Experimental Analysis of the Effect of Wear Factors on Guide Vane of Hydraulic Turbine

Abstract

:1. Introduction

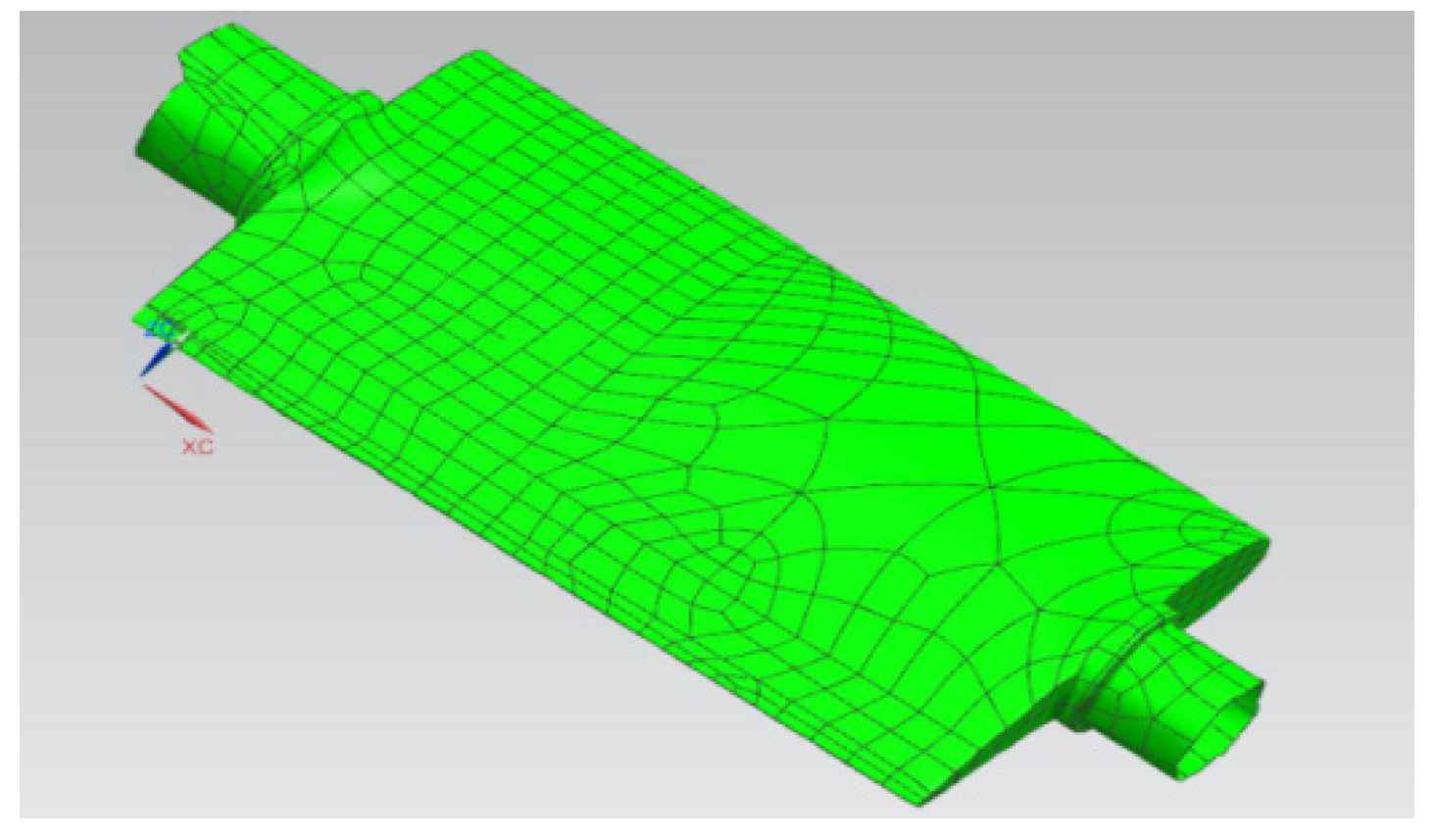

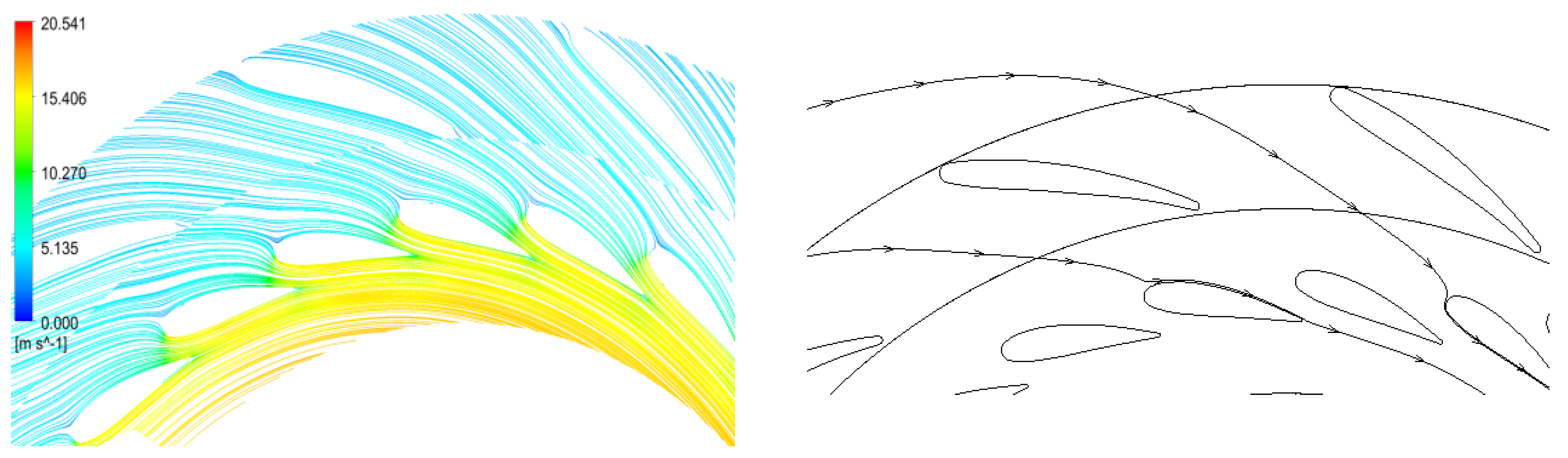

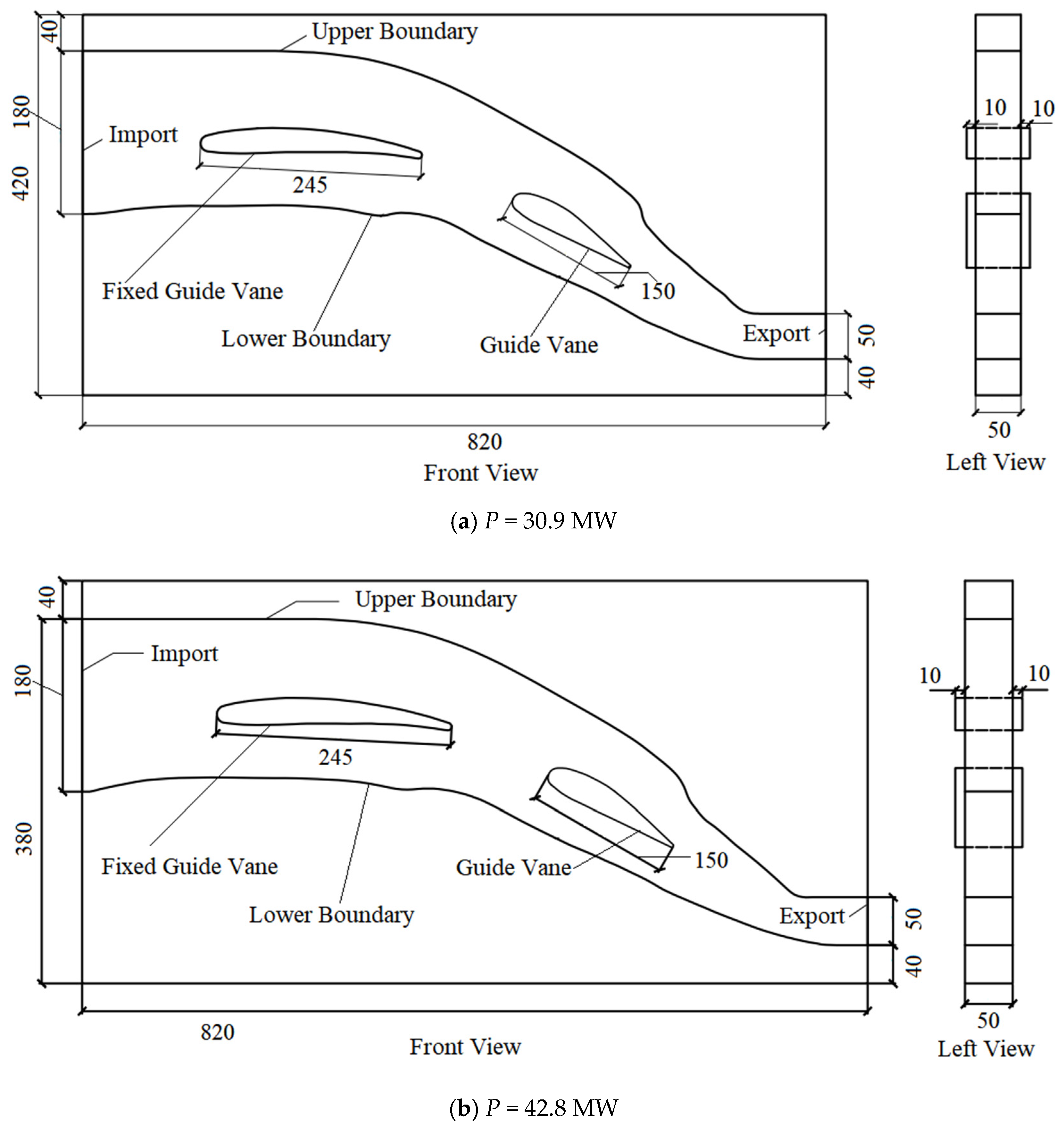

