Techniques of Pre-Concentration by Sensor-Based Sorting and Froth Flotation Concentration Applied to Sulfide Ores—A Review

Abstract

:1. Introduction

- To conduct a critical review of the main concepts and techniques of froth flotation and pre-concentration by sensor-based sorting;

- To identify potential and limitations in the application of the technique, as well as future perspectives on the subject.

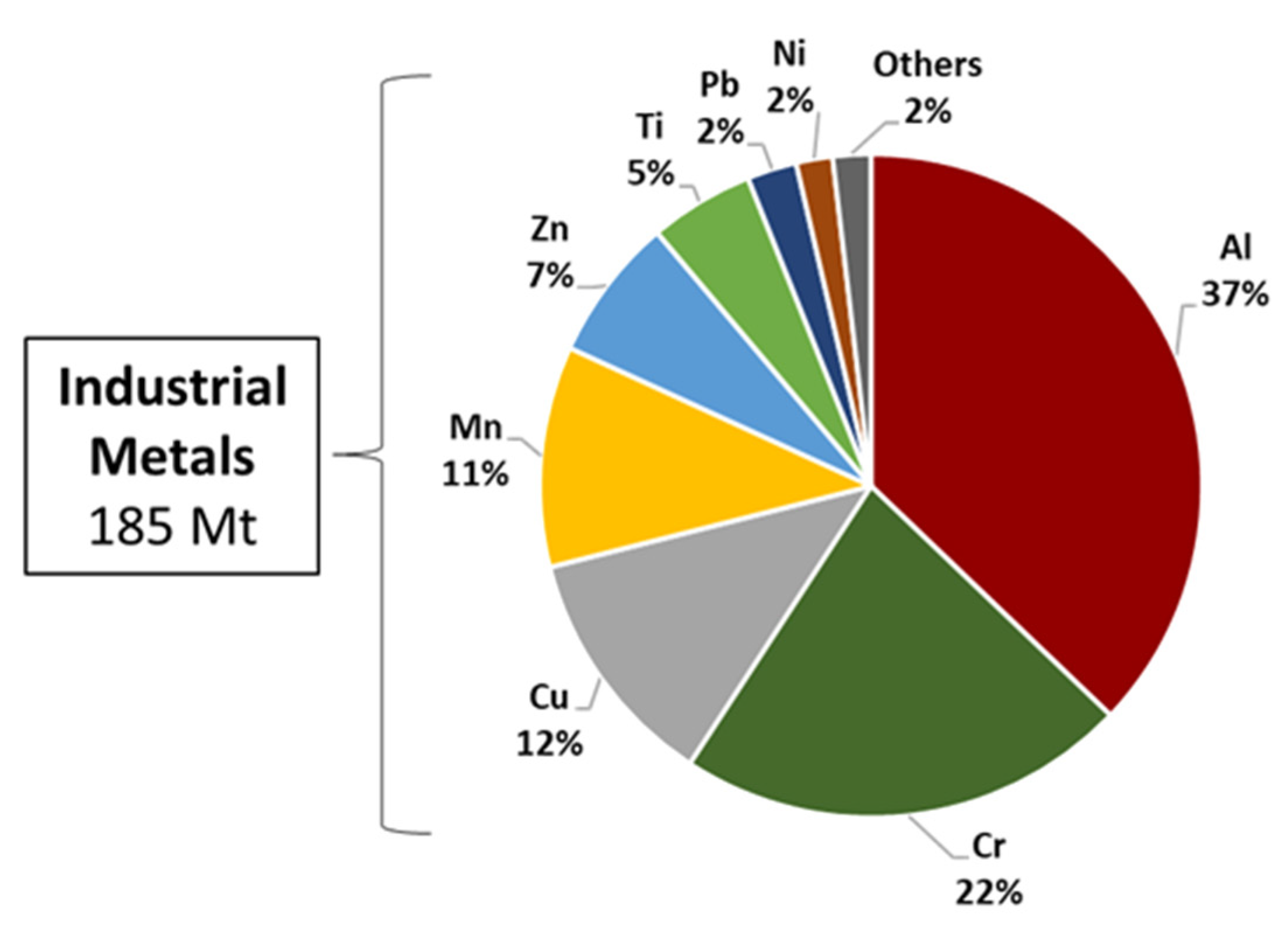

2. Beneficiation of Metallic Sulfides

2.1. Main Metallic Sulfides and Their Beneficiation

2.2. Concentration by Flotation

2.2.1. General Flotation Concepts

- Collision of mineral particles with air bubbles;

- Adhesion (adsorption) and/or formation of air bubble–particle aggregate;

- Transport of the aggregate to the liquid surface, where the particles are collected in a froth format.

2.2.2. Challenges and Opportunities in Flotation

3. Pre-Concentration by Sensor-Based Sorting (SBS)

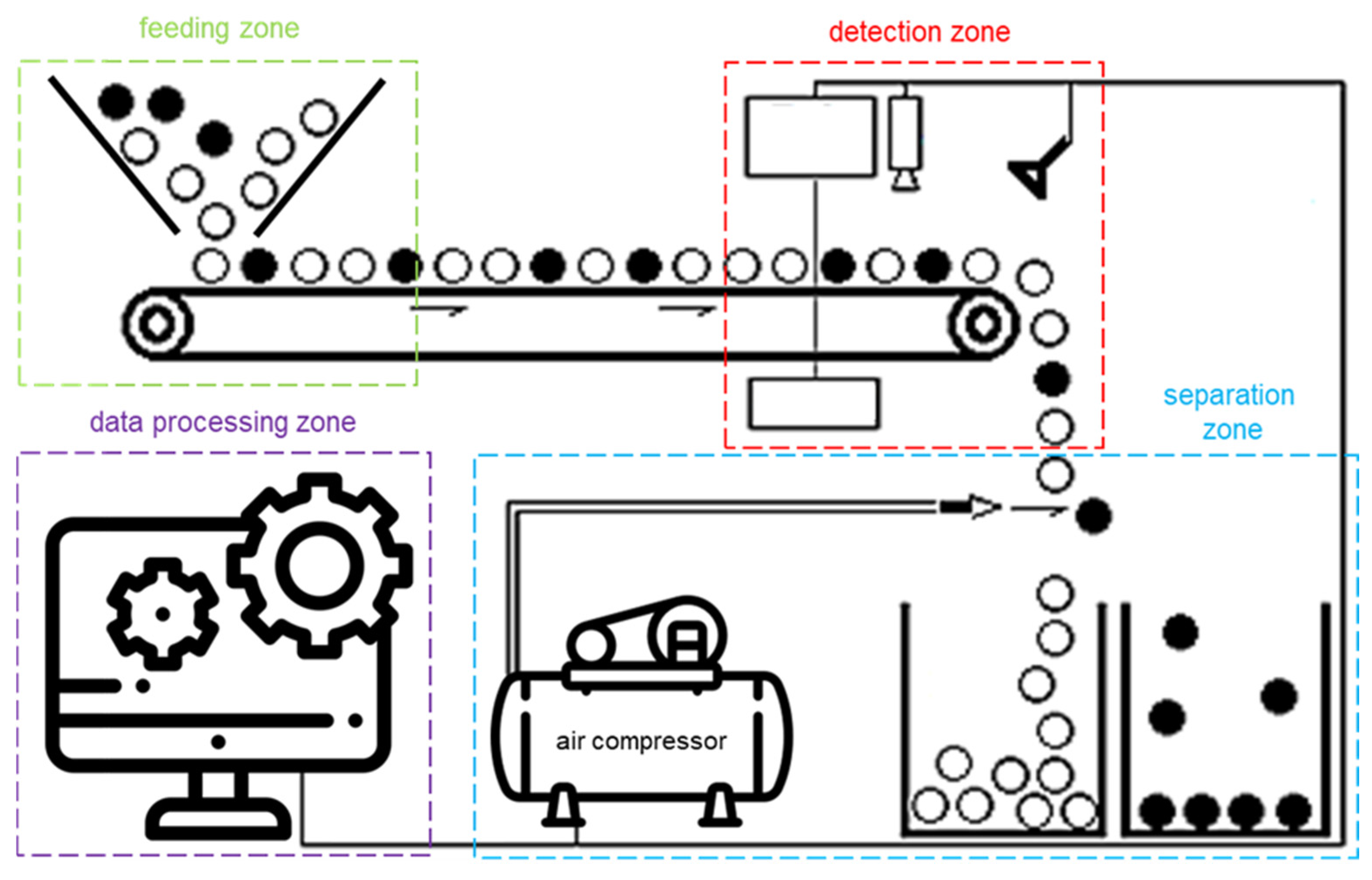

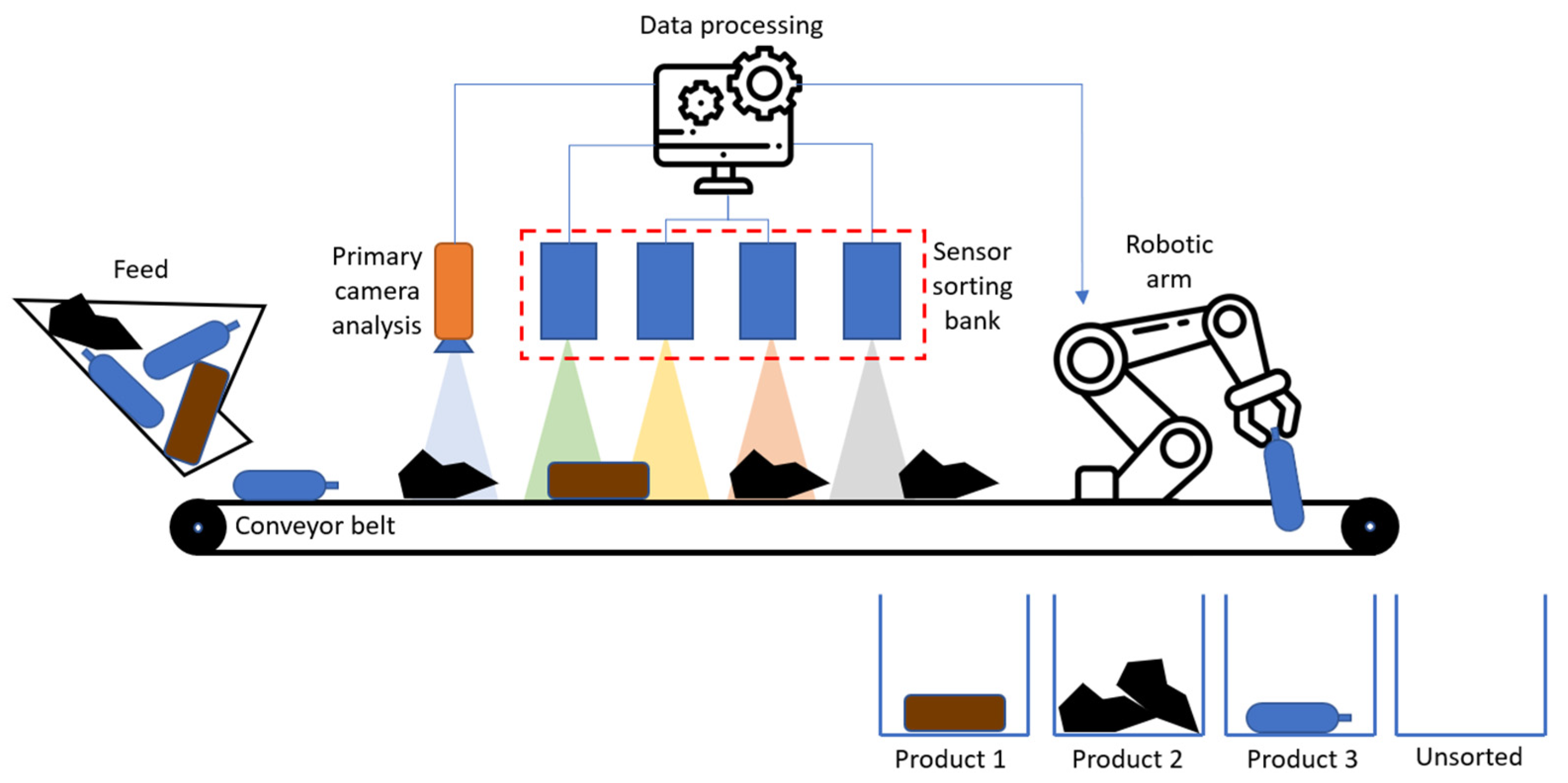

3.1. General SBS Concepts

- Feeding presentation system;

- Detection system (sensor/sensors);

- Processing system;

- Material separation system.

