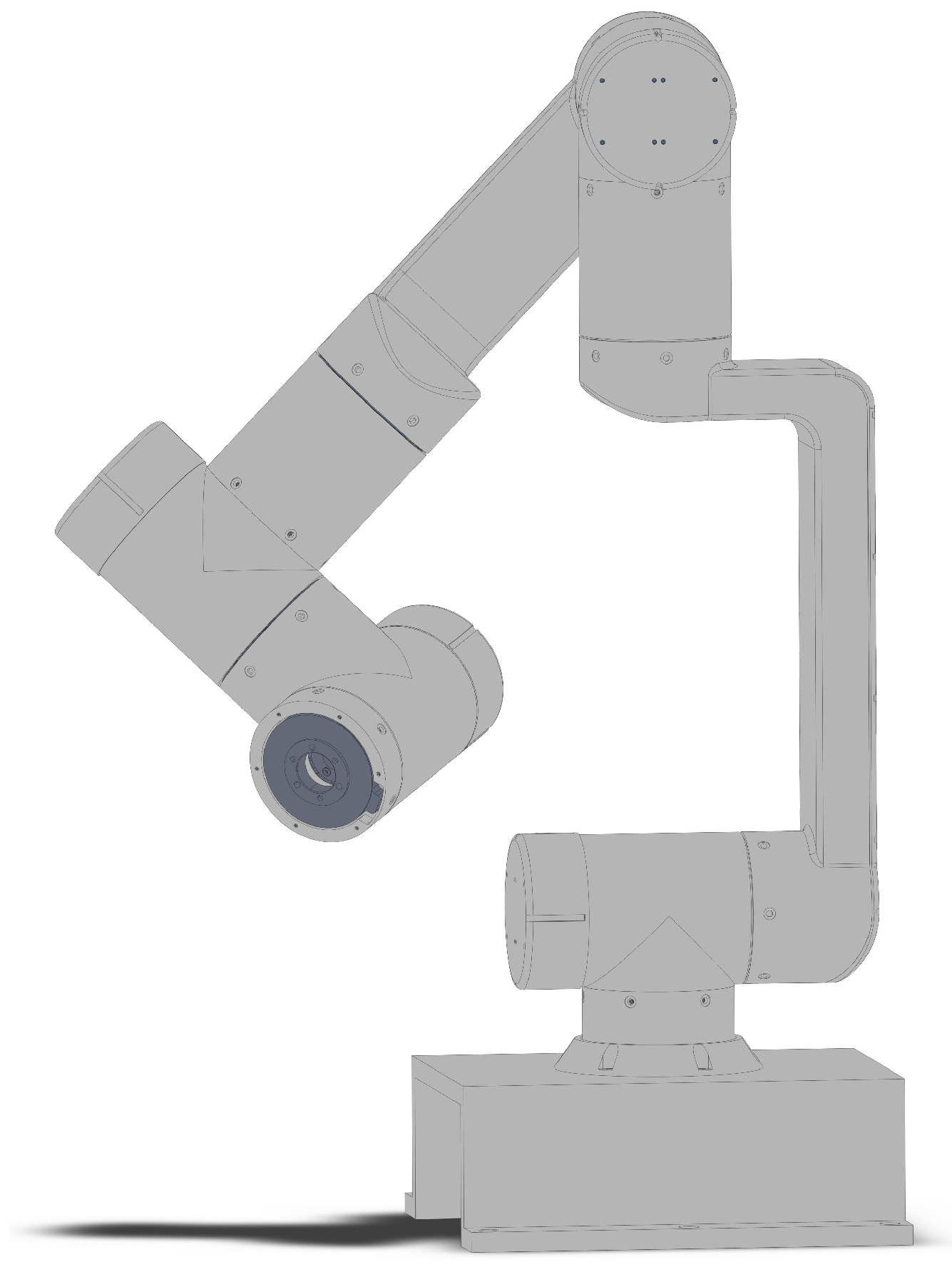

The Dexterity Capability Map for a Seven-Degree-of-Freedom Manipulator

Abstract

1. Introduction

2. Analytical Solution of the Manipulator

2.1. Kinematics Model and Analysis

2.2. Analytical Method for , , and

2.3. Geometric Method for , , and

2.4. The Obstacle Avoidance Ability Index

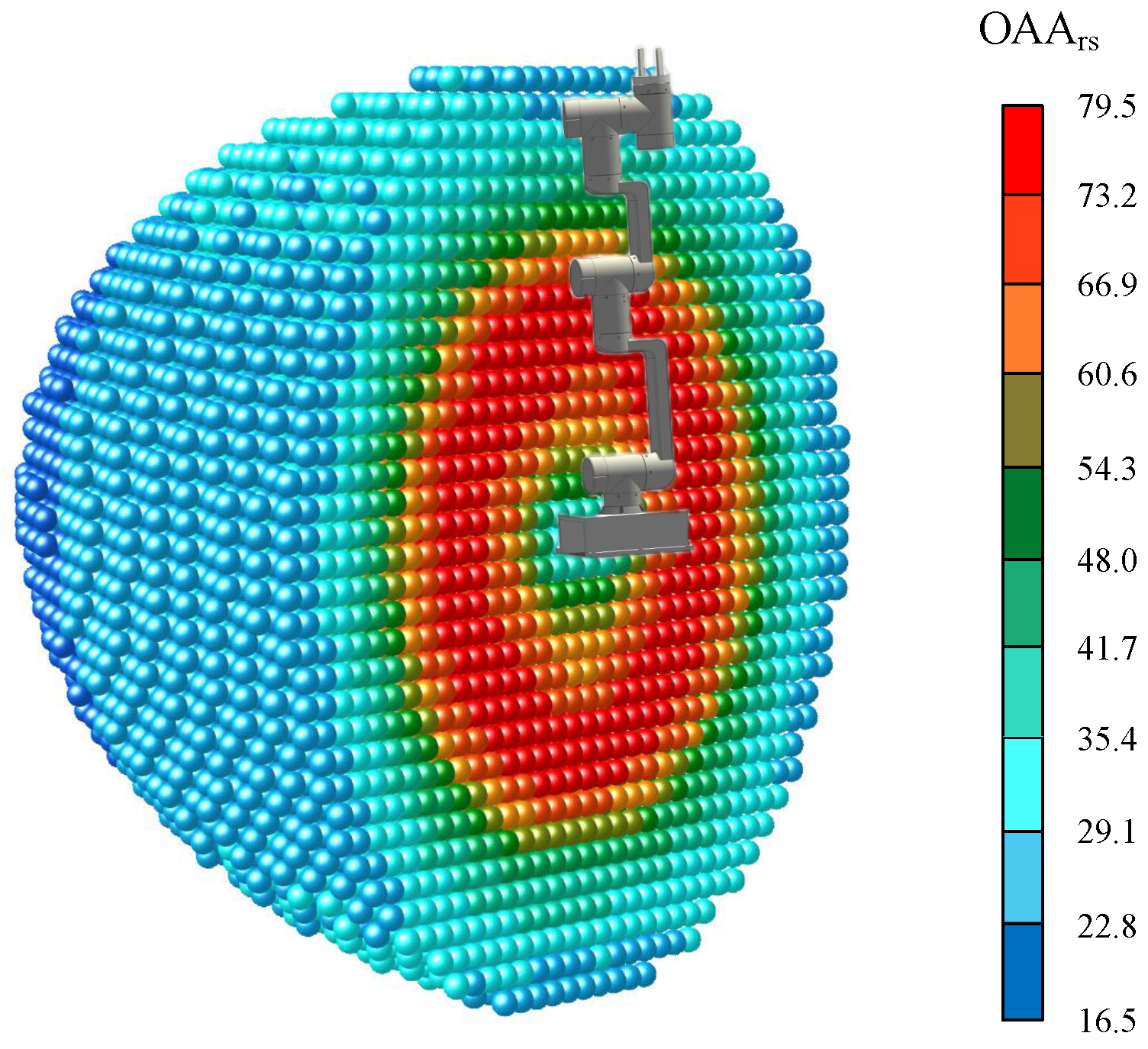

3. The Reachability Capability Map Approach

3.1. Reachability Index of the Workspace

3.2. Capturing the Structure to Construct a Map

4. Dexterity Capability Map

4.1. The Description of the Obstacle Avoidance Ability of the Workspace

4.2. Distribution and Fitting of the OAA Index of Reachability Spheres

4.3. Pre-Planners for Grasping Tasks

5. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Ma, R.R.; Dollar, A.M. On dexterity and dexterous manipulation. In Proceedings of the 2011 15th International Conference on Advanced Robotics (ICAR), Tallinn, Estonia, 20–23 June 2011; pp. 1–7. [Google Scholar]