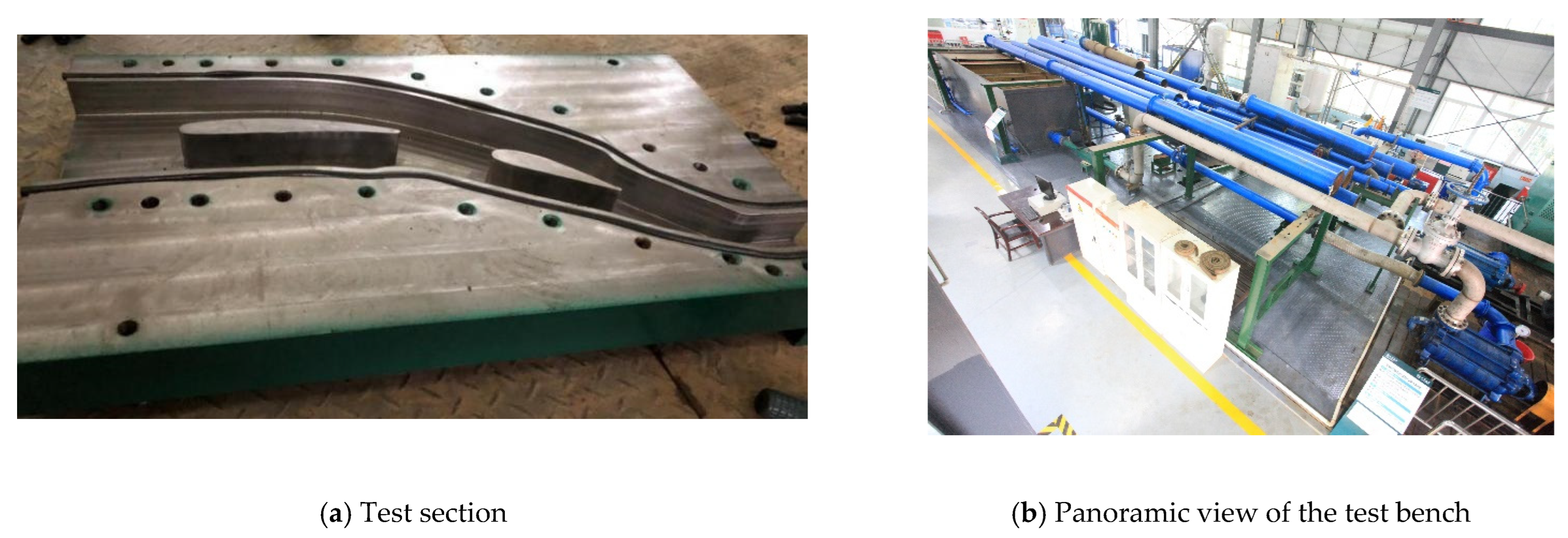

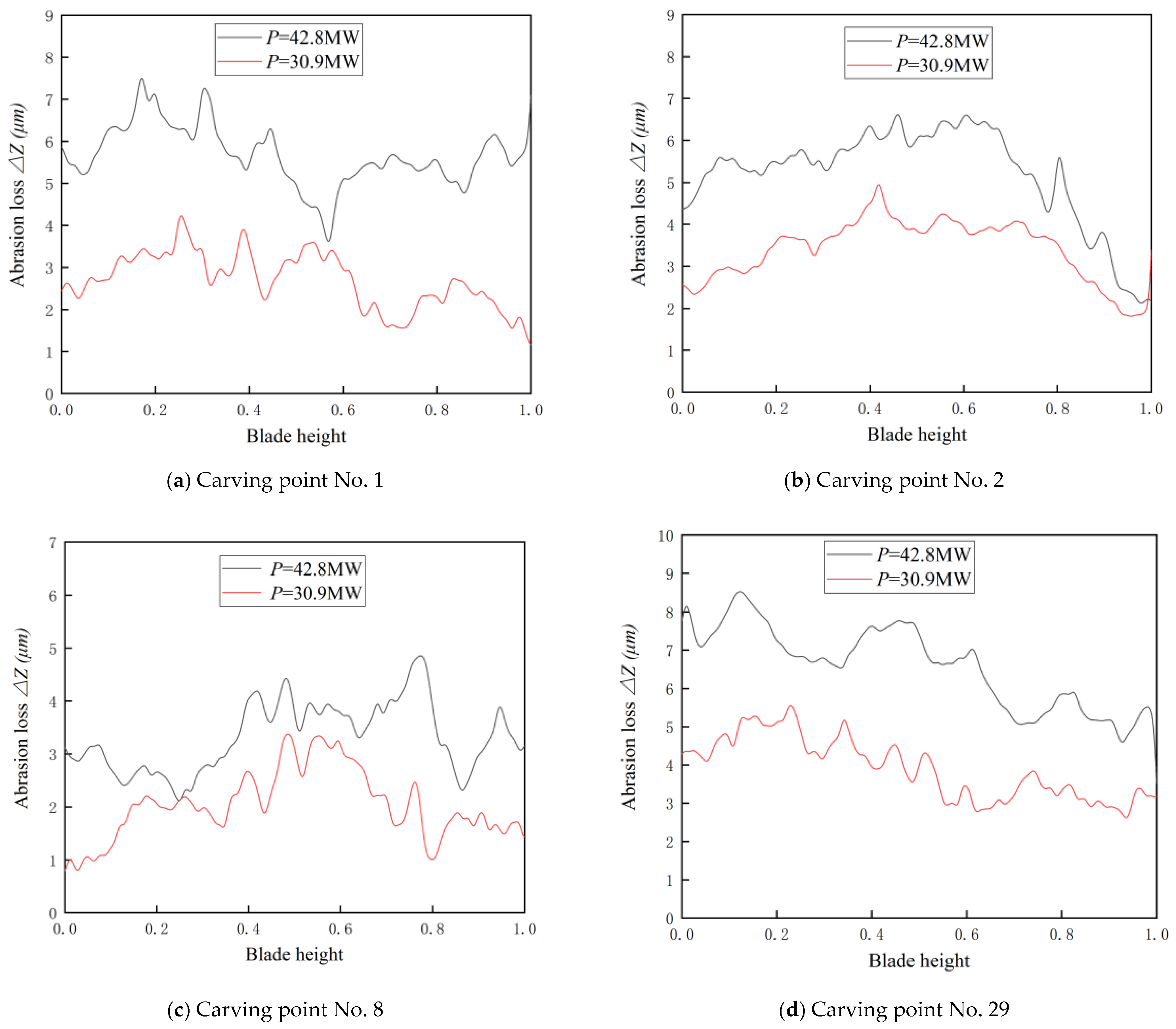

2. Test Bench Design and Prototype Processing

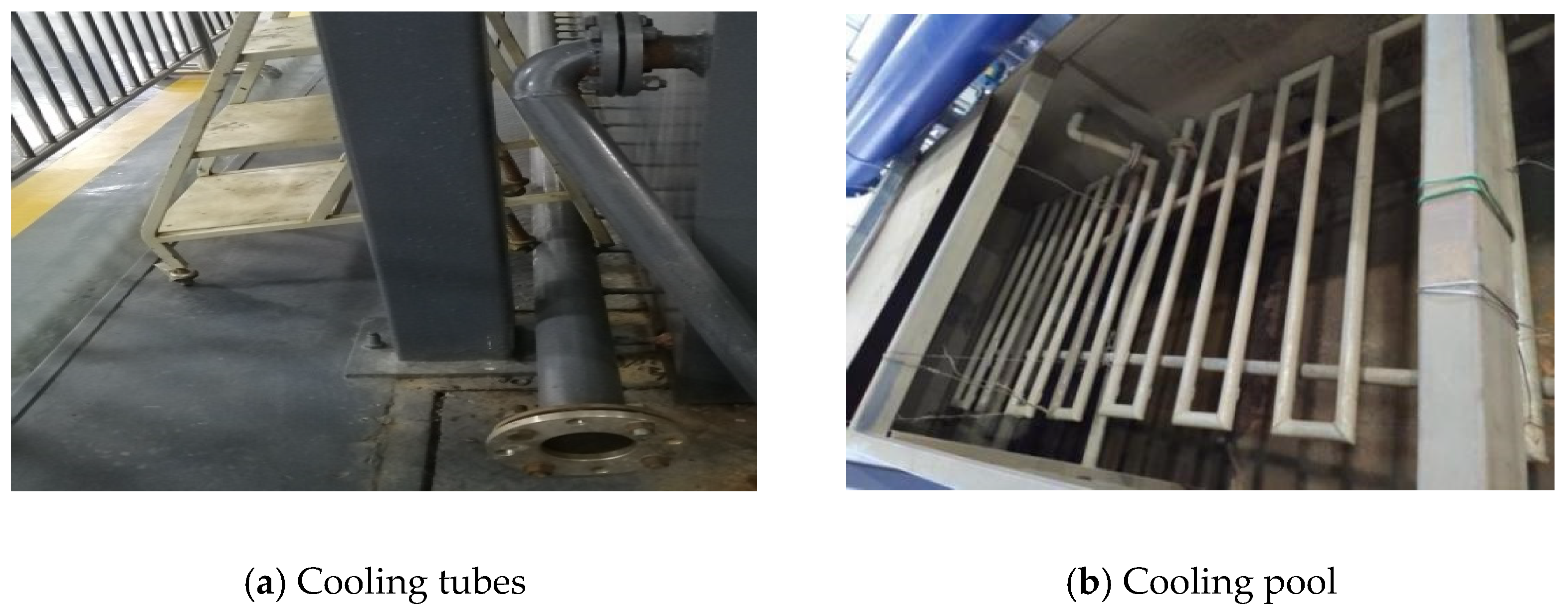

2.1. Test Bench Design

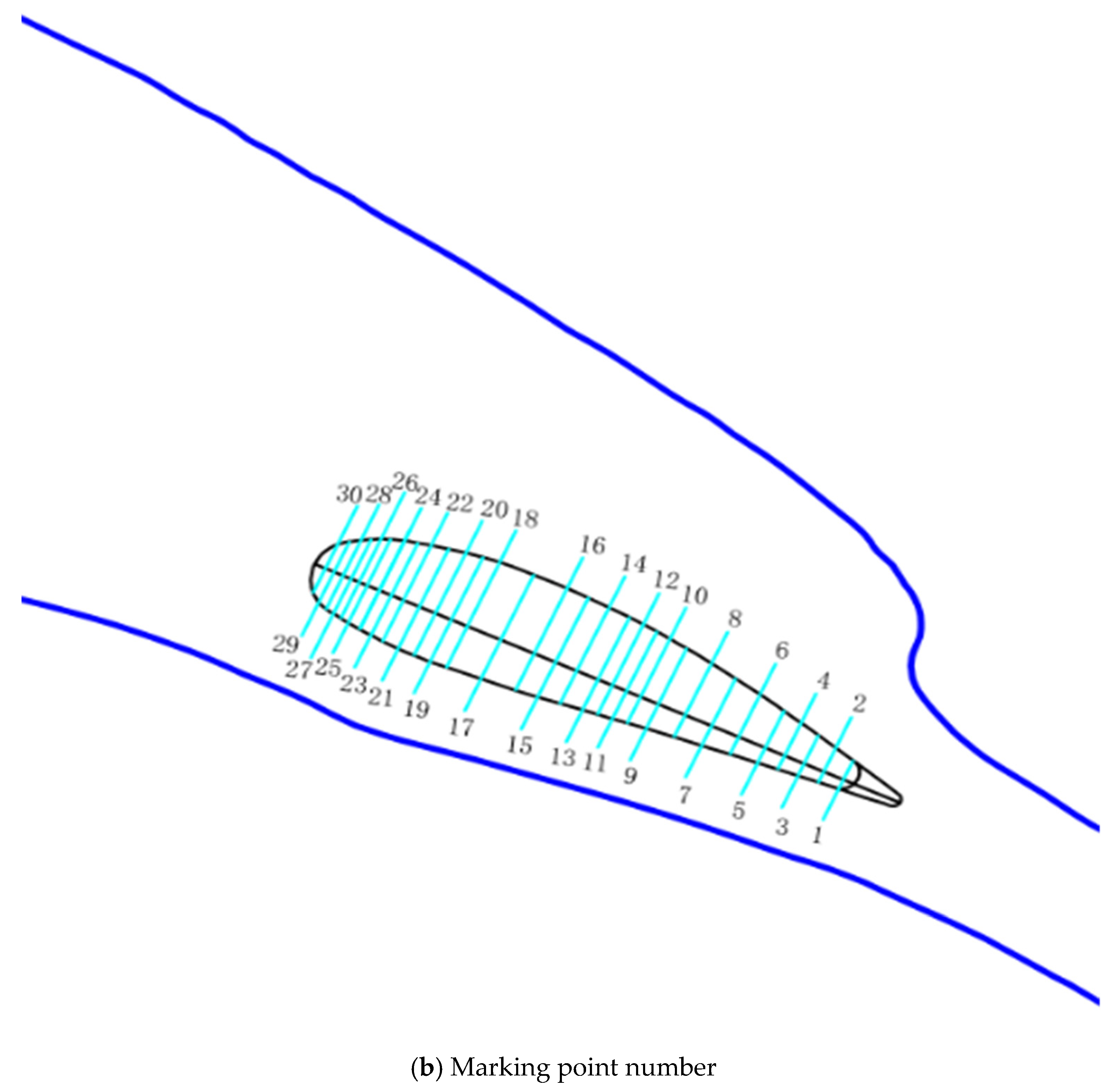

