Properties of Cutting Tool Composite Material Diamond–(Fe–Ni–Cu–Sn) Reinforced with Nano-VN

Abstract

1. Introduction

- appearance of a liquid phase at a relatively low temperature during sintering in the Cu–Sn system, which contributes to preserving the strength of diamond bits;

- the ability of metal matrix components to undergo cold pressing, which makes it possible to form tools of different shapes and expand the limits of their applications;

- the low cost of metal matrix components;

- the absence of toxic cobalt, and ability to improve environmental conditions.

2. Materials and Methods

2.1. Sample Preparation

2.2. Microstructure and Micromechanical Characteristics

2.3. Initial Cutting Tests

3. Results and Discussion

3.1. Morphology of Initial Powders

3.2. Microstructure of Sintered CDM Samples

3.3. Effect of Nano-VN Additive on Mechanical Properties on Fe–Ni–Cu–Sn System

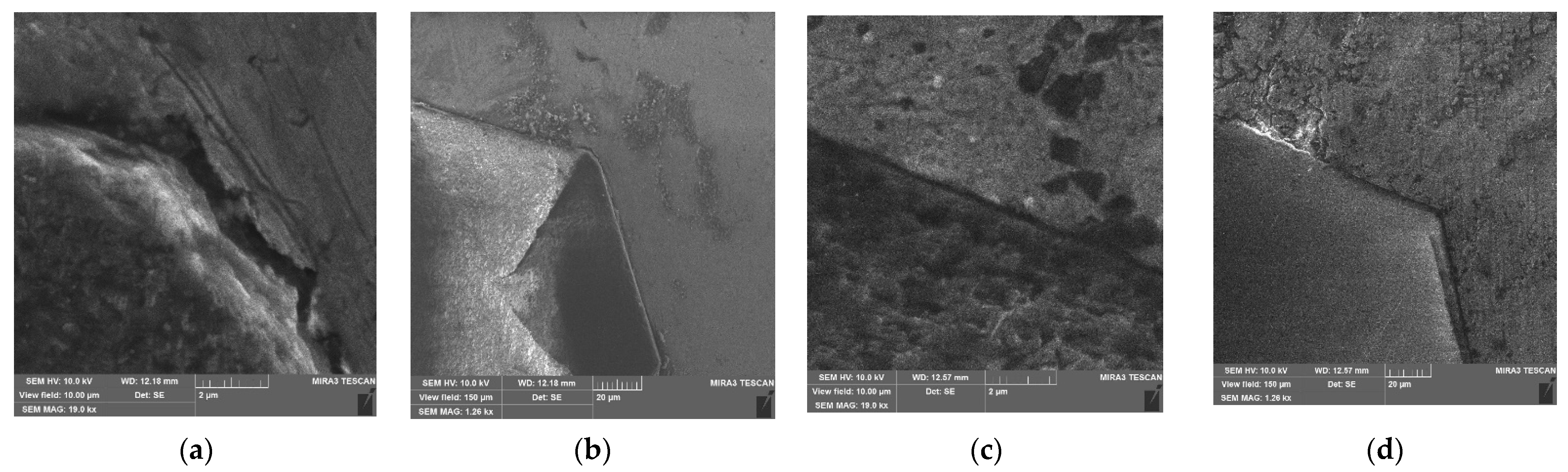

3.4. Fractography and Failure Analysis

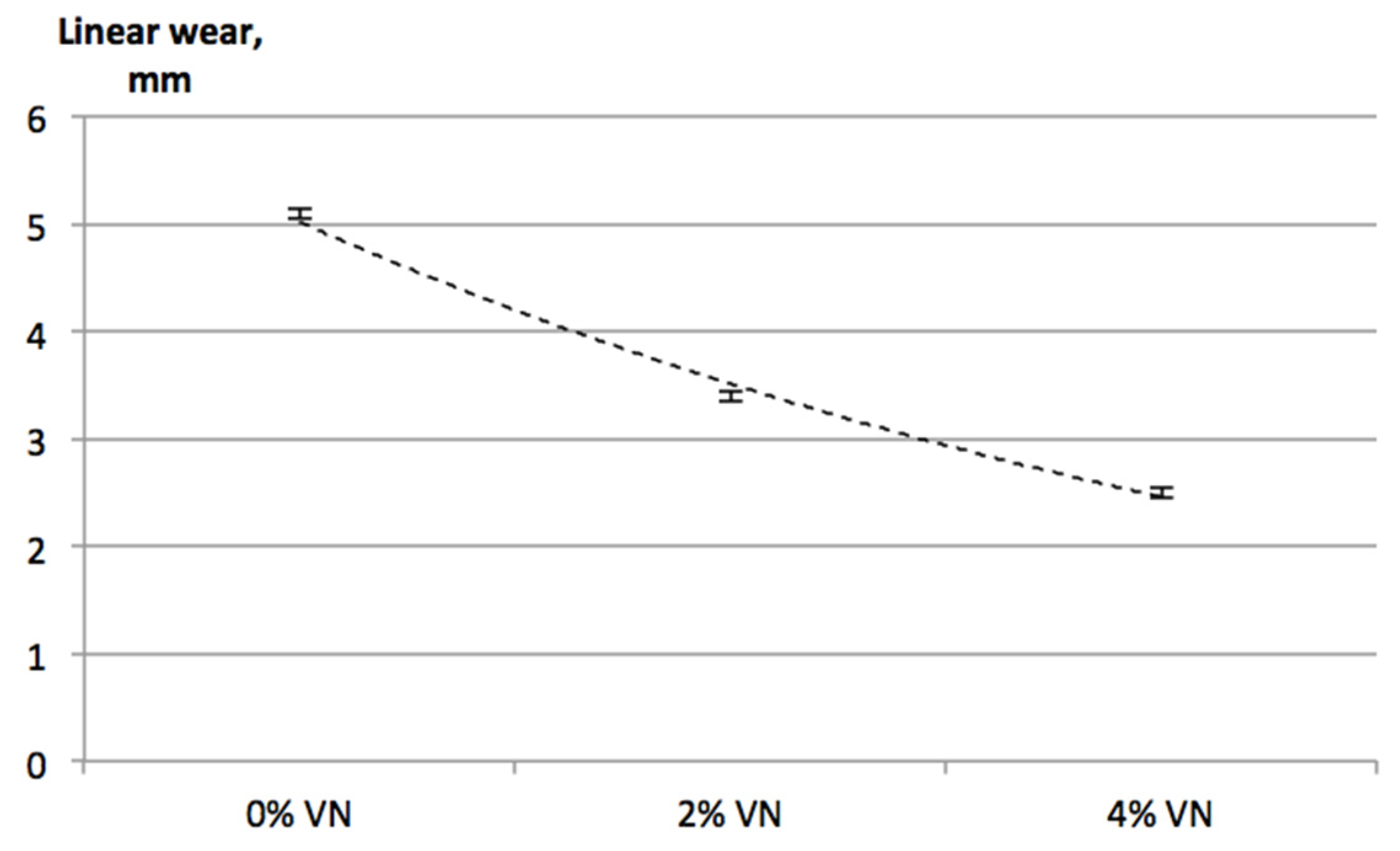

3.5. Results of Initial Cutting Tests

- cutting depth for a single cut 0.10 m;

- longitudinal feeding speed 3 m/min;

- cutting speed 30 m/s;

- the coolant was the technical water of amounts 20 L/min;

- the volume of the cut granite corresponded with 10 m2 of the cut surface.

- energy and time-saving electroconsolidation technology used for samples fabrication;

- at least 30% increased lifetime of the diamond cutting discs when cutting hard, abrasive rocks.

4. Conclusions

- The diamond composites based on 51Fe–32Cu–9Ni–8Sn metal matrix with no VN reinforcement consisted of diamond grains and FCC of solid solutions containing iron, copper, nickel, and tin in different ratios. Some gaps and discontinuities were observed in the area of a diamond–matrix interface, and pores were found in the matrix.

- Addition of nano-VN resulted in the formation of a finer-grained structure of the composites. They consisted of solid solutions incorporating iron, copper, nickel, vanadium, and tin in varying ratios. The formation of a tight diamond–matrix contact with no visible gaps, discontinuities, or other defects was observed. On the surface of diamond grains, metal overflows of Fe, Ni, V, Cu, and Sn were found.