3.2. Techniques and Equipment

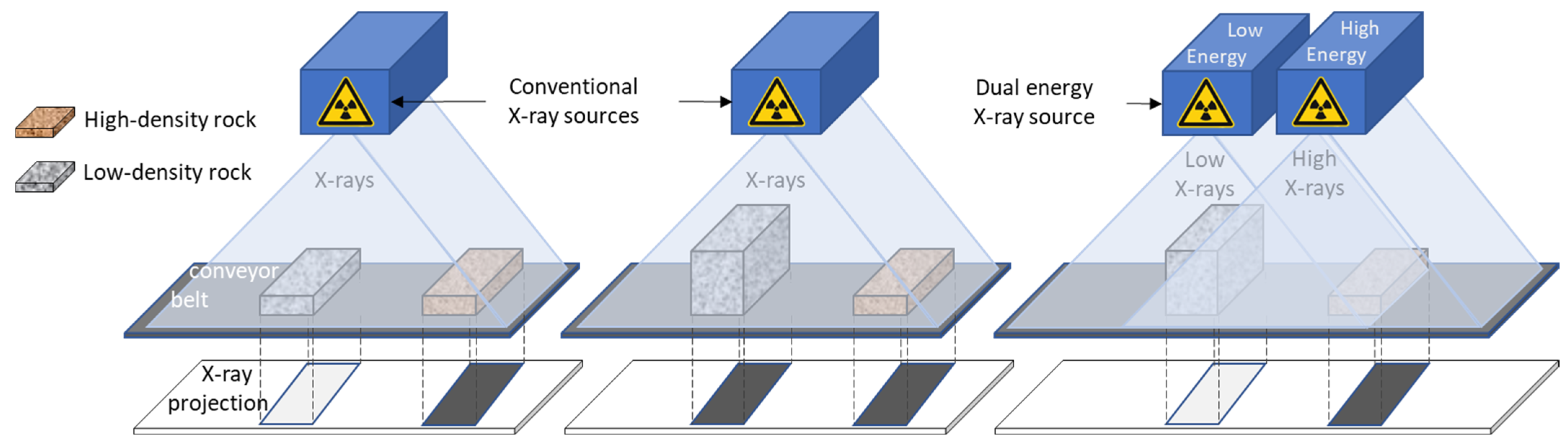

3.2.1. X-Ray Sensors

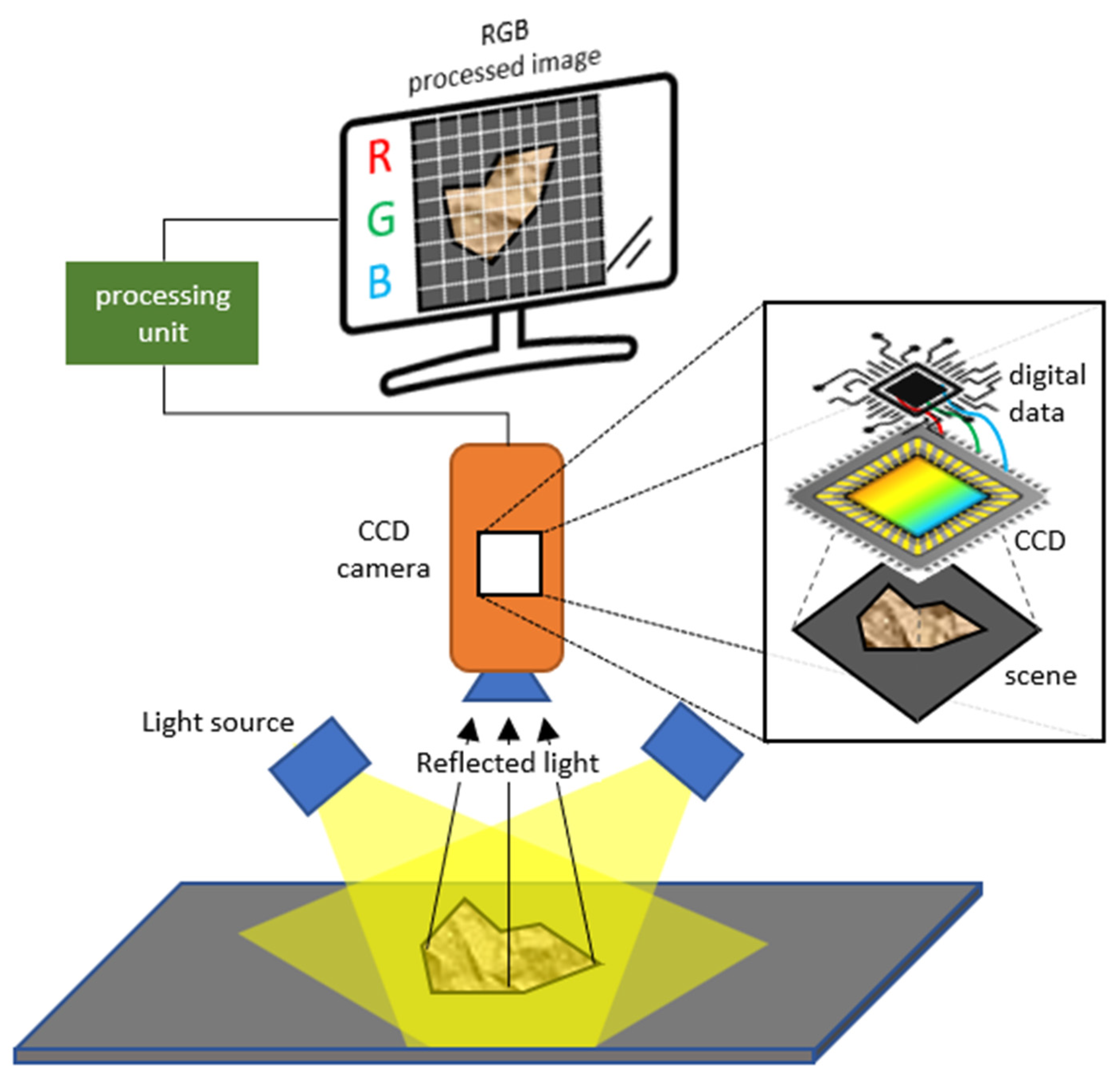

3.2.2. Visible Light

3.2.3. Laser

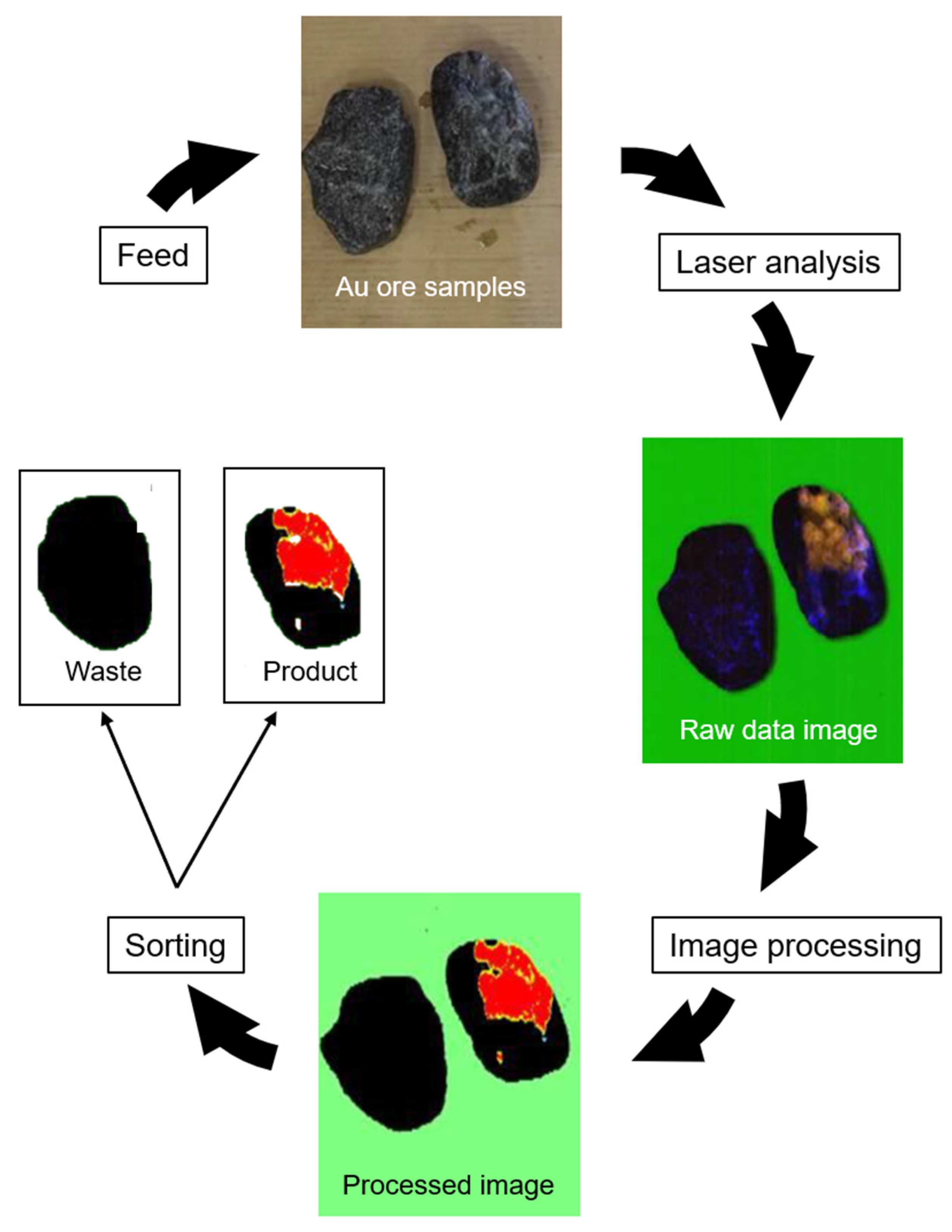

3.2.4. Near-Infrared and Short-Wave Infrared (VNIR-SWIR)

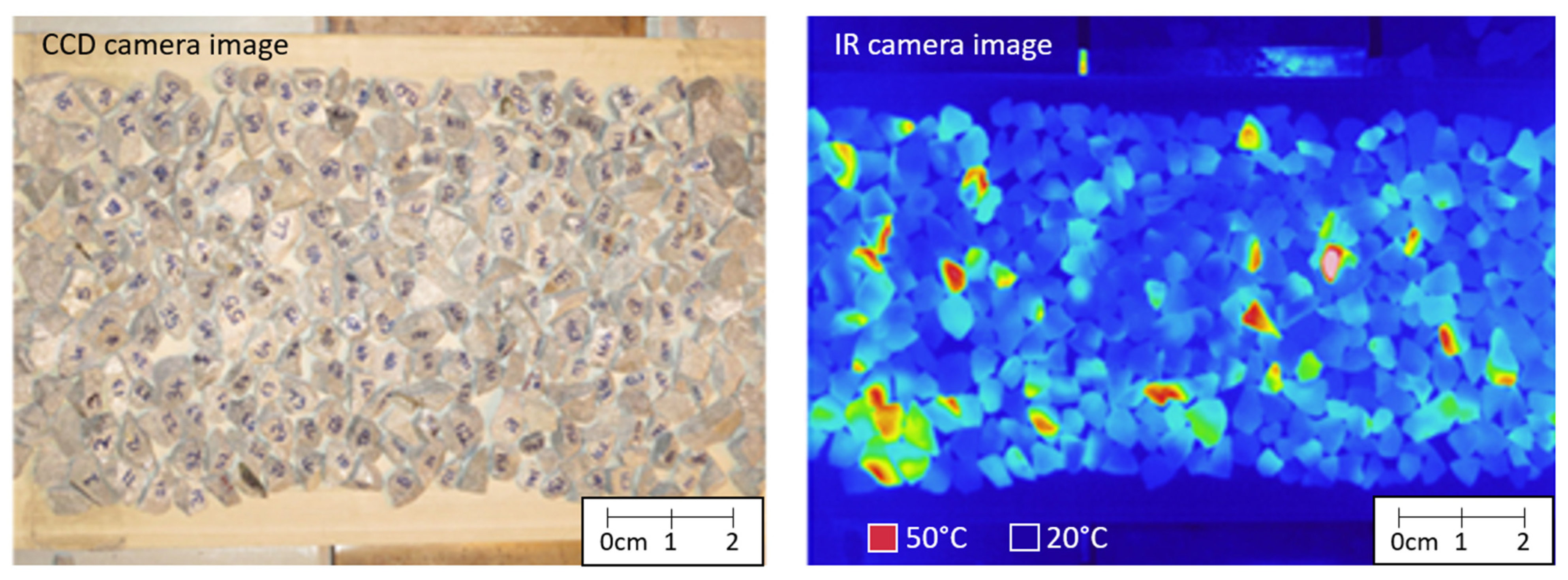

3.2.5. Microwaves (MW-IRT)

3.2.6. Radiowaves

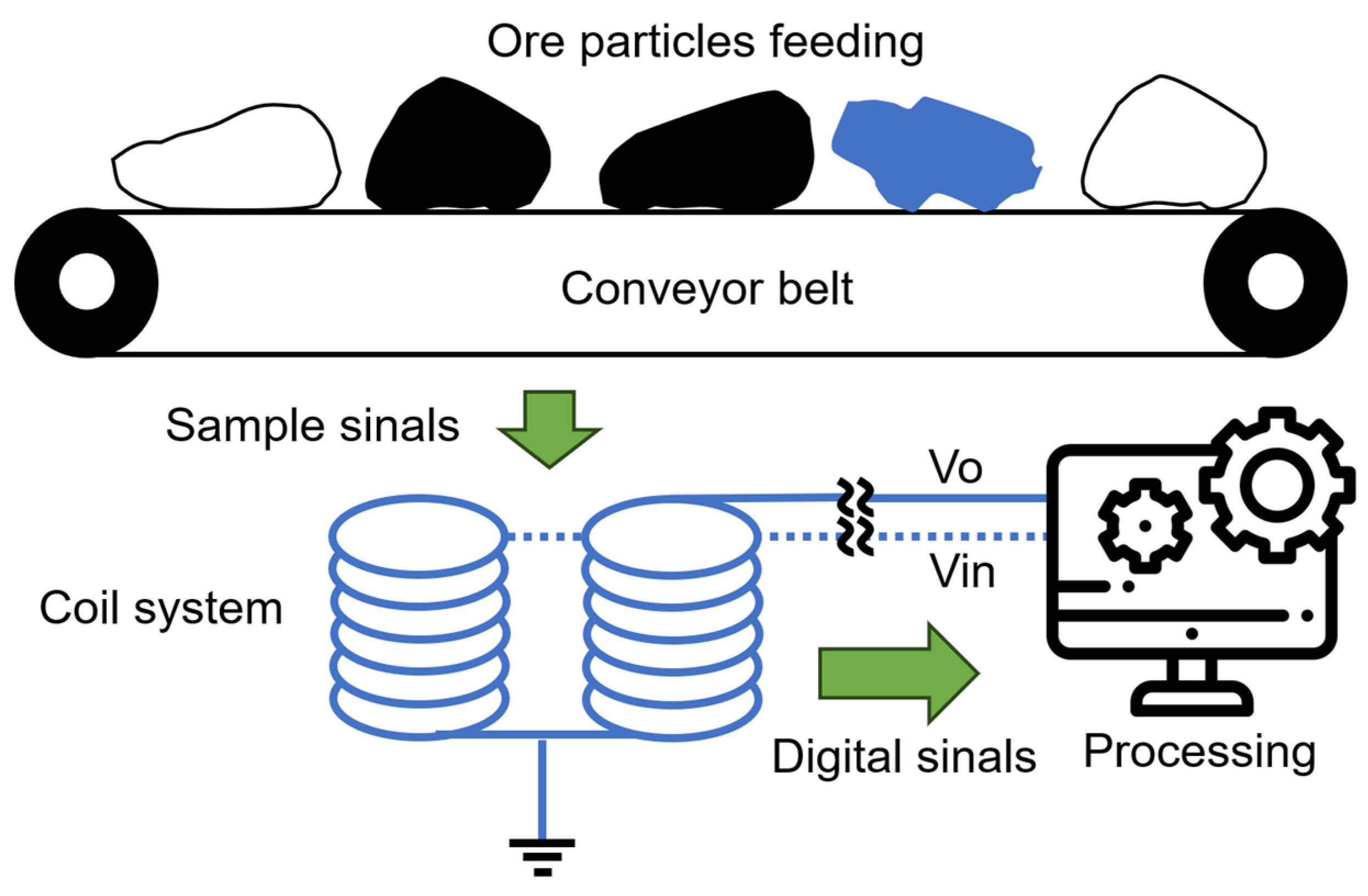

3.2.7. Electromagnetic Devices

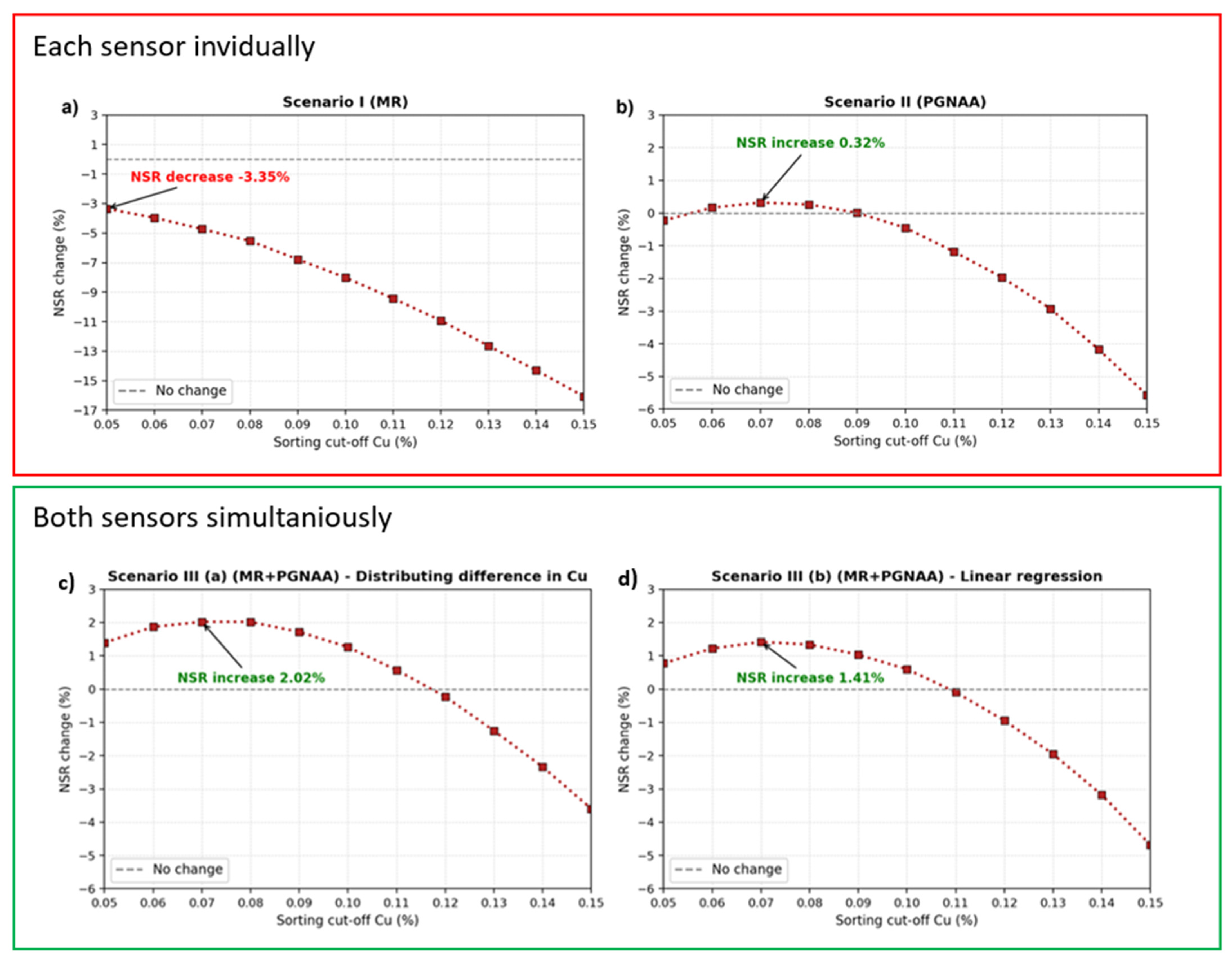

3.2.8. Sensor Fusion

3.2.9. Other Techniques

