Tool Wear Rate and Surface Integrity Studies in Wire Electric Discharge Machining of NiTiNOL Shape Memory Alloy Using Diffusion Annealed Coated Electrode Materials

Abstract

:1. Introduction

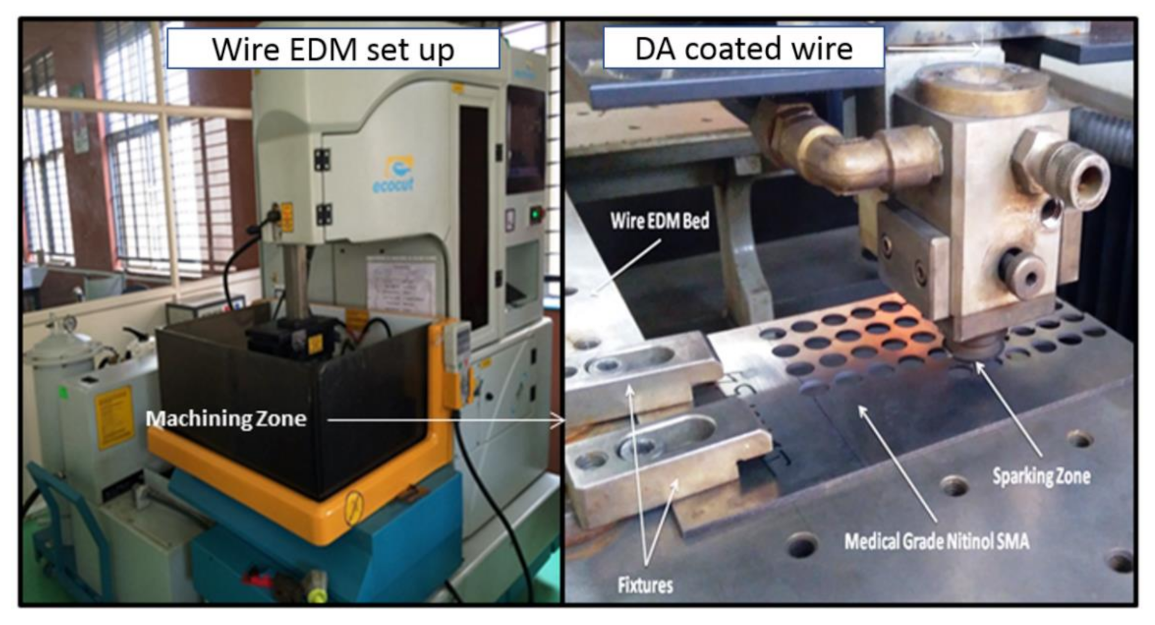

2. Materials and Methods

2.1. Work Material

2.2. Wire Electrode Materials

2.3. Experimental Setup

2.4. Process Variables and Output Responses

2.5. Methodology

3. Results and Discussions

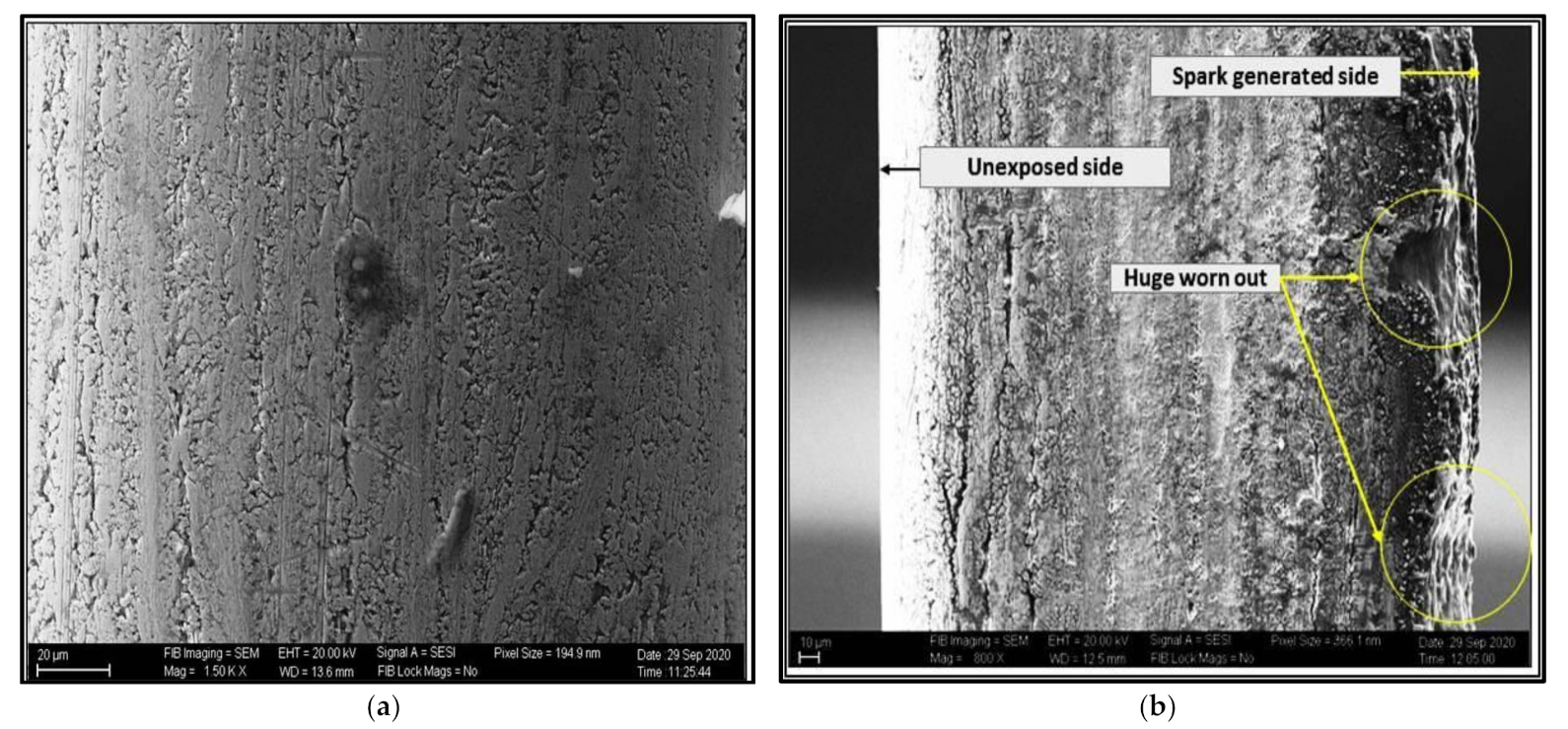

3.1. Analysis of TWR of X-Type Diffusion Annealed Coated Wire Electrode

