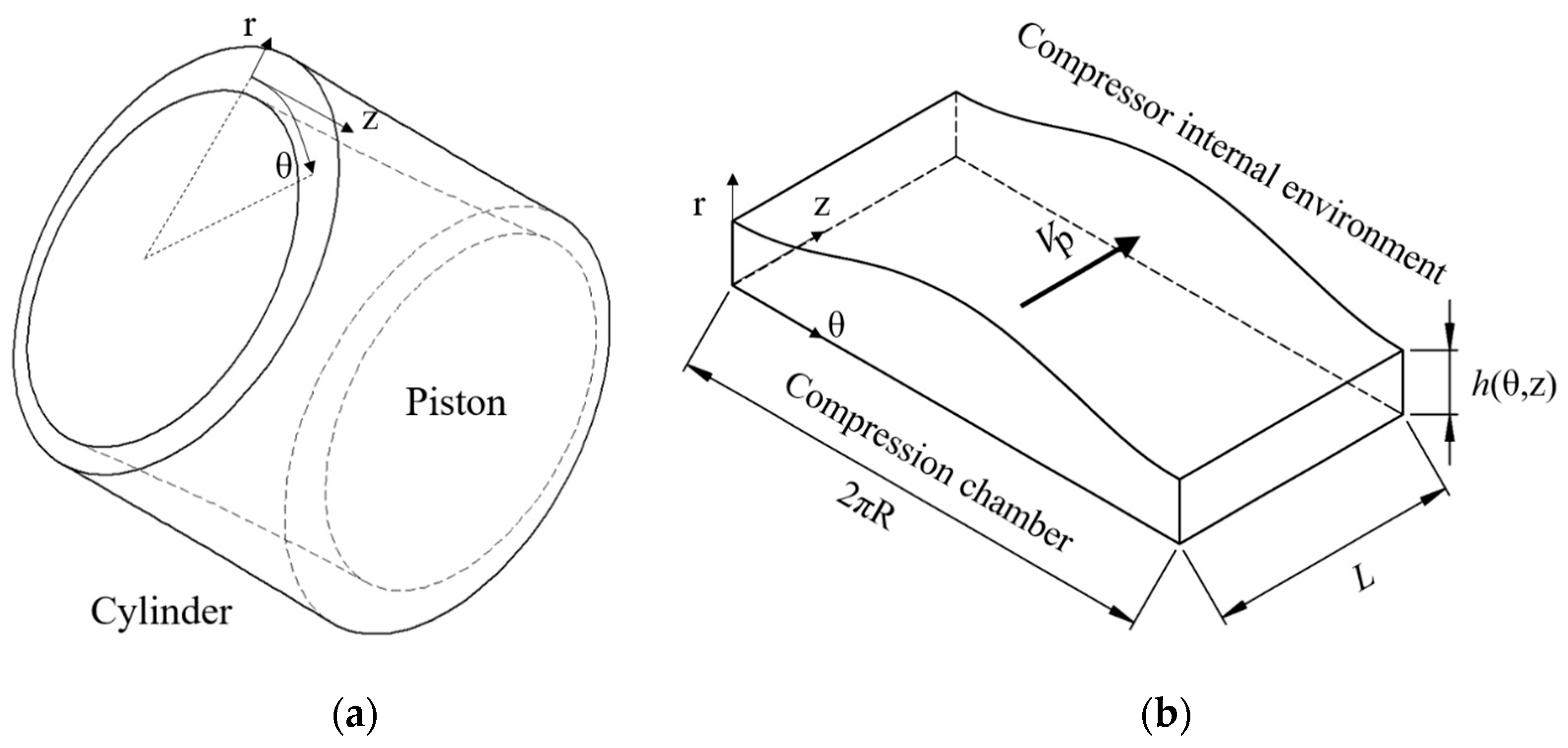

The present investigation considers a low-capacity reciprocating compressor with a displacement of 3 cm

3,

R = 10.5 mm,

L = 18.1 mm, operating with R-600a, operating with condensing temperature of 54.4 °C and evaporating temperature of −23.3 °C, unless stated otherwise. Firstly, the effects of gas compressibility and compressor speed were investigated by applying the 1D model that assumes the piston is concentric inside the cylinder. The 2D model was then adopted to assess the influence of the piston secondary motion on the leakage. It should be mentioned that the results of models were obtained considering the worst-case scenario, in which the clearance is filled only with gas. Naturally, had we considered the oil, the total leakage would be smaller, since the lubricating oil also acts as a sealing agent. However, although oil is not considered when evaluating the leakage of gas, lubrication must be considered to evaluate the piston trajectory required in the 2D model. To this extent, we adopted a model based on the Reynolds equation described by Prata et al. [

6]. Further details and the results of each analysis are presented below.

