Analysis and Prediction of Flow-Induced Vibration of Convection Pipe for 200 t/h D Type Gas Boiler

Abstract

:1. Introduction

2. Numerical Calculation Models and Methods

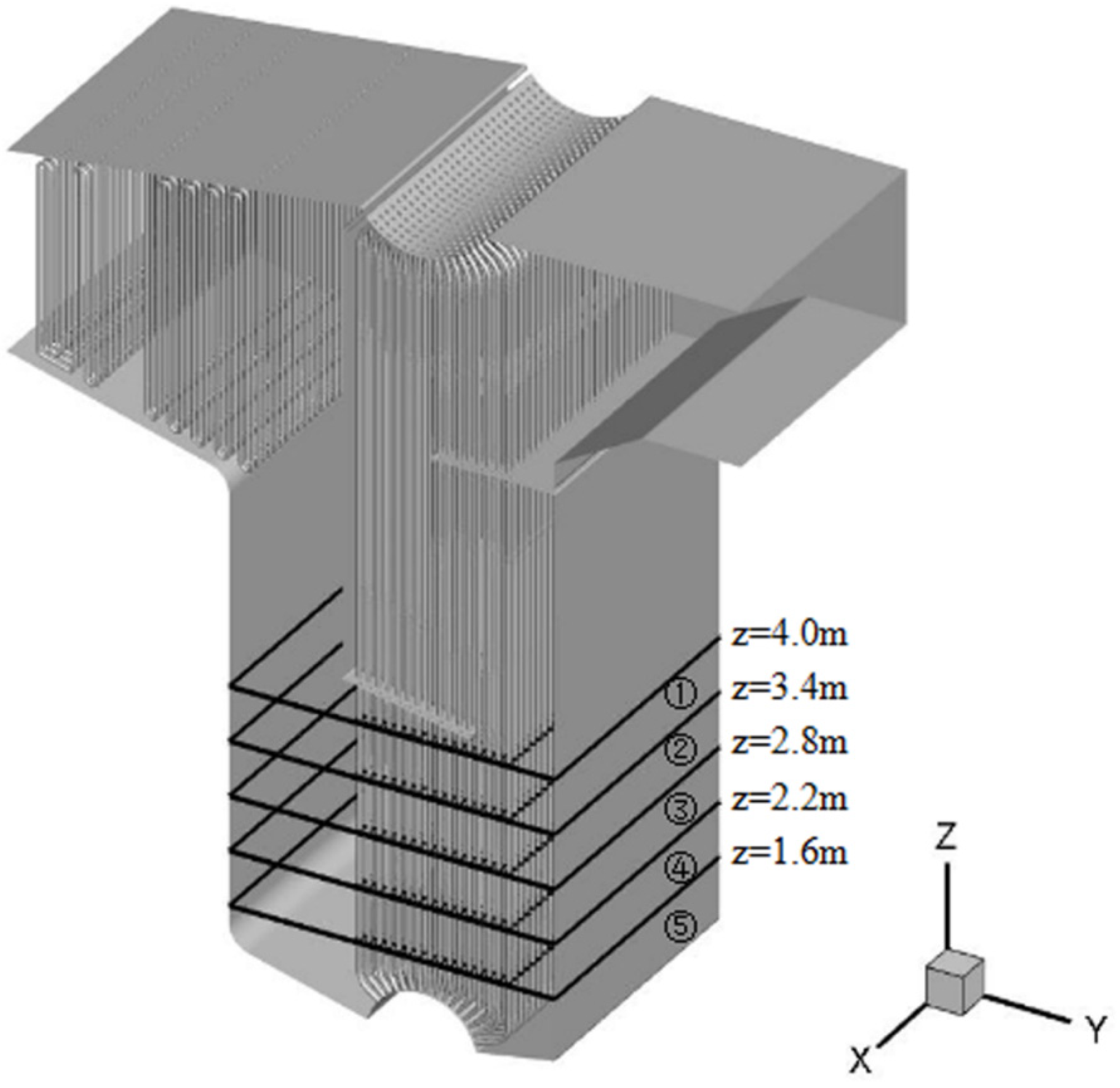

2.1. Physical Model

- (1)

- Disregard the influence of gravity and the pipe flow field on flue gas flow.

