Defining the Number of Mobile Robotic Systems Needed for Reconfiguration of Modular Manufacturing Systems via Simulation

Abstract

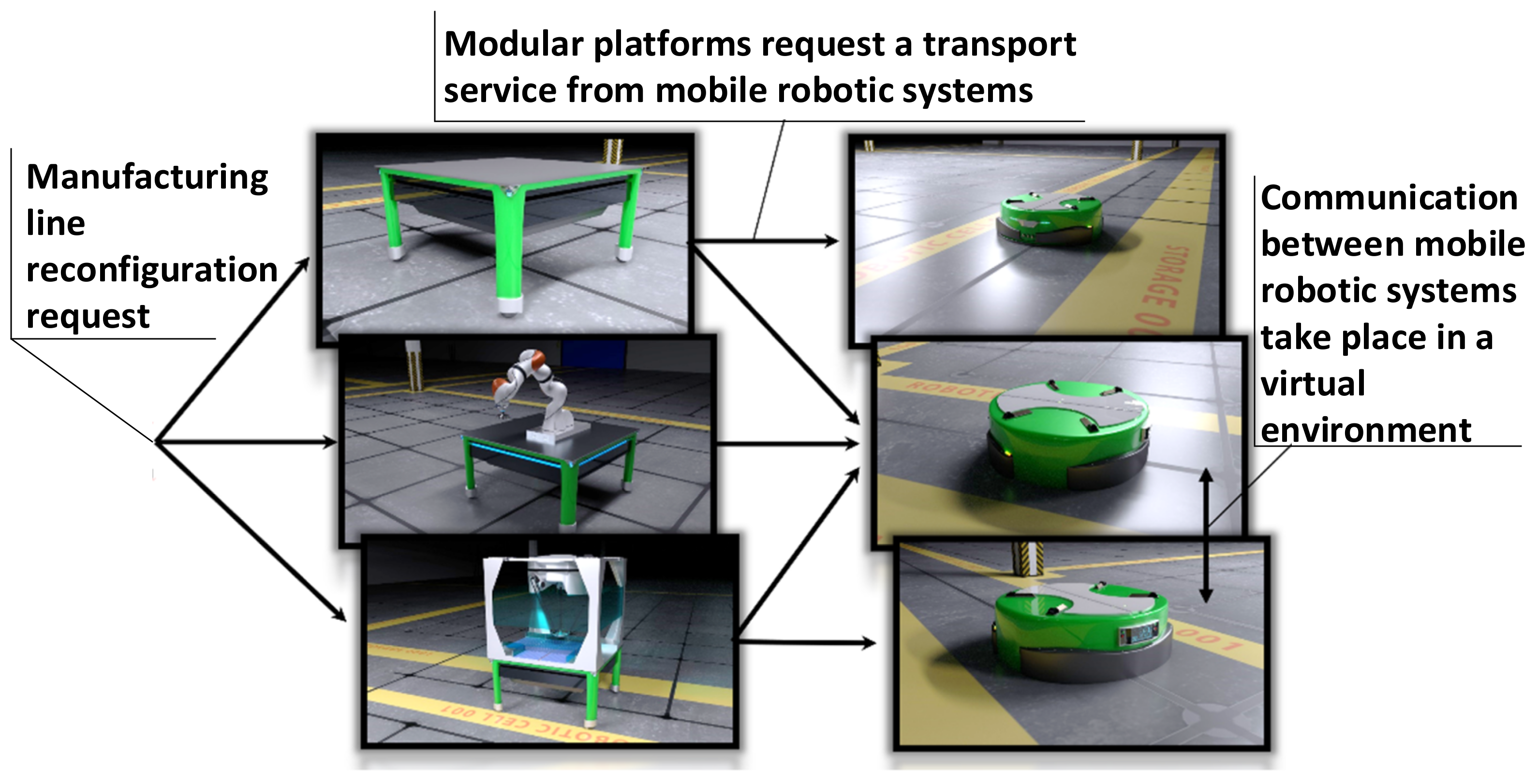

:1. Introduction

2. Materials and Methods

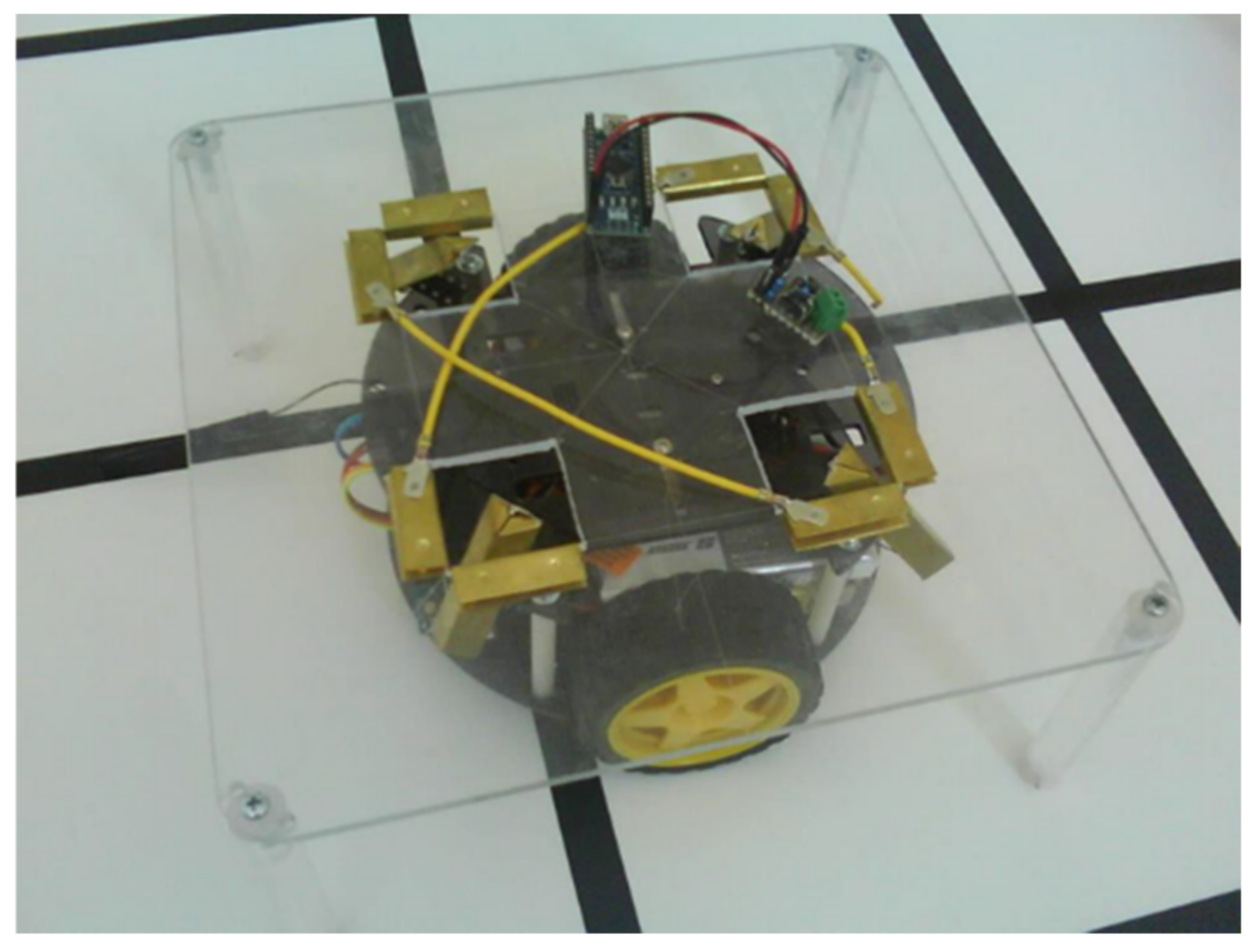

2.1. Mobile Robotics System

2.2. Modular Platform

- hosting of the superstructure—the modular platform must be sufficiently rigid to accommodate the necessary superstructure

- mechanical fixation—the modular platform can firmly connect to other modular platforms and thus create a manufacturing island

- power transmission—connectors that serve as mechanical fixation also transmit electricity, which is then used to power the superstructure

- connectivity with the Mobile Robotic System—the modular platform can connect to the Mobile Robotic System using an appropriate type of connector

- Communication—part of the modular platform is a communication module that is used to communicate with the Mobile Robotic System and control system. The platform must also be able to communicate with its superstructure

Superstructure

- The pallet provides logistical service for an intelligent product (semi-product) and materials for a manufacturing modular line, and it returns to storage after use. If the material resources that are being carried are used up, the pallet requests logistical service from MRS, which then takes it to the storage area. There, it refills and puts the pallet back in its place on the line.

- A modular conveyor—consists of several conveyor belt parts. Each of these can be controlled separately. It provides transport for the intelligent products and materials on the modular line.

- CNC milling machine—offers operations for grinding, drilling, cutting, and machining of intelligent products and materials.

- The Delta robot—helps to sort out and arrange the material.

- A robotic arm—is controlled by inverse kinematics and provides transport of the intelligent product as well as other services based on its defined task: loader loads a product or material on the manufacturing line; a CNC operator provides transport into a machine tool and back to a conveyor; a screwdriver, welder, or assembler; an unloader unloads an intelligent product from a conveyor to a pallet.

