Investigation into the Influence of Parallel Offset Wear on Stirling Engine Piston Rod Oil-Free Lubrication Seal

Abstract

1. Introduction

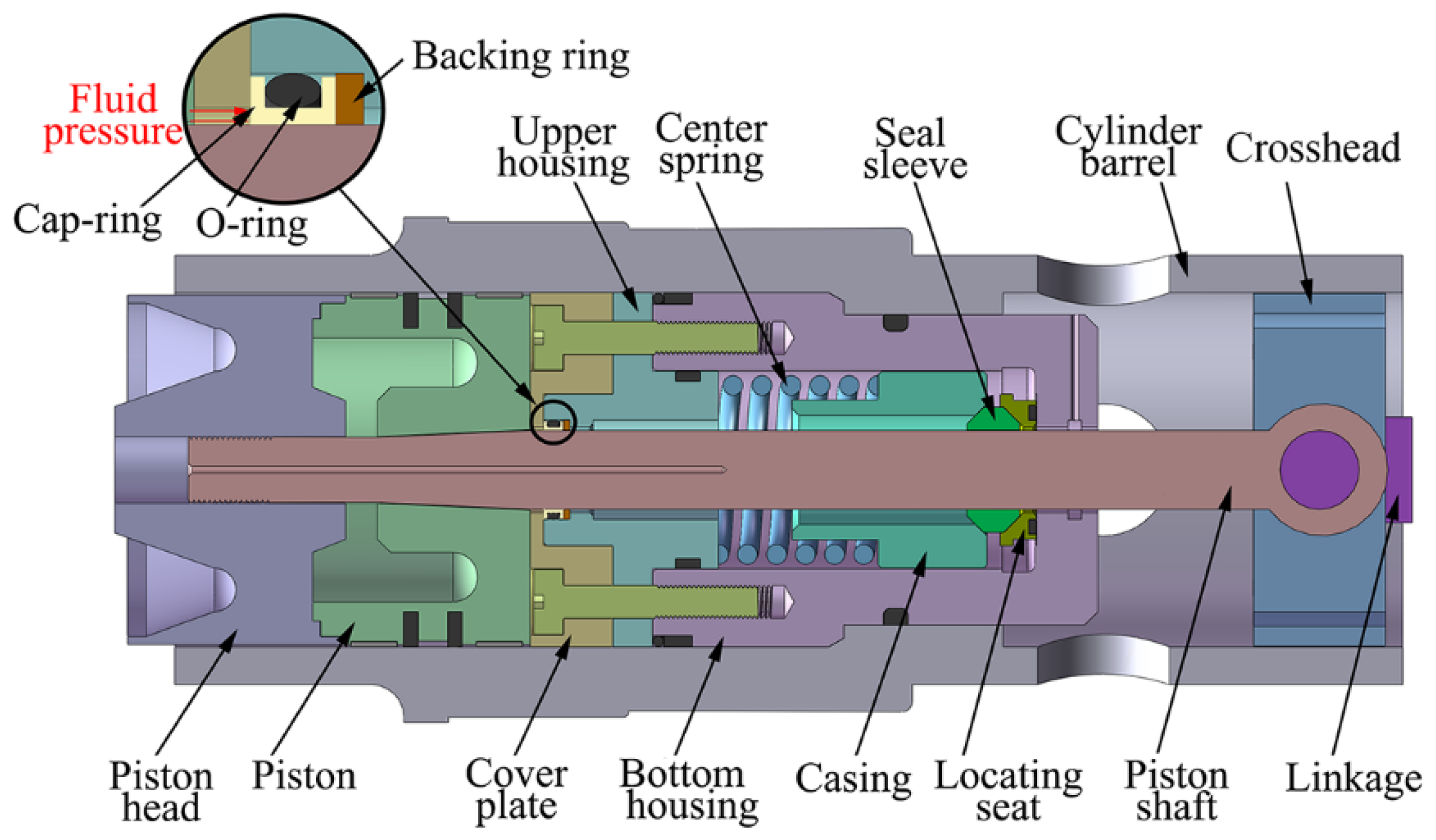

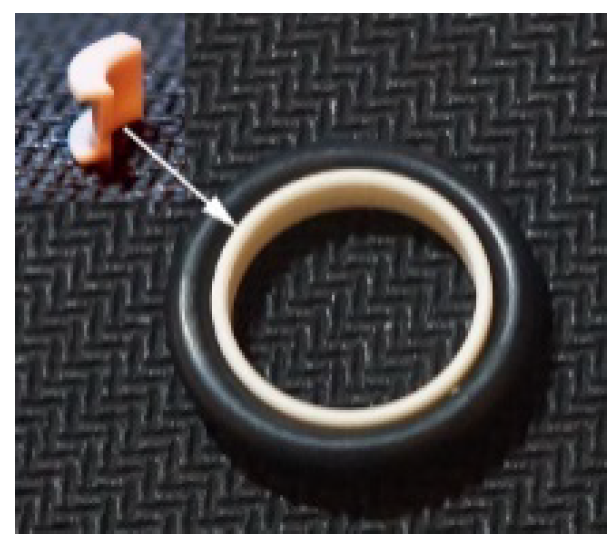

2. Sealing Description

3. Material and Method

3.1. Material Model

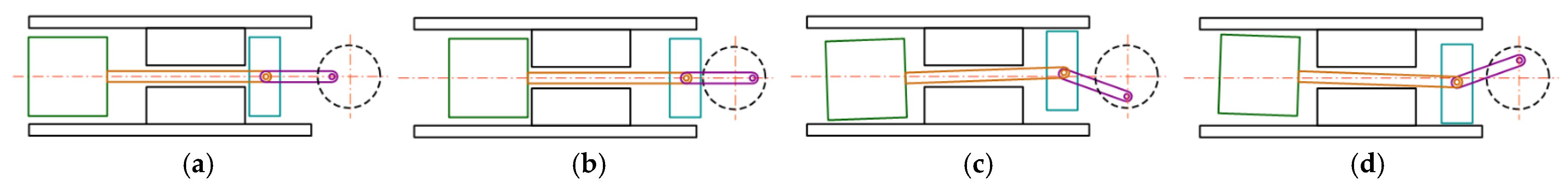

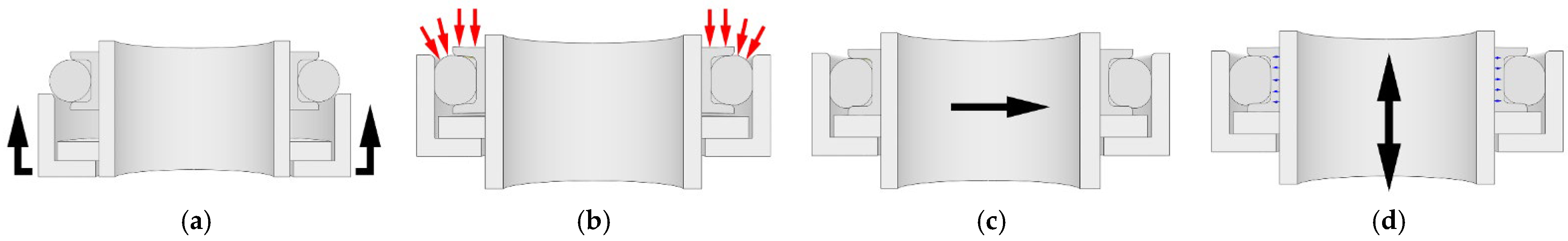

3.2. Parallel-Offset Analysis

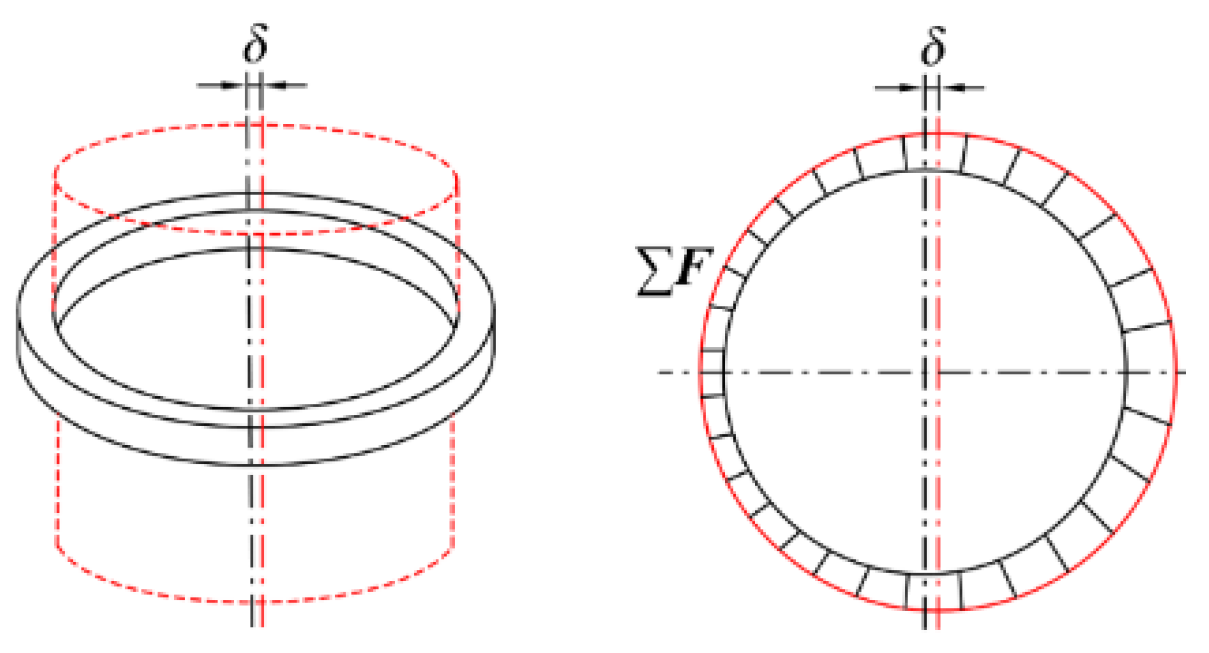

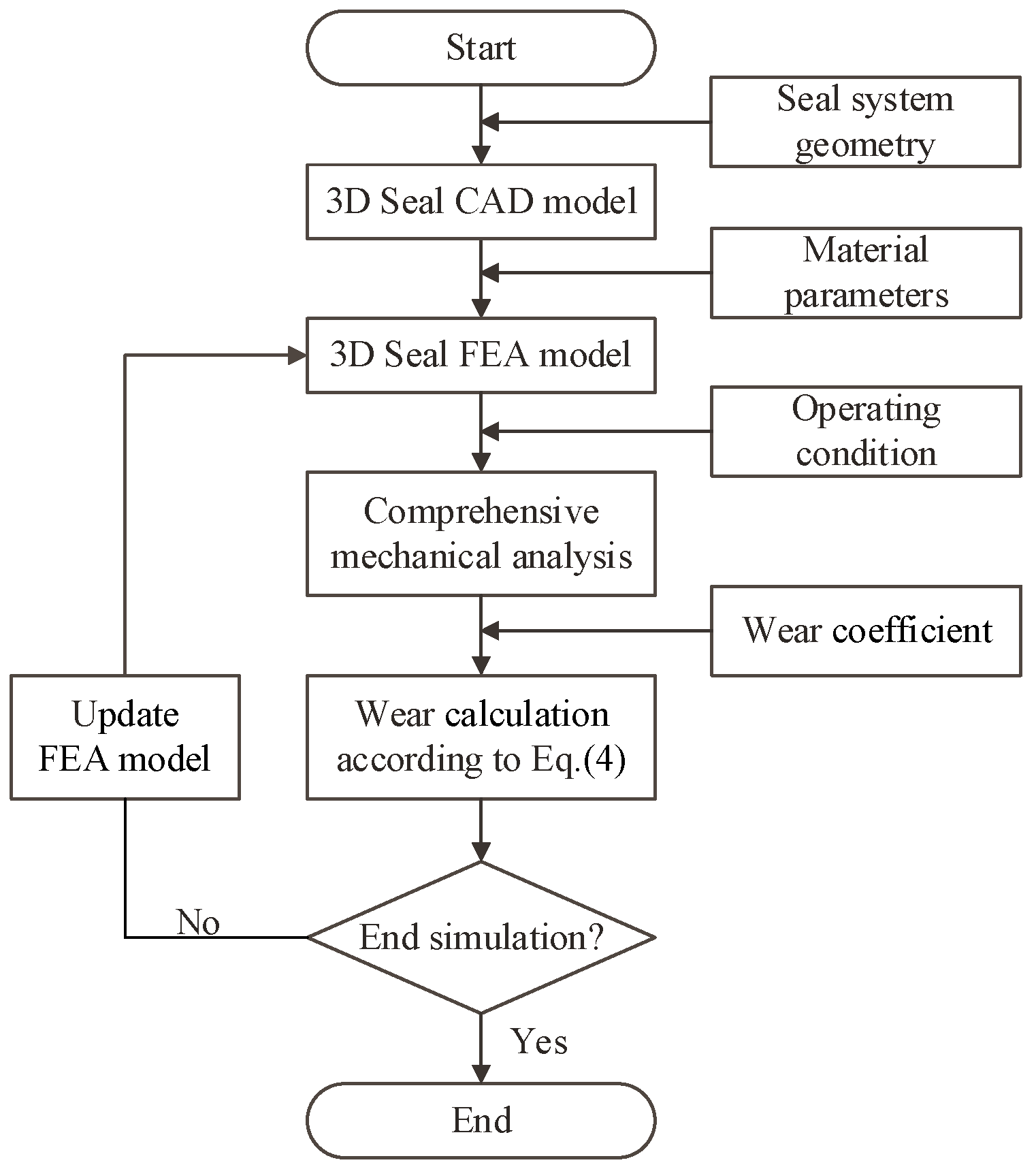

3.3. Wear Analysis