3.2. Analysis of SR of Machined NiTiNOL SMA Using X-Type Wire Electrode

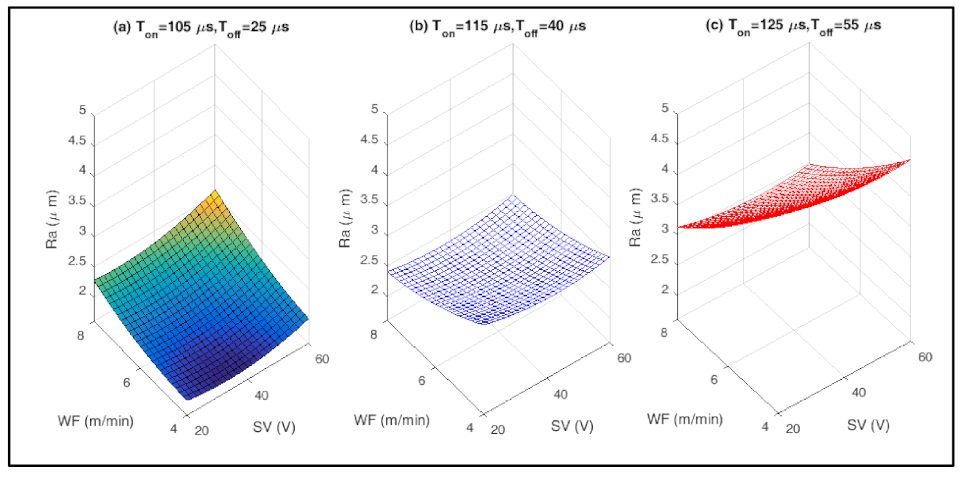

3.3. Analysis of TWR of A-Type Diffusion Annealed Coated Wire Electrode

3.4. Analysis of SR of Machined NiTiNOL SMA Using A-Type Wire Electrode

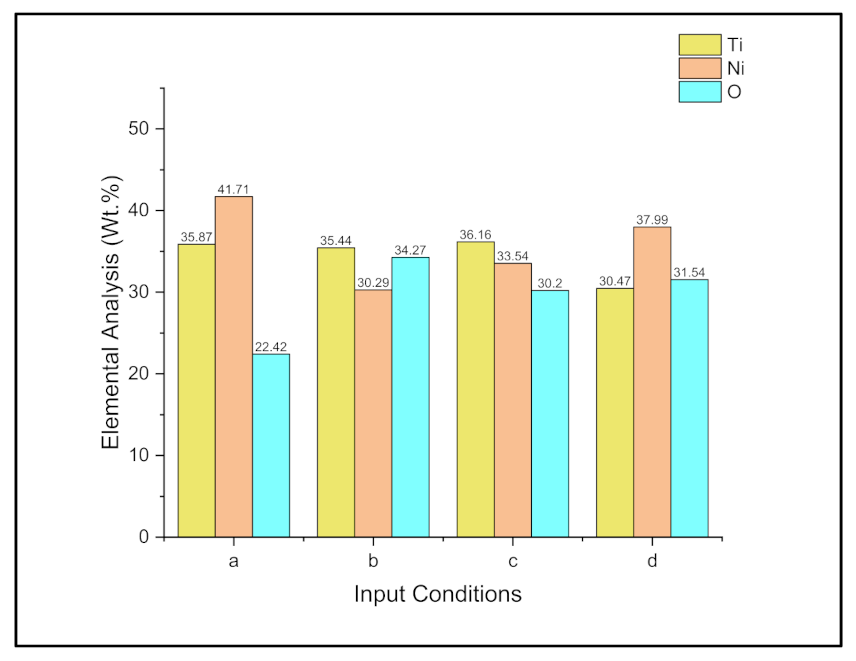

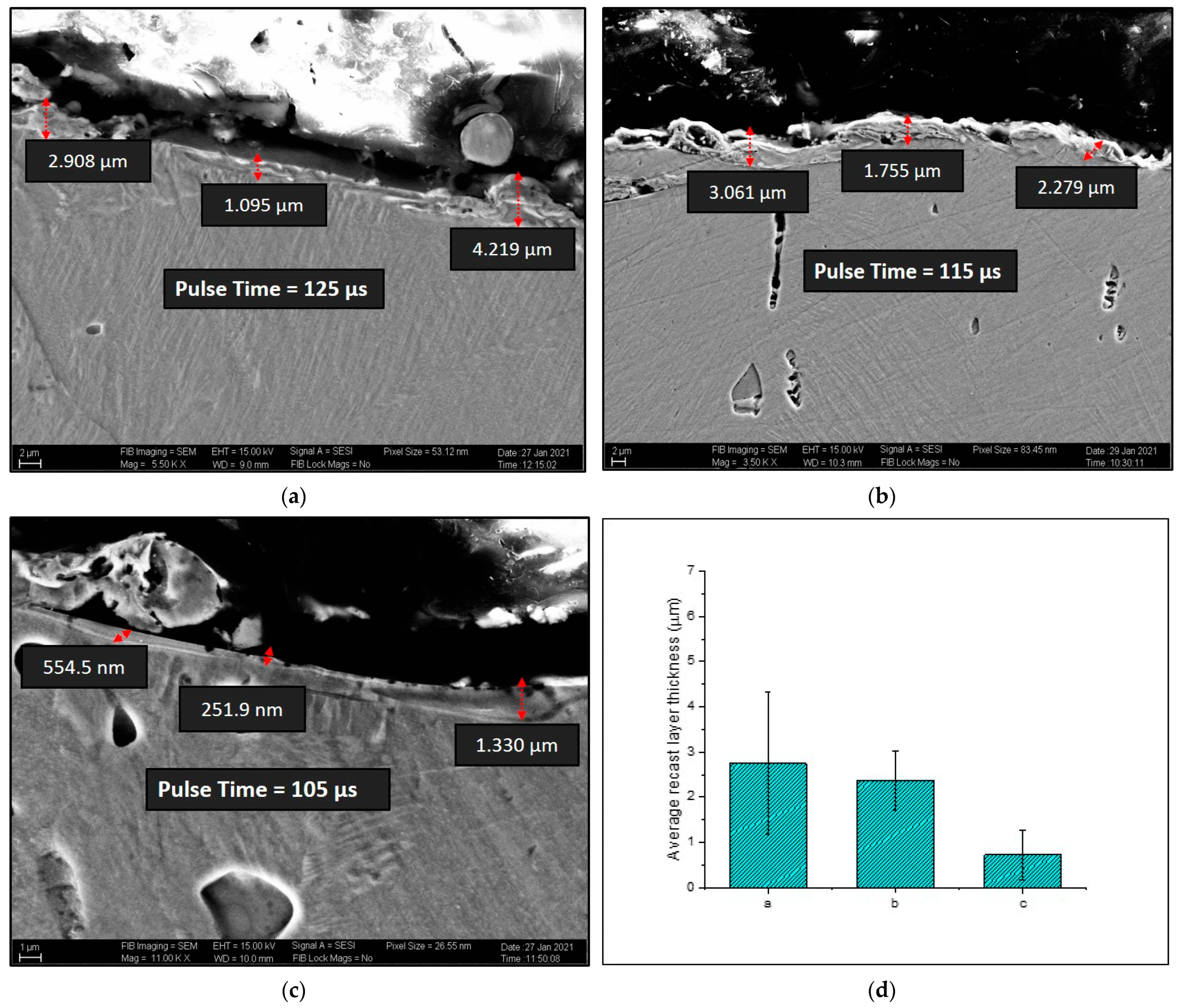

3.5. Surface Integrity Studies of Machined NiTiNOL SMA

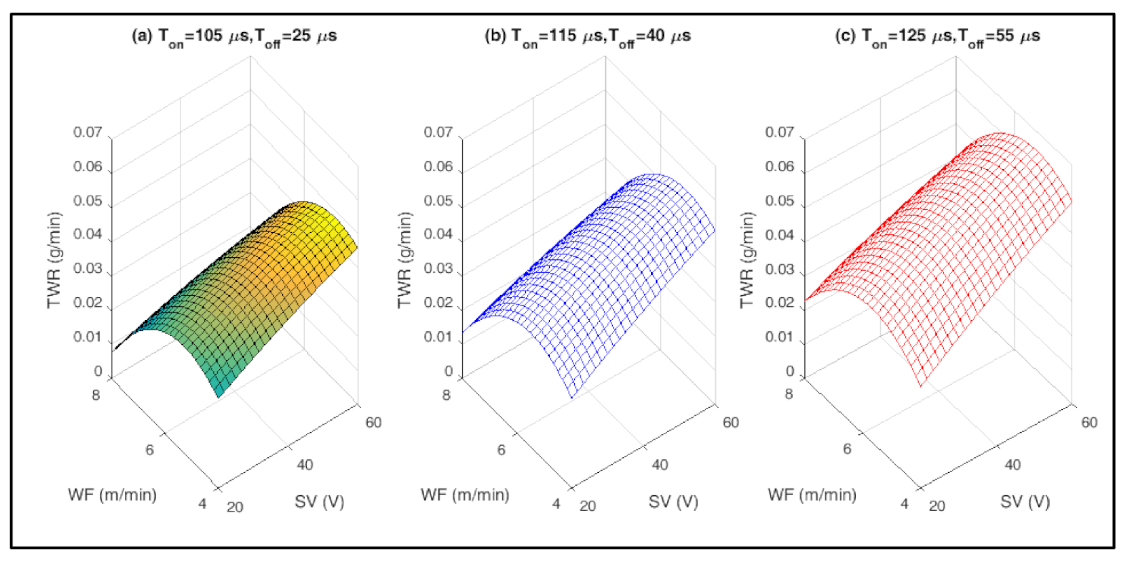

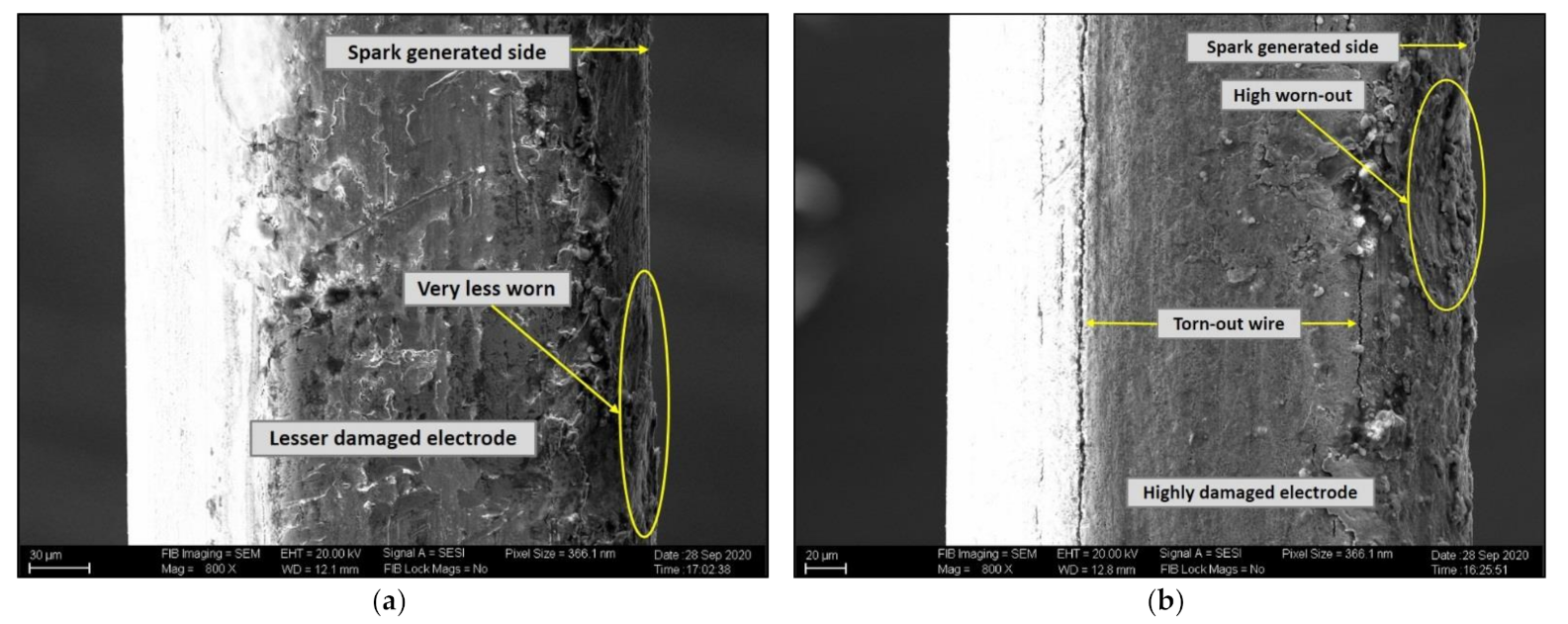

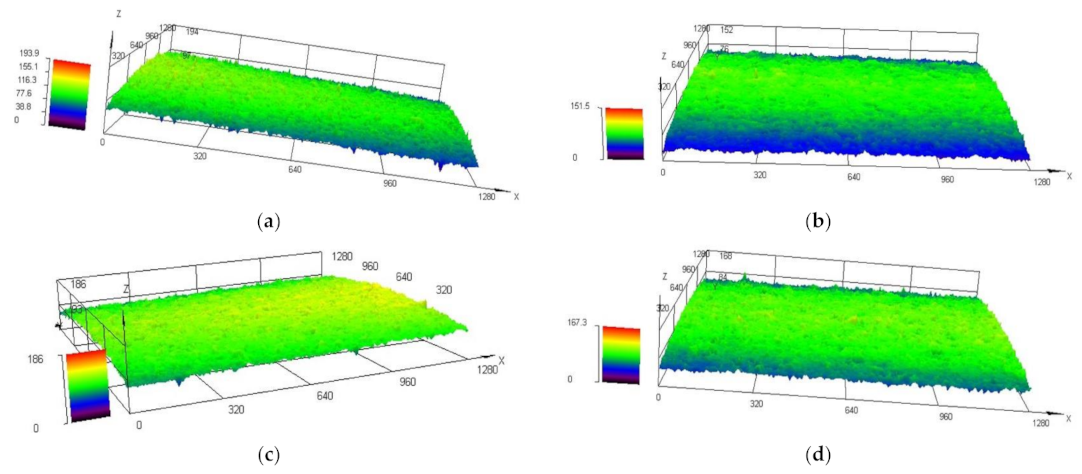

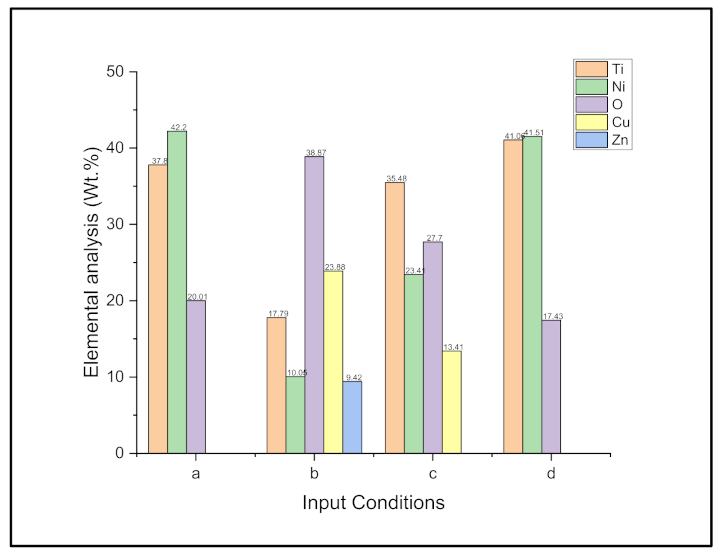

