A Triboelectric Nanogenerator for Energy Harvesting from Transformers’ Vibrations †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of ZnO NRs

2.2. Preparation of the PDMS:GO Composite

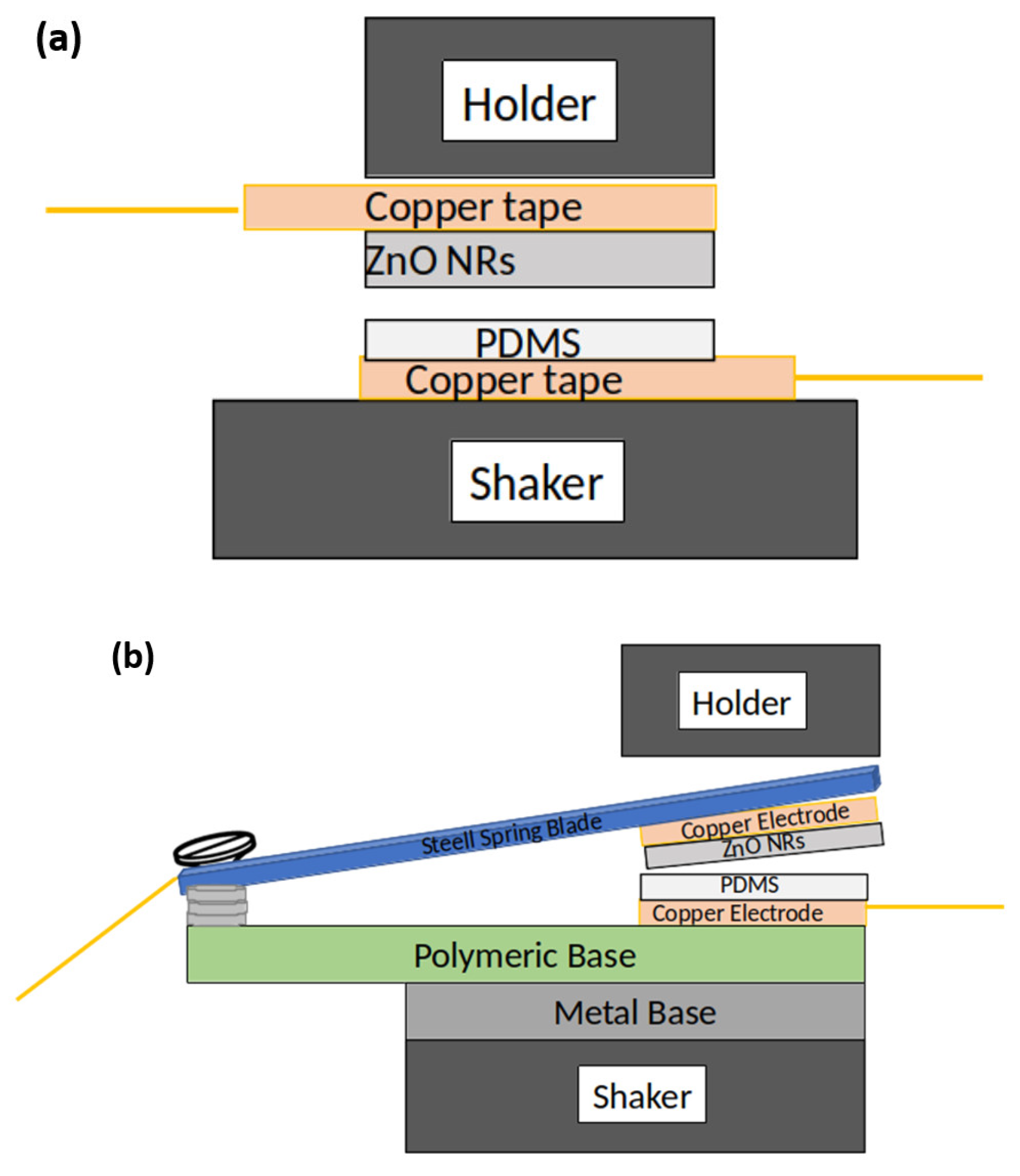

2.3. Assembly of Triboelectric Nanogenerators (TENGs)

2.4. Electrical Characterization of the TENGs

2.5. Mechanical Characterization of the TENG

2.6. Measurements of the Vibrations in Transformers

3. Results and Discussion

3.1. Zno NRs onto the Copper Tape: Electron-Donating Material Characterization

3.2. Pdms and PDMS:GO Films: Electron-Receiving Material Characterization

3.3. Characteristics of the Razor Blade Used as Steel Spring

3.4. Teng Devices

3.5. Calculated Frequency in the External Walls of the Transformers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 2D | two dimensional |