3.4. Numerical Model

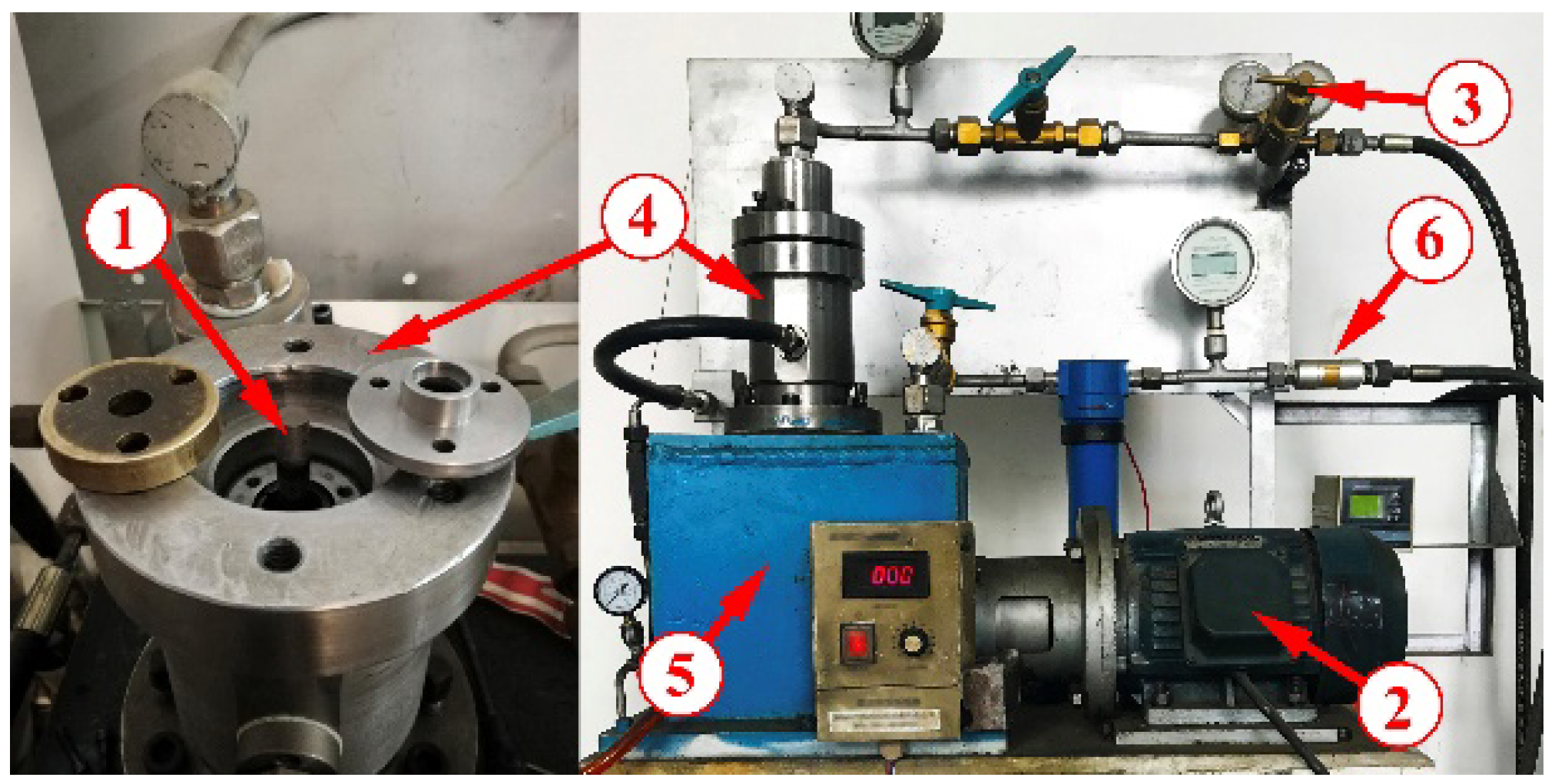

4. Experimental Measurements

5. Results and Discussion

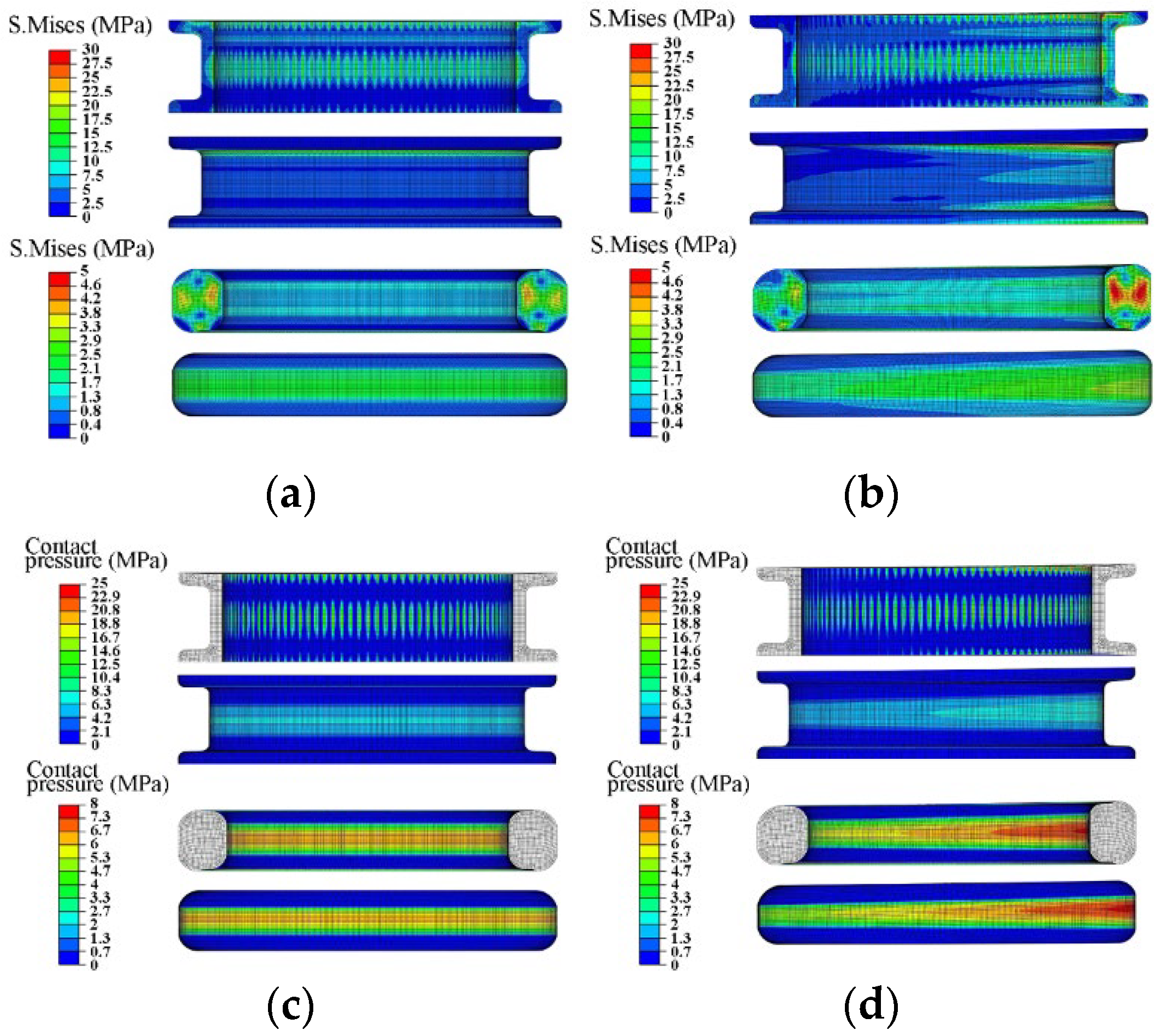

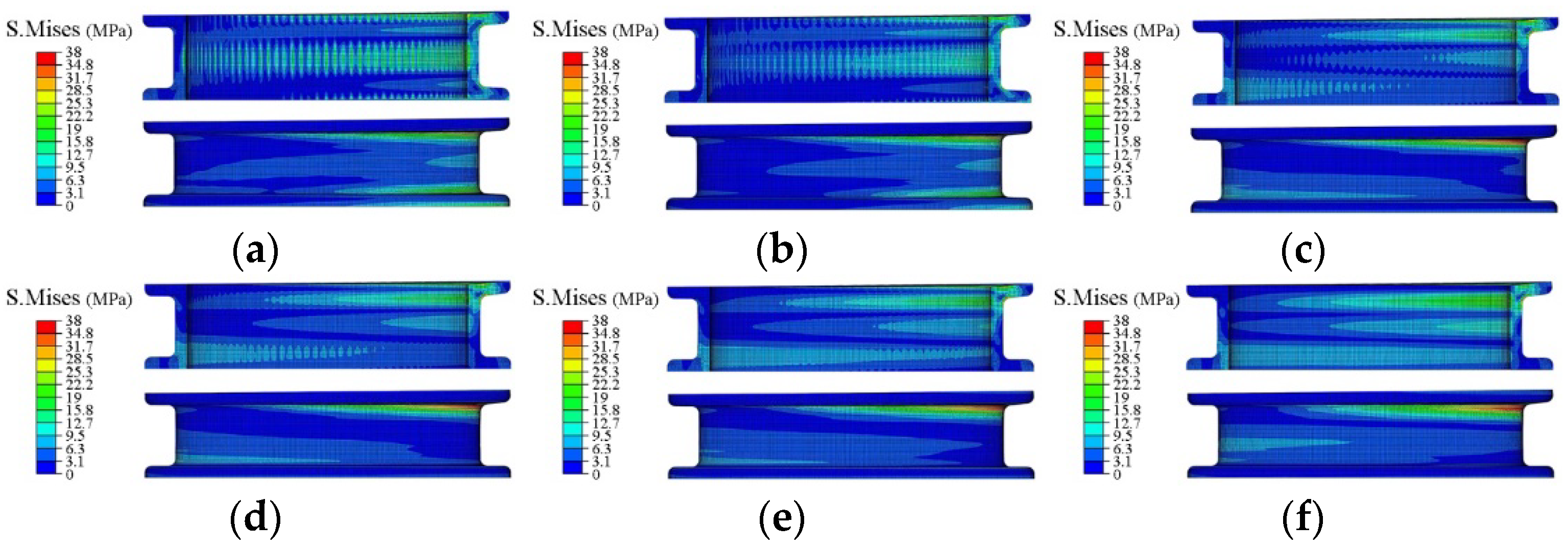

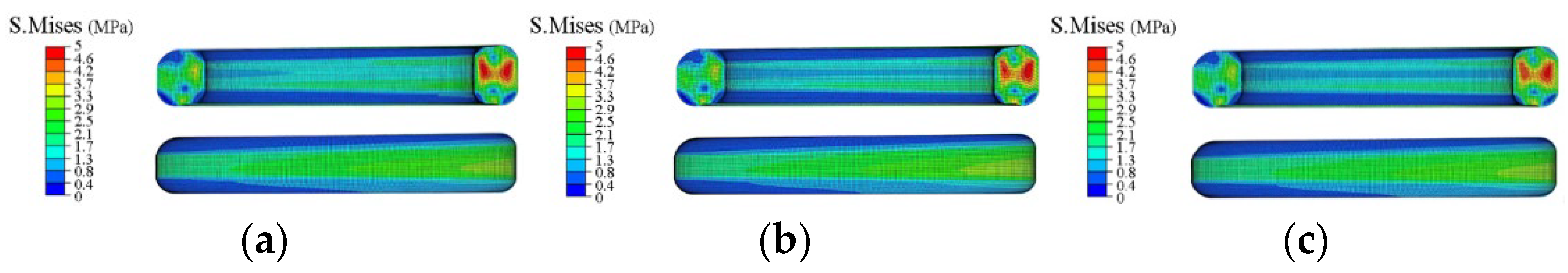

5.1. Initial State

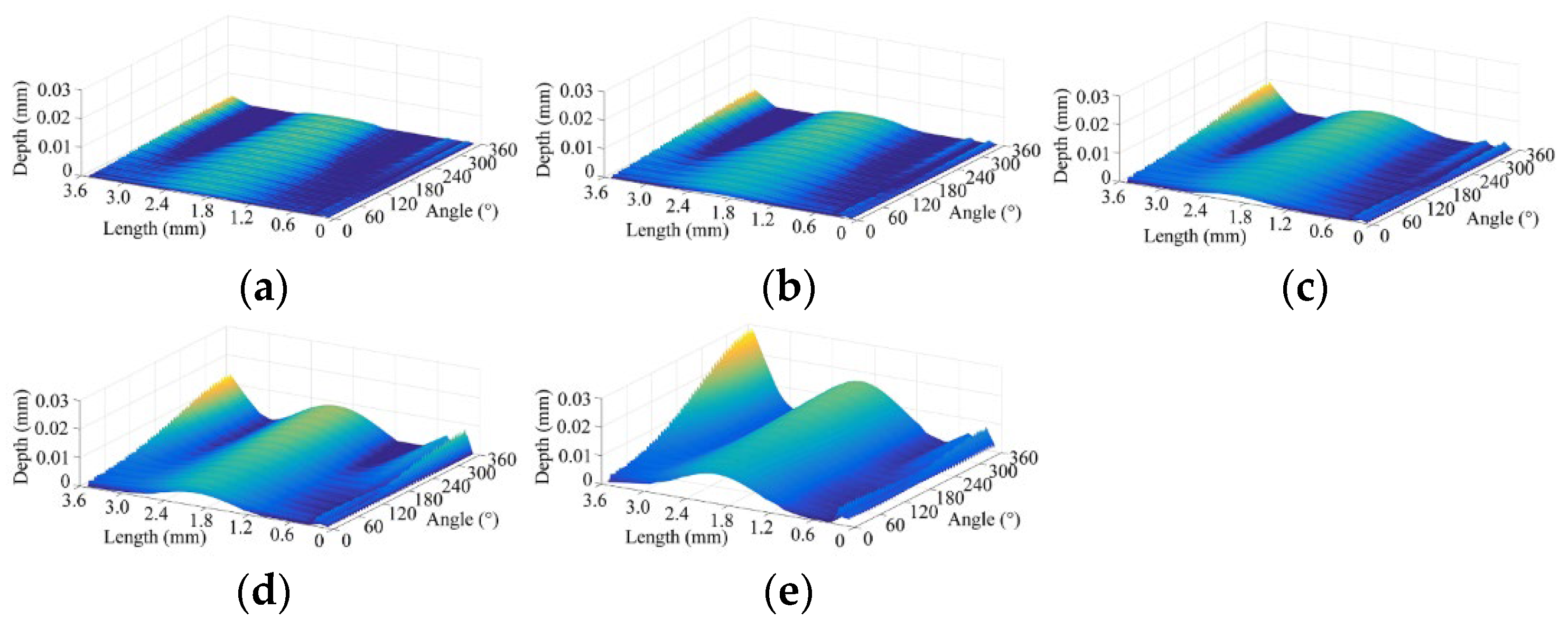

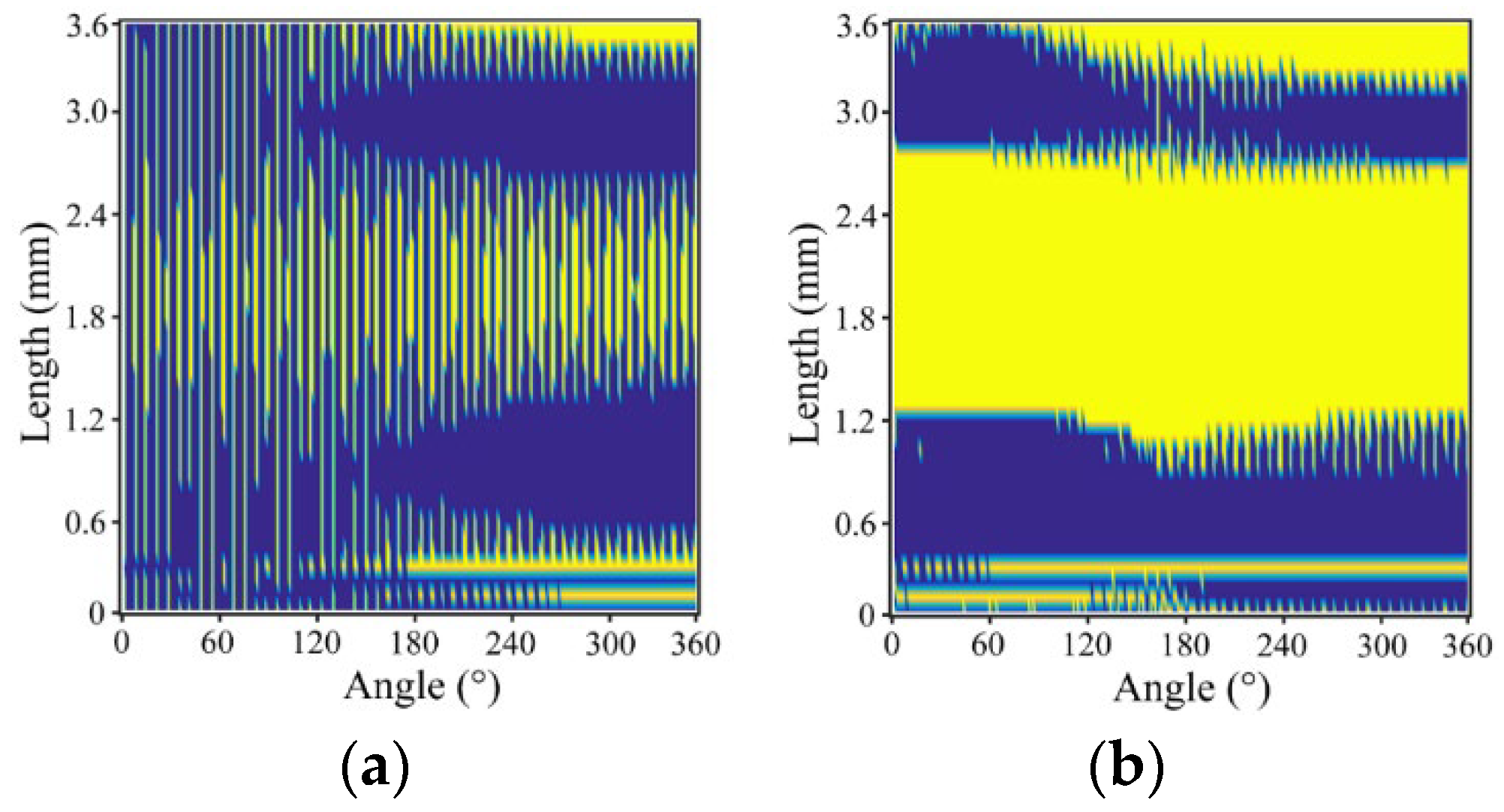

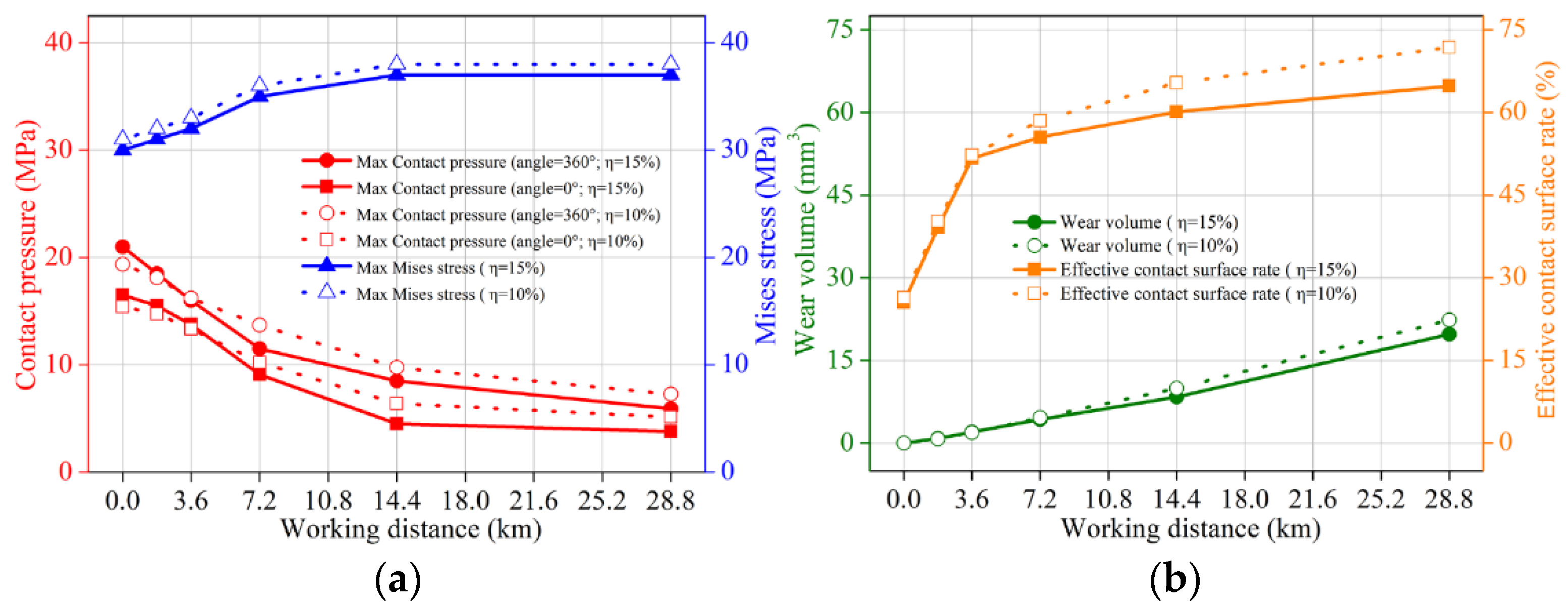

5.2. Wearing Process

5.3. Effects of the Working Conditions

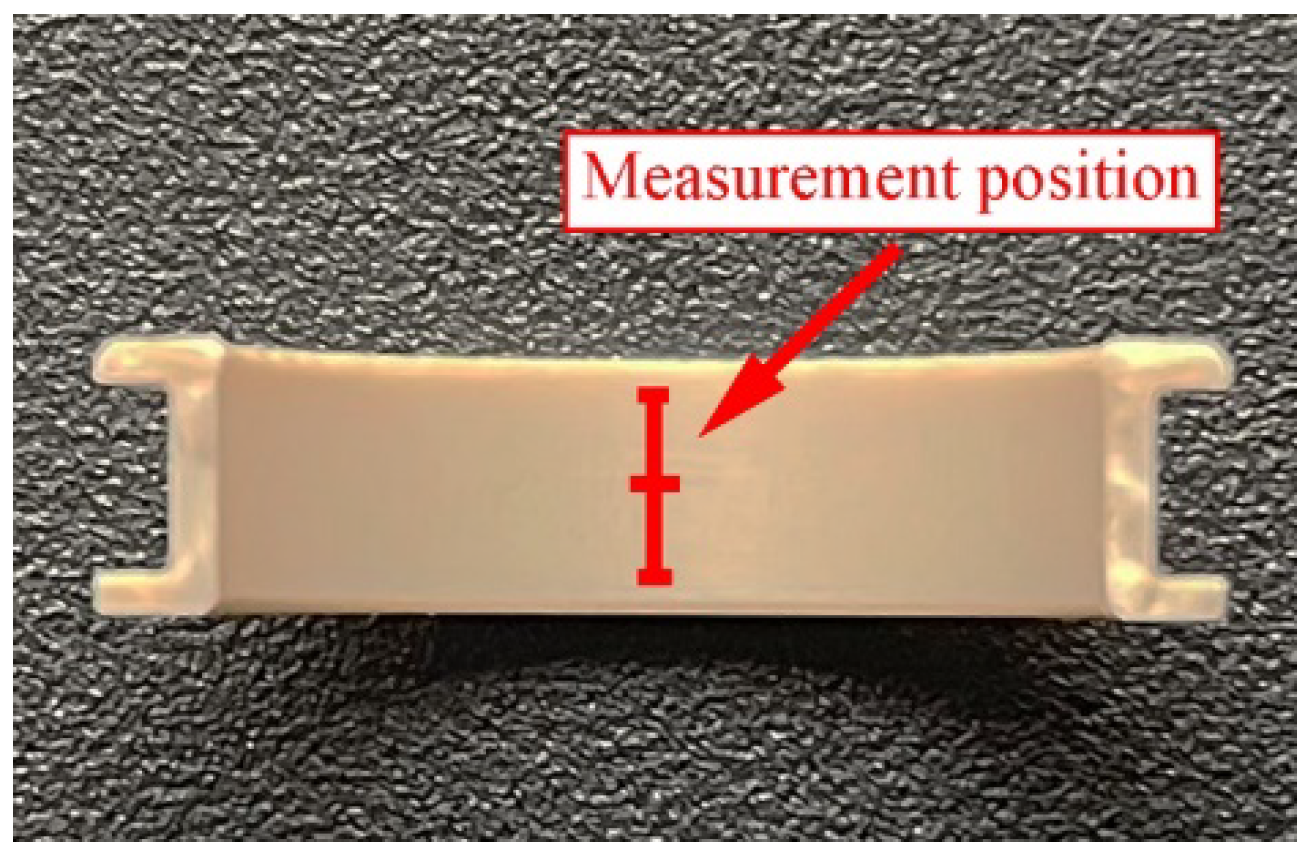

