Review on Motion and Load-Bearing Characteristics of the Planetary Roller Screw Mechanism

Abstract

:1. Introduction

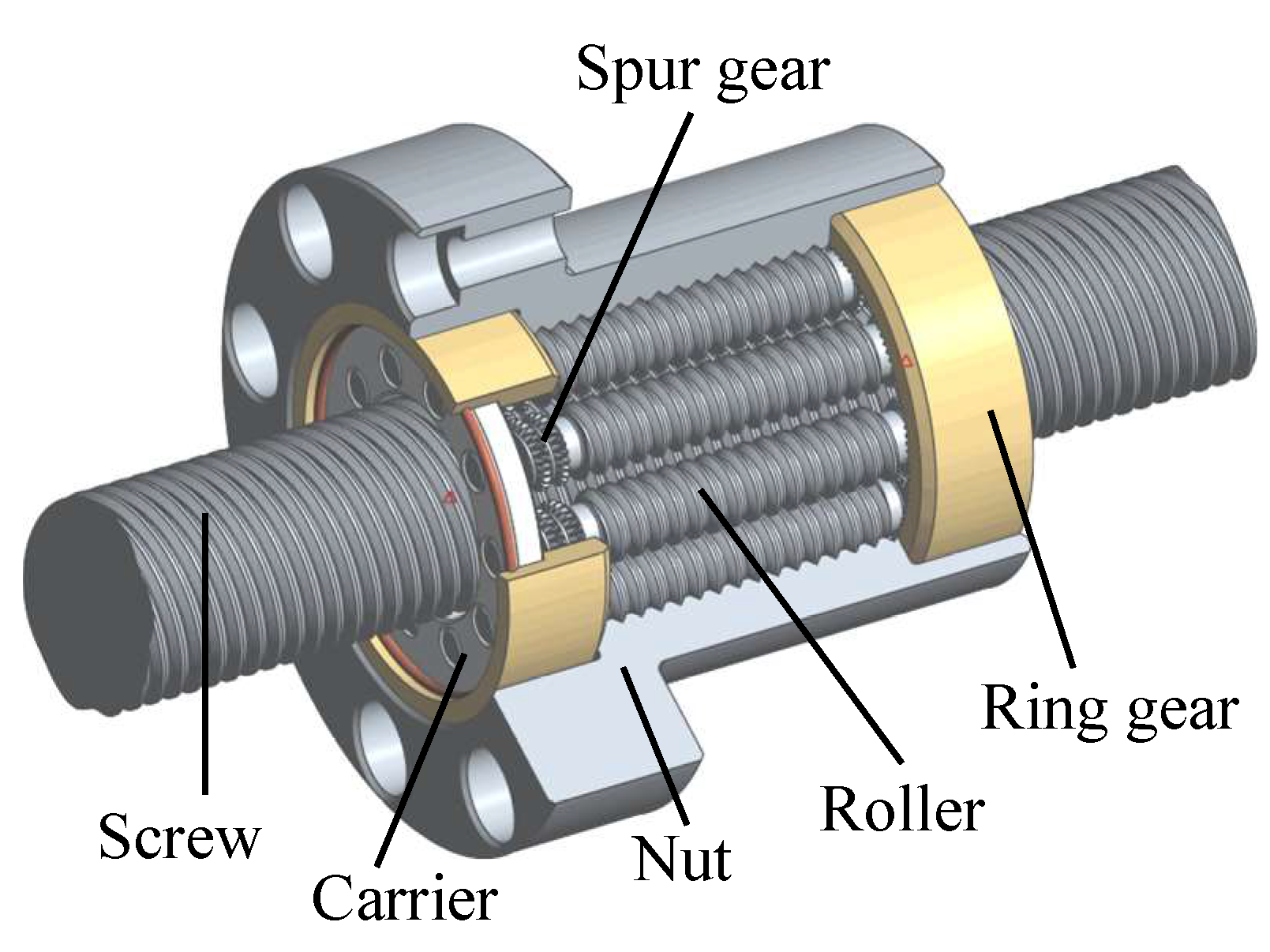

2. Mechanical Structure

2.1. Standard Planetary Roller Screw Mechanism (Standard PRSM)

2.2. Inverted Planetary Roller Screw Mechanism (Inverted PRSM)

2.3. Multi-Stage Planetary Roller Screw Mechanism (Multi-Stage PRSM)

3. Published Models

3.1. Kinematic Models

3.2. Load-Bearing Models

3.3. Dynamic Models

4. Conclusions

- 1.