3.5.1. Surface Analysis of Machined NiTiNOL SMA—X-Type Electrode Material

3.5.2. Surface Analysis of Machined NiTiNOL SMA—A-Type Electrode Material

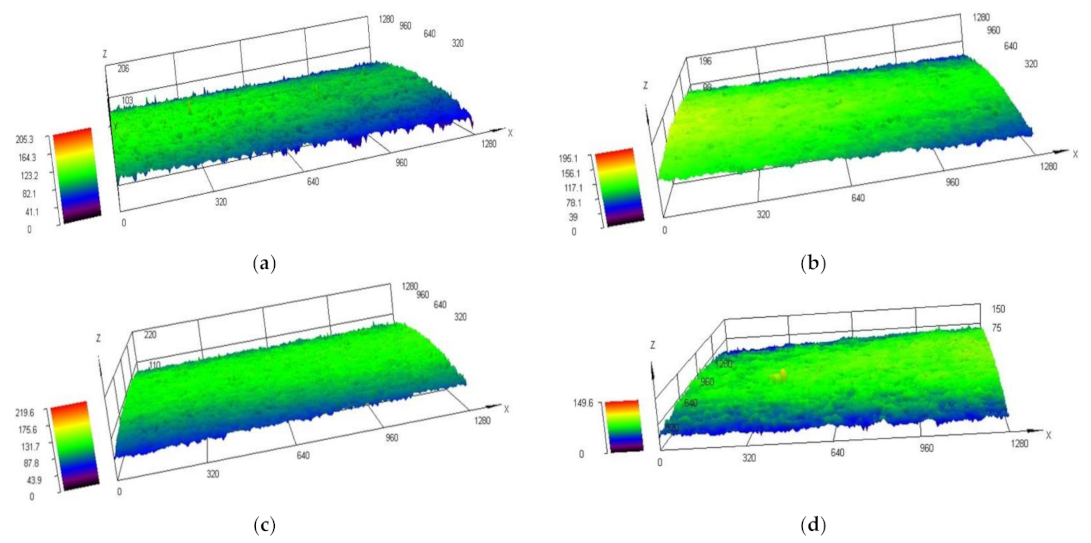

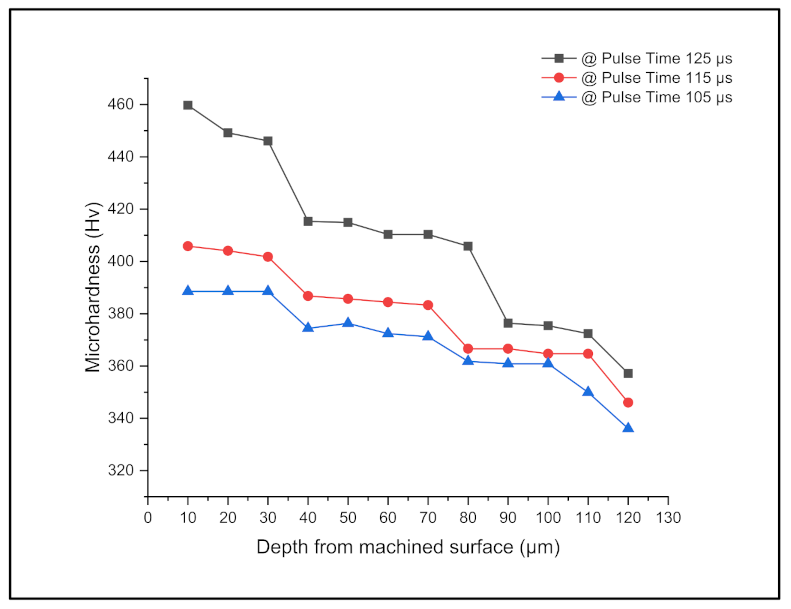

3.5.3. Subsurface Analysis of Machined NiTiNOL SMA—X-Type Electrode Material

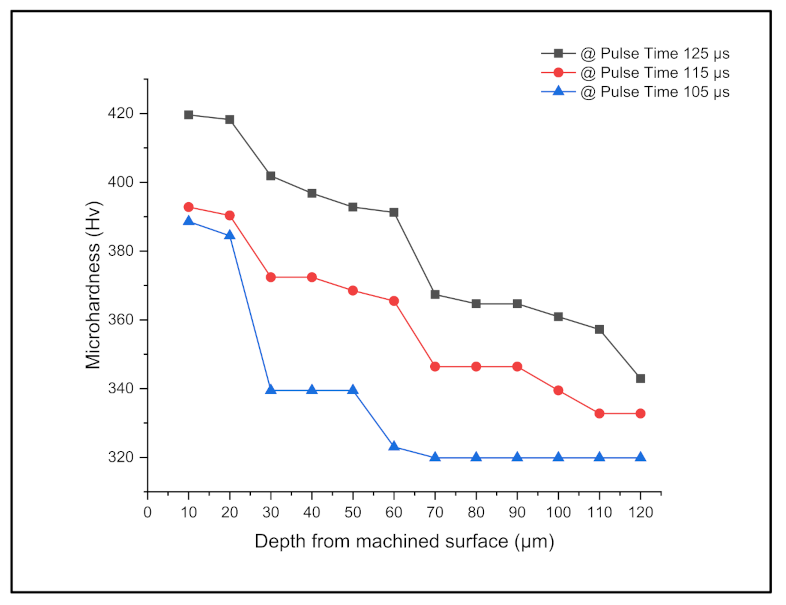

3.5.4. Subsurface Analysis of Machined NiTiNOL SMA—A-Type Electrode Material

3.5.5. Comparing the Surface Integrity Performances of Brass, Zn-Coated Brass, DX and DA Electrodes

4. Conclusions

- For higher values of pulse and pause times with higher WF rate and lower SV, a very high TWR of 0.07 g/min was observed when NiTiNOL was machined with X-type electrode material.

- Huge wire depositions and larger microcracks were observed on the machined NiTiNOL samples through SEM analysis when X-type wire electrode material was used.

- While machining NiTiNOL SMA, A-type electrodes showed lesser tool wear, as low as 0.0054 g/min for input combinational values of Ton = 105 µs, Toff = 55 µs, WF = 4 m/min and SV = 60 V, also resulting in lower SR (1.17 µm) of the machined sample.