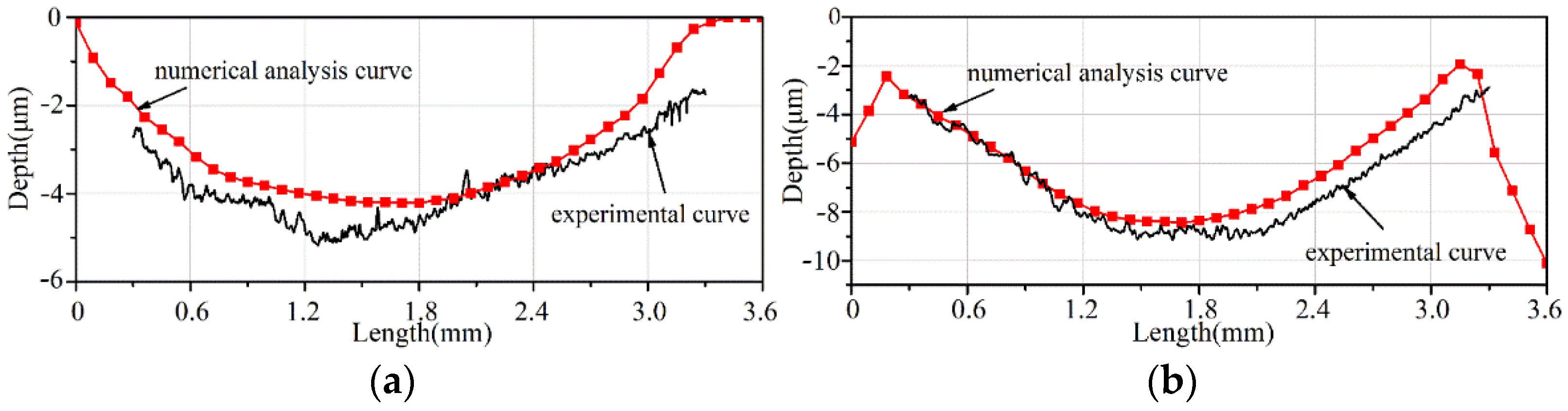

5.4. Experimental

6. Conclusions

- The offset of the piston rod will aggravate wear, which increases the possibility of seal damage under greater stress.

- The contact pressure is not obviously affected by the seal wear when the piston rod is offset, and the opposite side of the offset is more prone to leakage.

- Cap-seal shows good a sealing capability under high pressures and low pre-compression ratios, but it exhibits a higher propensity for mechanical damage.

