New Insights of Historical Mortars Beyond Pompei: The Example of Villa del Pezzolo, Sorrento Peninsula

Abstract

:1. Introduction

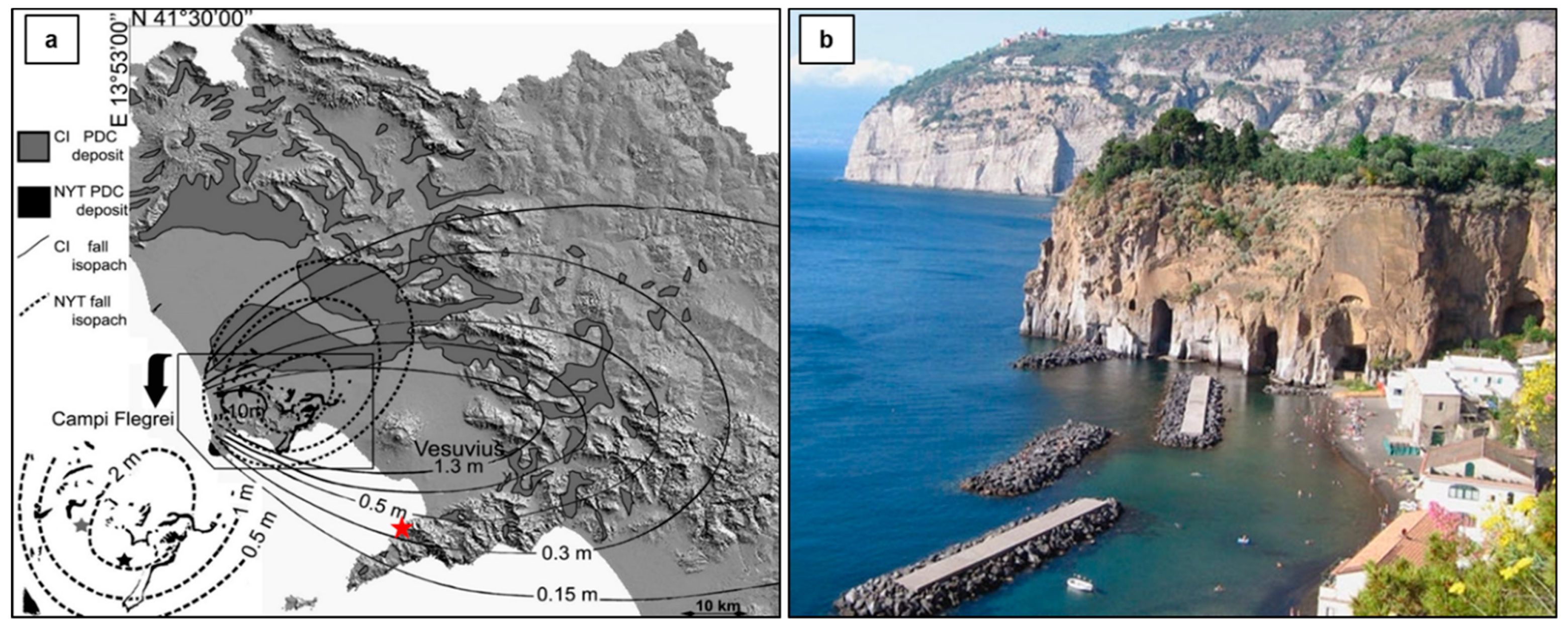

2. Geological and Archaeological Background

3. Materials and Methods

4. Results

4.1. Texture and Optical Microscopy of the Mortar

4.2. Mineralogical Analyses

4.3. Micro-Morphology and Chemical Analysis

4.4. Thermogravimetric Analysis

4.5. Mercury Intrusion Porosimetry

5. Discussion

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- De Bonis, A.; Febbraro, S.; Germinario, C.; Giampaola, D.; Grifa, C.; Guarino, V.; Langella, A.; Morra, V. Distinctive Volcanic Material for the Production of Campana a Ware: The Workshop Area of Neapolis at the Duomo Metro Station in Naples, Italy. Geoarchaeology 2016, 31, 437–466. [Google Scholar] [CrossRef]

- Guarino, V.; De Bonis, A.; Faga, I.; Giampaola, D.; Grifa, C.; Langella, A.; Liuzza, V.; Pierobon Benoit, R.; Romano, P.; Morra, V. Production and circulation of thin walled pottery from the Roman port of Neapolis, Campania (Italy). Period. Mineral. 2016, 85, 95–114. [Google Scholar]

- Di Benedetto, C.; Graziano, S.F.; Guarino, V.; Rispoli, C.; Munzi, P.; Morra, V.; Cappelletti, P. Romans’ established skills: Mortars from D46b Mausoleum, Porta Mediana Necropolis, Cuma (Naples). Mediterr. Archaeol. Archaeom. 2018, 18, 131–146. [Google Scholar]

- Graziano, S.F.; Di Benedetto, C.; Guarino, V.; Rispoli, C.; Munzi, P.; Cappelletti, P.; Morra, V. Technology and building materials in Roman age (1st BC—2nd AD): The “Mausoleo Della Sfinge” from the archaeological site of Cuma (Italy). Mediterr. Archaeol. Archaeom. 2018, 18, 81–94. [Google Scholar]

