Archaeometric Approach for Studying Architectural Earthenwares from the Archaeological Site of S. Omobono (Rome-Italy)

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

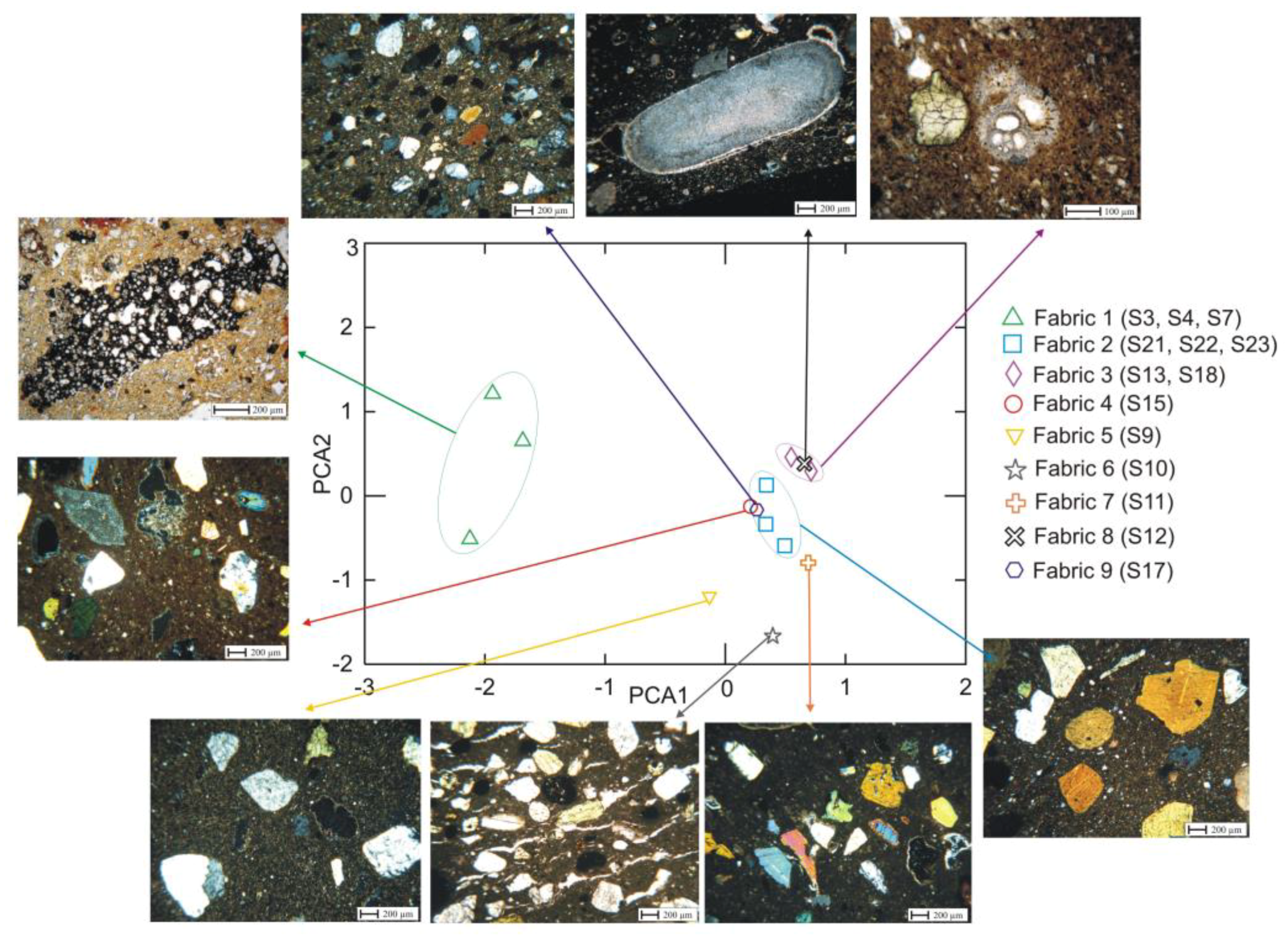

3.1. Mineralogical, Petrographic and Chemical Characterization

3.2. Provenance Hypothesis of the Raw Materials

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pisani Sartorio, G.; Virgili, P.; Ioppolo, G. La scoperta dei Templi della Fortuna e della Mater Matuta. In Il Viver Quotidiano in Roma Arcaica: Materiali dagli scavi del tempio arcaico nell’area sacra di S. Omobono; Pisani Sartorio, G., Virgili, P., Ioppolo, G., Eds.; Edizioni Procom: Roma, Italy, 1989; pp. 13–15. [Google Scholar]

- Mura, A.S. La decorazione architettonica del tempio arcaico. La Parol. del Passato 1977, 32, 62–71. [Google Scholar]

- Colonna, G. Le due fasi del tempio arcaico di S. Omobono. In Stips Votiva: Papers presented to C.M. Stibbe; Gnade, M., Ed.; University of Amsterdam: Amsterdam, The Netherlands, 1991; pp. 51–59. [Google Scholar]

- Brocato, P.; Ceci, M.; Terrenato, N. Ricerche nell’area dei templi di Fortuna e Mater Matuta; Dipartimento di Studi Umanistici dell’Università della Calabria: Rende, Italy, 2016. [Google Scholar]

- Brocato, P.; Terrenato, N. Nuove ricerche nell’area archeologica di S. Omobono; Dipartimento di Studi Umanistici dell’Università della Calabria: Rende, Italy, 2012. [Google Scholar]

