A Numerical Analysis of Hybrid Spur Gears with Asymmetric Teeth: Stress and Dynamic Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Stiffness Evaluation

2.2. Dynamic Behavior Evaluation

3. Results and Discussion

3.1. Root and Joint Region Stress Results

3.1.1. Effect of Rack Tip Radius on Root Stress

3.1.2. Effect of Rack Tip Radius on Joint Normal Stress

3.1.3. Effect of Rack Tip Radius on Joint Shear Stress

3.1.4. Effect of Drive Side Pressure Angle on Root Stress

3.1.5. Effect of Drive Side Pressure Angle on Joint Normal Stress

3.1.6. Effect of Drive Side Pressure Angle on Joint Shear Stress

3.2. Single Tooth and Mesh Stiffness Results

3.3. Dynamic Analysis Results

3.3.1. Dynamic Factor Results

3.3.2. Static Transmission Error Results

4. Conclusions

- As the RT increases, the root stresses decrease; however, this decrease reduces significantly after 1.5 xm RT.

- The effect of RT on joint region normal stresses is higher than its effect on shear stresses. When the RT is increased from 0.5 xm to 2 xm, the normal stresses decrease by about 80%, while this ratio remains at the level of 65% in shear stresses.

- When the increased DSPA is increased from 20° to 25°, the root stresses decrease by 5% at the same moment transmission and by approximately 9% when it is increased to 30°.

- Increasing DSPAs for the same RT reduces the normal stresses of the joint region. However, this effect remains quite low. When the DSPA is increased to 25°, the normal stresses decrease by 2.5%, while this ratio becomes 3.5% for 30°.

- For the same RT, increasing DSPAs increases the joint region shear stresses. When the DSPA is increased to 25°, the shear stresses increase by 6%, while this ratio becomes 13% for 30°.

- STS and MS increase with increasing RT. When the RT is increased from 0.5 xm to 2 xm for all DSPAs, single tooth stiffness increases by approximately 20%.

- Increasing DSPA also increases STS and MS. When the DSPA is increased to 25°, the single tooth stiffness is 5% on average, while this ratio becomes 30% at 30°.

- When the DSPA is increased to 25°, MS increases by 12%, while this ratio becomes 22% on average at 30° averagely.

- Mesh stiffness increases by 20%, 33%, and 40% for 20°, 25°, and 30° DSPAs, respectively.

- Increasing RT does not significantly affect the dynamic factor. It is observed that the location of the resonance regions changes.

- Increasing the DSPA increases the dynamic factor. In the first resonance region, the dynamic factor is about 1.45 for 20°, while the dynamic factor is about 1.8 for 30°.

- Static transmission errors decrease as the RT and DSPA are increased. While the maximum static transmission error is approximately 9.5 μm for 20° and RT of 0.5 xm in hybrid gears, this value is 8.5 μm at 30°. At 2 xm RT, these values are 7.7 μm and 6.4 μm, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Litvin, F.; Fuentes, A. Gear Geometry and Applied Theory, 2nd ed.; Cambridge University Press: Cambridge, UK, 2004; ISBN 9780521815178. [Google Scholar]

- Vullo, V. Gears: General Concepts, Definitions and Some Basic Quantities; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Kapelevich, A. Asymmetric Gearing, 1st ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2018. [Google Scholar]

- Brown, B.F.W.; Davidson, S.R.; Hanes, D.B.; Weires, D.J.; Brown, F.W.; Davidson, S.R.; Hanes, D.B.; Weires, D.J.; Company, T.B.; Kapelevich, A.; et al. Analysis and Testing of Gears with Asymmetric Involute Tooth Form and Optimized Fillet Form for Potential Application in Helicopter Main Drives; AGMA Technical Paper; AGMA: Alexandria, VA, USA, 2010. [Google Scholar]

- U.S. Energy Information Administration. International Energy Outlook Report; U.S. Energy Information Administration: Washington, DC, USA, 2013.