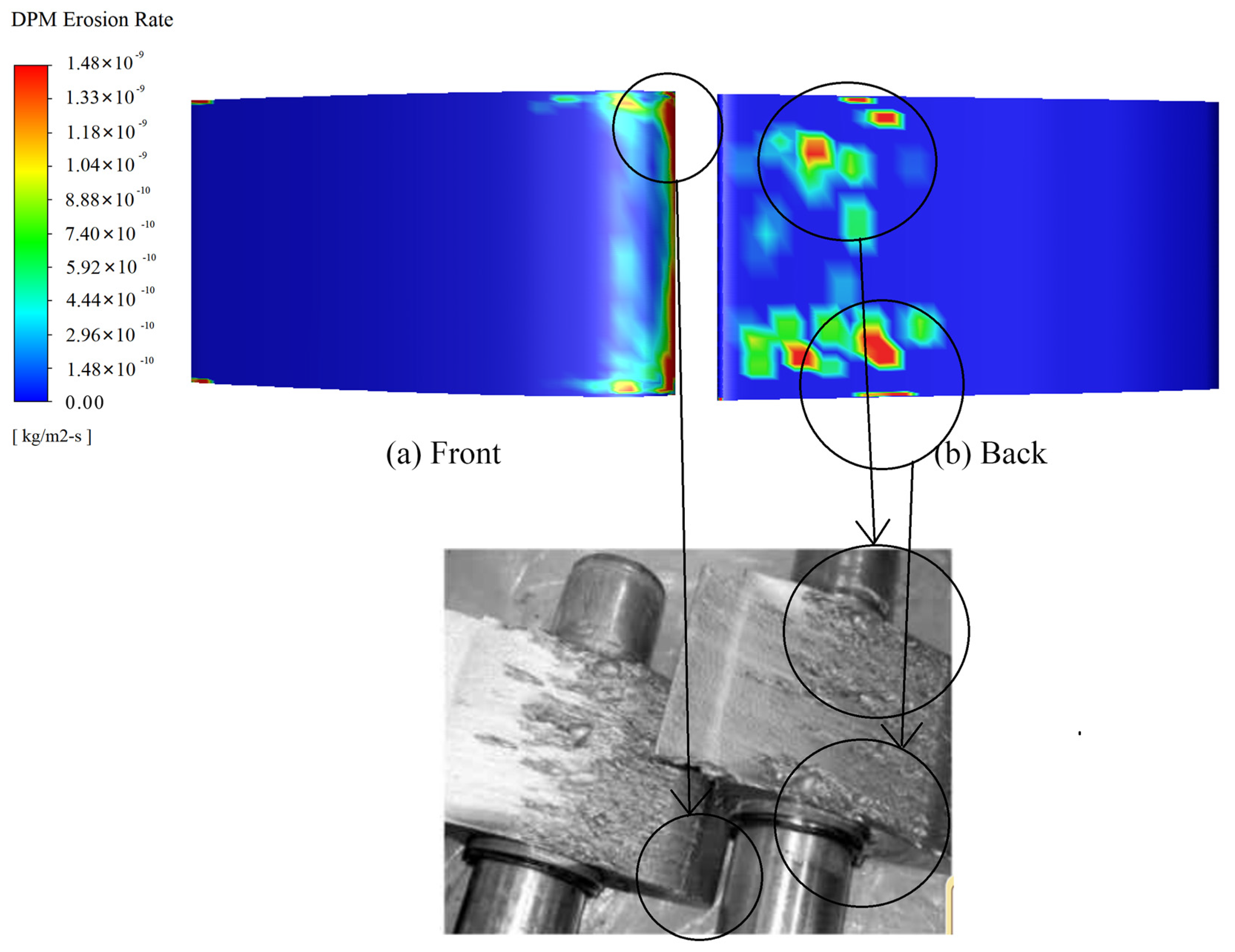

2.2. Prototype Processing

3. Analysis of Test Results

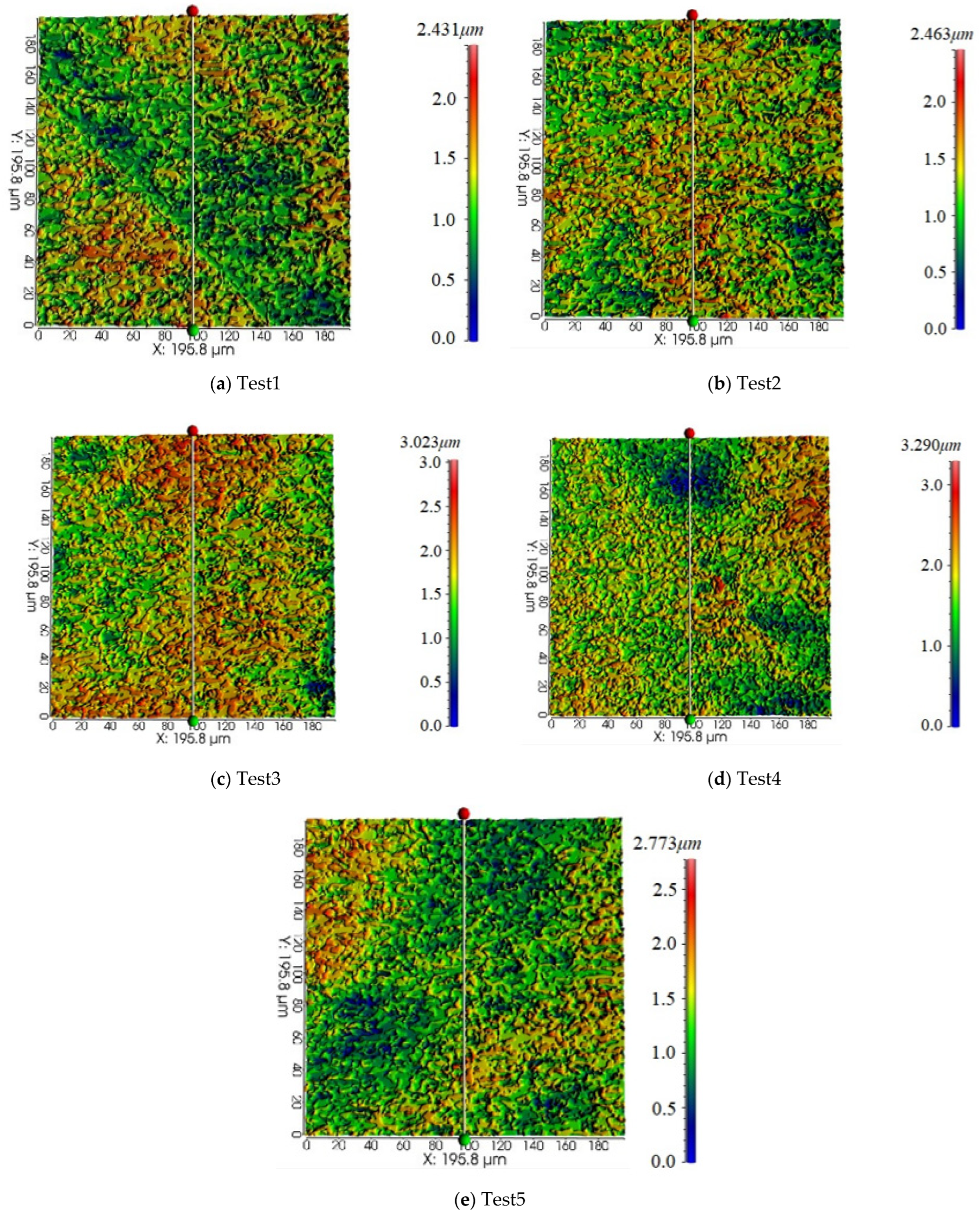

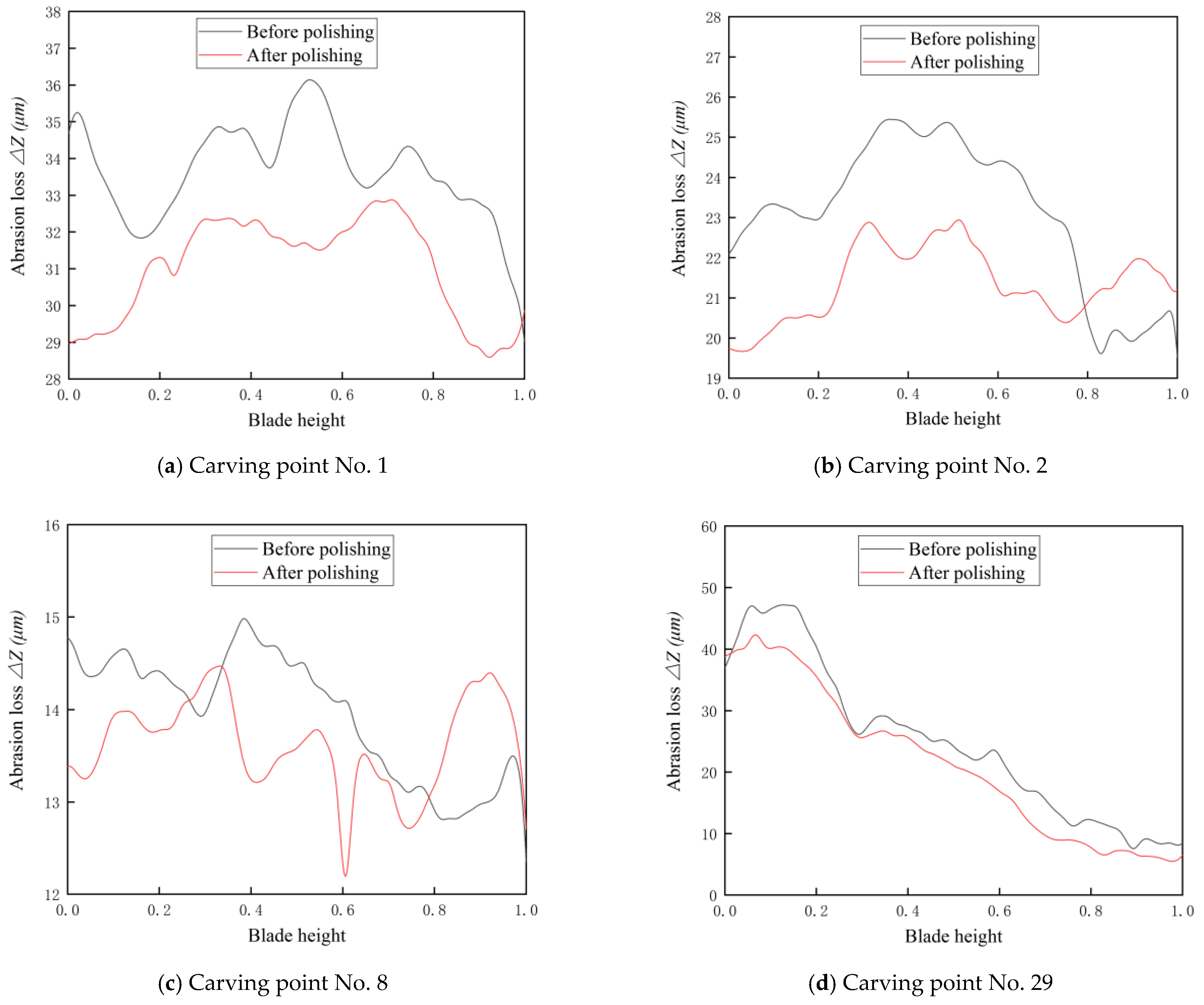

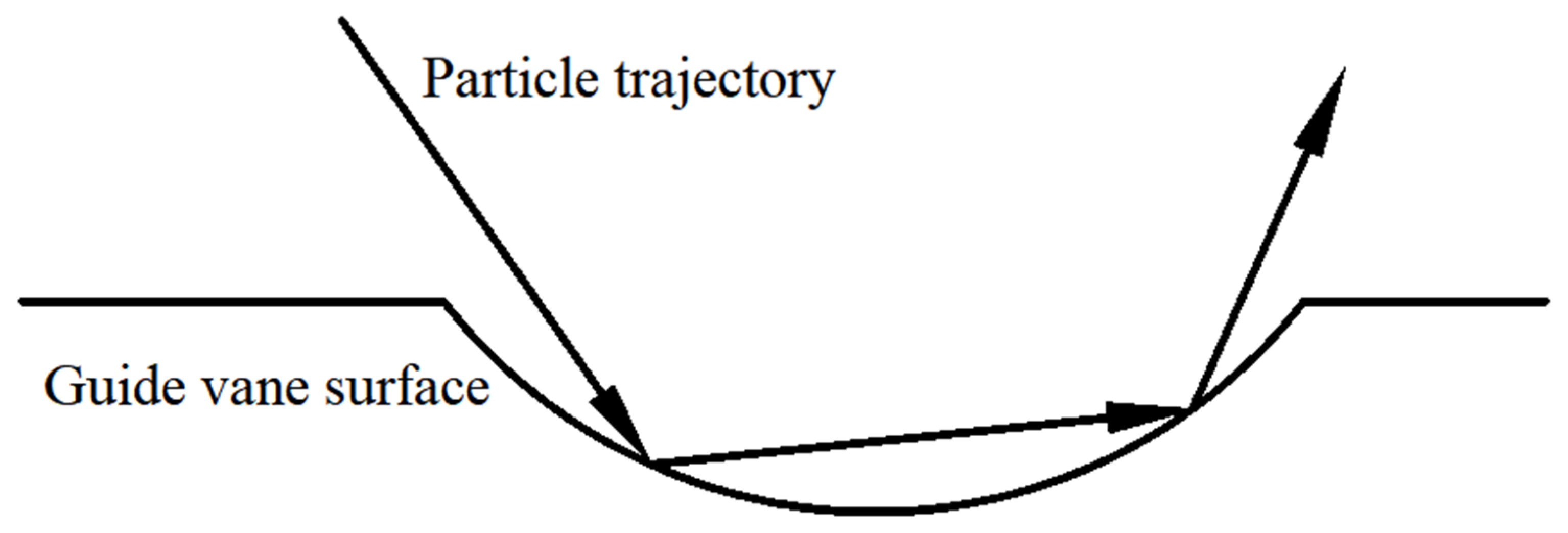

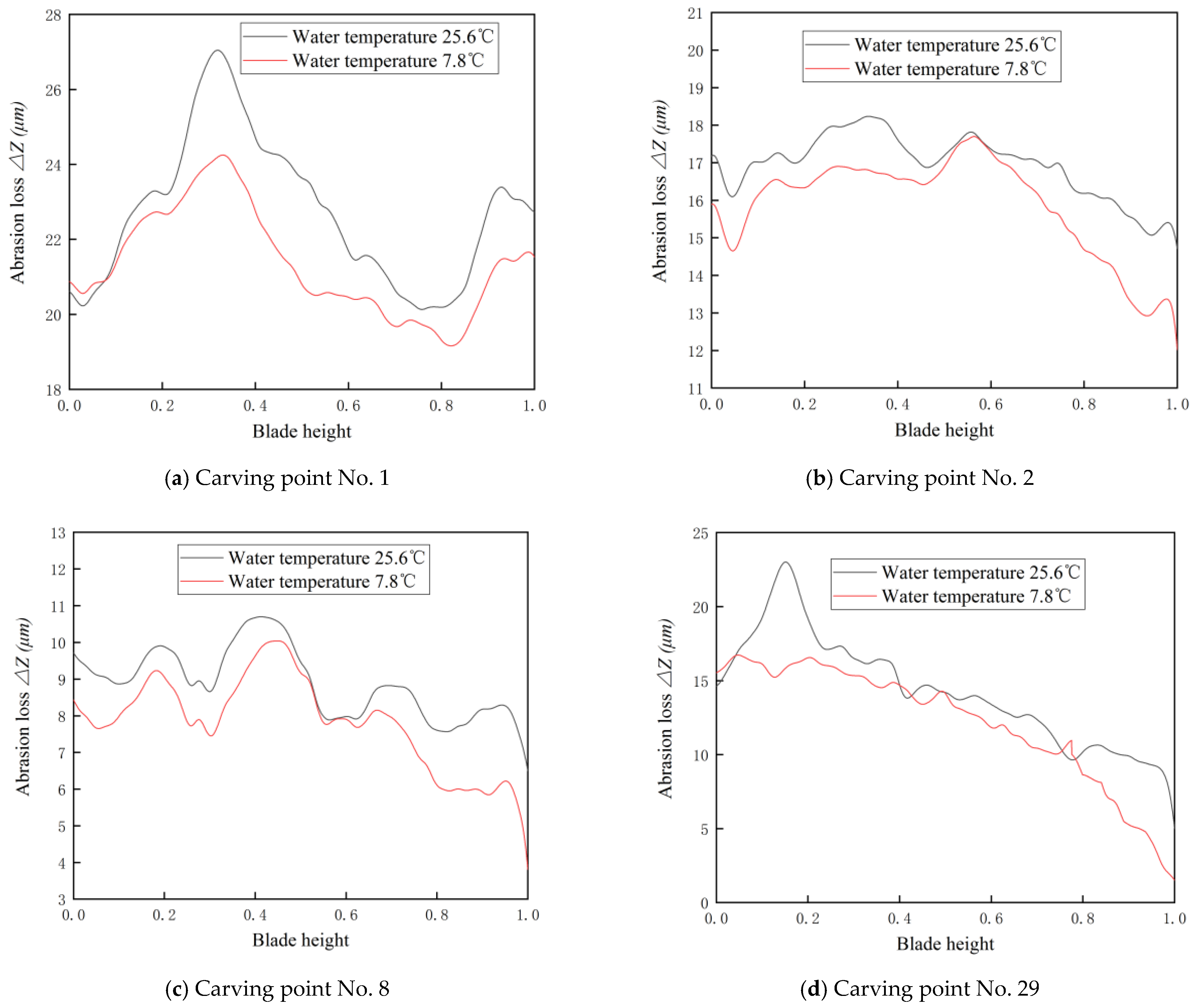