- Considering non-linear variations of the parameters, some sort of optimization can be considered in respect of nano-VN proportion. The maximum values of nanohardness H = 7.8 GPa, elastic modulus E = 213 GPa, ratio H/E = 0.0366, and index H3/E2 = 10.46 MPa were reached at proportion of 8 wt.% of nano-VN reinforcement, while maximal ultimate flexural strength Rbm = 1110 MPa and compressive strength Rcm = 1410 MPa were obtained at 4 wt.% of VN. At the same time, maximal fracture toughness corresponded with a minimal concentration of VN reinforcement. An excessive increase of nano-VN content in the tested composites demonstrated a decrease of mechanical properties due to the agglomeration of VN powder inclusions and the formation of gaps and discontinuities around them.

- Initial cutting tests demonstrated improvement of wear resistance by 36% and 51%, which means substantially prolonged service time and effectiveness of the diamond cutting discs. Combined with the applied cheaper, less energy-consuming and time-saving electroconsolidation technology that allows for the achievement of the desired structures and properties, proposed composites appear economically very efficient.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morozow, D.; Barlak, M.; Werner, Z.; Pisarek, M.; Konarski, P.; Zagórski, J.; Rucki, M.; Chałko, L.; Łagodziński, M.; Narojczyk, J.; et al. Wear Resistance Improvement of Cemented Tungsten Carbide Deep-Hole Drills after Ion Implantation. Materials 2021, 14, 239. [Google Scholar] [CrossRef]

- Li, M.; Sun, Y.; Meng, Q.; Wu, H.; Gao, K.; Liu, B. Fabrication of Fe-based diamond composites by pressureless infiltration. Materials 2016, 9, 1006. [Google Scholar] [CrossRef]

- Zhao, X.; Duan, L. A review of the diamond retention capacity of metal bond matrices. Metals 2018, 8, 307. [Google Scholar] [CrossRef]

- Borowiecka-Jamrozek, J.M.; Konstanty, J.; Lachowski, J. The application of aball-milled Fe–Cu–Ni powder mixture to fabricate sintered diamond tools. Arch. Foundry Eng. 2018, 18, 5–8. [Google Scholar]

- Mariani, M.; Goncharov, I.; Mariani, D.; De Gaudenzi, G.P.; Popovich, A.; Lecis, N.; Vedani, M. Mechanical and microstructural characterization of WC–Co consolidated by binder jetting additive manufacturing. Int. J. Refract. Met. Hard Mater. 2021, 100, 105639. [Google Scholar] [CrossRef]

- Hu, H.; Chen, W.; Deng, C.; Yang, J. Effect of matrix composition on the performance of Fe-based diamond bits for reinforced concrete structure drilling. Int. J. Refract. Met. Hard Mater. 2021, 95, 105419. [Google Scholar] [CrossRef]

- Bulut, B.; Gunduz, O.; Baydogan, M.; Kayali, E.S. Determination of matrix composition for diamond cutting tools according to the hardness and abrasivity properties of rocks to be cut. Int. J. Refract. Met. Hard Mater. 2021, 95, 105466. [Google Scholar] [CrossRef]

- Boland, J.N.; Li, X.S. Microstructural Characterisation and Wear Behaviour of Diamond Composite Materials. Materials 2010, 3, 1390–1419. [Google Scholar] [CrossRef]

- Vynohradova, O.P.; Zakora, A.P.; Shul’zhenko, A.A.; Gargin, V.G.; Sokolov, A.N.; Efrosinin, D.V.; Zakora, I.A. Comparative Evaluation of the Performance of Drill Bits with a Diamond-Containing Matrix and Inserts Made of Diamond-Containing Composites. J. Superhard Mater. 2022, 44, 57–61. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, F.; Zha, M.; Zhu, M.; Zhou, Y.; Tang, H.; Xie, D. Mechanical properties and tribological behavior of Fe/nano-diamond composite prepared by hot-press sintering. Int. J. Refract. Met. Hard Mater. 2021, 95, 105412. [Google Scholar] [CrossRef]

- Dong, P.; Zhang, J.; Wu, J.; Wang, J. Performance investigation of traditional diamond frame saw in processing granite. Int. J. Refract. Met. Hard Mater. 2021, 99, 105601. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Dong, P. Comparison of wear characteristics of diamond segments under different sawing modes in sawing hard stone. Int. J.Refract. Met. HardMater. 2020, 87, 105149. [Google Scholar] [CrossRef]