3.3. Technical Challenges

- Existence of a sufficient degree of ore vs. gangue liberation;

- Feasibility of identifying ore and gangue using an available SBS technique;

- Production rate.

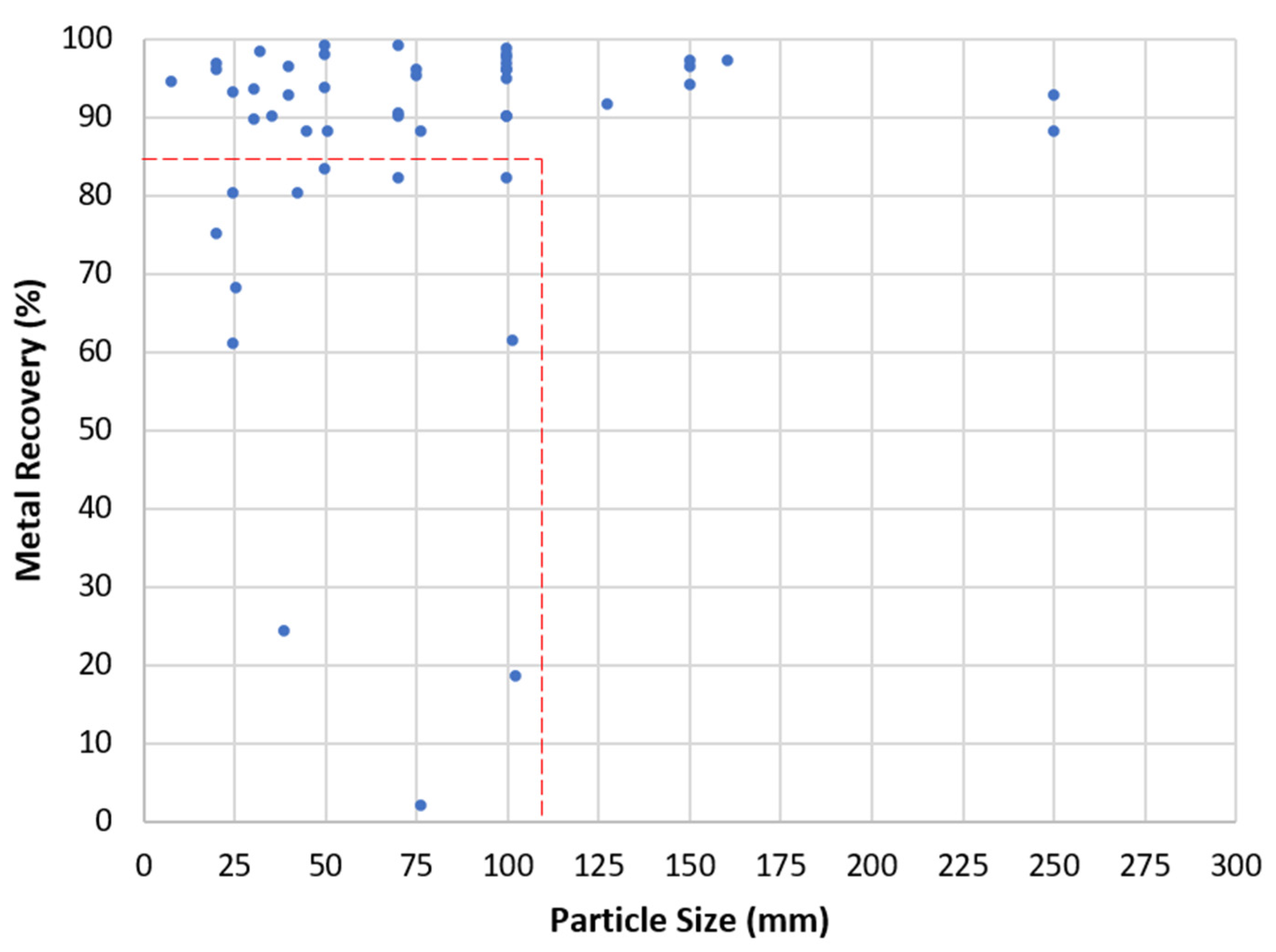

3.4. Performance Analysis

- Samples with higher ore vs. reject contrast (e.g., magnesite and quartz) yielded better results than samples with moderate contrast (lignite and hematite) or low contrast (copper and gold).

- Efficiency of classification decreased as the feed rate increased.

