Google Scholar]

- Jiménez-Peñalvarez, J.D. Nieve, Oro, Sal, Estroncio. Historia de la Minería en Granada. 2008. Available online: https://www.ugr.es (accessed on 17 September 2023).

- Ariza-Rodríguez, N.; Rodríguez-Navarro, A.B.; de Hoces, M.C.; Muñoz-Batista, M.J. Laboratory-Scale Optimization of Celestine Concentration Using a Hydrocyclone System. Appl. Sci. 2023, 13, 10206. [Google Scholar] [CrossRef]

- Luukkanen, S.; Tanhua, A.; Zhang, Z.; Mollehuara Canales, R.; Auranen, I. Towards waterless operations from mine to mill. Miner. Eng. 2022, 187, 107793. [Google Scholar] [CrossRef]

- Sulman, H.L.; Picard, H.F.K.; Ballot, J. Ore Concentration. 835 120, 6 November 1906. Available online: https://patentimages.storage.googleapis.com/31/20/dc/39d20dc025985d/US835120.pdf (accessed on 10 September 2023).

- Wills, B.A. Tecnología de Procesamiento de Minerajes: Tratamiento de Menas y Recuperación de Minerales; Limusa: Mexico City, Mexico, 1987; Volume 517. [Google Scholar]

- Ballester, A.; Verdejo, L.F.; Sancho, J. Metalurgia Extractiva; Síntesis: Madrid, Spain, 2014; Volume 1. [Google Scholar]

- Gálvez Borrego, A. Agentes de Superficie Aniónicos en la Flotación de Celestina y Calcita. Ph.D. Thesis, Universidad de Granada, Granada, Spain, 1993. [Google Scholar]

- Corpas-Martínez, J.R. Concentración de Minerales Mediante Métodos Físico-Químicos. Aplicación a la Obtención de Fluorita de Alta Pureza. 2021. Available online: http://hdl.handle.net/10481/66396 (accessed on 5 December 2023).

- Feng, Q.; Yang, W.; Chang, M.; Wen, S.; Liu, D.; Han, G. Advances in depressants for flotation separation of cu-fe sulfide minerals at low alkalinity: A critical review. Int. J. Miner. Metall. Mater. 2024, 31, 1–17. [Google Scholar] [CrossRef]

- Ariza-Rodríguez, N.; Rodríguez-Navarro, A.B.; Calero de Hoces, M.; Martin, J.M.; Muñoz-Batista, M.J. Chemical and Mineralogical Characterization of Montevive Celestine Mineral. Minerals 2022, 12, 1261. [Google Scholar] [CrossRef]

- Lv, Z.; Wei, M.; Zhao, D.; Wu, D.; Liu, C.; Cheng, H. Preconcentration of a low-grade betafite ore by dense medium cyclone. Physicochem. Probl. Miner. Process. 2022, 58, 143338. [Google Scholar] [CrossRef]

- Sobhy, A. Recent Trends in Mineral Processing Based on Density and Particle Size—A review. Int. J. Mater. Technol. Innov. 2022, 2, 13–30. [Google Scholar] [CrossRef]

- Mular, A.L.; Jull, N.A. Classification. In Mineral Processing Plant Design; Mular, A.L., Bhappu, R.B., Eds.; Elsevier B. V.: Amsterdam, The Netherlands, 2006; Chapter 17; p. 385. [Google Scholar]

- Sanchez, Z.; Emilio, L.E. Operaciones Unitarias en Preparación de Minerales; Universidad Nacional, Facultad de Minas: Medellín, Columbia, 1988. [Google Scholar]

- Tórres, I.D.A.; Molina, C.A.S.; Tascón, C.E.O. Parámetros de diseño de un hidrociclón para clasificar café pergamino. Rev. Fac. Nac. Agron. Medellín 1998, 51, 191–215. [Google Scholar]

- Lodoño, R.G.E.; Pérez, G.J.E. Hijrolciclones: Alternativa en la Separación Sólido Líquido; Universidad Pontificia Bolivariana, Facultad de Ingeniería: Medellín, Columbia, 1988; 253p. [Google Scholar]

- Bustamante, M.O. Efecto de la Geometría de un Hidrociclón Sobre las Condiciones Normales de Operación. Master’s Thesis, Universidad de Concepción, Concepcion, Chile, 1989. [Google Scholar]

- Box, G.E.P.; Behnken, D.W. Some new three level designs for the study of quantitative variables. Technometrics 1960, 2, 455–475. [Google Scholar] [CrossRef]