- Aucelli, P.; Cinque, A.; Mattei, G.; Pappone, G. Historical sea level changes and effects on the coasts of Sorrento Peninsula (Gulf of Naples): New constrains from recent geoarchaeological investigations. Palaeogeogr. Palaeoclimatol. Palaeoecol. 2016, 463, 112–125. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Bisbikou, K. Investigation of the technology of historic mortars. J. Cult. Herit. 2000, 1, 45–58. [Google Scholar] [CrossRef]

- Moropoulou, A.; Cakmak, A.; Labropoulos, K.C.; Van Grieken, R.; Torfs, K. Accelerated microstructural evolution of a calcium-silicate-hydrate (C-S-H) phase in pozzolanic pastes using fine siliceous sources: Comparison with historic pozzolanic mortars. Cem. Concr. Res. 2004, 34, 1–6. [Google Scholar] [CrossRef]

- Collepardi, M. La lezione dei romani: Durabilità e sostenibilità delle opere architettoniche e strutturali. In Proceedings of the III Convegno AIMAT “Restauro e Conservazione dei Beni Culturali: Materiali e Tecniche”, Cassino, Italy, 3–4 October 2003. [Google Scholar]

- Jackson, M.D.; Mulcahy, S.R.; Chen, H.; Li, Y.; Li, Q.; Cappelletti, P.; Wenk, H.R. Phillipsite and Al-tobermorite mineral cements produced through low-temperature water-rock reactions in Roman marine concrete. Am. Mineral. 2017, 102, 1435–1450. [Google Scholar] [CrossRef] [Green Version]

- Jackson, M.D.; Oleson, J.P.; Moon, J.; Zhang, Y.; Chen, H.; Gudmundsson, M.T. Extreme durability in ancient Roman concretes. Am. Ceram. Soc. Bull. 2018, 97, 22–28. [Google Scholar]

- La Russa, M.F.; Ruffolo, S.A.; Ricca, M.; Rovella, N.; Comite, V.; De Buergo, M.A.; Crisci, G.M.; Barca, D. Archaeometric approach for the study of mortars from the underwater archaeological site of Baia (Naples) Italy: Preliminary results. Period. Mineral. 2015, 84, 553–567. [Google Scholar]

- Vola, G.; Stanislao, C.; Rispoli, C.; Morra, V.; De Gennaro, M. Petrographic quantitative analysis of pozzolanic mortars from ancient Roman marine concrete cores, drilled by Romacons team (2006–2009). Rend. Online Soc. Geol. Ital. 2010, 11, 561–562. [Google Scholar]

- Rispoli, C.; Graziano, S.F.; De Bonis, A.; Cappelletti, P.; Esposito, R.; Talamo, P. Piscina Mirabilis: Characterization of geomaterials. In Proceedings of the 1st International Conference on Metrology for Archaeology, Benevento, Italy, 22–23 October 2015; pp. 266–270. [Google Scholar]

- Rispoli, C.; Fedele, L.; Di Benedetto, C.; Esposito, R.; Graziano, S.F.; Guarino, V.; Morra, V.; Cappelletti, P. Characterization of building materials from the Anfiteatro Flavio (Pozzuoli, southern Italy): A mineralogical and petrographic study. Ital. J. Geosci. 2019, 138, 103–115. [Google Scholar] [CrossRef]

- Izzo, F.; Arizzi, A.; Cappelletti, P.; Cultrone, G.; De Bonis, A.; Germinario, C.; Graziano, S.F.; Grifa, C.; Guarino, V.; Mercurio, M. The art of building in the Roman period (89 B.C.—79 A.D.): Mortars, plasters and mosaic floors from ancient Stabiae (Naples, Italy). Constr. Build. Mater. 2016, 117, 129–143. [Google Scholar] [CrossRef]

- Rispoli, C. Ancient Roman Mortars: Mix Design, Mineralogical Composition and Minerogenetic Secondary Processes. Ph.D. Thesis, Federico II University of Naples, Naples, Italy, 2017. [Google Scholar]

- Vitale, S.; Tramparulo, F.D.; Ciarcia, S.; Amore, F.O.; Prinzi, E.P.; Laiena, F. The northward tectonic transport in the southern Apennines: Examples from the Capri Island and western Sorrento Peninsula (Italy). Int. J. Earth Sci. 2017, 106, 97–113. [Google Scholar] [CrossRef]

- Cinque, A.; Robustelli, G.; Russo, M. The consequences of pyroclastic fallout on the dynamics of Mountain Catchments: Geomorphic events in the Rivo D’Arco Basin Sorrento Peninsula Italy after the plinian eruption of vesuvius in 79 Ad. Geogr. Fis. Din. Quat. 2000, 23, 117–129. [Google Scholar]

- Cinque, A.; Robustelli, G. Alluvial and coastal hazards caused by long-range effects of Plinian eruptions: The case of the Lattari Mts. After the AD 79 eruption of Vesuvius. Geol. Soc. Spec. Publ. 2009, 322, 155–171. [Google Scholar] [CrossRef]

