Adsorption of Polycyclic Aromatic Hydrocarbons from Wastewater Using Iron Oxide Nanomaterials Recovered from Acid Mine Water: A Review

Abstract

1. Introduction

2. Iron Oxide Nanomaterials

2.1. Magnetite

2.2. Maghemite

2.3. Hematite

2.4. Goethite

3. Synthesis of Iron Oxide Nanomaterials from Acid Mine Drainage

3.1. Overview of the Environmental Effects of Acid Mine Drainage

3.2. Processes for Recovering Iron Oxide from Acid Mine Water

- Neutralization: the AMD is neutralized using alkaline substances such as lime (Ca(OH)2), sodium carbonate (Na2CO3), and sodium hydroxide (NaOH), which raises the pH, causing dissolved iron to precipitate as iron hydroxides (Fe(OH)3) [58].

- Precipitation and coagulation: the neutralization process promotes the formation of iron hydroxide flocs, which coagulate and settle out of the solution [59].

- Filtration and washing: The precipitated iron hydroxides are separated from the treated water through filtration. The solids are then washed to remove impurities and excess neutralizing agents [32].

- Oxidation: The iron hydroxide precipitates are oxidized to form iron oxide nanomaterials. This can be achieved by the following:

- Air oxidation: allowing the hydroxides to air-dry and oxidize naturally.

- Chemical oxidation: using oxidizing agents like hydrogen peroxide (H2O2) to accelerate the conversion [55].

- Thermal treatment: the oxidized materials are subjected to thermal treatment (calcination) at controlled temperatures to produce the desired phase of iron oxide, such as magnetite, maghemite, or hematite [33].

- Characterization: the synthesized nanomaterials are characterized using techniques like scanning electron microscopy (SEM), X-ray diffraction (XRD), and Fourier-transform infrared spectroscopy (FTIR) to verify their phase, morphology, and functional properties.