- Terrenato, N.; Brocato, P.; Caruso, G.; Ramieri, A.M.; Becker, H.W.; Cangemi, I.; Mantiloni, G.; Regoli, C. The S. Omobono Sanctuary in Rome: Assessing eighty years of fieldwork and exploring perspectives for the future. Internet Archaeol. 2012, 31. [Google Scholar] [CrossRef]

- Maggetti, M. Mineralogical and Petrographical Methods for the Study of Ancient Pottery; Università La Sapienza: Roma, Italy, 1994. [Google Scholar]

- Belfiore, C.M.; Day, P.M.; Hein, A.; Kilikoglou, V.; La Rosa, V.; Mazzoleni, P.; Pezzino, A. Petrographic and chemical characterization of pottery production of the Late Minoan I kiln at Haghia Triada, Crete. Archaeometry 2007, 49, 621–653. [Google Scholar] [CrossRef]

- Miriello, D.; Crisci, G.M. Mixing and provenance of raw materials in the bricks from the Svevian castle of Rocca Imperiale (North Calabria, Italy). Eur. J. Mineral. 2007, 19, 137–144. [Google Scholar] [CrossRef]

- Lindsay, I.; Minc, L.; Descantes, C.; Speakman, R.J.; Glascock, M.D. Exchange patterns, boundary formation, and sociopolitical change in Late Bronze Age Southern Caucasia: Preliminary results from a pottery provenance study in northwestern Armenia. J. Archaeol. Sci. 2008, 35, 1673–1682. [Google Scholar] [CrossRef]

- Barone, G.; Belfiore, C.M.; Mazzoleni, P.; Pezzino, A.; Viccaro, M. A volcanic inclusions based approach for provenance studies of archaeological ceramics: Application to pottery from southern Italy. J. Archaeol. Sci 2010, 37, 713–726. [Google Scholar] [CrossRef]

- Scarpelli, R.; De Francesco, A.M.; Perri, F.; Osanna, M.; Colangelo, L.; Miriello, D.; La Russa, M.F.; Barca, D.; Crisci, G.M. Archaeometric study of sub-geometric pottery found in Potenza, Italy: Relationship and trade between near indigenous centers. Period. Mineral. 2010, 79, 81–94. [Google Scholar]

- Montana, G.; Cau Ontiveros, M.Á.; Polito, A.M.; Azzaro, E. Characterisation of clayey raw materials for ceramic manufacture in ancient Sicily. Appl. Clay Sci. 2011, 53, 476–488. [Google Scholar] [CrossRef]

- Cau Ontiveros, M.Á.; Montana, G.; Tsantini, E.; Randazzo, L. Ceramic Ethnoarchaeometry in Western Sardinia: Production of Cooking Ware at Pabillonis. Archaeometry 2015, 57, 453–475. [Google Scholar] [CrossRef]

- Cano, N.F.; Ribeiro, R.B.; Munita, C.S.; Watanabe, S.; Neves, E.G.; Tamanaha, E.K. Dating and determination of firing temperature of ancient potteries from São Paulo II archaeological site, Brazil by TL and EPR techniques. J. Cult. Herit. 2015, 16, 361–364. [Google Scholar] [CrossRef]

- Miriello, D.; Bloise, A.; De Luca, R.; Apollaro, C.; Crisci, G.M.; Medaglia, S.; Grasso, A.T. First compositional evidences on the local production of Dressel 2–4 amphorae in Calabria (Southern Italy): Characterization and mixing simulations. Appl. Phys. A Mater. Sci. Process. 2015, 119, 1595–1608. [Google Scholar] [CrossRef]

- Taranto, M.; Barba, L.; Blancas, J.; Bloise, A.; Cappa, M.; Chiaravalloti, F.; Crisci, G.M.; Cura, M.; De Angelis, D.; De Luca, R.; Lezzerini, M.; Pecci, A.; Miriello, D. The bricks of Hagia Sophia (Istanbul, Turkey): A new hypothesis to explain their compositional difference. J. Cult. Herit. 2019. [Google Scholar] [CrossRef]

- Columbu, S.; Sitzia, F.; Verdiani, G. Contribution of petrophysical analysis and 3D digital survey in the archaeometric investigations of the Emperor Hadrian’s Baths (Tivoli, Italy). Rend. Lincei 2015, 26, 455–474. [Google Scholar] [CrossRef]

- Columbu, S.; Sitzia, F.; Ennas, G. The ancient pozzolanic mortars and concretes of Heliocaminus baths in Hadrian’s Villa (Tivoli, Italy). Archaeol. Anthr. Sci. 2017, 9, 523–553. [Google Scholar] [CrossRef]

- Columbu, S.; Palomba, M.; Sitzia, F.; Murgia, M. Geochemical and mineral-petrographic studies of stones and mortars from the Romanesque Saccargia Basilica (Sardinia, Italy) to define their origin and alteration. Ital. J. Geosci. 2018, 137, 369–395. [Google Scholar] [CrossRef]

- Ramacciotti, M.; Rubio, S.; Gallello, G.; Lezzerini, M.; Columbu, S.; Hernandez, E.; Morales-Rubio, A.; Pastor, A.; De La Guardia, M. Chronological classification of ancient mortars employing spectroscopy and spectrometry techniques: Sagunto (Valencia, Spain) Case. J. Spectrosc. 2018. [Google Scholar] [CrossRef]

