Study of Heat Transfer and Leakage Characteristics of Brush Seals Based on Local Temperature Non-Equilibrium Model

Abstract

:1. Introduction

2. Numerical Method for Heat Transfer Characteristics of Brush Seals

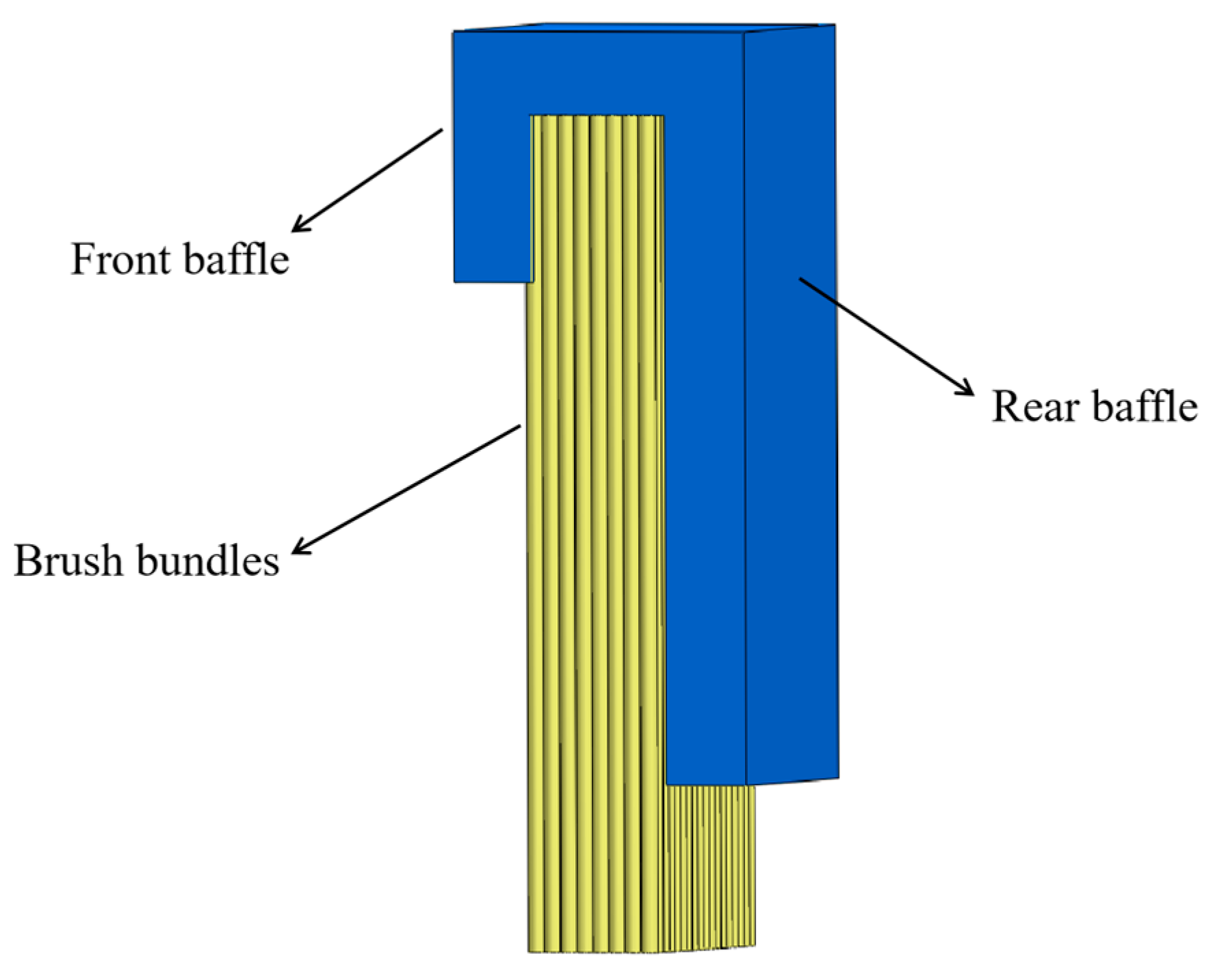

2.1. Brush Seal Construction

2.2. Theoretical Model of Heat Transfer in Porous Media

- (1)

- The leakage gas of the brush seal is an ideal compressible gas;

- (2)

- During the heat flow transfer process of the brush seal, half of the heat is transferred to the rotor, and half of the heat is transferred to the free end of the brush wire;

- (3)

- The filament material of the brush seal is Haynes25, and the uniform cylinder;