2.3. Experimental Time Characteristics Prototypes

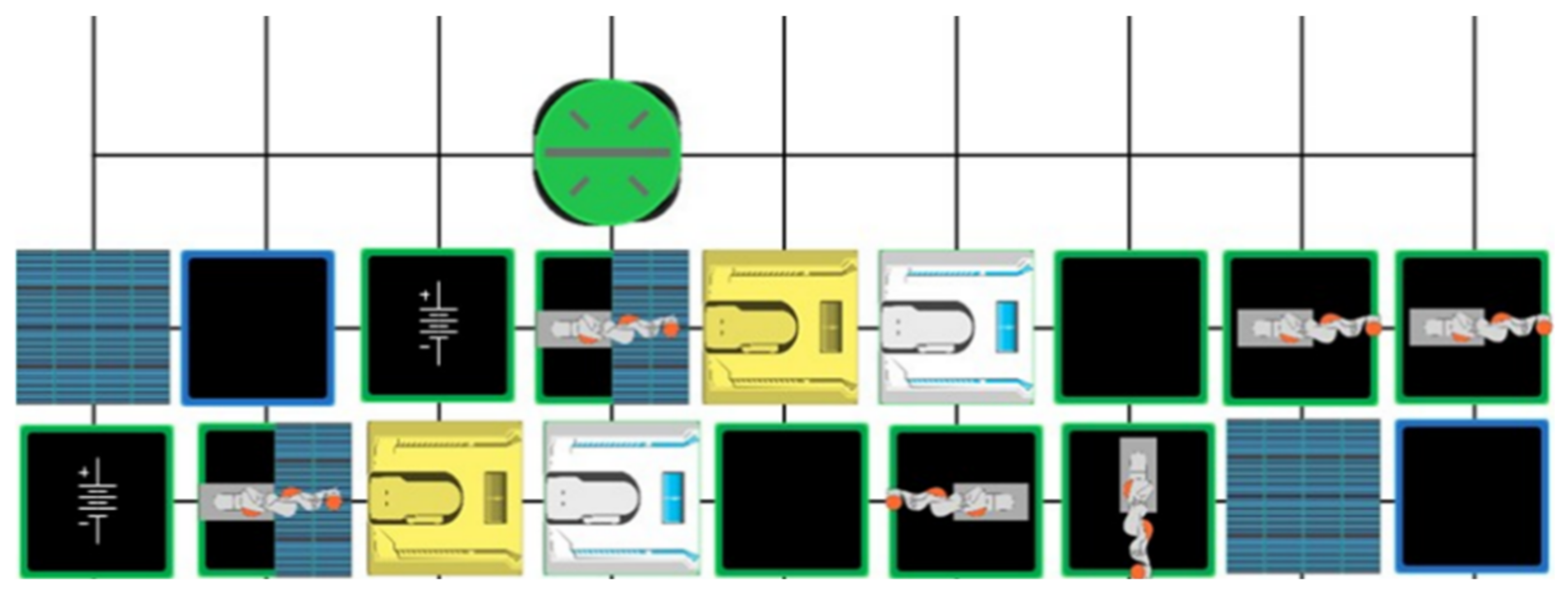

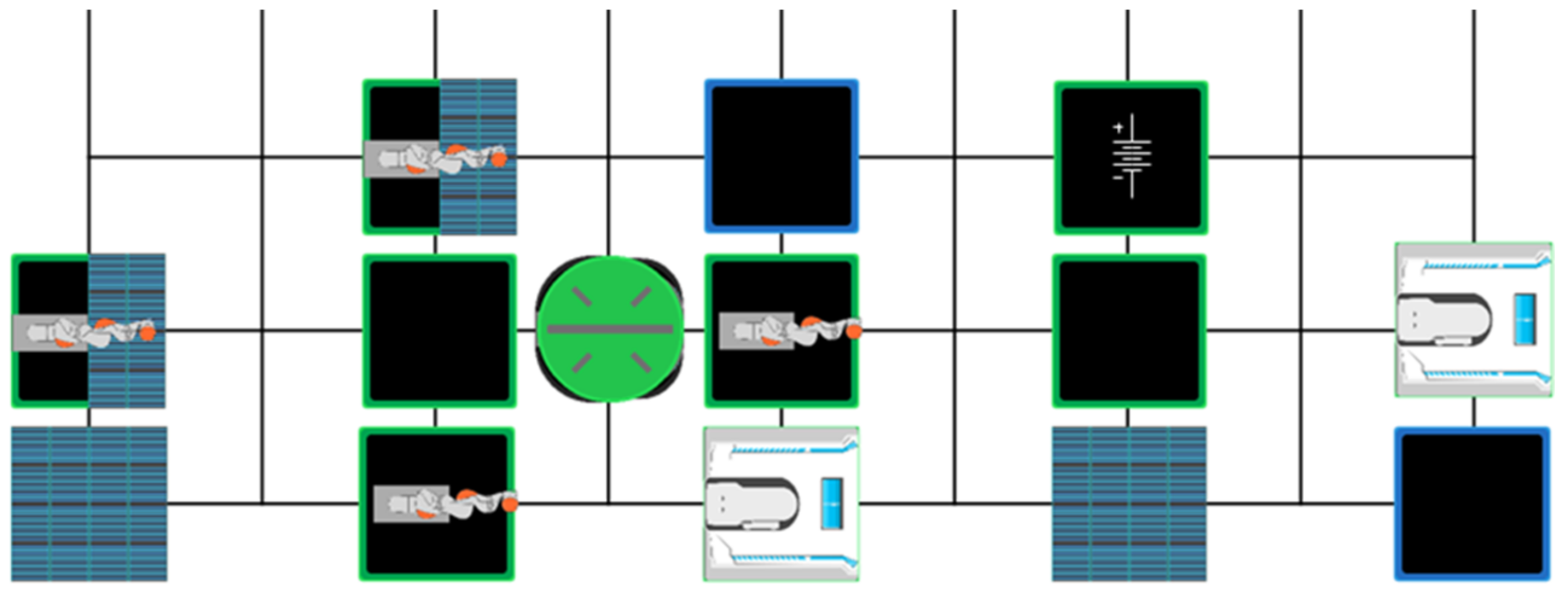

2.4. Description of Manufacturing Systems Interconnection Scheme

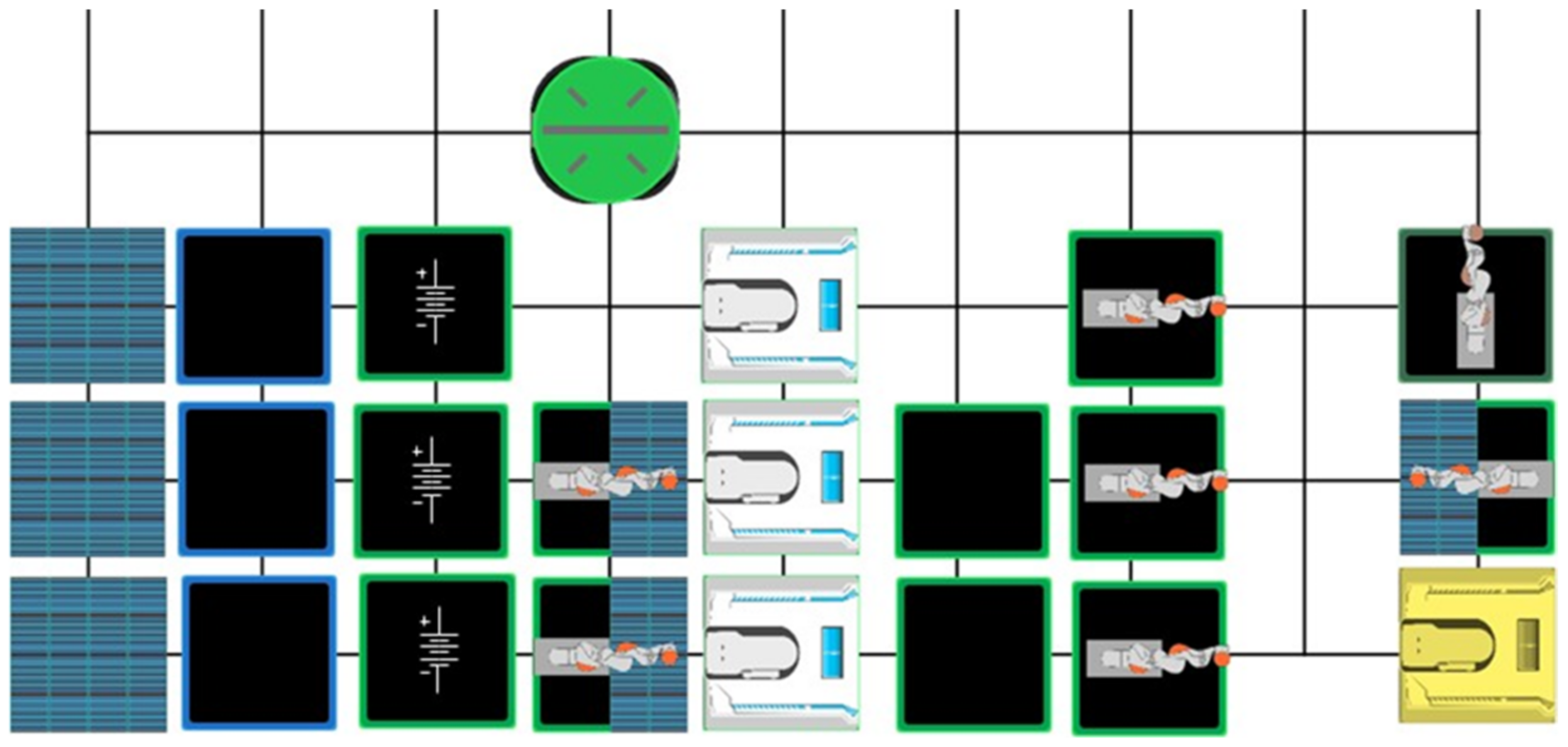

2.4.1. Modular Platform Warehouse Layout

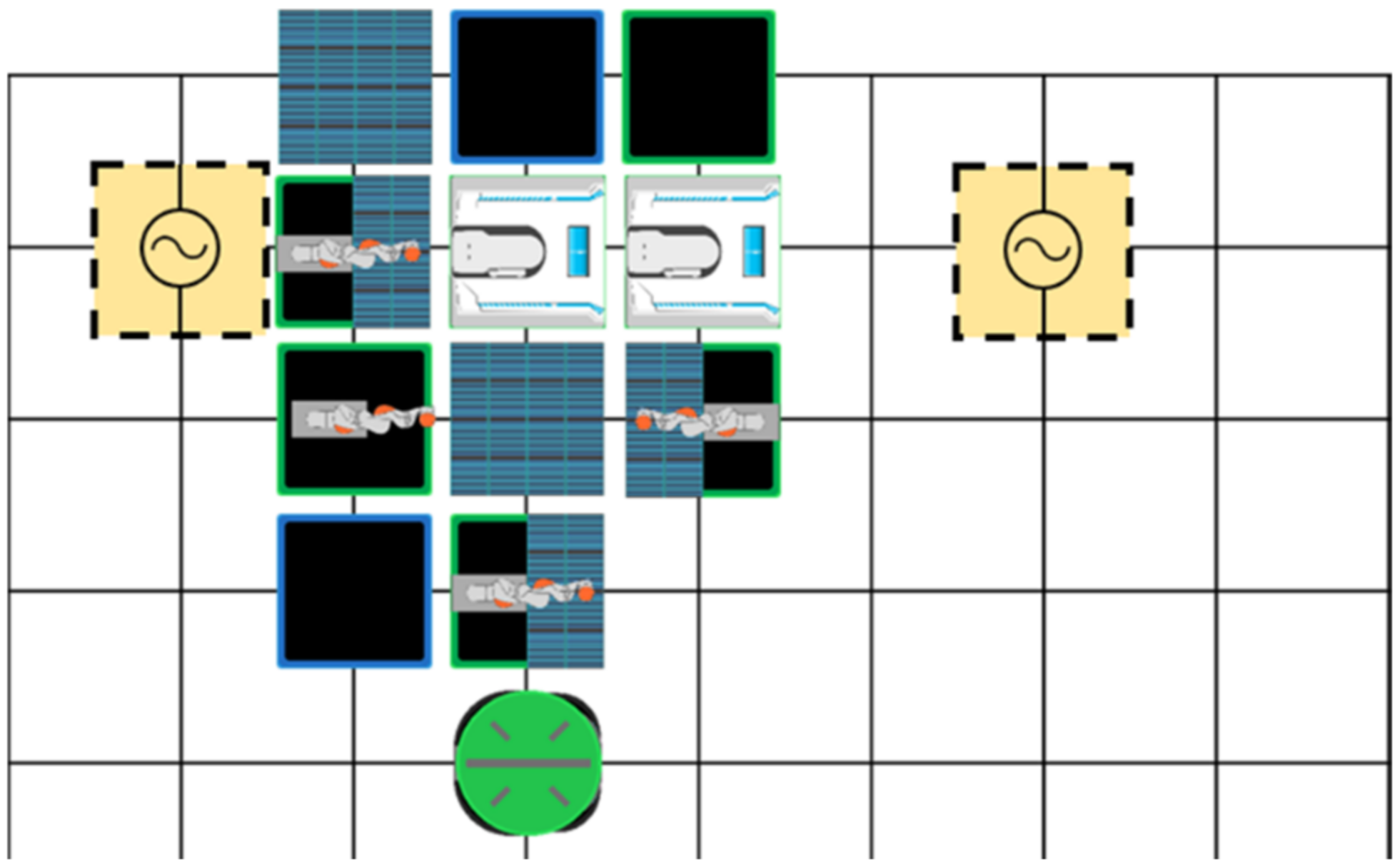

2.4.2. Optimal Manufacturing Island Layout

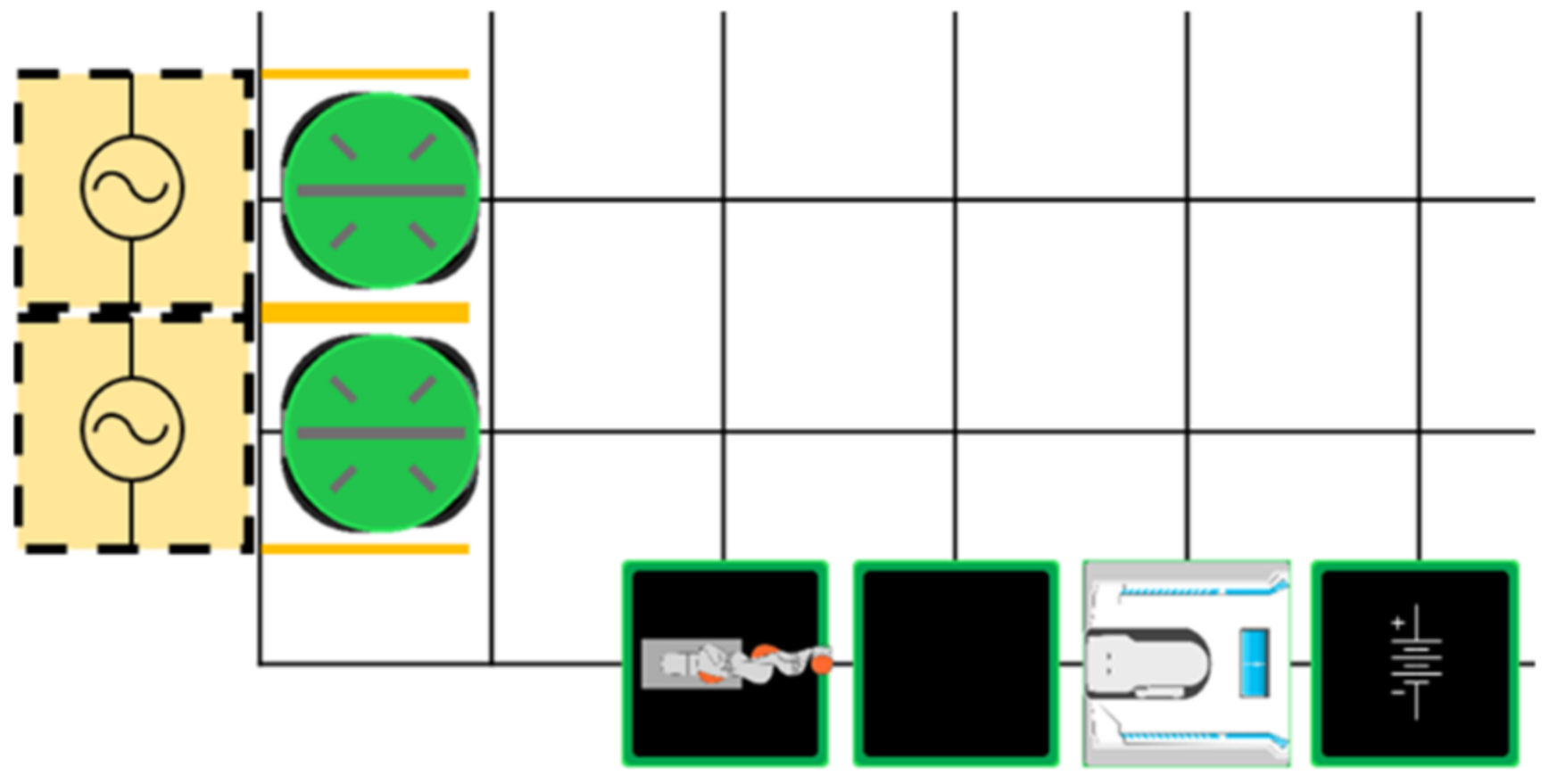

2.4.3. Method of Supplying Power to the Manufacturing Island

2.4.4. Method of Charging Mobile Robotic Systems

3. Results