- (2)

- The gap between the baffle plate and the shell wall as well as the heat exchange tube is considered to be closely connected.

- (3)

- Due to the large calculation area of the target, the influence of the outer membrane water wall tube wall on the flow area is ignored, and the wall surface is simplified into a non-slip plane.

- (4)

- The inlet of flow field calculation in the flue is set at the inlet of the flue.

2.2. Physical Mode

2.3. Physical Parameters and Boundary Conditions

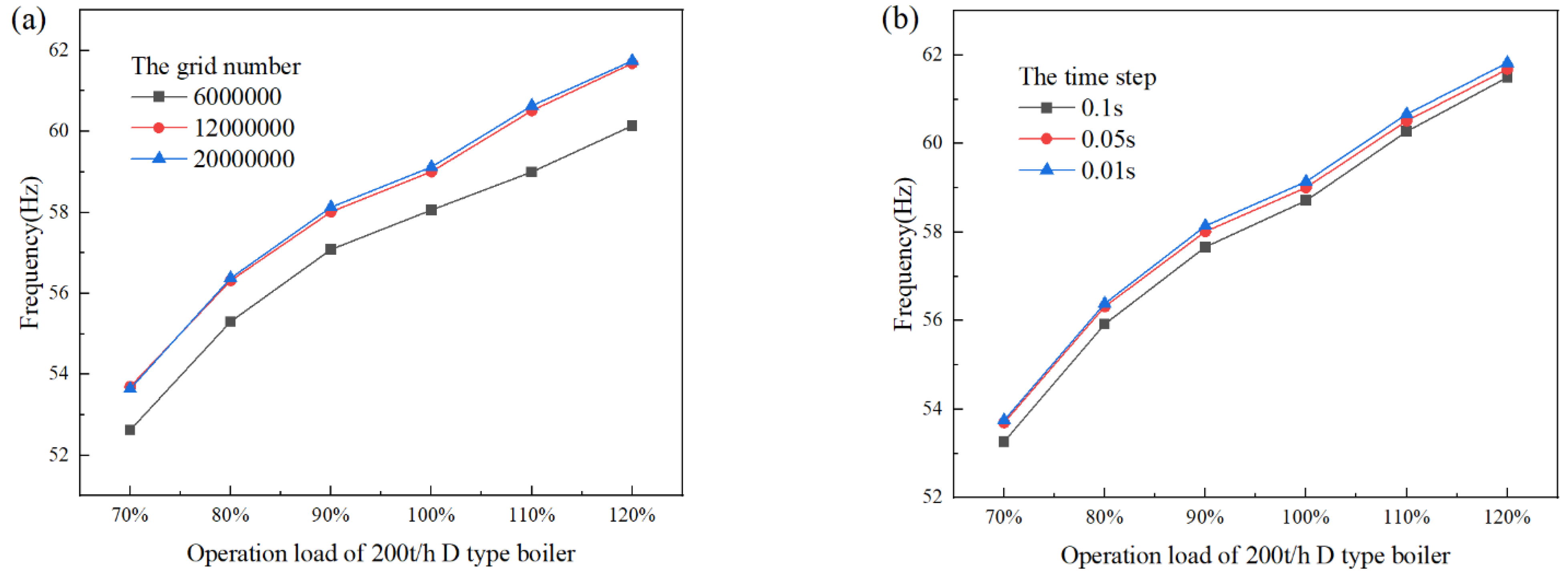

2.4. Meshing and Numerical Methods

3. Results and Discussion

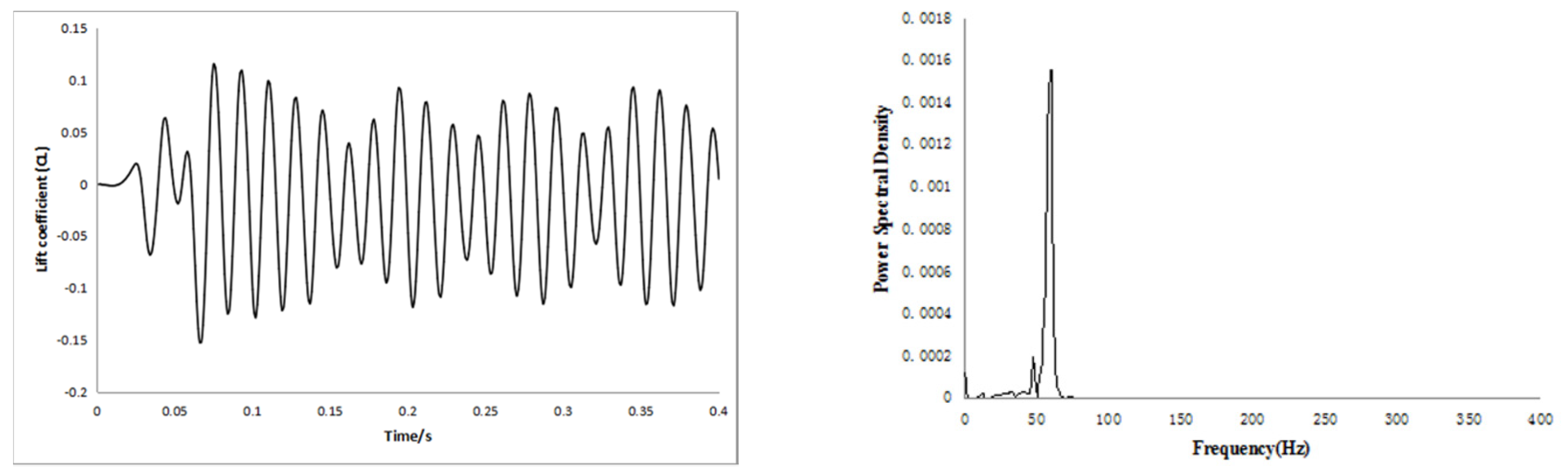