- (4)

- When modeling the brush filament bundle area of the brush seal, the brush filaments are not drawn, and the entire area is regarded as a porous medium;

2.2.1. LTE Model

2.2.2. The LTNE Model

2.3. Heat Transfer Calculation of Brush Seal and Setting of Brush Material Parameters

3. Brush Seal Porous Media Solver Model

3.1. Structure and Boundary Conditions

3.2. Finite Element Solution Process

3.3. Grid-Independent Verification

3.4. Verification of the Accuracy of the Finite Element Analysis Model

4. Characterization of Brush Seal Flow and Temperature Field Distribution

4.1. Pressure Distribution Characteristics Analysis

4.2. Characterization of the Velocity Distribution

4.3. Characterization of the Temperature Distribution

5. Comparative Analysis of the Factors Influencing the Heat Transfer and Leakage Characteristics of Brush Seals

5.1. Comparative Analysis of Factors Influencing Heat Transfer Characteristics

5.2. Comparative Analysis of the Factors Influencing Flow Characteristics

5.3. Comparative Analysis of Factors Influencing Leakage Rates

6. Conclusions

- The fluid reached its maximum velocity below the rear baffle and reached its maximum velocity near the rotor surface, flowing out in a jet; the temperature at the free end of the brush filament was then at its maximum and transferred heat to the root of the filament, where it gradually decreased.

- The maximum temperature of the brush filament increased with an increase in the pressure ratio, interference volume, and rotational speed. As the pressure ratio increased, the flow velocity increased, which accelerated the convective heat transfer between the brush filament and the airflow. Thus, the temperature increased with the pressure ratio, but the gradient of the increase became increasingly smaller. When comparing the maximum brush filament temperatures in the two models, the maximum brush filament temperature in the LTNE model was higher than that in the LTE model, and the maximum brush filament temperature in the LTNE model varied more significantly.

- The fluid flow velocity increased with an increase in the pressure ratio, interference volume, and rotational speed. The factors that influenced how fast the fluid flow velocity increased from large to small were: interference volume, rotational speed, and pressure ratio. However, the fluid velocity in the LTNE model always remained slightly higher than that in the LTE model.

- The leakage rate increased linearly with an increase in the pressure ratio. Additionally, the leakage rate decreased with an increase in interference under an increasing gradient. The leakage rate also decreased linearly with an increase in speed. Overall, the leakage rate values under the LTNE model were significantly lower than those under the LTE model, making the LTNE model preferable in this regard.

- The LTNE model had a higher temperature and fluid flow rate than the LTE model. Moreover, the LTNE model offered a lower leakage rate than the LTE model. The numerical calculations under the LTNE model were also better than those under the LTE model. Therefore, the numerical calculation under the LTNE model is better than that of the LTE model.

- On the whole, when using the porous medium model to analyze the sealing performance of the brush seal in the future, the numerical calculation will be more accurate and more in line with the actual working conditions by using the LTNE model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Fi | Additional drag source term |

| Ai | Viscous drag coefficient |

| Bi | Inertia drag coefficient |

| Δp | Differential pressure |

| L | Upstream and downstream distance |

| Dp | Average diameter of solid particles |

| D | Filament diameter |

| va | Average velocity |

| Vs | Filament volume |

| V | Total volume of porous media region |

| N | Tow Density |

| Dr | Rotor diameter |

| r | Radial height of filament |

| T | Temperature |

| Cpf | Fluid constant pressure specific heat capacity |

| Cps | Solid constant pressure specific heat capacity |

| Ts | Solid temperature |

| Tf | Fluid temperature |

| Re | Reynolds number |

| Pr | Prandtl number |

| Ff | Friction between filament bundle and rotor |

| v | Relative sliding speed of the filament bundle to the rotor |

| Fn | The normal contact force between the filament bundle and the rotor |

| Δr | The amount of interference between the filament bundle and the rotor |

| T0 | Normal temperature |

| TS | Sutherland constant |

| Greek Symbols | |

| ρ | Density |

| μ | Dynamic viscosity |

| ε | Porosity |

| ω | Axial thickness of filament bundle |

| φ | Tow angle of inclination |

| ρf | Fluid density |

| ρs | Solid density |

| κeff | Equivalent thermal conductivity |

| κf | Thermal conductivity of fluid |

| κs | Thermal conductivity of solid |

| ρj | Interfacial area density |

| κ | Convective heat transfer coefficient between fluid and solid surface |

| ξ | Friction factor |

| γBTP | Tow hardness |

| Abbreviations | |

| LTNE | Local temperature non-equilibrium |

| LTE | Local temperature equilibrium |

| FVM | Finite volume method |

| UDF | User-defined function |

| RANS | Reynolds-averaged Navier-Stokes |

| CFD | Computational fluid dynamics |

| RNG | Renormalization Group |

References

- Zhao, H.; Jiao, Z.; Sun, D.; Liu, Y.; Zhan, P.; Xin, Q. Numerical and experimental study on the influencing factors of pressure drop distribution between stages of multi-stage brush seals. J. Acta Aeronaut. Astronaut. Sin. 2020, 41, 74–86. [Google Scholar]

