Experimental Study on the Microstructure Evolution of Mixed Disposal Paste in Surface Subsidence Areas

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.1.1. Mill Tailings

2.1.2. Waste Rock

2.1.3. Binders

2.1.4. Water

2.2. Preparation of the Specimens

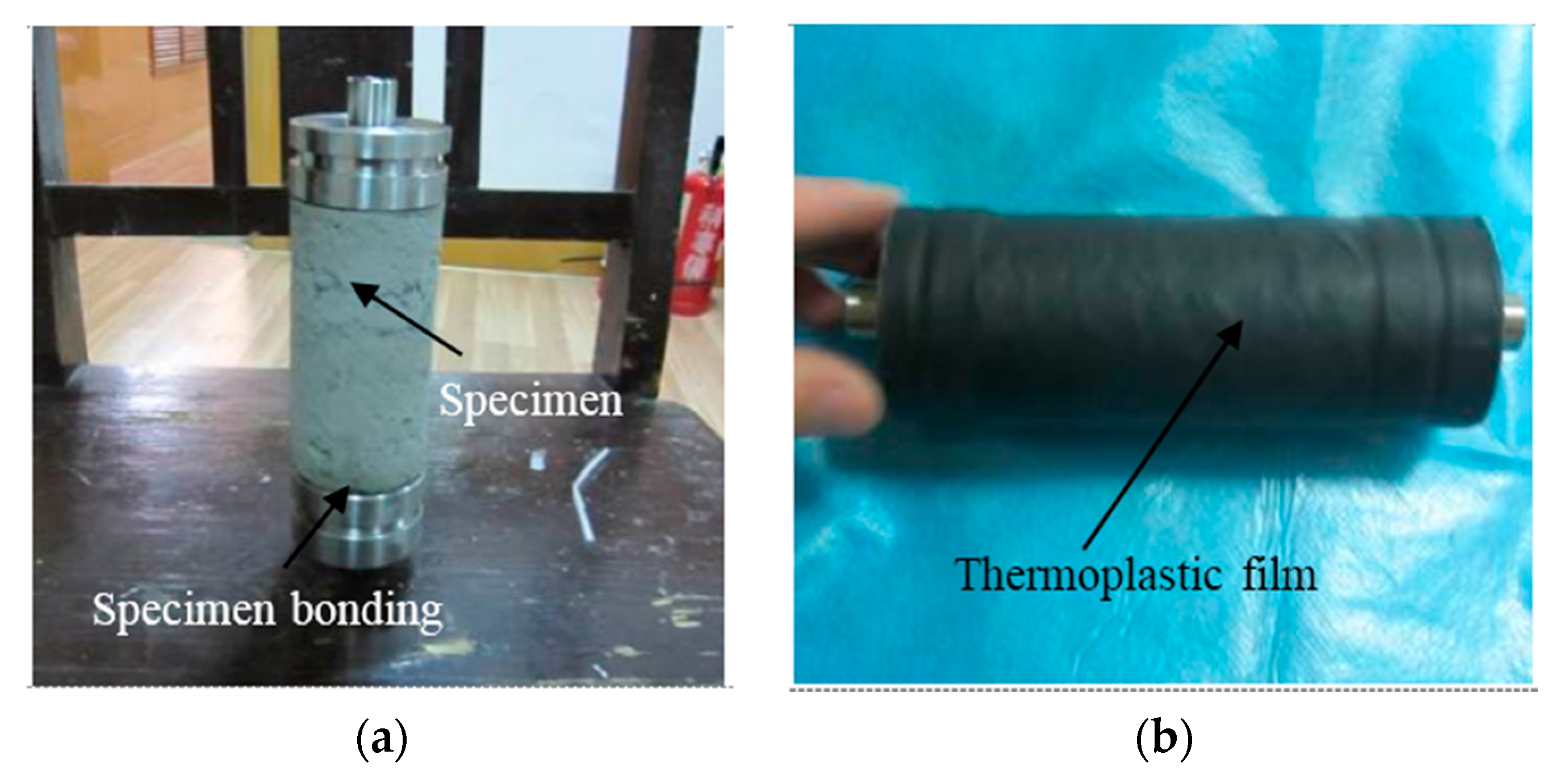

2.3. Testing Device and Process

2.3.1. Testing Device

2.3.2. Testing Process

2.4. CT Analysis Principle

3. Results and Discussion

3.1. Uniaxial Compression Test Results

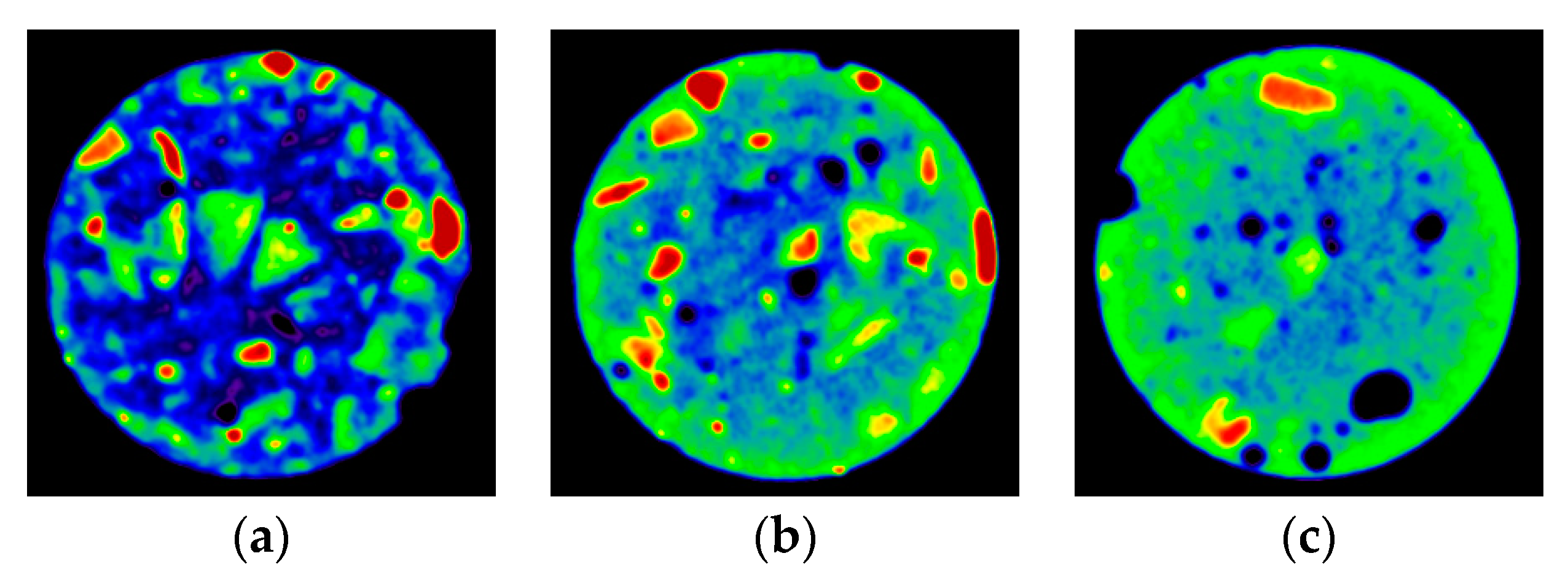

3.2. Microstructure Evolution

- Continuous compaction of pores: as depicted in the first 10th layer (the CT image in Figure 8), the volume of pore number 1 decreases under axial stress. Furthermore, the pore shrinks and declines from the initial 0.3475 to 0.2324 cm2 after peaking.

- Pore expansion after compaction: as displayed in Figure 8, which illustrates the 10th layer of pore number 2, the pore decreases from the initial state of 0.707 to 0.201 cm2 before peaking under the axial stress, in accordance with evolution law. Moreover, the pore size increases to 0.762 cm2 following the intensity peak.

- Continuous expansion of pores: as shown in the image of the 10th layer of pore number 3 in Figure 8, the pore continuously expands under axial stress, in accordance with evolution law. Pore number 3 also increases from the initial 0.523 to 0.950 cm2 after peaking.