3.1. Verification of the Simplifying Hipotheses

Before carrying out the analysis, it is important to verify the validity of the hypotheses of continuum flow and ideal gas adopted in the simulation model.

A gas can be assumed as a continuum if the molecular mean free path, λ, is small compared to the characteristic length of the flow, L. Rarefaction effects become more important as the Knudsen number, , increases. In fact, the Knudsen number is used to classify different flow regimes as follows: continuum flow (), slip flow (), transitional flow (), and free-molecular flow (). It should be noted that the continuum hypothesis starts to fail when , but the Navier–Stokes equation can still be used in such situations with modified boundary conditions.

For a simple gas of hard molecules in thermodynamic equilibrium, the mean free path

is given by the following relationship [

19]:

where

d and

n are the molecular diameter and the number density of the gas, respectively.

The molecular diameter

d can be obtained from the viscosity and the Chapman–Enskong theory of transport properties for hard sphere molecules:

where

is the molecular mass,

(=1.3805 × 10

−23 J/K) is the Boltzmann constant and

is the temperature. The mean free path can be expressed more conveniently by combining Equations (10) and (11), resulting:

The mean free path

is a function of the properties of the flow through the piston–cylinder clearance, which vary with the crank angle

ωt. Hence, the Knudsen number was calculated for the entire cycle of compression, using the rigid sphere model described by Bird [

19] and considering the LBP operating condition (condensing temperature of 54.4 °C and evaporating temperature of −23.3 °C), since this condition presents the widest range of pressure and temperature.

Figure 4 shows the variation of

throughout the cycle, for two nominal diametric clearances taken as the characteristic length. As can be seen, part of the cycle is in the slip flow regime when

c = 5 µm. However, the most important part of the crank angle for the leakage calculation, i.e., the region where the pressure difference is the greatest (between 90° and 270°), is located within continuum theory, which validates the continuum flow hypothesis adopted herein.

Next, the ideal gas hypothesis was investigated by calculating the compressibility factor

Z for isobutane (R-600a), employing the REFPROP [

20] software and considering the LBP condition.

Figure 5 shows that the minimum compressibility factor along the compression cycle is approximately 91%, so the deviation from ideal gas behavior is less than 10%, allowing the ideal gas hypothesis to be considered with small deviation.

3.2. Results for Concentric Piston and Cylinder (1D Model)

The solution domain for the simplified geometry of concentric piston and cylinder is shown in

Figure 6. A first step in the analysis was to verify if the model implementation accurately represents the conceptual description and the solution of the model [

21]. In the study reported herein, the model was verified in terms of the truncation error, convergence criterion and implementation of the mathematical equations.

A grid convergence study was performed to assess the sensitivity of the numerical results to the spatial discretization. The grid convergence index (GCI) of Roache [

22] was used as a quantitative indicator to assess the required grid resolution. Accordingly, the GCI is applied to each grid resolution and estimates the discretization error via the extrapolation method of Richardson, which represents a measure of the percentage deviation from the calculated value in relation to the asymptotic solution. The GCI ratio is calculated to ensure a grid-independent solution. In this respect, a total of 250 control volumes were employed to discretize the solution domain, i.e., the piston–cylinder clearance, to guarantee that the difference between the model predictions and the estimates obtained via the Richardson extrapolation was less than 0.01%. The compression cycle was solved for small increments of the crank angle (Δ

wt = 0.001°) without considering the valve dynamics and heat transfer at the compression chamber walls.

The results of the 1D model were initially validated through comparison with the experimental data of Suefuji et al. [

23] for mass flow rate of R22 through a channel with a constant clearance (

h). The length and width of the channel were 4.5 mm and 126 mm, respectively, whereas the clearance value and the inlet pressure were varied throughout the tests. The temperature was set at 300 K and the outlet pressure was kept at 100 kPa. For completeness, we also compared our results to predictions of other models available in the literature. First, we included the correlation developed by Bell et al. [

24] for radial leakage in scroll compressors, which can also be applied for the piston–cylinder clearance if we consider a constant gap. Next, we included the analytical model proposed by Zuk and Smith [

2].

As can be seen from

Figure 7, the leakage mass flow rate (

) predicted by the model described herein and the measurements of Suefuji et al. [

23] are in reasonable agreement.

Table 1 shows the comparison between the measurements and predictions for three representative values of the pressure ratio span of each clearance. As can be seen, the maximum differences are around 10% for

h = 9 µm and 21 µm. For the most challenging case for measurements (

h = 3.6 µm) the maximum difference between the prediction and experimental data is approximately 40%. We also observe that Bell et al. [

24] correlation underpredicts leakage for the three gaps. Additionally, the predictions regarding the Zuk and Smith [

2] model were found coincident with the results of our model, which is an expected result, because for constant gap and neglecting piston velocity the two models are the same.