- Ebert-Uphoff, I.; Chirikjian, G.S. Inverse kinematics of discretely actuated hyper-redundant manipulators using workspace densities. In Proceedings of the IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; Volume 1, pp. 139–145. [Google Scholar]

- Yoshikawa, T. Manipulability of robotic mechanisms. Int. J. Robot. Res. 1985, 4, 3–9. [Google Scholar] [CrossRef]

- Vahrenkamp, N.; Asfour, T.; Metta, G.; Sandini, G.; Dillmann, R. Manipulability analysis. In Proceedings of the 2012 12th IEEE-Ras International Conference on Humanoid Robots (Humanoids 2012), Osaka, Japan, 29 November–1 December 2012; pp. 568–573. [Google Scholar]

- Vahrenkamp, N.; Asfour, T. Representing the robot’s workspace through constrained manipulability analysis. Auton. Robot. 2015, 38, 17–30. [Google Scholar] [CrossRef]

- Xu, R.; Luo, J.; Wang, M. Optimal grasping pose for dual-arm space robot cooperative manipulation based on global manipulability. Acta Astronaut. 2021, 183, 300–309. [Google Scholar] [CrossRef]

- Stocco, L.; Salcudean, S.E.; Sassani, F. Fast constrained global minimax optimization of robot parameters. Robotica 1998, 16, 595–605. [Google Scholar] [CrossRef]

- Zacharias, F.; Borst, C.; Hirzinger, G. Capturing robot workspace structure: Representing robot capabilities. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 3229–3236. [Google Scholar]

- Zacharias, F.; Borst, C.; Hirzinger, G. Online generation of reachable grasps for dexterous manipulation using a representation of the reachable workspace. In Proceedings of the 2009 International Conference on Advanced Robotics, Munich, Germany, 22–26 June 2009; pp. 1–8. [Google Scholar]

- Borst, C.; Fischer, M.; Hirzinger, G. Grasping the dice by dicing the grasp. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003) (Cat. No. 03CH37453), Las Vegas, NV, USA, 27–31 October 2003; Volume 4, pp. 3692–3697. [Google Scholar]

- Zacharias, F.; Borst, C.; Wolf, S.; Hirzinger, G. The capability map: A tool to analyze robot arm workspaces. Int. J. Humanoid Robot. 2013, 10, 1350031. [Google Scholar] [CrossRef]

- Ruehl, S.W.; Hermann, A.; Xue, Z.; Kerscher, T.; Dillmann, R. Graspability: A description of work surfaces for planning of robot manipulation sequences. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 496–502. [Google Scholar]

- Wu, W. A grasp-pose generation method based on Gaussian mixture models. Int. J. Adv. Robot. Syst. 2015, 12, 167. [Google Scholar] [CrossRef]

- Cao, B.; Sun, K.; Gu, Y.; Jin, M.; Liu, H. Workspace Analysis Based on Manipulator Pose Dexterity Map. In Proceedings of the 2018 3rd International Conference on Robotics and Automation Engineering (ICRAE), Guangzhou, China, 17–19 November 2018; pp. 166–170. [Google Scholar]

- Cao, B.; Sun, K.; Gu, Y.; Jin, M.; Liu, H. Humanoid Robot Torso Motion Planning Based on Manipulator Pose Dexterity Index. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 853, p. 012040. [Google Scholar]

- Baciu, G.; Wong, W.S.K. Image-based collision detection for deformable cloth models. IEEE Trans. Vis. Comput. Graph. 2004, 10, 649–663. [Google Scholar] [CrossRef]

- Moore, M.; Wilhelms, J. Collision detection and response for computer animation. In Proceedings of the 15th Annual Conference on Computer Graphics and Interactive Techniques, Atlanta, GA, USA, 1–5 August 1988; pp. 289–298. [Google Scholar]

- Ganter, M.; Isarankura, B. Dynamic collision detection using space partitioning. J. Mech. Des. 1993, 115, 150–155. [Google Scholar] [CrossRef]

- Webster, N.; McKechnie, J.L. Webster’s New Universal Unabridged Dictionary; Dorset & Baber: Houston, TX, USA, 1983. [Google Scholar]

- Smith, A.; Kitamura, Y.; Takemura, H.; Kishino, F. A simple and efficient method for accurate collision detection among deformable polyhedral objects in arbitrary motion. In Proceedings of the Virtual Reality Annual International Symposium’95, Online, 11–15 March 1995; pp. 136–145. [Google Scholar]