- Dixit, P.; Tiwari, R.; Mukherjee, A.K.; Banerjee, P.K. Application of response surface methodology for modeling and optimization of spiral separator for processing of iron ore slime. Powder Technol. 2015, 275, 105–112. [Google Scholar] [CrossRef]

- Özgen, S.; Yildiz, A. Application of Box–Behnken design to modeling the effect of smectite content on swelling to hydrocyclone processing of bentonites with various geologic properties. Clays Clay Miner. 2010, 58, 431–448. [Google Scholar] [CrossRef]

- Krukowski, S.T. Sodium metatungstate: A new heavy-mineral separation medium for the extraction of conodonts from insoluble residues. J. Paleontol. 1988, 62, 314–316. [Google Scholar] [CrossRef]

- Mazarío, F.P.; Martínez, R.R.; Costa, S.H. Mejoras en la separación de minerales pesados usando politungstato sódico. Geogaceta 1991, 11, 54–56. [Google Scholar]

- Savage, N.M. The use of sodium polytungstate for conodont separations. J. Micropalaeontol. 1988, 7, 39–40. [Google Scholar] [CrossRef]

- Skipp, G.; Brownfield, I.K. Improved Density Gradient Separation Techniques Using Sodium Polytungstate and a Comparison to the Use of Other Heavy Liquids; US Department of the Interior, US Geological Survey: Denver, CO, USA, 1993.

- Ozgen, S.; Yildiz, A.; Çalışkan, A.; Sabah, E. Modeling and optimization of hydrocyclone processing of low grade bentonites. Appl. Clay Sci. 2009, 46, 305–313. [Google Scholar] [CrossRef]

- Bhandary, A.; Mukherjee, S.; Rajib, D.; Ghosh Chaudhuri, M. Mineralogical studies and optimization of tabling parameters of low grade chromite ore by box behnken design of experiments. J. Met. Mater. Miner. 2022, 32, 174–185. [Google Scholar] [CrossRef]

- Vakamalla, T.; Narasimha, M. Rheology-based CFD modeling of magnetite medium segregation in a dense medium cyclone. Powder Technol. 2015, 277, 275–286. [Google Scholar] [CrossRef]

- Arroug, L.; Elaatmani, M.; Zegzouti, A. A preliminary study to investigate the beneficiation of low-grade phosphate sludge using reverse flotation: Modeling and optimization through box-behnken design and response surface methodology. Chem. Eng. Res. Des. 2024, 204, 228–237. [Google Scholar] [CrossRef]

- Huo, Q.; Liu, X.; Chen, L.; Wu, Y.; Wu, H.; Xie, J.; Liu, X.-X.; Qiu, G. Treatment of backwater in bauxite flotation plant and optimization by using box-behnken design. Trans. Nonferrous Met. Soc. China 2019, 29, 821–830. [Google Scholar] [CrossRef]

- He, Y.B.; Laskowski, J.S. Effect of dense medium properties on the separation performance of a dense medium cyclone. Miner. Eng. 1994, 7, 209–221. [Google Scholar] [CrossRef]

- Bhaskar, K.U.; Murthy, Y.R.; Raju, M.R.; Tiwari, S.; Srivastava, J.K.; Ramakrishnan, N. CFD simulation and experimental validation studies on hydrocyclone. Miner. Eng. 2007, 20, 60–71. [Google Scholar] [CrossRef]

- Wang, B.; Chu, K.W.; Yu, A.B.; Vince, A. Modeling the Multiphase Flow in a Dense Medium Cyclone. Ind. Eng. Chem. Res. 2009, 48, 3628–3639. [Google Scholar] [CrossRef]

- Suresh, P.D.; Kumar, V.; Sripriya, R.; Chakraborty, S.; Meikap, B.C. Performance characteristics of pilot plant dense media hydrocyclone for beneficiation of coal and 3-D CFD simulation. Chem. Eng. Sci. 2010, 65, 4661–4671. [Google Scholar] [CrossRef]

- He, Y.B.; Laskowski, J.S. Dense Medium Cyclone Separation of Fine Particles Part 1. The Effect of Medium Split Ratio on Dense Medium Cyclone Performance. Coal Prep. 1995, 16, 1–25. [Google Scholar] [CrossRef]

- Asomah, A.K.; Napier-Munn, T.J. An empirical model of hydrocyclones incorporating angle of cyclone inclination. Miner. Eng. 1997, 10, 339–347. [Google Scholar] [CrossRef]

- Banisi, S.; Deghan-Nayeri, H. Effect of angle of hydrocyclone inclination on cut size. Can. Metall. Q. 2005, 44, 79–84. [Google Scholar] [CrossRef]