3.3. Characterization of Recovered Iron Oxide Nanomaterials

4. Mechanisms of PAH Adsorption onto Iron Oxide Nanomaterials

4.1. Adsorption Isotherms and Kinetics

4.2. Factors Influencing Adsorption Efficiency

4.3. Interaction Mechanisms between PAHs and Iron Oxide Surfaces

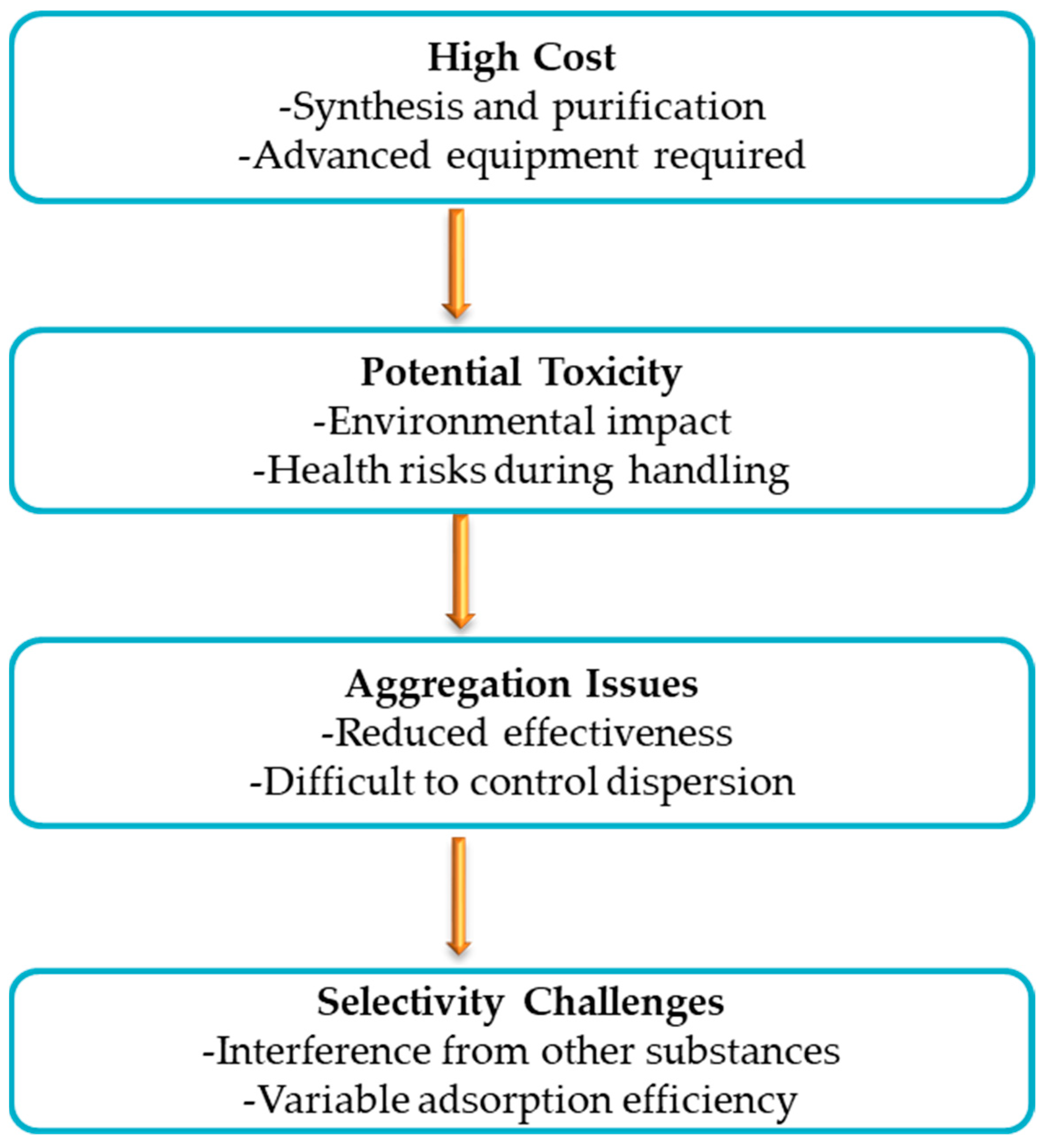

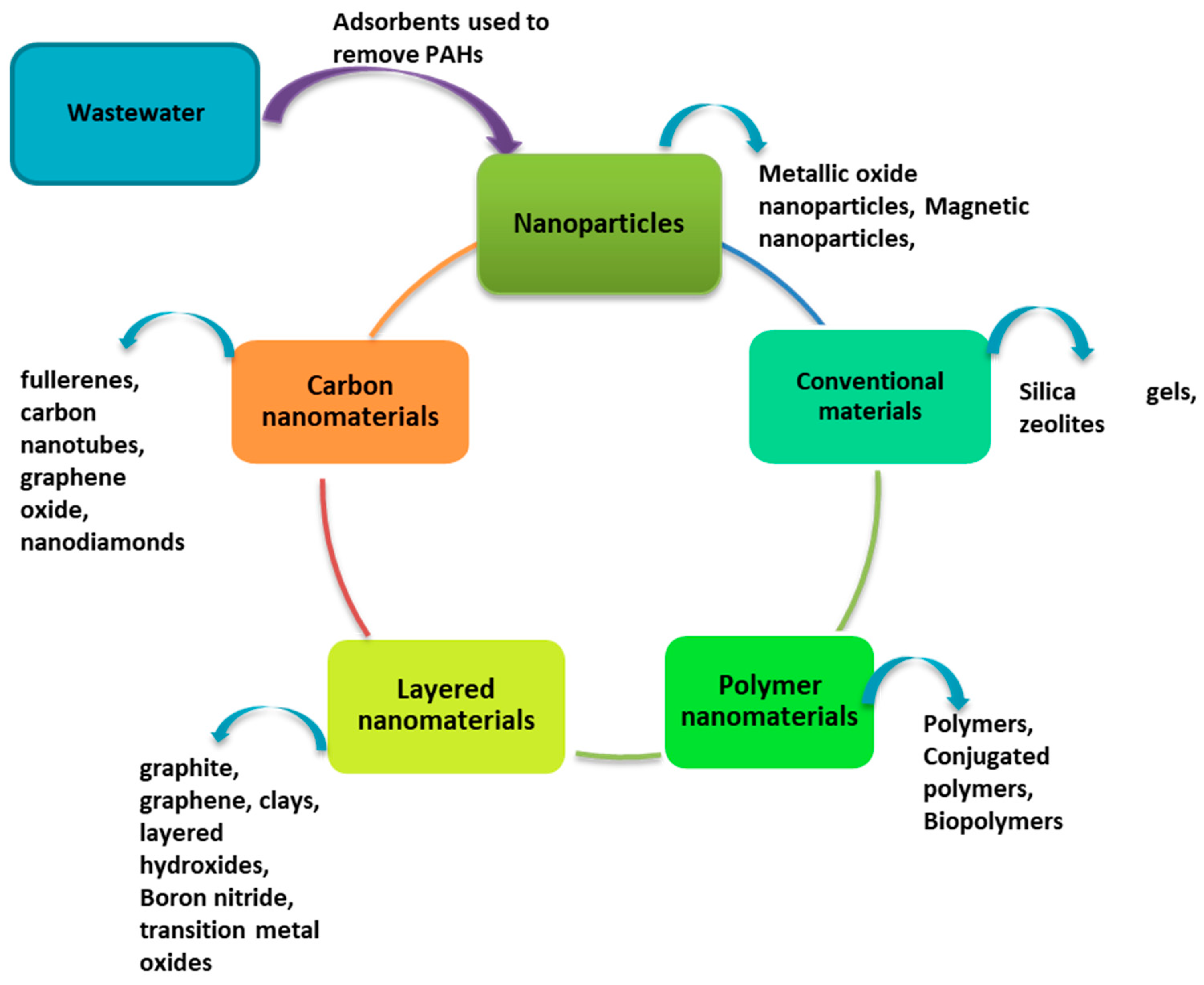

5. Comparison of Iron Oxide Nanomaterials with Other Adsorbents

5.1. Performance Comparison with Other Commonly Used Adsorbents

5.2. Cost-Effectiveness and Availability

5.3. Regeneration and Reusability

5.4. Advantages of Using IONs for Adsorption Processes

6. Treatment

6.1. Wastewater Containing PAHs

6.2. Case Studies and Practical Applications

6.2.1. Examples of Lab-Scale and Field-Scale Studies on PAH Removal Using Iron Oxide Nanomaterials

6.2.2. Success Stories and Challenges Encountered

6.2.3. Real-World Applications and Pilot Projects

7. Environmental and Economic Implications

7.1. Environmental Benefits of Using Recovered Materials

7.2. Economic Analysis of Using Iron Oxide Nanomaterials for Wastewater Treatment

7.3. Sustainability and Scalability of This Approach

7.4. Feasibility

8. Future Prospects and Research Directions

8.1. Emerging Trends and Innovations in Nanomaterial-Based Adsorption

8.2. Potential Improvements in Recovery and Synthesis Methods

8.3. Future Research Needs and Directions for Enhancing Adsorption Efficiency and Practical Applicability

9. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mogashane, T.M.; Mujuru, M.; McCrindle, R.I.; Ambushe, A.A. Quantification, source apportionment and risk assessment of polycyclic aromatic hydrocarbons in sediments from Mokolo and Blood Rivers in Limpopo Province, South Africa. J. Environ. Sci. Health Part A 2020, 55, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Khoury, D.; Millet, M.; Jabali, Y.; Delhomme, O. Occurrence of Polycyclic Aromatic Hydrocarbons and Polychlorinated Biphenyls in Fogwater at Urban, Suburban, and Rural Sites in Northeast France between 2015 and 2021. Atmosphere 2024, 15, 291. [Google Scholar] [CrossRef]

- Daso, A.P.; Akortia, E.; Okonkwo, J.O. Concentration profiles, source apportionment and risk assessment of polycyclic aromatic hydrocarbons (PAHs) in dumpsite soils from Agbogbloshie e-waste dismantling site, Accra, Ghana. Environ. Sci. Pollut. Res. 2016, 23, 10883–10894. [Google Scholar] [CrossRef] [PubMed]

- Kariyawasam, T.; Doran, G.S.; Howitt, J.A.; Prenzler, P.D. Optimization and Comparison of Microwave-Assisted Extraction, Supercritical Fluid Extraction, and Eucalyptus Oil-Assisted Extraction of Polycyclic Aromatic Hydrocarbons from Soil and Sediments. Environ. Toxicol. Chem. 2023, 42, 982–994. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Chen, X.; Duan, Y.; Wu, Z.; Xu, L. Distribution, sources and health risk assessment of polycyclic aromatic hydrocarbons in urban soils under different landform conditions of Taiyuan, China. Front. Environ. Sci. 2024, 12, 1363297. [Google Scholar] [CrossRef]