- Senatore, M.R.; Ciarallo, A.; Stanley, J.-D. Pompeii damaged by volcaniclastic debris flows triggered centuries prior to the 79 A.D. vesuvius eruption. Geoarchaeology 2014, 29, 1–15. [Google Scholar] [CrossRef]

- Mingazzini, P. Forma Italiae: Latium et Campania. Surrentum; Roma De Luca: Roma, Italy, 1946. [Google Scholar]

- Adam, J.P. L’arte di costruire presso i Romani. Materiali e tecniche; Longanesi: Milano, Italy, 1988. [Google Scholar]

- Rispoli, C.; Graziano, S.F.; Guarino, V.; De Bonis, A.; Di Benedetto, C.; Esposito, R.; Budetta, T.; Morra, V.; Cappelletti, P. Characterization of ancient mortars: Preliminary results from Villa del Pezzolo, Sorrento Peninsula, Italy. In Proceedings of the IMEKO International Conference on Metrology for Archeology and Cultural Heritage, MetroArcheo 2016, Torino, Italy, 19–21 October 2016; pp. 151–156. [Google Scholar]

- UNI Ente Italiano Di Normazione. UNI-EN 11305:2009. Beni Culturali: Malte Storiche, Linee Guida per la Caratterizzazione Mineralogico Petrografica, Fisica e Chimica Delle Malte; UNI: Roma, Italy, 2009. [Google Scholar]

- Munsell, A.H. Color Soil Charts; Fonte/Imprenta: New Windsor, NY, USA, 1994. [Google Scholar]

- Howarth, R.J. Improved estimators of uncertainty in proportions, point-counting, and pass-fail test results. Am. J. Sci. 1998, 298, 594–607. [Google Scholar] [CrossRef]

- Klug, H.P.; Aexander, L.E. X-ray Diffraction Procedures or Polycrystalline and Amorphous Materials; J. Wiley and Sons: New York, NY, USA, 1974. [Google Scholar]

- Bish, D.; Chipera, S.J. Problems and solution in quantitative analysis of complex mixture by X-ray powder diffraction. Adv. Xray Anal. 1988, 31, 295–307. [Google Scholar]

- Rispoli, C.; De Bonis, A.; Guarino, V.; Graziano, S.F.; Di Benedetto, C.; Esposito, R.; Morra, V.; Cappelletti, P. The ancient pozzolanic mortars of the Thermal complex of Baia (Campi Flegrei, Italy). J. Cult. Herit. 2019. [Google Scholar] [CrossRef]

- Boynton, R.S. Chemistry and Technology of Lime and Limestone, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- Moropoulou, A.; Bakolas, A.; Anagnostopoulou, S. Composite materials in ancient structures. Cem. Concr. Compos. 2005, 27, 295–300. [Google Scholar] [CrossRef]

- Whitney, D.L.; Evans, B.W. Abbreviations for names of rock-forming minerals. Am. Mineral. 2010, 95, 185–187. [Google Scholar] [CrossRef]

- Jackson, M.; Deocampo, D.; Marra, F.; Scheetz, B. Mid-Pleistocene pozzolanic volcanic ash in ancient Roman concretes. Geoarchaeology 2010, 25, 36–74. [Google Scholar] [CrossRef]

- Jackson, M.D.; Chae, S.R.; Mulcahy, S.R.; Meral, C.; Taylor, R.; Li, P.; Emwas, A.-H.; Moon, J.; Yoon, S.; Vola, G.; et al. Unlocking the secrets of Al-tobermorite in Roman seawater concrete. Am. Mineral. 2012, 98, 1669–1687. [Google Scholar] [CrossRef]

- Fernández, R.; Nebreda, B.; De La Villa, R.V.; García, R.; Frías, M. Mineralogical and chemical evolution of hydrated phases in the pozzolanic reaction of calcined paper sludge. Cem. Concr. Compos. 2010, 32, 775–782. [Google Scholar] [CrossRef]

- Le Bas, M.J.; Le Maitre, R.W.; Streckeisen, A.; Zanettin, B. A chemical classification of volcanic rocks based on the total alkali-silica diagram. J. Petrol. 1986, 27, 745–750. [Google Scholar] [CrossRef]

- Locock, A.J. An Excel spreadsheet to recast analyses of garnet into end-member components, and a synopsis of the crystal chemistry of natural silicate garnets. Comput. Geosci. 2008, 34, 1769–1780. [Google Scholar] [CrossRef]

- Morra, V.; Calcaterra, D.; Cappelletti, P.; Colella, A.; Fedele, L.; de Gennaro, R.; Langella, A.; Mercurio, M.; de Gennaro, M. Urban geology: Relationships between geological setting and architectural heritage of the Neapolitan area. J. Virtual Explor. 2010, 36. [Google Scholar] [CrossRef]

- Langella, A.; Bish, D.L.; Cappelletti, P.; Cerri, G.; Colella, A.; de Gennaro, R.; Graziano, S.F.; Perrotta, A.; Scarpati, C.; de Gennaro, M. New insights into the mineralogical facies distribution of Campanian Ignimbrite, a relevant Italian industrial material. Appl. Clay Sci. 2013, 72, 55–73. [Google Scholar] [CrossRef]