- Under the influence of errors, the meshing and motion states of each element of the PRSM need to be calculated, and the dynamic interactions of the meshing, movement and deformation of the elements need to be explored as well. In the multi-stage PRSM, the position and movement of one stage of the screw and nut will affect those of the next stage of the screw and nut, which is likely to cause complex motion coupling under the effect of errors.

- 2.

- The load sharing among rollers should be considered in the load-bearing models. The influence of the bending and torsional stiffness of the screw on the load-bearing characteristics of the PRSM needs to be investigated. For the multi-stage PRSM, the bending and torsion deformation of the screws need to be taken into account in strength check, instability analysis and transmission accuracy calculation due to the uneven load distribution caused by errors.

- 3.

- The influence of manufacturing and assembly errors on the motion, force and deformation of the PRSM needs to be comprehensively analysed. A dynamic analysis of the PRSM considering errors and elastic deformation is very important to reveal the dynamic bearing characteristics of the mechanism and to design a high-speed and high-dynamic PRSM-based EMA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mare, J.C.; Fu, J. Review on signal-by-wire and power-by-wire actuation for more electric aircraft. Chin. J. Aeronaut. 2017, 30, 857–870. [Google Scholar] [CrossRef]

- Gruszecki, J.; Grzybowski, J.; Rzucidło, P. Electro-mechanical actuators for general aviation fly-by-wire aircraft. Aviation 2005, 9, 19–25. [Google Scholar] [CrossRef]

- Vander, F.L.; Schlegel, C.; Christmann, M.; Regula, G.; Hill, C.; Giangrande, P.; Maré, J.; Egaña, I. Implementation of a modelica library for simulation of electromechanical actuators for aircraft and helicopters. In Proceedings of the 10th International Modelica Conference, Lund, Sweden, 10 March 2014. [Google Scholar] [CrossRef] [Green Version]

- Albright, J.; Moore, D. Development and implementation of electromechanical actuators for the X-38 atmospheric test vehicles. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference and Exhibit, Honolulu, HI, USA, 18–21 March 2008. [Google Scholar] [CrossRef]

- Cleayssen, F.; Janker, P.; Leletty, R.; Sosniki, O. New actuators for aircraft, space and military applications. In Proceedings of the 12th International Conference on New Actuator, Bremen, Germany, 14–16 June 2010. [Google Scholar]

- Kawamoto, Y.; Suda, Y.; Inoue, H.; Kondo, T. Electro-mechanical suspension system considering energy consumption and vehicle manoeuvre. Veh. Syst. Dyn. 2008, 46, 1053–1063. [Google Scholar] [CrossRef]

- Vanthuyne, T. An electrical thrust vector control system for the VEGA launcher. In Proceedings of the 13th European Space Mechanisms and Tribology Symposium, Vienna, Austria, 23–25 September 2009. [Google Scholar]

- Lemor, P.C. The roller screw: An efficient and reliable mechanical component of electro-mechanical actuators. In Proceedings of the 31st Intersociety Energy Conversion Engineering Conference, Washington, DC, USA, 11–16 August 1996. [Google Scholar] [CrossRef]

- Pochettini, P.; Ballesio, M.; Gallieni, D.; Gill, S. Hexapod/Sage III roller screws lifetime and lubrication tests. Eur. Space Agency-Publ. 1999, 438, 49–56. [Google Scholar]

- Budinger, M.; Reysset, A.; Halabi, T.; Vasiliu, C.; Maré, J. Optimal preliminary design of electro -mechanical actuators. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2014, 228, 1598–1616. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Ma, S.J.; Tong, R.T.; Guan, D. New development and key technology of planetary roller screw. J. Mech. Transm. 2012, 36, 103–108. [Google Scholar]

- Csonka, G.; Waldron, K.J. Characterization of an electric-pneumatic hybrid prismatic actuator. J. Mech. Robot. 2010, 2, 021008. [Google Scholar] [CrossRef]

- Munn, P. A roller screw with special qualities. In Proceedings of the 22nd International Machine Tool Design and Research Conference, London, UK, 1 April 1982. [Google Scholar] [CrossRef]

- Sokolov, P.A.; Blinov, D.S.; Ryakhovskii, O.A.; Ochkasov, E.E. Promising rotation–translation converters. Russ. Eng. Res. 2008, 28, 949–956. [Google Scholar] [CrossRef]

- Arriola, D.; Thielecke, F. Model-based design and experimental verification of a monitoring concept for an active-active electromechanical aileron actuation. Mech. Syst. Signal. Process. 2017, 94, 322–345. [Google Scholar] [CrossRef]

- Ohashi, Y.; Andrade, A.D.; Muller, J.; Nose, Y. Control System modification of an electromechanical pulsatile total artifical heart. Artif. Organs 1997, 21, 1308–1311. [Google Scholar] [CrossRef]