- Mogashane, T.M.; Mujuru, M.; Ambushe, A.A. Comparison and optimization of extraction methods for the determination of polycyclic aromatic hydrocarbons in sediment from blood river in limpopo province, south africa. In Proceedings of the 39th Johannesburg International Conference on “Chemical, Biological and Environmental Engineering” (JCBEE-23), Johannesburg, South Africa, 16–17 November 2023. [Google Scholar]

- Seopela, M.P.; McCrindle, R.I.; Combrinck, S.; Regnier, T.T.-C. Hazard assessment of polycyclic aromatic hydrocarbons in water and sediments in the vicinity of coal mines. J. Soil Sediments 2016, 16, 2740–2752. [Google Scholar] [CrossRef]

- Mogashane, T.M.; Mujuru, M.; Ambushe, A.A. Determination and distribution of 16 polycyclic aromatic hydrocarbons in water samples from Blood and Mokolo Rivers in Limpopo Province, South Africa. Phys. Chem. Earth Parts A/B/C 2022, 127, 103165. [Google Scholar] [CrossRef]

- Mirsadeghi, S.A.; Zakaria, M.P.; Yap, C.K.; Shahbazi, A. Risk assessment for the daily intake of polycyclic aromatic hydrocarbons from the ingestion of cockle (Anadara granosa) and exposure to contaminated water and sediments along the west coast of Peninsular Malaysi. J. Environ. Sci. 2011, 23, 336–345. [Google Scholar] [CrossRef] [PubMed]

- Emoyan, O.; Agbaire, P.O.; Akporido, S.O. Variability in Polycyclic Aromatic Hydrocarbons (PAHs) Isomer Pair Ratio: Source Identification Concern. Int. J. Environ. Monit. Anal. 2015, 3, 111–117. [Google Scholar]

- Lee, C.C.; Chen, C.S.; Wang, Z.X.; Tien, C.J. Polycyclic Aromatic Hydrocarbons in 30 River Ecosystems, Taiwan: Sources, and Ecological and Human Health Risks. Sci. Total Environ. 2021, 795, 148867. [Google Scholar] [CrossRef]

- Delgado-Saborit, J.M.; Stark, C.; Harrison, R.M. Carcinogenic potential, levels and sources of polycyclic aromatic hydrocarbon mixtures in indoor and outdoor environments and their implications for air quality standards. Environ. Int. 2011, 37, 383–392. [Google Scholar] [CrossRef] [PubMed]

- Mekonnen, K.N.; Chandravanshi, B.S.; Redi-Abshiro, M.; Abayneh, A.A.; McCrindle, R.I.; Moyo, S. Distribution of polycyclic aromatic hydrocarbons in sediments of Akaki River, Lake Awasa, and Lake Ziway, Ethiopia. Environ. Assess. Monit. 2015, 187, 1–13. [Google Scholar] [CrossRef]

- Nasher, E.; Heng, L.Y.; Zakaria, Z.; Suri, S. Assessing the Ecological Risk of Polycyclic Aromatic Hydrocarbons in Sediments at Langkawi Island, Malaysia. Sci. World J. 2013, 2023, 858309. [Google Scholar] [CrossRef] [PubMed]

- Edokpayi, J.N.; Odiyo, J.O.; Popoola, O.E.; Msagati, T.A.E. Determination and Distribution of Polycyclic Aromatic Hydrocarbons in Rivers, Sediments and Wastewater Effluents in Vhembe District, South Africa. Int. J. Environ. Res. Public Health 2016, 13, 387. [Google Scholar] [CrossRef] [PubMed]

- Nekhavhambe, T.J.; Van Ree, T.; Fatoki, O.S. Determination and distribution of polycyclic aromatic hydrocarbons in rivers, surface runoff and sediments in and around Thohoyandou, Limpopo Province, South Africa. Water South Afr. 2014, 40, 415–424. [Google Scholar] [CrossRef]

- Hussain, J.; Zhao, Z.; Pang, Y.; Xia, L.; Hussain, I.; Jian, X. Effects of Different Water Seasons on the Residual Characteristics and Ecological Risk of Polycyclic Aromatic Hydrocarbons in Sediments from Changdang Lake, China. J. Chem. 2016, 2016, 8545816. [Google Scholar] [CrossRef]

- Chen, C.F.; Chen, C.; Dong, C.D.; Kao, C.M. Assessment of toxicity of polycyclic aromatic hydrocarbons in sediments of Kaohsiung Harbor, Taiwan. Sci. Total Environ. 2013, 463, 1174–1181. [Google Scholar] [CrossRef] [PubMed]

- Hassan, S.S.M.; Abdel-Shafy, H.I.; Mansour, M.S. Removal of pyrene and benzo(a)pyrene micropollutant from water via adsorption by green synthesized iron oxide nanoparticles. Adv. Nat. Sci. Nanosci. Nanotechnol. 2018, 9, 015006. [Google Scholar] [CrossRef]

- Yunker, M.B.; Macdonald, R.W.; Vingarzan, R.; Mitchell, R.H.; Goyette, D.; Sylvestre, S. PAHs in the Fraser River Basin: A critical appraisal of PAH ratios as indicators of PAH source and composition. Org. Geochem. 2002, 33, 489–515. [Google Scholar] [CrossRef]

- Zhi, H.; Zhao, Z.; Zhang, L. The fate of polycyclic aromatic hydrocarbons (PAHs) and organochlorine pesticides (OCPs) in water from Poyang Lake, the largest freshwater lake in China. Chemosphere 2015, 119, 1134–1140. [Google Scholar] [CrossRef]

- Solano, R.A.; De León, L.D.; De Ávila, G.; Herrera, A.P. Polycyclic aromatic hydrocarbons (PAHs) adsorption from aqueous solution using chitosan beads modified with thiourea, TiO2 and Fe3O4 nanoparticles. Environ. Technol. Innov. 2021, 21, 10137. [Google Scholar] [CrossRef]

- Queiroz, R.N.; Prediger, P.; Vieira, M.G.A. Adsorption of polycyclic aromatic hydrocarbons from wastewater using graphene-based nanomate- rials synthesized by conventional chemistry and green synthesis: A critical review. J. Hazard Mater. 2022, 422, 126904. [Google Scholar] [CrossRef] [PubMed]