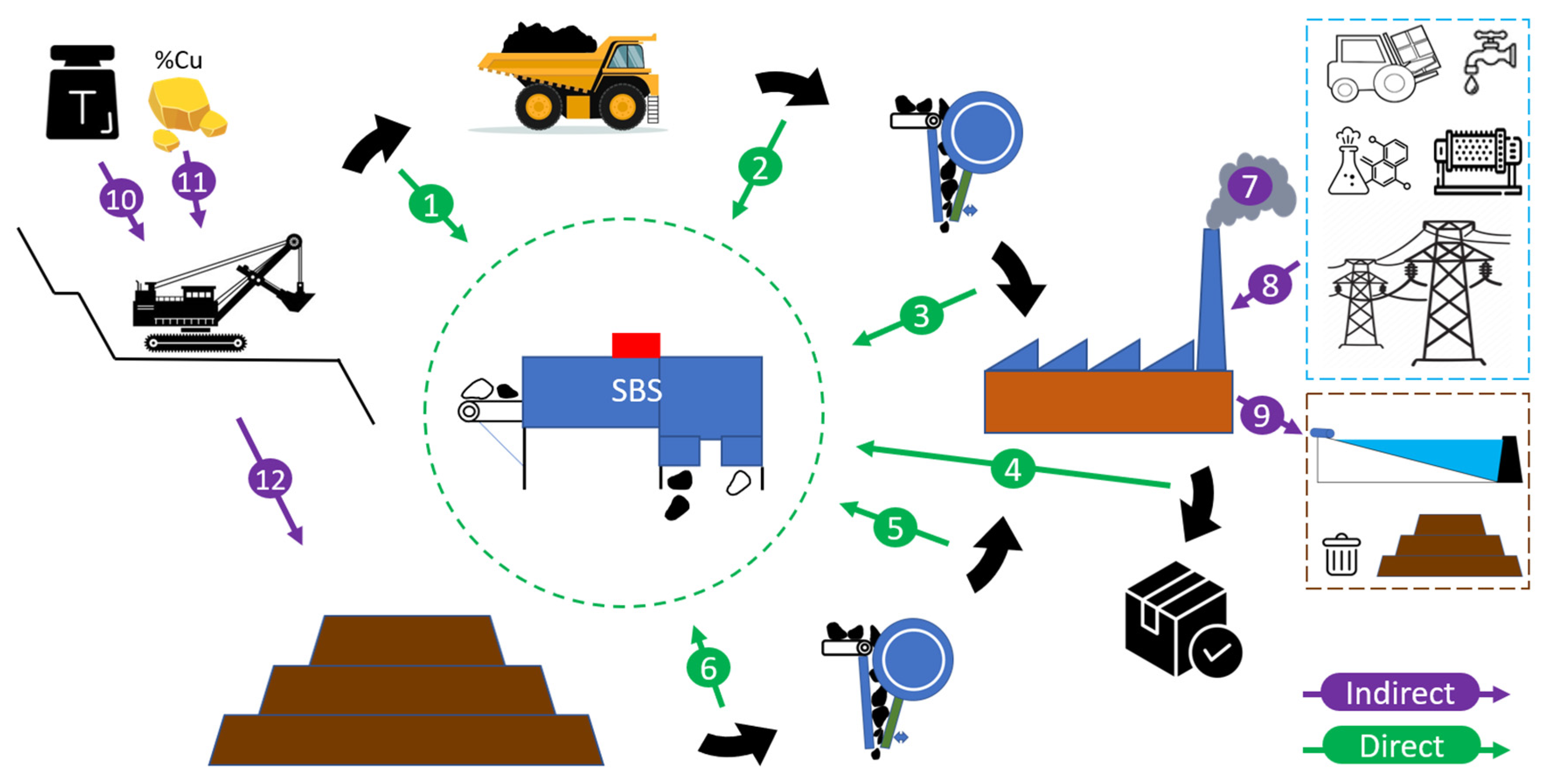

4. Impacts of Pre-Concentration in the Beneficiation Process

4.1. Case Study I: QZ Ohio Ore—Australia

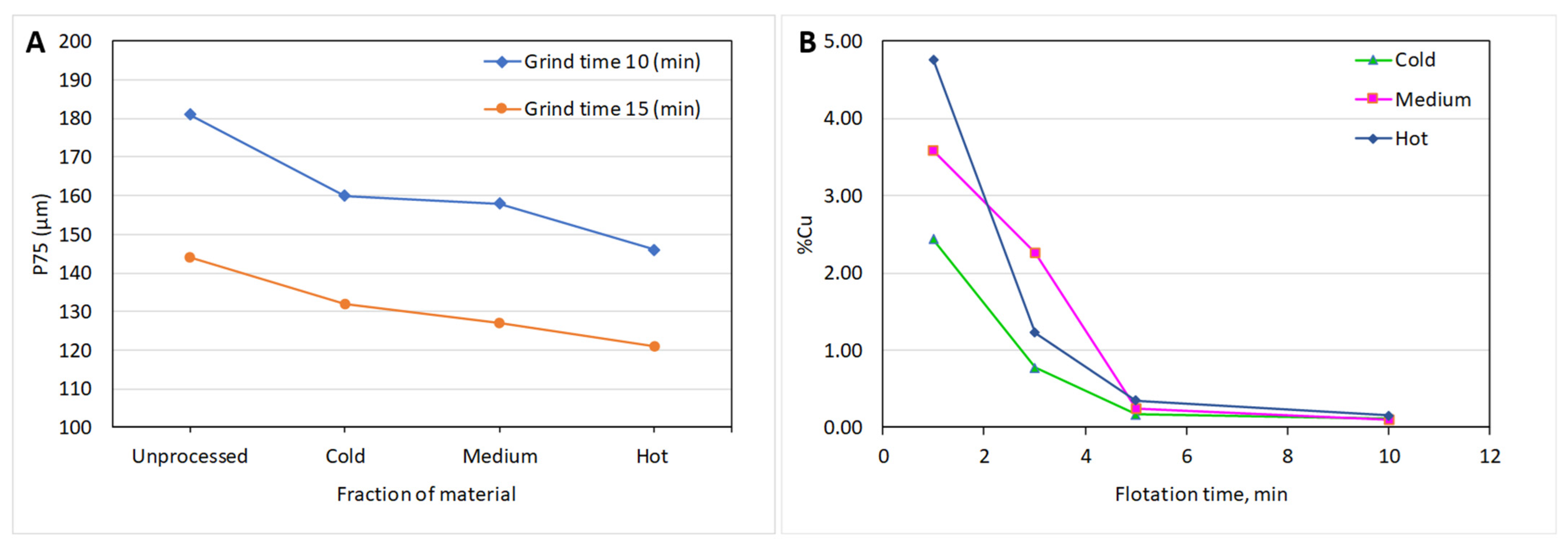

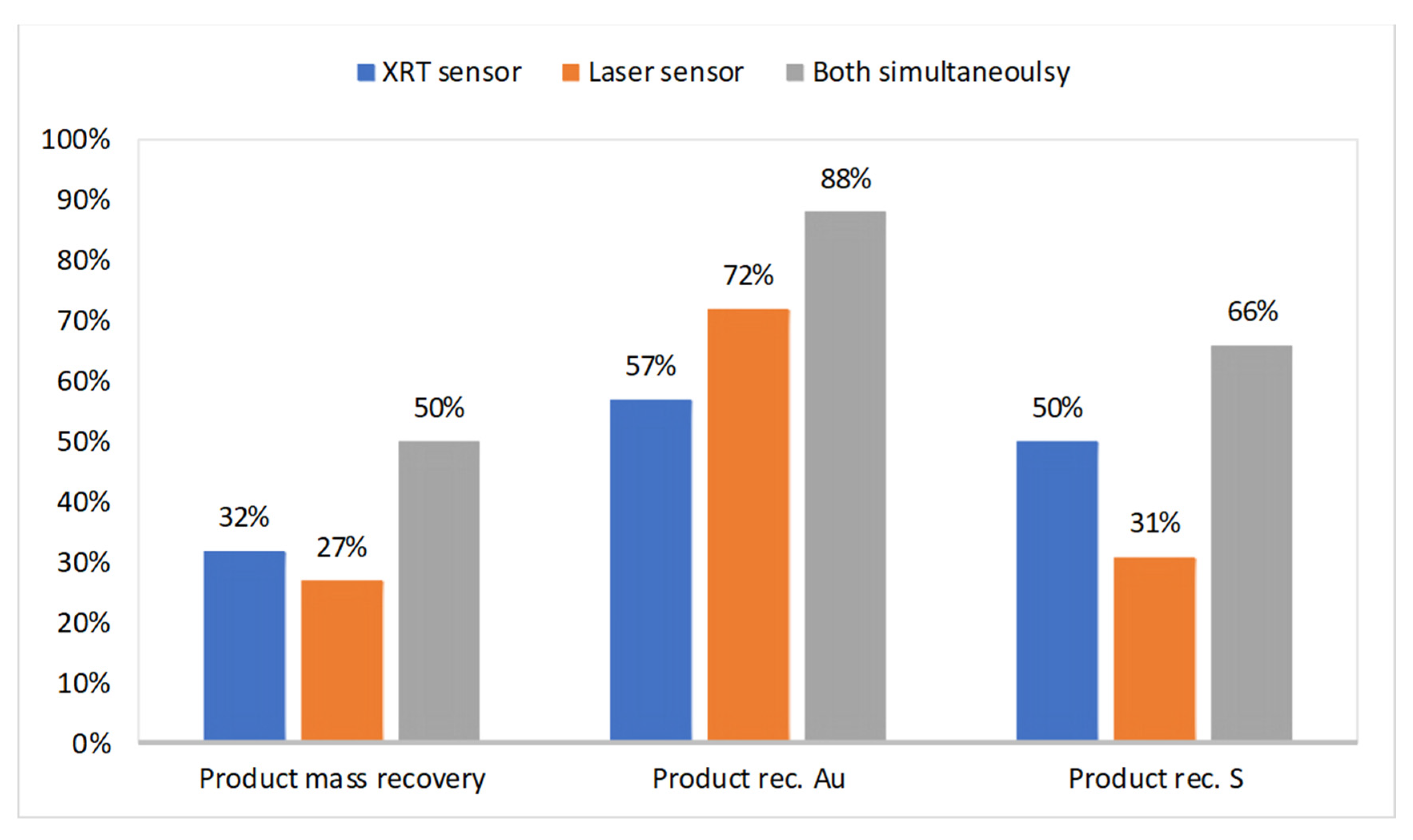

4.2. Case Study II: Polymetallic Ore—Aripuanã, Brazil

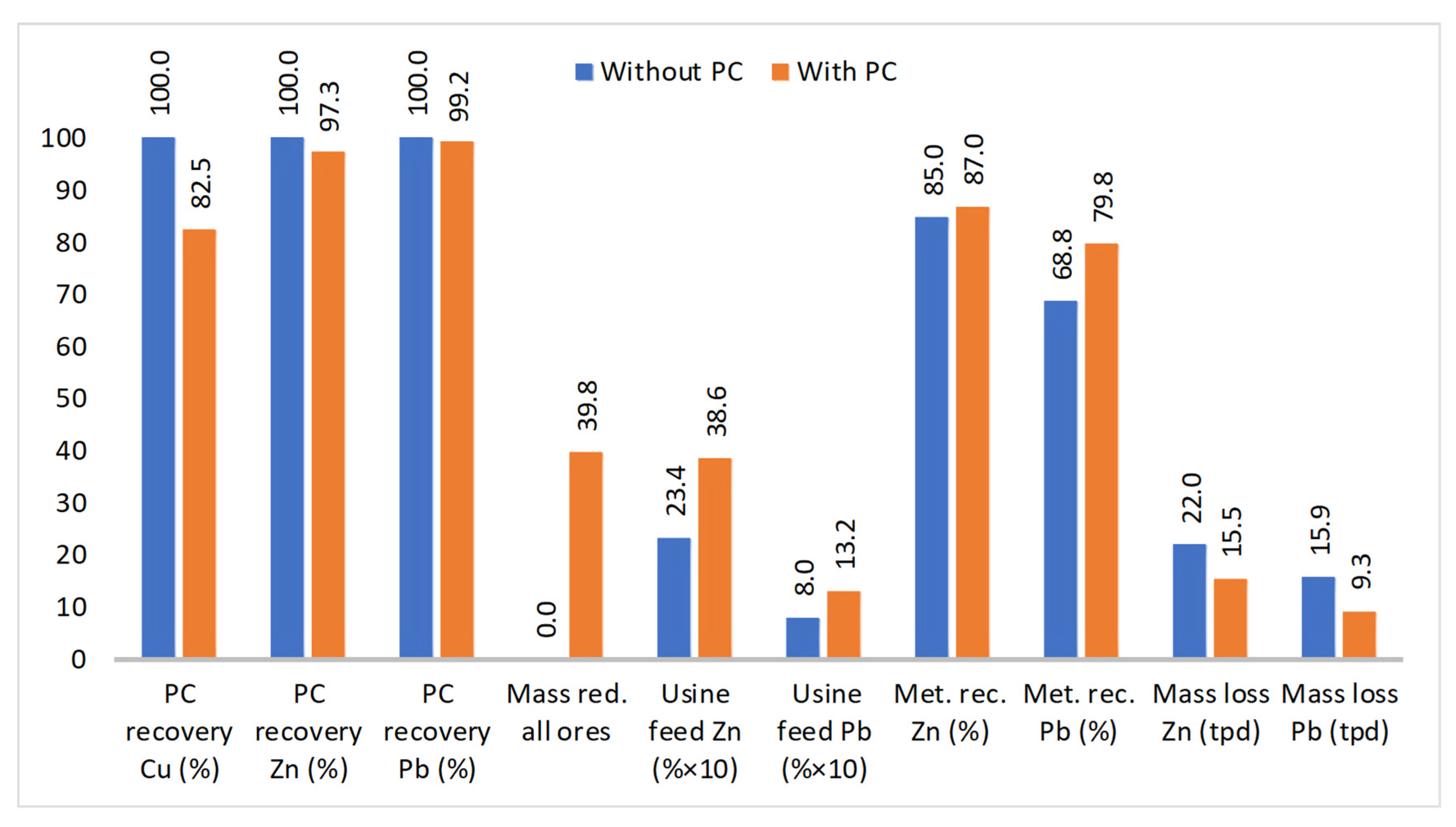

4.3. Case Study III: Córrego do Sítio Mine—Brazil

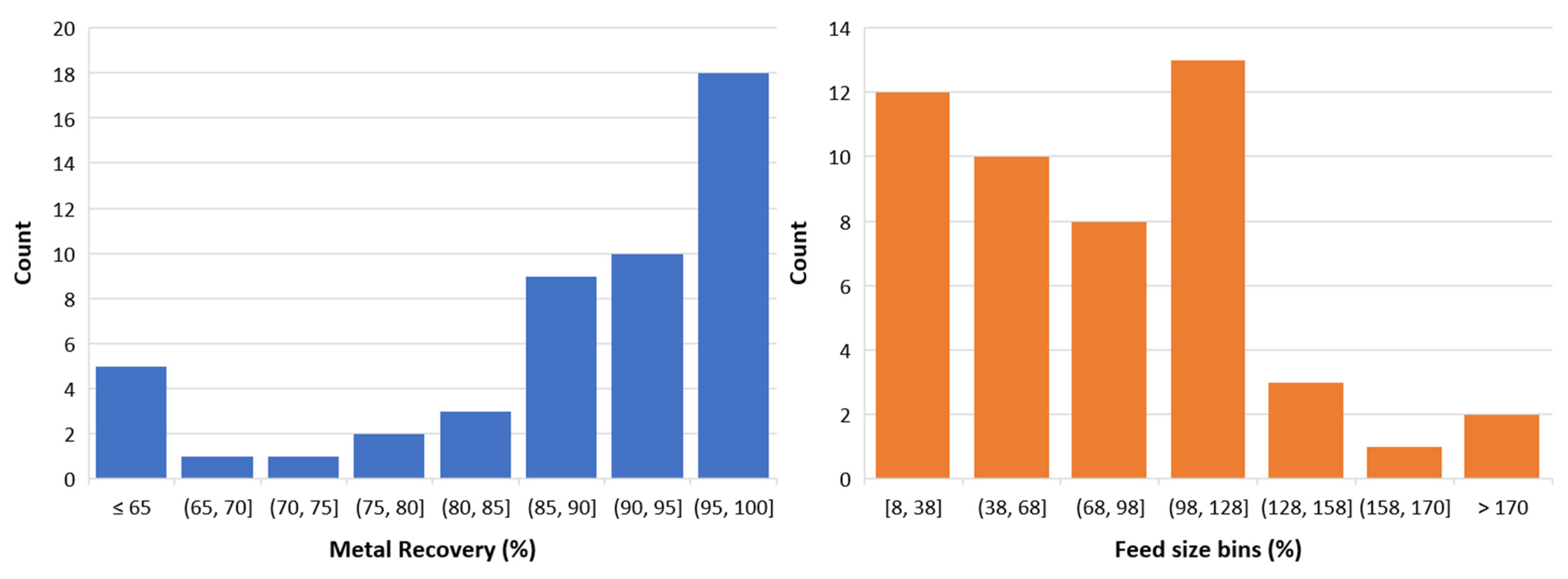

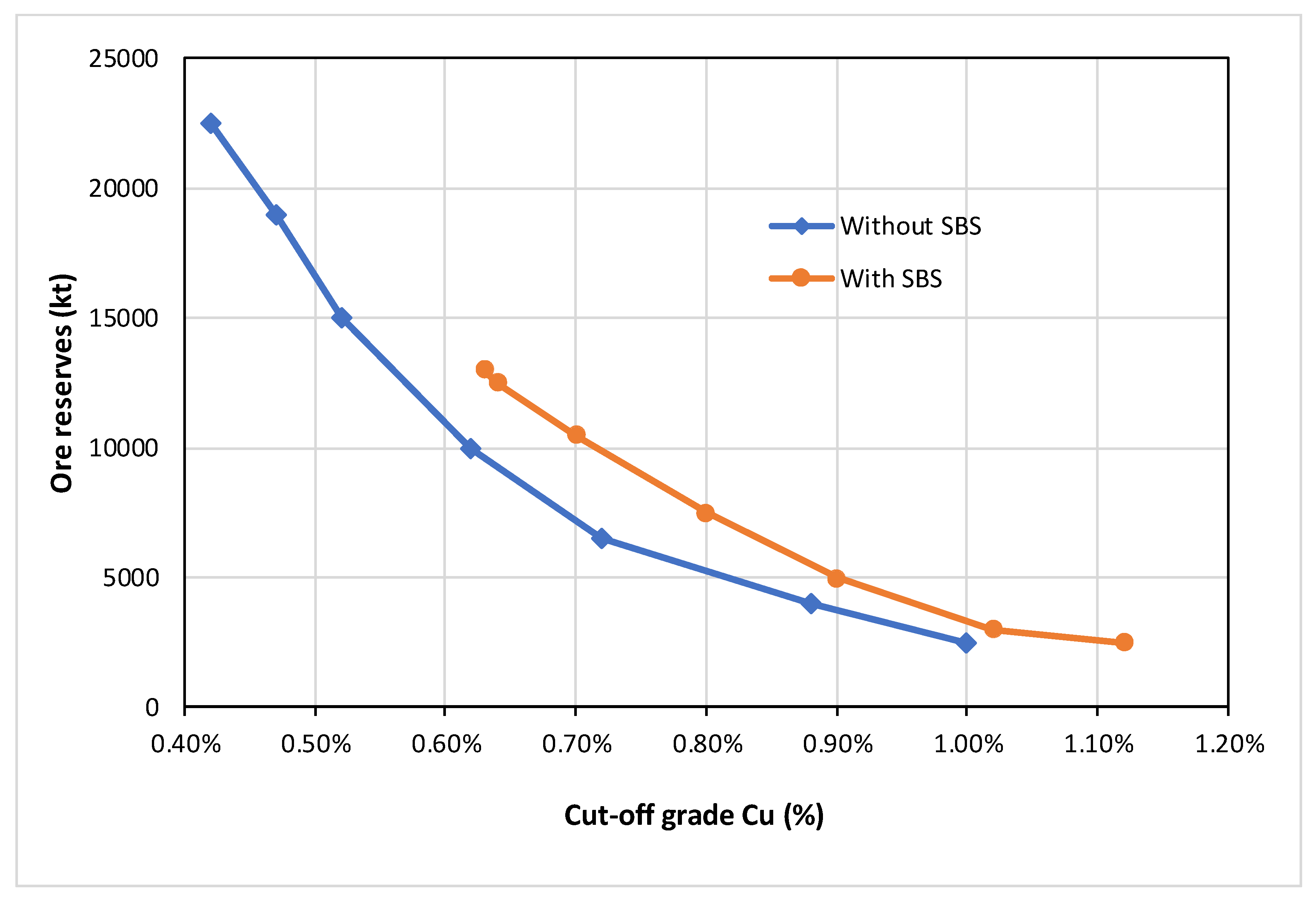

4.4. Case Study IV: Phu Kam Mine—Laos

4.5. Case Study V: San Rafael Tin Mine—Peru

- Value addition, through the possibility of treating the material below the cut-off grade (0.9% Sn). In other words, the SBS plant is fed with ore within 0.2%–1.1% Sn, allowing recovery until old marginal piles and generating a pre-concentrated plant feed with 1.9% Sn;

- The plant capacity was increased by 105 t/d, from 2950 to 3200 t/d;

- The plant metal recovery was increased from 90.5 before SBS to 92.5% after it;

- There was an increase in ore reserves, once the SBS feed was composed of 24% low-grade ore, contributing to the overall reserve tonnage and the mine life-span;

- The potential of acid mine drainage generation was reduced, because old stock piles could be recovered after the SBS implantation;

- Another important environmental feature, the tailing disposal, and consequently, the tailing storage facilities, was importantly reduced, replacing it with cheaper and safer dump piles.

4.6. Case Study VI: Souzmetallresource (SMR) Molybdenum Mines—Russia

5. Summary of Sensor-Based Sorting

5.1. Main Advantages and Limitations

5.2. Future Perspectives

- Reduction in overall energy consumption (electricity, fuels, etc.);

- Potential use of hydraulic transport systems (hydraulic hoisting);