- Zhang, Y.; Jun, L.I.; Zhigang, L.I.; Xin, Y.A. Effect of bristle pack position on the rotordynamic characteristics of brush-labyrinth seals at various operating conditions. J. Chin. J. Aeronaut. 2020, 33, 1192–1205. [Google Scholar] [CrossRef]

- Lee, K.; Ha, T. Analysis of hybrid brush seal rotordynamic coefficients according to position of brush and clearance using 3D CFD. J. Int. J. Fluid Mach. Syst. 2020, 13, 90–102. [Google Scholar] [CrossRef]

- Wei, Y.; Liu, S. Numerical analysis of the dynamic behavior of a rotor-bearing-brush seal system with bristle interference. J. Mech. Sci. Technol. 2019, 33, 3895–3903. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Zhang, Y.; Wang, L.; Liu, L. Research progress of brush seal technology. J. Aeroengine 2019, 45, 78–88. [Google Scholar]

- Fu, T. Research on Thermal Fluid Brush Seal at Rudder Shaft of Aircraft. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2015. [Google Scholar]

- Kirk, T.; Bowsher, A.; Crudgington, P. High Temperature Brush Seal Development. In Turbo Expo: Power for Land, Sea, and Air; ASME: New York, NY, USA, 2017; Volume 50886. [Google Scholar]

- Chew, J.W.; Hogg, S.I. Porosity Modeling of Brush Seals. J. Tribol. 1997, 119, 769–775. [Google Scholar] [CrossRef]

- Qiu, B.; Li, J. Numerical Investigations on the Heat Transfer Behavior of Brush Seals Using Combined Computational Fluid Dynamics and Finite Element Method. J. Heat Transf. 2013, 135, 122601. [Google Scholar] [CrossRef]

- Dogu, Y.; Aksit, M.F. Brush Seal Temperature Distribution Analysis. J. Eng. Gas Turbines Power 2005, 128, 599–609. [Google Scholar] [CrossRef]

- Chai, B.; Fu, X. Numerical simulation of the flow and temperature fields of brush seals. Lubr. Eng. 2016, 41, 121–125. [Google Scholar]

- Qiu, B.; Li, J.; Feng, Z. Investigation of Conjugate Heat Transfer in Brush Seals Using Porous Media Approach Under Local Thermal Non-Equilibrium Conditions. In Turbo Expo: Power for Land, Sea, and Air; ASME: New York, NY, USA, 2015; Volume 56734. [Google Scholar]

- Zhang, Y.; Wang, Y.; Yan, X.; Li, J. Study on the leakage flow and heat transfer characteristics of brush seals Part II: Heat transfer characteristics. J. Eng. Thermophys. 2018, 39, 970–976. [Google Scholar]

- Bayley, F.J.; Long, C.A. A Combined Experimental and Theoretical Study of Flow and Pressure Distributions in a Brush Seal. J. Eng. Gas Turbines Power 1993, 115, 404–410. [Google Scholar] [CrossRef]

- Dogu, Y.; Aksit, M.F.; Demiroglu, M.; Dinc, O.S. Evaluation of Flow Behavior for Clearance Brush Seals. J. Eng. Gas Turbines Power 2008, 130, 012507. [Google Scholar] [CrossRef]

- Li, P.; Hu, Y.; Ji, H. Study on the leakage characteristics and hysteresis effect of low hysteresis brush seals. Lubr. Eng. 2020, 45, 52–58. [Google Scholar]

- Liu, L.; Zhang, Y.; Li, J. Study on the effect of brush seal on the aerodynamic performance of turbine stage. J. Eng. Thermophys. 2020, 41, 122–127. [Google Scholar]

- Chang, Y.; Sun, B.; Zhang, L. Leakage performance predictions of a brush seal based on fluid--solid coupling method. J. Sci. Prog. 2020, 103, 399502459. [Google Scholar]