- Scarpati, C.; Perrotta, A. Erosional characteristics and behavior of large pyroclastic density currents. Geology 2012, 40, 1035–1038. [Google Scholar] [CrossRef] [Green Version]

- Scheibner, B.; Wörner, G.; Civetta, L.; Stosch, H.-G.; Simon, K.; Kronz, A. Rare earth element fractionation in magmatic Ca-rich garnets. Contrib. Mineral. Petrol. 2007, 154, 55–74. [Google Scholar] [CrossRef]

- Baronio, G.; Binda, L. Study of the pozzolanicity of some bricks and clays. Constr. Build. Mater. 1997, 11, 41–46. [Google Scholar] [CrossRef]

- De Luca, R.; Miriello, D.; Pecci, A.; Dominguez-Bella, S.; Bernal-Casasola, D.; Cottica, D.; Bloise, A.; Crisci, G.M. Archaeometric Study of Mortars from the Garum Shop at Pompeii, Campania, Italy. Geoarchaeology 2015, 30, 330–351. [Google Scholar] [CrossRef]

- Middendorf, B.; Knöfel, D. Gypsum and lime mortars of historic German brick buildings: Analytical results as well as requirements for adapted restoration material. In Conservation of Historic Brick Structures: Case Studies and Reports of Research; Baer, N.S., Fitz, S., Livingston, R.A., Eds.; Donhead publishing: Shaftsbury, UK, 1998. [Google Scholar]

- Barba, L.; Blancas, J.; Manzanilla, L.R.; Ortiz, A.; Barca, D.; Crisci, G.M.; Miriello, D.; Pecci, A. Provenance of the limestone used in Teotihuacan (Mexico): A methodological approach. Archaeometry 2009, 51, 525–545. [Google Scholar] [CrossRef]

- De Gennaro, M.; Colella, C.; Pansini, M. Hydrothermal conversion of trachytic glass into zeolite. II Reactions with high-salinity waters. Neues Jahrb. Far Mineral. 1993, 3, 97–110. [Google Scholar]

- Stanislao, C.; Rispoli, C.; Vola, G.; Cappelletti, P.; Morra, V.; De Gennaro, M. Contribution to the knowledge of ancient Roman seawater concretes: Phlegrean pozzolan adopted in the construction of the harbour at Soli-Pompeiopolis (Mersin, Turkey). Period. Mineral. 2011, 80, 471–488. [Google Scholar]

- Zawawi, R. Artificial hydraulic lime mortar obtained by calcining limestone and siliceous waste materials. J. Adv. Appl. Ceram. 2006, 10, 175–178. [Google Scholar] [CrossRef]

- Izzo, F.; Grifa, C.; Germinario, C.; Mercurio, M.; De Bonis, A.; Tomay, L.; Langella, A. Production technology of mortar-based building materials from the Arch of Trajan and the Roman Theatre in Benevento, Italy. Eur. Phys. J. Plus 2018, 133, 1–12. [Google Scholar] [CrossRef]

- Genestar, C.; Pons, C.; Más, A. Analytical characterisation of ancient mortars from the archaeological Roman city of Pollentia (Balearic Islands, Spain). Anal. Chim. Acta 2006, 557, 373–379. [Google Scholar] [CrossRef]

- Brandon, C.J.; Hohlfelder, R.L.; Jackson, M.D.; Oleson, J.P. Building for Eternity. The History and Technology of Roman Concrete Engineering in the Sea; Oxbow Books: Oxford, UK, 2014. [Google Scholar]

- Sutter, L. Mineral Characterization and Cataloging of Quarried Aggregate Sources. Volume I: Final Report; Michigan Department of Transportation: Lansing, MI, USA, 2005. [Google Scholar]

- Cultrone, G.; Sebastián, E.; Huertas, M.O. Durability of masonry systems: A laboratory study. Constr. Build. Mater. 2007, 21, 40–51. [Google Scholar] [CrossRef]

- Ontiveros-Ortega, E.; Rodríguez-Gutiérrez, O.; Navarro, A.D. Mineralogical and physical-chemical characterisation of Roman mortars used for monumental substructures on the hill of San Antonio, in the Roman city of Italica (prov. Baetica, Santiponce, Seville, Spain). J. Archaeol. Sci. Rep. 2016, 7, 205–223. [Google Scholar] [CrossRef]