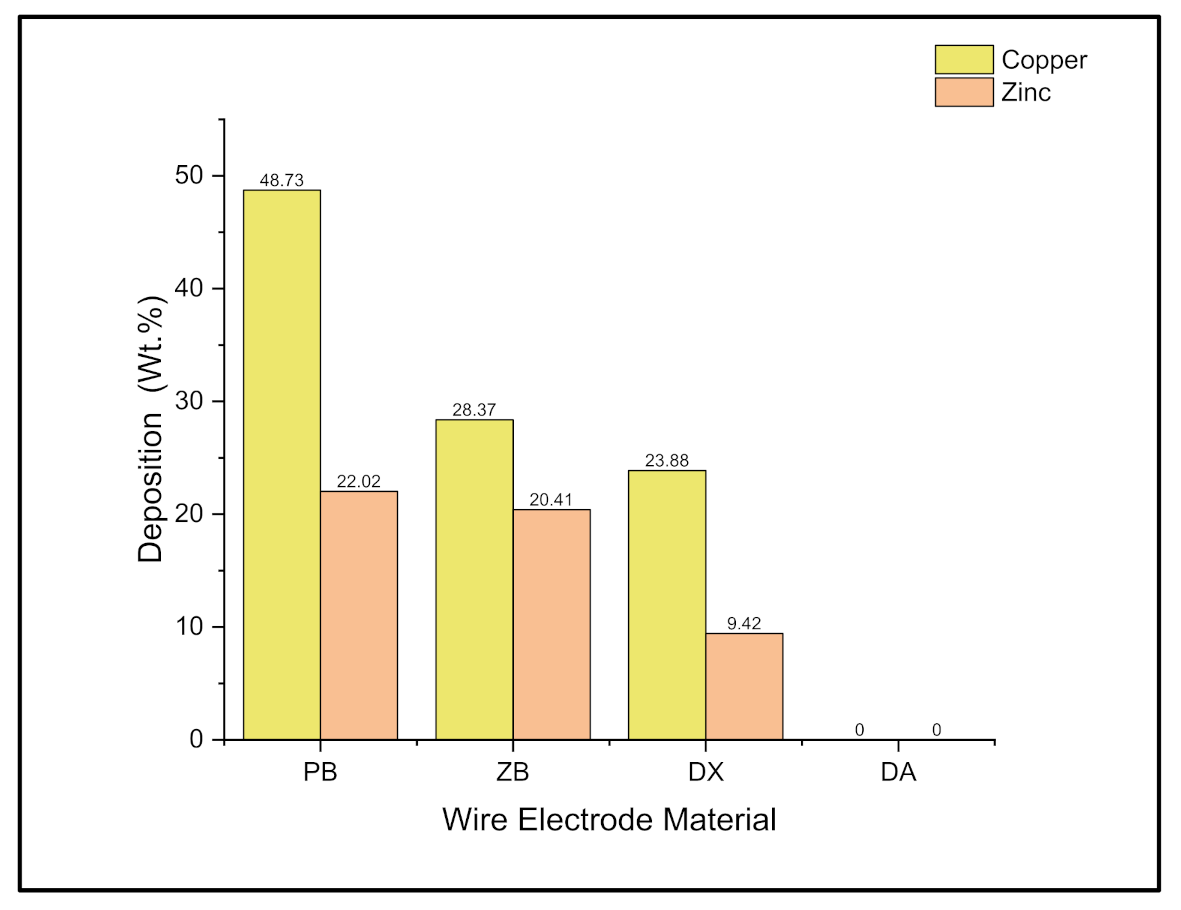

- EDS analysis confirmed the higher depositions of 23.88 wt.% of Cu and 9.42 wt.% of Zn elements of wire electrode onto the machined sample for X-type electrode and no depositions of Cu and Zn were seen when the samples were machined with A-type electrode material.

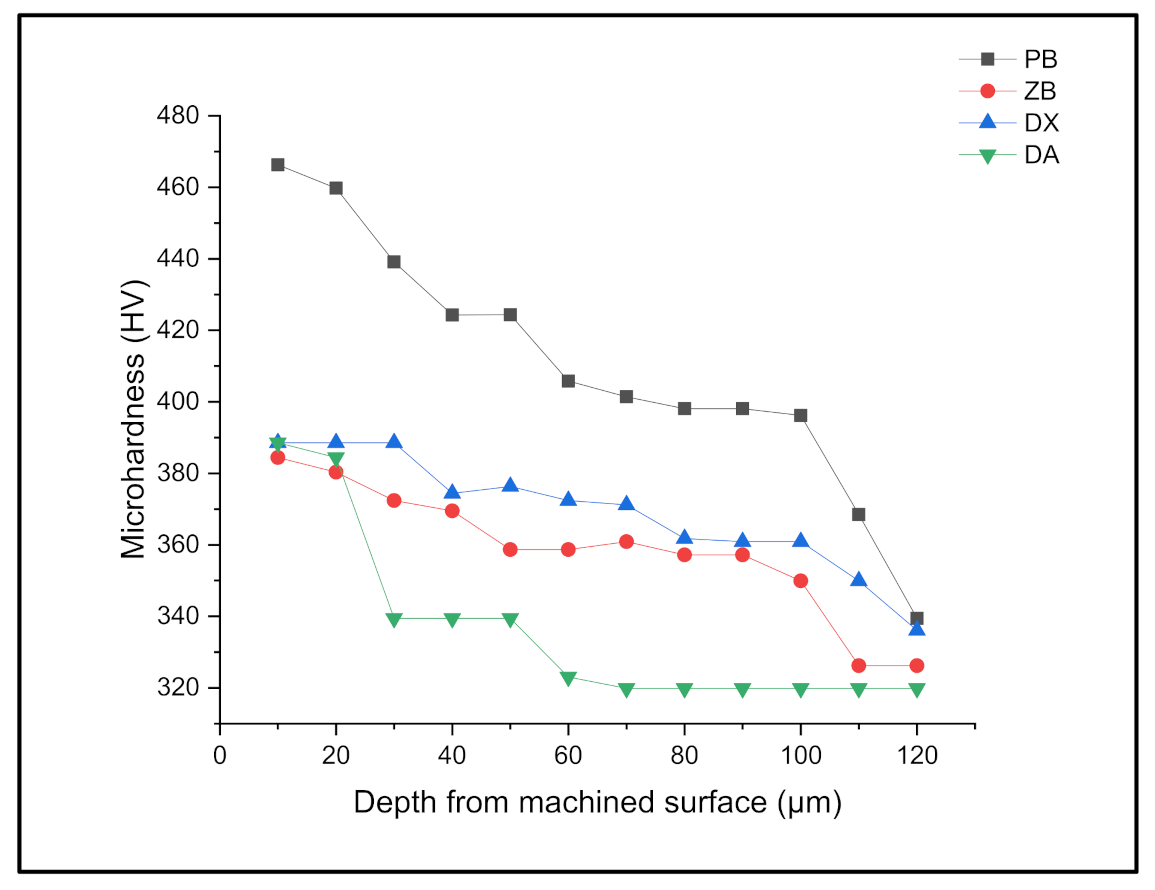

- X-type diffusion annealed electrode showed the highest MH values for all three pulse time conditions compared to MH values of samples machined with A-type electrode material.

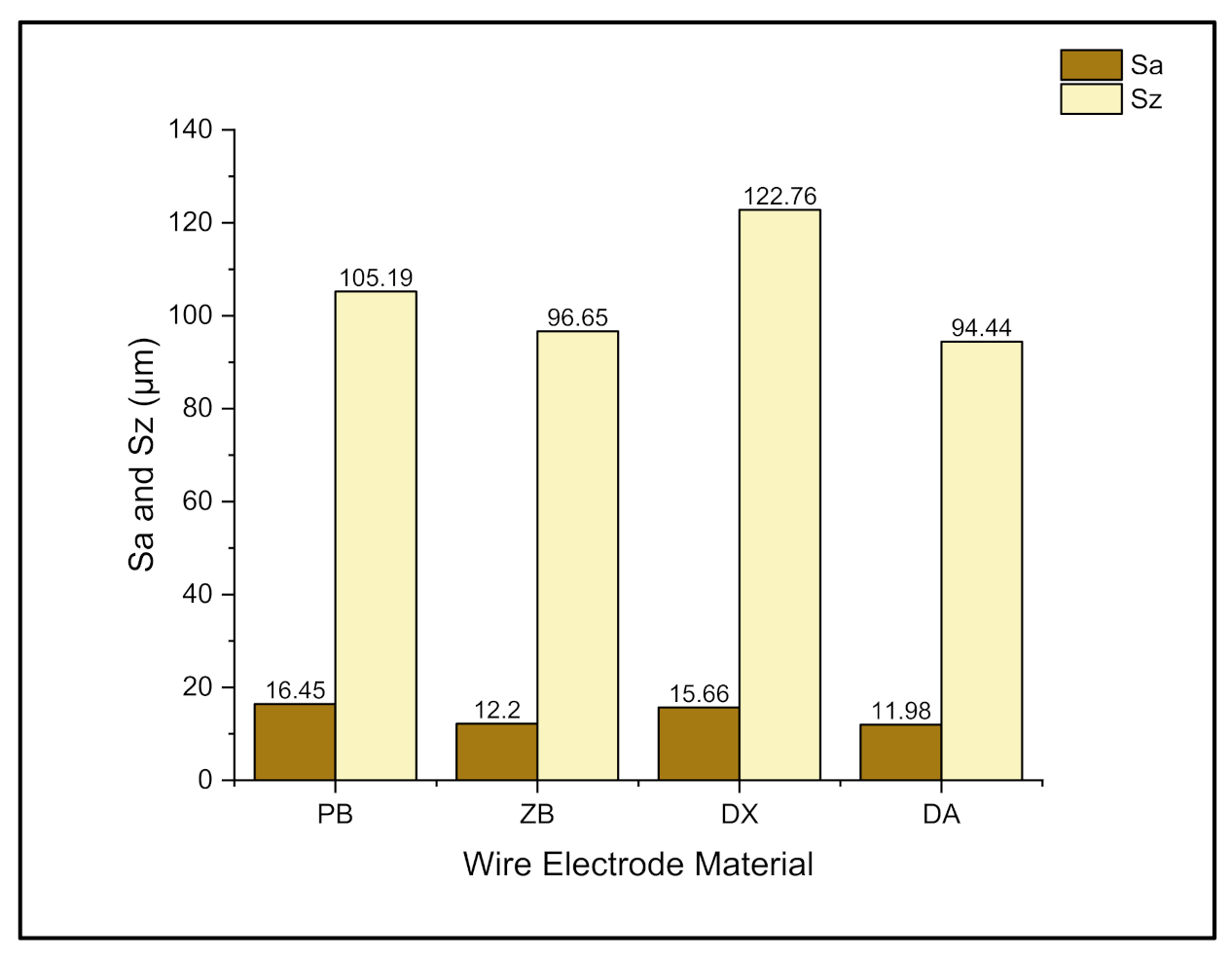

- The peaks and valleys during measurement of average surface roughness of the machined alloy were greater when the alloy was machined with X-type electrode material, with Sa of 15.66 µm and Sz of 122.76 µm compared to A-type electrode material, with Sa and Sz of 11.98 µm and 94.44 µm, respectively, for higher pulse time condition of 125 µs.