- Yuce, C.; Karpat, F.; Yavuz, N.; Sendeniz, G. A Case Study: Designing for Sustainability and Reliability in an Automotive Seat Structure. Sustainability 2014, 6, 4608–4631. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz, T.G.; Tüfekçi, M.; Karpat, F. A Study of Lightweight Door Hinges of Commercial Vehicles Using Aluminum Instead of Steel for Sustainable Transportation. Sustainability 2017, 9, 1661. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Kim, B.; Lee, H.-J.; Yoon, J. Warm Forging of an Aluminium Alloy for the Differential Case in an Automobile Transmission. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230, 1131–1139. [Google Scholar] [CrossRef]

- Cho, S.K.; Kim, H.J.; Chang, S.H. The Application of Polymer Composites to the Table-Top Machine Tool Components for Higher Stiffness and Reduced Weight. Compos. Struct. 2011, 93, 492–501. [Google Scholar] [CrossRef]

- Kim, J.H.; Chang, S.H. Design of μ-CNC Machining Centre with Carbon/Epoxy Composite-Aluminium Hybrid Structures Containing Friction Layers for High Damping Capacity. Compos. Struct. 2010, 92, 2128–2136. [Google Scholar] [CrossRef]

- Doğan, O.; Yılmaz, T.G.; Karpat, F. Stress Analysis of Involute Spur Gears with Different Parameters by Finite Element and Graphical Method. J. Fac. Eng. Archit. Gazi Univ. 2018, 33, 1493–1504. [Google Scholar] [CrossRef]

- Yılmaz, T.; Doğan, O.; Karpat, F. A Comparative Numerical Study of Forged Bi-Metal Gears: Bending Strength and Dynamic Response. Mech. Mach. Theory 2019, 141, 117–135. [Google Scholar] [CrossRef]

- Cho, D.H.; Lee, D.G.; Choi, J.H. Manufacture of One-Piece Automotive Drive Shafts with Aluminum and Composite Materials. Compos. Struct. 1997, 38, 309–319. [Google Scholar] [CrossRef]

- Bae, J.H.; Jung, K.C.; Yoo, S.H.; Chang, S.H.; Kim, M.; Lim, T. Design and Fabrication of a Metal-Composite Hybrid Wheel with a Friction Damping Layer for Enhancement of Ride Comfort. Compos. Struct. 2015, 133, 576–584. [Google Scholar] [CrossRef]

- Handschuh, R.; Roberts, G.D.; Sinnamon, R.; Stringer, D.; Dykas, B.; Kohlman, L. Hybrid Gear Preliminary Results—Application of Composites to Dynamic Mechanical Components. In Proceedings of the Annual Forum Proceedings—AHS International, Fort Worth, TX, 1–3 May 2012; Volume 4, pp. 2356–2366. [Google Scholar]

- Handschuh, R.F.; Laberge, K.E.; Deluca, S.; Pelagalli, R. Vibration and Operational Characteristics of a Composite-Steel (Hybrid) Gear; NASA/TM—2014-216646; NASA: Washington, DC, USA, 2014.

- Catera, P.; Gagliardi, F.; Mundo, D.; De Napoli, L.; Matveeva, A.; Farkas, L. Multi-Scale Modeling of Triaxial Braided Composites for FE-Based Modal Analysis of Hybrid Metal-Composite Gears. Compos. Struct. 2017, 182, 116–123. [Google Scholar] [CrossRef]

- Catera; Mundo, D.; Treviso, A.; Gagliardi, F.; Visrolia, A. On the Design and Simulation of Hybrid Metal-Composite Gears. Appl. Compos. Mater. 2018, 26, 817–833. [Google Scholar] [CrossRef]

- Catera, P.G.; Mundo, D.; Gagliardi, F.; Treviso, A. A Comparative Analysis of Adhesive Bonding and Interference Fitting as Joining Technologies for Hybrid Metal- Composite Gear Manufacturing. Int. J. Interact. Des. Manuf. 2020, 14, 535–550. [Google Scholar] [CrossRef]