- Nitkiewicz, Z.; Swierzy, M. Tin influence on diamond-metal matrix hot pressed tools for stone cutting. J. Mater. Proc. Tech. 2006, 175, 306–315. [Google Scholar] [CrossRef]

- Mechnik, V.A.; Bondarenko, N.A.; Kuzin, N.O.; Lyashenko, B.A. The role of structure formation in forming the physicomechanical properties of composites of the diamond–(Fe–Cu–Ni–Sn) system. J. Frict. Wear. 2016, 37, 377–384. [Google Scholar] [CrossRef]

- Dinaharan, I.; Sathiskumar, R.; Murugan, N. Effect of ceramic particulate type on microstructure and properties of copper matrix composites synthesized by friction stir processing. J. Mater. Res. Technol. 2016, 5, 302–316. [Google Scholar] [CrossRef]

- Dai, H.; Wang, L.; Zhang, J.; Liu, Y.; Wang, Y.; Wang, L.; Wa, X. Iron based partially pre-alloyed powders as matrix materials for diamond tools. J. Powder Metall. 2015, 58, 83–86. [Google Scholar] [CrossRef]

- Wang, J.; Han, Y.; Zhao, Y.; Li, X.; Yi, D.; Guo, Z.; Cao, Y.; Liu, B.; Tang, H.P. Microstructure and properties of WC-12Co cemented carbide fabricated via selective electron beam melting. Int. J. Refract. Met. Hard Mater. 2022, 106, 105847. [Google Scholar] [CrossRef]

- Kolodnits’kyi, V.N.; Bagirov, O.E. On the structure formation of diamond containing composites used in drilling and stone working tools (A review). J. Superhard Mater. 2017, 39, 1–17. [Google Scholar] [CrossRef]

- Mechnik, V.A.; Bondarenko, N.A.; Kuzin, N.O.; Gevorkian, E.S. Influence of the addition of vanadium nitride on the structure and specifications of a diamond–(Fe–Cu–Ni–Sn) composite system. J. Frict. Wear. 2018, 39, 108–113. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, S.; Bai, R.; Zhou, H.; Su, Z.; Wu, J.; Wang, J. Effect of nano-vanadium nitride on microstructure and properties of sintered Fe–Cu-based diamond composites. Int. J. Refract. Met. Hard Mater. 2020, 91, 105256. [Google Scholar] [CrossRef]

- Cygan-Bączek, E.; Wyżga, P.; Cygan, S.; Bała, P.; Romański, A. Improvement in Hardness and Wear Behaviour of Iron-Based Mn–Cu–Sn Matrix for Sintered Diamond Tools by Dispersion Strengthening. Materials 2021, 14, 1774. [Google Scholar] [CrossRef]

- Mechnik, V.A. Production of diamond–(Fe–Cu–Ni–Sn) composites with high wear resistance. Powder Metall. Met. Ceram. 2014, 52, 577–587. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimized tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Musil, J. Tribological and mechanical properties of nanocrystalline n-TiC/a-C nanocomposite thin films. J. Vac. Sci. Technol. A. 2010, 28, 244–249. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Mechnik, V.; Bondarenko, N.; Vovk, R.; Lytovchenko, S.; Chishkala, V.; Melnik, O. Peculiarities of obtaining diamond–(Fe–Cu–Ni–Sn) hot pressing. Funct. Mater. 2017, 24, 31–45. [Google Scholar] [CrossRef][Green Version]

- Uemura, M. An Analysis of the catalysis of Fe, Ni, or Co on the wear of diamonds. Tribol. Int. 2004, 37, 887–892. [Google Scholar] [CrossRef]

- Bondarenko, M.O.; Mechnik, V.A.; Suprun, M.V. Shrinkage and shrinkage rate behavior in Cdiamond–Fe–Cu–Ni–Sn–CrB2 system during hot pressing of pressureless-sintered compacts. J. Superhard Mater. 2009, 31, 232–240. [Google Scholar] [CrossRef]

- de Oliveira, L.J.; Bobrovnitchii, G.S.; Filgueira, M. Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix. Int. J. Refract. Met. Hard Mater. 2007, 25, 328–335. [Google Scholar] [CrossRef]

- Borowiecka-Jamrozek, J.; Lachowski, J. Modelling of the mechanical state of a diamond particle in the metallic matrix. Adv. Mater. Res. 2014, 874, 127–132. [Google Scholar] [CrossRef]