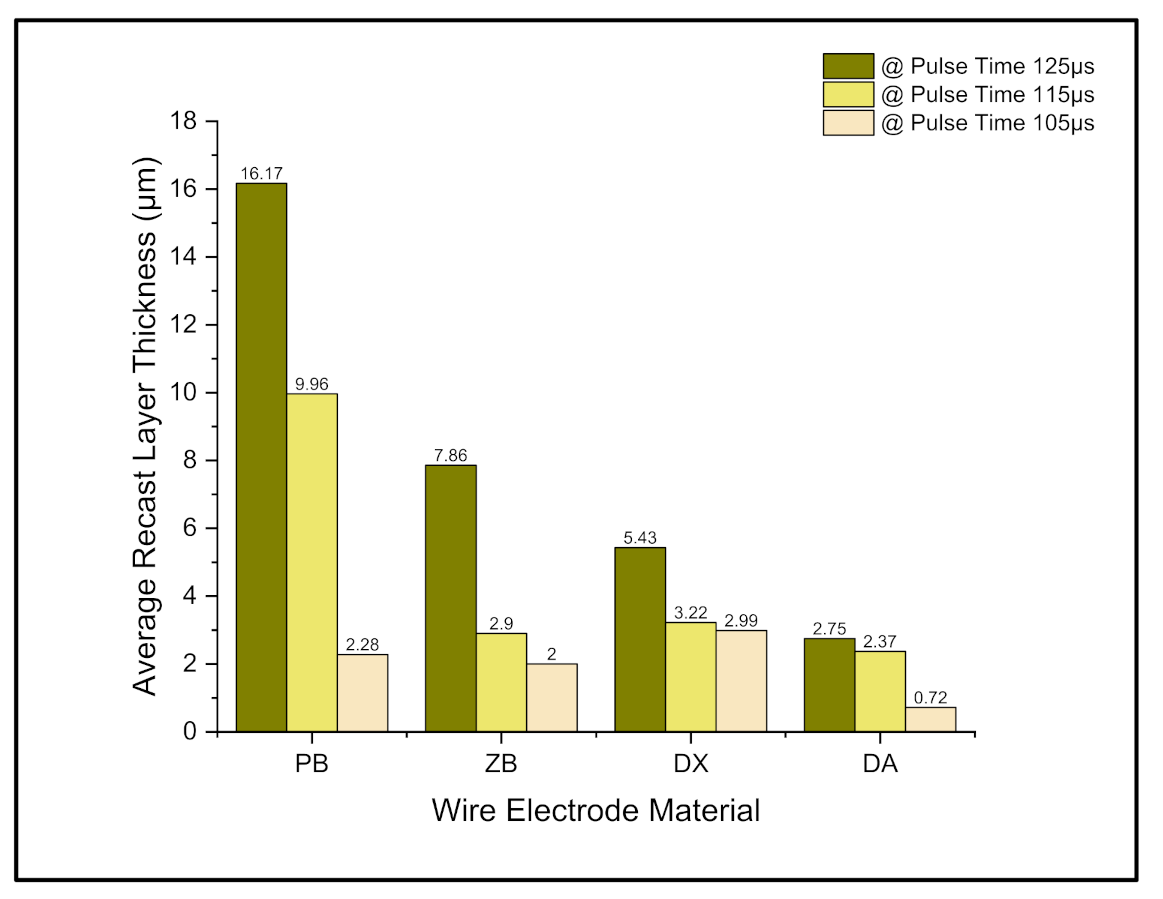

- For pulse time of 125 µs, the RLT was found to be high and medium for 115 µs and low for lower pulse time of 105 µs. As the pulse time decreases, the RLT was found to be low for all the samples and the trend was found to be the same for machining of NiTiNOL using all PB, ZB, DX and DA electrode material.

- Average recast layer thickness of NiTiNOL sample machined with A-type electrode materials was found to be much lower, almost 50–80% less than the average RLT of the sample machined with other electrode materials.

- A-type electrode material showed overall better performances for TWR, SR and surface integrity studies compared to the performances of all other electrode materials while machining NiTiNOL medical grade SMA. In the present investigations, the TWR results of A-type material were found to be 45%, 95% and 58% better than the plain brass, Zn-coated brass and X-type electrode materials. As shown in Figure 18, the Sa value of the sample machined with A-type electrode showed 37%, 2% and 31% better results as compared to plain brass, Zn-coated brass and X-type electrode values, respectively. Further, as seen from Figure 21, the average recast layer thickness of alloy machined with A-type electrode was less when compared to the alloys machined with plain brass, Zn-coated brass and X-type electrodes. Therefore, A-type diffusion annealed electrode is found to be a better choice for WEDM of NiTiNOL alloy on the basis of TWR, SR and surface integrity results and analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pelton, A.R.; Dicello, J.; Miyazaki, S. Optimization of processing and properties of medical grade Nitinol wire. Minim. Invasive Allied Technol. 2000, 9, 107–118. [Google Scholar] [CrossRef]

- Kadadevaru, S.G.; Kulkarni, V.N.; Gaitonde, V.N. A Review on Surface Integrity Studies in Machining of Biomedical Alloys. Mater. Today Proc. 2019, 18, 5494–5501. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Wu, S.K.; Lin, H.C.; Chen, C.C. A study on the machinability of a Ti49. 6Ni50. 4 shape memory alloy. Mater. Lett. 1999, 40, 27–32. [Google Scholar] [CrossRef]

- Lin, H.C.; Lin, K.M.; Chen, Y.C. A study on the machining characteristics of TiNi shape memory alloys. J. Mater. Process. Technol. 2000, 105, 327–332. [Google Scholar] [CrossRef]

- Liu, J.F.; Guo, Y.B.; Butler, T.M.; Weaver, M.L. Crystallography, compositions, and properties of white layer by wire electrical discharge machining of nitinol shape memory alloy. Mater. Des. 2016, 109, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Satish, G.J.; Gaitonde, V.N.; Kulkarni, V.N. Traditional and non-traditional machining of nickel-based superalloys: A brief review. Mater. Today Proc. 2021, 44, 1448–1454. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S. Review on non-conventional machining of shape memory alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 12–21. [Google Scholar] [CrossRef]

- Sharma, N.; Raj, T.; Jangra, K.K. Parameter optimization and experimental study on wire electrical discharge machining of porous Ni40Ti60 alloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2017, 231, 956–970. [Google Scholar] [CrossRef]

- Takale, A.M.; Chougule, N.K. Effect of wire electro discharge machining process parameters on surface integrity of Ti49. 4Ni50. 6 shape memory alloy for orthopedic implant application. Mater. Sci. Eng. C 2019, 97, 264–274. [Google Scholar] [CrossRef]