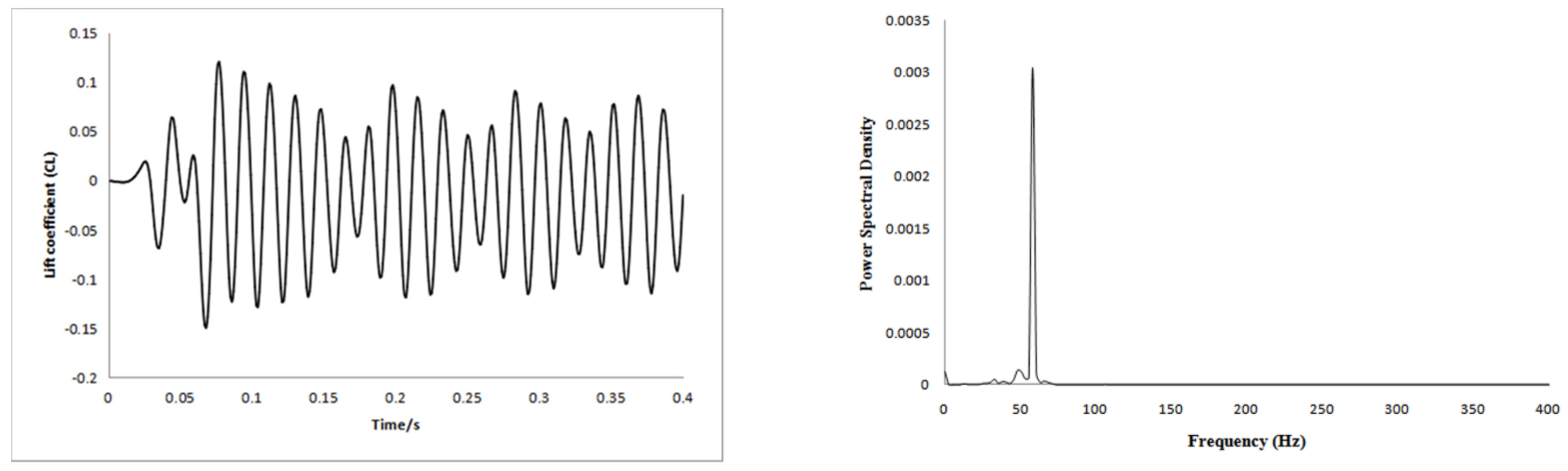

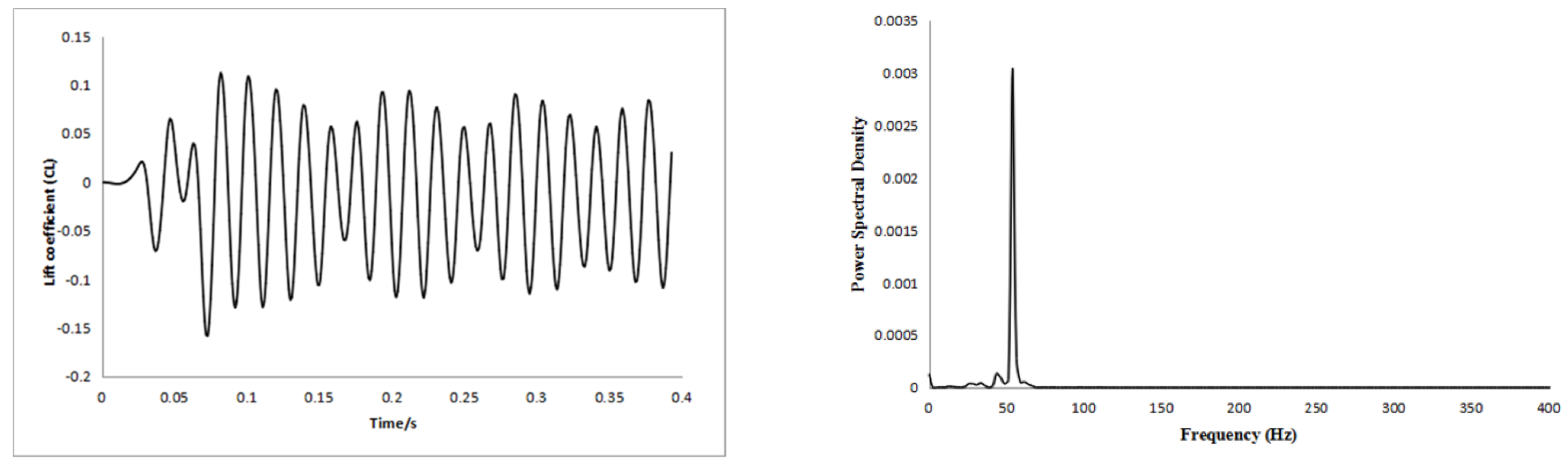

3.1. Numerical Calculation Results

3.2. Result Analysis

3.2.1. Result Verification

3.2.2. Analysis and Verdict

4. Conclusions

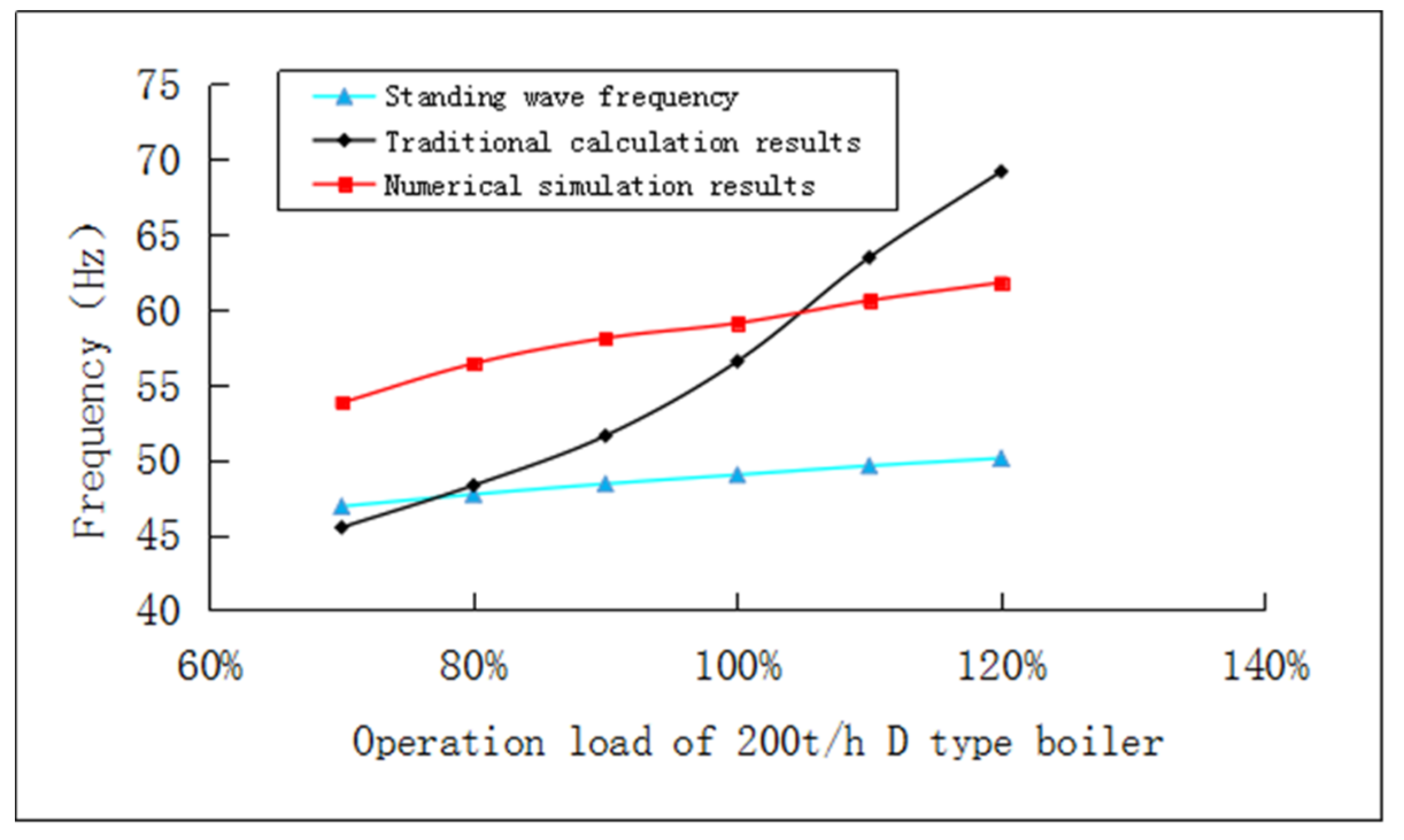

- (1)

- Based on the variable working conditions of a 100 t/h D-type gas-fired boiler, the numerical analysis model established in this paper is reliable. Compared with the Karmen vortex shedding frequency obtained by traditional calculation methods, the Karmen vortex shedding frequency obtained with the numerical simulation method in this paper is closer to the true value of the Karmen vortex shedding frequency.

- (2)