- Oliveira, F.A.C.; Anjinho, C.A.; Coelho, A.; Amaral, P.M.; Coelho, M. PM materials selection: The key for improved performance of diamond tools. Met. Powder Rep. 2017, 72, 339–344. [Google Scholar] [CrossRef]

- Wang, J.; Shang, S.; Peng, F. Influence mechanism of hard brittle grits on the drilling performance of diamond bit. Ann. Chim.-Sci. Matériaux 2018, 42, 209–220. [Google Scholar] [CrossRef]

- Wu, Y.; Yan, Q.; Zhang, X. Wear characteristics of Fe-based diamond composites with cerium oxide (CeO2) reinforcements. Int. J. Refract. Met. Hard Mater. 2020, 86, 105093. [Google Scholar] [CrossRef]

- Mechnyk, V.A. Regularities of structure formation in diamond–Fe–Cu–Ni–Sn–CrB2 systems. Mater. Sci. 2013, 49, 93–101. [Google Scholar] [CrossRef]

- Mechnik, V.A. Effect of hot recompaction parameters on the structure and properties of diamond–(Fe–Cu–Ni–Sn–CrB2) composites. Powder Metall. Met. Ceram. 2014, 52, 709–721. [Google Scholar] [CrossRef]

- Mechnik, V.A.; Bondarenko, N.A.; Kolodnitskyi, V.M.; Zakiev, V.I.; Zakiev, I.M.; Ignatovich, S.R.; Yutskevych, S.S. Mechanical and tribological properties of Fe−Cu−Ni−Sn materials with different amountsof CrB2 used as matrices for diamond-containing composites. J. Superhard Mater. 2020, 42, 251–263. [Google Scholar] [CrossRef]

- Mechnik, V.A.; Bondarenko, N.A.; Kolodnitskyi, V.M.; Zakiev, V.I.; Zakiev, I.M.; Ignatovich, S.R.; Dub, S.N.; Kuzin, N.O. Effect of vacuum hot pressing temperature on the mechanical and tribological properties of the Fe–Cu–Ni–Sn–VN composites. Powder Metall. Met. Ceram. 2020, 58, 679–691. [Google Scholar] [CrossRef]

- Mechnik, V.A.; Bondarenko, N.A.; Kolodnitskyi, V.M.; Zakiev, V.I.; Zakiev, I.M.; Storchak, M.; Dub, S.N.; Kuzin, N.O. Physico-mechanical and tribological properties of Fe–Cu−Ni−Sn and Fe−Cu–Ni−Sn–VN nanocomposites obtained by powder metallurgy methods. Tribol. Ind. 2019, 41, 188–198. [Google Scholar] [CrossRef]

- Mechnik, V.A.; Bondarenko, N.A.; Dub, S.N.; Kolodnitskyi, V.M.; Nesterenko, Y.V.; Kuzin, N.O.; Zakiev, I.M.; Gevorkyan, E.S. A study of microstructure of Fe–Cu–Ni–Sn and Fe–Cu–Ni–Sn––VN metal matrix for diamond containing composites. Mater. Charact. 2018, 146, 209–216. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Lavrynenko, S.; Rucki, M.; Siemiątkowski, Z.; Kislitsa, M. Preparation of nanostructured materials by electrical sintering. In Proceedings of the 7th International Conference on Mechanics and Materials in Design (M2D2017), Albufeira, Portugal, 11–15 June 2017; Silva Gomes, J.F., Meguid, S.A., Eds.; INEGI: Porto, Portugal, 2017; pp. 663–666. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Mechnik, V.A.; Bondarenko, N.A.; Kolodnitskyi, V.M.; Zakiev, V.I.; Zakiev, I.M.; Kuzin, M.O.; Gevorkyan, E.S. Influence of diamond–matrix transition zone structure on mechanical properties and wear of sintered diamond-containing composites based on Fe–Cu–Ni–Sn matrix with varying CrB2 content. Int. J. Refract. Met. Hard Mater. 2021, 100, 105655. [Google Scholar] [CrossRef]

- Selected Powder Diffraction Data for Education Straining (Search Manual and Data Cards); International Centre for Diffraction Data: Swarthmore, PA, USA, 1988.