- Columbu, S.; Lisci, C.; Sitzia, F.; Lorenzetti, G.; Lezzerini, M.; Pagnotta, S.; Raneri, S.; Legnaioli, S.; Palleschi, V.; Gallello, G.; et al. Mineralogical, petrographic and physical-mechanical study of Roman construction materials from the Maritime Theatre of Hadrian’s Villa (Rome, Italy). Measurement 2018, 127, 264–276. [Google Scholar]

- Columbu, S.; Garau, A.M.; Lugliè, C. Geochemical characterisation of pozzolanic obsidian glasses used in the ancient mortars of Nora Roman theatre (Sardinia, Italy): Provenance of raw materials and historical–archaeological implications. Archaeol. Anthrop. Sci. 2018, 1–30. [Google Scholar] [CrossRef]

- Columbu, S.; Garau, A.M. Mineralogical, petrographic and chemical analysis of geomaterials used in the mortars of Roman Nora theatre (south Sardinia, Italy). Ital. J. Geosci. 2017, 136, 238–262. [Google Scholar] [CrossRef]

- Raneri, S.; Pagnotta, S.; Lezzerini, M.; Legnaioli, S.; Palleschi, V.; Columbu, S.; Neri, N.F.; Mazzoleni, P. Examining the reactivity of volcanic ash in ancient mortars by using a micro-chemical approach. Mediter. Archaeol. Archaeom. 2018, 18, 147–157. [Google Scholar]

- Columbu, S.; Gioncada, A.; Lezzerini, M.; Marchi, M. Hydric dilatation of ignimbritic stones used in the Church of Santa Maria di Otti (Oschiri, northern Sardinia, Italy). Ital. J. Geosci. 2014, 133, 149–160. [Google Scholar] [CrossRef]

- Antonelli, F.; Columbu, S.; De Vos Raaijmakers, M.; Andreoli, M. An archaeometric contribution to the study of ancient millstones from the Mulargia area (Sardinia, Italy) through new analytical data on volcanic raw material and archaeological items from Hellenistic and Roman North Africa. J. Archaeol. Sci. 2014, 50, 243–261. [Google Scholar] [CrossRef]

- Columbu, S.; Lisci, C.; Sitzia, F.; Buccellato, G. Physical-mechanical consolidation and protection of Miocenic limestone used on Mediterranean historical monuments: The case study of Pietra Cantone (southern Sardinia, Italy). Environ. Earth Sci. 2017, 76, 148. [Google Scholar] [CrossRef]

- Verdiani, G.; Columbu, S. E.Stone, an Archive for the Sardinia Monumental Witnesses. Lect. Notes Comput. Sci. 2010, 6436, 356–372. [Google Scholar] [Green Version]

- Columbu, S. Petrographic and geochemical investigations on the volcanic rocks used in the Punic-Roman archaeological site of Nora (Sardinia, Italy). Environ. Earth Sci. 2018, 77, 577. [Google Scholar] [CrossRef]

- Antonelli, F.; Columbu, S.; Lezzerini, M.; Miriello, D. Petrographic characterization and provenance determination of the white marbles used in the Roman sculptures of Forum Sempronii (Fossombrone, Marche, Italy). Appl. Phys. A Mater. Sci. Process. 2014, 115, 1033–1040. [Google Scholar] [CrossRef]

- Columbu, S. Provenance and alteration of pyroclastic rocks from the Romanesque Churches of Logudoro (north Sardinia, Italy) using a petrographic and geochemical statistical approach. Appl. Phys. A Mater. Sci. Process. 2017, 123, 1–28. [Google Scholar] [CrossRef]

- Columbu, S.; Antonelli, F.; Sitzia, F. Origin of Roman worked stones from St. Saturno Christian Basilica (south Sardinia, Italy). Mediterr. Archaeol. Archaeom. 2018, 18, 17–36. [Google Scholar]

- Columbu, S.; Piras, G.; Sitzia, F.; Pagnotta, S.; Raneri, S.; Legnaioli, S.; Palleschi, V.; Lezzerini, M.; Giamello, M. Petrographic and mineralogical characterization of volcanic rocks and surface-depositions on Romanesque monuments. Mediterr. Archaeol. Archaeom. 2018, 18, 37–63. [Google Scholar]

- Coarelli, F. Il Foro Boario: Dalle origini alla fine della Repubblica; Quasa: Roma, Italy, 1988. [Google Scholar]

- Brocato, P.; Diffendale, D.; Di Giuliomaria, D.; Gaeta, M.; Marra, F.; Terrenato, N. Identification of a previously unknown tuff for the construction of the archaic Temple Podium at Sant’Omobono, Rome. J. Mediterr. Archaeol. 2019, in press. [Google Scholar]

- Ammerman, A.J.; Iliopoulos, I.; Bondioli, F.; Filippi, D.; Hilditch, J.; Manfredini, A.; Pennisi, L.; Winter, N. The clay beds in the Velabrum and the earliest tiles in Rome. J. Rom. Archaeol. 2008, 21, 7–30. [Google Scholar] [CrossRef]

- Powers, M.C. A new roundness scale for sedimentary particles. J. Sediment. Res. 1953, 23, 117–119. [Google Scholar] [CrossRef]

- Boggs, S. Petrology of Sedimentary Rocks; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Jerram, D.A. Visual comparators for degree of grain-size sorting in two and three-dimensions. Comput. Geosci. 2001, 27, 485–492. [Google Scholar] [CrossRef]

- Ricci Lucchi, F. Sedimentologia Parte I: Materiali e Tessiture dei Sedimenti; Cooperativa Libraria Universitaria: Bologna, Italy, 1980. [Google Scholar]