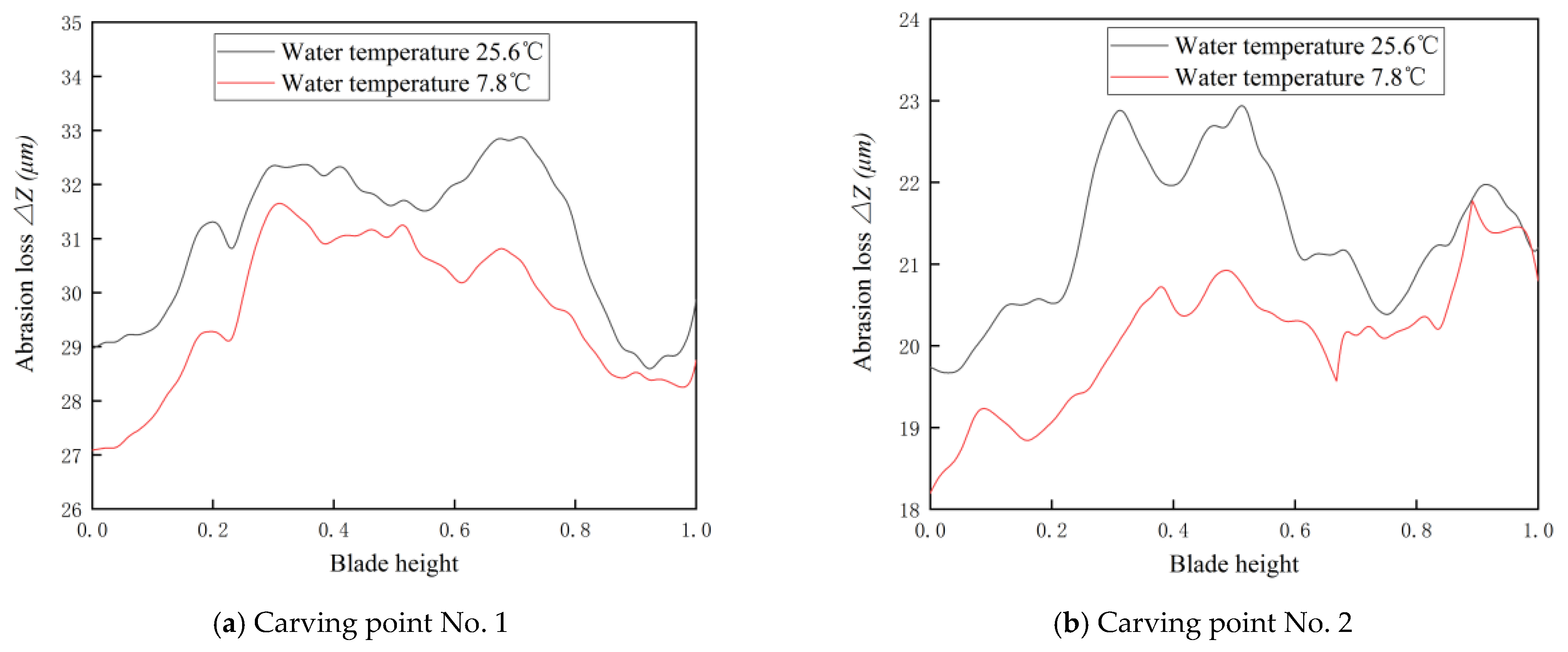

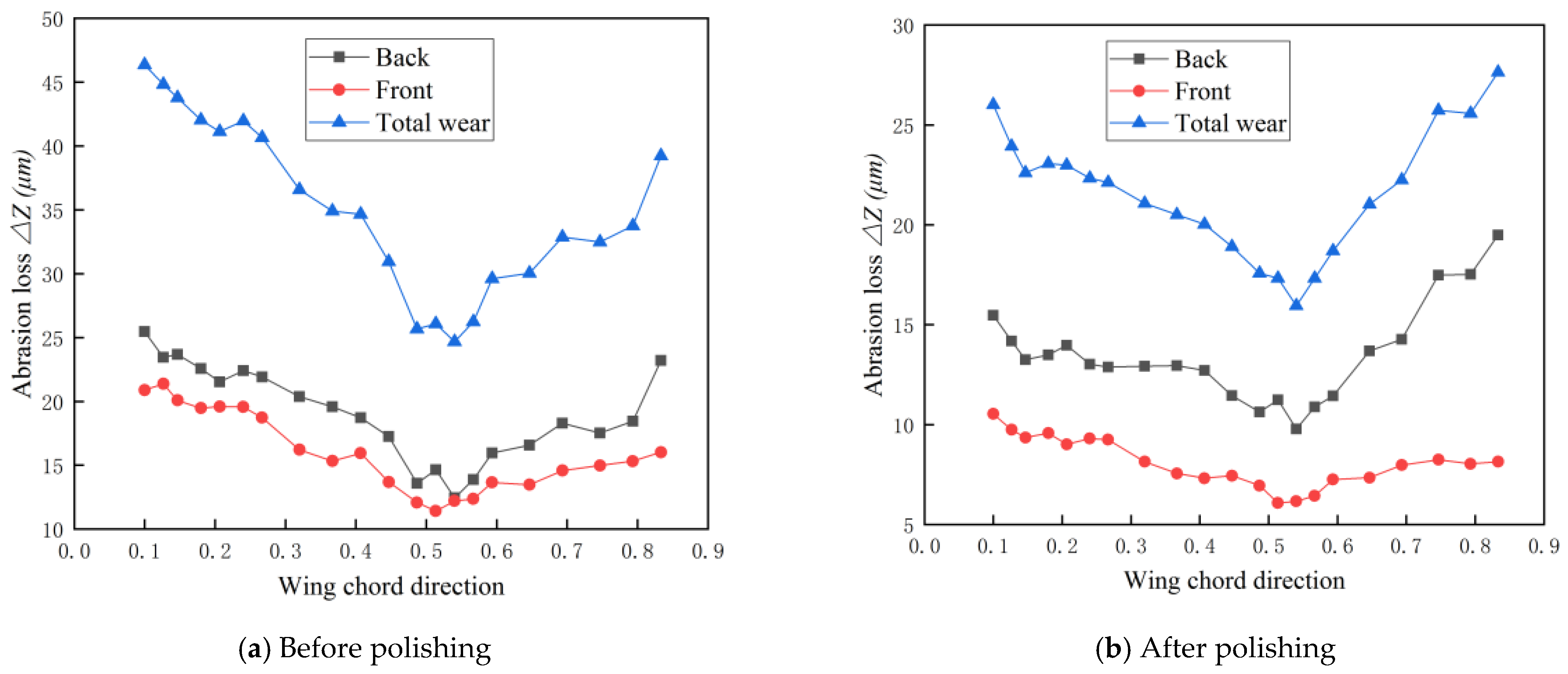

3.1. Effect of Roughness on Wear of Guide Vane

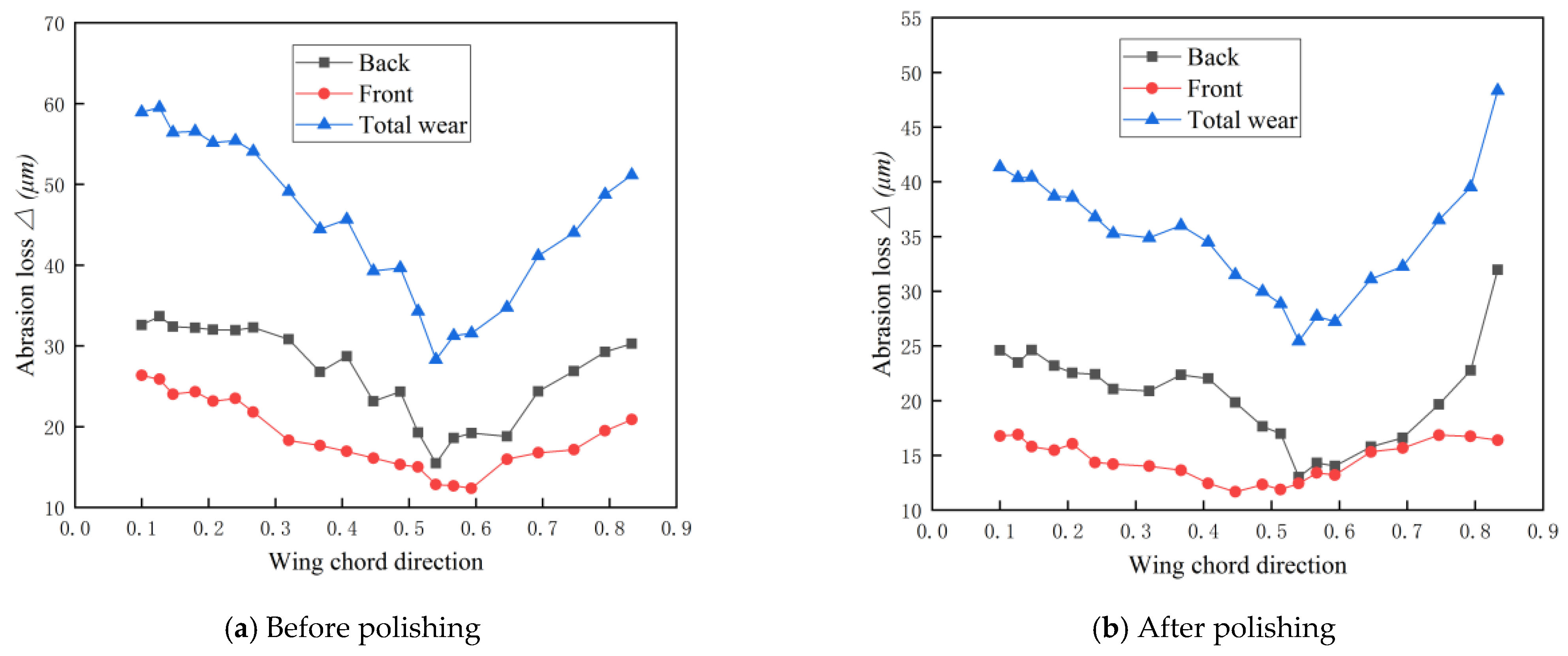

3.2. Wear after Tungsten Carbide Spraying

3.3. Effect of Power Station River pH on Wear of Guide Vane