- Karpat, F.; Yılmaz, T.G.; Dogan, O.; Kalay, O. Stress and Mesh Stiffness Evaluation of Bimaterial Spur Gears. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Salt Lake City, UT, USA, 11–14 November 2019. [Google Scholar]

- Gauntt, S.M.; Campbell, R.L. Characterization of a Hybrid (Steel-Composite) Gear with Various Composite Materials and Layups. In Proceedings of the International Student Conference—Masters Category, AIAA 2019-0146, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Yılmaz, T.G.; Doğan, O.; Karpat, F. A Numerical Investigation on the Hybrid Spur Gears: Stress and Dynamic Analysis. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 354–369. [Google Scholar] [CrossRef]

- Yuce, C.; Karpat, F. Effects of Rim Thickness and Drive Side Pressure Angle on Gear Tooth Root Stress and Fatigue Crack Propagation Life. Eng. Fail. Anal. 2021, 122, 105260. [Google Scholar] [CrossRef]

- DIN DIN 3990-3; Calculation of Load Capacity of Cylindrical Gears. Calculation of Tooth Strength. Deutsches Institut fur Normung E.V. (DIN) Location: Berlin, Germany, 1987.

- Gasparini, G.; Mariani, U.; Gorla, C.; Filippini, M.; Rosa, F.F. Bending Fatigue Tests of Helicopter Case Carburized Gears: Influence of Material, Design and Manufacturing Parameters. Gear Technol. 2009. Available online: https://www.geartechnology.com/articles/20082-bending-fatigue-tests-of-helicopter-case-carburized-gears-influence-on-material-design-and-manufacturing-parameters (accessed on 7 October 2022).

- Karpat, F.; Dogan, O.; Yilmaz, T.; Yuce, C.; Kalay, O.C.; Karpat, E.; Kopmaz, O. Effects of Drive Side Pressure Angle on Gear Fatigue Crack Propagation Life for Spur Gears with Symmetric and Asymmetric Teeth. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Salt Lake City, UT, USA, 11–14 November 2019; Volume 9. [Google Scholar]

- Cavdar, K.; Karpat, F.; Babalik, F.C. Computer Aided Analysis of Bending Strength of Involute Spur Gears with Asymmetric Profile. J. Mech. Des. 2005, 127, 477. [Google Scholar] [CrossRef]

- Deng, G.; Nakanishi, T.; Inoue, K. Bending Load Capacity Enhancement Using an Asymmetric Tooth Profile. JSME Int. J. Ser. C 2003, 46, 1171–1177. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz, T. Structural Analysis of New Generation Lightened Spur Gears with Dual Material; Bursa Uludag University: Bursa, Turkey, 2021. [Google Scholar]

- Ribeiro, T.E.A.; Campilho, R.D.S.G.; da Silva, L.F.M.; Goglio, L. Damage Analysis of Composite-Aluminium Adhesively-Bonded Single-Lap Joints; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; Volume 136. [Google Scholar]

- Khoramishad, H.; Hamzenejad, M.; Ashofteh, R.S. Characterizing Cohesive Zone Model Using a Mixed-Mode Direct Method. Eng. Fract. Mech. 2016, 153, 175–189. [Google Scholar] [CrossRef]

- Cooley, C.G.; Liu, C.; Dai, X.; Parker, R.G. Gear Tooth Mesh Stiffness: A Comparison of Calculation Approaches. Mech. Mach. Theory 2016, 105, 540–553. [Google Scholar] [CrossRef] [Green Version]

- Liang, X.; Zhang, H.; Liu, L.; Zuo, M.J. The Influence of Tooth Pitting on the Mesh Stiffness of a Pair of External Spur Gears. Mech. Mach. Theory 2016, 106, 1–15. [Google Scholar] [CrossRef]