- Sasaki, Y.; Chikazawa, G.; Nogawa, M.; Nishida, H.; Koyanagi, H.; Takatani, S. Evaluation of a roller screw linear muscle actuator for an implantable ventricular assist device using trained and untrained latissimus dorsi muscles. Artif. Organs 1999, 23, 262–267. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.H.; Velinsky, S.A. Contact kinematics in the roller screw mechanism. J. Mech. Des. 2012, 135, 451–459. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Ma, S.J.; Tong, R.T.; Lim, T.C. A comprehensive contact analysis of planetary roller screw mechanism. J. Mech. Des. 2017, 139, 98. [Google Scholar] [CrossRef]

- Sandu, S.; Biboulet, N.; Nelias, D.; Abevi, F. An efficient method for analyzing the roller screw thread geometry. Mech. Mach. Theory 2018, 126, 243–264. [Google Scholar] [CrossRef]

- Abevi, F.; Daidie, A.; Chaussumier, M.; Sartor, M. Static load distribution and axial stiffness in a planetary roller screw mechanism. J. Mech. Des. 2016, 138, 012301-1–012301-11. [Google Scholar] [CrossRef]

- Zhang, W.J.; Liu, G.; Tong, R.T.; Ma, S.J. Load distribution of planetary roller screw mechanism and its improvement approach. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2015, 230, 3304–3318. [Google Scholar] [CrossRef]

- Jones, M.H.; Velinsky, S.A. Kinematics of roller migration in the planetary roller screw mechanism. J. Mech. Des. 2012, 134, 061006-1–061006-6. [Google Scholar] [CrossRef]

- Auregan, G.; Fridrici, V.; Kapsa, P.; Rodrigues, F. Experimental simulation of rolling-sliding contact for application to planetary roller screw mechanism. Wear 2015, 332–333, 1176–1184. [Google Scholar] [CrossRef]

- Xie, Z.J.; Xue, Q.H.; Wu, J.Q.; Gu, L.; Wang, L.Q.; Song, B.Y. Mixed-lubrication analysis of planetary roller screw. Tribol. Int. 2019, 140, 105883. [Google Scholar] [CrossRef]

- Zhang, D.W.; Zhao, S.D.; Wu, S.B.; Zhang, Q.; Fan, S.Q.; Li, J.X. Phase characteristic between dies before rolling for thread and spline synchronous rolling process. Int. J. Adv. Manuf. Technol. 2015, 81, 513–528. [Google Scholar] [CrossRef]

- Qiao, G.; Liu, G.; Ma, S.J.; Wang, Y.W.; Li, P.; Lim, T.C. Thermal characteristics analysis and experimental study of the planetary roller screw mechanism. Appl. Therm. Eng. 2019, 149, 1345–1358. [Google Scholar] [CrossRef]

- Jin, Q.Z.; Yang, J.; Sun, J.L. Motion characteristics and parameter selection of the planetary roller screw mechanism. Manuf. Technol. Mach. Tool 1998, 1998, 13–15. [Google Scholar]

- Chen, M.L. Transmission performance of the differential screw mechanism. J. Mech. Transm. 2008, 2008, 98–100. [Google Scholar]

- Dang, J.L.; Liu, G.; Ma, S.J.; Tong, R.T.; Luo, H. Motion principle and simulation analysis of inverted planetary roller screw mechanism. J. Syst. Simul. 2013, 25, 1646–1651. [Google Scholar]

- Hojjat, Y.; Agheli, M. A comprehensive study on capabilities and limitations of roller screw with emphasis on slip tendency. Mech. Mach. Theory. 2009, 44, 1887–1899. [Google Scholar] [CrossRef]

- Velinsky, S.A.; Chu, B.; Lasky, T.A. Kinematics and efficiency analysis of the planetary roller screw mechanism. J. Mech. Des. 2009, 131, 011016-1–011016-8. [Google Scholar] [CrossRef]

- Ma, S.J.; Liu, G.; Tong, R.T.; Zhang, W.J. Kinematic analysis of an inverted planetary roller screw considering roller pitch circle mismatch. China Mech. Eng. 2014, 25, 1421–1426. [Google Scholar] [CrossRef]

- Ma, S.J.; Zhang, T.; Liu, G.; Tong, R.T.; Fu, X.J. Kinematics of planetary roller screw mechanism considering helical directions of screw and roller threads. Math. Probl. Eng. 2015, 2015, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.Q.; Wang, J.S.; Cheng, H.X.; Sun, Y.P. Kinematics analysis of the roller screw based on the accuracy of meshing point calculation. Math. Probl. Eng. 2015, 2015, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Fu, X.J.; Liu, G.; Ma, S.J.; Tong, R.T.; Lim, T.C. Kinematic model of planetary roller screw mechanism with run-out and position errors. J. Mech. Des. 2018, 140, 032301-1–032301-10. [Google Scholar] [CrossRef]