- The simulation results show that with the working condition load decreasing, the Karmen vortex shedding frequency obtained by numerical simulation is decreased and the position where the periodic shedding of the Karmen vortex is formed also moves upward from the bottom area of the lower baffle.

- (3)

- Under the 200 t/h load, at the location of Section 4 at the bottom of the lower baffle, the Karmen vortex shedding frequency is 59.1 Hz. At this time, mild resonance will occur. Taking the 200 t/h load as the boundary, the vibration strength is increased gradually when the operation load is decreased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mirek, P. Field Test of Superheater Pipes Vibration Caused by Sound Energy in the 235 MWe Circulating Fluidized Bed Boiler. Energies 2021, 14, 7678. [Google Scholar] [CrossRef]

- Cveticanin, D.; Herisanu, N.; Biro, I.; Zukovic, M.; Cveticanin, L. Vibration of the Biomass Boiler Tube Excited with Impact of the Cleaning Device. Mathematics 2020, 8, 1519. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, Y.; Amandolese, X. A Review on Fluid-Induced Flag Vibrations. Appl. Mech. Rev. 2019, 71, 010801. [Google Scholar] [CrossRef]

- Dong, K. Impact on the safety of boiler and control measures of Karmen vortex. Therm. Power Gener. 2008, 12, 31–34. [Google Scholar]