- Feasibility of more productive bulk mining techniques, as greater ore dilution during extraction becomes viable;

- Opportunity to employ backfill techniques to both optimize mining and prevent future environmental subsidence issues.

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kumar, D.R.; Srinivas, R.D.; Ram, R.P.S. Magnetic Separation Studies for a Low Grade Siliceous Iron Ore Sample. Int. J. Min. Sci. Technol. 2013, 23, 1–5. [Google Scholar]

- Barros, K.S.; Vielmo, V.S.; Moreno, G.; Riveros, G.; Cifuentes, G.; Bernardes, A.M. Chemical Composition Data of the Main Stages of Copper Production from Sulfide Minerals in Chile: A Review to Assist Circular Economy Studies. Minerals 2022, 12, 250. [Google Scholar] [CrossRef]

- Bamber, A.S. Integrated Mining, Pre-Concentration and Waste Disposal Systems for the Increased Sustainability of Hard Rock Metal Mining. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2008. [Google Scholar]

- Hassanzadeh, A.; Safari, M.; Hoang, D.H.; Khoshdast, H.; Albijanic, B.; Kowalczuk, P.B. Technological Assessments on Recent Developments in Fine and Coarse Particle Flotation Systems. Miner. Eng. 2022, 180, 107509. [Google Scholar]

- Luo, X.; Kunzhong, H.; Zhang, Y.; He, P.; Zhang, Y. A Review of Intelligent Ore Sorting Technology and Equipment Development. Int. J. Miner. Metall. Mater. 2022, 29, 1647. [Google Scholar] [CrossRef]

- Mudd, G.M. The Sustainability of Mining in Australia: Key Production Trends and Their Environmental Implications for the Future; Research Report No RR5; Department of Civil Engineering, Monash University and Mineral Policy Institute: Melbourne, Australia, 2009; Available online: https://users.monash.edu.au/~gmudd/files/SustMining-Aust-Report-2009-Master.pdf (accessed on 6 February 2024).

