Abstract

With the continuous expansion of system scale, the parameter coupling of the system is prominent. Due to limitations in knowledge and experience, it is difficult for designers to objectively analyze the interaction relationship between parameters, resulting in the low accuracy of engineering parameter selection, hence affecting conflict solving. In order to improve the accuracy of engineering parameter selection and the efficiency of conflict solving, this paper proposes a conflict solving process based on mapping between physical parameters and engineering parameters. First, the physical parameters related to the components of the system function model are extracted, and dimensional analysis is used to construct a physical parameter logical network. Secondly, the physical parameter change path related to the problem in the physical parameter logical network is found, and the physical parameter sets corresponding to both conflicting parties are obtained. Then, the engineering parameters corresponding to conflicts can be selected through the mapping model between physical parameters and engineering parameters, which is trained by a neural network with the sample data of physical parameter sets and engineering parameters in existing cases. Finally, Theory of Inventive Problem Solving (TRIZ) tools are used to solve conflicts, and the final design scheme is obtained through evaluation. The feasibility and effectiveness of the proposed method are verified by redesigning a bulk traditional Chinese medicine dispenser.

1. Introduction

With continuous change in market demand, the complex features of systems, such as nonlinearity and coupling are prominent [1], which has an impact on solving conflict. In addition, limitations in knowledge and experience lead to poor accuracy in transforming conflicts into engineering parameters for designers in the conflict solving process [2]. TRIZ theory proposes to solve conflicts by abstracting both conflicting parties into engineering parameters and querying the conflict matrix according to it to determine invention principles [3]. Failure to accurately obtain engineering parameters may lead to poor effect or even development failure of the scheme obtained from solving conflict. Therefore, it is of great significance to propose a method that can enhance the accuracy of engineering parameter selection for conflict resolution.

The process of conflict generation can be regarded as the solution of an original problem leading to the emergence of a new problem in the system [4]. Engineering parameters can be used to describe the problem state of systems [5]. Some studies believe that all problems in the system can also be expressed by physical terms such as physical parameters [6,7]. It can be found that there is a certain relationship between engineering parameters and physical parameters in the description of system problems. The analysis of physical parameters can help designers understand the system problem more deeply [6]. Therefore, this study intends to select engineering parameters by mapping from physical parameters to engineering parameters in the perspective of physical parameter analysis, so as to reduce the difficulty of directly searching engineering parameters from both conflicting parties. However, due to parameter coupling, it is difficult to map multiple physical parameters to engineering parameters, and their mapping relationship is relatively complex. The neural network has an intelligent adaptive learning ability and can effectively handle the mapping relationship between data [8], so using the neural network to train the mapping relationship between physical parameters and engineering parameters, so as to obtain the mapping model between them, has been considered. The mapping model can assist the designer to select engineering parameters.

On the basis of the above research, in order to reduce the influence of parameter coupling on engineering parameter selection and improve the efficiency of conflict resolution, a conflict solving process based on mapping between physical parameters and engineering parameters is proposed. Firstly, the existing problems of the system are determined, and its function model is constructed. Secondly, the components of the system function model are divided, and different types of physical parameters are extracted according to different components; hence, the physical parameter logic network is constructed by dimensional analysis. Thirdly, the improvement goal is determined by using the current reality tree, and the conflict analysis is carried out in the physical parameter logic network. Then, taking the physical parameter sets and engineering parameters in the existing cases as sample data, the mapping model between physical parameters and engineering parameters is trained by a back propagation (BP) neural network. According to the results of conflict analysis, the engineering parameters corresponding to the conflict can be selected through the mapping model. Finally, the conflict is solved by TRIZ tools, and the final design scheme is obtained through the analytic hierarchy process and the expert scoring method.

The contributions of this study are as follows:

- The study proposes a mapping model between physical parameters and engineering parameters, which is trained by BP neural network. The mapping model assists the designer to select engineering parameters, which improves the accuracy of the designer’s engineering parameter selection during conflict solving.

- The proposed conflict solving process can guide the designer to discover the conflicts in the design process, thus optimizing the application process of the classical TRIZ conflict matrix.

The following sections of this paper are arranged as follows. Section 2 is the literature review, which introduces the related research status of the engineering parameters and artificial neural network. In Section 3 theoretical methods are described, including the mapping relationship between physical parameters and engineering parameters, the construction process of the mapping model between physical parameters and engineering parameters, and the conflict solving process based on mapping between physical parameters and engineering parameters. Section 4 is the case study, taking the bulk Chinese medicine dispenser as an engineering case to prove the feasibility of the proposed method. Section 5 discusses the scientific nature and effectiveness of the method. Section 6 summarizes the contributions and shortcomings of the paper and puts forward future directions of the work.

2. Literature Review

2.1. Engineering Parameter in Conflict Matrix

The engineering parameter is an abstract description of both sides of conflict in the conflict matrix of TRIZ. The system runs as one, so any attempt to improve one part (functions, characteristics) of the system through known technologies may lead to the deterioration of other parts (functions, characteristics) of the system, which leads to conflicts [9]. TRIZ describes the improvement target and deterioration result with engineering parameters respectively, and then uses the conflict matrix to find invention principles, so as to obtain the scheme to solve conflict [10]. The 39 engineering parameters are shown in Table 1.

Table 1.

39 Engineering parameters.

The conflict can be solved by querying invention principles with 39 engineering parameters, and its effectiveness has been verified in the published research [11,12,13]. However, due to the increase in system complexity, there is an impact on the solution of system conflict, which is usually manifested in the low accuracy of selecting engineering parameters.

Some scholars have studied the selection of engineering parameters. Among them, Coelho [5] considered the human factors in the manufacturing process and proposed a preliminary correspondence between the human factors and engineering parameters. According to common unit operations and specific problems in the chemical industry, Pokhrel [14] et al. summed up new engineering parameters to enhance the application of TRIZ in chemical processes. By analyzing a large number of patents, Zhai [15] extracted keywords reflecting the changes of engineering parameter entities and attributes, constructed a technical conflict dictionary, and used the keywords to construct the regular expression of each engineering parameter. Huang [16] et al. quickly transformed conflicts into engineering parameters and solved them by constructing an association table between the scheme design attributes of machine fixtures and 39 engineering parameters. Rajic [17,18] classified 39 engineering parameters according to basic quantities, derived quantities and conditional expressions from the perspective of dimension, in which the conditional expression is expressed by multiplying or dividing two known parameters with LT dimension. In addition, some authors also combine the standard factors affecting ecological efficiency with engineering parameters to solve the conflict between technology and ecology [19,20,21]. The above research focuses on the formulation of mapping rules from specific problems to engineering parameters, which has made a certain contribution to the selection of engineering parameters, but only for a certain product or field. In addition, in the formulation and application of relevant rules, the designer’s subjective tendency has a great impact and there is a lack of consideration of the system coupling problem, meaning accuracy in engineering parameter selection cannot be guaranteed.

In order to improve the accuracy of engineering parameter selection, this paper proposes analysis from the perspective of physical parameters in order to reduce the difficulty of directly searching engineering parameters from both conflicting parties. However, due to the parameter coupling relationship, it is difficult to map multiple physical parameters to engineering parameters, and the mapping relationship is relatively complex. We consider using the artificial neural network to assist the mapping process.

2.2. Artificial Neural Network

The artificial neural network (ANN), which is a set composed of artificial neurons or nodes, has been proved to be one of the most useful artificial intelligence techniques in multidisciplinary applications [22]. It can be used to predict and analyze the nonlinear mapping relationship of data with self-learning properties and has been successfully applied in the fields of pattern recognition, prediction, classification, image annotation, semantic analysis and audio parsing.

In view of the self-learning characteristics of ANN, many scholars have applied it to the product design process. Quan [23] et al. combined perceptual engineering with ANN for product innovation, which can convert the color, pattern, etc., of an image into a shape of the product in real time. Lin [24] et al. used ANN to train the product design data obtained by the Taguchi method to predict the most suitable variable eigenvalues. Kang [25] used ANN to establish the mapping relationship between key perceptual factors and representative product design elements and, based on this, found the most perceptually attractive product designs. Wang [26] used engineering parameters as an intermediary between complexity and the law of technological evolution, then trained ANN to predict the law of technological evolution to control the negative effects of product complexity.

It can be seen from the above literature that using an ANN-assisted mapping process can achieve good results. In order to obtain better results, the widely used BP neural network is selected [27]. The BP neural network implements a mapping function from input to output. It can automatically extract rules between the input and output data during training, and adaptively memorize the learning content in weights of the network. At the same time, the BP neural network has a certain fault tolerance ability, which will ensure global training results are not affected after some neurons or nodes are damaged.

To sum up, this paper proposes that it is feasible to use the BP neural network to establish the mapping model between physical parameters and engineering parameters, and to assist designers in selecting engineering parameters.

3. Theoretical Methods

The research content of theoretical methods in the paper is mainly divided into three parts: the mapping relationship between physical parameters and engineering parameters, the construction process of the mapping model between physical parameters and engineering parameters, and the conflict solving process based on mapping between physical parameters and engineering parameters.