- McLanahan. Los 5 Aspectos Que Deber Saber Sobre los Hidrociclones. 29 April 2019. Available online: https://www.mclanahan.com/es/blog/los-5-aspectos-que-deber-saber-sobre-los-hidrociclones (accessed on 27 November 2023).

| Sr (%) | Ba (%) | Fe (%) | Si (%) | Mg (%) | Ca (%) | |

|---|---|---|---|---|---|---|

| Float–sink test | 60.08 | 2.27 | 1.52 | 4.55 | 1.20 | 18.39 |

| Validation test | 54.75 | 1.80 | 2.70 | 1.80 | 1.54 | 16.66 |

| (Figure S2) |

| Celestine (%) | Strontianite (%) | Quartz (%) | Dolomite (%) | Calcite (%) | Illite (%) | |

|---|---|---|---|---|---|---|

| Float–sink test | 83.33 | 0.40 | 3.39 | 2.54 | 9.79 | 0.55 |

| Validation test | 77.23 | 0.00 | 2.45 | 4.88 | 12.89 | 2.55 |

| (Figure S2) |

| Celestine % | Strontianite % | Quartz % | Dolomite % | Calcite % | Illite % | ||

|---|---|---|---|---|---|---|---|

| Raw fraction | 100.00 | 83.33 | 0.4 | 3.39 | 2.54 | 9.79 | 0.55 |

| >5 mm | 30.55 | 84.10 | 0.21 | 3.36 | 3.15 | 8.68 | 0.51 |

| (−5 mm + 3.15 mm) | 25.01 | 83.04 | 0.14 | 2.75 | 3.14 | 7.53 | 0.41 |

| (−3.15 mm + 2 mm) | 15.25 | 80.99 | 0.30 | 2.41 | 3.93 | 11.96 | 0.41 |

| (−2 mm + 1 mm) | 14.10 | 80.42 | 0.34 | 3.39 | 3.16 | 12.20 | 0.45 |

| <1 mm | 15.09 | 74.81 | 0.69 | 9.04 | 2.29 | 12.41 | 0.76 |

| Density (Kg/L) | Size Fraction | Yield (%) | Products | Recovery Mass (g) | Celestine % | Trontianite % | Quartz % | Dolomite % | Calcite % | Illite % |

|---|---|---|---|---|---|---|---|---|---|---|

| 2.7 | (−6 mm + 5 mm) | 30.55 | Floats | 1.87 | 10.25 | 0.17 | 3.00 | 41.72 | 43.72 | 1.14 |

| Sink | 98.13 | 85.51 | 0.33 | 2.16 | 1.70 | 9.84 | 0.47 | |||

| Feed | 100.00 | |||||||||

| (−5 mm + 3.15 mm) | 25.01 | Floats | 1.78 | 4.86 | 0.18 | 3.69 | 59.69 | 30.52 | 1.06 | |

| Sink | 98.22 | 84.46 | 0.04 | 2.75 | 2.12 | 10.22 | 0.42 | |||

| Feed | 100.00 | |||||||||

| (−3.15 mm + 2 mm) | 15.25 | Floats | 2.95 | 4.07 | 0.77 | 7.94 | 35.68 | 50.73 | 0.79 | |

| Sink | 97.05 | 83.33 | 0.27 | 1.60 | 1.97 | 12.31 | 0.52 | |||

| Feed | 100.00 | |||||||||

| (−2 mm + 1 mm) | 14.10 | Floats | 4.19 | 3.98 | 0.54 | 4.30 | 32.67 | 54.41 | 1.10 | |

| Sink | 95.81 | 83.76 | 0.06 | 1.87 | 1.90 | 11.91 | 0.49 | |||

| Feed | 100.00 | |||||||||

| 2.8 | (−6 mm + 5 mm) | 30.55 | Floats | 11.88 | 26.01 | 0.61 | 5.12 | 1.21 | 67.01 | 0.04 |

| Sink | 88.12 | 91.93 | 0.22 | 1.83 | 0.41 | 5.12 | 0.50 | |||

| Feed | 100.00 | |||||||||

| (−5 mm + 3.15 mm) | 25.01 | Floats | 12.36 | 29.80 | 1.05 | 5.33 | 2.76 | 58.93 | 2.13 | |

| Sink | 87.64 | 90.55 | 0.01 | 3.45 | 0.43 | 4.79 | 0.77 | |||

| Feed | 100.00 | |||||||||

| (−3.15 mm + 2 mm) | 15.25 | Floats | 13.81 | 18.77 | 0.59 | 12.84 | 0.71 | 65.95 | 1.15 | |