- Bilal, M.; Park, I.; Hornn, V.; Ito, M.; Hassan, F.U.; Jeon, S.; Hiroyoshi, N. The Challenges and Prospects of Recovering Fine Copper Sulfides from Tailings Using Different Flotation Techniques: A Review. Minerals 2022, 12, 586. [Google Scholar] [CrossRef]

- Santander, M.; Valderrama, L. Recovery of Pyrite from Copper Tailings by Flotation. J. Mater. Res. Technol. 2019, 8, 4312–4317. [Google Scholar] [CrossRef]

- Baltar, C.A.M. Flotação em Nova Abordagem; UFPE: Recife, Brazil, 2021. [Google Scholar]

- Mondal, S.; Acharjee, A.; Mandal, U.; Saha, B. Froth Flotation Process and Its Application. Vietnam. J. Chem. 2021, 59, 417–425. [Google Scholar]

- Varela, J.J.; Brum, I.A.S. Reagentes e Equipamentos Aplicados ao Processo de Flotação no Tratamento de Minérios; XXII ENTMME/VII MSHMT: Ouro Preto, Brazil, 2007. [Google Scholar]

- Arvidson, B.R.; Wotruba, H. Ore Sorting. In Mineral Processing and Extractive Metallurgy: 100 Years of Innovation; Society for Mining Metallurgy and Exploration (SME): Englewood, CO, USA, 2014; pp. 209–221. [Google Scholar]

- Murphy, B.; Van Zyl, J.; Domingo, G. Underground Preconcentration by Ore Sorting and Coarse Gravity Separation. In Proceedings of the Narrow Vein Mining Conference, Perth, Australia, 26–27 March 2012. [Google Scholar]

- U.S. Geological Survey. Mineral Commodity Summaries 2023; U.S. Geological Survey: Washington, DC, USA, 2023. [Google Scholar]

- Dimitrijević, M.; Kostov, A.; Tasić, V.; Milosević, N. Influence of Pyrometallurgical Copper Production on the Environment. J. Hazard. Mater. 2009, 164, 892–899. [Google Scholar]

- Valeriano, C.M.; Dias, P.H.A.; Carvalho, M.O.; Heilbron, M. Recursos Minerais de Minas Gerais; RMMG—CODEMGE: Belo Horizonte, Brazil, 2018. [Google Scholar]

- Russo, M.L.C. Beneficiamento de Rejeito de Minério de Zinco. Master’s Thesis, Federal University of Ouro Preto, Ouro Preto, Brazil, 2007. [Google Scholar]

- Özçelik, S.; Ekmekçi, Z. Reducing Negative Effects of Oxidation on Flotation of Complex Cu–Zn Sulfide Ores. Minerals 2022, 12, 1016. [Google Scholar] [CrossRef]

- Luz, A.B.; Penna, M.T.M.; Souza Filho, L.G. Estudo do Beneficiamento do Minério de Cobre, Chumbo e Zinco de Palmeirópolis; Mines and Energy Ministry, Department of Mineral Production, Centro de Tecnologia Mineral—CETEM: Rio de Janeiro, Brazil, 1982. [Google Scholar]

- Brito, L.F.; Juliani, C.; Lago, S.B. O Depósito de Santa Maria e as Ocorrências de Metais de Base na Bacia do Camaquã. Geol. USP Série Cient. 2023, 23, 187–206. [Google Scholar] [CrossRef]

- Aguia Resourses. Andrade Copper Deposit—Updated Resource Estimate and Scoping Study Showing Positive Economics; ASX Market Announcements: Sydney, Australia, 2021. [Google Scholar]

- Medeiros, A.R.S.; Baltar, C.A.M. Importance of Collector Chain Length in Flotation of Fine Particles. Miner. Eng. 2018, 122, 179–184. [Google Scholar] [CrossRef]

- Chaves, A.P.; Leal Filho, L.S.; Braga, P.F.A. Flotação. In Tratamento de Minérios, 5th ed.; Luz, A.B., Sampaio, J.A., França, S.C.A., Eds.; CETEM: Rio de Janeiro, Brazil, 2010. [Google Scholar]

- Agheli, S.; Hassanzadeh, A.; Hassas, B.V.; Hasanzadeh, M. Effect of Pyrite Content of Feed and Configuration of Locked Particles on Rougher Flotation of Copper in Low and High Pyritic Ore Types. Int. J. Min. Sci. Technol. 2019, 28, 167–176. [Google Scholar] [CrossRef]

- Hassas, B.V.; Caliskan, H.; Guven, O.; Karakas, F.; Cinar, M.; Celik, M.S. Effect of Roughness and Shape Factor on Flotation Characteristics of Glass Beads. Colloids Surf. A Physicochem. Eng. Asp. 2016, 492, 88–99. [Google Scholar]

- Rao, S.R.; Labonte, G.; Finch, J.A. Electrochemistry in the Plant. In Innovations in Flotation Technology; Mavros, P., Matis, K.A., Eds.; NATO ASI Series: Kallithea, Greece, 1991; pp. 57–100. [Google Scholar]

- Shammas, N.K.; Bennett, G.F. Principles of Air Flotation Technology. In Handbook of Environmental Engineering; Wang, L.K., Shammas, N.K., Selke, W.A., Aulenbach, D.B., Eds.; Flotation Technology; Springer: New York, NY, USA, 2010; Volume 12, pp. 20–48. [Google Scholar]

- Bulatovic, S.M. Handbook of Flotation Reagents: Chemistry, Theory and Practice: Flotation of Sulfide Ores; Elsevier Science & Technology Book; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Nguyen, A.V. Froth Flotation. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Braga, A.S.; Souza Pinto, T.C.; Matai, P.H.L.S.; Leal Filho, L.S. Concentração Micelar Crítica e Concentração Crítica de Coalescência de Reagentes de Flotação. Ph.D. Thesis, University of São Paulo (USP-SP), São Paulo, Brazil, 2015. Available online: https://www2.ifrn.edu.br/ojs/index.php/HOLOS/article/view/3824/1281 (accessed on 11 December 2023).

- Kawatra, S.K. Fundamental Principles of Froth Flotation. In SME Mining Engineering Handbook, 3rd ed.; Darling, P., Ed.; Society for Mining Metallurgy and Exploration: Littleton, CO, USA, 2011; Volume 2. [Google Scholar]

- Michaux, B.; Rudolph, M.; Reuter, M.A. Challenges in Predicting the Role of Water Chemistry in Flotation through Simulation with an Emphasis on the Influence of Electrolytes. Miner. Eng. 2018, 125, 252–264. [Google Scholar]

- METSO. Process Water Recycling Plant. Available online: https://www.metso.com/portfolio/process-water-recycling-plant (accessed on 28 December 2023).

- Castro, S. Challenges in Flotation of Cu–Co Sulfide Ores in Sea Water. In The First International Symposium on Water in Mineral Processing; Society for Mining, Metallurgy & Exploration (SME): Littleton, CO, USA, 2012; pp. 29–40. [Google Scholar]

- Tabelin, C.B.; Park, I.; Phengsaart, T.; Jeon, S.; Villacorte-Tabelin, M.; Alonzo, D.; Yoo, K.; Ito, M.; Hiroyoshi, N. Copper and Critical Metals Production from Porphyry Ores and E-Wastes: A Review of Resource Availability, Processing/Recycling Challenges, Socio-Environmental Aspects, and Sustainability Issues. Resour. Conserv. Recycl. 2021, 170, 105610. [Google Scholar]

- Cetin, M.C.; Klein, B.; Futcher, W. A Conceptual Strategy for Effective Bulk Ore Sorting of Copper Porphyries: Exploiting the Synergy between Two Sensor Technologies. Miner. Eng. 2023, 201, 108182. [Google Scholar]

- CSIRO (Commonwealth Scientific and Industrial Research Organisation). MRI for Rapid Copper Ore Sorting. Available online: https://www.csiro.au/en/work-with-us/industries/mining-resources/Sensing/Ore-sorter (accessed on 8 November 2023).

- Tanaka, Y.; Miki, H.; Suyantara, G.P.W.; Aoki, Y.; Hirajima, T. Mineralogical Prediction on the Flotation Behavior of Copper and Molybdenum Minerals from Blended Cu–Mo Ores in Seawater. Minerals 2021, 11, 869. [Google Scholar] [CrossRef]

- Videla, A.R.; Morales, R.; Saint-Jean, T.; Gaete, L.; Vargas, Y.; Miller, J.D. Ultrasound Treatment on Tailings to Enhance Copper Flotation Recovery. Miner. Eng. 2016, 99, 89–95. [Google Scholar] [CrossRef]

- Aras, A.; Rasa, M.H. Investigation of Flotation Conditions for Cobalt Recovery from Mine Tailings. Min. Metall. Explor. 2023, 40, 939–948. [Google Scholar]

- Zhang, L.; Gao, J.; Khoso, S.A.; Liu, Y.; Tian, M. Interaction Mechanism of the Adopted Reagents in the Flotation Recovery of Sphalerite and Pyrite from a Galena Flotation Tailing: First-Principles Calculations. Colloids Surf. A Physicochem. Eng. Asp. 2021, 617, 126378. [Google Scholar]

- Amar, H.; Benzaazoua, M.; Elghali, A.; Taha, Y.; El Ghorfi, M.; Krause, A.; Hakkou, R. Mine Waste Rock Reprocessing Using Sensor-Based Sorting (SBS): Novel Approach toward Circular Economy in Phosphate Mining. Miner. Eng. 2023, 204, 108415. [Google Scholar]

- Arriagada, S.; Acuña, C.; Vera, M. New Technology to Improve the Recovery of Fine Particles in Froth Flotation Based on Using Hydrophobized Glass Bubbles. Miner. Eng. 2020, 156, 106364. [Google Scholar]

- Chen, P.; Chen, Y.; Liu, H.; Li, H.; Chai, X.; Lu, X.; Sun, W.; Wang, H.; Luo, Y.; Wang, X. Novel Approach for Fine Ilmenite Flotation Using Hydrophobized Glass Bubbles as the Buoyant Carrier. Minerals 2021, 11, 231. [Google Scholar] [CrossRef]

- Brill, C.; Verster, I.; Franks, G.V.; Forbes, L. Aerosol Collector Addition in Coarse Particle Flotation—A Review. Miner. Process. Extr. Metall. Rev. 2023, 44, 522–531. [Google Scholar]

- Patil, D.P.; Laskowski, J.S. Development of Zero Conditioning Procedure for Coal Reverse Flotation. Miner. Eng. 2008, 21, 373–379. [Google Scholar]

- Pattanaik, A.; Venugopal, R. Role of Surfactants in Mineral Processing: An Overview. In Surfactants and Detergents; Dutta, A.K., Ed.; IntechOpen: London, UK, 2019. [Google Scholar]

- Han, J.; Chen, P.; Liu, T.; Li, Y. Research and Application of Fluidized Flotation Units: A Review. J. Ind. Eng. Chem. 2023, 126, 50–68. [Google Scholar]

- Han, J.; Liu, T.; Li, Y.; Chen, P.; Yin, M.; Ma, M.; Evans, G.M. Bed Hydrodynamics of a New Three-Phase Fluidized Bed Flotation Column with Steel Ball Particles. Miner. Eng. 2022, 184, 107669. [Google Scholar]

- Awatey, B.; Thanasekaran, H.; Kohmuench, J.N.; Skinner, W.; Zanin, M. Optimization of Operating Parameters for Coarse Sphalerite Flotation in the HydroFloat Fluidised-Bed Separator. Miner. Eng. 2013, 50, 99–105. [Google Scholar]

- Jameson, G.J.; Emer, C. Coarse Chalcopyrite Recovery in a Universal Froth Flotation Machine. Miner. Eng. 2019, 134, 118–133. [Google Scholar] [CrossRef]

- Schulze, H.J. Physicochemical Elementary Processes in Flotation; Elsevier: Amsterdam, The Netherlands, 1984. [Google Scholar]

- Shatwell, D.G.; Murray, V.; Barton, A. Real-Time Ore Sorting Using Color and Texture Analysis. Int. J. Min. Sci. Technol. 2023, 33, 659–674. [Google Scholar] [CrossRef]

- Ergün, L.Ş.; Gülsoy, Ö.Y.; Gülsoy, G. Optical Sorting of Iron and Chromite Ores; Sensor Based Sorting: Aachen, Germany, 2012. [Google Scholar]

- Veras, M.M.; Young, A.S.; Born, C.R.; Szewczuk, A.; Bastos Neto, A.C.; Petter, C.O.; Sampaio, C.H. Affinity of Dual Energy X-Ray Transmission Sensors on Minerals Bearing Heavy Rare Earth Elements. Miner. Eng. 2020, 147, 106151. [Google Scholar] [CrossRef]

- Duffy, K.W.; Valery, A.; Jankovic, P.; Holtham, P. Integrating Bulk Ore Sorting into a Mining Operation to Maximise Profitability. In Proceedings of the MetPlant 2015: Plant Design and Operating Strategies—World’s Best Practice, Perth, Australia, 7–8 September 2015. [Google Scholar]

- Strauss, T. Ore Sorting in Mining; Association of Mining Analysts, Merlyn Consulting. 2016. Available online: http://merlyn-consulting.com/wp-content/uploads/2016/04/Ore-Sorting-in-Mining.pdf (accessed on 29 December 2023).

- Robben, M.; Knapp, H.; Dehler, M.; Wotruba, H. X-Ray Transmission Sorting of Tungsten Ore. In OCM 2013—Conference Proceedings; Beyerer, J., León, F.P., Längle, T., Eds.; Scientific Publishing: Karlsruhe, Germany, 2013; pp. 245–258. [Google Scholar]

- Ketelhodt, L.; Bergman, C. Dual Energy X-Ray Transmission Sorting of Coal. In Proceedings of the 16th International Coal Preparation Congress, Lexington, KY, USA, 25–30 April 2010. [Google Scholar]

- Nienhaus, K.; Vallone, B.; Renzi, F.; Wiedenmann, J.; Nienhaus, G.U. Crystallization and Preliminary X-Ray Diffraction Analysis of the Red Fluorescent Protein eqFP611. Acta Crystallogr. D 2003, 59, 1253–1255. [Google Scholar] [CrossRef]

- Scuri, A.E. Fundamentos da Imagem Digital; Tecgraf/PUC-Rio: Rio de Janeiro, Brazil, 2002. [Google Scholar]

- Kolacz, J. Sensor Based Sorting with Signal Pattern Recognition: The New Powerful Tool in Mineral Processing. In Proceedings of the XXVII International Mineral Processing Congress, Santiago, Chile, 20–24 October 2014; pp. 106–115. [Google Scholar]

- McMillan, N. Laser-Induced Breakdown Spectroscopy (LIBS); SERC, National Science Foundation. 2023. Available online: https://serc.carleton.edu/msu_nanotech/methods/libs.html (accessed on 2 January 2024).