| CBD | chemical bath deposition |

| EDX | energy dispersive X-ray analisys |

| GO | graphene oxide |

| IoT | Internet of Things |

| JCPDS | International Centre for Diffraction Data Sample |

| Preparation Methods in X-Ray Powder Diffraction | |

| PDMS | Polydimethylsiloxane |

| SEM | scanning electron microscopy |

| SHM | simple harmonic movement |

| TENG | triboelectric nanogenerator |

| XRD | X-ray diffraction |

| ZnO NRs | Zinc oxide nanorods |

References

- Zhang, H.; Lu, Y.; Ghaffarinejad, A.; Basset, P. Progressive Contact-Separate Triboelectric Nanogenerator Based on Conductive Polyurethane Foam Regulated with a Bennet Doubler Conditioning Circuit. Nano Energy 2018, 51, 10–18. [Google Scholar] [CrossRef]

- Secor, E.B.; Lim, S.; Zhang, H.; Frisbie, C.D.; Francis, L.F.; Hersam, M.C. Gravure Printing of Graphene for Large-area Flexible Electronics. Adv. Mater. 2014, 26, 4533–4538. [Google Scholar] [CrossRef] [PubMed]

- Son, D.; Lee, J.; Qiao, S.; Ghaffari, R.; Kim, J.; Lee, J.E.; Song, C.; Kim, S.J.; Lee, D.J.; Jun, S.W.; et al. Multifunctional Wearable Devices for Diagnosis and Therapy of Movement Disorders. Nat. Nanotechnol. 2014, 9, 397–404. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, B.; Yuan, W.; Kraft, M.; Chang, H. An Acceleration Sensing Method Based on the Mode Localization of Weakly Coupled Resonators. J. Microelectromech. Syst. 2016, 25, 286–296. [Google Scholar] [CrossRef]

- Tao, K.; Tang, L.; Wu, J.; Lye, S.W.; Chang, H.; Miao, J. Investigation of Multimodal Electret-Based MEMS Energy Harvester with Impact-Induced Nonlinearity. J. Microelectromech. Syst. 2018, 27, 276–288. [Google Scholar] [CrossRef]

- Fan, F.R.; Tang, W.; Wang, Z.L. Flexible Nanogenerators for Energy Harvesting and Self-Powered Electronics. Adv. Mater. 2016, 28, 4283–4305. [Google Scholar] [CrossRef]

- Khazaee, M.; Rezaniakolaie, A.; Rosendahl, L. A Broadband Macro-Fiber-Composite Piezoelectric Energy Harvester for Higher Energy Conversion from Practical Wideband Vibrations. Nano Energy 2020, 76, 104978. [Google Scholar] [CrossRef]

- Cai, M.; Liao, W.H. Enhanced Electromagnetic Wrist-Worn Energy Harvester Using Repulsive Magnetic Spring. Mech. Syst. Signal Process. 2021, 150, 107251. [Google Scholar] [CrossRef]

- Qiao, G.; Wang, J.; Yu, X.; Jia, R.; Cheng, T.; Wang, Z.L. A Bidirectional Direct Current Triboelectric Nanogenerator with the Mechanical Rectifier. Nano Energy 2021, 79, 105408. [Google Scholar] [CrossRef]

- Zhao, C.; Yang, Y.; Upadrashta, D.; Zhao, L. Design, Modeling and Experimental Validation of a Low-Frequency Cantilever Triboelectric Energy Harvester. Energy 2021, 214, 118885. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E.; et al. Conductive Fiber-Based Ultrasensitive Textile Pressure Sensor for Wearable Electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef] [PubMed]

- Cui, S.; Zheng, Y.; Zhang, T.; Wang, D.; Zhou, F.; Liu, W. Self-Powered Ammonia Nanosensor Based on the Integration of the Gas Sensor and Triboelectric Nanogenerator. Nano Energy 2018, 49, 31–39. [Google Scholar] [CrossRef]

- Cao, R.; Wang, J.; Zhao, S.; Yang, W.; Yuan, Z.; Yin, Y.; Du, X.; Li, N.W.; Zhang, X.; Li, X.; et al. Self-Powered Nanofiber-Based Screen-Print Triboelectric Sensors for Respiratory Monitoring. Nano Res. 2018, 11, 3771–3779. [Google Scholar] [CrossRef]