- Li, Z.; Zhang, T.; Chen, Y.; Ziqi Wang, Z. The Effect of Continuous Trapezoidal Straight Spoiler Plates on the Vortex-Induced Vibration of Wind Turbine Towers. Atmosphere 2022, 13, 447. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, B.; Zhang, M.; Wang, G.; Zhao, X. Experimental and numerical investigation of ventilated cavitating flow structures with special emphasis on vortex shedding dynamics. Int. J. Multiph. Flow 2018, 98, 79–95. [Google Scholar] [CrossRef]

- Oliveira, M.A.D.; Moraes, P.G.D.; Andrade, C.L.D.; Bimbato, A.M.; Alcântara Pereira, L.A. Control and Suppression of Vortex Shedding from a Slightly Rough Circular Cylinder by a Discrete Vortex Method. Energies 2020, 13, 4481. [Google Scholar] [CrossRef]

- Min, Q. Numerical simulation of low Reynolds number Karmen vortex. Sichuan Ordnance J. 2009, 30, 81–83. [Google Scholar]

- Lai, Y.; Liu, M.; Dong, Q. Numerical simulation of the heat exchanger tube flow and vortex shedding frequency analysis. Pet. Mach. 2005, 33, 18–20. [Google Scholar]

- Wang, J. Failure Analysis of Fluid Induced Vibration of Heat Exchanger Based on the Weak Fluid Solid Coupling Method; East China University of Science and Technology: Shanghai, China, 2011. [Google Scholar]

- Du, L.; Chen, Z.; Liu, D. Dooley Mei, a boiler air heater and auxiliary air duct vibration mechanism. Heilongjiang Electr. Power 2013, 35, 247–249. [Google Scholar]

- Chen, W.Q.; Ren, A.L.; Deng, J. Numerical simulation of flow-induced vibration on two circular cylinders in a cross-flow. Acta Aerodyn. Sin. 2005, 23, 442–448. [Google Scholar]

- Kim, S.; Alam, M.M. Characteristics and suppression of flow-induced vibrations of two side-by-side circular cylinders. J. Fluids Struct. 2015, 54, 629–642. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S.C. Suppression of flow-induced vibration of a circular cylinder by means of a flexible sheet. J. Mech. Sci. Technol. 2012, 26, 1773–1779. [Google Scholar] [CrossRef]

- Blevins, R.D. Models for Vortex-Induced Vibration of Cylinders Based on Measured Forces. J. Fluids Eng. 2009, 131, 101203. [Google Scholar] [CrossRef]

- Shi, Y.H.; Li, M.W.; Wen, J.; Yang, Y.R.; Cui, F.S.; Zeng, J.C. Heat Transfer Efficiency Prediction of Coal-Fired Power Plant Boiler Based on CEEMDAN-NAR Considering Ash Fouling. Energies 2021, 14, 4000. [Google Scholar] [CrossRef]

- Chai, X.; Xiong, J.; Zhu, Y. Analysis and Countermeasures for the vibration of flue gas in boiler tail. Zhejiang Electr. Power 2004, 23, 6–9. [Google Scholar]

- Hong, F. Analysis and treatment of vibration in the tail flue of 600MW supercritical boiler. Beijing Electr. Power Coll. Nat. Sci. Ed. 2010, 27, 64–65. [Google Scholar]

- Koizumi, H.; Tsutsumi, S.; Shima, E. Feedback Control of Karman Vortex Shedding from a Cylinder using Deep Reinforcement Learning. In Proceedings of the 2018 Flow Control Conference, Atlanta, Georgia, 25–29 June 2018. [Google Scholar] [CrossRef]

- Khan, U.; Zevenhoven, R.; Tveit, T.M. Evaluation of the Environmental Sustainability of a Stirling Cycle-Based Heat Pump Using LCA. Energies 2020, 13, 4469. [Google Scholar] [CrossRef]

- Hu, Y.; Li, H.; Yan, J. Numerical investigation of heat transfer characteristics in utility boilers of oxy-coal combustion. Appl. Energy 2014, 130, 543–551. [Google Scholar] [CrossRef]