- Wotruba, H. Sensor Sorting Technology—Is the Minerals Industry Missing a Chance? In Proceedings of the XXIII International Mineral Processing Congress, Istanbul, Turkey, 3–8 September 2006. [Google Scholar]

- Robben, C.; Wotruba, H. Review Sensor-Based Ore Sorting Technology in Mining—Past, Present and Future. Minerals 2019, 9, 523. [Google Scholar] [CrossRef]

- Clark, R.N. Spectroscopy of Rocks and Minerals, and Principles of Spectroscopy. In Manual of Remote Sensing; Rencz, A.N., Ed.; John Wiley & Sons: New York, NY, USA, 1999; Volume 3, pp. 3–58. [Google Scholar]

- Robben, M.; Wotruba, H. Near-Infrared Sorting for Minerals; RWTH Aachen University, Department of Mineral Processing: Aachen, Germany, 2010. [Google Scholar]

- Jacq, K.; Rapuc, W.; Benoit, A.; Coquin, D.; Fanget, B.; Perrette, Y.; Sabatier, P.; Wilhelm, B.; Debret, M.; Arnaud, F. Sedimentary structure discrimination with hyperspectral imaging in sediment cores. Sci. Total Environ. 2022, 817, 152018. [Google Scholar] [CrossRef] [PubMed]

- Teodoro, L.P.R.; Estevão, R.; Santana, D.C.; Oliveira, I.C.; Lopes, M.T.G.; Azevedo, G.B.; Rojo Baio, F.H.; Silva Junior, C.A.; Teodoro, P.E. Eucalyptus species discrimination using hyperspectral sensor data and machine learning. Forests 2024, 15, 39. [Google Scholar] [CrossRef]

- Dalm, M.; Buxton, M.W.N.; Van Ruitenbeek, F.J.A. Ore–Waste Discrimination in Epithermal Deposits Using Near-Infrared to Short-Wavelength Infrared (NIR-SWIR) Hyperspectral Imagery. Math. Geosci. 2019, 51, 849–875. [Google Scholar] [CrossRef]

- Tuşa, L.; Kern, M.; Khodadadzadeh, M.; Blannin, R.; Gloaguen, R.; Gutzmer, J. Evaluating the performance of hyperspectral short-wave infrared sensors for the pre-sorting of complex ores using machine learning methods. Miner. Eng. 2020, 146, 106150. [Google Scholar] [CrossRef]

- Okada, N.; Nozaki, H.; Nakamura, S.; Manjate, E.P.A.; Gebretsadik, A.; Ohtomo, Y.; Arima, T.; Kawamura, Y. Optimizing multi-spectral ore sorting incorporating wavelength selection utilizing neighborhood component analysis for effective arsenic mineral detection. Sci. Rep. 2024, 14, 11544. [Google Scholar] [CrossRef]

- Batchelor, A.R.; Ferrari-John, R.S.; Katrib, J.; Udoudo, O.; Jones, D.A.; Dodds, C.; Kingman, S.W. Pilot scale microwave sorting of porphyry copper ores: Part 1–Laboratory investigations. Miner. Eng. 2016, 98, 303–327. [Google Scholar] [CrossRef]

- Rizmanoski, V. The Effect of Microwave Heating on Ore Sorting. Ph.D. Thesis, University of Queensland, Brisbane, Australia, 2012. [Google Scholar]

- Ferrari-John, R.S.; Batchelor, A.R.; Katrib, J.; Dodds, C.; Kingman, S.W. Understanding selectivity in radio frequency and microwave sorting of porphyry copper ores. Int. J. Miner. Process. 2016, 155, 64–73. [Google Scholar] [CrossRef]

- Magnetic Resonance. Nextore LTD. Our Technology. Silverwater-Australia. 2023. Available online: https://nextore.com.au/technology/ (accessed on 8 November 2023).

- Vatcha, M.T.; Cochrane, L.B.; Rousell, D.H. Pre-concentration by magnetic sorting of Ni-Cu ore at Whistle mine, Sudbury, Canada. Trans. Inst. Min. Metall. C Miner. Process. Extr. Metall. 2000, 109, 156–160. [Google Scholar] [CrossRef]

- YouTube. Future Materials. Magnetic Separation. Available online: https://www.youtube.com/watch?v=y0-FQ423gAE (accessed on 14 February 2023).

- Li, M.; Caushaj, A.; Silva, R.; Lowther, D. A neural network for electromagnetic based ore sorting. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2018, 37, 691–703. [Google Scholar]

- Kattentidt, H.U.R.; de Jong, T.P.R.; Dalmijn, W.L. Multi sensor identification and sorting of bulk solids. Control. Eng. Pract. 2011, 11, 41–47. [Google Scholar]

- Wheeler, M.G.B. The development of a model for the simulation of the radiometric sorting of gold and uranium ores. J. S. Afr. Inst. Min. Metall. 1989, 89, 313–322. [Google Scholar]

- Clark, G.J.; Dickson, B.L.; Gray, F.E. Ore Sorting Using Natural Gamma. Radiation. Patent Code 16034794, 6 July 1978. [Google Scholar]

- Silva, D.P. Ore Sorting Technology in Cariba Mining. In the Mine. 29 September 2021. Available online: https://www.inthemine.com.br/site/tecnologia-ore-sorting-na-mineracao-caraiba/ (accessed on 8 November 2023).

- Fickling, R.S. An introduction to the rados XRT ore sorter. In Proceedings of the 6th Southern African Base Metals Conference, Phalaborwa, South Africa, 18–22 July 2011. [Google Scholar]

- Raman, C.V.; Jayaraman, A. The luminescence of diamond and its relation to crystal structure. Proc. Indian Acad. Sci. (Math. Sci.) 1950, 32, 65. [Google Scholar]

- Van der Westhuyzen, P.; Bouwer, W.; Jakins, A. Current Trends in the Development of New or Optimization of Existing Diamond Processing Plants, with Focus on Beneficiation. J. S. Afr. Inst. Min. Metall. 2014, 114, 537–546. [Google Scholar]

- Mironov, V.P.; Emelyanova, A.S.; Shabalin, S.A.; Bubyr, E.V.; Kazakov, L.V.; Martynovich, E.F. X-ray Luminescence in Diamonds and Its Application in Industry. AIP Conf. Proc. 2021, 2392, 020010. [Google Scholar]

- Robben, C.; Condori, P.; Pinto, A.; Machaca, R.; Takala, A. X-Ray-Transmission-Based Ore Sorting at the San Rafael Tin Mine. Miner. Eng. 2020, 145, 105870. [Google Scholar]

- Dias Júnior, E.A. Análise de Dados de Rochas de Cromita Visando a Melhoria de um Algoritmo de Classificação Baseada em Sensores; Monograph, Federal University of Minas Gerais: Belo Horizonte, Brazil, 2023. [Google Scholar]

- Amorim Júnior, G.S. Estudo da Aplicação de ore Sorting Para Minério Silicatado de Zinco. Master’s Thesis, Federal University of Minas Gerais, Belo Horizonte, Brazil, 2022. [Google Scholar]

- Peukert, D.; Xu, C.; Dowd, P. A Review of Sensor-Based Sorting in Mineral Processing: The Potential Benefits of Sensor Fusion. Minerals 2022, 12, 1364. [Google Scholar] [CrossRef]

- Wilkinson, S. Techniques for Coarse Particle Beneficiation of Some Gold Ores and Methods of Determining Potential for Sorting Any Gold Operation. In Proceedings of the 17th Annual Meeting of The Canadian Mineral Processors—CIM, Ottawa, ON, Canada, 13–31 January 1985; pp. 258–284. [Google Scholar]

- Sivamohan, R.; Forssberg, E. Electronic Sorting and Other Pre-Concentration Methods. Miner. Eng. 1991, 4, 797–814. [Google Scholar] [CrossRef]

- Collins, D.N.; Bonney, C.F. The Separation of Coarse Particles (>1 mm) Using Sorting Methods Based on Optical, Electrical, Gravity, and Magnetic Processes; MIRO: West Yorkshire, UK, 1995; Volume 18. [Google Scholar]

- Kowalcyk, P. Radiometric Ore Sorting Study, South Deep Mine; Placer Dome Internal Report; Placer Dome: Vancouver, BC, Canada, 2002. [Google Scholar]

- Neto, D.J.; Bergerman, M.G.; Young, A.S.; Petter, C.O. Pre-Concentration Potential Evaluation for a Silicate Zinc Ore by Density and Sensor-Based Sorting Methods. Rev. Esc. Minas 2019, 72, 335–343. [Google Scholar] [CrossRef]

- Kern, M.; Tusa, L.; Leißner, T.; van den Boogaart, K.G.; Gutzmer, J. Optimal Sensor Selection for Sensor-Based Sorting Based on Automated Mineralogy Data. J. Clean. Prod. 2019, 234, 1144–1152. [Google Scholar] [CrossRef]

- Jin, J.; Lin, C.-L.; Miller, J.D.; Zhao, C.; Li, T. X-Ray Computed Tomography Evaluation of Crushed Copper Sulfide Ore for Pre-Concentration by Ore Sorting. Min. Metall. Explor. 2022, 39, 13–21. [Google Scholar] [CrossRef]

- Cardenas-Vera, A.; Hesse, M.; Möckel, R.; Merker, R.G.; Heinig, T.; Van Phan, Q. Investigation of Sensor-Based Sorting and Selective Comminution for Pre-Concentration of an Unusual Parisite-Rich REE Ore, South Namxe, Vietnam. Miner. Eng. 2022, 177, 107371. [Google Scholar] [CrossRef]

- Valente, B.A.; Bechir, J.L.C.; Silva, T.A.V.D.; Pina, P.D.S.; Souza, A.D.D.; Mazzinghy, D.B. Aplicação de Tecnologia de Ore Sorting para Aproveitamento de Minérios de Baixo Teor de Zinco em Vazante/MG. In Proceedings of the XXVIII National Meeting of Mineral Treatment and Extractive Metallurgy, Belo Horizonte, Brazil, 4–8 November 2019. [Google Scholar]

- Moreira, B.H.M.; Uehara, B.H.; Neto, D.J.; Bergerman, M.G. Avaliação do Consumo de Energia em Circuitos de Moagem Alimentados com Produtos de Pré-concentração de Minérios de Vanádio e Cobre. In Proceedings of the XXVII National Meeting of Mineral Treatment and Extractive Metallurgy, Belem, Brazil, 23–27 October 2017. [Google Scholar]

- Valery, W.; Duffy, K.A.; Prati, F.; Reple, A.C.S.; Holtham, P. Evaluation of Bulk Ore Sorting for Pre-concentration of Copper Ore at Pan Aust Phu Kham Operation. In Proceedings of the 24th World Mining Congress, Rio de Janeiro, Brazil, 18–21 October 2016. [Google Scholar]

- Sanches, J.G.; Neto, D.J.; Bergerman, M.G. Comparação das Etapas de Flotação e Lixiviação de um Minério Silicatado de Zinco entre Circuito com e sem Pré-concentração. In Proceedings of the XXVIII National Meeting of Mineral Treatment and Extractive Metallurgy, Belo Horizonte, Brazil, 4–8 November 2019. [Google Scholar]

- Filippov, L.O.; Filippova, I.V.; Crumiere, G.; Sousa, R.; Leite, M.M.; Sousa, A.B.; Korbel, C.; Tripathy, S.K. Separation of Lepidolite from Hard-rock Pegmatite Ore via Dry Processing and Flotation. Miner. Eng. 2022, 187, 107768. [Google Scholar] [CrossRef]

- Fawcett, T. An Introduction to ROC Analysis. Pattern Recognit. Lett. 2006, 27, 861–874. [Google Scholar] [CrossRef]

- Ooms, D.; Palm, R.; Leemans, V.; Destain, M.F. A Sorting Optimization Curve with Quality and Yield Requirements. Pattern Recognit. Lett. 2010, 31, 983–990. [Google Scholar] [CrossRef]

- Gülcan, E.; Gülsoy, Ö.Y. Performance Evaluation of Optical Sorting in Mineral Processing—A Case Study with Quartz, Magnesite, Hematite, Lignite, Copper and Gold Ores. Int. J. Miner. Process. 2017, 169, 129–141. [Google Scholar]