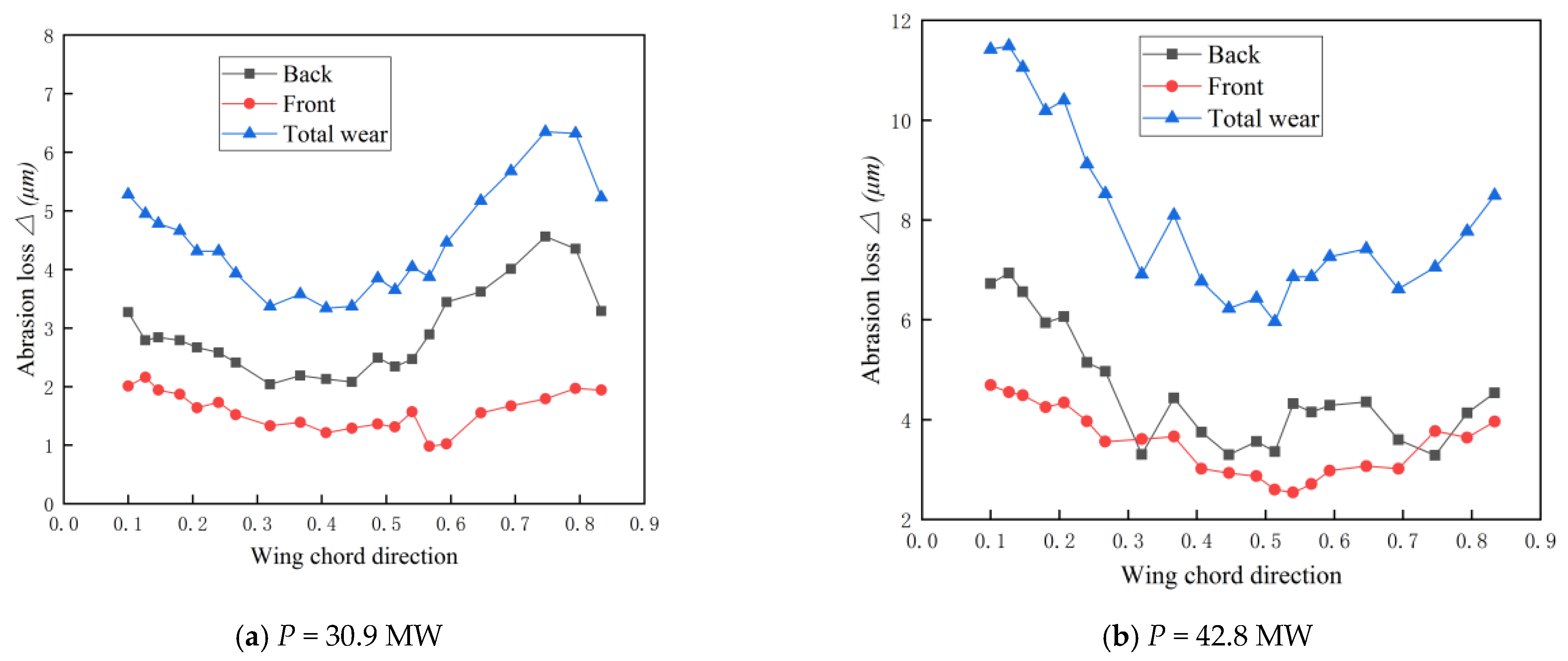

3.4. Estimated Life of Guide Vane

4. Conclusions

- By setting up a bypass test bench to restore the flow situation of the over-flow components of the power station, the test bench was built by using reverse engineering, and the more serious wear was obtained at the back of the guide vane at 1, 2, 8 and 29 engraved points according to the simulation, and the specific study of these four engraved points was carried out.