- Liang, X.; Zuo, M.J.; Patel, T.H. Evaluating the Time-Varying Mesh Stiffness of a Planetary Gear Set Using the Potential Energy Method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 535–547. [Google Scholar] [CrossRef]

- Karpat, F.; Dogan, O.; Yuce, C.; Ekwaro-Osire, S. An Improved Numerical Method for the Mesh Stiffness Calculation of Spur Gears with Asymmetric Teeth on Dynamic Load Analysis. Adv. Mech. Eng. 2017, 9, 1–12. [Google Scholar] [CrossRef]

- Kuang, J.H.; Lin, A.D. The Effect of Tooth Wear on the Vibration Spectrum of a Spur Gear Pair. J. Vib. Acoust. 2001, 123, 311. [Google Scholar] [CrossRef]

- Karpat, F.; Yuce, C.; Doğan, O. Experimental Measurement and Numerical Validation of Single Tooth Stiffness for Involute Spur Gears. Measurement 2020, 150, 107043. [Google Scholar] [CrossRef]

- Munro, R.G.; Palmer, D.; Morrish, L. An Experimental Method to Measure Gear Tooth Stiffness throughout and beyond the Path of Contact. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2001, 215, 793–803. [Google Scholar] [CrossRef]

- Yuce, C.; Dogan, O.; Karpat, F. Effects of Asymmetric Tooth Profile on Single-Tooth Stiffness of Polymer Gears. Mater. Test. 2022, 64, 513–523. [Google Scholar] [CrossRef]

- Doğan, O.; Karpat, F. Temel dişli tasarim parametrelerinin tek diş ve kavrama rijitliğine etkisinin sonlu elemanlar metodu ile incelenmesi. Uludağ Univ. J. Fac. Eng. 2018, 23, 381–402. [Google Scholar] [CrossRef] [Green Version]

- Coy, J.J.; Chao, C.H. A Method of Selecting Grid Size to Account for Hertz Deformation in Finite Element Analysis of Spur Gears. J. Mech. Des. 1982, 104, 759–764. [Google Scholar] [CrossRef]

- Wang, Z.G.; Lo, C.C.; Chen, Y.C. Comparison and Verification of Dynamic Simulations and Experiments for a Modified Spur Gear Pair. Machines 2022, 10, 191. [Google Scholar] [CrossRef]

- Karpat, F.; Ekwaro-Osire, S.; Cavdar, K.; Babalik, F.C. Dynamic Analysis of Involute Spur Gears with Asymmetric Teeth. Int. J. Mech. Sci. 2008, 50, 1598–1610. [Google Scholar] [CrossRef]

- Doğan, O.; Karpat, F. Crack Detection for Spur Gears with Asymmetric Teeth Based on the Dynamic Transmission Error. Mech. Mach. Theory 2019, 133, 417–431. [Google Scholar] [CrossRef]

- Doğan, O.; Karpat, F.; Kopmaz, O.; Ekwaro-Osire, S. Influences of Gear Design Parameters on Dynamic Tooth Loads and Time-Varying Mesh Stiffness of Involute Spur Gears. Sadhana-Acad. Proc. Eng. Sci. 2020, 45, 258. [Google Scholar] [CrossRef]

- Hou, L.; Lei, Y.; Fu, Y.; Hu, J. Effects of Lightweight Gear Blank on Noise, Vibration and Harshness for Electric Drive System in Electric Vehicles. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2020, 234, 447–464. [Google Scholar] [CrossRef]