- Santos, E.G. Análise da Performance dos Sensores Óptico e por Transmitância de Raios-X no Processo de Classificação de Calcário em Mina de Caçapava do Sul/RS. Master’s Thesis, Federal University of Pampa, Bagé, Brazil, 2018. [Google Scholar]

- Paranhos, R.S.; Santos, E.G.; Veras, M.M.; Guadagnin, F.; Pasetto, G.A. Performance Analysis of Optical and X-Ray Transmitter Sensors for Limestone Classification in the South of Brazil. J. Mater. Res. Technol. 2020, 9, 1305–1313. [Google Scholar] [CrossRef]

- Lessard, J.; Sweetser, W.; Bartram, K.; Figueroa, J.; Mchugh, L. Bridging the Gap: Understanding the Economic Impact of Ore Sorting on a Mineral Processing Circuit. Miner. Eng. 2016, 91, 92–99. [Google Scholar] [CrossRef]

- Lopes, L.M.C.E.; Pina, P.S.; Oliveira, A.C.R.; Mayrink, A.C.S. Aplicação da Tecnologia de Ore Sorting para Pre-concentração de Minérios Sulfetados Polimetálicos de Aripuanã. In Proceedings of the XIX National Meeting of Mineral Treatment and Extractive Metallurgy, Rio de Janeiro, Brazil, 25–28 September 2022. [Google Scholar]

- Assis, V.M.; Henriques, A.B.; Lemos, M.G.; Dumont, J.A. Technological Innovation in Córrego do Sítio Mineração—A Study of Technical and Economic Aspects by Using Sensor-Based Sorting for Refractory Gold Ore. REM Int. Eng. J. 2021, 74, 117–125. [Google Scholar]

- Reple, A.C.S. Bulk Ore Sorter: Um Estudo de Caso para a Mina de Phu Klam. Master’s Thesis, Federal University of São Paulo, São Paulo, Brazil, 2017. [Google Scholar]

- Lessard, J.; de Bakker, J.; McHugh, L. Development of Ore Sorting and Its Impact on Mineral Processing Economics. Miner. Eng. 2014, 65, 88–97. [Google Scholar] [CrossRef]

- Li, G.; Klein, B.; Sun, C.; Kou, J. Insight in Ore Grade Heterogeneity and Potential of Bulk Ore Sorting Application for Block Cave Mining. Miner. Eng. 2021, 170, 106999. [Google Scholar]

- Cetin, M.C.; Li, G.; Klein, B.; Futcher, W. Key Factors Determining the Bulk Ore Sorting Potential in a Caving Mine. Miner. Eng. 2023, 201, 108237. [Google Scholar]

- Nadolski, S.; Samuels, M.; Klein, B.; Hart, C.J.R. Evaluation of Bulk and Particle Sensor-Based Sorting Systems for the New Afton Block Caving Operation. Miner. Eng. 2018, 121, 169–179. [Google Scholar]

- Xu, Y.; Klein, B.; Li, G.; Gopaluni, B. Evaluation of Logistic Regression and Support Vector Machine Approaches for XRF Based Particle Sorting for a Copper Ore. Miner. Eng. 2023, 192, 108003. [Google Scholar]

- Jia, W.; Zhang, Z.; Shan, Q.; Zhang, J.; Hei, D.; Zhang, Y.; Sun, A.; Liao, M.; Ling, Y. Determination of Molybdenum in Geological Ores by Laser-Induced Breakdown Spectroscopy (LIBS) with Support Vector Machine Regression (SVMR) and Data Preprocessing. Anal. Lett. 2024, 57, 2004–2017. [Google Scholar]

- Konstantinidis, F.K.; Sifnaios, S.; Tsimiklis, G.; Mouroutsos, S.G.; Amditis, A.; Gasteratos, A. Multi-sensor Cyber-Physical Sorting System (CPSS) Based on Industry 4.0 Principles: A Multi-functional Approach. Procedia Comput. Sci. 2023, 217, 227–237. [Google Scholar]

- Tan, W.; Duan, Q.; Yao, L.; Li, J. A Sensor Combination Based Automatic Sorting System for Waste Washing Machine Parts. Resour. Conserv. Recycl. 2022, 181, 106270. [Google Scholar]

- Koschinsky, A.; Heinrich, L.; Boehnke, K.; Cohrs, J.C.; Markus, T.; Shani, M.; Singh, P.; Stegen, K.S.; Werner, W. Deep-Sea Mining: Interdisciplinary Research on Potential Environmental, Legal, Economic, and Societal Implications. Integr. Environ. Assess. Manag. 2018, 14, 672–691. [Google Scholar]

- Mizell, K.; Hein, J.R.; Au, M.; Gartman, A. Estimates of Metals Contained in Abyssal Manganese Nodules and Ferromanganese Crusts in the Global Ocean Based on Regional Variations and Genetic Types of Nodules. In Perspectives on Deep-Sea Mining; Sharma, R., Ed.; Springer: Cham, Switzerland, 2022; pp. 53–80. [Google Scholar]

- Hornsey, M.J.; Fielding, K.S.; Harris, E.A.; Bain, P.G.; Grice, T.; Chapman, C.M. Protecting the Planet or Destroying the Universe? Understanding Reactions to Space Mining. Sustainability 2022, 14, 4119. [Google Scholar] [CrossRef]

- Deberdt, R.; Le Billon, P. Outer Space Mining: Exploring Techno-Utopianism in a Time of Climate Crisis. Ann. Am. Assoc. Geogr. 2023, 113, 1878–1899. [Google Scholar]

| Type | Mineral | Formula |

|---|---|---|

| Sulfides | Chalcocite | Cu2S |

| Covellite | CuS | |

| Chalcopyrite | CuFeS2 | |

| Bornite | Cu5FeS4 | |

| Stannite | Cu2FeSnS4 | |

| Enargite | Cu3AsS4 | |

| Tennantite | Cu12As4S13 | |

| Famatinite | Cu3SbS4 | |

| Tetrahedrite | Cu12Sb4S13 | |

| Others | Cuprite | Cu2O |

| Tenorite | CuO | |

| Chrysocolla | (Cu,Al)2H2Si2O5(OH)4·nH2O | |

| Atacamite | Cu2Cl(OH)3 | |

| Malachite | Cu2CO3(OH)2 | |

| Azurite | Cu3(CO3)2(OH)2 |

| Step | Considerations | |

|---|---|---|

| 1 | Preparation | - Material may need to be washed, depending on the property being detected. - Key factors: removing surface contaminants, improve sensor accuracy. |

| 2 | Feeding | - Preliminary classification based on a specific particle size range (typically maintaining a 3:1 ratio between larger and smaller particles). - Key factors: belt or feeder fill factor, feeding speed, and liberation degree. |

| 3 | Presentation to the sensor | - Proper arrangement of the material on the conveyor belt is critical. - Key factors: fill factor of the belt and uniformity of particle distribution, distance between the samples and the sensor, conveyor belt velocity. |

| 4 | Sensor detection | - Detectable contrast between particles is essential. - Appropriate sensor selection (or combination of sensors) must align with material properties. - Key factors: sensor resolution, calibration and recalibration, especially to account for deposit variations. |

| 5 | Separation | - Considerations include the quality of the air feeding the ejection system and the type of separation device used to ensure precise and efficient material sorting. |

| Spectrum | Detected Features | Penetration | Interaction with | Examples of Applications |

|---|---|---|---|---|

| X-ray transmission (XRT) | Primary features, atomic density | Deep | Transmission of RX through the material | Metals, precious metals, industrial minerals, coal, diamonds, recycling |

| Visible light (VIS) | Secondary features | Superficial | Reflection, absorption, transmission, luminescence | Industrial minerals, precious stones, recycling, diamonds |

| Near-infrared (NIR) | Secondary features | Superficial | Monochromatic reflection and absorption | Base metal ores, industrial minerals, precious stones, diamonds |

| Infrared (IR) + microwaves | Secondary features | Superficial | Heat dissipation after microwave submission | Metals, industrial minerals |

| Radiowaves [magnetic resonance (MR)] | Primary features, mineralogy | Deep | Excitation and detection of spectral radiowave lines | Bulk ore sorting (BOS), calcopyrite |

| Alternating current (AC) | Secondary features | Deep | Conductivity, magnetic susceptibility | Iron and other base metals, recycling |

| Category | Mineral | Temp. (°C) | Time (min) |

|---|---|---|---|

| Easy heating | FeS2 | 1019 | 6.75 |

| PbS | 956 | 7.00 | |

| CuFeS2 | 920 | 1.00 | |

| Hard heating | SiO2 | 79 | 7.00 |

| Al2O3 | 78 | 4.50 | |

| KAlSi3O8 | 67 | 7.00 | |

| CaCO3 | 74 | 4.25 |

| Mineral | Category | MR Sensitivity |

|---|---|---|

| Chalcopyrite | Copper | High |

| Cubanite | Copper | High |

| Covellite | Copper | Medium |

| Chalcocite | Copper | Medium |

| Enargite | Copper | Low |

| Tennantite | Copper | Low |

| Cuprite + delafossites | Copper | High |

| Tenorite | Copper | Low |

| Arsenopyrite | Arsenic | High |

| Orpiment | Arsenic | High |

| Realgar | Arsenic | High |

| Lollingite | Arsenic | High |

| Niccolite | Nickel/Arsenic | Medium |

| Hematite | Iron | High |

| Magnetite | Iron | Very High |

| Maghemite | Iron | High |

| Pyrrhotite | Iron | High |

| Bismuthinite + others | Several | Medium |

| Stibnite + others | Several | High |

| Zircon | Zircon | Low |

| Cobaltite | Cobalt | High |

| Spectrum | Detected Features | Penetration | Interaction with | Examples of Applications |

|---|---|---|---|---|

| Gamma-radiation | Secondary features, emission | Deep | Natural gamma radiation | Uranium and other radioactive minerals, precious metals |

| X-ray fluorescence (XRF) | Secondary features, emission | Superficial | Electrons of external atomic layer | Diamonds, sample analysis |

| X-ray luminescence (XRL) | Secondary features | Superficial | Excitation of luminescence by X-rays | Diamonds |

| Ultraviolet (UV) | Secondary features | Superficial | Reflection, absorption, transmission, luminescence | Diamonds |

| Particle Size Interval (mm) | Capacity Limit (t/h×m) | No. of Cases | % |

|---|---|---|---|

| 5.6–8 | 15 | 1 | 2.04% |

| 8–20 | 30 | 1 | 2.04% |

| 20–40 | 60 | 13 | 26.53% |

| >40 | >110 | 34 | 69.39% |

| 49 | 100.00% |

| Feed | Product | Waste |

|---|---|---|

| Positive fraction | True positives (TPs) | False negatives (FNs) |

| Negative fraction | False positives (FPs) | True negatives (TNs) |

| ∑ | Product fraction (P) | Waste fraction (N) |

| Mine A | Mine B | ||

|---|---|---|---|

| Relaxed threshold | Metal recovery | 86.4% | 65.5% |

| Concentration factor | 8.8 | 19.8 | |

| Waste fraction | 90.0% | 93.7% | |

| Moderate threshold | Metal recovery | 88.0% | 79.7% |

| Concentration factor | 5.1 | 10.2 | |

| Waste fraction | 82.9% | 79.2% | |

| Aggressive threshold | Metal recovery | 93.4% | 87.0% |

| Concentration factor | 2.9 | 6.0 | |

| Waste fraction | 66.5% | 54.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, E.G.d.; Brum, I.A.S.d.; Ambrós, W.M. Techniques of Pre-Concentration by Sensor-Based Sorting and Froth Flotation Concentration Applied to Sulfide Ores—A Review. Minerals 2025, 15, 350. https://doi.org/10.3390/min15040350

Santos EGd, Brum IASd, Ambrós WM. Techniques of Pre-Concentration by Sensor-Based Sorting and Froth Flotation Concentration Applied to Sulfide Ores—A Review. Minerals. 2025; 15(4):350. https://doi.org/10.3390/min15040350

Chicago/Turabian StyleSantos, Evandro Gomes dos, Irineu Antonio Schadach de Brum, and Weslei Monteiro Ambrós. 2025. "Techniques of Pre-Concentration by Sensor-Based Sorting and Froth Flotation Concentration Applied to Sulfide Ores—A Review" Minerals 15, no. 4: 350. https://doi.org/10.3390/min15040350

APA StyleSantos, E. G. d., Brum, I. A. S. d., & Ambrós, W. M. (2025). Techniques of Pre-Concentration by Sensor-Based Sorting and Froth Flotation Concentration Applied to Sulfide Ores—A Review. Minerals, 15(4), 350. https://doi.org/10.3390/min15040350