- van den Bergen, G. Efficient collision detection of complex deformable models using AABB trees. J. Graph. Tools 1997, 2, 1–13. [Google Scholar] [CrossRef]

- Palmer, I.J.; Grimsdale, R.L. Collision detection for animation using sphere-trees. In Proceedings of the Computer Graphics Forum; Wiley Online Library: Hoboken, NJ, USA, 1995; Volume 14, pp. 105–116. [Google Scholar]

- Gottschalk, S.; Lin, M.C.; Manocha, D. OBBTree: A hierarchical structure for rapid interference detection. In Proceedings of the 23rd annual Conference on Computer Graphics and Interactive Techniques, New Orleans, LA, USA, 4–9 August 1996; pp. 171–180. [Google Scholar]

- Klosowski, J.T.; Held, M.; Mitchell, J.S.; Sowizral, H.; Zikan, K. Efficient collision detection using bounding volume hierarchies of k-DOPs. IEEE Trans. Vis. Comput. Graph. 1998, 4, 21–36. [Google Scholar] [CrossRef]

- Chang, J.W.; Wang, W.; Kim, M.S. Efficient collision detection using a dual bounding volume hierarchy. In Proceedings of the International Conference on Geometric Modeling and Processing, Hangzhou, China, 23–25 April 2008; Springer: Berlin, Germany, 2008; pp. 143–154. [Google Scholar]

- Chang, J.W.; Wang, W.; Kim, M.S. Efficient collision detection using a dual OBB-sphere bounding volume hierarchy. Comput.-Aided Des. 2010, 42, 50–57. [Google Scholar] [CrossRef]

- Liang, T.; Song, W.G.; Hou, T.C.; Liu, L.L.; Cao, W.X.; Yan, Z. Collision detection of virtual plant based on bounding volume hierarchy: A case study on virtual wheat. J. Integr. Agric. 2018, 17, 306–314. [Google Scholar]

- Hentout, A.; Maoudj, A.; Aouache, M. A review of the literature on fuzzy-logic approaches for collision-free path planning of manipulator robots. In Artificial Intelligence Review; Springer: Berlin, Germany, 2022; pp. 1–76. [Google Scholar]

- Lee, K.K.; Buss, M. Obstacle avoidance for redundant robots using Jacobian transpose method. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 3515–3520. [Google Scholar]

- Xiao, L.; Zhang, Y. Dynamic design, numerical solution and effective verification of acceleration-level obstacle-avoidance scheme for robot manipulators. Int. J. Syst. Sci. 2016, 47, 932–945. [Google Scholar] [CrossRef]

- Chiriatti, G.; Palmieri, G.; Scoccia, C.; Palpacelli, M.C.; Callegari, M. Adaptive obstacle avoidance for a class of collaborative robots. Machines 2021, 9, 113. [Google Scholar] [CrossRef]

- Orin, D.E.; Schrader, W.W. Efficient computation of the Jacobian for robot manipulators. Int. J. Robot. Res. 1984, 3, 66–75. [Google Scholar] [CrossRef]

- Wolovich, W.A.; Elliott, H. A computational technique for inverse kinematics. In Proceedings of the 23rd IEEE Conference on Decision and Control, Las Vegas, NV, USA, 12–14 December 1984; pp. 1359–1363. [Google Scholar]

- Maciejewski, A.A.; Klein, C.A. Obstacle avoidance for kinematically redundant manipulators in dynamically varying environments. Int. J. Robot. Res. 1985, 4, 109–117. [Google Scholar] [CrossRef]

- Wampler, C.W. Manipulator inverse kinematic solutions based on vector formulations and damped least-squares methods. IEEE Trans. Syst. Man Cybern. 1986, 16, 93–101. [Google Scholar] [CrossRef]

- Nakamura, Y.; Hanafusa, H. Inverse kinematic solutions with singularity robustness for robot manipulator control. J. Dyn. Syst. Meas. Control 1986, 108, 163–171. [Google Scholar] [CrossRef]

- Deo, A.S.; Walker, I.D. Robot subtask performance with singularity robustness using optimal damped least-squares. In Proceedings of the 1992 IEEE International Conference on Robotics and Automation, Nice, France, 12–14 May 1992; IEEE Computer Society: Washington, DC, USA, 1992; pp. 434–435. [Google Scholar]