3.1. Layout of the Modular Platform Warehouse

3.2. Manufacturing Island Distribution

3.3. Power Supply to the Manufacturing Island

3.4. MRS Charging

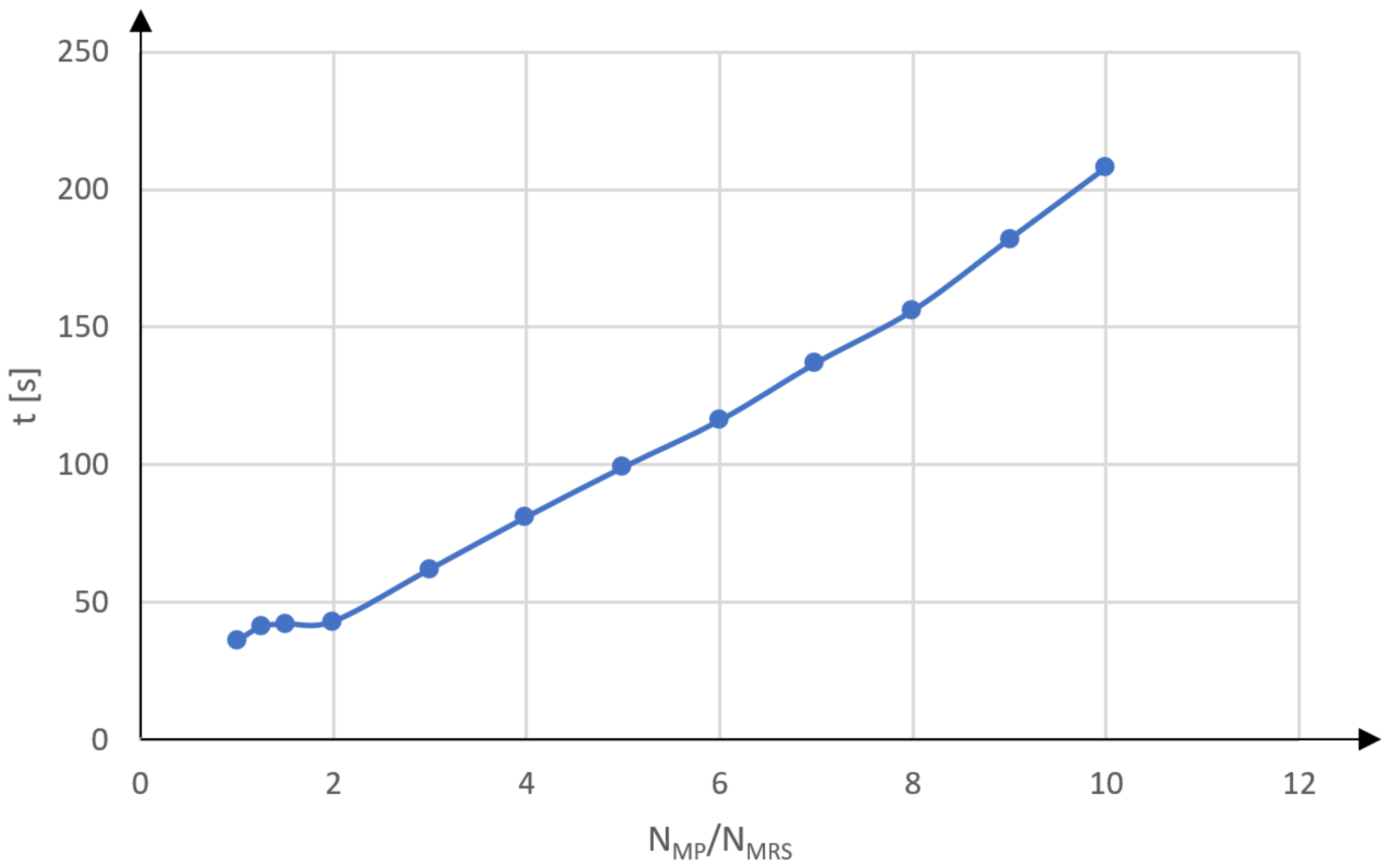

3.5. The Required Number of Mobile Robotic Systems

3.6. The Effect of the Manufacturing Island’s Size on the Time Required to Reconfigure It

4. Discussion and Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gola, A. Design and Management of Manufacturing Systems. Appl. Sci. 2021, 11, 2216. [Google Scholar] [CrossRef]