- Park, I.; Maeng, J.; Lim, D.; Shim, M.; Jeong, J.; Kim, C. A 4.5-to-16 μW Integrated Triboelectric Energy-Harvesting System Based on High-Voltage Dual-Input Buck Converter with MPPT and 70V Maximum Input Voltage. In Proceedings of the 2018 IEEE International Solid—State Circuits Conference—(ISSCC), San Francisco, CA, USA, 11–15 February 2018; pp. 146–148. [Google Scholar] [CrossRef]

- Hinchet, R.; Seung, W.; Kim, S.W. Recent Progress on Flexible Triboelectric Nanogenerators for SelfPowered Electronics. ChemSusChem 2015, 8, 2327–2344. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef] [PubMed]

- Basset, P.; Blokhina, E.; Galayko, D. Electrostatic Kinetic Energy Harvesting; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Costa, S.V.; Azana, N.T.; Shieh, P.; Mazon, T. Synthesis of ZnO Rod Arrays on Aluminum Recyclable Paper and Effect of the Rod Size on Power Density of Eco-Friendly Nanogenerators. Ceram. Int. 2018, 44, 12174–12179. [Google Scholar] [CrossRef]

- Dharmasena, R.D.I.G.; Jayawardena, K.D.G.I.; Mills, C.A.; Deane, J.H.B.; Anguita, J.V.; Dorey, R.A.; Silva, S.R.P. Triboelectric Nanogenerators: Providing a Fundamental Framework. Energy Environ. Sci. 2017, 10, 1801–1811. [Google Scholar] [CrossRef]

- Kim, D.W.; Lee, J.H.; Kim, J.K.; Jeong, U. Material Aspects of Triboelectric Energy Generation and Sensors. NPG Asia Mater. 2020, 12, 1–17. [Google Scholar] [CrossRef]

- Muthu, M.; Pandey, R.; Wang, X.; Chandrasekhar, A.; Palani, I.A.; Singh, V. Enhancement of Triboelectric Nanogenerator Output Performance by Laser 3D-Surface Pattern Method for Energy Harvesting Application. Nano Energy 2020, 78, 105205. [Google Scholar] [CrossRef]

- Yin, X.; Liu, D.; Zhou, L.; Li, X.; Zhang, C.; Cheng, P.; Guo, H.; Song, W.; Wang, J.; Wang, Z.L. Structure and Dimension Effects on the Performance of Layered Triboelectric Nanogenerators in Contact-Separation Mode. ACS Nano 2019, 13, 698–705. [Google Scholar] [CrossRef]

- Simões, A.N.; Carvalho, D.J.; de Souza Morita, E.; Vendrameto, H.V.; Fu, L.; Torres, F.; de Souza, A.N.; Bizzo, W.A.; Mazon, T. Application of Steel Spring on the ZnO Nanorods Self-Powered Triboelectric Nanogenerator for Efficient Energy Harvest in Transformers. In Proceedings of the 2021 14th IEEE International Conference on Industry Applications (INDUSCON), São Paulo, Brazil, 15–18 August 2021; pp. 904–909. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, X.; Zhao, D.; Gao, M.; Xie, S. ZnO Nanorods: Morphology Control, Optical Properties, and Nanodevice Applications. Sci. China Phys. Mech. Astron. 2013, 56, 2243–2265. [Google Scholar] [CrossRef]

- Cherumannil Karumuthil, S.; Rajeev, S.P.; Varghese, S. Piezo-Tribo Nanoenergy Harvester Using Hybrid Polydimethyl Siloxane Based Nanocomposite. Nano Energy 2017, 40, 487–494. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, X.; Liao, Q.; Liu, H.; Huang, Y.; Song, Y.; Zhao, Y.; Zhang, Y. Enzymatic Lactic Acid Sensing by In-doped ZnO Nanowires Functionalized AlGaAs/GaAs High Electron Mobility Transistor. Sens. Actuators B Chem. 2015, 212, 41–46. [Google Scholar] [CrossRef]

- Anand, K.; Singh, O.; Singh, R.C. Different Strategies for the Synthesis of Graphene/ZnO Composite and Its Photocatalytic Properties. Appl. Phys. A 2014, 116, 1141–1148. [Google Scholar] [CrossRef]