- Crane III, C.D.; Duffy, J.; Carnahan, T. A kinematic analysis of the space station remote manipulator system (SSRMS). J. Robot. Syst. 1991, 8, 637–658. [Google Scholar] [CrossRef]

- Lee, S.; Bejczy, A.K. Redundant arm kinematic control based on parameterization. In Proceedings of the 1991 IEEE International Conference on Robotics and Automation, Sacramento, CA, USA, 9–11 April 1991; IEEE Computer Society: Washington, DC, USA, 1991; pp. 458–459. [Google Scholar]

- Shimizu, M.; Kakuya, H.; Yoon, W.K.; Kitagaki, K.; Kosuge, K. Analytical inverse kinematic computation for 7-DOF redundant manipulators with joint limits and its application to redundancy resolution. IEEE Trans. Robot. 2008, 24, 1131–1142. [Google Scholar] [CrossRef]

- Tondu, B. A closed-form inverse kinematic modeling of a 7R anthropomorphic upper limb based on a joint parametrization. In Proceedings of the 2006 6th IEEE-RAS International Conference on Humanoid Robots, Genova, Italy, 4–6 December 2006; pp. 390–397. [Google Scholar]

- Craig, J.J. Introduction to Robotics: Mechanics and Control; Pearson Education: London, UK, 2005. [Google Scholar]

- Siciliano, B.; Khatib, O.; Kröger, T. Springer Handbook of Robotics; Springer: Berlin, Germany, 2008; Volume 200. [Google Scholar]

- Raghavan, M.; Roth, B. Inverse kinematics of the general 6R manipulator and related linkages. J. Mech. Des. 1993, 115, 502–508. [Google Scholar] [CrossRef]

- Saff, E.B.; Kuijlaars, A.B. Distributing many points on a sphere. Math. Intell. 1997, 19, 5–11. [Google Scholar] [CrossRef]

- Székely, G.J.; Rizzo, M.L.; Bakirov, N.K. Measuring and testing dependence by correlation of distances. Ann. Stat. 2007, 35, 2769–2794. [Google Scholar] [CrossRef]

- Moré, J.J. The Levenberg–Marquardt Algorithm: Implementation and Theory. In Numerical Analysis; Springer: Berlin, Germany, 1978; pp. 105–116. [Google Scholar]

| i | ||||

|---|---|---|---|---|

| 1 | 0 | 0 | 0 | |

| 2 | 90° | 0 | 0 | 0 |

| 3 | −90° | 0 | 0 | |

| 4 | 90° | 0 | 0 | 0 |

| 5 | −90° | 0 | 0 | |

| 6 | 90° | 0 | 0 | 0 |

| Time 1 (s) | Time 2 (s) | MAE | |

|---|---|---|---|

| Case 1 | 0.161 | 2.822 | |

| Case 2 | 0.153 | 2.367 | |

| Case 3 | 0.122 | 2.659 | |

| Case 4 | 0.096 | 2.842 | |

| Case 5 | 0.159 | 3.156 | |

| Case 6 | 0.038 | 7.432 |

| Accuracy Rate | MAE | Time (s) | |

|---|---|---|---|

| Grasping scenario 1 | 94.35% | 4.239 | |

| Grasping scenario 2 | 93.69% | 5.621 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quan, Y.; Zhao, C.; Lv, C.; Wang, K.; Zhou, Y. The Dexterity Capability Map for a Seven-Degree-of-Freedom Manipulator. Machines 2022, 10, 1038. https://doi.org/10.3390/machines10111038

Quan Y, Zhao C, Lv C, Wang K, Zhou Y. The Dexterity Capability Map for a Seven-Degree-of-Freedom Manipulator. Machines. 2022; 10(11):1038. https://doi.org/10.3390/machines10111038

Chicago/Turabian StyleQuan, Yuan, Chong Zhao, Congmin Lv, Ke Wang, and Yanlin Zhou. 2022. "The Dexterity Capability Map for a Seven-Degree-of-Freedom Manipulator" Machines 10, no. 11: 1038. https://doi.org/10.3390/machines10111038

APA StyleQuan, Y., Zhao, C., Lv, C., Wang, K., & Zhou, Y. (2022). The Dexterity Capability Map for a Seven-Degree-of-Freedom Manipulator. Machines, 10(11), 1038. https://doi.org/10.3390/machines10111038