- The result of the wear test is in good agreement with that of the numerical simulation, which verifies the correctness of the finite element analysis method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smith, P.J.; Keith JR, T.J. Simulation of an oil-pumping ring seal for a Stirling engine. Simulation 1980, 35, 49–60. [Google Scholar] [CrossRef]

- Mao, J.; Wang, W.; Liu, Y. Experimental and theoretical investigation on the sealing performance of the combined seals for reciprocating rod. J. Mech. Sci. Technol. 2012, 26, 1765–1772. [Google Scholar] [CrossRef]

- Frölich, D.; Magyar, B.; Sauer, B. A comprehensive model of wear, friction and contact temperature in radial shaft seals. Wear 2014, 311, 71–80. [Google Scholar] [CrossRef]

- Pinedo, B.; Aguirrebeitia, J.; Conte, M.; Igartua, A. Tri-dimensional eccentricity model of a rod lip seal. Tribol. Int. 2014, 78, 68–74. [Google Scholar] [CrossRef]

- Pinedo, B.; Conte, M.; Aguirrebeitia, J.; Igartua, A. Effect of misalignments on the tribological performance of elastomeric rod lip seals: Study methodology and case study. Tribol. Int. 2017, 116, 9–18. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, J. Investigation of static and dynamic seal performances of a rubber O-ring. J. Tribol. 2018, 140, 042202. [Google Scholar] [CrossRef]

- Hu, G.; Wang, G.; Dai, L.; Zhang, P.; Li, M.; Fu, Y. Sealing failure analysis on V-shaped sealing rings of an inserted sealing tool used for multistage fracturing processes. Energies 2018, 11, 1432. [Google Scholar] [CrossRef]

- Belforte, G.; Conte, M.; Bertetto, A.M.; Mazza, L.; Raparelli, T.; Viscontea, C. Indirect contact pressure evaluation on pneumatic rod seals. Tribol. Int. 2018, 118, 240–245. [Google Scholar] [CrossRef]

- Gong, R.; Wang, H.; Zhang, H.; Xu, L. Influence of wear on hot banding migration of sealing ring using FEM. Wear 2019, 428, 449–456. [Google Scholar] [CrossRef]

- Yakovlev, N. An experimental study of the wear of the radial shaft seals of rotary shafts. J. Mach. Manuf. Reliab. 2019, 48, 179–183. [Google Scholar] [CrossRef]