- Campos, E.; Pinto, D.; de Oliveira, J.; Mattos, D.; Dutra, R. Synthesis, Characterization and Applications of Iron Oxide Nanoparticles—A Short Review. J. Aerosp. Technol. Manag. 2015, 7, 267–276. [Google Scholar] [CrossRef]

- Gonçalves, J.O.; Strieder, M.M.; Silva, L.F.O.; dos Reis, G.S.; Dotto, G.L. Advanced technologies in water treatment: Chitosan and its modifications as effective agents in the adsorption of contaminants. Int. J. Biol. Macromol. 2024, 270, 132307. [Google Scholar] [CrossRef]

- Gautam, I.; Fernando, H. Removal of small-ring polycyclic aromatic hydrocarbons using cow and goat milk iron oxide nanoparticles. Green Chem. Lett. Rev. 2024, 17, 2335183. [Google Scholar] [CrossRef]

- Xu, P.; Zeng, G.M.; Huang, D.L.; Feng, C.L.; Hu, S.; Zhao, M.H.; Liu, Z.F. Use of iron oxide nanomaterials in wastewater treatment: A review. Sci. Total Environ. 2012, 424, 1–10. [Google Scholar] [CrossRef]

- Sher, S.; Waseem, M.; Leta, M.K. Review of Techniques for the Removal of Polycyclic Aromatic Hydrocarbons from Produced Water. Environments 2023, 10, 40. [Google Scholar] [CrossRef]

- Xu, C.; Deng, K.; Li, J.; Xu, R. Impact of environmental conditions on aggregation kinetics of hematite and goethite nanoparticles. J. Nanopart. Res. 2015, 17, 1–13. [Google Scholar] [CrossRef]

- Wei, X.; Viadero, R.C. Synthesis of magnetite nanoparticles with ferric iron recovered from acid mine drainage: Implications for environmental engineering. Colloids Surf. A Physicochem. Eng. Asp. 2007, 294, 280–286. [Google Scholar] [CrossRef]

- Akinwekomi, V.; Maree, J.P.; Strydom, A.; Zvinowanda, C. Recovery of Magnetite from Iron-Rich Mine Water. In Proceedings of the Wisa Biennial Conference, Durban, South Africa, 15–19 June 2016. [Google Scholar]

- Mariani, F.; Borth, K.; Müller, M.; Dalpasquale, M.; Anaissi, F. Sustainable innovative method to synthesize different shades of iron oxide pigments. Dye. Pigment. 2017, 137, 403–409. [Google Scholar] [CrossRef]

- Akinwekomi, V.; Maree, J.; Zvinowanda, C.; Masindi, V. Synthesis of magnetite from iron-rich mine water using sodium carbonate. J. Environ. Chem. Eng. 2017, 5, 2699–2707. [Google Scholar] [CrossRef]

- Legodi, M.; Dewaal, D. The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste. Dye. Pigment. 2007, 74, 161–168. [Google Scholar] [CrossRef]

- Akinwekomi, V.; Maree, J.; Masindi, V.; Zvinowanda, C.; Osman, M.; Foteinis, S.; Chatzisymeon, E. Beneficiation of acid mine drainage (AMD): A viable option for the synthesis of goethite, hematite, magnetite, and gypsum- Gearing towards a circular economy concept. Miner. Eng. 2020, 148, 106–204. [Google Scholar] [CrossRef]

- Fouad, D.E.; Zhang, C.; El-Didamony, H.; Yingnan, L.; Mekuria, T.D.; Shah, A.H. Improved size, morphology and crystallinity of hematite (α-Fe2O3) nanoparticles synthesized via the precipitation route using ferric sulfate precursor. Results Phys. 2019, 12, 1253–1261. [Google Scholar] [CrossRef]

- Meng, J.; Yang, G.; Yan, L.; Wang, X. Synthesis and characterization of magnetic nanometer pigment Fe3O4. Dye. Pigment. 2004, 66, 109–113. [Google Scholar] [CrossRef]

- Cornell, R.M.; Schwertmann, U. The Iron Oxides: Structure, Properties, Reactions, Occurrences and Uses; Wiley-VCH: Weinheim, Germany, 2000. [Google Scholar]

- Mogashane, T.M.; Maree, J.P.; Letjiane, L.; Masindi, V.; Modibane, K.D.; Mujuru, M.; Mphahlele-Makgwane, M.M. Recovery of drinking water and nano-sized Fe2O3 pigment from iron rich acid mine water. In Application of Nanotechnology in Mining Processes: Beneficiation and Sustainability; Fosso-Kankeu, E., Mkandawire, M., Mamba, B., Eds.; Scrivener Publishing: Beverly, MA, USA, 2022; pp. 237–288. [Google Scholar]

- Cui, X.; Choo, K. Granular iron oxide adsorbents to control natural organic matter and membrane fouling in ultrafiltration water treatment. Water Res. 2013, 47, 4227–4237. [Google Scholar] [CrossRef] [PubMed]

- Mirzaee, E.; Sartaj, M. Remediation of PAH-contaminated soil using a combined process of soil washing and adsorption by nano iron oxide/granular activated carbon composite. Environ. Nanotechnol. Monit. Manag. 2023, 20, 100800. [Google Scholar] [CrossRef]

- Gupta, H.; Gupta, B. Photocatalytic degradation of polycyclic aromatic hydrocarbon benzo[a]pyrene by iron oxides and identification of degradation products. Chemosphere 2015, 138, 924–931. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez, A.M.; Dziubla, T.D.; Hilt, J.Z. Recent advances on iron oxide magnetic nanoparticles as sorbents of organic pollutants in water and wastewater treatment. Rev. Environ. Health 2017, 32, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Choo, K.; Kang, S. Removal of residual organic matter from secondary effluent by iron oxides adsorption. Desalination 2003, 154, 139–146. [Google Scholar] [CrossRef]

- Gupta, H.; Kumar, R.; Park, H.S.; Jeon, B.H. Photocatalytic efficiency of iron oxide nanoparticles for the degradation of priority pollutant anthracene. Geosyst. Eng. 2016, 20, 21–27. [Google Scholar] [CrossRef]

- Mogashane, T.; Maree, J.; Mujuru, M.; Mphahlele-Makgwane, M.; Modibane, K. Ferric Hydroxide Recovery from Iron-Rich Acid MineWater with Calcium Carbonate and a Gypsum Scale Inhibitor. Minerals 2023, 13, 167. [Google Scholar] [CrossRef]