Leakage in the piston–cylinder clearance is brought about by the piston motion and pressure difference between the compression chamber and the internal environment of the compressor shell. The compressor rotational speed (n) or drive frequency determines the piston velocity, which is also responsible for the flow in the piston–cylinder clearance. In order to investigate the effect of the piston velocity on the leakage throughout the compression cycle, the 1D model was applied with different values for the rotational speed.

Figure 8 shows the results of these simulations for the diametric clearance

c = 5 µm (radial clearance

h =

c/2 = 2.5 µm) and the LBP condition. The ‘no velocity’ curve represents the results of Equation (9) with

Vp = 0 m/s. The vertical axis represents the relative leakage mass flow rate (

), defined as the leakage mass flow rate divided by the mass flow rate that an ideal compressor without leakage could supply. Positive values for

represent gas leaking from the compression chamber and negative values indicate leakage into the compression chamber. The results show that an increase in the piston velocity reduces the leakage rate in the compression and discharge processes (crank angles between 0° and 180°) and the opposite occurs in the expansion and suction processes (crank angles between 180° and 360°). In fact, the piston moves towards the top dead center in the compression process and therefore drags gas into the compression chamber through viscous friction, which reduces the

value. The opposite effect occurs when the piston moves towards the bottom dead center.

Figure 8 also shows that the piston velocity plays a minor role in the leakage, with only a small reduction of the overall leakage in the cycle. For instance, even when the piston velocity is increased to

n = 5400 rpm the total leakage throughout the cycle is reduced by approximately 5%.

The compressor operating conditions are defined by the evaporating and condensing temperatures of the refrigeration cycle, which defines the compressor suction and discharge pressures. Reference operating conditions used to test refrigeration compressors are the low-back pressure (LBP), medium-back pressure (MBP) and high-back pressure (HBP), as shown in

Table 2. The effect of such operating conditions on gas leakage is also investigated.

The results for

c = 9 µm and

n = 3600 rpm shown in

Figure 9 reveal that the leakage mass flow rate in the compressor increases with the evaporating pressure (

pevap). This may seem unexpected since the pressure difference decreases as the evaporating pressure increases, keeping the same condensing pressure (7.62 bar). Nevertheless, as indicated by Equation (9), the leakage mass flow rate also depends on the gas density, which is highest for the HBP condition, because the gas temperature in the discharge process reaches its lowest value. This aspect compensates for the smaller pressure difference of the HBP condition. As opposed to the leakage mass rate (

), the relative leakage (

) decreases with evaporating pressure, which shows that the relative influence of the gas leakage is more significant for the LBP case.

The effect of gas compressibility on leakage was investigated by comparing the results of the simulation models for compressible and incompressible fluid flow formulations. In the calculations, the LBP condition and different rotational speeds were considered.

Figure 10 shows the results for the leakage mass flow rate for two diametric clearances (

c = 5 and 13 µm). As can be observed, fluid compressibility effects are present in the flow and must be considered in the simulation model, otherwise predictions would overestimate the leakage in the piston–cylinder clearance. For instance, for

n = 1800 rpm, the leakage predicted with the incompressible fluid formulation is approximately twice the value provided by the compressible fluid model. Hence, even without evidence from measurements, the incompressible formulation can be discarded as a physically meaningful representation of the critical scenario of only gas in the clearance.

The volumetric efficiency and isentropic efficiency are commonly used to assess compressor performance. The volumetric efficiency

is defined as the ratio between the actual mass flow rate,

, and the ideal mass flow rate,

:

The ideal mass flow rate is that which undergoes no reduction due to different factors such as leakage, cylinder clearance volume, suction gas superheating and flow viscous friction.

The isentropic efficiency is defined as the ratio between the compression power required by an isentropic process and the actual indicated power, i.e.,

Figure 11 shows the results obtained for the reduction in the efficiency due to leakage, for different rotational speeds and clearances, considering the LBP condition. The reduction in efficiency is defined herein as the absolute difference between the volumetric and isentropic efficiencies with and without gas leakage (subscript ‘

nl’):

As can be seen in

Figure 11, the effect of leakage on the reduction of both efficiencies is more significant for a lower drive speed and larger clearance. In the worst cases, the reduction can reach more than 8% for the volumetric efficiency and more than 22% for the isentropic efficiency.

3.3. Effect of the Piston Secondary Motion

To the authors’ knowledge, there is no available experimental data for leakage in the piston–cylinder clearance of reciprocating compressors when the piston secondary motion is considered. Because of that, the validation of the 2D model was carried out by comparing the model predictions with the results of CFD simulations performed in ANSYS Fluent v15. The simulations considered laminar, steady fluid flow, using a coupled scheme for the pressure and velocity solution, and second order discretization schemes for the momentum, density, and pressure. Five boundary conditions were adopted: (i) pressure at the inlet equal to 7.62 bar; (ii) pressure at the outlet equal to 0.629 bar; (iii) moving nonslip condition for the piston wall; (iv) static nonslip condition for the cylinder wall; (v) symmetry for the faces across the

rz plane, as shown in

Figure 12.