- Liu, J.F.; Guo, Y.B. Process capability of wire-EDM of NiTi shape memory alloy at main cut and trim cut modes. Procedia Manuf. 2015, 1, 904–914. [Google Scholar] [CrossRef] [Green Version]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S.; Gaitonde, V.N. Wire electric discharge machining characteristics of titanium nickel shape memory alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 3201–3209. [Google Scholar] [CrossRef]

- Bisaria, H.; Shandilya, P. Experimental studies on electrical discharge wire cutting of Ni-rich NiTi shape memory alloy. Mater. Manuf. Process. 2018, 33, 977–985. [Google Scholar] [CrossRef]

- Soni, H.; Ramesh, M.R. Effects of wire electro-discharge machining process parameters on the machined surface of Ti50Ni49Co1 shape memory alloy. Silicon 2019, 11, 733–739. [Google Scholar] [CrossRef]

- Kulkarni, V.N.; Gaitonde, V.N.; Karnik, S.R.; Manjaiah, M.; Davim, J.P. Performance studies on wire electric discharge machining of medical grade nickel titanium (niti) shape memory alloy. J. Manuf. Technol. Res. 2019, 11, 101–120. [Google Scholar]

- Daneshmand, S.; Hessami, R.; Esfandiar, H. Investigation of wire electro discharge machining of Nickel-Titanium shape memory alloys on surface roughness and MRR. Life Sci. 2012, 9, 2904–2909. [Google Scholar]

- Lotfi Neyestanak, A.A.; Daneshmand, S. The effect of operational cutting parameters on Nitinol-60 in wire electro discharge machining. Adv. Mater. Sci. Eng. 2013, 2013, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S.; Gaitonde, V.N. Effect of electrode material in wire electro discharge machining characteristics of Ti50Ni50− xCux shape memory alloy. Precis. Eng. 2015, 41, 68–77. [Google Scholar] [CrossRef]

- Kulkarni, V.N.; Gaitonde, V.N.; Karnik, S.R.; Manjaiah, M.; Davim, J.P. Machinability Analysis and Optimization in Wire EDM of Medical Grade NiTiNOL Memory Alloy. Materials 2020, 13, 2184. [Google Scholar] [CrossRef]

- Kulkarni, V.N.; Gaitonde, V.N.; Nalavade, K.S.; Doddamani, M.; Naik, G.M. Optimization of Wire EDM Process Parameters for Medical Grade Nickel Titanium Shape Memory Alloy. Stroj. J. Mech. Eng. 2020, 70, 69–80. [Google Scholar] [CrossRef]

- Kulkarni, V.N.; Gaitonde, V.N.; Aiholi, V.; Hadimani, V. Multi performance characteristics optimization in wire electric discharge machining of nitinol superelastic alloy. Mater. Today Proc. 2018, 5, 18857–18866. [Google Scholar] [CrossRef]

- Zeng, Q.; Qin, Y.; Chang, W.; Luo, X. Correlating and evaluating the functionality-related properties with surface texture parameters and specific characteristics of machined components. Int. J. Mech. Sci. 2018, 149, 62–72. [Google Scholar] [CrossRef]

- Czifra, Á.; Barányi, I. Sdq-Sdr Topological Map of Surface Topographies. Front. Mech. Eng. 2020, 6, 50. [Google Scholar] [CrossRef]

- Dijmărescu, M.R.; Abaza, B.F.; Voiculescu, I.; Dijmărescu, M.C.; Ciocan, I. Surface Roughness Analysis and Prediction with an Artificial Neural Network Model for Dry Milling of Co–Cr Biomedical Alloys. Materials 2021, 14, 6361. [Google Scholar] [CrossRef] [PubMed]

- Tavakoli, J.; Khosroshahi, M.E. Surface morphology characterization of laser-induced titanium implants: Lesson to enhance osseointegration process. Biomed. Eng. Lett. 2018, 8, 249–257. [Google Scholar] [CrossRef]

- Baş, D.; Boyacı, I.H. Modeling and optimization I: Usability of response surface methodology. J. Food Eng. 2007, 78, 836–845. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