- Masindi, V.; Gitari, M.; Tutu, H.; DeBeer, M. Synthesis of cryptocrystalline magnesite–bentonite clay composite and its application for neutralization and attenuation of inorganic contaminants in acidic and metalliferous mine drainage. J. Water Process Eng. 2017, 15, 2–17. [Google Scholar] [CrossRef]

- Maree, J.P.; Mtombeni, T. Treatment of Brine for the Recovery of Drinking Water, Calcium Carbonate and Sodium Sulphate. In Proceedings of the WISA Biennial Conference 2018, Cape Town, South Africa, 24–27 June 2018. [Google Scholar]

- Anekwe, I.M.S.; Isa, Y.M. Bioremediation of acid mine drainage—Review. Alex. Eng. J. 2023, 65, 1047–1075. [Google Scholar] [CrossRef]

- Li, N.; Zhou, Y.; Liu, J.; Tsang, D.C.; Wang, J.; She, J.; Zhou, Y.; Yin, M.; Chen, Z.; Chen, D. Persistent thallium contamination in river sediments, source apportionment and environmental implications. Ecotoxicol. Environ. Saf. 2020, 202, 110874. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; She, J.; Zhou, Y.; Daniel, C.W.; Beiyuan, T.B.; Xiao, T.; Dong, X.; Chen, Y.; Liu, J.; Yin, M.; et al. Microbial insights into the biogeochemical features of thallium occurrence: A case study from polluted river sediments. Sci. Total Environ. 2020, 739, 139957. [Google Scholar] [CrossRef] [PubMed]

- Gunther, P.; Mey, W. Selection of Mine Water Treatment Technologies for the eMalahleni (Witbank) Water Reclamation Project. In Proceedings of the WISA Biennial Conference, Sun City, South Africa, 18–22 May 2008. [Google Scholar]

- Demers, I.; Benzaazoua, M.; Mbonimpa, M.; Bouda, M.; Bois, D.; Gagnon, M. Valorisation of acid mine drainage treatment sludge as remediation component to control acid generation from mine wastes, part 1: Material characterization and laboratory kinetic testing. Miner. Eng. 2015, 76, 109–116. [Google Scholar] [CrossRef]

- Magagane, N.; Masindi, V.; Ramakokovhu, M.M.; Shongwe, M.B.; Muedi, K.L. Facile thermal activation of non-reactive cryptocrystalline magnesite and its application on the treatment of acid mine drainage. J. Environ. Manag. 2019, 236, 499–509. [Google Scholar] [CrossRef]

- Maree, J.P.; Letjiane, S.L.; Ramothole, R.; Oyewo, A.O.; Mogashane, T.M.; Sebothoma, P.S.; Vellem, S.; Ntumba, N.; Germanis, J. Treatment for the Recovery of Drinking Water and Valuable Products from Mine Water; Water Research Commission: Pretoria, South Africa, 2021. [Google Scholar]

- Ighalo, J.O.; Kurniawan, S.B.; Iwuozor, K.O.; Aniagor, C.O.; Ajala, O.J.; Oba, S.N.; Iwuchukwu, F.U.; Ahmadi, S.; Igwegbe, C.A. A review of treatment technologies for the mitigation of the toxic environmental effects of acid mine drainage (AMD). Process Saf. Environ. Prot. 2022, 157, 37–58. [Google Scholar] [CrossRef]

- Mogashane, T.M.; Maree, J.P.; Mujuru, M.; Mphahlele-Makgwane, M.M. Technologies that can be Used for the Treatment of Wastewater and Brine for the Recovery of Drinking Water and Saleable Products. In Recovery of Byproducts from Acid Mine Drainage Treatment, Editors: Elvis Fosso-Kankeu, Jo Burgess and Christian Wolkersdorfer; Wiley Scrivener: New York, NY, USA, 2020; pp. 97–151. [Google Scholar]

- Maree, J.; Mujuru, M.; Bologo, V.; Daniels, N.; Mpholoane, D. Neutralisation treatment of AMD at affordable cost. Water SA 2013, 39, 245–250. [Google Scholar] [CrossRef]

- Silva, R.D.; Secco, M.P.; Lermen, R.T.; Schneider, I.A.H.; Hidalgo, G.E.N.; Sampaio, C.H. Optimizing the selective precipitation of iron to produce yellow pigment from acid mine drainage. Miner. Eng. 2019, 135, 111–117. [Google Scholar] [CrossRef]

- Mirzaei, A.; Janghorban, K.; Hashemi, B.; Hosseini, S.; Bonyani, M.; Leonardi, S.; Bonavita, A.; Neri, G. Synthesis and characterization of mesoporous Fe2O3 nanoparticles and investigation of electrical properties of fabricated thick films. Process. Appl. Ceram. 2016, 10, 209–217. [Google Scholar] [CrossRef]

- Rayaroth, M.P.; Marchel, M.; Boczkaj, G. Advanced oxidation processes for the removal of mono and polycyclic aromatic hydrocarbons—A review. Sci. Total Environ. 2023, 857, 159043. [Google Scholar] [CrossRef] [PubMed]

- Mokgohloa, C.P.; Maree, J.P.; van Vuuren, D.S.; Modibane, K.D.; Mujuru, M.; Mokhonoana, M. Recovery of Na2CO3 and nano CaCO3 from Na2SO4 and CaSO4 wastes. In Nano Technology; Wiley Scrivener: New York, NY, USA, 2022; pp. 1–2. [Google Scholar]

- Adeola, A.O.; Forbes, P.B.C. Advances in Water Treatment Technologies for Removal of Polycyclic Aromatic Hydrocarbons: Existing Concepts, Emerging Trends, and Future Prospects. Water Environ. Res. 2021, 93, 343–359. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Yeerkenbieke, G.; Shi, S.; Wang, Z.; Yi, L.; Lu, X. Adsorption of Pyrene and Arsenite by Micro/Nano Carbon Black and Iron Oxide. Toxics 2024, 12, 251. [Google Scholar] [CrossRef] [PubMed]

- Inbaraj, B.S.; Sridhar, K.; Chen, B. Removal of polycyclic aromatic hydrocarbons from water by magnetic activated carbon nanocomposite from green tea waste. J. Hazard. Mater. 2021, 415, 12570. [Google Scholar] [CrossRef] [PubMed]