- Sandu, S.; Biboulet, N.; Nelias, D.; Abevi, F. Analytical prediction of the geometry of contact ellipses and kinematics in a roller screw versus experimental results. Mech. Mach. Theory 2019, 131, 115–136. [Google Scholar] [CrossRef]

- Ma, S.J.; Liu, G.; Tong, R.T.; Zhang, X.C. Finite element analysis of axial elastic deformation for planetary roller screw. J. Mech. Transm. 2012, 36, 78–81. [Google Scholar]

- Ryś, J.; Lisowski, F. The computational model of the load distribution between elements in planetary roller screw. J. Theor. Appl. Mech. 2014, 52, 699–705. [Google Scholar]

- Sun, J.L.; Jin, Q.Z. A study of static stiffness of planetary roller screw. J. Hubei Inst. Technol. 1993, 8, 24–29. [Google Scholar]

- Lisowski, F. The analysis of displacements and the load distribution between elements in a planetary roller screw. Appl. Mech. Mater. 2014, 680, 326–329. [Google Scholar] [CrossRef]

- Lisowski, F. The specific dynamic capacity of a planetary roller screw with random deviations of a thread pitch. J. Theor. Appl. Mech. 2017, 55, 991–1001. [Google Scholar] [CrossRef] [Green Version]

- Lisowski, F. Optimization of thread root undercut in the planetary roller screw. Tech. Trans. 2017, 9, 219–227. [Google Scholar] [CrossRef]

- Abevi, F.; Daidie, A.; Chaussumier, M.; Orieux, S. Static analysis of an inverted planetary roller screw mechanism. J. Mech. Robot. 2016, 8, 041020-1–041020-14. [Google Scholar] [CrossRef]

- Liu, S.M.; Liu, G.; Ma, S.J.; Tong, R.T.; Zhang, W.J. Research of the load distribution of planetary roller screw mechanism under different working temperatures. J. Mech. Transm. 2016, 40, 14–19. [Google Scholar]

- Zu, L.; Zhang, Z.; Gao, L. Design and bearing characteristics of planetary roller screws based on aerospace high-load conditions. Adv. Mech. Eng. 2018, 10, 1–11. [Google Scholar] [CrossRef]

- Yang, J.J.; Wei, Z.X.; Zhu, J.S.; Du, W. Calculation of load distribution of planetary roller screws and static rigidity. J. Huazhong Univ. of Sci. Tech. 2011, 39, 1–4. [Google Scholar]

- Jones, M.H.; Velinsky, S.A. Stiffness of the roller screw mechanism by the direct method. Mech. Based Des. Struct. Mach. 2014, 42, 17–34. [Google Scholar] [CrossRef]

- Ma, S.J.; Liu, G.; Fu, X.J.; Zhang, W.J. Load distribution of rollers considering errors in planetary roller screw mechanism. J. Harbin Inst. Technol. 2015, 47, 98–102. [Google Scholar] [CrossRef]

- Ma, S.J.; Liu, X.F.; Liu, G.; Peng, C.; Guo, H. Load distribution of planetary roller screw mechanism with error, thread wear and temperature change. J. Northwestern Polytech. Univ. 2017, 35, 655–660. [Google Scholar]

- Zhang, W.J.; Liu, G.; Ma, S.J.; Tong, R.T. Load distribution of planetary roller screw mechanism with different installations. J. Northwestern Polytech. Univ. 2015, 33, 229–236. [Google Scholar] [CrossRef]

- Zhang, W.J.; Liu, G.; Tong, R.T.; Ma, S.J. Thread load balance design method of planetary roller screw mechanism. J. Northwestern Polytech. Univ. 2016, 34, 499–507. [Google Scholar] [CrossRef]

- Guo, J.N.; Peng, H.; Huang, H.Y.; Liu, Z.S. Analytical and experimental of planetary roller screw axial stiffness. In Proceedings of the IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Kagawa, Japan, 6–9 August 2017. [Google Scholar]

- Zhang, W.J.; Liu, G.; Ma, S.J.; Tong, R.T. Load distribution over threads of planetary roller screw mechanism with pitch deviation. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2018, 233, 4653–4666. [Google Scholar] [CrossRef]