- Gola, A.; Pastuszak, Z.; Relich, M.; Sobaszek, Ł.; Szwarc, E. Scalability analysis of selected structures of a reconfigurable manufacturing system taking into account a reduction in machine tools reliability. Eksploat. Niezawodn. Maint. Reliab. 2021, 23, 242–252. [Google Scholar] [CrossRef]

- Jumyung, U.M.; Fischer, K.; Spieldenner, T.; Kolberg, D. Development a Modular Factory with Modular Software Components. Proceedia Manuf. 2017, 11, 922–930. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, Z.; Feng, Y.; Yang, J. An integrated method for flexible platform modular architecture design. J. Eng. Des. 2013, 24, 25–44. [Google Scholar] [CrossRef]

- da Silva, E.R.; Schou, C.; Hjorth, S.; Tryggvason, F.; Sørensen, M.S. Plug & Produce robot assistants as shared resources: A simulation approach. J. Manuf. Syst. 2022, 63, 107–117. [Google Scholar] [CrossRef]

- Wally, B.; Vyskocil, J.; Novak, P.; Huemer, C.; Sindelar, R.; Kadera, P.; Mazak, A.; Wimmer, M. Flexible Production Systems: Automated Generation of Operations Plans Based on ISA-95 and PDDL. IEEE Robot. Autom. Lett. 2019, 4, 4062–4069. [Google Scholar] [CrossRef] [Green Version]

