A Unified Constitutive Model of Stress Relaxation of Ti-6Al-4V Alloy with Different Temperatures from Elastic to Plastic Loading

Abstract

:1. Introduction

2. Experimental Method

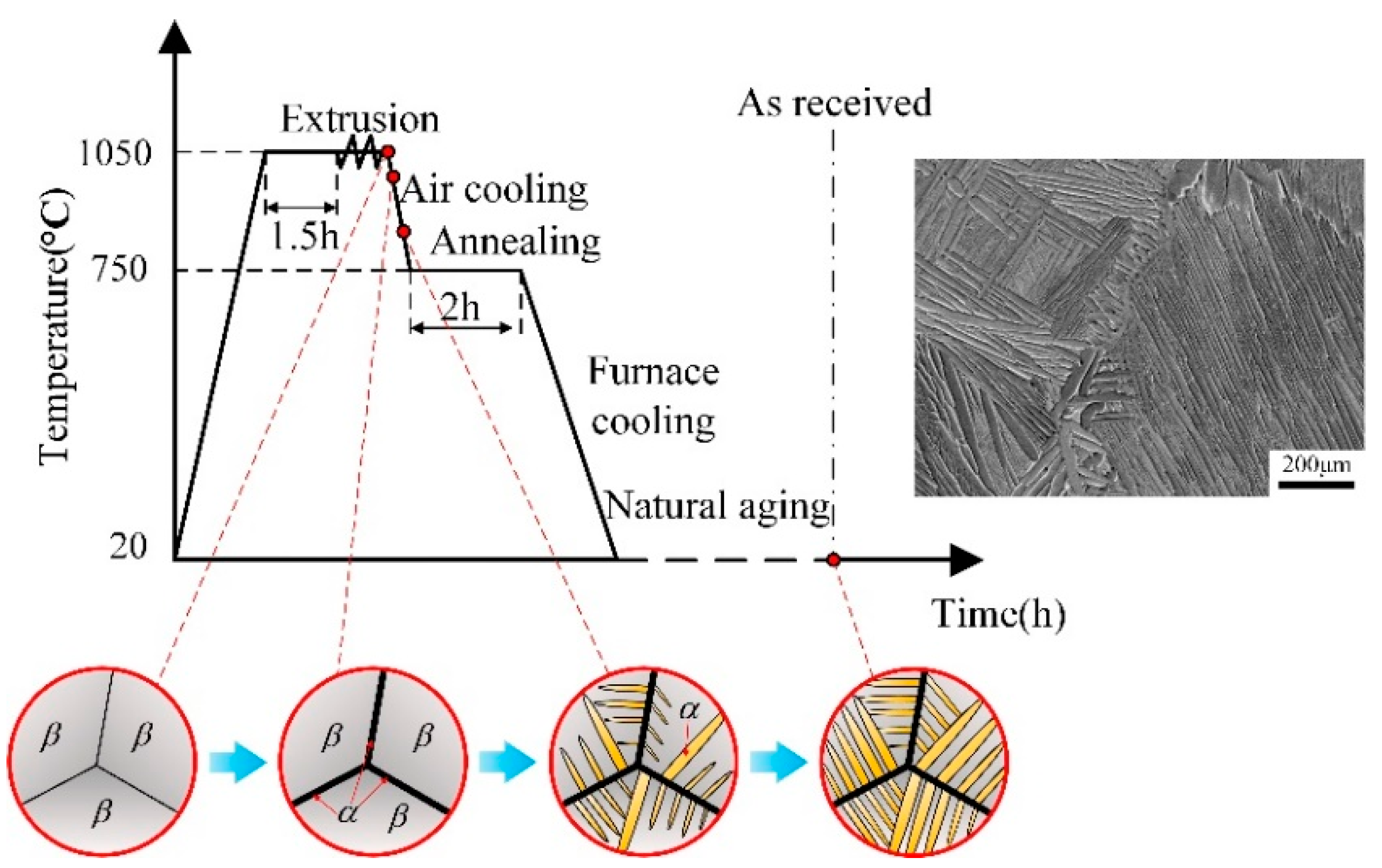

2.1. Materials

2.2. Experimental Process

2.3. Microstructure Characterization

3. Experimental Results and Discussion

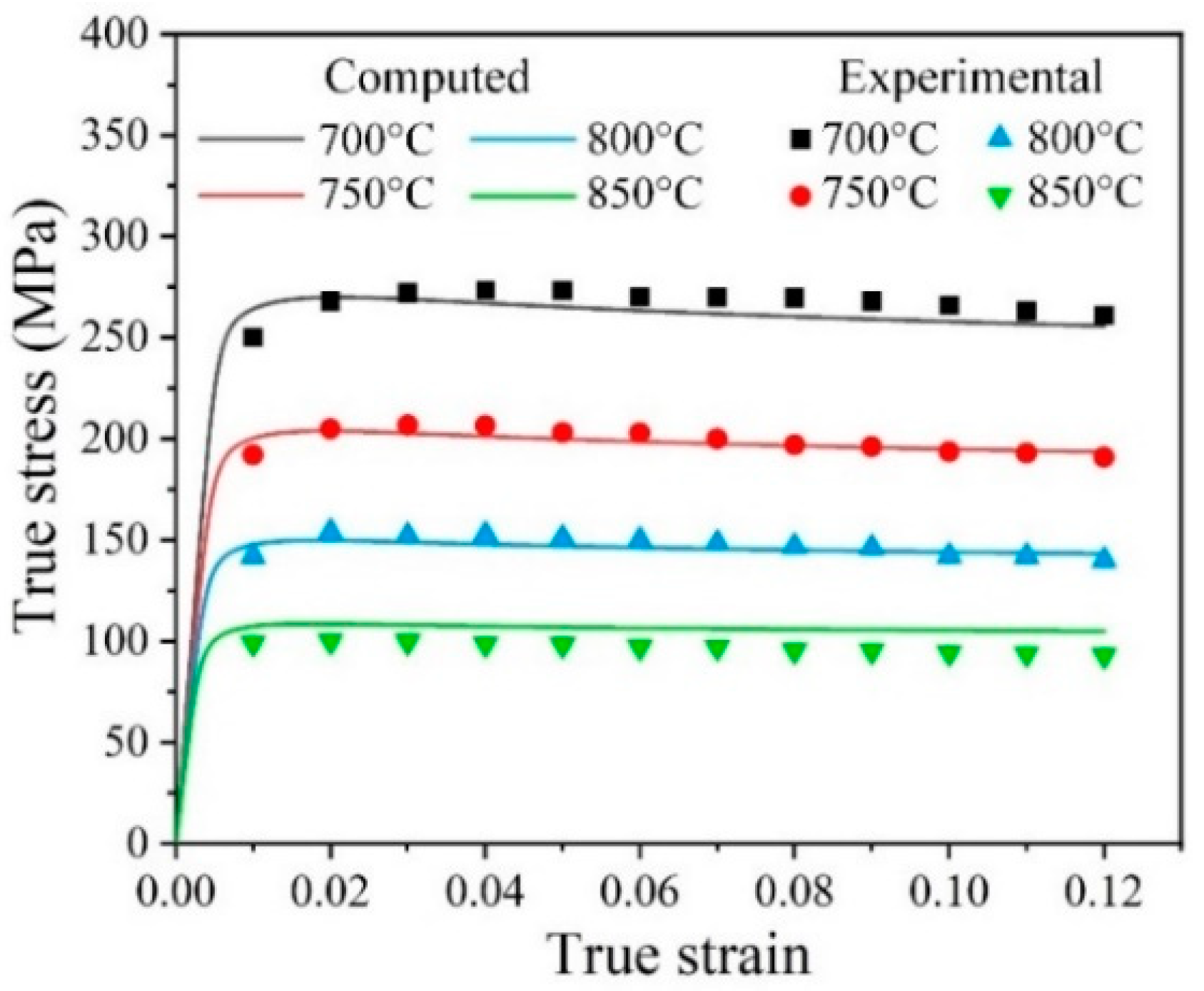

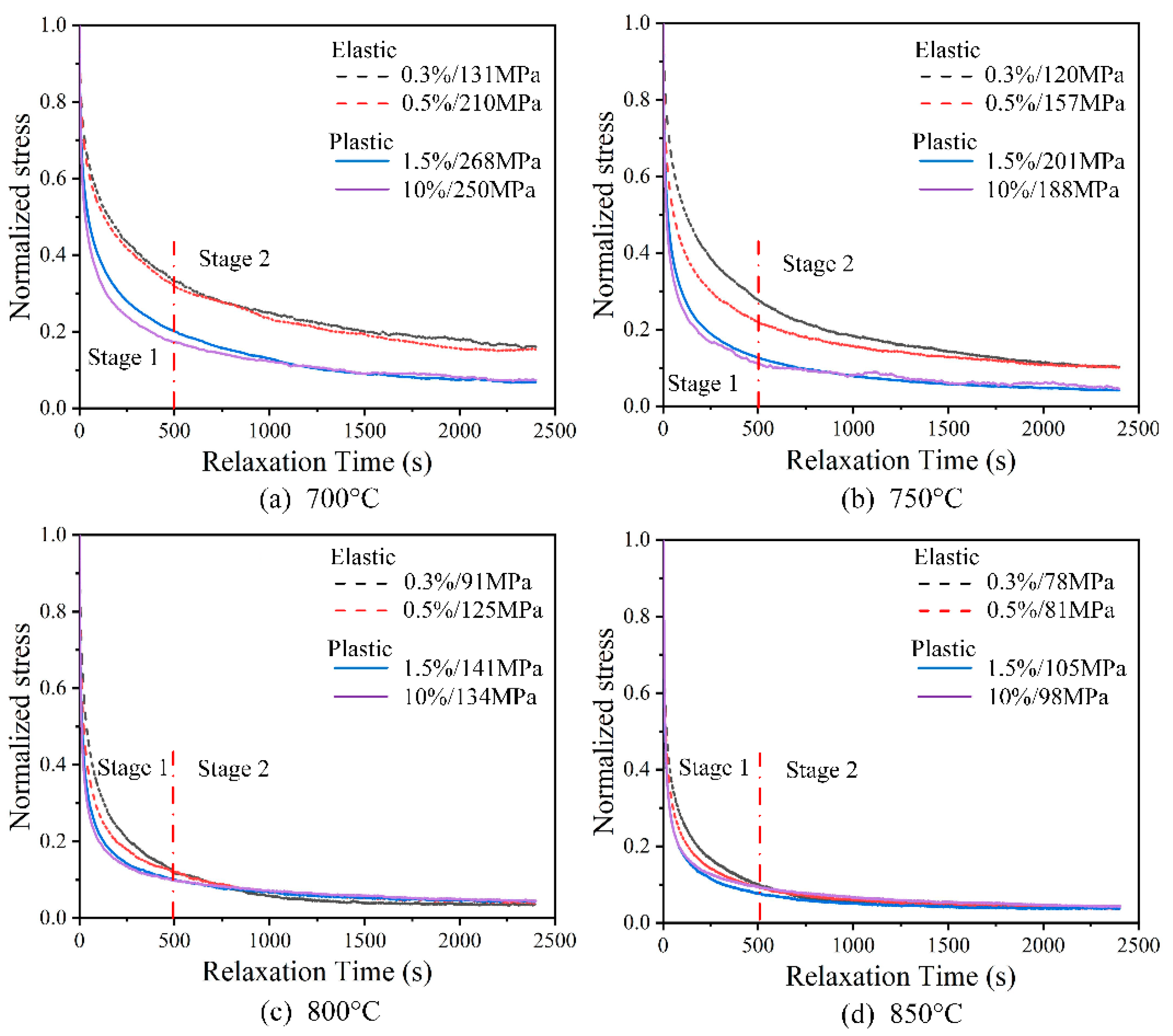

3.1. Loading Deformation and Long-Term Stress Relaxation Behavior

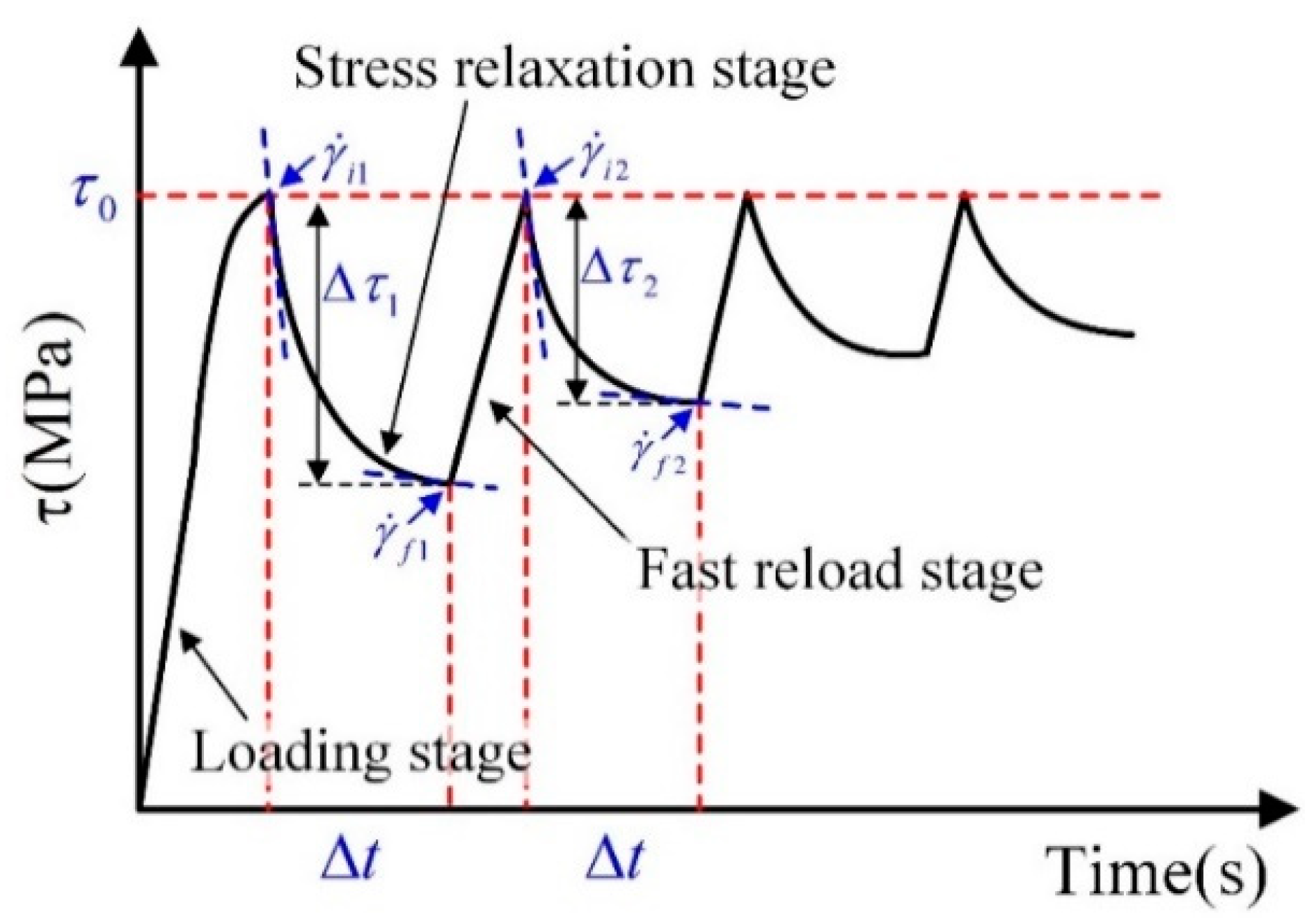

3.2. Repeated Stress Relaxation Behavior

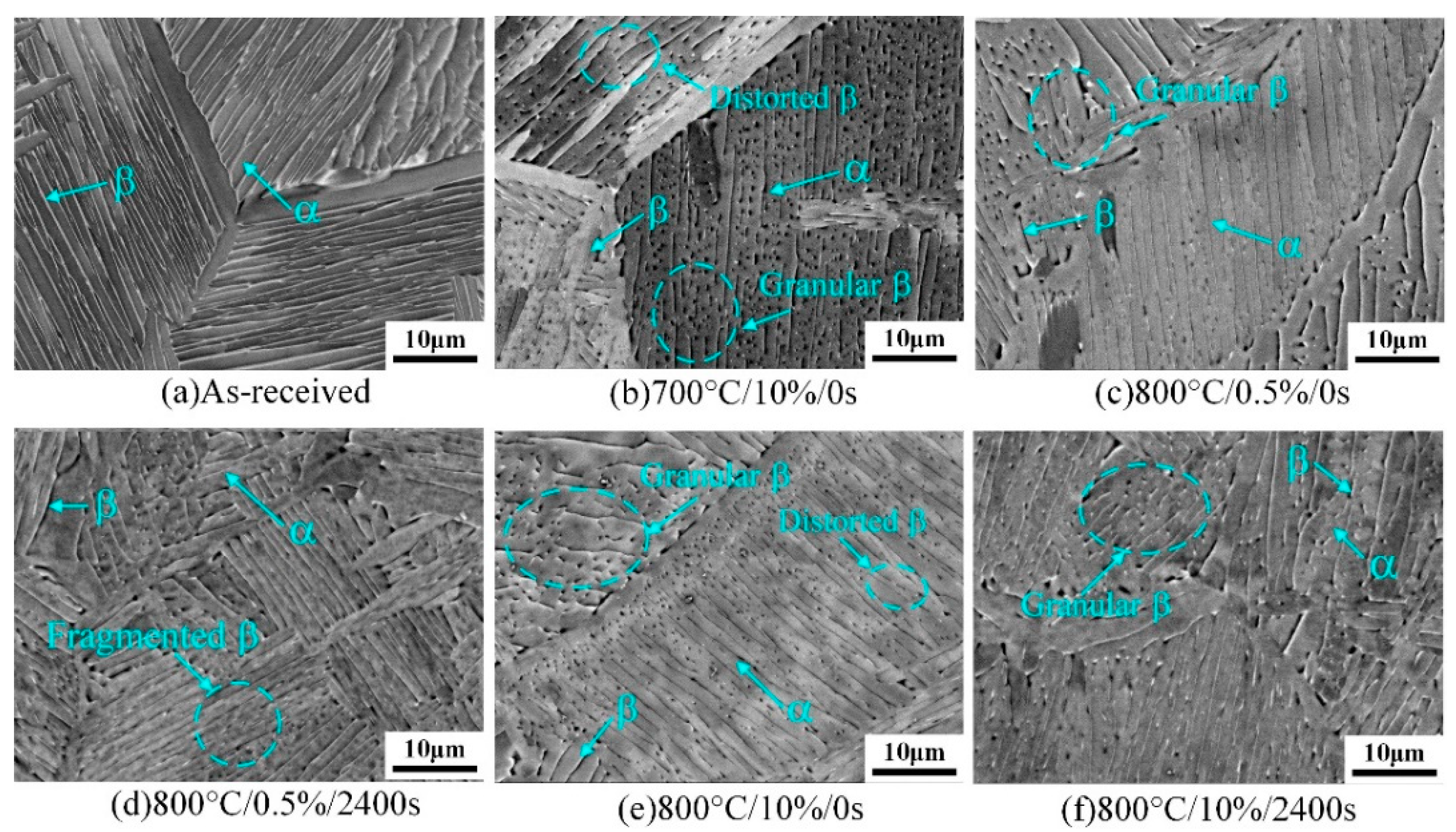

3.3. Microstructural Evolution

4. Mechanisms-Based Constitutive Modeling