- Gevorkyan, E.; Rucki, M.; Panchenko, S.; Sofronov, D.; Chałko, L.; Mazur, T. Effect of SiC Addition to Al2O3 Ceramics Used in Cutting Tools. Materials 2020, 13, 5195. [Google Scholar] [CrossRef] [PubMed]

- Mechnik, V.; Bondarenko, N.; Kolodnitskyi, V.; Zakiev, V.I.; Zakiev, I.M.; Gevorkyan, E.S.; Kuzin, N.O. Microstructural Features and Mechanical and Tribological Properties of Fe–Cu–Ni–Sn Composites Precipitation-Hardened with CrB2 Additions. Powder Metall. Met. Ceram. 2021, 60, 204–215. [Google Scholar] [CrossRef]

- He, L.; Ma, E. Processing and microhardness of bulk Cu–Fe. Nanostruct. Mater. 1996, 7, 327–339. [Google Scholar] [CrossRef]

- Mechnik, V.A.; Bondarenko, N.A.; Kolodnitskyi, V.M.; Zakiev, V.I.; Zakiev, I.M.; Ignatovich, S.R.; Dub, S.N.; Kuzin, N.O. Formation of Fe-Cu-Ni-Sn-VN nanocrystalline matrix by vacuum hot pressing for diamond-containing composite. Mechanical and Tribological Properties. J. Superhard Mater. 2019, 41, 388–401. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Prikhna, T.; Vovk, R.; Rucki, M.; Siemiatkowski, Z.; Kucharczyk, W.; Chishkala, V.; Chałko, L. Sintered nanocomposites ZrO2-WC obtained with field assisted hot pressing. Compos. Struct. 2021, 259, 113443. [Google Scholar] [CrossRef]

- Chishkala, V.; Lytovchenko, S.; Mazilin, B.; Gevorkyan, E.; Shkuropatenko, V.; Voyevodin, V.; Rucki, M.; Siemiątkowski, Z.; Matijošius, J.; Dudziak, A.; et al. Novel Microwave-Assisted Method of Y2Ti2O7 Powder Synthesis. Materials 2020, 13, 5621. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Rucki, M.; Sałaciński, T.; Siemiątkowski, Z.; Nerubatskyi, V.; Kucharczyk, W.; Chrzanowski, J.; Gutsalenko, Y.; Nejman, M. Feasibility of Cobalt-Free Nanostructured WC Cutting Inserts for Machining of a TiC/Fe Composite. Materials 2021, 14, 3432. [Google Scholar] [CrossRef]

| Sample No. | Fe | Cu | Ni | Sn | VN |

|---|---|---|---|---|---|

| 1 | 51 | 32 | 9 | 8 | – |

| 2 | 50.745 | 31.84 | 8.955 | 7.96 | 0.5 |

| 3 | 50.49 | 31.68 | 8.91 | 7.92 | 1 |

| 4 | 50.235 | 31.52 | 8.865 | 7.88 | 1.5 |

| 5 | 49.98 | 31.36 | 8.82 | 7.84 | 2 |

| 6 | 48.96 | 30.72 | 8.64 | 7.68 | 4 |

| 7 | 47.94 | 30.08 | 8.46 | 7.52 | 6 |

| 8 | 46.92 | 29.44 | 8.28 | 7.36 | 8 |

| 9 | 45.9 | 28.8 | 8.1 | 7.2 | 10 |

| Sample No | H, GPa | E, GPa | H/E | H3/E2, MPa | ||||

|---|---|---|---|---|---|---|---|---|

| Matrix | Inclusions | Matrix | Inclusions | Matrix | Inclusions | Matrix | Inclusions | |