A mesh convergence study was performed to assess the sensitivity of the numerical results to different levels of discretization. The grid convergence index (GCI) of Roache [

22] was then used as a quantitative indicator to assess how far the numerical result was from mesh independence, which in our case was found to be 4% for the 3D model and 0.02% for the 2D model.

Figure 13 shows the 2D and 3D mesh model diagrams.

Figure 13a depicts the uniform 40 × 40 discretization mesh used in the 2D model, with volume indexation up to

40. The mesh discretization of the 3D model shown in

Figure 13b had 1.6 million hexahedral volumes (32 × 250 × 200 in the r, θ, and z directions, respectively), with a progressive refinement towards the solution domain outlet since the greatest pressure gradient is found in this region.

Figure 14 shows the comparison for two cases, in case 1, the piston is symmetrically tilted, i.e.,

= 0.5 and

= −0.5, whereas in case 2, the piston undergoes pure radial displacement:

=

= 0.5, where

c = 13 µm and

and

are illustrated in

Figure 2. For case 1, the comparison between our model and Fluent shows a very good agreement, with a maximum deviation of 3.4%. On the other hand, the difference for case 2 is within 14%, which is still considered acceptable. The increase in deviation from case 1 to case 2 probably comes from the fact that our model neglects the inertial terms. These terms are more important for case 2, because the radial displacement of the piston produces a path with a considerably larger clearance to the leakage flow.

Before calculating the secondary motion of the piston, its influence on the leakage was assessed by prescribing different eccentricities for the piston which was kept in a fixed position. The two configurations depicted in

Figure 14 (case 1 and case 2) were analyzed for different values of dimensionless eccentricity

ε =

e/

c. The CFD model employed to obtain the results in

Figure 14 was used with the same boundary conditions, except for the piston speed which was considered zero in all cases.

Regarding case 1,

Figure 15a shows that leakage decreases in comparison with the concentric case, since the symmetrical tilted position of the piston restricts the gas flow in the clearance, forcing the fluid to circumvent the piston. This effect can be observed by the streamlines depicted in

Figure 16 together with the radial clearance field contour, showing the flow is directed towards the regions of greater radial clearance.

Figure 15b compares the leakage for case 2 as a function of piston eccentricities in comparison with the leakage for the concentric case (

). The results show that leakage is intensified as the eccentricity increases. This is because the piston radial displacement creates a region with high radial clearances, making it easier for the gas to flow through this region. In fact, leakage can increase by up to 150% when the piston is almost contacting the cylinder. This finding is corroborated by Liang [

5], who also found that leakage is intensified by a factor of 2.5 when the piston positioning is fully eccentric inside the cylinder.

To assess the influence of piston secondary motion on leakage for the geometry detailed in

Figure 17, we first determined the piston trajectory with a lubrication model described by Prata et al. [

6], considering the oil alkylbenzene ISO VG 5. The required parameters are listed in

Table 3, where

zCM is the position of the piston center of mass,

Crod is the connecting rod length and

CCM is the position of connecting rod center of mass. The piston trajectory was calculated for different piston wrist-pin positions (

zp) and different clearances (

c). The results for the dimensionless eccentricity

ε are shown in

Figure 18.

Once the piston trajectory is known, we can determine the thickness of the fluid film for any point inside the clearance (

h), applying Equation (2). Then the gas leakage can be predicted throughout the compression cycle using the 2D leakage model.

Figure 19 shows the percentage difference between values for the leakage obtained with the 2D model (piston secondary motion) and 1D model (piston concentric motion). It should be noted that that leakage is greatly intensified by the piston secondary motion.

Figure 19a shows that the wrist-pin position is a very important parameter, when

zp/

L = 0.75, i.e., the wrist-pin is located below the piston center, leakage is increased by almost 90%; on the other hand, if the wrist-pin is located in the piston center, the increase in leakage is below 20%. These results can be explained considering the eccentricities reported on

Figure 18a, where it shows that

zp/

L = 0.75 produce the largest eccentricities. As the top and bottom eccentricities increase, and both have the same sign, the piston–cylinder assembly resembles the configuration of case 2 depicted in

Figure 14 and analyzed through the results in

Figure 15b. Therefore, the piston secondary motion intensifies the overall leakage through the clearance. The same effect can be observed in

Figure 19b. As the diametric clearance c increases, the eccentricities in

Figure 18b also increase, increasing the leakage in the clearance by approximately 90% when

c = 13 µm.