3.1. Mapping Relationship between Physical Parameters and Engineering Parameters

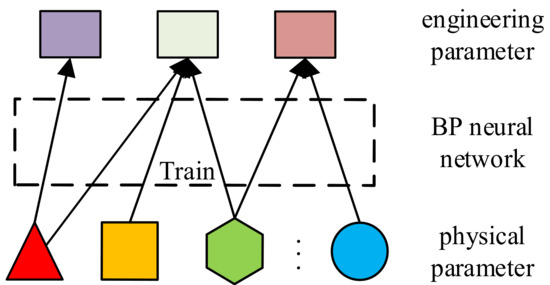

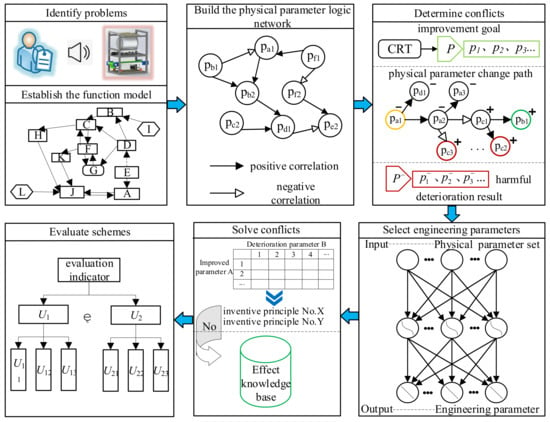

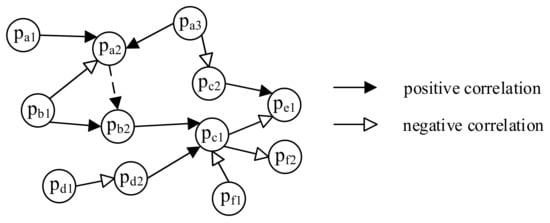

When using a BP neural network to train the mapping model between physical parameters and engineering parameters, the mapping relationship between them must be clarified first. According to the specific introduction of engineering parameters in the conflict matrix [4], engineering parameters are a description of physical parameters in systems. For example, “No.7 Volume of moving object” is related to speed and volume; “No.12 shape” is related to length, width, radian and other parameters; “No.31 Object-affected harmful” is related to physical parameters such as radiation intensity, sound intensity, vibration displacement and speed. Each engineering parameter is related to at least one physical parameter and problems are often caused by the action of multiple physical parameters due to the increased coupling of systems. From this, it is found that the engineering parameters can be mapped by multiple physical parameters. They are in a many-to-one relationship, which can be trained through the BP neural network, as shown in Figure 1.

Figure 1.

Mapping relationship between physical parameters and engineering parameters.

3.2. Construction Process of the Mapping Model between Physical Parameters and Engineering Parameters

The construction process of the mapping model between physical parameters and engineering parameters is divided into four steps: the determination of case sets, the extraction of sample data, the coding of sample data and the training of the mapping model.

3.2.1. Determination of Case Set

As a kind of supervised learning, the BP neural network needs to be fully trained to achieve a better classification effect. This paper takes the authorized patent and enterprise application cases as the case sources and collects 200 cases as the case set for training. Among them, the patents come from the authorized patents in the relevant machinery field retrieved from Patsnap [28], and the enterprise application cases are mainly selected from case books [29,30].

3.2.2. Extraction of Sample Data

The sample data includes physical parameter sets and engineering parameters. The following describes the extraction process of the physical parameter set and engineering parameters, respectively.

- (1)

- Extraction of the physical parameter set.

In the extraction process of the physical parameter set, it is necessary to extract the root causes related to the system problem from the case and extract the physical parameter set corresponding to the root causes as the input data of the BP neural network. It is mainly divided into the following steps.

Step 1: Establishing a function model [31], which can help designers better analyze the system.

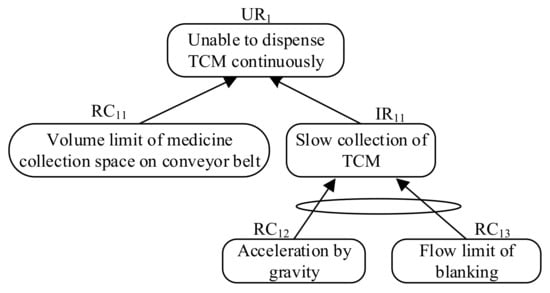

Step 2: Building a current reality tree (CRT) model of the system problem based on the function model.

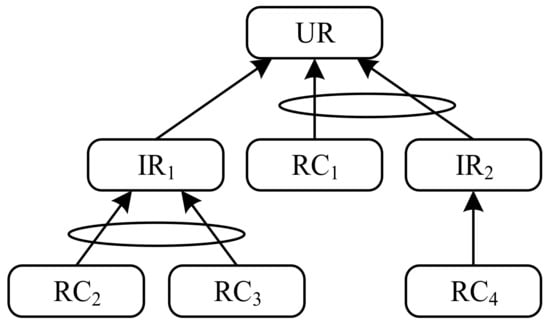

CRT is a logical analysis tool that describes the current state of a product, locating root causes in reverse through a series of causal relationships [32]. As shown in Figure 2, the CRT model consists of an undesirable result (UR), intermediate result (IR) and root cause (RC), where the ellipse represents the logical “and” relationship.

Figure 2.

CRT model.

Step 3: Extracting root causes related to the system problem according to the logical “and” relationship of the CRT model.

The logical “and” means that the causes work together to derive a result, so the root causes of the “and” relationship should be considered together. For example, in the CRT model shown in Figure 2, {RC2, RC3} and {RC1, RC4} are extracted respectively as the root causes related to UR.

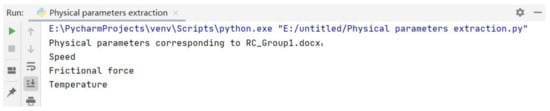

Step 4: Using Python to extract physical parameters corresponding to root causes with the rules, which are formed according to the definition of physical parameters, keywords and relevant description, and obtaining the physical parameter set by sorting physical parameters according to the influence degree on the problem.

As shown in Figure 3, for example, if the extracted root causes are “high-speed friction” and “poor cooling effect”, the corresponding parameters for extraction are speed, frictional force and temperature. The physical parameters corresponding to each group of root causes are extracted, and then sorted according to their influence on the problem to determine the input position in the neural network, thereby forming a physical parameter set, which is expressed as with the influence degree of . Using the above procedure, 530 physical parameter sets are extracted from the case set.

Figure 3.

Extracted physical parameters corresponding to root causes with Python.

- (2)

- Extraction of engineering parameters.

After extracting the physical parameter sets, it is necessary to determine the engineering parameters corresponding to the physical parameter sets and take them as output data. Firstly, five experts with more than 10 years of mechanical innovation design experience are invited to determine the engineering parameters corresponding to each physical parameter set in the case set. Secondly, in order to reduce the influence of subjectivity and ensure the accuracy of determined engineering parameters, the Kendall synergy coefficient is used for a consistency test [33]. The consistency test result is shown in Table 2.

Table 2.

Consistency test result.

The asymptotic significance is 0.000, less than the threshold value of 0.005, and the Kendall synergy coefficient is 0.967, greater than 0.8, indicating high data consistency. Finally, the determined engineering parameters are modified. For a small number of sample data with different opinions, if there are three or more experts who agree, the minority shall obey the majority, and the opinions shall not be adopted in the other cases. According to the above process, the engineering parameters corresponding to the physical parameter sets are finally obtained.

3.2.3. Coding of Sample Data

After obtaining the sample data, it is necessary to code the data so that it can be trained in the BP neural network.

- (1)

- Coding of the physical parameter set.

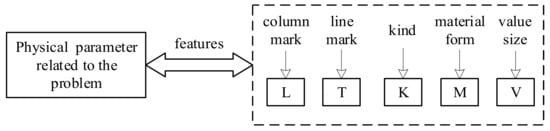

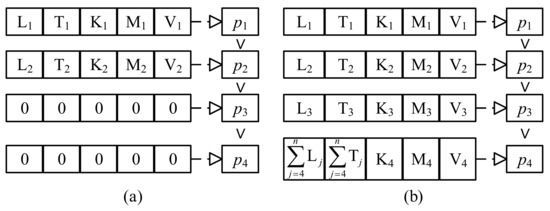

In the paper, the mapping relationship between physical parameters and engineering parameters is trained by the BP neural network. Because the physical parameter is a basic concept used to describe physical phenomena in a broad definition, it cannot be trained directly, so a reasonable code method is needed to represent the physical parameter. The Length-Time (LT) dimension is considered to reflect the inherent attributes of physical parameters, and the LT matrix formed by LT dimensions is an orderly combination of physical parameters, which is similar to the conflict matrix in TRIZ theory [17,18,34]. Therefore, the physical parameter is coded based on the LT dimension to facilitate training. However, with only using dimension as input, there are some cases where some data cannot be distinguished, so it is necessary to introduce other features of the physical parameter, mainly including the kind, material form and value size. In the paper, the features of each physical parameter are represented by column mark (L), line mark (T), kind (K), material form (M) and value size (V), as shown in Figure 4.

Figure 4.

Features of the physical parameter.