| Samples | Typology | Group | Building Phase | Probable Dating |

|---|---|---|---|---|

| VP1 | bedding mortar | A | 1st | I century B.C.-I century A.D. |

| VP2 | bedding mortar | A | 1st | I century B.C.-I century A.D. |

| VP3 | bedding mortar | A | 1st | I century B.C.-I century A.D. |

| VP4 | bedding mortar | A | 1st | I century B.C.-I century A.D. |

| VP5 | bedding mortar | A | 1st | I century B.C.-I century A.D. |

| VP6 | bedding mortar | A | 1st | I century B.C.-I century A.D. |

| VP7 | bedding mortar | B | 2nd | II century A.D. |

| VP8 | bedding mortar | B | 2nd | II century A.D. |

| VP9 | bedding mortar | B | 2nd | II century A.D. |

| VP10 | bedding mortar | B | 2nd | II century A.D. |

| VP11 | bedding mortar | B | 2nd | II century A.D. |

| VP12 | bedding mortar | B | 2nd | II century A.D. |

| VP13 | bedding mortar | C | 3rd | III century A.D. |

| VP14 | bedding mortar | C | 3rd | III century A.D. |

| VP15 | bedding mortar | C | 3rd | III century A.D. |

| VP16 | bedding mortar | C | 3rd | III century A.D. |

| VP17 | bedding mortar | C | 3rd | III century A.D. |

| VP18 | bedding mortar | C | 3rd | III century A.D. |

| VP19 | floor mortar | C | 3rd | III century A.D. |

| VP20 | floor mortar | C | 3rd | III century A.D. |

| Mortars | (Group A) | (Group B) | (Group C) | (Group C-Floor Mortar) |

|---|---|---|---|---|

| Constituents (vol.%) | ||||

| Feldspars (Sa, Pl) | 3.4 | 2.6 | 2.3 | 3.1 |

| Mafic Minerals (Cpx, Amp, Bt) | 3.1 | 6.0 | 4.8 | 5.9 |

| Garnets | - | 0.3 | 1.6 | 1.2 |

| Volcanic fragments | 10.6 | 0.9 | 0.5 | 0.8 |

| Scoriae | 3.7 | 1.2 | 1.3 | 0.7 |

| Leucite-bearing scoriae | - | 13.3 | 4.6 | 3.7 |

| Pumice | 13.3 | 12.1 | 15.0 | 17.3 |

| Fictile fragments | - | - | 15.5 | 16.2 |

| Carbonate fragments | 2.1 | 5.3 | 6.9 | 4.5 |

| Lime lumps | 3.0 | 1.8 | 1.8 | 2.2 |

| Micritic matrix | 12.6 | 4.9 | 10.6 | 25.4 |

| Cryptocrystalline matrix | 35.4 | 43.8 | 28.3 | 11.3 |

| Macroporosity | 12.1 | 7.3 | 6.4 | 7.0 |

| Others | 0.6 | 0.6 | 0.6 | 0.7 |

| Total points% | 100.0 | 100.0 | 100.0 | 100.0 |

| Total Binder% | 51.0 | 50.6 | 40.6 | 38.9 |

| Total Aggregate% | 36.3 | 41.6 | 52.4 | 53.4 |

| Binder/Aggregate ratio | 1.4 | 1.2 | 0.8 | 0.7 |

| Samples | Group | Main Binder Phases | Main Aggregate Phases | Main FictileFragments Phases | Other Phases |

|---|---|---|---|---|---|

| VP1 | group A | Cal | Anl, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP2 | group A | Cal, Gp | Cbz, Anl, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP3 | group A | Cal, Gp | Anl, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP4 | group A | Cal, Gp | Cbz, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP5 | group A | Cal, Gp | Anl, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP6 | group A | Cal, Gp | Cbz, Anl, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP7 | group B | Cal | Anl, Lct, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP8 | group B | Cal | Anl, Lct, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP9 | group B | Cal, Gp | Anl, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP10 | group B | Cal | Anl, Lct, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP11 | group B | Cal, Gp | Anl, Lct, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP12 | group B | Cal | Anl, Sa, Pl, Cpx, Mca, Cal | Hl | |

| VP13 | group C | Cal | Anl, Lct, Sa, Pl, Cpx, Mca, Cal | Qz, Cal, Hem, Sa, Cpx, Pl | Hl |

| VP14 | group C | Cal,Gp | Anl, Lct, Sa, Pl, Cpx, Mca, Cal | Qz, Cal, Hem, Sa, Cpx, Pl | Hl |

| VP15 | group C | Cal | Anl, Sa, Pl, Cpx, Mca, Cal | Qz, Cal, Hem, Sa, Pl | Hl |

| VP16 | group C | Cal, Gp | Anl, Lct, Sa, Pl, Cpx, Mca, Cal | Qz, Cal, Hem, Sa, Cpx, Pl | Hl |

| VP17 | group C | Cal | Anl, Sa, Pl, Cpx, Mca, Cal | Qz, Cal, Hem, Sa, Cpx | Hl |

| VP18 | group C | Cal, Gp | Anl, Lct, Sa, Pl, Cpx, Mca, Cal | Qz, Cal, Hem, Sa, Cpx, Pl | Hl |

| VP19 | Group C-Floor mortar | Cal | Anl, Sa, Pl, Cpx, Mca, Cal | Qz, Cal, Hem, Sa, Cpx, Pl | Hl |

| VP20 | Group C-Floor mortar | Cal, Gp | Anl, Sa, Pl, Cpx, Mca, Cal | Qz,Cal, Hem, Sa, Cpx, Pl | Hl |