4.1. Constitutive Modelling

4.1.1. Stress–Strain Model in Loading Stage

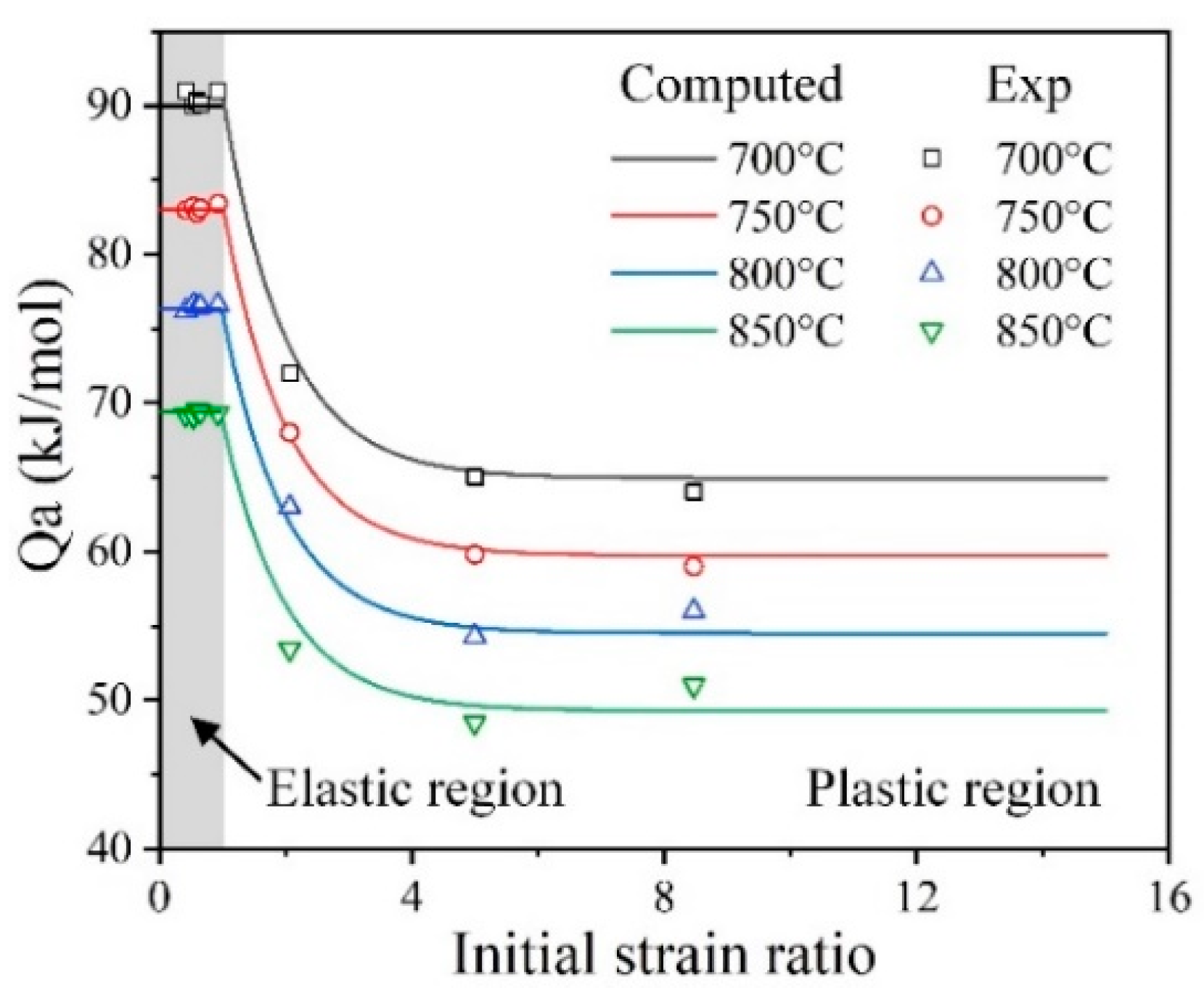

4.1.2. Creep Strain Model in Stress Relaxation Stage

4.1.3. Continuous Microstructures in Multi-Stages

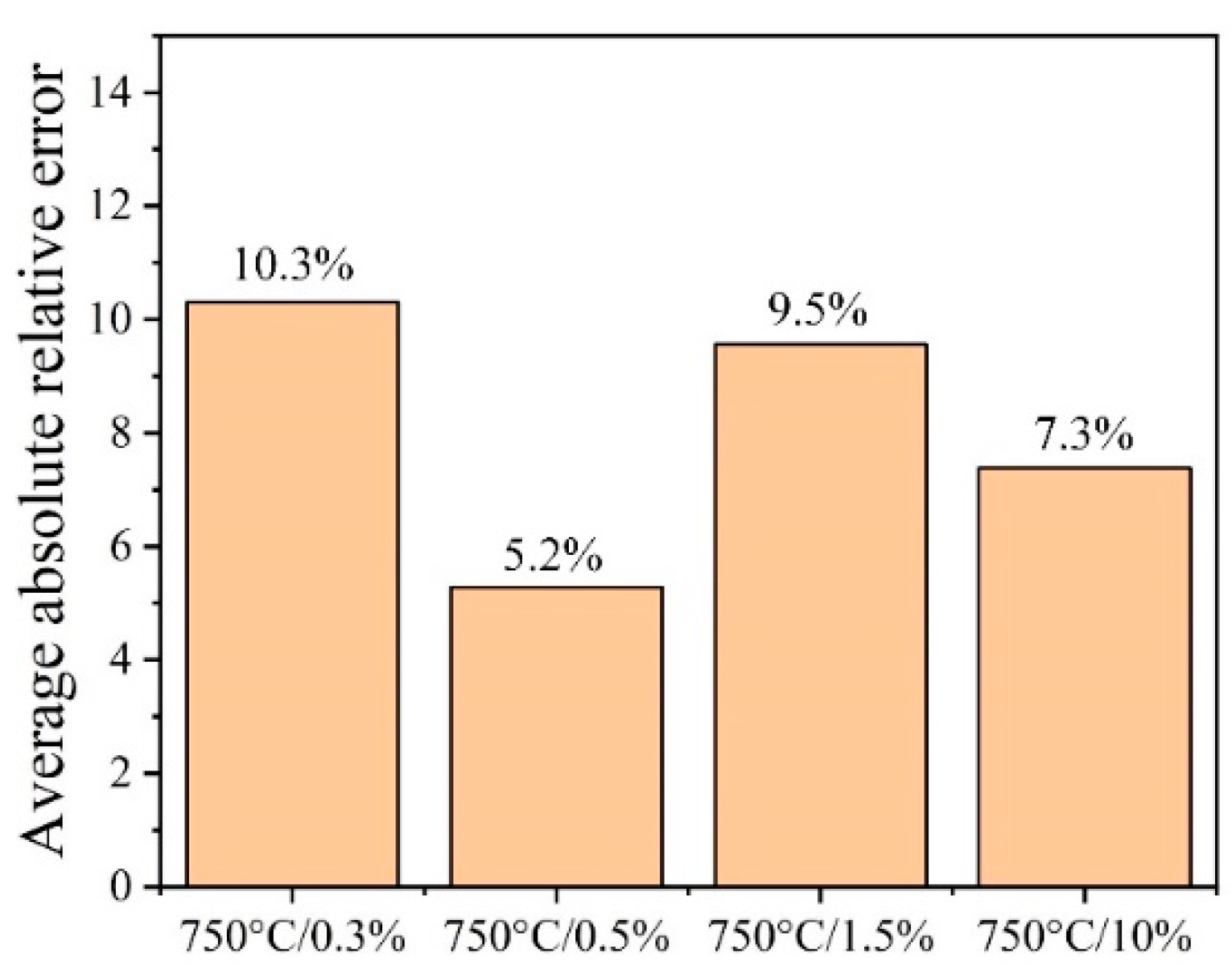

4.2. Model Calibration and Results

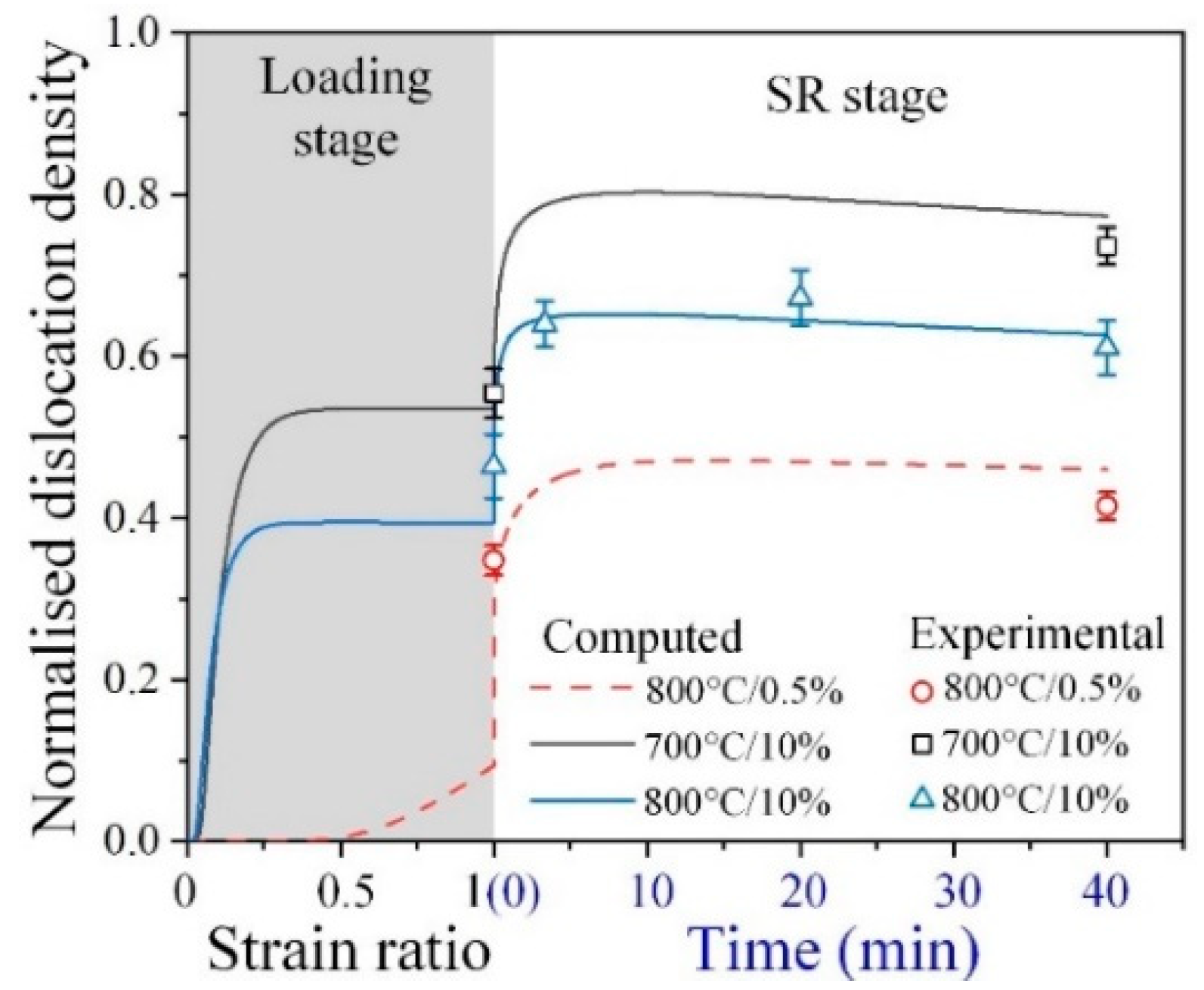

4.3. Verification and Discussion

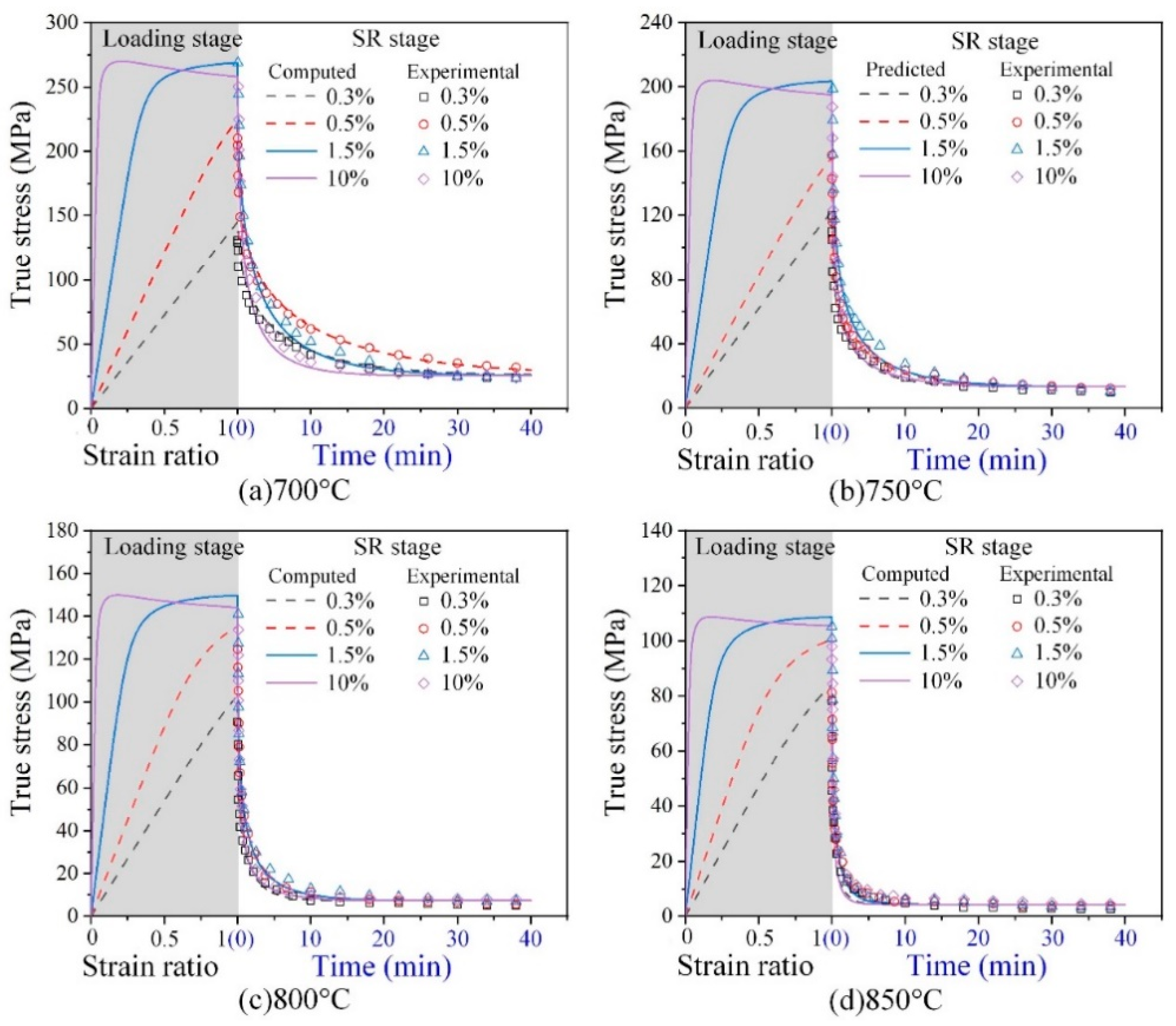

4.3.1. Verification of Stress Relaxation Behavior

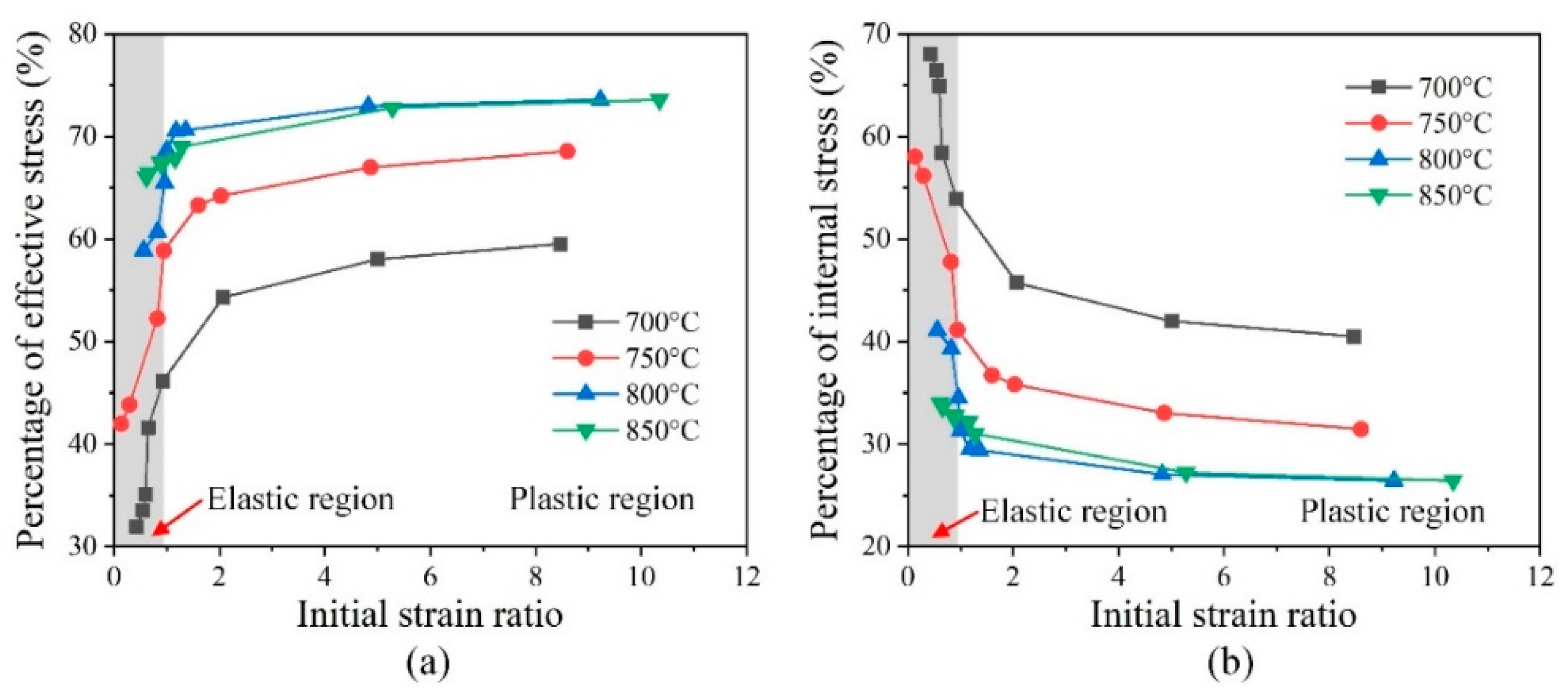

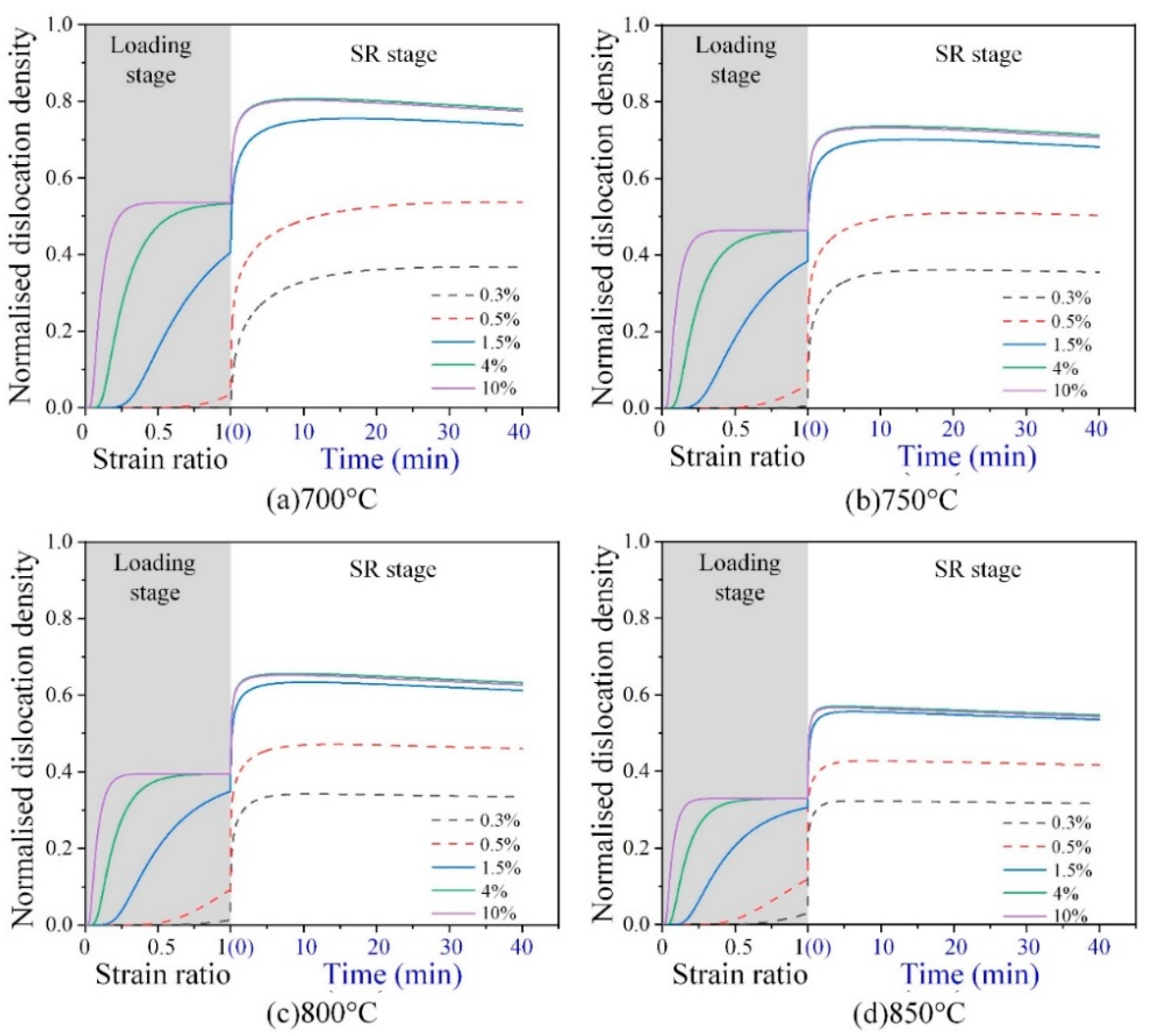

4.3.2. Internal Variable Evolution under Different Thermomechanical Conditions

5. Conclusions

- (1)