L and T represent the LT dimension of the physical parameter, and the corresponding values are the dimensional indexes of L and T. K represents the kind of physical parameter, where 0 represents space and time, 1 represents mechanics, 2 represents heat, 3 represents electromagnetism, 4 represents optics and 5 represents acoustics. The classification basis is Chinese national standard GB 3102-93. M represents the material form of the physical parameter carrier, where 0 represents the absence of carrier, 1 represents solid state, 2 represents liquid state, 3 represents gaseous state and 4 represents field state. V represents the value size of a physical parameter, where −1 represents small, 0 represents normal, 1 represents large and 2 represents fluctuation.

From the analysis of extracted sample data and the actual physical phenomena, it can be recognized that there are generally about four physical parameters related to the problem, so the number of input physical parameters is determined to be four. However, in the extraction process of physical parameters, the number is not fixed, so the code of the physical parameter set is divided into the following two cases.

- When the number of physical parameters in the physical parameter set is , the feature codes of the ()th to the 4th physical parameter are all set to 0. Taking the number as an example, the code of the physical parameter set is shown in Figure 5a.

Figure 5. (a) Code of the physical parameter set when ; (b) code of the physical parameter set when .

Figure 5. (a) Code of the physical parameter set when ; (b) code of the physical parameter set when . - When the number of extracted physical parameters is , the 4th to th physical parameters need to be synthesized, and the synthesized physical parameter is used as the 4th input parameter. The parameter synthesis rules are derived from the genetic idea of Bartini in the LT matrix. A new dimension LnTm is obtained by multiplying the dimensions Ln1Tm1 and Ln2Tm2 of two physical parameters x and y. Then the physical parameter z corresponding to LnTm will inherit the attributes of both x and y [35,36].

When physical parameters need to be synthesized, times dimension multiplication is completed to obtain the synthesized new dimension. According to the synthesized new dimension, the codes of L and T are and respectively. At the same time, because the 4th physical parameter has a greater impact on the system problem than other physical parameters, the code of K, M and C shall be subject to the 4th physical parameter. As shown in Figure 5b, it is the code of the physical parameter set when .

- (2)

- Coding of engineering parameters.

After determining the code of the physical parameter set, the engineering parameters need to be coded. If 39 engineering parameters are coded directly according to the serial number 1–39, it may affect the training effect due to the large classification dimension. Therefore, it is necessary to classify the engineering parameters before coding. Applying system or super system resources to solve the problems existing in the system is a basic viewpoint of TRIZ [4]. According to the form of resources, they can be divided into six categories: material resource, space resource, time resource, field resource, structure resource and information resource. Since each engineering parameter has the characteristics of a resource [37], it is classified according to the relationship between engineering parameters and resources as shown in Table 3.

Table 3.

The relationship between engineering parameters and resources.

According to the classification of 39 engineering parameters, the engineering parameters are coded. The code of the engineering parameter is , where represents the code of the engineering parameter category, corresponding to value 1–6; in turn, represents the code of the engineering parameter sequence in each category, which is accumulated one by one from 1, according to the sequence number from small to large.

The coding results are shown in Table 4. The value in the bracket is the code of the engineering parameter sequence in each category. In the extraction process of sample data, No.24 Loss of information, No.35 Adaptability of versatility and No.38 Level of automation are difficult to express with physical parameters. Therefore, such labels are deleted before coding.

Table 4.

Code of engineering parameters.

3.2.4. Training of Mapping Model

- (1)

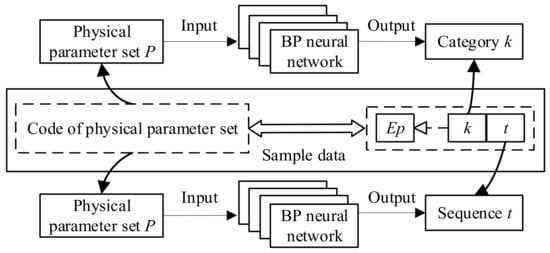

- Determining the training method of the mapping model.

According to the code of the sample data, the training method of the mapping model can be obtained. As shown in Figure 6, firstly, the engineering parameter category is trained. Its input is the physical parameter set and the output is the category. Then, the engineering parameter sequence in each category is trained. Its input is also the physical parameter set and the output is the sequence. Finally, the mapping model between the physical parameter set and category/sequence of the engineering parameter is obtained. It is called the mapping model between physical parameters and engineering parameters in the paper, hereinafter referred to as the mapping model.

Figure 6.

Training method of the mapping model.

- (2)

- Determining the training algorithm for the mapping model.

In this paper, the Genetic Algorithm (GA) [38] and Levenberg–Marquardt (LM) [39] are used to optimize the BP neural network to improve the accuracy of the mapping model. Among them, LM has a faster convergence speed and can avoid falling into the minimum value. GA can optimize the initial connection weights and thresholds of the BP neural network, avoiding the uncertainty of random selection.

- (3)

- Training the mapping model.

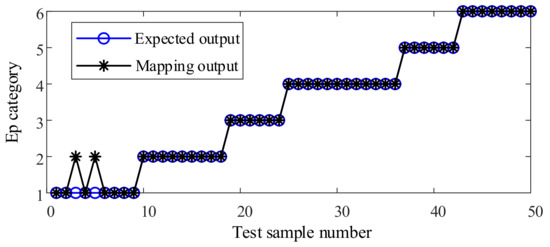

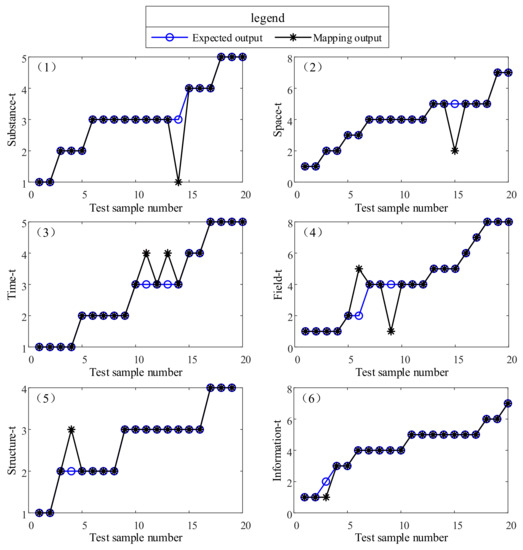

In this study, 80% of the sample data was randomly selected for training and 20% for testing. The mapping model is finally obtained by using MATLAB to write relevant programs for training. Appendix A is the training results of test samples, in which the expected output is the label of each test sample, and the mapping output is the result obtained by BP neural network training. According to the difference between the expected output and the mapped output, the accuracy of engineering parameter category training is 96%, and the accuracy of engineering parameter sequence training in each category is shown in Table 5. The training results are good and increasing the amount of sample data can further improve the accuracy rate.

Table 5.

Accuracy of engineering parameter sequence training in each category.

In order to facilitate the designer to quickly select the engineering parameter, a calling module of mapping model between physical parameters and engineering parameters is established through the GUI of MATLAB, as shown in Figure 7. This module includes inputting the code of physical parameter set, mapping of category , mapping of sequence and data initialization. For the situation where it is difficult to judge the engineering parameter due to the coupling effect of multiple physical parameters, the code of the corresponding physical parameter set is inputted, and the engineering parameter can be mapped for the designer to select.

Figure 7.

Calling module of the mapping model between physical parameters and engineering parameters.

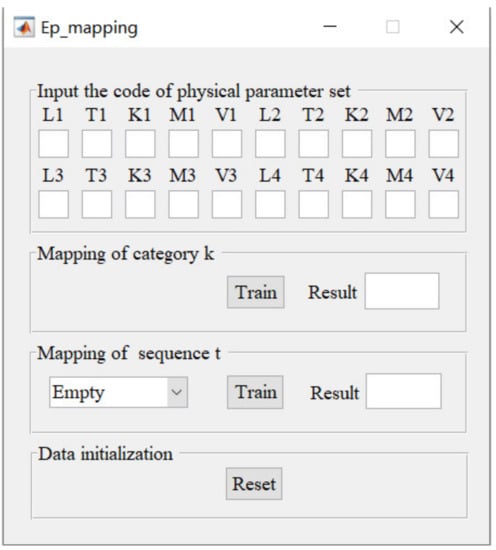

3.3. Conflict Solving Process Based on Mapping between Physical Parameters and Engineering Parameters

In order to enhance the accuracy of selecting engineering parameters and improve the efficiency of conflict resolution, the paper analyzes the process of conflict generation through the logical relationship between physical parameters, selects engineering parameters through the mapping model, and uses the TRIZ tools to solve the conflicts, so as to obtain the conflict solving process based on the mapping of physical parameters and engineering parameters. The process is shown in Figure 8.

Figure 8.

Conflict solving process based on mapping between physical parameters and engineering parameters.

The process is mainly divided into six steps. The first step is to identify system problems and build the function model; the second step is to build a physical parameter logical network; the third step is to determine system conflicts; the fourth step is to select engineering parameters through the mapping model; the fifth step is to solve conflicts; and the sixth step is to evaluate schemes.

Step 1: Identifying the system problem and building the function model.

The current system problem is identified through market research and user feedback, and a function model [31] is established to help the designer fully understand the system.

Step 2: Building the physical parameter logical network.