| wt.% | VP1 L | VP2 L | VP3 L | VP4 L | VP5 L | VP6 L | VP7 L | VP8 L | VP9 L | VP10 L | VP11 L | VP12 L | VP13 L | VP14 L | VP15 L | VP16 L | VP17 L | VP18 L | VP19 L | VP20 L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | 1.59 | 1.89 | 2.42 | 2.71 | 2.42 | 2.89 | 1.42 | 3.11 | 1.16 | 1.58 | 3.25 | 3.28 | 2.40 | 3.21 | 3.04 | 1.81 | 1.57 | 2.68 | 2.32 | 3.02 |

| TiO2 | 0.24 | bdl | bdl | bdl | bdl | bdl | 0.35 | bdl | 0.80 | 0.35 | 0.30 | 0.15 | 0.35 | bdl | 0.02 | bdl | 0.07 | bdl | bdl | 0.11 |

| Al2O3 | 0.22 | 0.95 | 0.95 | 1.63 | 0.95 | 0.95 | 0.26 | 0.62 | 0.88 | 0.20 | 0.73 | 0.60 | 0.69 | 0.55 | 0.58 | 0.61 | 0.92 | 1.65 | 1.52 | 0.63 |

| Fe2O3 | 0.80 | 0.65 | 0.07 | 0.52 | 0.07 | 0.65 | 0.16 | 0.18 | 0.52 | 0.37 | 0.31 | 0.29 | 0.26 | 0.20 | 1.35 | 0.07 | 0.17 | 0.23 | bdl | bdl |

| MnO | 0.22 | bdl | bdl | 0.12 | bdl | bdl | bdl | 0.23 | 0.16 | 0.31 | 0.24 | 0.16 | 0.21 | 0.23 | bdl | bdl | bdl | 0.06 | bdl | bdl |

| MgO | 0.68 | 0.26 | 2.15 | 1.28 | 2.15 | 0.26 | 0.87 | 2.98 | 0.70 | 3.30 | 0.70 | 1.20 | 0.84 | 2.24 | 2.14 | 2.15 | 2.05 | 1.26 | 1.87 | 2.35 |

| CaO | 93.83 | 94.65 | 92.16 | 92.60 | 92.16 | 93.65 | 95.32 | 92.07 | 95.10 | 93.34 | 94.01 | 93.93 | 94.79 | 92.87 | 91.85 | 93.81 | 92.46 | 91.15 | 93.50 | 92.70 |

| Na2O | 0.52 | 0.59 | 0.56 | 0.52 | 0.56 | 0.59 | 0.14 | 0.33 | 0.23 | bdl | bdl | bdl | bdl | 0.13 | 0.41 | 0.56 | 0.52 | 0.29 | 0.16 | 0.31 |

| K2O | 0.54 | 0.12 | bdl | bdl | bdl | 0.12 | bdl | 0.11 | bdl | bdl | bdl | bdl | bdl | 0.03 | 0.02 | bdl | bdl | 0.12 | bdl | bdl |

| P2O5 | bdl | bdl | bdl | bdl | bdl | bdl | bdl | 0.18 | 0.25 | 0.27 | 0.24 | 0.17 | 0.10 | 0.18 | bdl | bdl | 0.06 | bdl | bdl | 0.23 |

| V2O3 | bdl | 0.45 | bdl | bdl | bdl | 0.45 | bdl | bdl | bdl | 0.06 | 0.02 | 0.05 | 0.03 | 0.07 | 0.08 | bdl | bdl | 0.06 | bdl | 0.39 |

| BaO | bdl | 0.15 | 0.26 | bdl | 0.26 | 0.15 | bdl | 0.20 | bdl | bdl | bdl | bdl | bdl | 0.07 | 0.15 | 0.26 | 0.16 | 0.25 | 0.49 | bdl |

| Cl− | 0.18 | 0.12 | 0.52 | 0.18 | 0.52 | 0.12 | 0.81 | bdl | bdl | 0.23 | 0.20 | 0.17 | 0.26 | 0.14 | 0.22 | 0.52 | 0.32 | 1.12 | bdl | bdl |

| SO3 | 1.18 | 0.18 | 0.91 | 0.43 | 0.91 | 0.18 | 0.67 | bdl | 0.22 | bdl | bdl | bdl | 0.07 | 0.09 | 0.16 | 0.21 | 1.70 | 1.14 | 0.13 | 0.27 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| SiO2 + Al2O3 + Fe2O3 | 2.61 | 3.49 | 3.45 | 4.86 | 3.45 | 4.49 | 2.61 | 1.90 | 2.55 | 2.15 | 4.28 | 4.17 | 3.34 | 3.95 | 4.97 | 2.50 | 2.67 | 4.56 | 3.85 | 3.65 |

| CaO + MgO | 94.51 | 94.91 | 94.31 | 93.88 | 94.31 | 93.91 | 94.51 | 97.06 | 95.79 | 96.64 | 94.71 | 95.13 | 95.64 | 95.12 | 93.99 | 95.96 | 94.51 | 92.41 | 95.38 | 95.05 |

| HI | 0.03 | 0.04 | 0.04 | 0.05 | 0.04 | 0.05 | 0.03 | 0.02 | 0.03 | 0.02 | 0.05 | 0.04 | 0.03 | 0.04 | 0.05 | 0.03 | 0.03 | 0.05 | 0.04 | 0.04 |