- Integration and expansion of pore groups: as depicted in Figure 8, the pore group in the 20th layer consists of three tiny pores in close proximity. Stress is gradually concentrated in the three micro pores under axial stress, and the low pore under maximum stress continues to expand, eventually inducing the integration of the three holes and the formation of new cracks.

- Integration of adjacent microcracks: as presented in the microcrack stress path of the 30th layer (Figure 8), no significant pores and cracks are observed in the original path. Fine cracks and pore structures are initiated in the stress path when axial stress increases. Penetrative cracks eventually form with the expansion of these cracks and structures. This model was mainly developed to address the expansion of pore structures in the adjacent layers under stress.

- Pore expansion in heterogeneous areas: the microstructures rupture in the areas that display local heterogeneity in terms of coarse material, pores, and tailings. As exhibited in Figure 8, the pores are first generated in the 30th layer of the inhomogeneous weak area when axial stress increases. These pores mainly appear in the area that is subject to the composite effect of porosity, aggregation, and tailings; this observation is consistent with the core area extension mechanism shown in Figure 9.

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Inhye, P.; Jaewon, C.; Jin, L.M.; Saro, L. Application of an adaptive neuro-fuzzy inference system to ground subsidence hazard mapping. Comput. Geosci. 2012, 48, 1–11. [Google Scholar]

- He, G.Q.; Yang, L.; Ling, G.D. Mining Subsidence Science; China University of Mining and Technology Press: Beijing, China, 1991. (In Chinese) [Google Scholar]

- He, F.; Xu, Y.N.; Qiao, G. Distribution characteristics of mine geological hazards in China. Geol. Bull. Chin. 2012, 31, 476–485. [Google Scholar]

- Liu, Q.; Liu, Z.X.; Li, D.Y. Knowledge bank model to predict motion angle of terrane in metal deposit and its application in engineering. J. Cent. South. Univ. Technol. 2011, 2, 2446–2452. [Google Scholar]

- Gray, R.E. Mining subsidence—Past, present, future. Geotech. Geol. Eng. 1990, 4, 400–408. [Google Scholar] [CrossRef]

- Fall, M.; Célestin, J.; Sen, H.F. Potential use of densified polymer-pastefill mixture as waste containment barrier materials. Waste Manag. 2010, 30, 2570–2578. [Google Scholar] [CrossRef] [PubMed]

- Hounsfield, G.N. Computerized transverse axial scanning (tomography). Part 1. Description of system. Br. J. Radiol. 1973, 46, 1016–1022. [Google Scholar] [CrossRef] [PubMed]

- Wellington, S.L.; Vinegar, H.J. X-ray computerized tomography. J. Pet. Technol. 1987, 8, 885–898. [Google Scholar] [CrossRef]

- Colletta, B.; Letouzey, J. Thin-skinned thrust systems. Geology 1991, 19, 1063–1067. [Google Scholar] [CrossRef]

- Nakashima, Y. The use of X-ray CT to measure diffusion coefficients of heavy ions in water-saturated porous media. Eng. Geol. 2000, 56, 11–17. [Google Scholar] [CrossRef]

- Kawakata, H.; Cho, A.; Kiyama, T. Three-dimensional observations of faulting process in Westerly granite under uniaxial and triaxial conditions by X-ray CT scan. Tectonophysics 1999, 313, 293–305. [Google Scholar] [CrossRef]

- Ma, W.; Wu, Z.W.; Pu, Y.B. Monitoring the change of structures in frozen soil in triaxial creep process by CT. J. Glaciol. Geocryol. 1997, 19, 52–55. [Google Scholar]

- Wu, Z.W.; Ma, W.; Pu, Y.B.; Chang, X.X. Submicroscopic analysis on deformation characteristics in creep process of frozen soil. Chin. J. Geotech. Eng. 1997, 19, 1–8. [Google Scholar]

- Cnudde, V.; Boone, M.; Dewanckele, J. 3D characterization of sandstone by means of X-ray computed tomography. Geosphere 2011, 7, 54–61. [Google Scholar] [CrossRef]

- Raynaud, S.; Vasseur, G.; Soliva, R. In vivo CT X-ray observations of porosity evolution during triaxial deformation of a calcarenite. Int. J. Rock Mech. Min. 2012, 56, 161–170. [Google Scholar] [CrossRef]