- Best, M.G. Igneous and Metamorphic Petrology, 2nd ed.; Blackwell Publishing: Hoboken, NJ, USA, 2013. [Google Scholar]

- Bloise, A.; Abd El Salam, S.; De Luca, R.; Crisci, G.M.; Miriello, D. Flux growth and characterization of cuprorivaite: The influence of temperature, flux and silica source. Appl. Phys. A Mater. Sci. Process. 2016, 122, 1–8. [Google Scholar] [CrossRef]

- Rietveld, H. A profile refinement method for nuclear and magnetic structures. J. Appl. Cryst. 1969, 2, 65–71. [Google Scholar] [CrossRef] [Green Version]

- Young, R.A. Introduction to the Rietveld method. In The Rietveld Method; Young, R.A., Ed.; Oxford University Press: Oxford, UK, 1993; pp. 1–38. [Google Scholar]

- Aitchison, J. The statistical analysis of compositional data (with discussion). J. R. Stat. Soc. Series B Stat. Methodol. 1982, 44, 139–177. [Google Scholar]

- Aitchison, J. The Principal component analysis of compositional data. Biometrika 1983, 70, 57–65. [Google Scholar] [CrossRef]

- Aitchison, J. The Statistical Analysis of Compositional Data; Monographs on Statistics and Applied Probability; Chapman & Hall Ltd, London Reprinted (2003) with Additional Material by The Blackburn Press: Caldwell, NJ, USA, 1986. [Google Scholar]

- Wentworth, C.K. A scale of grade and class terms for clastic sediments. J. Geol. 1922, 30, 377–392. [Google Scholar] [CrossRef]

- Whitbread, I.K. The characterisation of argillaceous inclusions in ceramic thin sections. Archaeometry 1986, 28, 79–88. [Google Scholar] [CrossRef]

- Peters, T.J.E.R.K.; Iberg, R. Mineralogical changes during firing of calcium-rich brick clays. Ceram. Bull. 1978, 57, 503–509. [Google Scholar]

- Riccardi, M.P.; Messiga, B.; Duminuco, P. An approach to the dynamics of clay firing. Appl. Clay Sci. 1999, 15, 393–409. [Google Scholar] [CrossRef]

- Dondi, M.; Ercolani, G.; Guarini, G.; Marsigli, M.; Venturi, I. Evoluzione della microstruttura durante la cottura rapida di impasti per piastrelle porose. Ceramurgia 1995, 25, 301–314. [Google Scholar]

- Rice, P.M. Pottery Analysis: A Sourcebook; University of Chicago Press: Chicago, IL, USA, 2015. [Google Scholar]

- De Bonis, A.; Cultrone, G.; Grifa, C.; Langella, A.; Morra, V. Clays from the Bay of Naples (Italy): New insight on ancient and traditional ceramics. J. Eur. Ceram. Soc. 2014, 34, 3229–3244. [Google Scholar] [CrossRef]

- Grifa, C.; Germinario, C.; De Bonis, A.; Mercurio, M.; Izzo, F.; Pepe, F.; Bareschino, P.; Cucciniello, C.; Monetti, V.; Morra, V.; et al. Traditional brick productions in Madagascar: From raw material processing to firing technology. Appl. Clay Sci. 2017, 150, 252–266. [Google Scholar] [CrossRef]

- Maggetti, M.; Neururer, C.; Ramseyer, D. Temperature evolution inside a pot during experimental surface (bonfire) firing. Appl. Clay Sci. 2011, 53, 500–508. [Google Scholar] [CrossRef] [Green Version]

- De Bonis, A.; D’Angelo, M.; Guarino, V.; Massa, S.; Anaraki, F.S.; Genito, B.; Morra, V. Unglazed pottery from the masjed-i jom’e of Isfahan (Iran): Technology and provenance. Archaeol. Anthr. Sci. 2017, 9, 617–635. [Google Scholar] [CrossRef]

- Peccerillo, A.; Perugini, D. Introduzione Alla Petrografia Ottica; Morlacchi Editore: Perugia, Italy, 2003. [Google Scholar]

- Negro, A.D.; Carbonin, S.; Salviulo, G.; Piccirillo, E.M.; Cundari, A. Crystal Chemistry and Site Configuration of the Clinopyroxene from Leucite-bearing Rocks and Related Genetic Significance: The Sabatini Lavas, Roman Region, Italy. J. Petrol. 1985, 26, 1027–1040. [Google Scholar] [CrossRef]

- Aurisicchio, C.; Federico, M.; Gianfagna, A. Clinopyroxene chemistry of the high-potassium suite from the Alban Hills, Italy. Mineral. Petrol. 1988, 39, 1–19. [Google Scholar]

- Querci, D. Studio di alcuni litotipi messi in opera nel Duomo di Orvieto (Terni): Caratteristiche chimico-fisiche e confronto con i materiali prelevati in cava. Ph.D. Thesis, University of Perugia, Perugia, Italy, 1995. [Google Scholar]

- Di Battistini, G.; Montanini, A.; Bargossi, G.M.; Vernia, L.; Castorina, F. Petrology and geochemistry of ultrapotassic rocks from the Montefiascone Volcanic Complex (Central Italy): Magmatic evolution and petrogenesis. Lithos 1998, 43, 169–195. [Google Scholar] [CrossRef]