| wt.% | VP1 B | VP2 B | VP3 B | VP4 B | VP5 B | VP6 B | VP7 B | VP8 B | VP9 B | VP10 B | VP11 B | VP12 B | VP13 B | VP14 B | VP15 B | VP16 B | VP17 B | VP18 B | VP19 B | VP20 B |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | 9.56 | 9.52 | 7.60 | 9.60 | 9.73 | 10.32 | 5.84 | 5.72 | 3.36 | 6.79 | 8.81 | 10.00 | 9.74 | 10.17 | 9.98 | 8.59 | 9.84 | 7.85 | 12.70 | 13.81 |

| TiO2 | 0.41 | bdl | bdl | bdl | 0.25 | 0.07 | 0.40 | bdl | bdl | bdl | 0.40 | 0.20 | 0.06 | bdl | 0.14 | bdl | bdl | 0.27 | 0.44 | 0.42 |

| Al2O3 | 5.65 | 3.13 | 3.95 | 4.61 | 2.48 | 2.14 | 3.16 | 3.20 | 5.58 | 3.77 | 1.69 | 1.96 | 4.16 | 2.51 | 3.19 | 6.01 | 3.17 | 4.42 | 3.82 | 5.73 |

| Fe2O3 | bdl | 0.33 | 0.70 | 0.37 | bdl | 0.53 | 0.54 | 0.23 | 0.12 | 0.19 | bdl | 0.12 | 0.38 | 0.20 | 0.23 | 0.31 | 0.58 | 0.28 | 1.27 | bdl |

| MnO | bdl | 0.11 | bdl | bdl | bdl | 0.08 | bdl | bdl | bdl | bdl | 0.48 | 0.03 | 0.12 | 0.14 | 0.08 | bdl | 0.09 | bdl | bdl | bdl |

| MgO | 7.01 | 1.51 | 3.08 | 2.12 | 3.18 | 2.02 | 1.17 | 6.57 | 0.21 | 1.42 | 1.74 | 1.18 | 1.14 | 1.12 | 1.02 | 11.42 | 5.22 | 0.06 | 7.78 | 12.86 |

| CaO | 75.95 | 79.38 | 80.25 | 79.37 | 80.95 | 80.44 | 86.49 | 82.70 | 88.86 | 84.83 | 85.58 | 83.07 | 83.08 | 83.23 | 82.44 | 71.97 | 78.71 | 85.52 | 71.74 | 65.64 |

| Na2O | 0.23 | 0.88 | 0.56 | 0.36 | 0.83 | 0.28 | 0.41 | 0.24 | 0.23 | 0.89 | 0.37 | 0.53 | 0.88 | 0.08 | 0.28 | 0.17 | 0.87 | 0.03 | 0.53 | 0.19 |

| K2O | bdl | 1.25 | 0.49 | 0.16 | 0.74 | 0.95 | 0.45 | bdl | bdl | 0.43 | 0.24 | bdl | 0.08 | 0.06 | 0.07 | bdl | 0.13 | bdl | 0.30 | bdl |

| P2O5 | bdl | 0.14 | 0.00 | 0.11 | 0.08 | 0.11 | bdl | bdl | bdl | bdl | 0.30 | 0.08 | 0.14 | 0.09 | 0.11 | bdl | 0.09 | bdl | bdl | bdl |

| V2O3 | bdl | bdl | 0.44 | bdl | 0.13 | 0.24 | bdl | 0.23 | 0.29 | bdl | bdl | 0.15 | bdl | bdl | 0.14 | 0.07 | bdl | bdl | bdl | bdl |

| BaO | bdl | bdl | 0.53 | 0.04 | 0.05 | 0.10 | bdl | bdl | bdl | 1.01 | 0.14 | 0.05 | bdl | 0.03 | 0.10 | 0.33 | bdl | bdl | bdl | bdl |

| Cl− | 0.37 | 0.22 | 0.46 | 0.36 | 0.47 | 0.19 | 1.41 | 0.78 | 0.05 | 0.10 | 0.26 | 0.57 | 0.16 | 0.26 | 0.19 | 0.23 | 0.52 | 0.45 | 0.83 | 0.31 |

| SO3 | 0.82 | 3.52 | 1.96 | 2.90 | 1.11 | 2.53 | 0.12 | 0.34 | 0.30 | 0.56 | bdl | 2.05 | 0.05 | 2.10 | 2.03 | 0.89 | 0.78 | 1.12 | 0.60 | 1.04 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 99.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| SiO2 + Al2O3 + Fe2O3 | 15.21 | 12.98 | 12.24 | 14.58 | 12.21 | 12.99 | 9.54 | 9.15 | 9.06 | 10.76 | 10.49 | 12.08 | 14.28 | 12.88 | 13.40 | 14.92 | 13.59 | 12.55 | 17.79 | 19.54 |

| CaO + MgO | 82.96 | 80.89 | 83.33 | 81.49 | 84.13 | 82.46 | 87.66 | 89.27 | 89.08 | 86.25 | 87.32 | 84.25 | 84.22 | 84.35 | 83.46 | 83.39 | 83.93 | 85.58 | 79.52 | 78.50 |