- Zou, T.; Shaker, M.; Angeles, J.; Morozov, A. An Innovative Tooth Root Profile for Spur Gears and Its Effect on Service Life. Meccanica 2017, 52, 1825–1841. [Google Scholar] [CrossRef]

| Design Parameters | Case I | Case II |

|---|---|---|

| Module m (mm) | 3 | 3 |

| Number of teeth z | 20 | 20 |

| Drive side pressure angle αd | 20° | 20°-25°-30° |

| Addendum ha (mm) | 1 xm | 1 xm |

| Dedendum hf (mm) | 1.25 xm | 1.25 xm |

| Tip radius of cutter pfp (xm) | 0.1-0.2-0.3 | 0.3 |

| Profile shifting x | 0 | 0 |

| Facewidth b (mm) | 1 | 1 |

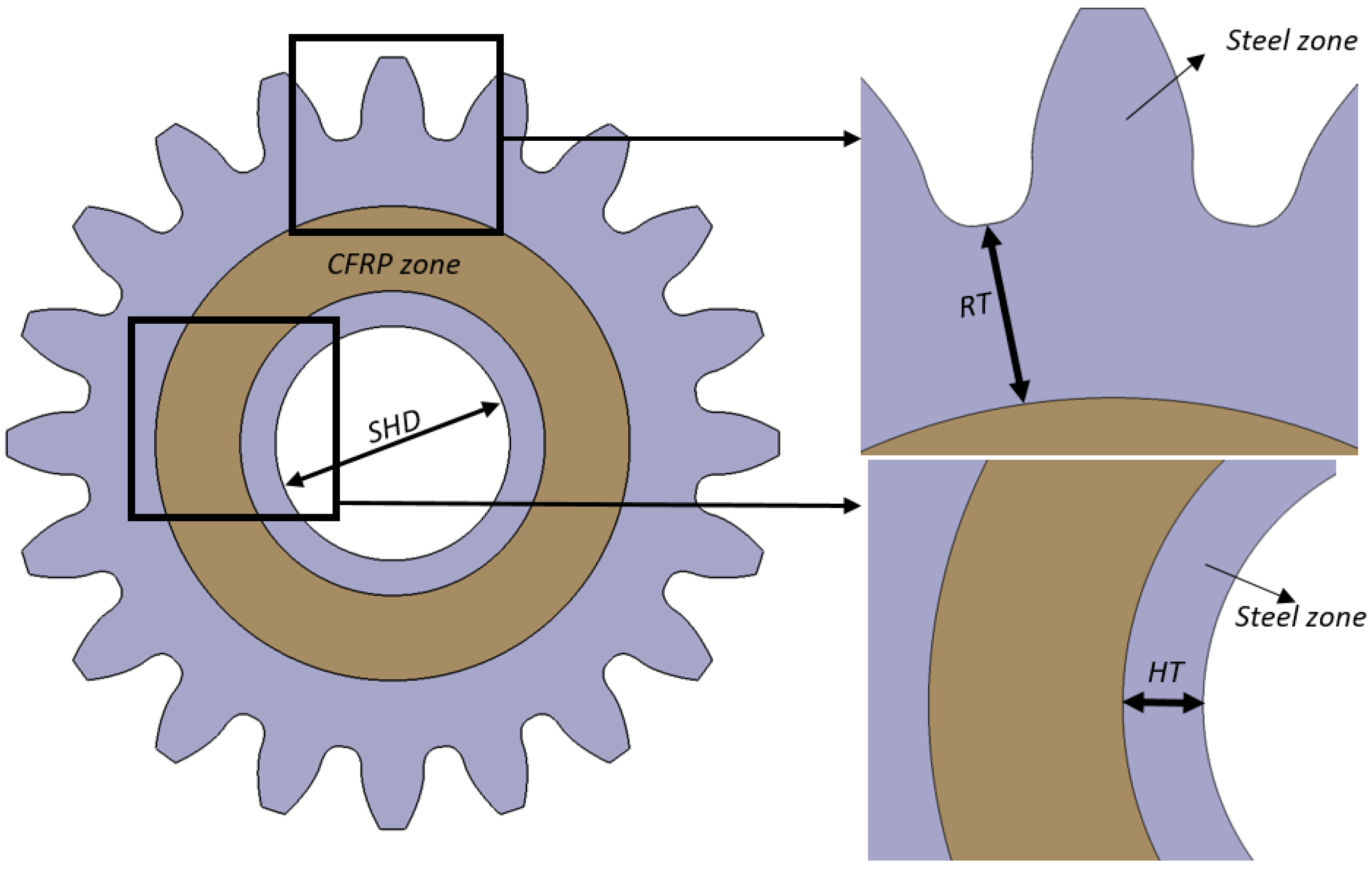

| Rim thickness-RT (xm) | 0.5-1-1.5-2 | 0.5-1-1.5-2 |

| Hub thickness-HT (xm) | 1 | 1 |

| Shaft hole diameter-SHD (mm) | 10 | 10 |

| Gear ratio i | 1 | 1 |

| Teeth-rim and hub material | 16MnCr5 | 16MnCr5 |

| Web material | CFRP | CFRP |

| E1 (GPa) | E2 (GPa) | E3 (GPa) | υ1 | υ2 | υ3 | G12 (GPa) | G13 (GPa) | G23 (GPa) |

|---|---|---|---|---|---|---|---|---|

| 81.65 | 81.65 | 6.81 | 0.32 | 0.27 | 0.27 | 30.76 | 2.76 | 2.76 |

| Property | XNR6823 |

|---|---|

| Young modulus E (MPa) | 2600 |

| Tensile failure strength σn (MPa) | 57 |

| Shear modulus G (MPa) | 1000 |

| Shear failure strength τn (MPa) | 32.9 |

| Toughness in tension GIC (J/m2) | 1180 |

| Toughness in shear GIIC (J/m2) | 1500 |

| RT (mm) | Weight (g) |

|---|---|

| 0.5 xm | 10.302 |

| 1 xm | 11.744 |

| 1.5 xm | 13.097 |

| 2 xm | 14.359 |

| Steel | 19.381 |