- Mahgoub, H.A. Nanoparticles Used for Extraction of Polycyclic Aromatic Hydrocarbons. J. Chem. 2019, 2019, 4816849. [Google Scholar] [CrossRef]

- Soares, S.F.; Simões, T.R.; Trindade, T.; Anal, L.; da-Silva, D. Highly Efficient Removal of Dye from Water Using Magnetic Carrageenan/Silica Hybrid Nano-adsorbents. Water Air Soil Pollut. 2017, 228, 87. [Google Scholar] [CrossRef]

- Inbaraj, B.S.; Chen, B.H. Dye adsorption characteristics of magnetite nanoparticles coated with a biopolymer poly(γ-glutamic acid. Bioresour. Technol. 2011, 102, 8868–8876. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, S.; Zhao, G.; Wang, Q.; Wang, X. Adsorption of Polycyclic Aromatic Hydrocarbons on Graphene Oxides and Reduced Graphene Oxides. Chem.-Asian J. 2013, 8, 2755–2761. [Google Scholar] [CrossRef]

- Wang, L.; Shi, C.; Pan, L.; Zhang, X.; Zou, J.J. Rational design, synthesis, adsorption principles and applications of metal oxide adsorbents: A review. Nanoscale 2020, 12, 4790–4815. [Google Scholar] [CrossRef]

- Mehta, D.; Mazumdar, S.; Singh, S.K. Magnetic adsorbents for the treatment of water/wastewater—A review. J. Water Process Eng. 2015, 7, 244–265. [Google Scholar] [CrossRef]

- EL-Mekkawi, D.M.; Ibrahim, F.A.; Selim, M.M. Removal of methylene blue from water using zeolites pre-pared from Egyptian kaolins collected from different sources. J. Environ. Chem. Eng. 2016, 4, 1417–1422. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, L.; Xia, H.; Peng, J.; Shu, J.; Li, C. Ultrasound and microwave-assisted preparation of Fe-activated carbon as an effective low-cost adsorbent for dyes wastewater treatment. RSC Adv. 2016, 6, 78936–78946. [Google Scholar] [CrossRef]

- Gupta, H. Removal of Phenanthrene from Water Using Activated Carbon Developed from Orange Rind. Int. J. Sci. Res. Environ. Sci. 2015, 3, 248–255. [Google Scholar] [CrossRef]

- Mittal, H.; Ray, S.S. A study on the adsorption of methylene blue onto gum ghatti/TiO2 nanoparticles-based hydrogel nanocomposite. Int. J. Biol. Macromol. 2016, 88, 66–80. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Gregorio, M.R.; García-Falcón, M.S.; Martínez-Carballo, E.; Simal-Gándara, J. Removal of polycyclic aromatic hydrocarbons from organic solvents by ashes wastes. J. Hazard. Mater. 2010, 178, 273–281. [Google Scholar] [CrossRef]

- Kefeni, K.K.; Msagati, A.T.; Nkambule, T.T.; Mamba, B.B. Synthesis and application of hematite nanoparticles for acid mine drainage treatment. J. Environ. Chem. Eng. 2018, 6, 1865–1874. [Google Scholar] [CrossRef]

- Munyengabe, A.; Zvinowanda, C.; Zvimba, J.N.; Ramontja, J. Characterization and reusability suggestions of the sludge generated from a synthetic acid mine drainage treatment using sodium ferrate (VI). Heliyon 2020, 6, e05244. [Google Scholar] [CrossRef]

- Rashad, E.; Saleh, H.N.; Eltaweil, A.S. Pinewood sawdust biochar as an effective biosorbent for PAHs removal from wastewater. Biomass. Conv. Bioref. 2023, 13, 13443–13459. [Google Scholar] [CrossRef]

- Awad, A.M.; Shaikh, S.M.R.; Jalab, R.H.; Gulied, M.H.; Nasser, M.S.; Benamor, A.; Adham, S. Adsorption of organic pollutants by natural modified clays: A comprehensive review. Sep. Purif. Technol. 2019, 228, 115719. [Google Scholar] [CrossRef]

- Satouh, S.; Martín, J.; Orta, M.d.M.; Medina-Carrasco, S.; Messikh, N.; Bougdah, N.; Santos, J.L.; Aparicio, I.; Alonso, E. Adsorption of Polycyclic Aromatic Hydrocarbons by Natural, Synthetic and Modified Clays. Environments 2021, 8, 124. [Google Scholar] [CrossRef]

- Hall, S.; Tang, R.; Baeyens, J.; Dewil, R. Removing polycyclic aromatic hydrocarbons from water by adsorption on silicagel. Polycycl. Aromat. Compd. 2009, 29, 160–183. [Google Scholar] [CrossRef]

- Ryan, M.J.; Kney, A.D.; Carley, T.L. A study of selective precipitation techniques used to recover refined iron oxide pigments for the production of paint from a synthetic acid mine drainage solution. Appl. Geochem. 2017, 79, 27–35. [Google Scholar] [CrossRef]

- Shanker, U.; Jassal, V.; Rani, M. Green synthesis of iron hexacyanoferrate nanoparticles: Potential candidate for the degradation of toxic PAHs. J. Environ. Chem. Eng. 2017, 5, 4108–4120. [Google Scholar] [CrossRef]

- Kim, J.H.; Bae, K.S.; Lee, S.H.; Choi, W. Laboratory and pilot-scale field experiments for application of iron oxide nanoparticle-loaded chitosan composites to phosphate removal from natural water. Environ. Technol. 2018, 39, 770–779. [Google Scholar] [CrossRef] [PubMed]

- Haneef, T.; Mustafa, M.R.U.; Wan Yusof, K.; Isa, M.H.; Bashir, M.J.K.; Ahmad, M.; Zafar, M. Removal of Polycyclic Aromatic Hydrocarbons (PAHs) from Produced Water by Ferrate (VI) Oxidation. Water 2020, 12, 3132. [Google Scholar] [CrossRef]

- Teng, R.; Jiang, J.; Shi, D.; Li, H. Synthesis of Acid Mine Drainage (AMD) Sludge-Derived Al–Fe3O4 as Fenton-like Catalysts for the Efficient Degradation of Tetracycline. Langmuir 2023, 39, 14275–14283. [Google Scholar] [CrossRef]