According to the logical relationship in the physical parameter logical network of the system, it can be recognized that when a physical parameter changes, there are changes in other related physical parameters. The construction process of the physical parameter logical network is as follows:

- (1)

- According to the integrity law of technical systems [40], the system components in the function model are divided into four types: energy device, transmission device, execution device and operation control device.

- (2)

- The physical parameters of the corresponding types of components are extracted [41]. In addition, it is also necessary to consider the physical parameters corresponding to targets and super-system components that affect the system.

- (3)

- According to the theorem in dimensional analysis [42], the logical relationship between physical parameters is obtained. Dimensional analysis is a well-established and widely used method in the physical and engineering sciences that enables the analysis of relationships between variables, reducing the number of potential causes that need to be considered. The steps of dimensional analysis are as follows:

① The main related parameters including the dependent variable from the extracted physical parameters, are found according to the interaction between components.

② Basic quantities involved in these physical parameters are determined, then the dimensions of parameters can be represented by Equation (1), where is the dimension index of basic quantity, and .

③ The dimensional product of these physical parameters is expressed in the dimensional form. It is shown in Equation (2), in which the undetermined coefficient is the index of physical parameter.

④ According to the dimensional form and homogeneity principle, the homogeneous linear equations can be obtained. It is expressed as , where and . Then, the basic solution system is obtained by solving the homogeneous linear equations.

⑤ is obtained according to , respectively. Then, the expression including the dependent variable is selected and converted into the form , which is used as the basis for the reasoning of the logical relationship between physical parameters. is shown in Equation (3), where represent relevant physical parameters, and are their indices. According to the positive and negative conditions of the index in the equation, the logical relationship between parameters can be obtained.

- (4)

- According to the logical relationship displayed by the expression and the interaction relationship between components, the physical parameters are connected to generate a physical parameter logical network as shown in Figure 9. The direction of the arrow points from the independent variable to the dependent variable, indicating the logical relationship between physical parameters. The solid arrow indicates a positive correlation, and the hollow arrow indicates a negative correlation.

Figure 9. Physical parameter logic network.

Figure 9. Physical parameter logic network.

Step 3: Determining system conflicts.

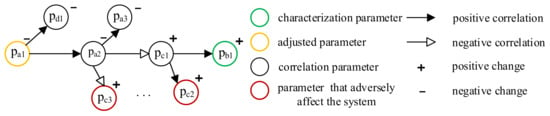

The conflicts existing in the system are determined by the changes of parameters in the physical parameter logic network. The specific process of conflict determination is as follows.

- (1)

- Determining the improvement goal.

① The CRT model of the system problem is built, in which the root causes are extracted according to the logical “and” relationship.

② Physical parameters related to root causes are extracted by Python and then sorted according to the influence degree to form a physical parameter set . is regarded as the improvement goal of the system.

- (2)

- Determining the deterioration result.

① The characterization parameter and its improvement direction are determined. The characterization parameter refers to the physical parameter that can describe the problem state, which is generally determined by the problem carrier. By adjusting the characterization parameter, the problem can be improved. The improvement direction refers to the direction from the current state to the ideal state of the system.

② By adjusting the parameter to make the characterization parameter change according to its improvement direction and analyzing the changes of the correlation parameters in the physical parameter logic network, the physical parameter change path is obtained, as shown in Figure 10. According to the physical parameter change path, it is judged whether the change in correlation parameters will have adverse effects on the system. The parameters that adversely affect the system may act alone or together, which need to be analyzed according to the actual situation. They are regarded as the deterioration result, which is represented by the physical parameter set. It is expressed as with the influence degree of .

Figure 10.

Physical parameter change path.

- (3)

- Determining conflicts.

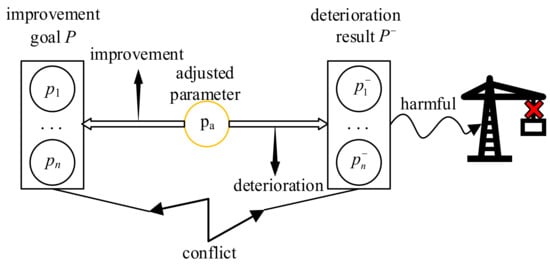

There is a conflict between the improvement goal P and deterioration result , where P is the side that introduces useful effects or eliminates harmful effects (increasing useful effects or weakening harmful effects), and is the side that leads to system deterioration, as shown in Figure 11.

Figure 11.

System conflicts determination.

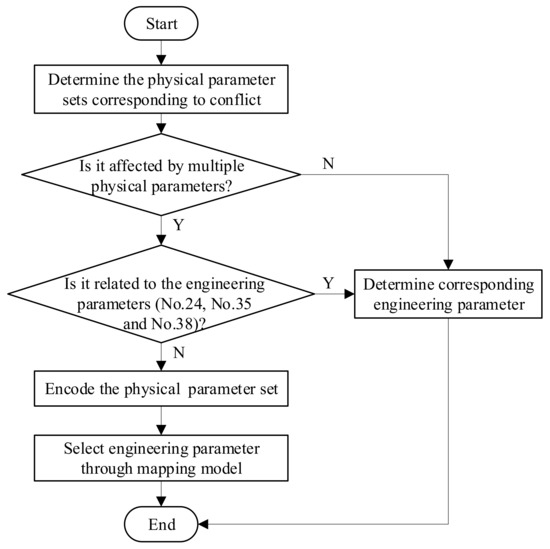

Step 4: Selecting engineering parameters through the mapping model.

After the physical parameter sets corresponding to both conflicting parties are determined, the mapping model constructed in Section 3.2 is used to select engineering parameters. As shown in Figure 12, the engineering parameter selection process is as follows.

Figure 12.

Engineering parameter selection process through mapping model.

- (1)

- The physical parameter sets and , corresponding to both conflicting parties, are determined;

- (2)

- Judging whether or are affected by multiple physical parameters. If it is a single physical parameter, the corresponding engineering parameters can be directly determined; otherwise, the next step can be proceeded to;

- (3)

- Judging whether or is related to the engineering parameters (No.24, No.35 and No.38). If it is related, it doesn’t need to be selected through the mapping model to avoid engineering parameter selection errors; otherwise, the next step can be proceeded to;

- (4)

- The physical parameter set or is encoded according to the LT dimension and other physical parameter characteristics;

- (5)

- The encoded physical parameter set or is inputted into the mapping model. Then, the corresponding engineering parameter is selected according to the mapping result.

Step 5: Solving conflicts.

According to the engineering parameters corresponding to the improvement goal and deterioration result , the corresponding invention principle for solving conflict is selected by querying the conflict matrix, so as to produce a design scheme. If the engineering parameters corresponding to and are the same, it is necessary to analyze whether it can be transformed into a physical conflict for solution.

Usually, the conflict caused by the parameter coupling can be solved by a small improvement of the system according to the invention principle, but there may be special circumstances that make it difficult to solve the conflict, resulting in poor solution effect or no solution. If the above situation exists, the effect knowledge base in TRIZ is used as a supplementary method, and the solution is continued to generate design scheme.

Step 6: Evaluating schemes.

After obtaining the design schemes generated by the conflict solution, the schemes are evaluated by combining the analytic hierarchy process (AHP) and the expert scoring method to determine the final design scheme [43]. Firstly, the evaluation indicator system is established. Secondly, the indicator weight is determined by AHP, and then each indicator is scored by the expert scoring method. Finally, the best design scheme is determined according to the ranking of schemes obtained through the weighted evaluation.

4. Case Study

4.1. Case Background

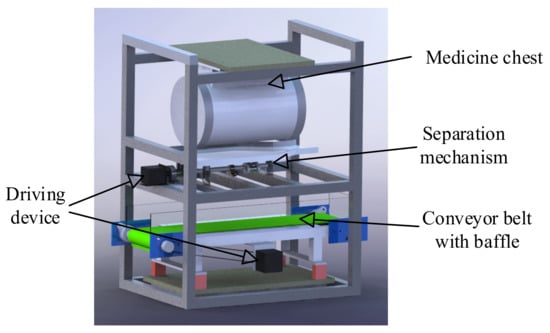

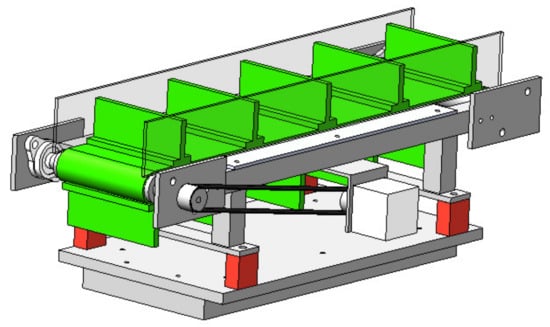

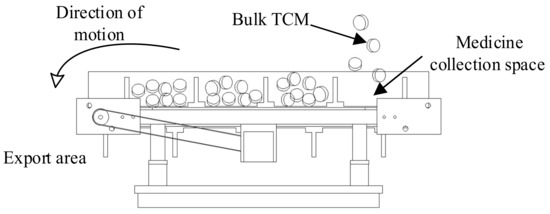

At present, most traditional Chinese medicines (TCM) are stored in bulk, and the manual dispensing method is still mainly used for bulk TCM in the pharmacy. There are some problems in the process of TCM proportioning, such as low efficiency, inaccurate weighing, long processing time, difficult review and so on. The low efficiency of TCM has caused the unfavorable phenomenon that patients experience a short time in which they can see a doctor but a long waiting time. The innovative design of TCM-dispensing devices and methods has become an inevitable trend [44]. Therefore, there is an urgent need for an automatic dispensing machine for bulk TCM to improve the efficiency of pharmacy dispensing. After analyzing the relevant equipment and patents, a bulk TCM dispenser is selected as the prototype product, as shown in Figure 13.