- The difference in SR behavior between the elastic and plastic regions is attributed to the transformation of the creep mechanism at an elevated temperature. At lower temperatures (700 °C and 750 °C), the dislocation creep caused by the gradually obvious dislocation activity from the elastic region to plastic region leads to a rapid increase in effective stress (), which promotes different SR behavior. At a higher temperature (800 °C and 850 °C), the complicated interaction between diffusion creep and dislocation creep does not change the significantly, resulting in similar relaxation behavior after different loading.

- (2)

- Considering the underlying deformation mechanism and continuous evolution of the microstructure in the two stages of stress relaxation, a set of unified constitutive models are proposed. The microstructure models, incorporating dislocation recovery, lamellar growth and Hall–Petch strengthening loss, are integrated into the loading module. Based on the thermal activation theory, the microstructure related parameters, i.e., dislocation density and lamellar, and the deformation related parameters, i.e., apparent activation energy and threshold stress, are coupled to the SR module. These crucial internal variables, i.e., dislocation density and lamellar width, are used as the transmission media between the loading stage and the relaxation stage.

- (3)

- The temperature, pre-strain and time-dependent relaxation behaviors of Ti-6Al-4V alloys, including loading and subsequent SR stages, are successfully predicted under a wide range of temperatures (700~850 °C) and pre-strains (0.3~10%). The model eliminates the limitations of the traditional model in the prediction of the continuous evolution of parameters in multi-stages and can provide a basis for the effective prediction of springback in the hot forming process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Thermally Activated Theoretical Background

References

- Gao, P.; Fu, M.; Zhan, M.; Lei, Z.; Li, Y. Deformation behavior and microstructure evolution of titanium alloys with lamellar microstructure in hot working process: A review. J. Mater. Sci. Technol. 2020, 39, 56–73. [Google Scholar] [CrossRef]

- Wang, K.; Kopec, M.; Chang, S.; Qu, B.; Liu, J.; Politis, D.J.; Wang, L.; Liu, G. Enhanced formability and forming efficiency for two-phase titanium alloys by Fast light Alloys Stamping Technology (FAST). Mater. Des. 2020, 194, 108948. [Google Scholar] [CrossRef]

- Guo, G.; Li, D.; Li, X.; Deng, T.; Wang, S. Finite element simulation and process optimization for hot stretch bending of Ti-6Al-4V thin-walled extrusion. Int. J. Adv. Manuf. Technol. 2017, 92, 1707–1719. [Google Scholar] [CrossRef]