| Sink | 86.19 | 90.96 | 0.03 | 3.51 | 0.48 | 4.45 | 0.57 | |||

| Feed | 100.00 | |||||||||

| (−2 mm + 1 mm) | 14.10 | Floats | 6.95 | 17.61 | 0.23 | 1.70 | 22.89 | 56.05 | 1.52 | |

| Sink | 93.05 | 85.11 | 0.27 | 5.54 | 0.05 | 9.04 | 0.00 | |||

| Feed | 100.00 | |||||||||

| 2.9 | (−6 mm + 5 mm) | 30.55 | Floats | 16.24 | 48.68 | 2.11 | 5.52 | 0.64 | 41.24 | 1.80 |

| Sink | 83.76 | 90.97 | 0.45 | 1.92 | 0.55 | 5.48 | 0.64 | |||

| Feed | 100.00 | |||||||||

| (−5 mm + 3.15 mm) | 25.01 | Floats | 4.54 | 41.65 | 2.08 | 8.93 | 0.83 | 44.98 | 1.51 | |

| Sink | 95.46 | 85.01 | 0.39 | 2.93 | 0.50 | 10.48 | 0.69 | |||

| Feed | 100.00 | |||||||||

| (−3.15 mm + 2 mm) | 15.25 | Floats | 5.85 | 37.02 | 2.03 | 4.55 | 0.88 | 54.23 | 1.29 | |

| Sink | 94.15 | 83.72 | 0.10 | 5.25 | 1.55 | 9.00 | 0.38 | |||

| Feed | 100.00 | |||||||||

| (−2 mm + 1 mm) | 14.10 | Floats | 16.85 | 36.81 | 2.15 | 3.58 | 0.90 | 55.99 | 0.57 | |