| Expt No | Ton (µs) | Toff (µs) | WF (m/min) | SV (V) | DX | DA | ||

|---|---|---|---|---|---|---|---|---|

| TWR (g/min) | SR (µm) | TWR (g/min) | SR (µm) | |||||

| 1 | 105 | 25 | 4 | 20 | 0.0353 | 2.0659 | 0.0255 | 2.0121 |

| 2 | 105 | 25 | 6 | 20 | 0.0507 | 1.9402 | 0.0402 | 1.6678 |

| 3 | 105 | 25 | 8 | 20 | 0.0715 | 1.7149 | 0.0434 | 1.933 |

| 4 | 105 | 40 | 4 | 20 | 0.0365 | 1.8853 | 0.0251 | 1.8828 |

| 5 | 105 | 40 | 6 | 20 | 0.0524 | 1.9344 | 0.0358 | 1.685 |

| 6 | 105 | 40 | 8 | 20 | 0.0656 | 1.6627 | 0.0499 | 2.0963 |

| 7 | 105 | 55 | 4 | 20 | 0.0269 | 1.4825 | 0.0133 | 2.2195 |

| 8 | 105 | 55 | 6 | 20 | 0.0453 | 1.6597 | 0.0258 | 2.1522 |

| 9 | 105 | 55 | 8 | 20 | 0.0542 | 1.6131 | 0.042 | 2.2959 |

| 10 | 115 | 25 | 4 | 20 | 0.031 | 3.797 | 0.0297 | 2.868 |

| 11 | 115 | 25 | 6 | 20 | 0.0453 | 3.9486 | 0.04 | 2.7452 |

| 12 | 115 | 25 | 8 | 20 | 0.0608 | 3.0972 | 0.0501 | 2.883 |

| 13 | 115 | 40 | 4 | 20 | 0.037 | 2.6909 | 0.0281 | 2.8898 |

| 14 | 115 | 40 | 6 | 20 | 0.0529 | 2.8901 | 0.0392 | 2.9772 |

| 15 | 115 | 40 | 8 | 20 | 0.069 | 2.8505 | 0.052 | 3.0108 |

| 16 | 115 | 55 | 4 | 20 | 0.0366 | 2.3041 | 0.0183 | 2.9589 |

| 17 | 115 | 55 | 6 | 20 | 0.0556 | 2.6316 | 0.0355 | 2.8244 |

| 18 | 115 | 55 | 8 | 20 | 0.0637 | 2.6261 | 0.0445 | 2.8094 |

| 19 | 125 | 25 | 4 | 20 | 0.0313 | 5.1907 | 0.0337 | 5.3601 |

| 20 | 125 | 25 | 6 | 20 | 0.0474 | 6.1813 | 0.0472 | 4.4481 |

| 21 | 125 | 25 | 8 | 20 | 0.06 | 5.3402 | 0.0561 | 5.2488 |

| 22 | 125 | 40 | 4 | 20 | 0.0327 | 5.3798 | 0.0367 | 5.1977 |

| 23 | 125 | 40 | 6 | 20 | 0.053 | 5.7494 | 0.0483 | 5.0182 |

| 24 | 125 | 40 | 8 | 20 | 0.0686 | 5.7396 | 0.0651 | 5.0477 |

| 25 | 125 | 55 | 4 | 20 | 0.0419 | 4.375 | 0.0321 | 4.7375 |

| 26 | 125 | 55 | 6 | 20 | 0.0538 | 4.4475 | 0.0428 | 5.05 |

| 27 | 125 | 55 | 8 | 20 | 0.0696 | 5.4982 | 0.0544 | 4.3168 |

| 28 | 105 | 25 | 4 | 40 | 0.0283 | 1.8749 | 0.0275 | 2.1323 |

| 29 | 105 | 25 | 6 | 40 | 0.0397 | 1.7983 | 0.0377 | 2.1158 |

| 30 | 105 | 25 | 8 | 40 | 0.0499 | 1.6353 | 0.0424 | 2.3079 |

| 31 | 105 | 40 | 4 | 40 | 0.0236 | 1.9045 | 0.0265 | 2.1647 |

| 32 | 105 | 40 | 6 | 40 | 0.0377 | 1.8653 | 0.0358 | 1.8636 |

| 33 | 105 | 40 | 8 | 40 | 0.0468 | 1.539 | 0.0431 | 2.3158 |

| 34 | 105 | 55 | 4 | 40 | 0.0183 | 1.6853 | 0.0206 | 2.3679 |

| 35 | 105 | 55 | 6 | 40 | 0.0309 | 1.9176 | 0.0299 | 2.125 |

| 36 | 105 | 55 | 8 | 40 | 0.0484 | 1.6042 | 0.0379 | 2.2045 |

| 37 | 115 | 25 | 4 | 40 | 0.0303 | 2.4877 | 0.031 | 2.4854 |

| 38 | 115 | 25 | 6 | 40 | 0.045 | 2.7094 | 0.0391 | 2.7808 |

| 39 | 115 | 25 | 8 | 40 | 0.0501 | 2.6428 | 0.0471 | 3.0205 |

| 40 | 115 | 40 | 4 | 40 | 0.0309 | 2.28 | 0.03 | 2.8201 |

| 41 | 115 | 40 | 6 | 40 | 0.0429 | 2.2352 | 0.0463 | 2.6605 |

| 42 | 115 | 40 | 8 | 40 | 0.0509 | 2.4562 | 0.05 | 2.4527 |

| 43 | 115 | 55 | 4 | 40 | 0.0308 | 2.0121 | 0.0251 | 2.6779 |

| 44 | 115 | 55 | 6 | 40 | 0.0458 | 2.5188 | 0.036 | 2.8162 |

| 45 | 115 | 55 | 8 | 40 | 0.0604 | 2.0993 | 0.0521 | 2.8985 |

| 46 | 125 | 25 | 4 | 40 | 0.0247 | 4.5155 | 0.0448 | 3.7629 |

| 47 | 125 | 25 | 6 | 40 | 0.039 | 4.6652 | 0.0555 | 4.1522 |

| 48 | 125 | 25 | 8 | 40 | 0.0584 | 3.8211 | 0.0594 | 3.7877 |

| 49 | 125 | 40 | 4 | 40 | 0.034 | 3.3092 | 0.042 | 3.6058 |

| 50 | 125 | 40 | 6 | 40 | 0.05 | 3.584 | 0.0534 | 3.3994 |

| 51 | 125 | 40 | 8 | 40 | 0.0608 | 3.7036 | 0.0694 | 3.4825 |

| 52 | 125 | 55 | 4 | 40 | 0.0367 | 3.0068 | 0.0398 | 4.1396 |

| 53 | 125 | 55 | 6 | 40 | 0.0563 | 3.7546 | 0.0559 | 3.5016 |

| 54 | 125 | 55 | 8 | 40 | 0.0724 | 3.9911 | 0.0678 | 3.4467 |

| 55 | 105 | 25 | 4 | 60 | 0.0252 | 2.0905 | 0.0073 | 2.228 |

| 56 | 105 | 25 | 6 | 60 | 0.0364 | 1.7924 | 0.0133 | 2.3094 |

| 57 | 105 | 25 | 8 | 60 | 0.0438 | 1.5767 | 0.0164 | 2.493 |

| 58 | 105 | 40 | 4 | 60 | 0.0191 | 1.8278 | 0.0088 | 2.1912 |

| 59 | 105 | 40 | 6 | 60 | 0.0264 | 1.7963 | 0.0151 | 2.2178 |

| 60 | 105 | 40 | 8 | 60 | 0.038 | 1.5812 | 0.0196 | 2.4176 |

| 61 | 105 | 55 | 4 | 60 | 0.0118 | 1.7842 | 0.0054 | 2.5872 |

| 62 | 105 | 55 | 6 | 60 | 0.0232 | 1.8726 | 0.0116 | 2.3963 |

| 63 | 105 | 55 | 8 | 60 | 0.0345 | 1.7227 | 0.0156 | 2.5716 |

| 64 | 115 | 25 | 4 | 60 | 0.0253 | 1.898 | 0.0111 | 2.6597 |

| 65 | 115 | 25 | 6 | 60 | 0.037 | 2.0179 | 0.0176 | 2.6256 |

| 66 | 115 | 25 | 8 | 60 | 0.0434 | 1.8049 | 0.0204 | 2.5264 |

| 67 | 115 | 40 | 4 | 60 | 0.0213 | 1.9445 | 0.0129 | 2.2986 |

| 68 | 115 | 40 | 6 | 60 | 0.0316 | 2.0562 | 0.0204 | 2.1914 |

| 69 | 115 | 40 | 8 | 60 | 0.0441 | 1.7785 | 0.025 | 2.5433 |

| 70 | 115 | 55 | 4 | 60 | 0.022 | 1.7702 | 0.0098 | 2.5317 |

| 71 | 115 | 55 | 6 | 60 | 0.0312 | 2.0606 | 0.017 | 2.6213 |

| 72 | 115 | 55 | 8 | 60 | 0.0419 | 1.9019 | 0.023 | 2.7539 |

| 73 | 125 | 25 | 4 | 60 | 0.0247 | 2.735 | 0.023 | 3.1479 |

| 74 | 125 | 25 | 6 | 60 | 0.0379 | 2.6785 | 0.0299 | 2.926 |

| 75 | 125 | 25 | 8 | 60 | 0.0434 | 2.6351 | 0.0342 | 3.3614 |

| 76 | 125 | 40 | 4 | 60 | 0.0264 | 2.3833 | 0.0239 | 3.3578 |

| 77 | 125 | 40 | 6 | 60 | 0.0373 | 2.4609 | 0.0347 | 2.9103 |

| 78 | 125 | 40 | 8 | 60 | 0.0489 | 2.5366 | 0.0374 | 3.3761 |

| 79 | 125 | 55 | 4 | 60 | 0.0305 | 2.3521 | 0.0218 | 3.1386 |

| 80 | 125 | 55 | 6 | 60 | 0.0419 | 2.3868 | 0.03 | 2.7741 |

| 81 | 125 | 55 | 8 | 60 | 0.0624 | 2.401 | 0.0393 | 2.9971 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulkarni, V.N.; Gaitonde, V.N.; Mallaiah, M.; Karnik, R.S.; Davim, J.P. Tool Wear Rate and Surface Integrity Studies in Wire Electric Discharge Machining of NiTiNOL Shape Memory Alloy Using Diffusion Annealed Coated Electrode Materials. Machines 2022, 10, 138. https://doi.org/10.3390/machines10020138

Kulkarni VN, Gaitonde VN, Mallaiah M, Karnik RS, Davim JP. Tool Wear Rate and Surface Integrity Studies in Wire Electric Discharge Machining of NiTiNOL Shape Memory Alloy Using Diffusion Annealed Coated Electrode Materials. Machines. 2022; 10(2):138. https://doi.org/10.3390/machines10020138

Chicago/Turabian StyleKulkarni, Vinayak N., Vinayak N. Gaitonde, Manjaiah Mallaiah, Ramesh S. Karnik, and Joao Paulo Davim. 2022. "Tool Wear Rate and Surface Integrity Studies in Wire Electric Discharge Machining of NiTiNOL Shape Memory Alloy Using Diffusion Annealed Coated Electrode Materials" Machines 10, no. 2: 138. https://doi.org/10.3390/machines10020138

APA StyleKulkarni, V. N., Gaitonde, V. N., Mallaiah, M., Karnik, R. S., & Davim, J. P. (2022). Tool Wear Rate and Surface Integrity Studies in Wire Electric Discharge Machining of NiTiNOL Shape Memory Alloy Using Diffusion Annealed Coated Electrode Materials. Machines, 10(2), 138. https://doi.org/10.3390/machines10020138