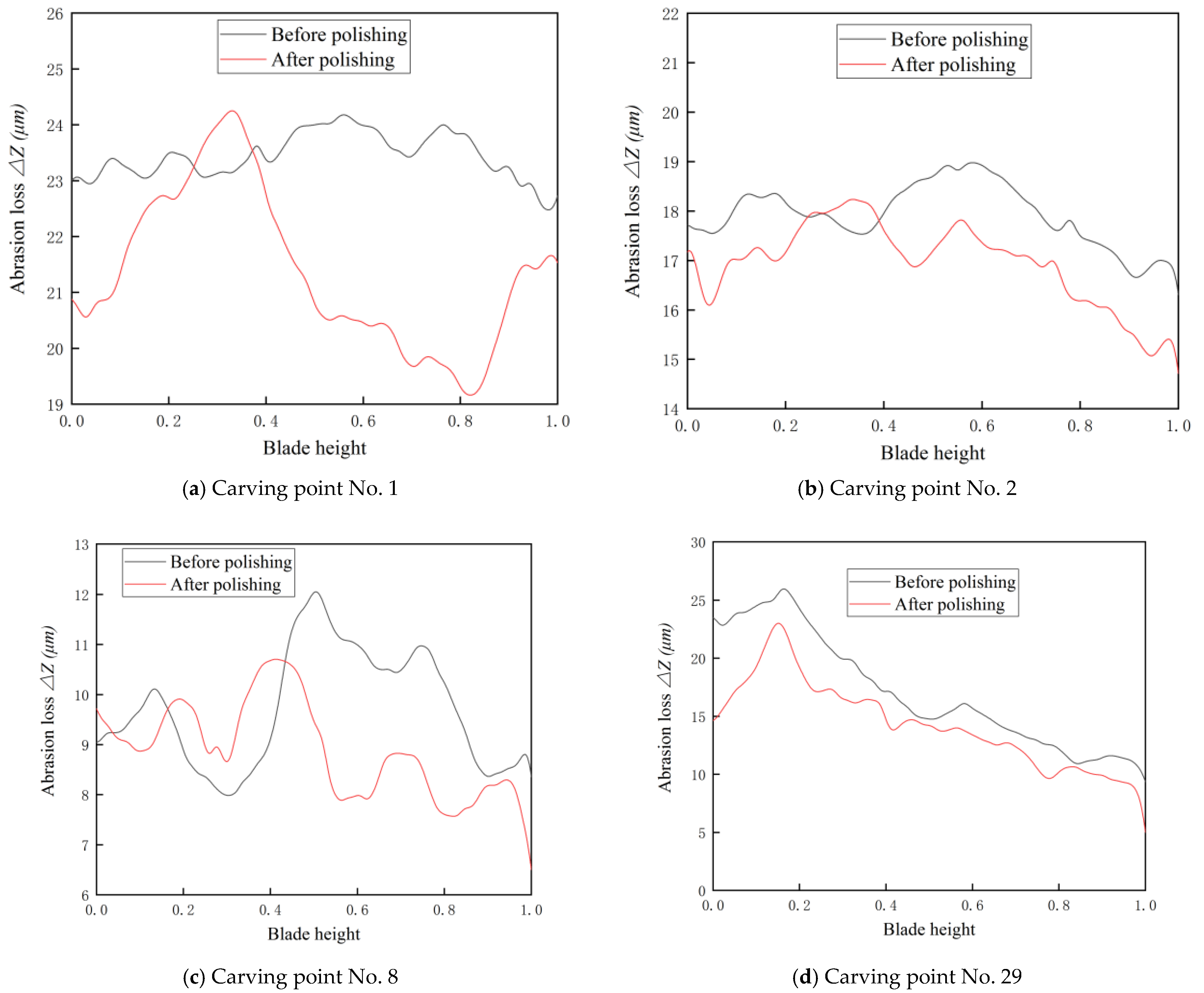

- The roughness of the guide vane specimen was measured by 3D morphometer. Comparing the wear amount of the guide vane with two kinds of roughness under two working conditions, we found that the guide vane head position is easy to be worn by the impact and collision of sediment particles, and the tail position is easily worn by the scouring of sediment particles.

- In spraying a 0.3 mm tungsten carbide coating on the surface of the guide vane specimen and conducting the mud and sand abrasion experiment, we found that the guide vane is subject to increased mud and sand abrasion performance which is three to four times greater than that before spraying.

- The average pH value of the water body measured in the power station is 6.73, and it was determined that the change of dissolved oxygen in the water body will affect the wear of the guide vane and the dissolved oxygen is susceptible to the change of the water body temperature. The test is conducted according to the simulation of the actual flood and dry water temperature in the power station, and the wear of the guide vane is more serious when the water temperature is 25.6 °C than when the water temperature is 7.8 °C.

- According to the test, we extracted the wear data of the guide vane in different airfoil chords upwards, extracted the average wear data of 40–60% as the basis for the estimation of the guide vane life, and estimated the service life of guide vane before and after polishing and after tungsten carbide spraying at P = 30.9 MW and P = 42.8 MW by the maximum wear amount in airfoil chord upwards. In order to be closer to the actual operation of the power plant, the life time of the guide vane was estimated by the wear data of the guide vane after polishing at two water temperatures, and the life time of the guide vane was 40.40 months and 23.39 months at P = 30.9 MW and P = 42.8 MW, respectively, while the lifetime increased by 9.50 months and 5.11 months after tungsten carbide coating, respectively.

- The design of this paper helps to analyze and study the influence of the guide vane under different working conditions by the sediment wear factor, but considering that the internal flow of the turbine is more complicated, a real model can be considered for the study if the funding is sufficient. Furthermore, the experimental measurement error cannot be neglected. In future research, we are committed to testing a real model and further reducing the test error.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Payambarpour, S.A.; Najafi, A.F.; Magagnato, F. Investigation of deflector geometry and turbine aspect ratio effect on 3D modified in-pipe hydro Savonius turbine: Parametric study. Renew. Energy 2020, 148, 44–59. [Google Scholar] [CrossRef]

- Messa, G.V.; Mandelli, S.; Malavasi, S. Hydroabrasive erosion in Pelton turbine injectors: A numerical study. Renew. Energy 2019, 130, 474–488. [Google Scholar] [CrossRef]

- Jung, I.H.; Kim, Y.S.; Shin, D.H.; Chung, J.T.; Shin, Y. Influence of spear needle eccentricity on jet quality in micro Pelton turbine for power generation. Energy 2019, 175, 58–65. [Google Scholar] [CrossRef]

- Chitrakar, S.; Neopane, H.P.; Dahihaug, O.G. Study of the simultaneous effects of secondary flow and sediment erosion in Francis turbines. Renew. Energy 2016, 97, 881–891. [Google Scholar] [CrossRef]

- Masoodi, J.H.; Harmain, G.A. A methodology for assessment of erosive wear on a Francis turbine runner. Energy 2017, 118, 644–657. [Google Scholar] [CrossRef]

- Gautam, S.; Neopane, H.P.; Acharya, N.; Chitrakar, S.; Thapa, B.S.; Zhu, B. Sediment erosion in low specific speed Francis turbines: A case study on effects and causes. Wear 2020, 442, 2020. [Google Scholar] [CrossRef]

- Thapa, B.S.; Dahlhaug, O.G.; Thapa, B. Sediment erosion in hydro turbines and its effect on the flow around guide vanes of Francis turbine. Renew. Sustain. Energy Rev. 2015, 49, 1100–1113. [Google Scholar] [CrossRef]

- Han, Y.; Tan, L. Dynamic mode decomposition and reconstruction of tip leakage vortex in a mixed flow pump as turbine at pump mode. Renew. Energy 2020, 155, 725–734. [Google Scholar] [CrossRef]

- Koirala, R.; Neopane, H.P.; Zhu, B.; Thapa, B. Effect of Sediment Erosion on Flow around Guide Vanes of Francis turbine. Renew. Energy 2019, 136, 1022–1027. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Theoretical model of energy performance prediction and BEP determination for centrifugal pump as turbine. Energy 2019, 172, 712–732. [Google Scholar] [CrossRef]

- Rajkarnikar, B.; Neopane, H.P.; Thapa, B.S. Development of rotating disc apparatus for test of sediment-induced erosion in Francis runner blades. Wear 2013, 306, 119–125. [Google Scholar] [CrossRef]

- Koirala, R.; Neopane, H.P.; Shrestha, O.; Zhu, B.S.; Thapa, B. Selection of guide vane profile for erosion handling in Francis turbines. Renew. Energy 2017, 112, 328–336. [Google Scholar] [CrossRef]

- Khanal, K.; Neopane, H.P.; Rai, S.; Thapa, M.; Bhatt, S.; Shrestha, R. A methodology for designing Francis runner blade to find minimum sediment erosion using CFD. Renew. Energy 2015, 87, 307–316. [Google Scholar] [CrossRef]

- Martinez, J.J.; Deng, Z.D.; Mueller, R.; Titzler, S. In situ characterization of the biological performance of a Francis turbine retrofitted with a modular guide vane. Appl. Energy 2020, 276, 1165492. [Google Scholar] [CrossRef]

- Rai, A.K.; Kumar, A.; Staubli, T. Analytical modeling and mechanism of hydroabrasive erosion in pelton buckets. Wear 2019, 436–437, 203003. [Google Scholar] [CrossRef]

- Rai, A.K.; Kumar, A.; Staubli, T.; Xiao, Y. Interpretation and application of the hydro-abrasive erosion model from IEC 62364 (2013) for Pelton turbines. Renew. Energy 2020, 160, 396–408. [Google Scholar] [CrossRef]