- Perini, G.; Conticelli, S.; Francalanci, L.; Davidson, J.P. The relationship between potassic and calc-alkaline post-orogenic magmatism at Vico volcano, central Italy. J. Volcanol. Geotherm. Res. 2000, 95, 247–272. [Google Scholar] [CrossRef]

- Scarpelli, R.; De Francesco, A.M.; Gaeta, M.; Cottica, D.; Toniolo, L. The provenance of the Pompeii cooking wares: Insights from LA–ICP-MS trace element analyses. Microchem. J. 2015, 119, 93–110. [Google Scholar] [CrossRef]

- Comodi, P.; Nazzareni, S.; Perugini, D.; Bergamini, M. Technology and Provenance of roman ceramics from Scoppieto, Italy: A mineralogical and petrological study. Period. Mineral. 2006, 75, 95–112. [Google Scholar]

- Nappi, G.; Antonelli, F.; Coltorti, M.; Milani, L.; Renzulli, A.; Siena, F. Volcanological and petrological evolution of the Eastern Vulsini District, Central Italy. J. Volcanol. Geotherm. Res. 1998, 87, 211–232. [Google Scholar] [CrossRef]

- Antonelli, F.; Nappi, G.; Lazzarini, L. Roman millstones from Orvieto (Italy): Petrographic and geochemical data for a new archaeometric contribution. Archaeometry 2001, 43, 167–189. [Google Scholar] [CrossRef]

- Santi, P.; Antonelli, F.; Renzulli, A.; Pensabene, P. Leucite phonolite millstones from the Orvieto production centre: New data and insights into the Roman trade. Period. Mineral. 2003, 73, 57–69. [Google Scholar]

- Antonelli, F.; Lazzarini, L. Mediterranean trade of the most widespread Roman volcanic millstones from Italy and petrochemical markers of their raw materials. J. Archaeol. Sci. 2010, 37, 2081–2092. [Google Scholar] [CrossRef]

- Morra, V.; Calcaterra, D.; Cappelletti, P.; Colella, A.; Fedele, L.; De’Gennaro, R.; Langella, A.; Mercurio, M. Urban geology: Relationships between geological setting and architectural heritage of the Neapolitan area. J. Virtual Explor. 2010, 36. [Google Scholar] [CrossRef]

- Cristofani, M. Osservazioni sulle decorazioni fittili arcaiche dal santuario di Sant’Omobono. Archeol. Laz. 1989, 10, 31–37. [Google Scholar]

- Barca, D.; Miriello, D.; Pecci, A.; Barba, L.; Ortiz, A.; Manzanilla, L.R.; Blancas, J.; Crisci, G.M. Provenance of glass shards in archaeological lime plasters by LA-ICP-MS: Implications for the ancient routes from the Gulf of Mexico to Teotihuacan in Central Mexico. J. Archeol. Sci. 2013, 40, 3999–4008. [Google Scholar] [CrossRef]

- De Luca, R.; Gigliotti, V.; Panarello, M.; Bloise, A.; Crisci, G.M.; Miriello, D. Spectroscopic, microchemical and petrographic analyses of plasters from ancient buildings in Lamezia Terme (Calabria, Southern Italy). Spectrochim. Acta Part A. 2016, 153, 184–193. [Google Scholar] [CrossRef]

- Miriello, D.; Barba, L.; Blancas, J.; Bloise, A.; Cappa, M.; Cura, M.; De Angelis, D.; De Luca, R.; Pecci, A.; Taranto, M.; et al. New compositional data on ancient mortars from Hagia Sophia (Istanbul, Turkey). Archaeol. Anthrop. Sci. 2017, 9, 499–514. [Google Scholar] [CrossRef]

- Miriello, D.; De Luca, R.; Bloise, A.; Dattola, L.; Mantella, G.; Gazineo, F.; De Natale, A.; Iannelli, M.T.; Cuteri, F.A.; Crisci, G.M. Compositional study of mortars and pigments from the “Mosaico della Sala dei Draghi e dei Delfini” in the archaeological site of Kaulonía (Southern Calabria, Magna Graecia, Italy). Archaeol. Anthrop. Sci. 2017, 9, 317–336. [Google Scholar] [CrossRef]

- Miriello, D.; Bloise, A.; Crisci, G.M.; De Luca, R.; De Nigris, B.; Martellone, A.; Osanna, M.; Pace, R.; Pecci, A.; Ruggieri, N. New compositional data on ancient mortars and plasters from Pompeii (Campania – Southern Italy): Archaeometric results and considerations about their time evolution. Mater. Charact. 2018, 146, 189–203. [Google Scholar] [CrossRef]

| Sample | Typology | Layer and Inventory Number | Sector | Historical Period Based on Archaeological Data |

|---|---|---|---|---|

| S3 | Impasto rosso pan-tile | Layer 877 (n. MA11081) | D 10 | End of 7th–begin of 6th century BC |

| S4 | Impasto rosso pan-tile | Layer 5 (n. 925) | VII-IX | End of 7th–begin of 6th century BC |

| S7 | Impasto rosso pan-tile | Layer 1244 (n. 1102) | A7 | End of 7th–begin of 6th century BC |

| S9 | Impasto chiaro sabbioso pan-tile | Layer 883 (n. 1080) | D 10 | 6th century BC (probably 580–520) |

| S10 | Impasto chiaro sabbioso pan-tile | Layer 1208 (n. MA1 1054) | D 10 | 6th century BC (probably 580–520) |

| S11 | Impasto chiaro sabbioso pan-tile | Layer 1214 (n. MA3 1044) | D 10 | 6th century BC (probably second half) |