- Sufian, A.; Russell, A.R. Microstructural pore changes and energy dissipation in Gosford sandstone during pre-failure loading using X-ray CT. Int. J. Rock Mech. Min. 2013, 57, 119–131. [Google Scholar] [CrossRef]

- Büyüköztürk, O. Imaging of concrete structures. NDT E Int. 1998, 31, 233–243. [Google Scholar] [CrossRef]

- Wong, R.C.K.; Chau, K.T. Estimation of air void and aggregate spatial distributions in concrete under uniaxial compression using computer tomography scanning. Cement Concrete Res. 2005, 35, 1566–1576. [Google Scholar] [CrossRef]

- Tian, W.; Dang, F.N.; Chen, H.Q. CT experimentl study on failure characteristics of concrete under dynamic loading. J. Earthq. Eng. Vib. 2011, 31, 30–34. [Google Scholar]

- Landriault, D. Paste backfill mix design for Canadian underground hard rock mining. In Proceedings of the 97th Annual General Meeting of CIM, Rock Mechanics and Strata Control Session, Halifax, NS, Canada, 14–18 May 1995; pp. 229–238.

- Brackebusch, F.; Shillabeer, J. Use of paste for tailings disposal. In Proceedings of the Sixth International Symposium on Mining with Backfill, Brisbane, Australia, 14–16 April 1998; pp. 53–58.

- Sun, W.; Wu, A.X.; Wang, H.J. The change laws of flow characteristics of backfill paste mixed by unclassified tailings and waste rock. Rock. Soil. Mech. 2013, 4, 3464–3470. [Google Scholar]

- Wu, A.X.; Sun, W.; Wang, H.J. Experiment research on shear behavior of subsidence backfill body mixed by unclassified tailings and waste rocks. Chin. J. Rock. Mech. Eng. 2013, 32, 917–925. [Google Scholar]

- Ge, X.R.; Ren, J.X.; Pu, Y.B. Damage Mechanics of Rock and Soil and Macro-Meso Test Research; Science Press: Beijing, China, 2004. (In Chinese) [Google Scholar]

- Chen, S.J.; Zhao, S.P.; Ma, W. Studying frozen soil with CT technology: Present studies and prospects. J. Glaciol. Geocryol. 2013, 35, 193–200. [Google Scholar]

| Element | Gs | D10 (mm) | D30 (mm) | D50 (mm) | D60 (mm) | D90 (mm) | Cu | Cc |

|---|---|---|---|---|---|---|---|---|

| Tailings | 3.1 | 6.2 × 10−3 | 25.43 × 10−3 | 58.31 × 10−3 | 70.5 × 10−3 | 192 × 10−3 | 11.37 | 1.48 |

| No. | Tailing/Rock | Cement wt % | Mass Concentration % |

|---|---|---|---|

| 1 | 7:3 | 2 | 82 |

| 2 | 5:5 | 1 | 82 |

| 3 | 7:3 | 1 | 82 |

| 4 | 9:1 | 1 | 82 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Wu, A.; Hou, K.; Yang, Y.; Liu, L.; Wen, Y. Experimental Study on the Microstructure Evolution of Mixed Disposal Paste in Surface Subsidence Areas. Minerals 2016, 6, 43. https://doi.org/10.3390/min6020043

Sun W, Wu A, Hou K, Yang Y, Liu L, Wen Y. Experimental Study on the Microstructure Evolution of Mixed Disposal Paste in Surface Subsidence Areas. Minerals. 2016; 6(2):43. https://doi.org/10.3390/min6020043

Chicago/Turabian StyleSun, Wei, Aixiang Wu, Kepeng Hou, Yi Yang, Lei Liu, and Yiming Wen. 2016. "Experimental Study on the Microstructure Evolution of Mixed Disposal Paste in Surface Subsidence Areas" Minerals 6, no. 2: 43. https://doi.org/10.3390/min6020043

APA StyleSun, W., Wu, A., Hou, K., Yang, Y., Liu, L., & Wen, Y. (2016). Experimental Study on the Microstructure Evolution of Mixed Disposal Paste in Surface Subsidence Areas. Minerals, 6(2), 43. https://doi.org/10.3390/min6020043