| 1 (no VN) | 5.2 ± 1.3 | – | 197 ± 11 | – | 0.0264 | – | 3.62 | – |

| 5 (2% VN) | 5.6 ± 0.4 | 12.7 ± 0.3 | 202 ± 8 | 345 ± 12 | 0.0277 | 0.0368 | 4.30 | 17.21 |

| 6 (4% VN) | 6.5 ± 0.6 | 14.8 ± 0.4 | 200 ± 8 | 390 ± 15 | 0.0325 | 0.0379 | 6.87 | 21.31 |

| 8 (8% VN) | 7.8 ± 0.3 | 16.7 ± 1.7 | 213 ± 6 | 428 ± 31 | 0.0366 | 0.0390 | 10.46 | 25.42 |

| 9 (10% VN) | 7.5 ± 0.6 | 14.8 ± 0.7 | 206 ± 16 | 388 ± 21 | 0.0364 | 0.0381 | 9.30 | 21.54 |

| Sample No. | VN, wt.% | HV, GPa | KIc, MPa∙m1/2 | Rbm, MPa | Rcm, MPa |

|---|---|---|---|---|---|

| 1 | 0 | 3.86 | - | 740 | 950 |

| 2 | 0.5 | 4.42 | 5.26 | 785 | 985 |

| 3 | 1.0 | 4.52 | 5.15 | 860 | 1098 |

| 4 | 1.5 | 4.91 | 5.12 | 992 | 1180 |

| 5 | 2.0 | 5.26 | 5.08 | 1071 | 1300 |

| 6 | 4.0 | 5.94 | 5.03 | 1110 | 1410 |

| 7 | 6.0 | 6.50 | 4.97 | 1078 | 1390 |

| 8 | 8.0 | 7.77 | 4.85 | 1012 | 1342 |

| 9 | 10.0 | 8.58 | 4.76 | 976 | 1313 |

| Sample No | Percentage of Elements, wt.% | |||||||

|---|---|---|---|---|---|---|---|---|

| Spectrum | C | N | V | Fe | Ni | Cu | Sn | |

| 1 | 1 | 100.00 | – | – | – | – | – | – |

| 2 | 100.00 | – | – | – | – | – | – | |

| 3 | 97.48 | – | – | – | – | 2.52 | – | |

| 4 | 12.72 | – | – | 68.62 | 9.00 | 8.73 | 0.92 | |

| 5 | 1 | 89.99 | – | 2.39 | 4.71 | 1.52 | 1.39 | – |

| 2 | 94.54 | – | 1.19 | 4.22 | – | – | – | |

| 3 | 90.16 | – | 2.50 | 6.51 | – | 0.83 | – | |

| 4 | 19.23 | – | 11.92 | 21.79 | 19.87 | 21.74 | 5.45 | |

| Tested Disc No | Composition of the Cutting Segments, wt.% | Linear Wear, mm |

|---|---|---|

| D1 | 8.75% Cdiamond + 46.5375% Fe + 29.2% Cu + 8.2175% Ni + 7.3% Sn | 5.1 ± 0.058 |

| D2 | 8.75% Cdiamond + 45.5175% Fe + 28.56% Cu + 8.0325% Ni + 7.14% Sn + 2% VN | 3.4 ± 0.052 |

| D3 | 8.75% Cdiamond + 44.4975% Fe + 27.92% Cu + 7.8525% Ni + 6.98% Sn +4% VN | 2.5 ± 0.048 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamalis, A.; Mechnik, V.; Morozow, D.; Ratov, B.; Kolodnitskyi, V.; Samociuk, W.; Bondarenko, N. Properties of Cutting Tool Composite Material Diamond–(Fe–Ni–Cu–Sn) Reinforced with Nano-VN. Machines 2022, 10, 410. https://doi.org/10.3390/machines10060410

Mamalis A, Mechnik V, Morozow D, Ratov B, Kolodnitskyi V, Samociuk W, Bondarenko N. Properties of Cutting Tool Composite Material Diamond–(Fe–Ni–Cu–Sn) Reinforced with Nano-VN. Machines. 2022; 10(6):410. https://doi.org/10.3390/machines10060410

Chicago/Turabian StyleMamalis, Athanasios, Vladimir Mechnik, Dmitrij Morozow, Boranbay Ratov, Vasyl Kolodnitskyi, Waldemar Samociuk, and Nikolai Bondarenko. 2022. "Properties of Cutting Tool Composite Material Diamond–(Fe–Ni–Cu–Sn) Reinforced with Nano-VN" Machines 10, no. 6: 410. https://doi.org/10.3390/machines10060410

APA StyleMamalis, A., Mechnik, V., Morozow, D., Ratov, B., Kolodnitskyi, V., Samociuk, W., & Bondarenko, N. (2022). Properties of Cutting Tool Composite Material Diamond–(Fe–Ni–Cu–Sn) Reinforced with Nano-VN. Machines, 10(6), 410. https://doi.org/10.3390/machines10060410