- Koirala, R.; Chitrakar, S.; Panthee, A.; Neopane, H.P.; Thapa, B. Implementation of Computer Aided Engineering for Francis Turbine Development in Nepal. Int. J. Manuf. Eng. 2015, 2015, 509808. [Google Scholar] [CrossRef] [Green Version]

- Butchers, J.; Cox, J.; Williamson, S.; Booker, J.D. Design for Localisation: A case study in the development and implementation of a low head propeller turbine in Nepal. Dev. Eng. 2020, 5, 100051. [Google Scholar] [CrossRef]

- Li, D.; Wang, H.; Li, Z.; Nielsen, T.K.; Goyal, R.; Wei, X.; Qin, D. Transient characteristics during the closure of guide vanes in a pump-turbine in pump mode. Renew. Energy 2018, 118, 973–983. [Google Scholar] [CrossRef]

- Mao, X.L.; Zheng, Y.; Pavesi, G.; Xie, Z. A new method of dynamic mesh used in continuous guide vane closure of a reversible pump-turbine in generating mode. J. Hydrodyn. 2019, 31, 976–986. [Google Scholar] [CrossRef]

- Varady, T.; Martin, R.R.; Cox, J. Reverse engineering of geometric models—An introduction. Comput.-Aided Des. 1997, 29, 255–268. [Google Scholar] [CrossRef]

- Udupa, S.K.; Debray, S.K.; Madou, M. Deobfuscation: Reverse engineering obfuscated code. In Proceedings of the Working Conference on Reverse Engineering, Pittsburgh, PA, USA, 7–11 November 2005. [Google Scholar]

- Canforaharman, G.; Di Penta, M. New Frontiers of Reverse Engineering. In Proceedings of the Future of Software Engineering, Minneapolis, MN, USA, 23–25 May 2007. [Google Scholar]

- Liu, J.; Lu, E.; Yi, H.; Wang, M. A new surface roughness measurement method based on a color distribution statistical matrix. Measurement 2017, 103, 165–178. [Google Scholar] [CrossRef]

- Chen, S.; Rui, F.; Zhang, C. Surface roughness measurement method based on multi-parameter modeling learning. Measurement 2018, 129, 664–676. [Google Scholar] [CrossRef]

- Bidgoli, M.A.; Golroo, A.; Nadjar, H.S.; Rashidabad, A.G.; Ganji, M.R. Road roughness measurement using a cost-effective sensor-based monitoring system. Autom. Constr. 2019, 104, 140–152. [Google Scholar] [CrossRef]

- Kim, S.Y.; Seo, J.H.; Yoon, Y.J.; Kim, J.S.; Cho, S.; Lee, J.-H.; Kang, I.M. Electrical Characteristics of Enhancement-Mode n-Channel Vertical GaN MOSFETs and the Effects of Sidewall Slope. J. Electr. Eng. Technol. 2015, 10, 1131–1137. [Google Scholar] [CrossRef] [Green Version]

- Clemens, N.T.; Mungal, M.G. Effects of sidewall disturbances on the supersonic mixing layer. J. Propuls. Power 2015, 8, 249–251. [Google Scholar] [CrossRef]

- Wood, R.; Herd, S.; Thakare, M.R. A critical review of the tribocorrosion of cemented and thermal sprayed tungsten carbide. Tribol. Int. 2018, 119, 491–509. [Google Scholar] [CrossRef]

- Mahdipoor, M.S.; Taras, F.; Moreau, C.; Dolatabadi, A.; Medraj, M. HVOF sprayed coatings of nano-agglomerated tungsten-carbide/cobalt powders for water droplet erosion application. Wear 2015, 330–331, 338–347. [Google Scholar] [CrossRef]

- Munday, G.; Hogan, J.; Mcdonald, A. On the microstructure-dependency of mechanical properties and failure of low-pressure cold-sprayed tungsten carbide-nickel metal matrix composite coatings. Surf. Coat. Technol. 2020, 396, 125947. [Google Scholar] [CrossRef]

- Li, X.; Yu, P.; Feng, Y.; Yang, Q.; Li, Y.; Ye, B. Specific adsorption and highly sensitive detection of methyl red in wastewater using an iron paste electrode modified with a molecularly imprinted polymer. Electrochem. Commun. 2021, 132, 107144. [Google Scholar] [CrossRef]

- Manthiram, A.; Goodenough, J.B. Synthesis of the high-Tc superconductor YBa2Cu3O7–δ in small particle size. Nature 1987, 329, 701–703. [Google Scholar] [CrossRef]

- Ishigami, Y.; Takada, K.; Yano, H.; Inukai, J.; Uchida, M.; Nagumo, Y.; Hyakutake, T.; Nishide, H.; Watanabe, M. Corrosion of carbon supports at cathode during hydrogen/air replacement at anode studied by visualization of oxygen partial pressures in a PEFC—Start-up/shut-down simulation. J. Power Sources 2011, 196, 3003–3008. [Google Scholar] [CrossRef]

- China National Standardization Management Committee. GB/T 29403—2012 Technical Guidelines for Sediment Abrasion of Counterattack Turbine; China Standards Press: Beijing, China, 2013.

| Component | Gravel | Sand | Silt | Clay | |||||

|---|---|---|---|---|---|---|---|---|---|

| 20~10 mm | 10~5 mm | 5~2 mm | 2~1 mm | 1~0.5 mm | 0.5~0.25 mm | 0.25~0.075 mm | 0.075~0.005 mm | <0.005 mm | |

| granulometric distribution (%) | 0.00 | 0.00 | 8.51 | 7.62 | 19.29 | 10.42 | 30.93 | 21.19 | 2.04 |

| Work Conditions (MW) | Test1 | Test2 | Test3 | Test4 | Test5 | Average Value (μm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ra (μm) | Rq (μm) | Ra (μm) | Rq (μm) | Ra (μm) | Rq (μm) | Ra (μm) | Rq (μm) | Ra (μm) | Rq (μm) | Ra (μm) | Rq (μm) | |

| 30.9 | 0.164 | 0.204 | 0.209 | 0.256 | 0.151 | 0.185 | 0.174 | 0.226 | 0.194 | 0.231 | 0.178 | 0.220 |

| 42.8 | 0.175 | 0.223 | 0.198 | 0.261 | 0.157 | 0.196 | 0.173 | 0.215 | 0.169 | 0.224 | 0.174 | 0.224 |

| Work Conditions | Before Polishing | After Polishing | ||||

|---|---|---|---|---|---|---|

| Before Test (g) | After Test (g) | Wear Amount (g) | Before Test (g) | After Test (g) | Wear Amount (g) | |

| P = 30.9 MW | 4731.25 | 4711.39 | 19.86 | 4710.84 | 4698.73 | 12.11 |

| P = 42.8 MW | 4734.97 | 4703.34 | 31.63 | 4716.08 | 4695.69 | 20.39 |

| Melting Point | 2870 °C | Micro-Penetration Hardness | 17,300 MPa |

| Boiling point | 6000 °C | Modulus of elasticity | 710 GPa |

| Density | 15.63 | Compressive strength | 56 MPa |

| Poisson ratio | 0.31 | Thermal expansion coefficient | 6.9 × 10−6/K |

| Work Conditions (MW) | Before Test (g) | After Test (g) | Wear Amount (g) |

|---|---|---|---|

| 30.9 | 4744.28 | 4740.74 | 3.54 |

| 42.8 | 4740.01 | 4734.23 | 5.78 |

| Water Temperature (℃) | Working Condition (MW) | Before Polishing (μm) | After Polishing (μm) | Tungsten Carbide Spraying (μm) |

|---|---|---|---|---|

| 25.6 | 30.9 | 46.2 | 28.1 | 6.23 |

| 42.8 | 59.8 | 47.3 | 11.58 | |

| 7.8 | 30.9 | - | 25.2 | - |

| 42.8 | - | 43.9 | - |

| Working Condition (MW) | Wear Depth Up to 8 mm Before Polishing (h) | Wear Depth Up to 8 mm After Polishing (h) | Tungsten Carbide Spraying Wear Finished (h) | Continued Wear of Base Material (h) | |

|---|---|---|---|---|---|

| Before Polishing | After Polishing | ||||

| 30.9 | 16,623.38 | 29,090.91 | 6837.88 | 23,461.26 | 35,928.79 |

| 42.8 | 12,842.81 | 16,842.08 | 3678.76 | 16,521.57 | 20,520.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Peng, Y.; Yang, J.; Ren, M.; Liu, X. Experimental Analysis of the Effect of Wear Factors on Guide Vane of Hydraulic Turbine. Machines 2022, 10, 264. https://doi.org/10.3390/machines10040264

Zhao X, Peng Y, Yang J, Ren M, Liu X. Experimental Analysis of the Effect of Wear Factors on Guide Vane of Hydraulic Turbine. Machines. 2022; 10(4):264. https://doi.org/10.3390/machines10040264

Chicago/Turabian StyleZhao, Xiaoyi, Yuanjie Peng, Junxiang Yang, Minghui Ren, and Xiaobing Liu. 2022. "Experimental Analysis of the Effect of Wear Factors on Guide Vane of Hydraulic Turbine" Machines 10, no. 4: 264. https://doi.org/10.3390/machines10040264

APA StyleZhao, X., Peng, Y., Yang, J., Ren, M., & Liu, X. (2022). Experimental Analysis of the Effect of Wear Factors on Guide Vane of Hydraulic Turbine. Machines, 10(4), 264. https://doi.org/10.3390/machines10040264