- Muedi, K.L.; Masindi, V.; Maree, J.P.; Haneklaus, N.; Brink, H.G. Effective Adsorption of Congo Red from Aqueous Solution Using Fe/Al Di-Metal Nanostructured Composite Synthesised from Fe(III) and Al(III) Recovered from Real Acid Mine Drainage. Nanomaterials 2022, 12, 776. [Google Scholar] [CrossRef]

- Panayotova, M.; Mirdzveli, N.; Panayotov, V. Useful nanoparticles from mining waste and acid mine drainage. IOP Conf. Ser. Earth Environ. Sci. 2023, 1254, 012063. [Google Scholar] [CrossRef]

- Pan, Z.; Xie, R.; Chen, Z. One-step simultaneous biomass synthesis of iron nanoparticles using tea extracts for the removal of metal(loid)s in acid mine drainage. Chemosphere 2023, 337, 139366. [Google Scholar] [CrossRef] [PubMed]

- Gong, C.; Shen, G.; Huang, H.; He, P.; Zhang, Z.; Ma, B. Removal and transformation of polycyclic aromatic hydrocarbons during electrocoagulation treatment of an industrial wastewater. Chemosphere 2017, 168, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Parigoridi, I.E.; Tsoumani, E.; Akrida-Demertzi, K.; Demertzis, P.G. Evaluation of three extraction methods for the isolation of PAHs from recycled paperboard materials intended for food contact applications. Eur. Food Res. Technol. 2023, 249, 665–673. [Google Scholar] [CrossRef]

- Zhou, Y.; Long, T.; Zhu, X.; Wang, L.; Kong, L.; Li, Y.; Shi, J. Research Progress on Distribution and Remediation Technologies for the Combined Pollution of Heavy Metals and Polycyclic Aromatic Hydrocarbons in Soil. J. Ecol. Rural Environ. 2019, 35, 964–975. [Google Scholar]

| PAH | Chemical Formula | Number of Rings | Properties | Sources | Toxicity |

|---|---|---|---|---|---|

| Naphthalene | C10H8 | 2 | Volatile, used in mothballs and as a chemical intermediate | Fossil fuels, combustion of organic matter | Possible human carcinogen |

| Acenaphthylene | C12H8 | 3 | Pale yellow solid, used in dyes and plastics manufacturing | Incomplete combustion of fossil fuels | Toxic to aquatic life, not classifiable for humans |

| Acenaphthene | C12H10 | 3 | White solid, used in insecticides and fungicides | Coal tar, oil, wood burning | Low acute toxicity, not classifiable for humans |

| Fluorene | C13H10 | 3 | White crystalline solid, used in production of dyes, plastics, and pesticides | Fossil fuels, combustion of organic materials | Possible human carcinogen |

| Phenanthrene | C14H10 | 3 | White crystalline solid, used in dyes, drugs, and explosives | Coal tar, crude oil, combustion processes | Not classifiable as a human carcinogen |

| Anthracene | C14H10 | 3 | Used in the production of dyes, plastics, and pesticides | Coal tar, combustion of organic materials | Not classifiable as a human carcinogen |

| Fluoranthene | C16H10 | 4 | Pale yellow solid, used in the production of dyes and plastics | Incomplete combustion of fossil fuels | Possible human carcinogen |

| Pyrene | C16H10 | 4 | Pale yellow solid, used in the production of dyes and plastics | Fossil fuels, combustion of organic materials | Possible human carcinogen |

| Benzo[a]anthracene | C18H12 | 4 | Yellow solid, used in the production of dyes and pigments | Fossil fuels, incomplete combustion | Probable human carcinogen |

| Chrysene | C18H12 | 4 | Yellow solid, used in the production of dyes and pigments | Coal tar, oil, wood burning | Probable human carcinogen |

| Benzo[b]fluoranthene | C20H12 | 5 | Yellow solid, used in research | Fossil fuels, incomplete combustion | Probable human carcinogen |

| Benzo[k]fluoranthene | C20H12 | 5 | Yellow solid, used in research | Fossil fuels, incomplete combustion | Probable human carcinogen |

| Benzo[a]pyrene | C20H12 | 5 | Yellow solid, well-studied PAH | Fossil fuels, combustion of organic materials | Known human carcinogen |

| Indeno[1,2,3-cd]pyrene | C22H12 | 6 | Yellow solid, used in research | Fossil fuels, incomplete combustion | Probable human carcinogen |

| Dibenzo[a,h]anthracene | C22H14 | 5 | Yellow solid, used in research | Fossil fuels, incomplete combustion | Probable human carcinogen |

| Benzo[ghi]perylene | C22H12 | 6 | Yellow solid, used in research | Fossil fuels, incomplete combustion | Possible human carcinogen |

| Iron Oxide Nanomaterial | Chemical Formula | Crystal Structure | Magnetic Properties | Chemical Properties | Advantages | Limitations | Ability to Remove Organic Substances | References |

|---|---|---|---|---|---|---|---|---|

| Magnetite | Fe3O4 | Inverse Spinel | Strongly magnetic (ferromagnetic) | Fe2+ and Fe3+ present, black in colour | High magnetic response, easy separation, good conductivity | Prone to oxidation to maghemite, less stable in acidic conditions | High, effective for organic removal due to catalytic properties | [40,41] |

| Maghemite | γ-Fe2O3 | Cubic (defective spinel) | Ferrimagnetic | Fe3+ only, brownish red in colour | Stable over a wide range of pH, good for biomedical applications | Lower magnetic saturation compared to magnetite, more expensive | Moderate to high, good for catalytic degradation of organics | [42,43] |

| Goethite | FeO(OH) | Orthorhombic | Weakly magnetic (antiferromagnetic) | Fe3+, yellow to brown in colour | High surface area, good adsorption capacity for heavy metals | Lower magnetic properties, less effective for magnetic separation | Moderate, effective for adsorption and oxidation of certain organics | [42,44,45] |

| Hematite | α-Fe2O3 | Rhombohedral | Weakly magnetic (antiferromagnetic) | Fe3+, red in colour | High stability, corrosion-resistant, good for photocatalysis | Low magnetic properties, less effective for magnetic separation | Moderate, good for photocatalytic degradation of organics | [43,44] |

| Process | Description | Advantages | Limitations | References |

|---|---|---|---|---|

| Neutralization | Addition of alkaline substances (e.g., lime, limestone) to increase pH and precipitate iron as iron hydroxides | Simple, cost-effective, widely used | Generates large volumes of sludge, potential for incomplete reactions | [35,39] |