Figure 13.

Bulk traditional Chinese medicine dispenser.

4.2. Case Design Process

Taking the existing bulk TCM dispenser as an example, according to the process shown in Figure 8, this paper explains how to apply the proposed conflict solving process from the following six steps.

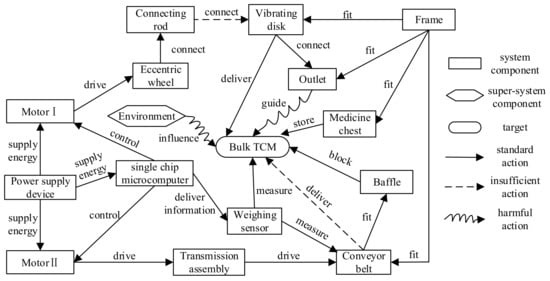

Step 1: Determining the problem of the bulk TCM dispenser and building its function model.

After market research and user feedback, it is found that the existing bulk TCM dispenser has the following problems: “Unable to dispense TCM continuously” and “TCM accumulation at outlet”. Through the function analysis of the bulk TCM dispenser, its function model is established, as shown in Figure 14.

Figure 14.

Function model of the bulk TCM dispenser.

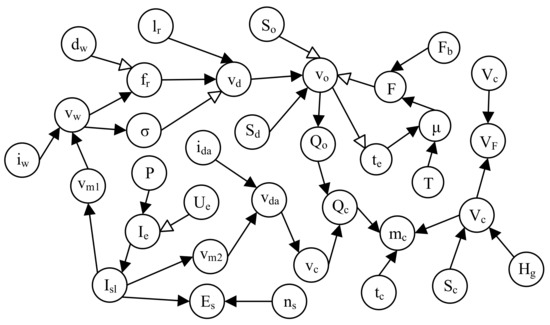

Step 2: Constructing the physical parameter logic network of the bulk TCM dispenser.

Firstly, the components in the function model are divided according to the integrity law, and the corresponding physical parameters, which are represented by symbols, are extracted according to the different types of components, as shown in Table 6. Then, the extracted parameters are analyzed by dimensional analysis, and the dimensionless expressions of relevant physical parameters are obtained, as shown in Table 7. Some relatively simple dimensionless expressions are not listed in the table. Finally, according to the mathematical model displayed by the expressions and the action relationship between components, the physical parameters are connected to generate a physical parameter logic network of the bulk TCM dispenser, as shown in Figure 15.

Table 6.

Physical parameters related to components in the function model.

Table 7.

Dimensionless expressions of system related physical parameters.

Figure 15.

Physical parameter logic network of the bulk TCM dispenser.

Step 3: Determining the conflict of the bulk TCM dispenser.

After constructing the physical parameter logic network of the bulk TCM dispenser, the corresponding conflicts are determined from the problems (“Unable to dispense TCM continuously” and “TCM accumulation at outlet”).

- (1)

- Conflict determination process of “Unable to dispense TCM continuously”.

First, the CRT model of “Unable to dispense TCM continuously” is constructed, as shown in Figure 16.

Figure 16.

CRT model of “Unable to dispense TCM continuously”.

According to the logic “and” relationship, the extracted root causes related to the problem are {RC11} and {RC12, RC13}, which correspond to “Volume limit of medicine collection space on conveyor belt” and “Acceleration by gravity, Flow limit of blanking”, respectively, where the medicine collecting space is the space formed by the conveyor belt and baffle for collecting TCM.

Then, Python is used to extract the physical parameters corresponding to {RC11} and {RC12, RC13}, which are “Volume” and “Gravity, Acceleration, Mass flow”, respectively, as shown in Table 8. By sorting the physical parameters of each group in Table 8 according to the influence degree on the problem, it can be obtained that the physical parameter sets related to “Unable to dispense TCM continuously” are and . and are the problem’s improvement goals.

Table 8.

Physical parameters extracted from root causes of “Unable to dispense TCM continuously”.

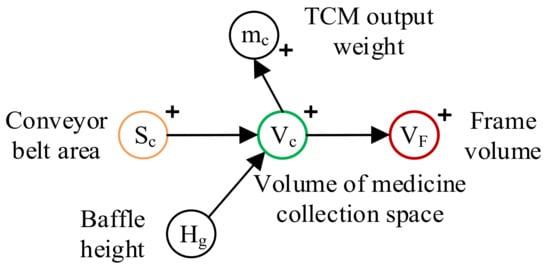

To achieve the purpose of continuous dispensing, on the one hand, is to improve the dispensing speed, but the accuracy of the TCM weight cannot be guaranteed. Decreased accuracy will make TCM review time longer, which is detrimental to continuous dispensing. At the same time, if the speed is too fast, it will inevitably lead to the splashing of granular TCM, resulting in waste. On the other hand, making multiple copies of TCM temporarily stored on the conveyor belt increases the volume of the medicine collection space, which can improve “Unable to dispense TCM continuously” caused by and ; hence, it is used as the characteristic parameter of the problem. Its improvement direction is to become larger. Then, the related physical parameter change path in the physical parameter logical network is determined, as shown in Figure 17.

Figure 17.

Physical parameter change path of “Unable to dispense TCM continuously”.

Increasing the conveyor belt area can increase the volume of the medicine collection space, but it will lead to an increase in the frame volume, which is contrary to the potential demand for the reduction of it, thus creating a conflict. Therefore, the deterioration result in the improvement process of the problem is represented by . The conflict is specifically described as improving “Unable to dispense TCM continuously” caused by and through increasing the conveyor belt area, but it will increase the frame volume, which is the deterioration result .

- (2)

- Conflict determination process of “TCM accumulation at outlet”.

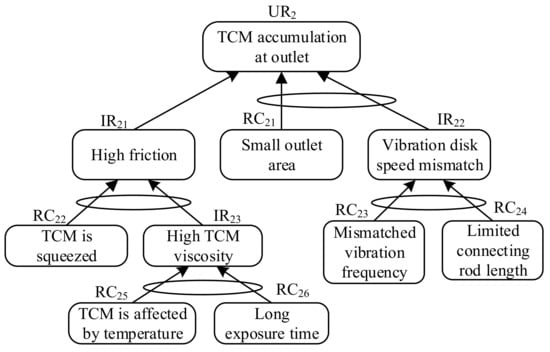

Firstly, the CRT model of “TCM accumulation at outlet” is constructed, as shown in Figure 18. According to the logic “and” relationship, the extracted root causes related to the problem are {RC22, RC25, RC26} and {RC21, RC23, RC24}, which correspond to “TCM is squeezed, TCM is affected by temperature, Long exposure time” and “Small outlet area, Mismatched vibration frequency, Limited connecting rod length”, respectively.

Figure 18.

CRT model of “TCM accumulation at outlet”.

Then, Python is used to extract the physical parameters corresponding to {RC22, RC25, RC26} and {RC21, RC23, RC24}, which are “Force, Temperature, Time” and “Area, Frequency, Length”, respectively, as shown in Table 9. By sorting the physical parameters of each group in Table 9 according to the influence degree on the problem, it can be obtained that the physical parameter sets related to “TCM accumulation at outlet” are and . and are the problem’s improvement goals.

Table 9.

Physical parameters extracted from root causes of “TCM accumulation at outlet”.

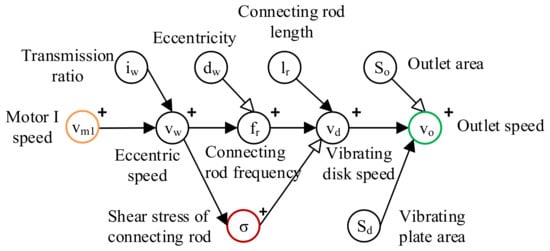

According to the problem analysis, it can be seen that increasing the outlet speed can improve “TCM accumulation at outlet”, caused by and . On the one hand, increasing the outlet speed can reduce the exposure time of TCM during the separation process, thereby reducing the influence of temperature on TCM; but on the other hand, the TCM can quickly pass through the outlet and fall. Therefore, the outlet speed is used as the characteristic parameter of the problem, and its improvement direction is to become larger. Then, the related physical parameter change path in the physical parameter logical network is determined, as shown in Figure 19.

Figure 19.

The physical parameter change path of “TCM accumulation at outlet”.

Increasing the motor I speed can achieve the purpose of increasing the outlet speed. However, in the process of increasing it, the shear stress of the connecting rod will increase, which will affect the connection strength, resulting in conflict. Therefore, the deterioration result in the improvement process of the problem is represented by . The conflict is specifically described as improving “TCM accumulation at outlet” caused by and through increasing the motor I speed; however, this will increase the shear stress of the connecting rod, which is the deterioration result .