- Kumar, B.; Kim, S.W. Energy Harvesting Based on Semiconducting Piezoelectric ZnO Nanostructures. Nano Energy 2012, 1, 342–355. [Google Scholar] [CrossRef]

- Diaz, A.F.; Felix-Navarro, R.M. A Semi-Quantitative Tribo-Electric Series for Polymeric Materials: The Influence of Chemical Structure and Properties. J. Electrost. 2004, 62, 277–290. [Google Scholar] [CrossRef]

- Hassani, F.A.; Lee, C. A Triboelectric Energy Harvester Using Low-Cost, Flexible, and Biocompatible Ethylene Vinyl Acetate (EVA). J. Microelectromech. Syst. 2015, 24, 1338–1345. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Tcho, I.W.; Kim, W.G.; Jeon, S.B.; Park, S.J.; Lee, B.J.; Bae, H.K.; Kim, D.; Choi, Y.K. Surface Structural Analysis of a Friction Layer for a Triboelectric Nanogenerator. Nano Energy 2017, 42, 34–42. [Google Scholar] [CrossRef]

- Wang, S.; Xie, Y.; Niu, S.; Lin, L.; Liu, C.; Zhou, Y.S.; Wang, Z.L. Maximum Surface Charge Density for Triboelectric Nanogenerators Achieved by Ionized-Air Injection: Methodology and Theoretical Understanding. Adv. Mater. 2014, 26, 6720–6728. [Google Scholar] [CrossRef]

- Wang, J.; Wu, C.; Dai, Y.; Zhao, Z.; Wang, A.; Zhang, T.; Wang, Z.L. Achieving Ultrahigh Triboelectric Charge Density for Efficient Energy Harvesting. Nat. Commun. 2017, 8, 88. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, C.; Kim, T.W.; Choi, H.Y. Reduced Graphene-Oxide Acting as Electron-Trapping Sites in the Friction Layer for Giant Triboelectric Enhancement. Nano Energy 2017, 32, 542–550. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, J.; Wang, Z.; Liu, Z.; Zhu, W.; Xia, H.; Yang, T.; He, F.; Wu, Y.; Fu, X.; et al. Ultrasensitive Triboelectric Nanogenerator for Weak Ambient Energy with Rational Unipolar Stacking Structure and Low-Loss Power Management. Nano Energy 2017, 41, 351–358. [Google Scholar] [CrossRef]

- Vessalli, B.A.; Zito, C.A.; Perfecto, T.M.; Volanti, D.P.; Mazon, T. ZnO Nanorods/Graphene Oxide Sheets Prepared by Chemical Bath Deposition for Volatile Organic Compounds Detection. J. Alloys Compd. 2017, 696, 996–1003. [Google Scholar] [CrossRef] [Green Version]

- Zargari, S.; Koozehkanani, Z.D.; Veladi, H.; Sobhi, J.; Rezania, A. Cost-Effective Fabrication Approaches for Improving Output Performance of Triboelectric Energy Harvesters. J. Electrost. 2022, 115, 103640. [Google Scholar] [CrossRef]

- Srivastava, V.; Gusain, D.; Sharma, Y.C. Synthesis, Characterization and Application of Zinc Oxide Nanoparticles (n-ZnO). Ceram. Int. 2013, 39, 9803–9808. [Google Scholar] [CrossRef]

- Ramyadevi, J.; Jeyasubramanian, K.; Marikani, A.; Rajakumar, G.; Rahuman, A.A. Synthesis and Antimicrobial Activity of Copper Nanoparticles. Mater. Lett. 2012, 71, 114–116. [Google Scholar] [CrossRef]

- Wardhana, E.M.; Mutsuda, H.; Tanaka, Y.; Nakashima, T.; Kanehira, T.; Taniguchi, N.; Maeda, S.; Yonezawa, T.; Yamauchi, M. Harvesting Contact-Separation-Compression Vibrations Using a Flexible and Compressible Triboelectric Generator. Sustain. Energy Technol. Assess. 2020, 42, 100869. [Google Scholar] [CrossRef]