- Du, X.; Chen, B.K.; Zheng, Z.D. Investigation on mechanical behavior of planetary roller screw mechanism with the effects of external loads and machining errors. Tribol. Int. 2021, 154, 3304–3318. [Google Scholar] [CrossRef]

- Yao, Q.; Zhang, M.C.; Liu, Y.S.; Ma, S.J. Multi-objective optimization of planetary roller screw mechanism based on improved mathematical modeling. Tribol. Int. 2021, 161, 98. [Google Scholar] [CrossRef]

- Liu, R.R.; Cheng, Y.H.; Du, X.; Cheng, B.K. Meshing and bearing characteristics of convex-concave contact planetary roller screw mechanism. J. Harbin Inst. Technol. 2022, 54, 49–57. [Google Scholar] [CrossRef]

- Jones, M.H.; Velinsky, S.A.; Lasky, T.A. Dynamics of the planetary roller screw mechanism. J. Mech. Robot. 2016, 8, 014503-1–014503-6. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Tong, R.T.; Ma, S.J.; Lim, T.C. A nonlinear six degrees of freedom dynamic model of planetary roller screw mechanism. Mech. Mach. Theory 2018, 119, 22–36. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Ma, S.J.; Tong, R.T.; Li, X. An efficient method for the dynamic analysis of planetary roller screw mechanism. Mech. Mach. Theory. 2020, 150, 22–36. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Li, X.; Ma, S.J.; Qiao, G. Dynamic modeling of the double-nut planetary roller screw mechanism considering elastic deformations. J. Comput. Nonlinear Dynam. 2021, 16, 103851. [Google Scholar] [CrossRef]

- Ma, S.J.; Liu, G.; Zhou, J.X.; Tong, R.T. Dynamic characteristic analysis of a planetary roller screw in operating process. J. Vib. Shock. 2013, 32, 167–171. [Google Scholar]

- He, J.P.; Liu, G.; Ma, S.J.; Tong, R.T. Bond graph based dynamic characteristic modeling and simulation of planetary roller screw mechanism. J. Vib. Shock. 2015, 34, 66–73. [Google Scholar]

- Ma, S.J.; Zhang, T.; Liu, G.; He, J.P. Bond graph-based dynamic model of planetary roller screw mechanism with consideration of axial clearance and friction. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2018, 232, 2899–2911. [Google Scholar] [CrossRef]

- Wu, L.P.; Ma, S.J.; Wan, Q.; Liu, G. Dynamic model of planetary roller screw mechanism with considering torsional degree of freedom. In Proceedings of the 6th International Conference on Mechatronics and Mechanical Engineering (ICMME 2019), Wuhan, China, 9–11 November 2019. [Google Scholar] [CrossRef] [Green Version]

- Yue, L.L.; Wang, W.Y.; Hu, B.G. Dynamic characteristic analysis based on finite element simulation for planetary roller screw. Mech. Eng. Autom. 2014, 2, 16–18. [Google Scholar]

- Guo, J.N.; Peng, H.; Huang, H.Y.; Liu, Z.S. Theoretical investigation and experimental study on planetary roller screw dynamics. J. Propuls. Technol. 2018, 39, 1814–1848. [Google Scholar]

- Li, X.; Liu, G.; Song, C.Y.; Fu, X.J.; Ma, S.J.; Wan, Q. Rigid-body dynamic analysis of multi-stage planetary roller screw mechanism. J. Northwestern Polytech. Univ. 2020, 38, 1001–1009. [Google Scholar] [CrossRef]

- Li, X.; Liu, G.; Fu, X.J.; Ma, S.J. Lagrange-method-based dynamic analysis of multi-stage planetary roller screw mechanism. Mech. Sci. 2021, 12, 471–478. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liu, G.; Fu, X.; Ma, S. Review on Motion and Load-Bearing Characteristics of the Planetary Roller Screw Mechanism. Machines 2022, 10, 317. https://doi.org/10.3390/machines10050317

Li X, Liu G, Fu X, Ma S. Review on Motion and Load-Bearing Characteristics of the Planetary Roller Screw Mechanism. Machines. 2022; 10(5):317. https://doi.org/10.3390/machines10050317

Chicago/Turabian StyleLi, Xin, Geng Liu, Xiaojun Fu, and Shangjun Ma. 2022. "Review on Motion and Load-Bearing Characteristics of the Planetary Roller Screw Mechanism" Machines 10, no. 5: 317. https://doi.org/10.3390/machines10050317

APA StyleLi, X., Liu, G., Fu, X., & Ma, S. (2022). Review on Motion and Load-Bearing Characteristics of the Planetary Roller Screw Mechanism. Machines, 10(5), 317. https://doi.org/10.3390/machines10050317