Step 4: Selecting engineering parameters through the mapping model.

According to the physical parameter sets obtained in the previous step, the mapping model between physical parameters and engineering parameters is used to select engineering parameters.

- (1)

- , and are only related to one parameter. It can be seen directly that the engineering parameters corresponding to and are No.8 Volume of stationary object, the engineering parameter corresponding to is No.11 Stress or pressure.

- (2)

- , and are related to the actions of multiple parameters respectively. Direct correspondence with engineering parameters is difficult. They have no relation to the engineering parameters (No.24, No.35 and No.38).

- (3)

- , and are encoded according to the code rules of the physical parameter set, and then inputted into the mapping model, respectively. The obtained engineering parameter mapping results are shown in Table 10. According to the mapping results, the engineering parameters corresponding to , and are selected as No.39 Productivity, No.30 Object-affected harmful and No.25 Loss of time, respectively.

Table 10. Mapping results of engineering parameters.

Table 10. Mapping results of engineering parameters.

Step 5: Solving the conflicts of the bulk TCM dispenser.

Through the invention principle or effect, the conflict existing in the bulk TCM dispenser is solved.

- (1)

- Conflict solving process of “Unable to dispense TCM continuously”.

The invention principles queried according to the relevant conflicts and , and determined in “Unable to dispense TCM continuously” are shown in Table 11.

Table 11.

Invention principles corresponding to conflicts of “Unable to dispense TCM continuously”.

It can be seen from Table 11 that and correspond to No.8 Volume of stationary object, which can be regarded as the volume of medicine collection space with opposite requirements, which belongs to physical conflict, and shall be solved by applying the space separation principle. By adding partitions, the conveyor belt is divided into a plurality of medicine collection spaces for collecting TCM, and each space area contains the fixed dose of TCM, as shown in Figure 20.

Figure 20.

Solution through space separation principle.

The engineering parameters corresponding to and are No.39 Productivity and No.8 Volume of stationary object, respectively. The corresponding invention principles in the conflict matrix are No.35 Parameter changes, No.37 Thermal expansion, No.10 Preliminary action and No.2 Taking out. The solution is obtained according to No.10 Preliminary action. After receiving the prescription information, the conveyor belt rotates counterclockwise in advance to make the next medicine collection space reach the blanking position, which is convenient for collection of the corresponding number of TCM on the conveyor belt in advance, so that when the medicine taking device reaches the export area, it can continuously take multiple copies of medicine, and ensure the accuracy of each TCM, as shown in Figure 21.

Figure 21.

Solution corresponding to Preliminary action.

- (2)

- Conflict solving process of “TCM accumulation at outlet”.

The invention principles queried according to the relevant conflicts and , and determined in “TCM accumulation at outlet”, are shown in Table 12.

Table 12.

Invention principles corresponding to conflicts of “TCM accumulation at outlet”.

It can be seen from Table 12 that the invention principles queried through engineering parameters corresponding to and are No.22 ‘Blessing in disguise’ or ‘Turn Lemons into Lemonade’, No.2 Taking out and No.37 Thermal expansion. According to No.2 Taking out, materials with thermal insulation performance should be used to make a relatively closed environment.

The invention principles queried through engineering parameters corresponding to and are No.37 Thermal expansion, No.36 Phase transitions and No.4 Asymmetry. According to the invention principles, there is no solution to the conflict, so the effect is used for further solution.

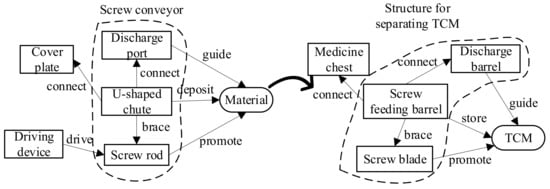

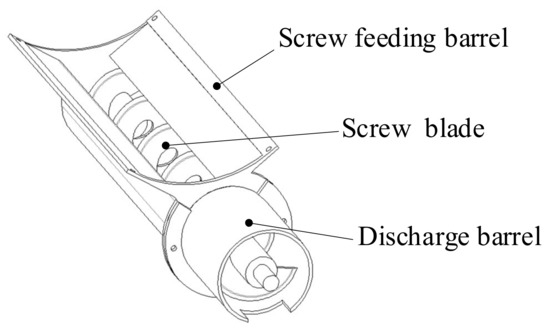

The above conflict can be abstracted as changing speed. Then, the available effects, such as roller, screw, rack and pinion, pulley, etc. are obtained by using the effect knowledge base [45]. The screw effect is selected according to the difficulty of realization, and the scheme is obtained by analogy between the case corresponding to the effect (screw conveyor) and the regional structure of “TCM accumulation at outlet” (TCM separation area), as shown in Figure 22 and Figure 23. The scheme analogy process refers to the existing research [26,34]. The scheme comprises a screw feeding barrel, a screw blade and a discharge barrel. The screw feeding barrel is eccentrically arranged and connected with the cylindrical medicine chest to make TCM fall into one side. The screw blade is used to push the TCM and make it drop at the discharge barrel.

Figure 22.

Analogy process of screw conveyor.

Figure 23.

Screw effect analogy scheme.

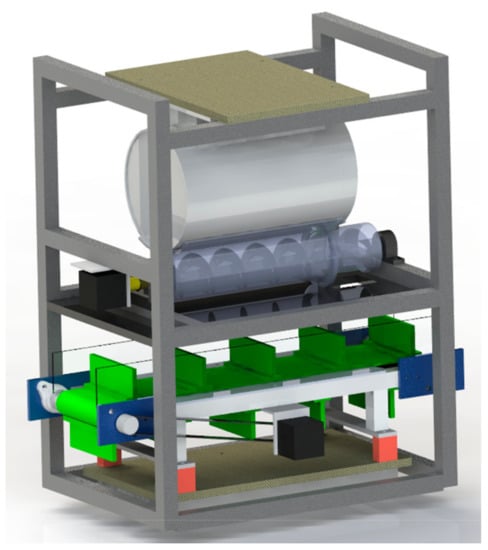

By combining the schemes obtained in the above solution process, a new scheme of the bulk TCM dispenser is formed and its 3D model is established, as shown in Figure 24.

Figure 24.

3D model of the new scheme.

Step 6:Evaluating schemes.

The mechanical system performance is the sum of the service performance, economic performance and green performance that the mechanical system must have to complete its specific function [46]. After analyzing the requirements of the dispensing machine, its key technical characteristics are “dispensing efficiency”, “automatic control” and “dispensing error”. Therefore, the service performance, economic performance and green performance are taken as three comprehensive indicators and subdivided to establish the evaluation indicator system of the bulk TCM dispenser, as shown in Table 13.

Table 13.

Evaluation indicator system.

The relative importance of evaluation indicators is divided into five levels: “unimportant”, “slightly important”, “important”, “relatively important” and “very important”, corresponding to values 1, 3, 5, 7, and 9 respectively, and values 2, 4, 6, and 8, respectively, representing values between the two levels. As shown in Equations (4)–(7), the indicators in the comprehensive indicator layer and the project indicator layer are compared according to the relative importance standard to obtain the judgment matrices , , , .

The above matrix meets the consistency test, and its eigenvector is obtained by the normalization algorithm [47], which are , , and respectively. Thus, the weight value of each indicator is obtained, as shown in Table 13.

In this paper, relevant experts, engineering technicians, manufacturing and maintenance personnel, etc., are invited to form a five-person evaluation team (E1–E5) to score each project indicator of the prototype dispenser (S1) and the newly designed bulk TCM dispenser (S2) using a ten-point system. The detailed scoring results are shown in Appendix B.

The scoring results are brought into Equations (8) and (9) for calculation, where is the final score of the scheme, refers to the number of evaluators, is the weighted score of the comprehensive indicator, is the number of comprehensive indicators, is the weight value of the comprehensive indicator, is the number of project indicators, is the weight value of the project indicator, and is the score of the project indicator. The final score results of the scheme’s mechanical properties are obtained, as shown in Table 14. According to the results, the new scheme is obviously better than the prototype.

Table 14.

Final score results.

5. Discussion

This paper mainly focuses on how to accurately select engineering parameters corresponding to conflict and applies the proposed method to the innovation design of a bulk traditional Chinese medicine dispenser. Through the mapping model, the engineering parameters are efficiently selected, and the conflict is solved by TRIZ, so as to obtain the design scheme. At the same time, the patent application is completed according to the scheme obtained. In order to further discuss the applicability and accuracy of the proposed method, four TRIZ engineers with product design experience are invited to conduct case analysis. As shown in Table 15, 15 cases are selected from the application cases of innovation methods, of which the key technical problems, improvement parameters and deterioration parameters of each case are known. Engineer T1 adopts the method proposed in the paper, and the other three engineers adopt the traditional method, that is, the process of analyzing conflict through causal analysis and conflict standardization. The four engineers analyzed the 15 cases in turn, compared the results of the improved parameters and deterioration parameters selected in the cases with the known results, and recorded the number of correct engineering parameters in Table 15.

Table 15.

Results of case analysis.