| S12 | Impasto chiaro sabbioso pan-tile | Layer 23 (n. 956) | I | 6th century BC (probably 580–520) |

| S13 | Impasto chiaro sabbioso pan-tile | Layer 10 (n. 1026) | Gjerstad excavation | 6th century BC (probably 580–520) |

| S15 | Impasto chiaro sabbioso cover-tile | Layer 1207 (n. 1207) | D 10 | 6th century BC (probably 580–520) |

| S17 | Impasto chiaro sabbioso cover-tile | Layer 1213 (n. 1067) | D 10 | 6th century BC (probably 580–520) |

| S18 | Impasto chiaro sabbioso cover-tile | Layer 1221 (n. 1075) | D 10 | 6th century BC (probably 580–520) |

| S21 | Fragment of pediment slab | Layer 7 (n. 966) | II | 6th century BC (about 580) |

| S22 | Architectural decoration (fragment of panther) | Layer 1214 | D 10 | 6th century BC (about 580) |

| S23 | Architectural decoration (fragment of voluta) | Layer 1214 | D 10 | 6th century BC (about 540) |

| By Polarized Microscopy | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fabric | Sample | Mean Non-Plastic Inclusions Size (µm) | Max. Non-Plastic Inclusions Size (µm) | Mean Macro Porosity (µm) | Max. Macro Porosity (µm) | Size Class | Roundness of Non-Plastic Inclusions | Sorting of Non Plastic-Inclusions | Matrix Colour | Optical Aspect of the Matrix |

| Fab. 1 | S3 | 844 | 3252 | 140 | 380 | Coarse Sand | HS-SR | PS | Reddish | OA |

| S4 | 667 | 2408 | 127 | 271 | Coarse Sand | HS-SA | PS | Reddish | OA | |

| S7 | 865 | 3876 | 142 | 275 | Coarse Sand | HS-SA | PS | Reddish | OA (sandwich effect) | |

| Fab. 2 | S21 | 340 | 1582 | 76 | 256 | Medium Sand | HS-A | MS | Brownish | OA |

| S22 | 319 | 1592 | 59 | 255 | Medium Sand | LS-SR/HS-A | MS | Brownish | OA | |

| S23 | 344 | 1048 | 66 | 190 | Medium Sand | LS-SA | MS | Brownish | OA | |

| Fab. 3 | S13 | 338 | 2086 | 51 | 130 | Medium Sand | LS-SR/HS-SA | MS | Brown-reddish | OA (sandwich effect) |

| S18 | 539 | 2230 | 106 | 373 | Coarse Sand | LS-SA | MS | Brown-reddish | OA (sandwich effect) | |

| Fab. 4 | S15 | 590 | 2660 | 80 | 210 | Coarse Sand | HS-A | MS | Brown-reddish | OI |

| Fab. 5 | S9 | 268 | 1074 | 88 | 183 | Medium Sand | HS-SA | MWS | Light brown | OI |

| Fab. 6 | S10 | 238 | 1165 | 53 | 92 | Fine Sand | HS/LS-SR | WS | Brownish | OI |

| Fab. 7 | S11 | 321 | 2822 | 180 | 304 | Medium Sand | HS/LS-SA | MS | Brownish | OI |

| Fab. 8 | S12 | 423 | 2686 | 150 | 215 | Medium Sand | HS-A | MS | Light brown | OI |

| Fab. 9 | S17 | 166 | 1882 | 88 | 375 | Fine Sand | HS-SA | MWS | Brownish | OA |

| Semiquantitative Visual Estimation by Polarized Microscopy | By Polarized Microscopy and XRPD | |||||||

|---|---|---|---|---|---|---|---|---|

| Fabric | Sample | % Non-Plastic Inclusions (size > 1/16 mm) | % Matrix (size < 1/16 mm) | Matrix/Non-Plastic Inclusions Ratio | % Macro Porosity (size > 1/16 mm) | Mineralogical Phases of the Non-Plastic Inclusions | Rock Fragments | Other |

| Fab. 1 | S3 | 15 | 75 | 5.0 | 10 | Qtz, Cpx, Pl, Or, Anl, Ms, Bt, Om, Ill, Grt(tr) | Volcanic rocks, flints (tr) | ARFs |

| S4 | 15 | 75 | 5.0 | 10 | Qtz, Pl, Or, Cpx, Ms, Bt, Om, Grt(tr), Kln(tr) | Volcanic rocks | ARFs | |

| S7 | 20 | 65 | 3.3 | 15 | Qtz, Pl, Or, Cpx, Anl, Bt, Om, Ill(tr), Grt(tr), Cal(tr) | Volcanic rocks | ARFs, secondary calcite inside porosity | |

| Fab. 2 | S21 | 20 | 65 | 3.3 | 15 | Qtz, Cpx, Cal, Pl, Or, Ms, Bt, Anl, Om(tr), Grt(tr), Lct(tr) | Quartzites, volcanic rocks (tr) | Secondary calcite inside porosity |

| S22 | 15 | 70 | 4.7 | 15 | Qtz, Cal, Cpx, Pl, Lct, Ill, Bt, Om, Anl(tr), Grt(tr), Or(tr) | Quartzites, volcanic rocks (tr) | Secondary calcite inside porosity | |

| S23 | 20 | 65 | 3.3 | 15 | Qtz, Cal, Cpx, Pl, Hem, Lct, Bt(tr), Grt(tr), Anl(tr) | Volcanic rocks (tr) | Secondary calcite inside porosity | |