| RT (mm) | TR = 0.1 xm | TR = 0.2 xm | TR = 0.3 xm |

|---|---|---|---|

| Steel | 158.72 | 142.03 | 133.23 |

| 0.5 xm | 184.26 | 168.32 | 152.71 |

| 1 xm | 166.97 | 151.54 | 139.34 |

| 1.5 xm | 160.32 | 145.99 | 134.11 |

| 2 xm | 158.96 | 142.39 | 133.18 |

| DSPA (°) | 20 | 25 | 30 | 20 | 25 | 30 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|---|---|

| RT (mm) | Root Stress | Normal Stress | Shear Stress | ||||||

| 0.5 xm | 152.71 | 148.45 | 145.37 | 20.94 | 20.41 | 20.22 | 17.02 | 18.26 | 19.63 |

| 1 xm | 139.34 | 133.69 | 130.43 | 11.14 | 10.60 | 10.23 | 11.38 | 12.09 | 12.82 |

| 1.5 xm | 134.11 | 129.21 | 125.99 | 6.01 | 5.43 | 4.98 | 8.47 | 8.99 | 9.53 |

| 2 xm | 133.18 | 128.08 | 125.66 | 3.22 | 2.65 | 2.19 | 6.9 | 7.30 | 7.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yılmaz, T.G.; Karadere, G.; Karpat, F. A Numerical Analysis of Hybrid Spur Gears with Asymmetric Teeth: Stress and Dynamic Behavior. Machines 2022, 10, 1056. https://doi.org/10.3390/machines10111056

Yılmaz TG, Karadere G, Karpat F. A Numerical Analysis of Hybrid Spur Gears with Asymmetric Teeth: Stress and Dynamic Behavior. Machines. 2022; 10(11):1056. https://doi.org/10.3390/machines10111056

Chicago/Turabian StyleYılmaz, Tufan G., Gültekin Karadere, and Fatih Karpat. 2022. "A Numerical Analysis of Hybrid Spur Gears with Asymmetric Teeth: Stress and Dynamic Behavior" Machines 10, no. 11: 1056. https://doi.org/10.3390/machines10111056