According to the engineering parameters in Table 15, the quantity () corresponding to category 1–6 is 5, 3, 5, 3, 6, and 8, respectively. Therefore, the mapping accuracy of the trained mapping model is about 89.9%, as shown in Equation (10), where represents the accuracy of the engineering parameter category trained and represents the accuracy of engineering parameter sequence trained in each category.

The accuracy of engineering parameters selected by engineer T1 using the method proposed in this paper is 90%, which is similar to the result of . The accuracy selected by the other three engineers was 76.7%, 66% and 70%, respectively. Therefore, the comparative analysis results show that compared with the traditional method, the engineering parameters selected through the method proposed in this paper can be effectively used in the above cases, and improve the accuracy of engineering parameter selection. The application of the invention principle is often completed by constantly trying and selecting engineering parameters, which greatly depend on the professional knowledge and experience of the development team. The wrong selection of engineering parameters may not only lead to poor effect in the obtained scheme, but also lead to the failure of product development. Therefore, the selection of engineering parameters by using the mapping model will effectively enhance the efficiency of conflict solving.

For enterprises, non-domain experts and inexperienced designers can also use the proposed methods to avoid unnecessary waste of resources, time and cost. Twenty engineers have been trained in the proposed method at Yueqing Institute of Technological Innovation. These enterprise engineers mastered this method proficiently within 2 weeks and applied it to the innovation design process of the company’s products. According to their feedback, compared with before the application of the proposed method, 70% thought that the design cycle was shortened, 85% thought that the resource cost was saved, and 95% thought that more problems could be found and solved, which improved the product performance. The method proposed in this paper will further optimize the application process of the conflict matrix in TRIZ, provide systematic operation process for enterprises, and enhance the innovation ability and competitive market advantages of enterprises.

Compared with the traditional method, the advantages of the method proposed in this paper are as follows. On the one hand, the use of physical parameters can reduce the difficulty of directly abstracting conflict into engineering parameters, which helps designers to understand the process of conflict generation at a deeper level. On the other hand, the BP neural network is used to train the mapping relationship between physical parameters and engineering parameters, and a mapping model is constructed, which is convenient for designers to use to select engineering parameters and avoids the incorrect selection of engineering parameters to a certain extent. At the same time, the mapping model proposed in this paper will increase applicability to a variety of physical problems in the industry. Additionally, with the continuous increase in sample data and the optimization of relevant details, the accuracy and applicability of the mapping model will be further increased, thereby promoting the development of this method.

6. Conclusions

The support of systematic methods is the key to improving the efficiency of product innovation design, which can enhance the market competitiveness of enterprises. In this paper, a conflict solving process based on mapping between physical parameters and engineering parameters is proposed. Firstly, the physical parameter logic network of the system is constructed, and the conflict analysis is carried out from it. Then, a BP neural network is used to train the mapping model between physical parameters and engineering parameters, and the engineering parameters are selected through the mapping model. Finally, the conflict is solved by using TRIZ tools, and the final design scheme is obtained through evaluation. The effectiveness of the proposed method is verified by a case study. When the engineering parameter cannot be accurately obtained due to the coupling effect of multiple physical parameters, it can be selected through the mapping model proposed in the paper, which improves the problem of low accuracy in engineering parameter selection.

Despite the contribution of the proposed method, the limitations of this study are also evident. First, for some complex problems, it can’t extract physical parameters correctly through Python, where manual adjustment is required in this case. Second, the mapping relationship between physical parameters and engineering parameters is determined by the expert group, which has a certain degree of subjectivity. In that case, consistency analysis shall be conducted, and data where there are different opinions shall be modified. Third, limited by the number and sources of sample data, it is necessary to further collect sample data to improve the accuracy and applicability of the BP neural network. In the current case of a small amount of sample data, the results obtained by the mapping model cannot be guaranteed to be close to 100% correct. Therefore, the designer needs to choose whether to use the results obtained by mapping according to the actual problems. Fourth, although the designer can analyze and judge the system deterioration by constructing a physical parameter logical network, it requires a large amount of calculation for a complex system. A software platform is being developed to help designers construct it.

Meanwhile, these limitations indicate the direction of future research. First, the extraction rules of physical parameters should be further refined, and engineering parameters should be expanded and updated according to relevant research to increase applicability. Secondly, the proposed method should be applied to more cases, so a cloud services platform [48], which can collect data in real time, should be built. The data collected should be supplemented to the training data. Then, other machine or deep learning computing models with the adoption of GPUs should be considered to train the mapping model on the cloud, hence reducing the time for computation and the sharing of results. Finally, the introduction of digital twins to dynamically reason about the impact of changes in relevant parameters on the system is planned. We hope to make the proposed method more general by improving these details described in the paper.

Author Contributions

Conceptualization, P.Z. and Q.M.; project administration, P.Z.; resources, P.Z.; supervision, Z.N. and P.Z.; writing-review and editing, Q.M. and X.L.; writing-original draft, Q.M., X.L. and Z.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant 51975181) and National innovation method work special project of China (Grant 2020IM020500).

Data Availability Statement

The data discussed in the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

There is no conflict of interest that exists in the submission of this manuscript, and the manuscript has been approved by all authors for publication.

Appendix A

Figure A1.

Training results of category () mapping model between physical parameters and engineering parameters.

Figure A2.

Training results of sequence () mapping model between physical parameters and various engineering parameters.

Appendix B

Table A1.

Evaluation results of service performance.

Table A1.

Evaluation results of service performance.

| Scheme | Project Indicator Layer | E1 | E2 | E3 | E4 | E5 |

|---|---|---|---|---|---|---|

| S1 | Dispensing efficiency | 4 | 5 | 5 | 6 | 4 |

| Automatic control | 6 | 5 | 6 | 6 | 6 | |

| Dispensing error | 4 | 6 | 5 | 5 | 4 | |

| S2 | Dispensing efficiency | 6 | 6 | 7 | 6 | 4 |

| Automatic control | 7 | 5 | 7 | 5 | 5 | |

| Dispensing error | 6 | 7 | 6 | 6 | 5 |

Table A2.

Evaluation results of economic performance.

Table A2.

Evaluation results of economic performance.

| Scheme | Project Indicator Layer | E1 | E2 | E3 | E4 | E5 |

|---|---|---|---|---|---|---|

| S1 | Design cost | 7 | 6 | 6 | 5 | 6 |

| Production cost | 6 | 5 | 4 | 5 | 4 | |

| Maintenance cost | 5 | 6 | 5 | 5 | 6 | |

| S2 | Design cost | 5 | 4 | 5 | 6 | 5 |

| Production cost | 5 | 4 | 6 | 5 | 5 | |

| Maintenance cost | 4 | 5 | 4 | 6 | 5 |

Table A3.

Evaluation results of green performance.

Table A3.

Evaluation results of green performance.

| Scheme | Project Indicator Layer | E1 | E2 | E3 | E4 | E5 |

|---|---|---|---|---|---|---|

| S1 | Environmental protection | 5 | 6 | 7 | 5 | 5 |

| Vibration and noise | 5 | 4 | 5 | 5 | 4 | |

| Energy saving | 6 | 5 | 4 | 4 | 5 | |

| S2 | Environmental protection | 7 | 8 | 6 | 7 | 8 |

| Vibration and noise | 8 | 6 | 7 | 6 | 7 | |

| Energy saving | 7 | 5 | 6 | 5 | 6 |

References

- Zhang, P.; Chen, S.H.; Zhao, B.Y.; Nie, Z.F. Research on Decision Making of Design for Coupling System Based on Complexity Composite. Processes 2022, 10, 542. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, C.L.; Ren, G.C. A fast solution method for single-objective problems based on TRIZ conflict matrix. J. Shanxi Univ. Sci. Technol. 2013, 31, 140–144. (In Chinese) [Google Scholar] [CrossRef]

- Tan, R.H. TRIZ and Applications, 1st ed.; Higher Education Press: Beijing, China, 2010; pp. 209–211. [Google Scholar]

- Zhang, H.G. Innovative Design: Systematic Innovation Based on TRIZ, 1st ed.; Machinery Industry Press: Beijing, China, 2017; pp. 85–114. [Google Scholar]

- Coelho, D.A. Matching TRIZ engineering parameters to human factors issues in manufacturing. Wseas Trans. Bus. Econ. 2009, 6, 547–556. [Google Scholar]

- Feng, H. Research on Design-Centric Complexity Synthesis and Evolution Mechanism Driven by Digital Twin Data. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2020. [Google Scholar]

- Liu, W.; Cao, G.Z.; Tan, R.H.; Li, M.L. Variant design based on product gene and physical expression. Comput. Integr. Manuf. Syst. 2015, 21, 381–391. (In Chinese) [Google Scholar] [CrossRef]

- Cao, Y.X.; Zhao, J.; Qu, X.T.; Wang, X.; Liu, B.W. Prediction of Abrasive Belt Wear Based on BP Neural Network. Machines 2021, 9, 314. [Google Scholar] [CrossRef]

- Montecchi, T.; Russo, D. Knowledge based approach for formulating TRIZ contradictions. Procedia. Eng. 2015, 131, 451–463. [Google Scholar] [CrossRef] [Green Version]