- Jayasvasti, S.; Thainiramit, P.; Yingyong, P.; Isarakorn, D. Technique for Measuring Power across High Resistive Load of Triboelectric Energy Harvester. Micromachines 2021, 12, 766. [Google Scholar] [CrossRef]

| Lenght | Width | Thickness | Mass | Moment of Inertia | Natural Frequency |

|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (g) | (kg m) | (Hz) |

| 35.0 | 9.5 | 0.1 | 0.26 | 7.9 × 10 | 32.8 |

| Element | Atomic No. | Netto | Mass (%) | Normalized Mass (%) | Atom (%) | Absolute Error (%) | Relative Error (%) |

|---|---|---|---|---|---|---|---|

| Iron | 26 | 98,975 | 21.26 | 84.77 | 83.83 | 0.59 | 2.79 |

| Chromium | 24 | 24,049 | 3.82 | 15.23 | 16.17 | 0.13 | 3.43 |

| Device | Frequency | Load | Voltage | Current | Power Density |

|---|---|---|---|---|---|

| (Hz) | (MΩ) | (V) | (µA) | (mW m) | |

| without steel | 45 | 10 | 6.5 | 0.65 | 92.8 |

| spring | 60 | 10 | 8.9 | 0.89 | 176 |

| (reading of an oscilloscope) | 200 | 10 | 5 | 0.5 | 54.9 |

| without steel | 45 | 8.1 | 4.36 | 0.5 | 51.5 |

| spring | 60 | 4.2 | 4.41 | 0.96 | 101.7 |

| (optimal value) | 200 | 6.9 | 4.05 | 0.5 | 52.2 |

| with steel | 45 | 10 | 6.8 | 0.68 | 124.3 |

| spring | 60 | 8.2 | 8.6 | 1.05 | 246.4 |

| (reading of an oscilloscope) | 200 | 60 | 9.5 | 0.15 | 40.4 |

| with steel | 45 | 8.1 | 4.69 | 0.6 | 63 |

| spring | 60 | 4.5 | 5.1 | 1 | 155.3 |

| (optimal value) | 200 | 13 | 2.87 | 0.19 | 22.1 |

| Transformer | Measurement | Amplitude | Speed Vibration | Vibration |

|---|---|---|---|---|

| Capacity | Location | (mm) | (mm s) | Frequency (Hz) |

| 133 MVA | front side (a) | 0.002605 | 2.38 | 205 |

| front side (b) | 0.004505 | 4.87 | 242 | |

| front side (c) | 0.008245 | 4.68 | 127 | |

| front side (d) | 0.00511 | 4.61 | 202 | |

| radiator | 0.00252 | 1.47 | 131 | |

| backside | 0.003825 | 2.49 | 146 | |

| 5 MVA | front side | 0.001475 | 0.34 | 52 |

| 41 MVA | front side | 0.004545 | 2.32 | 115 |

| front side | 0.001655 | 0.66 | 90 | |

| front side (j) | 0.002985 | 1.35 | 102 | |

| radiator | 0.00178 | 0.35 | 45 | |

| 25 MVA | front side | 0.001755 | 0.85 | 109 |

| front side | 0.00129 | 0.34 | 60 | |

| front side | 0.001155 | 0.51 | 99 | |

| radiator | 0.001625 | 0.39 | 54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simões, A.N.; Carvalho, D.J.; Morita, E.d.S.; Moretti, H.L.; Vendrameto, H.V.; Fu, L.; Torres, F.; Souza, A.N.d.; Bizzo, W.A.; Mazon, T. A Triboelectric Nanogenerator for Energy Harvesting from Transformers’ Vibrations. Machines 2022, 10, 215. https://doi.org/10.3390/machines10030215

Simões AN, Carvalho DJ, Morita EdS, Moretti HL, Vendrameto HV, Fu L, Torres F, Souza ANd, Bizzo WA, Mazon T. A Triboelectric Nanogenerator for Energy Harvesting from Transformers’ Vibrations. Machines. 2022; 10(3):215. https://doi.org/10.3390/machines10030215

Chicago/Turabian StyleSimões, Agnes Nascimento, Danilo José Carvalho, Eugênio de Souza Morita, Haroldo Luiz Moretti, Helen Velozo Vendrameto, Li Fu, Floriano Torres, André Nunes de Souza, Waldir Antonio Bizzo, and Talita Mazon. 2022. "A Triboelectric Nanogenerator for Energy Harvesting from Transformers’ Vibrations" Machines 10, no. 3: 215. https://doi.org/10.3390/machines10030215

APA StyleSimões, A. N., Carvalho, D. J., Morita, E. d. S., Moretti, H. L., Vendrameto, H. V., Fu, L., Torres, F., Souza, A. N. d., Bizzo, W. A., & Mazon, T. (2022). A Triboelectric Nanogenerator for Energy Harvesting from Transformers’ Vibrations. Machines, 10(3), 215. https://doi.org/10.3390/machines10030215