| Sink | 83.15 | 89.26 | 0.54 | 1.18 | 0.61 | 8.19 | 0.23 | |||

| Feed | 100.00 |

| Density (Kg/L) | Size Fraction | ε | E | R |

|---|---|---|---|---|

| 2.7 | >5 mm | 99.77 | 1.02 | 1.87 |

| (−5 mm + 3.15 mm) | 99.90 | 1.02 | 1.78 | |

| (−3.15 mm + 2 mm) | 99.85 | 1.03 | 2.95 | |

| (−2 mm + 1 mm) | 99.79 | 1.04 | 4.19 | |

| 2.8 | >5 mm | 96.33 | 1.09 | 11.88 |

| (−5 mm + 3.15 mm) | 95.56 | 1.09 | 12.36 | |

| (−3.15 mm + 2 mm) | 96.80 | 1.12 | 13.81 | |

| (−2 mm + 1 mm) | 98.48 | 1.06 | 6.95 | |

| 2.9 | >5 mm | 90.60 | 1.08 | 16.24 |

| (−5 mm + 3.15 mm) | 97.72 | 1.02 | 4.54 | |

| (−3.15 mm + 2 mm) | 97.33 | 1.03 | 5.85 | |

| (−2 mm + 1 mm) | 92.29 | 1.11 | 16.85 |

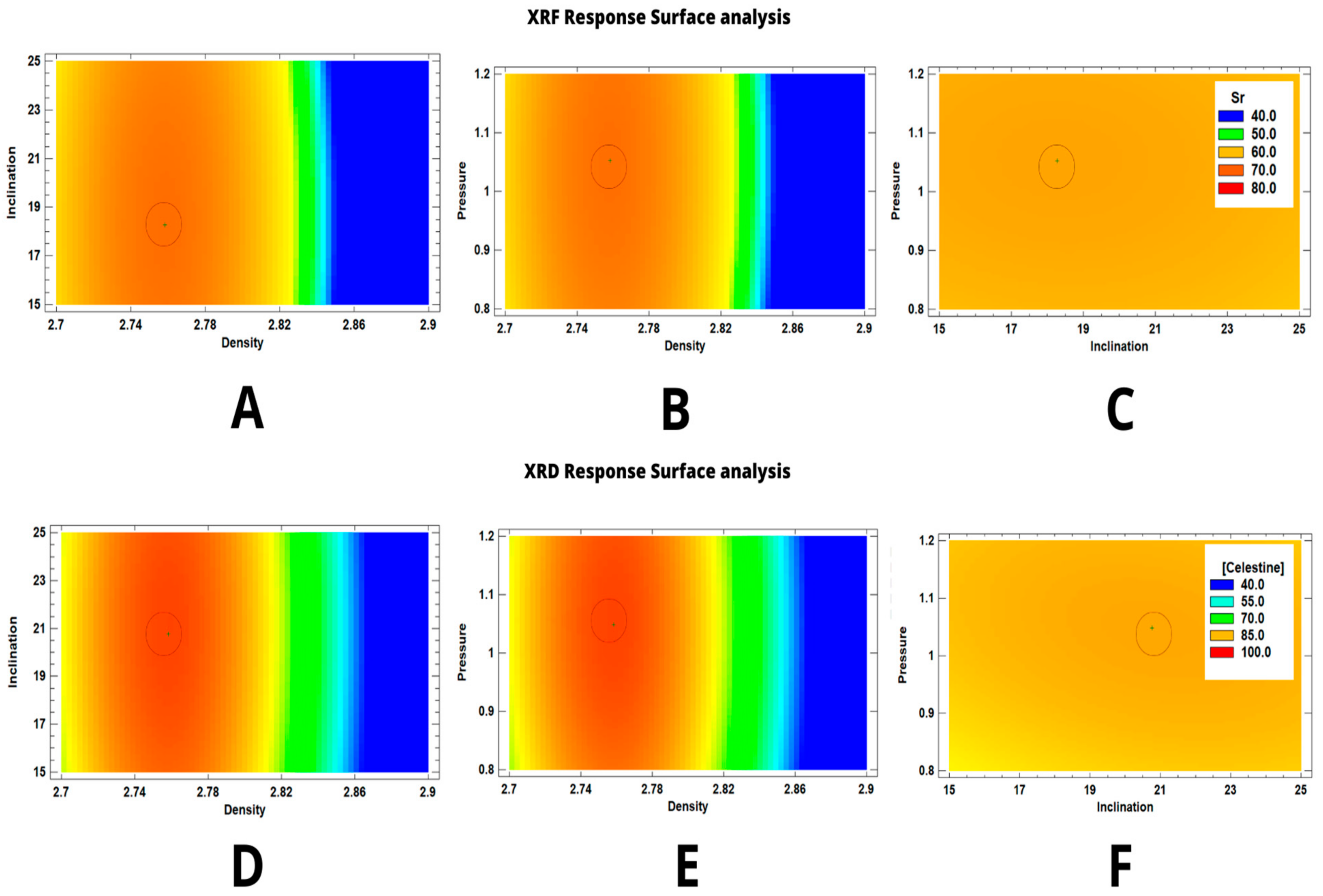

| Statistical Parameter | XRD Results | XRF Results |

|---|---|---|

| R-squared | 99.92% | 99.92% |

| R-squared (adjusted for g.l.) | 99.79% | 99.78% |

| Standard error | 1.70 | 1.26 |

| Mean absolute error | 0.84 | 0.64 |

| Factor | Optimun (XRF) | Optimun (DRX) | |

|---|---|---|---|

| Factors | Density | 2.75 | 2.75 |

| Inclination | 18.27 | 20.76 | |

| Pressure | 1.05 | 1.05 | |

| Response variable (to be maximised) | [Sr]/[Celestine] | 68.4 | 94.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ariza-Rodríguez, N.; Rodríguez-Navarro, A.B.; Ortega, F.; Calero de Hoces, M.; Muñoz-Batista, M.J. Preconcentration of a Medium-Grade Celestine Ore by Dense Medium Cyclone Using a Factorial Design. Minerals 2024, 14, 306. https://doi.org/10.3390/min14030306

Ariza-Rodríguez N, Rodríguez-Navarro AB, Ortega F, Calero de Hoces M, Muñoz-Batista MJ. Preconcentration of a Medium-Grade Celestine Ore by Dense Medium Cyclone Using a Factorial Design. Minerals. 2024; 14(3):306. https://doi.org/10.3390/min14030306

Chicago/Turabian StyleAriza-Rodríguez, Noemi, Alejandro B. Rodríguez-Navarro, Francisco Ortega, Mónica Calero de Hoces, and Mario J. Muñoz-Batista. 2024. "Preconcentration of a Medium-Grade Celestine Ore by Dense Medium Cyclone Using a Factorial Design" Minerals 14, no. 3: 306. https://doi.org/10.3390/min14030306

APA StyleAriza-Rodríguez, N., Rodríguez-Navarro, A. B., Ortega, F., Calero de Hoces, M., & Muñoz-Batista, M. J. (2024). Preconcentration of a Medium-Grade Celestine Ore by Dense Medium Cyclone Using a Factorial Design. Minerals, 14(3), 306. https://doi.org/10.3390/min14030306