- Zhou, C.; He, M.; Chen, G.; Jiang, S. Numerical study on sealing characteristic of rubber X-ring exposed to high-pressure hydrogen by considering swelling effect. Ind. Lubr. Tribol. 2019, 71, 133–138. [Google Scholar] [CrossRef]

- Azzi, A.; Maoui, A.; Fatu, A.; Fily, S.; Souchet, D. Experimental study of friction in pneumatic seals. Tribol. Int. 2019, 135, 432–443. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, D.; Pang, H.; Liu, U.; Wei, W.; Li, R. Extrusion-occlusion dynamic failure analysis of O-ring based on floating bush of water hydraulic pump. Eng. Fail. Anal. 2020, 109, 104358. [Google Scholar] [CrossRef]

- Sang, Y.; Wang, X.; Sun, W.; Liu, P. Numerical and experimental study on the friction of O ring for hydraulic seals. Aust. J. Mech. Eng. 2021, 19, 328–340. [Google Scholar] [CrossRef]

- Luo, H.; Wu, J.; Teng, F.; Su, B.; Li, H.; Lin, A.; Li, Z.; Wang, Y. Multiscale simulation on dynamic friction behavior of cylinder sealing rings under hydrothermal aging. J. Appl. Polym. Sci. 2021, 138, 50453. [Google Scholar] [CrossRef]

- Kaushal, N.; Patri, S.; Kumar, R.S.; Meikandamurthy, C.; Sreedhar, B.K.; Murugan, S.; Raghupathy, S. Characterising the dynamic seals used in absorber rod drive mechanisms in Indian FBR. Nucl. Eng. Technol. 2021, 53, 3438–3448. [Google Scholar] [CrossRef]

- Burris, D.L.; Boesl, B.; Bourne, G.R.; Sawyer, W.G. Polymeric nanocomposites for tribological applications. Macromol. Mater. Eng. 2007, 292, 387–402. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Tadokoro, C.; Yoshii, Y.; Hattori, H.; Nishina, D. Friction and Wear Properties of PTFE Sliding Seals-Influence of Surface Conditions of Seal Gland on Friction Properties. Tribol. Online 2010, 5, 266–270. [Google Scholar] [CrossRef][Green Version]

- Hu, Y.; Yan, W.; Wen, H.; Wen, C. Design and Analysis on a Kind of Oblique-Cone-Slid-Ring Assembly Seal Device with Self-Compensation to Seal Wear in Carbide Actor. Appl. Mech. Mater. 2011, 43, 247–252. [Google Scholar]

- Cao, W.; Gong, J.; Yang, D.; Gao, G.; Wang, H.; Ren, J.; Chen, S. Tribological behavior and energy dissipation characteristics of nano-Al2O3-reinforced PTFE-PPS composites in sliding system. J. Cent. South Univ. 2017, 24, 2001–2009. [Google Scholar] [CrossRef]

- Qi, Y.; Gong, J.; Cao, W.; Wang, H.; Ren, J.; Gao, G. Tribological behaviour of PTFE composites filled with PEEK and Nano-Al2O3. Tribol. Trans. 2018, 61, 694–704. [Google Scholar]

- Huang, R.; Ma, S.; Zhang, M.; Yang, J.; Wang, D.; Zhang, L.; Xu, J. Wear evolution of the glass fiber-reinforced PTFE under dry sliding and elevated temperature. Materials 2019, 12, 1082. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Gong, J.; Qi, Y.; Ren, J.; Wang, H.; Yang, D.; Chen, S. Tribological behavior of PTFE composites filled with PEEK and nano-ZrO2. Tribol. Trans. 2020, 63, 296–304. [Google Scholar] [CrossRef]

- Shen, M.; Li, B.; Zhang, Z.; Zhao, L.; Xiong, G. Abrasive wear behavior of PTFE for seal applications under abrasive-atmosphere sliding condition. Friction 2020, 8, 755–767. [Google Scholar] [CrossRef]

- Cao, W.; Gong, J.; Qi, Y.; Yang, D.; Gao, G.; Wang, H.; Ren, J.; Chen, S. Tribological Behavior of Nano-ZrO2 Reinforced PTFE-PPS Composites. J. Wuhan Univ. Technol. 2019, 34, 527–533. [Google Scholar] [CrossRef]

- Yeoh, O.H. Some forms of the strain energy function for rubber. Rubber Chem. Technol. 1993, 66, 754–771. [Google Scholar] [CrossRef]

- Peng, C.; Guo, S.; Ouyang, X.; Yang, H. An eccentric 3-D fluid-structure interaction model for investigating the effects of rod parallel offset on reciprocating-seal performance. Tribol. Int. 2018, 128, 279–290. [Google Scholar] [CrossRef]

- Sui, H.; Pohl, H.; Schomburg, U.; Upper, G.; Heine, S. Wear and friction of PTFE seals. Wear 1999, 224, 175–182. [Google Scholar] [CrossRef]

- Söderberg, A.; Andersson, S. Simulation of wear and contact pressure distribution at the pad-to-rotor interface in a disc brake using general purpose finite element analysis software. Wear 2009, 267, 2243–2251. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, W.; Chang, Z.; Zhou, A.; Dou, X.; Gao, G.; Gong, J. Investigation into the Influence of Parallel Offset Wear on Stirling Engine Piston Rod Oil-Free Lubrication Seal. Machines 2022, 10, 350. https://doi.org/10.3390/machines10050350

Cao W, Chang Z, Zhou A, Dou X, Gao G, Gong J. Investigation into the Influence of Parallel Offset Wear on Stirling Engine Piston Rod Oil-Free Lubrication Seal. Machines. 2022; 10(5):350. https://doi.org/10.3390/machines10050350

Chicago/Turabian StyleCao, Wenhan, Zhou Chang, Ao Zhou, Xuqiang Dou, Gui Gao, and Jun Gong. 2022. "Investigation into the Influence of Parallel Offset Wear on Stirling Engine Piston Rod Oil-Free Lubrication Seal" Machines 10, no. 5: 350. https://doi.org/10.3390/machines10050350

APA StyleCao, W., Chang, Z., Zhou, A., Dou, X., Gao, G., & Gong, J. (2022). Investigation into the Influence of Parallel Offset Wear on Stirling Engine Piston Rod Oil-Free Lubrication Seal. Machines, 10(5), 350. https://doi.org/10.3390/machines10050350