- Yim, M.; Shen, W.-M.; Salemi, B.; Rus, D.; Moll, M.; Lipson, H.; Klavins, E.; Chirikjian, G.S. Modular Self-Reconfigurable Robot Systems [Grand Challenges of Robotics]. IEEE Robot. Autom. Mag. 2007, 14, 43–52. [Google Scholar] [CrossRef]

- Chennareddy, S.S.R.; Agrawal, A.; Karuppiah, A. Modular Self-Reconfigurable Robotic Systems: A Survey on Hardware Architectures. J. Robot. 2017, 2017, e5013532. [Google Scholar] [CrossRef]

- Grznár, P.; Gregor, M.; Krajčovič, M.; Mozol, Š.; Schickerle, M.; Vavrík, V.; Ďurica, L.; Marschall, M.; Bielik, T. Modeling and Simulation of Processes in a Factory of the Future. Appl. Sci. 2020, 10, 4503. [Google Scholar] [CrossRef]

- Bhatia, A.P.S.; Han, S.; Moselhi, O. A simulation-based statistical method for planning modular construction manufacturing. J. Inf. Technol. Constr. 2022, 27, 130–144. [Google Scholar] [CrossRef]

- Pekarcikova, M.; Trebuna, P.; Kliment, M.; Trojan, J. Demand Driven Material Requirements Planning. Some Methodical and Practical Comments. Manag. Prod. Eng. Rev. 2019, 10, 50–59. [Google Scholar] [CrossRef]

- Shaik, A.M.; Rao, V.V.S.K.; Rao, C.S. Development of modular manufacturing systems—A review. Int. J. Adv. Manuf. Technol. 2015, 76, 789–802. [Google Scholar] [CrossRef]

- Psarommatis, F.; May, G.; Dreyfus, P.-A.; Kiritsis, D. Zero defect manufacturing: State-of-the-art review, shortcomings and future directions in research. Int. J. Prod. Res. 2020, 58, 1–17. [Google Scholar] [CrossRef]

- Psarommatis, F.; Sousa, J.; Mendonça, J.P.; Kiritsis, D. Zero-defect manufacturing the approach for higher manufacturing sustainability in the era of industry 4.0: A position paper. Int. J. Prod. Res. 2021, 60, 73–91. [Google Scholar] [CrossRef]

- Pekarčíková, M.; Trebuňa, P.; Markovič, J. Case Study of Modelling the Logistics Chain in Manufacturing. Procedia Eng. 2014, 96, 355–361. [Google Scholar] [CrossRef] [Green Version]

- Fusko, M.; Bučková, M.; Gašo, M.; Krajčovič, M.; Dulina, L.; Skokan, R. Concept of Long-Term Sustainable Intralogistics in Plastic Recycling Factory. Sustainability 2019, 11, 6750. [Google Scholar] [CrossRef] [Green Version]

- Krajcovic, M.; Plinta, D. Comprehensive Approach to the Inventory Control System Improvement. Manag. Prod. Eng. Rev. 2012, 3, 34–44. [Google Scholar] [CrossRef]

- Sung, I.; Choi, B.; Nielsen, P. On the training of a neural network for online path planning with offline path planning algorithms. Int. J. Inf. Manag. 2021, 57, 102142. [Google Scholar] [CrossRef]

- Malmborg, C.J. A model for the design of zone control automated guided vehicle systems. Int. J. Prod. Res. 1990, 28, 1741–1758. [Google Scholar] [CrossRef]

- Tsai, Y.-T.; Wang, K.-S. The development of modular-based design in considering technology complexity. Eur. J. Oper. Res. 1999, 119, 692–703. [Google Scholar] [CrossRef]

- Ďurica, L.; Gregor, M.; Vavrík, V.; Marschall, M.; Grznár, P.; Mozol, Š. A Route Planner Using a Delegate Multi-Agent System for a Modular Manufacturing Line: Proof of Concept. Appl. Sci. 2019, 9, 4515. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Wang, T.; Shao, S.; Yao, C.; Wang, Z. GR-LOAM: LiDAR-based sensor fusion SLAM for ground robots on complex terrain. Robot. Auton. Syst. 2021, 140, 103759. [Google Scholar] [CrossRef]

- Voges, R.; Wagner, B. Interval-Based Visual-LiDAR Sensor Fusion. IEEE Robot. Autom. Lett. 2021, 6, 1304–1311. [Google Scholar] [CrossRef]

- Zuo, X.; Geneva, P.; Lee, W.; Liu, Y.; Huang, G. LIC-Fusion: LiDAR-Inertial-Camera Odometry. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 1–8 November 2019; pp. 5848–5854. [Google Scholar] [CrossRef] [Green Version]

- Ďurica, L. Multiagentový Logistický Systém s Implementáciou vo Virtuálnej Realite. Ph.D. Thesis, University of Žilina, Žilina, Slovakia, 2016. [Google Scholar]

- Lam, Y.K.; Wong, E.K.; Loo, C.K. Explicit Communication in Designing Efficient Cooperative Mobile Robotic System. In Proceedings of the IEEE International Conference on Robotics and Automation, Taipei, Taiwan, 14–19 September 2003; pp. 3869–3874. [Google Scholar]

- Lampón, J.F.; Cabanelas, P.; González-Benito, J. The impact of modular platforms on automobile manufacturing networks. Prod. Plan. Control 2017, 28, 335–348. [Google Scholar] [CrossRef]