- Taler, D.; Trojan, M.; Dzierwa, P.; Kaczmarski, K.; Taler, J. Numerical simulation of convective superheaters in steam boilers. Int. J. Therm. Sci. 2018, 129, 320–333. [Google Scholar] [CrossRef]

- Pan, P.; Zhang, M.; Xu, G.; Chen, H.; Song, X.; Liu, T. Thermodynamic and Economic Analyses of a New Waste-to-Energy System Incorporated with a Biomass-Fired Power Plant. Energies 2020, 13, 4345. [Google Scholar] [CrossRef]

- Lu, G. Study on vibration calculation of large capacity D type boiler. Jiangsu Univ. Sci. Technol. 2016. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=1016735956.nh&DbName=CMFD2017 (accessed on 1 March 2022).

- Zhou, S. The reason analysis and Countermeasure of the local vibration of the horizontal flue in a power plant boiler. Boil. Technol. 2004, 12, 59–61. [Google Scholar]

| Horizontal Pitch | Longitudinal Pitch (mm) | Convection Flue Width B/m | Outer Diameter | Flue Gas Velocity | Karman Vortex Street Frequency (Hz) | First-Order Standing Wave Frequency (Hz) |

|---|---|---|---|---|---|---|

| (mm) | d/mm | V/m s−1 | ||||

| 116.5 | 121 | 6.7 | 57 | 12.4 | 56.56 | 49 |

| Velocity/ms−1 | Pressure/Pa | Temperature/K | Hydraulic Diameter/m | |

|---|---|---|---|---|

| Gas inlet | 20.3 | −18.5 | 1473 | 2.795 |

| Gas outlet | — | −276.6 | 730 | 2.345 |

| Wall Temperature/K | Emissivity ε (Internal Emissivity) | Wall Roughness/mm | |

|---|---|---|---|

| High-temperature superheater | 707 | 0.731 | 0.45 |

| Low-temperature superheater | 643 | 0.753 | |

| Convection tube bundle | 539 | 0.786 | |

| Water wall | 534 | 0.788 |

| Operation Load | 70% | 80% | 90% | 100% | 110% | 120% |

|---|---|---|---|---|---|---|

| Karmen vortex shedding frequency | 53.8 Hz | 56.4 Hz | 58.1 Hz | 59.1 Hz | 60.6 Hz | 61.8 Hz |

| The region that triggers the vibration | Section 3 | Section 3 | Section 4 | Section 4 | Section 4 | Section 4 |

| Operation Load | 80% | 90% | 100% | 110% | 120% |

|---|---|---|---|---|---|

| Numerical simulation result | 49 Hz | 51 Hz | 52 Hz | 54 Hz | 55 Hz |

| Traditional calculation result | 45 Hz | 47 Hz | 48 Hz | 52 Hz | 54 Hz |

| Vibration area | Section 2 | Section 3 | Section 3 | Section 3 | Section 4 |

| First-order acoustic standing wave frequency | 46.35 Hz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, S.; Huang, X.; Zhang, L.; Mao, H.; Sun, X. Analysis and Prediction of Flow-Induced Vibration of Convection Pipe for 200 t/h D Type Gas Boiler. Axioms 2022, 11, 163. https://doi.org/10.3390/axioms11040163

Yao S, Huang X, Zhang L, Mao H, Sun X. Analysis and Prediction of Flow-Induced Vibration of Convection Pipe for 200 t/h D Type Gas Boiler. Axioms. 2022; 11(4):163. https://doi.org/10.3390/axioms11040163

Chicago/Turabian StyleYao, Shouguang, Xinyu Huang, Linglong Zhang, Huiyi Mao, and Xiaofei Sun. 2022. "Analysis and Prediction of Flow-Induced Vibration of Convection Pipe for 200 t/h D Type Gas Boiler" Axioms 11, no. 4: 163. https://doi.org/10.3390/axioms11040163

APA StyleYao, S., Huang, X., Zhang, L., Mao, H., & Sun, X. (2022). Analysis and Prediction of Flow-Induced Vibration of Convection Pipe for 200 t/h D Type Gas Boiler. Axioms, 11(4), 163. https://doi.org/10.3390/axioms11040163