- Chen, Y.; Li, S.; Li, Y.; Wang, Y.; Li, Z.; Lin, Z. Constitutive modeling of TA15 alloy sheet coupling phase transformation in non-isothermal hot stamping process. J. Mater. Res. Technol. 2021, 12, 629–642. [Google Scholar] [CrossRef]

- Zong, Y.; Liu, P.; Guo, B.; Shan, D. Investigation on high temperature short-term creep and stress relaxation of titanium alloy. Mater. Sci. Eng. A 2015, 620, 172–180. [Google Scholar] [CrossRef]

- Zheng, Z.; Xiao, S.; Wang, X.; Guo, Y.; Yang, J.; Xu, L.; Chen, Y. High temperature creep behavior of an as-cast near-α Ti–6Al–4Sn–4Zr-0.8Mo–1Nb–1W-0.25Si alloy. Mater. Sci. Eng. A 2021, 803, 140487. [Google Scholar] [CrossRef]

- Peng, H.; Hou, Z.; Chen, X.; Li, T.; Luo, J.; Li, X. Effect of temperature and cyclic loading on stress relaxation behavior of Ti–6Al–4V titanium alloy. Mater. Sci. Eng. A 2021, 824, 141789. [Google Scholar] [CrossRef]

- Pan, S.; Liu, H.; Chen, Y.; Chi, G.; Yi, D. Lamellar α fencing effect for improving stress relaxation resistance in Ti-55511 alloy. Mater. Sci. Eng. A 2021, 808, 140945. [Google Scholar] [CrossRef]

- Nie, X.; Liu, H.; Zhou, X.; Yi, D.; Huang, B.; Hu, Z.; Xu, Y.; Yang, Q.; Wang, D.; Gao, Q. Creep of Ti–5Al–5Mo–5V–1Fe–1Cr alloy with equiaxed and lamellar microstructures. Mater. Sci. Eng. A 2016, 651, 37–44. [Google Scholar] [CrossRef]

- Luo, J.; Xiong, W.; Li, X.; Chen, J. Investigation on high-temperature stress relaxation behavior of Ti-6Al-4V sheet. Mater. Sci. Eng. A 2019, 743, 755–763. [Google Scholar] [CrossRef]

- Jia, C.L.; Kou, H.C.; Chen, N.N.; Liu, S.B.; Fan, J.K.; Tang, B.; Li, J.S. Stress relaxation induced spheroidization of the lamellar α phase in Ti-7333 alloy. J. Alloys Compd. 2019, 781, 674–679. [Google Scholar] [CrossRef]

- Wang, Z.; Stoica, A.D.; Ma, D.; Beese, A.M. Stress relaxation behavior and mechanisms in Ti-6Al-4V determined via in situ neutron diffraction: Application to additive manufacturing. Mater. Sci. Eng. A 2017, 707, 585–592. [Google Scholar] [CrossRef]

- Rong, Q.; Li, Y.; Shi, Z.; Meng, L.; Sun, X.; Sun, X.; Lin, J. Experimental investigations of stress-relaxation ageing behaviour of AA6082. Mater. Sci. Eng. A 2019, 750, 108–116. [Google Scholar] [CrossRef]

- Lyu, F.; Li, Y.; Shi, Z.; Huang, X.; Zeng, Y.; Lin, J. Stress and temperature dependence of stress relaxation ageing behaviour of an Al–Zn–Mg alloy. Mater. Sci. Eng. A 2020, 773, 138859. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, D.; Li, X.; Liu, X.; Zhao, S.; Li, Y. Creep deformation and strength evolution mechanisms of a Ti-6Al-4V alloy during stress relaxation at elevated temperatures from elastic to plastic loading. J. Mater. Sci. Technol. 2022, 126, 93–105. [Google Scholar] [CrossRef]

- Varma, A.; Krishnaswamy, H.; Jain, J.; Lee, M.-G.; Barlat, F. Advanced constitutive model for repeated stress relaxation accounting for transient mobile dislocation density and internal stress. Mech. Mater. 2019, 133, 138–153. [Google Scholar] [CrossRef]

- Mishra, S.; Beura, V.K.; Singh, A.; Yadava, M.; Nayan, N. Effect of Temper Condition on Stress Relaxation Behavior of an Aluminum Copper Lithium Alloy. Metall. Mater. Trans. A 2018, 49, 2631–2643. [Google Scholar] [CrossRef]

- Chong, Y.; Bhattacharjee, T.; Yi, J.; Zhao, S.; Tsuji, N. Achieving bi-lamellar microstructure with both high tensile strength and large ductility in Ti–6Al–4V alloy by novel thermomechanical processing. Materialia 2019, 8, 100479. [Google Scholar] [CrossRef]

- Cui, X.; Wu, X.; Wan, M.; Ma, B.; Zhang, Y. A novel constitutive model for stress relaxation of Ti-6Al-4V alloy sheet. Int. J. Mech. Sci. 2019, 161–162, 105034. [Google Scholar] [CrossRef]

- Lu, L.; Zhu, T.; Shen, Y.; Dao, M.; Lu, K.; Suresh, S. Stress relaxation and the structure size-dependence of plastic deformation in nanotwinned copper. Acta Mater. 2009, 57, 5165–5173. [Google Scholar] [CrossRef]

- Yasmeen, T.; Zhao, B.; Zheng, J.-H.; Tian, F.; Lin, J.; Jiang, J. The study of flow behavior and governing mechanisms of a titanium alloy during superplastic forming. Mater. Sci. Eng. A 2020, 788, 139482. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Murzinova, M.; Salishchev, G.; Semiatin, S.L. Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 2011, 59, 4138–4150. [Google Scholar] [CrossRef]

- Jha, J.S.; Toppo, S.P.; Singh, R.; Tewari, A.; Mishra, S.K. Flow stress constitutive relationship between lamellar and equiaxed microstructure during hot deformation of Ti-6Al-4V. J. Mater. Process. Technol. 2019, 270, 216–227. [Google Scholar] [CrossRef]

- Xiao, W.; Wang, B.; Wu, Y.; Yang, X. Constitutive modeling of flow behavior and microstructure evolution of AA7075 in hot tensile deformation. Mater. Sci. Eng. A 2018, 712, 704–713. [Google Scholar] [CrossRef]

- Yang, L.; Wang, B.; Liu, G.; Zhao, H.; Xiao, W. Behavior and modeling of flow softening and ductile damage evolution in hot forming of TA15 alloy sheets. Mater. Des. 2015, 85, 135–148. [Google Scholar] [CrossRef]

- Dang, N.; Liu, L.; Maire, E.; Adrien, J.; Cazottes, S.; Xiao, W.; Ma, C.; Zhou, L. Analysis of shear stress promoting void evolution behavior in an α/β Ti alloy with fully lamellar microstructure. Mater. Sci. Eng. A 2018, 737, 27–39. [Google Scholar] [CrossRef] [Green Version]

- Park, C.H.; Kim, J.H.; Hyun, Y.-T.; Yeom, J.-T.; Reddy, N.S. The origins of flow softening during high-temperature deformation of a Ti–6Al–4V alloy with a lamellar microstructure. J. Alloys Compd. 2014, 582, 126–129. [Google Scholar] [CrossRef]

- Gao, P.; Yang, H.; Fan, X.; Zhu, S. Unified modeling of flow softening and globularization for hot working of two-phase titanium alloy with a lamellar colony microstructure. J. Alloys Compd. 2014, 600, 78–83. [Google Scholar] [CrossRef]

- Semiatin, S.L. An Overview of the Thermomechanical Processing of α/β Titanium Alloys: Current Status and Future Research Opportunities. Metall. Mater. Trans. A 2020, 51, 2593–2625. [Google Scholar] [CrossRef] [Green Version]