| Fab. 3 | S13 | 25 | 62 | 2.5 | 13 | Qtz, Cal, Pl, Cpx, Lct, Or, Gh, Om, Bt, Grt(tr), Anl(tr) | Volcanic rocks, flints | Secondary calcite inside porosity, bioclasts (tr) |

| S18 | 18 | 69 | 3.8 | 13 | Qtz, Cal, Cpx, Pl, Anl, Hem, Bt(tr), Grt(tr), Or (tr) | Volcanic rocks, flints | Secondary calcite inside porosity, bioclasts (tr) | |

| Fab. 4 | S15 | 20 | 65 | 3.3 | 15 | Qtz, Cpx, Cal, Gh, Pl, Or, Hem, Lct, Bt(tr), Grt(tr) | Volcanic rocks, flints (tr), quartzites (tr) | Secondary calcite inside porosity |

| Fab. 5 | S9 | 20 | 67 | 3.4 | 13 | Qtz, Cpx, Pl, Cal, Or, Anl, Om, Bt, Grt(tr), Gh(tr), Hem(tr) | Volcanic rocks, quartzites | Secondary calcite inside porosity |

| Fab. 6 | S10 | 40 | 40 | 1.0 | 20 | Qtz, Cpx, Pl, Cal, Gh, Hem, Om, Ill, Grt, Bt(tr), Anl(tr) | Flints, quartzites, volcanic rocks, phyllites (tr) | Secondary calcite inside porosity |

| Fab. 7 | S11 | 30 | 52 | 1.7 | 18 | Qtz, Cpx, Cal, Gh, Pl, Or, Hem, Anl, Bt, Grt(tr) | Volcanic rocks, quartzites | Secondary calcite inside porosity |

| Fab. 8 | S12 | 35 | 47 | 1.3 | 18 | Qtz, Cal, Pl, Cpx, Or, Om, Ill(tr), Anl(tr), Bt(tr) | Flints, volcanic rocks, quartzites, carbonatic rocks | Secondary calcite inside porosity, bioclasts (tr) |

| Fab. 9 | S17 | 30 | 50 | 1.7 | 20 | Qtz, Cal, Pl, Cpx, Or, Om, Ms, Bt, Grt(tr) | Quartzites, filnts, volcanic rocks | Secondary calcite inside porosity, bioclasts (tr) |

| wt. % | Quartz | Orthoclase | Clinopyroxene | Analcime | Leucite | Kaolinite | Calcite | Hematite | Gehlenite | Mica | Plagioclase | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S3 | 29.09 | 14.28 | 9.87 | 5.25 | nd | nd | nd | nd | nd | 26.83 | 14.69 | 100 |

| S4 | 32.07 | 18.45 | 11.45 | nd | nd | 5.4 | nd | nd | nd | 8.79 | 23.84 | 100 |

| S7 | 17.35 | 8.43 | 29.48 | 4.22 | nd | nd | 5.76 | nd | nd | 5.66 | 29.09 | 100 |

| S9 | 18.93 | nd | 40.77 | 5.08 | nd | nd | 7.35 | 0.69 | 1.56 | 1.25 | 24.37 | 100 |

| S10 | 18.95 | nd | 40.82 | 5.07 | nd | nd | 7.36 | 0.69 | 1.57 | 1.26 | 24.28 | 100 |

| S11 | 12.97 | 3.75 | 34.75 | 3.45 | nd | nd | 10.77 | 0.52 | 9.91 | 1.27 | 22.59 | 100 |

| S12 | 24.46 | nd | 25.85 | 7.04 | nd | nd | 18.52 | nd | nd | 3.88 | 20.24 | 100 |

| S13 | 20.08 | 18.46 | 17.72 | 0.06 | 4.15 | nd | 23.26 | nd | 0.49 | 4.34 | 11.43 | 100 |

| S15 | 19.37 | 10.85 | 23.92 | nd | 2.54 | nd | 10.81 | 1.29 | 5.48 | 1.65 | 24.1 | 100 |

| S17 | 23.05 | 6.24 | 13.45 | nd | nd | nd | 9.45 | nd | nd | 12.15 | 35.66 | 100 |

| S18 | 18.33 | 5.7 | 17.98 | 5.10 | nd | nd | 22.51 | 0.37 | nd | 5.76 | 24.26 | 100 |

| S21 | 22.47 | 4.89 | 22.73 | 3.76 | 2.71 | nd | 10.34 | nd | nd | 6.27 | 26.83 | 100 |

| S22 | 20.17 | 5.17 | 24.05 | 2.90 | 2.57 | nd | 15.89 | nd | nd | 9.05 | 20.22 | 100 |

| S23 | 24.69 | nd | 16.98 | 0.77 | 2.75 | nd | 11.68 | nd | nd | 3.99 | 39.15 | 100 |

| wt. % | SiO2 | TiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S3 | 55.00 | 1.11 | 20.11 | 9.52 | 0.15 | 1.98 | 3.62 | 1.50 | 2.72 | 0.24 | 4.05 |