| HI | 0.18 | 0.16 | 0.15 | 0.18 | 0.15 | 0.16 | 0.11 | 0.10 | 0.10 | 0.12 | 0.12 | 0.14 | 0.17 | 0.15 | 0.16 | 0.18 | 0.16 | 0.15 | 0.22 | 0.25 |

| Sample | SBW% | CO2% | CO2/SBW | LOI |

|---|---|---|---|---|

| VP1 T range (°C) | 8.72 200–675 | 7.69 675–780 | 0.89 | 25.23 25–1000 |

| VP2 T range (°C) | 8.07 200–670 | 5.93 670–760 | 0.73 | 26.39 25–1000 |

| VP3 T range (°C) | 10.38 200–660 | 5.40 660–740 | 0.52 | 28.39 25–1000 |

| VP4 T range (°C) | 9.14 230–640 | 6.69 660–750 | 0.73 | 29.06 25–1000 |

| VP5 T range (°C) | 10.32 235–610 | 7.89 650–750 | 0.77 | 26.35 25–1000 |

| VP6 T range (°C) | 8.12 200–570 | 6.17 640–760 | 0.76 | 27.45 25–1000 |

| VP7 T range (°C) | 6.07 180–560 | 8.52 560–780 | 1.40 | 26.31 25–1000 |

| VP8 T range (°C) | 7.49 200–640 | 5.13 640–745 | 0.69 | 27.25 25–1000 |

| VP9 T range (°C) | 7.33 180–620 | 5.15 620–760 | 0.70 | 28.10 25–1000 |

| VP10 T range (°C) | 8.35 200–570 | 6.77 570–750 | 0.81 | 29.25 25–1000 |

| VP11 T range (°C) | 7.64 200–650 | 5.69 650–780 | 0.74 | 32.47 25–1000 |

| VP12 T range (°C) | 10.05 210–630 | 7.63 630–780 | 0.76 | 35.22 25–1000 |

| VP13 T range (°C) | 9.77 180–630 | 4.33 630–740 | 0.55 | 30.21 25–1000 |

| VP14 T range (°C) | 8.98 220–600 | 6.02 600–740 | 0.67 | 26.76 25–1000 |

| VP15 T range (°C) | 9.15 220–640 | 6.42 640–760 | 0.70 | 29.90 25–1000 |

| VP16 T range (°C) | 9.35 240–630 | 6.31 630–750 | 0.67 | 25.50 25–1000 |

| VP17 T range (°C) | 10.67 240–650 | 8.02 650–740 | 0.76 | 29.36 25–1000 |

| VP18 T range (°C) | 8.80 230–620 | 7.35 620–750 | 0.84 | 25.69 25–1000 |

| VP19 T range (°C) | 3.94 240–650 | 16.99 650–740 | 4.31 | 24.09 25–1000 |

| VP20 T range (°C) | 3.45 160–540 | 15.82 540–780 | 4.59 | 23.78 25–1000 |

| Sample | VP1 | VP8 | VP15 | VP20 |

|---|---|---|---|---|

| Cumulative volume (mm3/g) | 262.11 | 284.97 | 307.29 | 282.37 |

| Bulk density (g/cm3) | 1.64 | 1.52 | 1.46 | 1.50 |

| Apparent Density (g/cm3) | 2.74 | 2.66 | 2.65 | 2.62 |

| Open porosity (vol.%) | 40.42 | 42.96 | 44.65 | 42.46 |

| Specific surface (m2/g) | 24.25 | 31.02 | 15.68 | 20.06 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rispoli, C.; Graziano, S.F.; Di Benedetto, C.; De Bonis, A.; Guarino, V.; Esposito, R.; Morra, V.; Cappelletti, P. New Insights of Historical Mortars Beyond Pompei: The Example of Villa del Pezzolo, Sorrento Peninsula. Minerals 2019, 9, 575. https://doi.org/10.3390/min9100575

Rispoli C, Graziano SF, Di Benedetto C, De Bonis A, Guarino V, Esposito R, Morra V, Cappelletti P. New Insights of Historical Mortars Beyond Pompei: The Example of Villa del Pezzolo, Sorrento Peninsula. Minerals. 2019; 9(10):575. https://doi.org/10.3390/min9100575

Chicago/Turabian StyleRispoli, Concetta, Sossio Fabio Graziano, Claudia Di Benedetto, Alberto De Bonis, Vincenza Guarino, Renata Esposito, Vincenzo Morra, and Piergiulio Cappelletti. 2019. "New Insights of Historical Mortars Beyond Pompei: The Example of Villa del Pezzolo, Sorrento Peninsula" Minerals 9, no. 10: 575. https://doi.org/10.3390/min9100575

APA StyleRispoli, C., Graziano, S. F., Di Benedetto, C., De Bonis, A., Guarino, V., Esposito, R., Morra, V., & Cappelletti, P. (2019). New Insights of Historical Mortars Beyond Pompei: The Example of Villa del Pezzolo, Sorrento Peninsula. Minerals, 9(10), 575. https://doi.org/10.3390/min9100575