- Tang, X.; Wang, B.; Huo, Y.; Ma, W.; Zhou, J.; Ji, H.; Fu, X. Unified modeling of flow behavior and microstructure evolution in hot forming of a Ni-based superalloy. Mater. Sci. Eng. A 2016, 662, 54–64. [Google Scholar] [CrossRef]

- Wang, K.; Zhan, L.-H.; Yang, Y.-L.; Ma, Z.-Y.; Li, X.-C.; Liu, J. Constitutive modeling and springback prediction of stress relaxation age forming of pre-deformed 2219 aluminum alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 1152–1160. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Z. A New Method to Characterize and Model Stress-Relaxation Aging Behavior of Aluminum Alloys under Age Forming Conditions. Metall. Mater. Trans. A 2022, 53, 1345–1360. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Musharavati, F.; Spigarelli, S. Modelling of the flow behaviour of wrought aluminium alloys at elevated temperatures by a new constitutive equation. Mater. Des. (1980–2015) 2014, 54, 869–873. [Google Scholar] [CrossRef]

- Li, H.; Zhan, L.; Huang, M.; Zhao, X.; Zhou, C.; Qiang, Z. Effects of pre-strain and stress level on stress relaxation ageing behaviour of 2195 Al–Li alloy: Experimental and constitutive modelling. J. Alloys Compd. 2021, 851, 156829. [Google Scholar] [CrossRef]

- Rong, Q.; Shi, Z.; Li, Y.; Lin, J. Constitutive modelling and its application to stress-relaxation age forming of AA6082 with elastic and plastic loadings. J. Mater. Process. Technol. 2021, 295, 117168. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Z.; Lin, J.; Yang, Y.-L.; Rong, Q.; Huang, B.-M.; Chung, T.-F.; Tsao, C.-S.; Yang, J.-R.; Balint, D.S. A unified constitutive model for asymmetric tension and compression creep-ageing behaviour of naturally aged Al-Cu-Li alloy. Int. J. Plast. 2017, 89, 130–149. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Z.; Waheed, S.; Balint, D.S.; Dunne, F.P.E. Slip transfer across phase boundaries in dual phase titanium alloys and the effect on strain rate sensitivity. Int. J. Plast. 2018, 104, 23–38. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, J.; Ma, Y.; Zhang, S.; Youssef, S.S.; Qi, M.; Wang, H.; Qiu, J.; Xu, D.; Lei, J.; et al. Influence of thermal treatment on element partitioning in α+β titanium alloy. J. Alloys Compd. 2019, 791, 575–585. [Google Scholar] [CrossRef]

- Martin, J.L.; Kruml, T. Characterizing thermally activated dislocation mobility. J. Alloys Compd. 2004, 378, 2–12. [Google Scholar] [CrossRef]

- Kruml, T.; Coddet, O.; Martin, J.L. About the determination of the thermal and athermal stress components from stress-relaxation experiments. Acta Mater. 2008, 56, 333–340. [Google Scholar] [CrossRef]

- Trojanová, Z.; Máthis, K.; Lukáč, P.; Németh, G.; Chmelík, F. Internal stress and thermally activated dislocation motion in an AZ63 magnesium alloy. Mater. Chem. Phys. 2011, 130, 1146–1150. [Google Scholar] [CrossRef]

| Experiments | Temperature (°C) | Strain Rate (s−1), Stress (MPa) or Strain Levels | Time (s) | |

|---|---|---|---|---|

| Group 1 | Tensile tests | 700, 750, 800, 850 | 10−3 | —— |

| Group 2 | SR tests | 700, 750, 800, 850 | Elastic: 0.3%, 0.5% Plastic: 1.5%, 10% | 0, 1200, 2400 |

| Group 3 | RSR tests | 700, 750, 800, 850 | Elastic: 0.3%, 0.4%, 0.5%, 0.7%, 0.9% Plastic: 2%, 6%, 11% | 40 |

| Temperature (°C) | Elastic Modulus (MPa) | Yield Strength (MPa) |

|---|---|---|

| 700 | 47,920 | 236 |

| 750 | 42,000 | 171 |

| 800 | 38,590 | 125 |

| 850 | 35,210 | 86 |

| Material Constants | Optimal Value | Material Constants (J/mol) | Optimal Value |

|---|---|---|---|

| 6.01 × 103 | 3.77 × 104 | ||

| 1.88 × 102 | −1.87 × 104 | ||

| 1.28 × 101 | −4.16 × 104 | ||

| 5.96 × 105 | 1.67 × 104 | ||

| 1.36 × 103 | −3.4 × 104 | ||

| 8.63 × 101 | −2.07 × 104 | ||

| 1.97 × 101 | −2.89 × 104 | ||

| 2.78 × 10−3 | 2.42 × 104 | ||

| 1.04 × 100 | −2.13 × 103 | ||

| 0.1 × 100 | 2.03 × 104 | ||

| 7.94 × 101 | −4.86 × 104 | ||

| 4.51 × 10−2 | 4.15 × 104 | ||

| 3.09 × 10-1 | 1.35 × 104 | ||

| 4.30 × 10−1 | 3.79 × 104 | ||

| 8.61 × 104 | −2.6 × 104 | ||

| 2.5 × 10−2 | |||

| 1.59 × 102 | |||

| 1.00 × 100 |

| Material Constants | Optimal Value | Material Constants (J/mol) | Optimal Value |

|---|---|---|---|

| 1.15 × 10−6 | 1.26 × 105 | ||

| 1.93 × 102 | −7.01 × 104 | ||

| 1.59 × 101 | −2.11 × 104 | ||

| 1.21 × 101 | 2.35 × 104 | ||

| 2.67 × 10−2 | −2.29 × 104 | ||

| 7.94 × 101 | −6.12 × 104 | ||

| 3.29 × 101 | −4.45 × 103 | ||

| 1.01 × 100 (Elastic) | −2.35 × 104 | ||

| 1.04 × 100 (Plastic) | 2.87 × 104 | ||

| 4.8 × 10−1 | 1.08 × 105 | ||

| 1.00 × 100 | 3.19 × 102 (Elastic) | ||

| 2.56 × 101 | 3.47 × 102 (Plastic) | ||

| 5.00 × 10−2 | |||

| 1.00 × 100 | |||

| 8.00 × 10−2 | |||

| 4.09 × 10−5 | |||

| 1.58 × 103 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, D.; Li, Y.; Li, X. A Unified Constitutive Model of Stress Relaxation of Ti-6Al-4V Alloy with Different Temperatures from Elastic to Plastic Loading. Machines 2022, 10, 437. https://doi.org/10.3390/machines10060437

Zhang Y, Li D, Li Y, Li X. A Unified Constitutive Model of Stress Relaxation of Ti-6Al-4V Alloy with Different Temperatures from Elastic to Plastic Loading. Machines. 2022; 10(6):437. https://doi.org/10.3390/machines10060437

Chicago/Turabian StyleZhang, Ying, Dongsheng Li, Yong Li, and Xiaoqiang Li. 2022. "A Unified Constitutive Model of Stress Relaxation of Ti-6Al-4V Alloy with Different Temperatures from Elastic to Plastic Loading" Machines 10, no. 6: 437. https://doi.org/10.3390/machines10060437

APA StyleZhang, Y., Li, D., Li, Y., & Li, X. (2022). A Unified Constitutive Model of Stress Relaxation of Ti-6Al-4V Alloy with Different Temperatures from Elastic to Plastic Loading. Machines, 10(6), 437. https://doi.org/10.3390/machines10060437