- Rousselot, F.; Zanni-Merk, C.; Cavallucci, D. Towards a formal definition of contradiction in inventive design. Comput. Ind. 2012, 63, 231–242. [Google Scholar] [CrossRef]

- Nikolić, V.; Sajjadi, S.; Petković, D.; Shamshirband, S.; Ćojbašić, Ž.; Por, L.Y. Design and state of art of innovative wind turbine systems. Renew. Sust. Energ. Rev. 2016, 61, 258–265. [Google Scholar] [CrossRef]

- Chen, J.; Li, X.; Yang, H.; Wang, C. Innovative Design of a Vertical and Transverse Elevator in Double Shafts, Based on TRIZ Theory. J. Mech. Eng. 2019, 65, 297–310. [Google Scholar] [CrossRef]

- Almeida, S.T.; Mo, J.; Bil, C.; Ding, S.L.; Wang, X.Z. Conceptual Design of a High-Speed Wire EDM Robotic End-Effector Based on a Systematic Review Followed by TRIZ. Machines 2021, 9, 132. [Google Scholar] [CrossRef]

- Pokhrel, C.; Cruz, C.; Ramirez, Y.; Kraslawski, A. Adaptation of TRIZ contradiction matrix for solving problems in process engineering. Chem. Eng. Res. Des. 2015, 103, 3–10. [Google Scholar] [CrossRef]

- Zhai, D.; Li, M.; Cai, W. TRIZ technical contradiction extraction method based on patent semantic space mapping. In Proceedings of the 2020 11th International Conference on E-business, Management and Economics, Beijing, China, 15–17 July 2020; pp. 125–130. [Google Scholar] [CrossRef]

- Huang, B.D.; Zhou, L.S.; An, L.L.; Wei, W.; Bu, Q.K. Axiomatic design of TRIZ-integrated machining fixture scheme. Chin. J. Sci. Instrum. 2017, 38, 1031–1040. (In Chinese) [Google Scholar] [CrossRef]

- Rajic, D. Compatibility between TRIZ-contradiction matrix and LT-unit system. FME. Trans. 2020, 48, 460–467. [Google Scholar] [CrossRef]

- Rajic, D. LT-contradiction matrix. FME. Trans. 2021, 49, 95–102. [Google Scholar] [CrossRef]

- Cherifi, A.; Dubois, M.; Gardoni, M. Methodology for innovative eco-design based on TRIZ. Int. J. Interact. Des. Manuf. (IJIDeM) 2015, 9, 167–175. [Google Scholar] [CrossRef]

- Livotov, P.; Sekaran, A.P.C.; Law, R.; Reay, D.; Sarsenova, A.; Sayyareh, S. Eco-innovation in process engineering: Contradictions, inventive principles and methods. Therm. Sci. Eng. Prog. 2019, 9, 52–65. [Google Scholar] [CrossRef] [Green Version]

- Boavida, R.; Navas, H.; Godina, R.; Carvalho, H.; Hasegawa, H. A combined use of TRIZ methodology and eco-compass tool as a sustainable innovation model. Appl. Sci. 2020, 10, 3535. [Google Scholar] [CrossRef]

- Shieh, M.; Yan, W.; Chen, C. Soliciting customer requirements for product redesign based on picture sorts and ART2 neural network. Expert. Syst. Appl. 2008, 34, 194–204. [Google Scholar] [CrossRef]

- Quan, H.; Li, S.; Hu, J. Product innovation design based on deep learning and Kansei engineering. Appl. Sci. 2018, 8, 2397. [Google Scholar] [CrossRef] [Green Version]

- Lin, M.; Qiu, G.; Zhou, X.H.; Chen, C.N. Using Taguchi and neural network approaches in the optimum design of product development process. Int. J. Comput. Integr. Manuf. 2020, 33, 343–359. [Google Scholar] [CrossRef]

- Kang, X. Combining grey relationship analysis and neural network to develop attractive automobile booth design. Comput. Intel. Neurosci. 2020, 2020, 8863727. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Tan, R.; Peng, Q.; Wang, F.; Shao, P.; Gao, Z. A holistic method of complex product development based on a neural network-aided technological evolution system. Adv. Eng. Inform. 2021, 48, 101294. [Google Scholar] [CrossRef]

- Ding, S.; Su, C.; Yu, J. An optimizing BP neural network algorithm based on genetic algorithm. Artif. Intel. Rev. 2011, 36, 153–162. [Google Scholar] [CrossRef]

- Patsnap. Available online: https://www.zhihuiya.com (accessed on 5 September 2021).

- China Association for Science and Technology Enterprise Innovation Service Center. Front Line Engineer—Application Case of Innovative Methods, 1st ed.; Machinery Industry Press: Beijing, China, 2017; pp. 3–379. [Google Scholar]

- Pan, C.Y. TRIZ Practice: Mechanical Innovative Design Method and Example, 1st ed.; Chemical Industry Press: Beijing, China, 2019; pp. 204–270. [Google Scholar]

- Wu, C.; Zhou, Y.; Pessôa, M.V.P.; Peng, Q.; Tan, R. Conceptual digital twin modeling based on an integrated five-dimensional framework and TRIZ function model. J. Manuf. Syst. 2021, 58, 79–93. [Google Scholar] [CrossRef]

- Liu, X.M.; Tian, S.L.; Wang, Z.W. Defining method research of technological conflict based on improved current reality tree. Comput. Integr. Manuf. Syst. 2013, 19, 6. (In Chinese) [Google Scholar] [CrossRef]

- Madic, M.; Petrovic, D.; Petkovic, D.; Antucheviciene, J.; Marinkovic, D. Application of a Robust Decision-Making Rule for Comprehensive Assessment of Laser Cutting Conditions and Performance. Machines 2022, 10, 153. [Google Scholar] [CrossRef]

- Wang, K.; Tan, R.; Peng, Q.; Sun, Y.; Li, H.; Sun, J. Radical innovation of product design using an effect solving method. Comput. Ind. Eng. 2021, 151, 106970. [Google Scholar] [CrossRef]

- Zhang, P.; Nie, Z.; Dong, Y.; Zhang, Z.; Yu, F.; Tan, R. Smart concept design based on recessive inheritance in complex electromechanical system. Adv. Eng. Inform. 2020, 43, 101010. [Google Scholar] [CrossRef]

- Bushuev, A. Physico-mathematical resources search. TRIZ J. 2008, 7, 1–13. [Google Scholar]

- Rajic, D. Eco-innovative matrix based on TRIZ standards. In Proceedings of the 2018 International Thematic Monograph—Thematic Proceedings, Belgrade, Serbia, 6 December 2018; pp. 154–171. [Google Scholar]

- Liu, Q.Y.; Zha, Y.W.; Liu, T.; Lu, C. Research on Adaptive Control of Air-Borne Bolting Rigs Based on Genetic Algorithm Optimization. Machines 2021, 9, 240. [Google Scholar] [CrossRef]

- Smith, J.S.; Wu, B.; Wilamowski, B.M. Neural network training with Levenberg—Marquardt and adaptable weight compression. IEEE Trans. Neural Netw. Learn. Syst. 2018, 30, 580–587. [Google Scholar] [CrossRef] [PubMed]

- Han, B. Research on the application of the integrity law of technical system in TRIZ theory. Technol. Mark. 2014, 21, 34–35. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, B.Y. Research on Parameter Evolution Mechanism Based on Digital Twin and DCC Theory. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2021. [Google Scholar]

- Shen, W.; Davis, T.; Lin, D.K.; Nachtsheim, C.J. Dimensional analysis and its applications in statistics. J. Qual. Technol. 2014, 46, 185–198. [Google Scholar] [CrossRef]

- Zhang, P.; Li, X.; Nie, Z.; Yu, F.; Liu, W. A Trimming Design Method Based on Bio-Inspired Design for System Innovation. Appl. Sci. 2021, 11, 4060. [Google Scholar] [CrossRef]

- Gao, S.R.; Tian, J.X.; Du, W.W.; Yuan, Q.J. Application of auto-dispensing pharmacy in outpatient pharmacy of TCM hospital. China Med. Her. 2014, 11, 60–64. (In Chinese) [Google Scholar]

- Effects Database. Available online: http://wbam2244.dns-systems.net//EDB_Welcome.php (accessed on 3 February 2022).

- Wen, B.C. Inspection and Evaluation of Mechanical Product Design Quality, 1st ed.; Machinery Industry Press: Beijing, China, 2010; pp. 147–148. [Google Scholar]

- Li, H.; Díaz, H.; Soares, C.G. A failure analysis of floating offshore wind turbines using AHP-FMEA methodology. Ocean. Eng. 2021, 234, 109261. [Google Scholar] [CrossRef]

- Constantini, A.; Duma, D.C.; Martelli, B.; Antonacci, M.; Galletti, M.; Tisbenim, S.R.; Bellavista, P.; Di Modica, G.; Nehls, D.; Ahouangonou, J.; et al. A Cloud-Edge Orchestration Platform for the Innocative Industrial Scenarios of the Iotwins Project. In Computational Science and Its Applications, Proceedings of the ICCSA 2021, 21st International Conference, Cagliari, Italy, 13–16 September 2021; Lecture Notes in Computer Science; Goos, G., Hartmanis, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 533–543. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).