- Zhang, Y.; Yan, J.; Li, J. Numerical study of the factors influencing the leakage and heat transfer characteristics of brush seals. J. Propuls. Technol. 2018, 39, 116–124. [Google Scholar]

- Ma, D.; Zhang, Y.; Li, J.; Yan, X. Research on the influence of the rear splint structure considering the deformation of the brush wire on the leakage and heat transfer characteristics of the brush seal. J. Xi’an Jiaotong Univ. 2019, 53, 15–25. [Google Scholar]

- Li, H.; Sun, D.; Zhao, H. Numerical method for heat transfer characteristics of brush seal flow. J. Aerosp. Power 2021, 36, 1826–1838. [Google Scholar]

- Zhang, Y.; Li, J.; Li, Z.; Yan, X. Numerical comparison of leakage flow and rotordynamic characteristics for two types of labyrinth seals with baffles. J. Eng. Gas Turbines Power 2020, 142, 091008. [Google Scholar] [CrossRef]

- Hildebrandt, M.; Schwitzke, C.; Bauer, H. Analysis of heat flux distribution during brush seal rubbing using CFD with porous media approach. J. Energ. 2021, 14, 1888. [Google Scholar] [CrossRef]

- Qiu, B.; Li, J. Coupled heat transfer characteristics of brush seal based on local non-thermal equilibrium method for porous media. J. Aerosp. Power 2015, 30, 1067–1075. [Google Scholar]

- Lu, L.; Xin, C.; Liu, Z. A review of research on local non-thermal equilibrium models for porous media. Therm. Power Eng. 2019, 34, 1–8. [Google Scholar]

- Guo, Z. Study on the Thermal Characteristics of Fluid Dynamic Pressure Fingertip Seal Based on Experimental Environment. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2020. [Google Scholar]

- Zhang, G.; Sun, D.; Jiao, Z. Numerical and experimental study of heat transfer characteristics of two-stage brush seal flow. Chin. J. Turbomach. 2020, 62, 47–55. [Google Scholar]

- Zhao, R. Calculation method of carbon fiber brush seal performance and research on leakage characteristics. Mechanical Design and Theory. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

- Zhang, S. Performance Study of “L” Shaped Flexible Wire Brush Type Seal. Mechanical Engineering. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2019. [Google Scholar]

- Sun, D.; Li, G.; Ai, Y. Numerical study on heat transfer mechanism of brush seal based on 3D solid modeling. J. Aerosp. Power 2019, 34, 1633–1643. [Google Scholar]

| Physical Property Parameters | Unit | Numerical Values |

|---|---|---|

| Density | kg/m3 | 9130 |

| Poisson’s ratio | 0.29 | |

| Elastic Modulus (20 °C~300 °C) | GPa | 231~214 |

| Specific heat capacity | J/(kg°C) | 385 |

| Thermal conductivity (20 °C~300 °C) | w/(m°C) | 8.27~13.4 |

| Parameters/Name | Unit | Numerical Values |

|---|---|---|

| Inlet pressure | MPa | 0.2 to 0.6 |

| Outlet pressure | MPa | 0.1 |

| Inlet temperature | K | 293 |

| Outlet temperature | K | 300 |

| Brush wire stiffness | MPa/m | 271.45 to 1085.79 |

| Amount of interference | mm | 0.2 to 0.35 |

| Rotational speed | r/min | 1200 to 12,000 |

| Rotor diameter/D | mm | 129.5 |

| Brush wire diameter/d | mm | 0.102 |

| Bristle bundle thickness/ω | mm | 2.033 |

| Width of backsplash/L | mm | 2.033 |

| Height of backsplash/H | mm | 2.1 |

| Brush filament inclination angle/Φ | ° | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liu, M.; Peng, N. Study of Heat Transfer and Leakage Characteristics of Brush Seals Based on Local Temperature Non-Equilibrium Model. Machines 2022, 10, 823. https://doi.org/10.3390/machines10090823

Zhang J, Liu M, Peng N. Study of Heat Transfer and Leakage Characteristics of Brush Seals Based on Local Temperature Non-Equilibrium Model. Machines. 2022; 10(9):823. https://doi.org/10.3390/machines10090823

Chicago/Turabian StyleZhang, Jiahao, Meihong Liu, and Neng Peng. 2022. "Study of Heat Transfer and Leakage Characteristics of Brush Seals Based on Local Temperature Non-Equilibrium Model" Machines 10, no. 9: 823. https://doi.org/10.3390/machines10090823