| Precipitation and Coagulation | Addition of chemicals (e.g., ferric chloride, aluminium sulphate) to promote aggregation of iron particles for easier removal | Effective at low iron concentrations, enhances settling | Chemical costs, sludge disposal issues, may require pH adjustment | [46,55] |

| Filtration and Washing | Physical separation of precipitated iron particles through filtration, followed by washing to remove impurities | Produces relatively pure iron oxide, can be combined with other methods | Filter clogging, requires regular maintenance, may need pre-treatment | [47,60] |

| Oxidation | Oxidation of ferrous iron (Fe2+) to ferric iron (Fe3+) using oxidizing agents (e.g., air, oxygen, chlorine) to facilitate precipitation as iron hydroxide | Enhances iron removal efficiency, can be combined with biological methods | Requires controlled conditions, potential for incomplete oxidation | [61] |

| Thermal Treatment | Heating of precipitated iron hydroxides to convert them to more stable iron oxides (e.g., hematite, magnetite) | Produces high-purity iron oxides, potential for resource recovery | Energy-intensive, high operational costs, may release contaminants | [33,62] |

| Regeneration Method | Description | Advantages | Limitations |

|---|---|---|---|

| Chemical Regeneration | Uses chemical reagents (e.g., acids, bases) to desorb contaminants and regenerate nanoparticles | Effective for a wide range of contaminants, can be performed at room temperature | Use of chemicals can be hazardous, potential environmental impact |

| Thermal Regeneration | Heating nanoparticles to high temperatures to remove adsorbed contaminants | High effectiveness in removing organic contaminants, restores nanoparticle properties | Energy-intensive, can cause particle sintering and reduce surface area |

| Electrochemical Regeneration | Applying an electric field to facilitate desorption of contaminants | Environmentally friendly, selective desorption, no chemical use | Requires specialized equipment, limited to certain types of contaminants |

| Magnetic Separation | Using magnetic fields to separate and recover nanoparticles from the treated medium | Efficient and rapid recovery, minimal chemical use | May not fully regenerate adsorption capacity, requires magnetic equipment |

| Biological Regeneration | Using microorganisms to degrade or transform contaminants on nanoparticle surfaces | Sustainable and environmentally friendly | Slower process, effectiveness depends on contaminant type and microbial activity |

| Ultrasonic Treatment | Applying ultrasonic waves to agitate and clean nanoparticle surfaces | Effective in removing weakly adsorbed contaminants, can be combined with other methods | Limited to specific contaminants, requires specialized equipment |

| Solvent Extraction | Using organic solvents to dissolve and remove contaminants | Effective for organic contaminants | Use of organic solvents can be hazardous, solvent disposal issues |

| Adsorbent | Advantages | Limitations | Cost-Effectiveness | Availability | Reusability | Reference |

|---|---|---|---|---|---|---|

| Iron Oxide Nanoparticles | High surface area, high adsorption capacity, selective adsorption of certain contaminants, magnetic properties for easy separation | Potential toxicity, high synthesis cost, requires specialized equipment | Moderately high initial cost, but efficient in small quantities | Limited, requires specialized production facilities | Good, can be regenerated and reused multiple times | [26,36] |

| Activated Carbon | High surface area, effective for a wide range of contaminants, widely used | High cost, non-selective adsorption, regeneration can be challenging | High, especially for large-scale applications | Widely available commercially | Limited, performance decreases after regeneration | [65,73,74] |

| Zeolites | High selectivity, good for ion exchange processes, relatively low cost | Limited by pore size, less effective for large organic molecules | Moderate, depends on specific type and application | Readily available | Good, can be regenerated with proper treatment | [72] |

| Biochar | Low cost, sustainable, produced from waste biomass, good adsorption for organics and metals | Lower adsorption capacity compared to activated carbon, variable quality | Low to moderate, cost-effective for large-scale use | Widely available, can be locally produced | Moderate, depends on contaminant type and regeneration method | [79] |

| Clay Minerals | Low cost, natural availability, good for cation exchange | Low adsorption capacity, limited by specific surface area, possible desorption | Very cost-effective, especially for large volumes | Readily available, abundant in nature | Limited, often single-use due to low regeneration efficiency | [80,81] |

| Silica Gel | High surface area, good for polar compounds, relatively low cost | Limited to specific applications, can be affected by humidity | Moderate, depends on application | Widely available commercially | Limited, often not reused due to cost and practicality | [82] |

| Iron Oxide Nanomaterial | No. of PAHs | % Recovery | Country | Sample Matrix | Reference |

|---|---|---|---|---|---|

| Iron oxide nanoparticles | 3 | 70%–90% | USA | Water | [26] |

| Iron oxides | 1 | _ | China | Water | [64] |

| Iron oxides | 1 | _ | India | Soil | [42] |

| Iron hexacyanoferrate nanoparticles | 5 | 70%–90% | India | Water, Soil | [84] |

| Iron oxide nanoparticles | 2 | 98.5%–99% | Egypt | Water | [19] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mogashane, T.M.; Maree, J.P.; Mokoena, L. Adsorption of Polycyclic Aromatic Hydrocarbons from Wastewater Using Iron Oxide Nanomaterials Recovered from Acid Mine Water: A Review. Minerals 2024, 14, 826. https://doi.org/10.3390/min14080826

Mogashane TM, Maree JP, Mokoena L. Adsorption of Polycyclic Aromatic Hydrocarbons from Wastewater Using Iron Oxide Nanomaterials Recovered from Acid Mine Water: A Review. Minerals. 2024; 14(8):826. https://doi.org/10.3390/min14080826

Chicago/Turabian StyleMogashane, Tumelo M., Johannes P. Maree, and Lebohang Mokoena. 2024. "Adsorption of Polycyclic Aromatic Hydrocarbons from Wastewater Using Iron Oxide Nanomaterials Recovered from Acid Mine Water: A Review" Minerals 14, no. 8: 826. https://doi.org/10.3390/min14080826

APA StyleMogashane, T. M., Maree, J. P., & Mokoena, L. (2024). Adsorption of Polycyclic Aromatic Hydrocarbons from Wastewater Using Iron Oxide Nanomaterials Recovered from Acid Mine Water: A Review. Minerals, 14(8), 826. https://doi.org/10.3390/min14080826