- Nemec, D.; Gregor, M.; Bubeníková, E.; Hruboš, M.; Pirník, R. Improving the Hybrid A* method for a non-holonomic wheeled robot. Int. J. Adv. Robot. Syst. 2019, 16, 1729881419826857. [Google Scholar] [CrossRef] [Green Version]

- Marschall, M. Logistický Systém pre Rekonfigurovateľné Výrobné Systémy. Ph.D. Thesis, University of Žilina, Žilina, Slovakia, 2019. [Google Scholar]

- Marschall, M.; Mičieta, B.; Ďurica, L. New approach to manufacturing systems in factory of future. In InvEnt 2017: Industrial Engineering—Toward the Smart Industry; Wydawnictwo Akademii Techniczno-Humnistycznej w Bielsku-Białej: Bielsko-Biała, Poland, 2017; pp. 84–87. ISBN 978-83-947909-0-5. [Google Scholar]

- Bozer, Y.A. Guided Vehicle Systems: Information/Control System Implications of Alternative Design and Operation Strategies. In Advanced Information Technologies for Industrial Material Flow Systems; Nof, S.Y., Moodie, C.L., Eds.; NATO ASI Series; Springer: Berlin/Heidelberg, Germany, 1989; pp. 417–433. [Google Scholar] [CrossRef]

- Gkournelos, C.; Kousi, N.; Bavelos, A.C.; Aivaliotis, S.; Giannoulis, C.; Michalos, G.; Makris, S. Model based reconfiguration of flexible production systems. Procedia CIRP 2019, 86, 80–85. [Google Scholar] [CrossRef]

- Bauernhansl, T.; Hompel, M.; Vogel-Heuser, B. Industrie 4.0 in Produktion, Automatisierung und Logistik: Anwendung Technologien Migration; Springer International Publishing AG: Cham, Switzerland, 2014; 639p. [Google Scholar] [CrossRef]

| No Modular Platform [s] | With Modular Platform [s] | |

|---|---|---|

| Start-up of MRS from static position | 3 | 3.12 |

| Uniform movement of MRS | 2.8 | 2.8 |

| Slowing down and stopping MRS at a crossroads | 3.1 | 3.18 |

| MRS rotation by 90° | 1.4 | 1.42 |

| MRS rotation by 180° | 2.78 | 2.81 |

| Symbol | Interpretation | Symbol | Interpretation |

|---|---|---|---|

| A mobile robotic system |  | Conveyor-equipped modular platform |

| modular platform—with pallet |  | modular platform—with battery |

| modular platform—empty |  | modular platform—with traction line |

| modular platform with robotic arm superstructure—type 1 |  | CNC—type 1 |

| modular platform with robotic arm superstructure—type 2 |  | CNC—type 2 |

| modular platform with robotic arm superstructure—type 3 |  | CNC—type 3 |

| modular platform -with superstructure combination of robotic arm with conveyor |  | fixed obstacle in the space with the possibility of connecting the platforms to the power supply |

| How to Distribute a Platform Warehouse | Space Requirements | Number of Platforms | Impact of Reconfiguration Time |

|---|---|---|---|

| SRRDMP | High | Any | Moderate |

| MRRLMP | Low | Any | Tall |

| MRRLMPWAC | Medium | Any | Low |

| MRPLPT | Low–Medium | Medium | Low |

| CMPLS | Low | Medium–High | Low |

| Direct Access to Platforms | Space Requirements | Complexity of the Manufacturing Island | Service Time |

|---|---|---|---|

| Yes | Medium–High | Low–Medium | Low |

| Not | Low | Medium–High | Medium–High |

| Power Method | Input Costs | Maintenance Costs | Constraints |

|---|---|---|---|

| Battery | High | High | Slightly |

| Traction line | Medium | Low | Minimally |

| Power stations | Low | Low | High |

| Charging Method | Space Requirements | Costs | Number of MRS Charges |

|---|---|---|---|

| Charging stations | Higher | Low | Limited by number of stations |

| Modular platforms | Minimal | Higher | Limited by the number of modular platforms |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marschall, M.; Gregor, M.; Ďurica, L.; Vavrík, V.; Bielik, T.; Grznár, P.; Mozol, Š. Defining the Number of Mobile Robotic Systems Needed for Reconfiguration of Modular Manufacturing Systems via Simulation. Machines 2022, 10, 316. https://doi.org/10.3390/machines10050316

Marschall M, Gregor M, Ďurica L, Vavrík V, Bielik T, Grznár P, Mozol Š. Defining the Number of Mobile Robotic Systems Needed for Reconfiguration of Modular Manufacturing Systems via Simulation. Machines. 2022; 10(5):316. https://doi.org/10.3390/machines10050316

Chicago/Turabian StyleMarschall, Martin, Milan Gregor, Lukáš Ďurica, Vladimír Vavrík, Tomáš Bielik, Patrik Grznár, and Štefan Mozol. 2022. "Defining the Number of Mobile Robotic Systems Needed for Reconfiguration of Modular Manufacturing Systems via Simulation" Machines 10, no. 5: 316. https://doi.org/10.3390/machines10050316

APA StyleMarschall, M., Gregor, M., Ďurica, L., Vavrík, V., Bielik, T., Grznár, P., & Mozol, Š. (2022). Defining the Number of Mobile Robotic Systems Needed for Reconfiguration of Modular Manufacturing Systems via Simulation. Machines, 10(5), 316. https://doi.org/10.3390/machines10050316