| S4 | 54.10 | 1.26 | 20.33 | 9.66 | 0.11 | 1.68 | 3.22 | 0.96 | 2.67 | 0.36 | 5.65 |

| S7 | 57.65 | 1.19 | 21.92 | 9.72 | 0.15 | 2.07 | 2.66 | 1.33 | 2.27 | 0.13 | 0.91 |

| S9 | 52.73 | 0.66 | 13.92 | 7.66 | 0.10 | 3.82 | 15.12 | 1.08 | 1.64 | 0.17 | 3.10 |

| S10 | 53.42 | 0.71 | 11.35 | 8.63 | 0.13 | 4.15 | 15.25 | 1.09 | 1.54 | 0.16 | 3.57 |

| S11 | 48.43 | 0.64 | 11.30 | 8.68 | 0.16 | 3.94 | 18.36 | 0.97 | 1.71 | 0.27 | 5.54 |

| S12 | 47.59 | 0.63 | 12.39 | 7.54 | 0.20 | 4.02 | 15.04 | 0.84 | 1.98 | 0.28 | 9.49 |

| S13 | 46.13 | 0.68 | 11.70 | 8.54 | 0.21 | 3.48 | 17.02 | 0.57 | 2.60 | 0.24 | 8.83 |

| S15 | 49.28 | 0.65 | 11.86 | 8.24 | 0.18 | 3.24 | 16.77 | 1.21 | 2.12 | 0.29 | 6.16 |

| S17 | 50.11 | 0.71 | 12.44 | 7.82 | 0.15 | 3.27 | 14.53 | 0.70 | 2.34 | 0.27 | 7.66 |

| S18 | 45.72 | 0.74 | 11.71 | 9.60 | 0.18 | 3.63 | 16.91 | 0.56 | 2.40 | 0.27 | 8.28 |

| S21 | 49.52 | 0.73 | 12.06 | 8.34 | 0.16 | 4.14 | 15.87 | 0.72 | 2.15 | 0.22 | 6.09 |

| S22 | 49.20 | 0.71 | 11.69 | 8.20 | 0.17 | 4.15 | 16.71 | 0.65 | 2.07 | 0.20 | 6.25 |

| S23 | 49.52 | 0.73 | 12.16 | 8.38 | 0.18 | 3.28 | 15.58 | 0.67 | 2.27 | 0.24 | 6.99 |

| ppm | Nb | Zr | Y | Sr | Rb | Ce | Ba | La | Ni | Cr | V | Co |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S3 | 79 | 468 | 41 | 467 | 364 | 133 | 1377 | 31 | 68 | 140 | 174 | 25 |

| S4 | 103 | 530 | 41 | 374 | 341 | 117 | 1370 | <20 | 79 | 156 | 142 | 31 |

| S7 | 49 | 406 | 54 | 329 | 315 | 229 | 1992 | 168 | 98 | 156 | 154 | 28 |

| S9 | 34 | 58 | 35 | 501 | 155 | 262 | 564 | 104 | 87 | 149 | 144 | 22 |

| S10 | 23 | 127 | 31 | 452 | 111 | 170 | 325 | 77 | 72 | 243 | 196 | 22 |

| S11 | 30 | 105 | 29 | 614 | 124 | 180 | 297 | 53 | 56 | 174 | 162 | 17 |

| S12 | 47 | 96 | 23 | 434 | 124 | 116 | 331 | <20 | 41 | 174 | 124 | 11 |

| S13 | 50 | 160 | 28 | 561 | 141 | 157 | 400 | <20 | 39 | 149 | 162 | 19 |

| S15 | 40 | 136 | 31 | 558 | 156 | 168 | 410 | 40 | 53 | 139 | 127 | 19 |

| S17 | 44 | 161 | 29 | 422 | 118 | 143 | 382 | 27 | 54 | 251 | 157 | 23 |

| S18 | 44 | 180 | 27 | 489 | 116 | 127 | 204 | <20 | 44 | 153 | 195 | 19 |

| S21 | 36 | 131 | 32 | 454 | 123 | 142 | 260 | 29 | 65 | 159 | 159 | 25 |

| S22 | 31 | 114 | 29 | 449 | 117 | 158 | 235 | 54 | 65 | 160 | 160 | 21 |

| S23 | 39 | 141 | 29 | 385 | 127 | 117 | 247 | 24 | 59 | 172 | 133 | 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miriello, D.; Antonelli, F.; Bloise, A.; Ceci, M.; Columbu, S.; De Luca, R.; Lezzerini, M.; Pecci, A.; Mollo, B.S.; Brocato, P. Archaeometric Approach for Studying Architectural Earthenwares from the Archaeological Site of S. Omobono (Rome-Italy). Minerals 2019, 9, 266. https://doi.org/10.3390/min9050266

Miriello D, Antonelli F, Bloise A, Ceci M, Columbu S, De Luca R, Lezzerini M, Pecci A, Mollo BS, Brocato P. Archaeometric Approach for Studying Architectural Earthenwares from the Archaeological Site of S. Omobono (Rome-Italy). Minerals. 2019; 9(5):266. https://doi.org/10.3390/min9050266

Chicago/Turabian StyleMiriello, Domenico, Fabrizio Antonelli, Andrea Bloise, Monica Ceci, Stefano Columbu, Raffaella De Luca, Marco Lezzerini, Alessandra Pecci, Bina Sara Mollo, and Paolo Brocato. 2019. "Archaeometric Approach for Studying Architectural Earthenwares from the Archaeological Site of S. Omobono (Rome-Italy)" Minerals 9, no. 5: 266. https://doi.org/10.3390/min9050266

APA StyleMiriello, D., Antonelli, F., Bloise, A., Ceci, M., Columbu, S., De Luca, R., Lezzerini, M., Pecci, A., Mollo, B. S., & Brocato, P. (2019). Archaeometric Approach for Studying Architectural Earthenwares from the Archaeological Site of S. Omobono (Rome-Italy). Minerals, 9(5), 266. https://doi.org/10.3390/min9050266