Safety Analysis of Small Rail Roadway Stacker Based on Parametric Design

Abstract

:1. Introduction

2. Working Condition Analysis of Small Rail Roadway Stacker

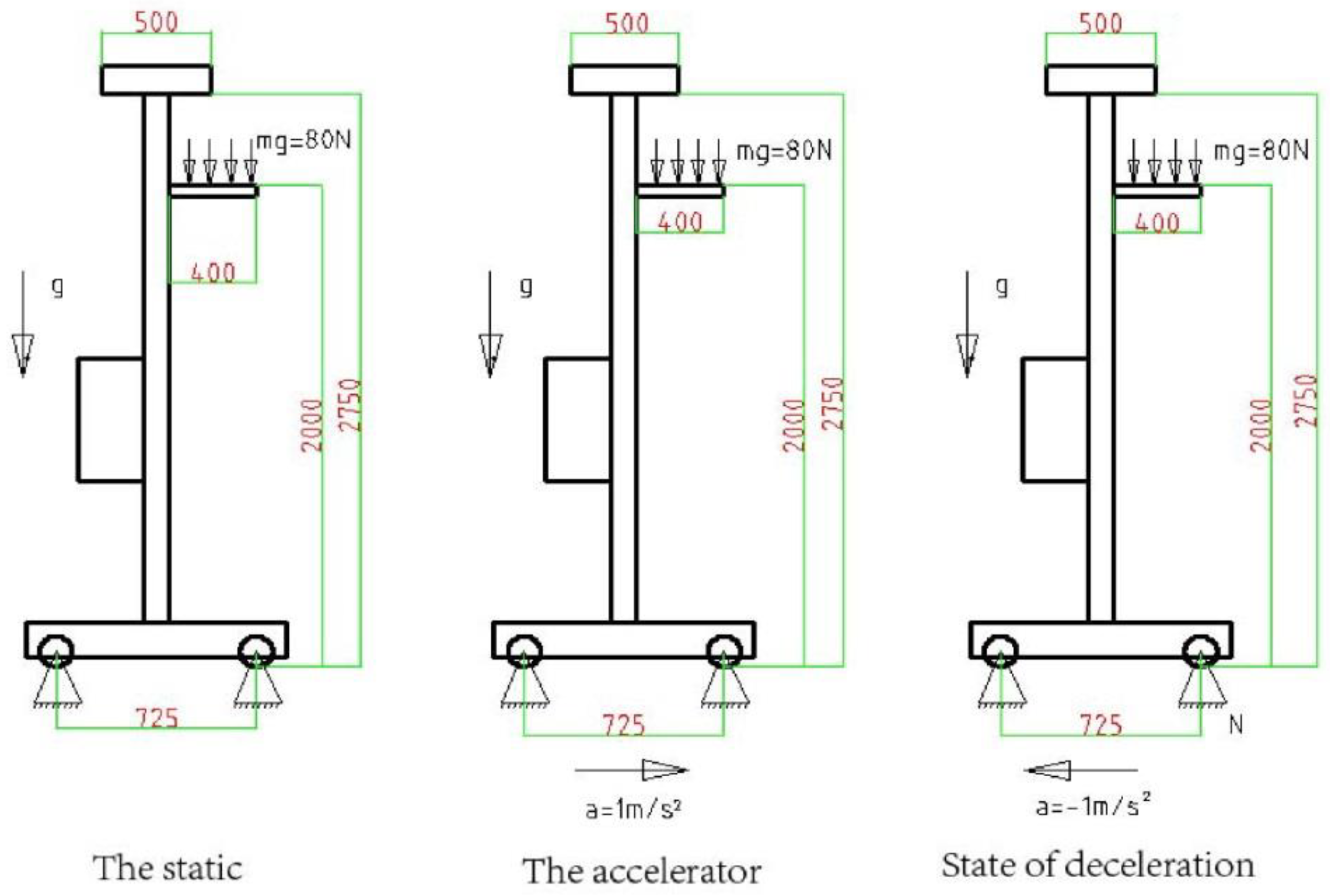

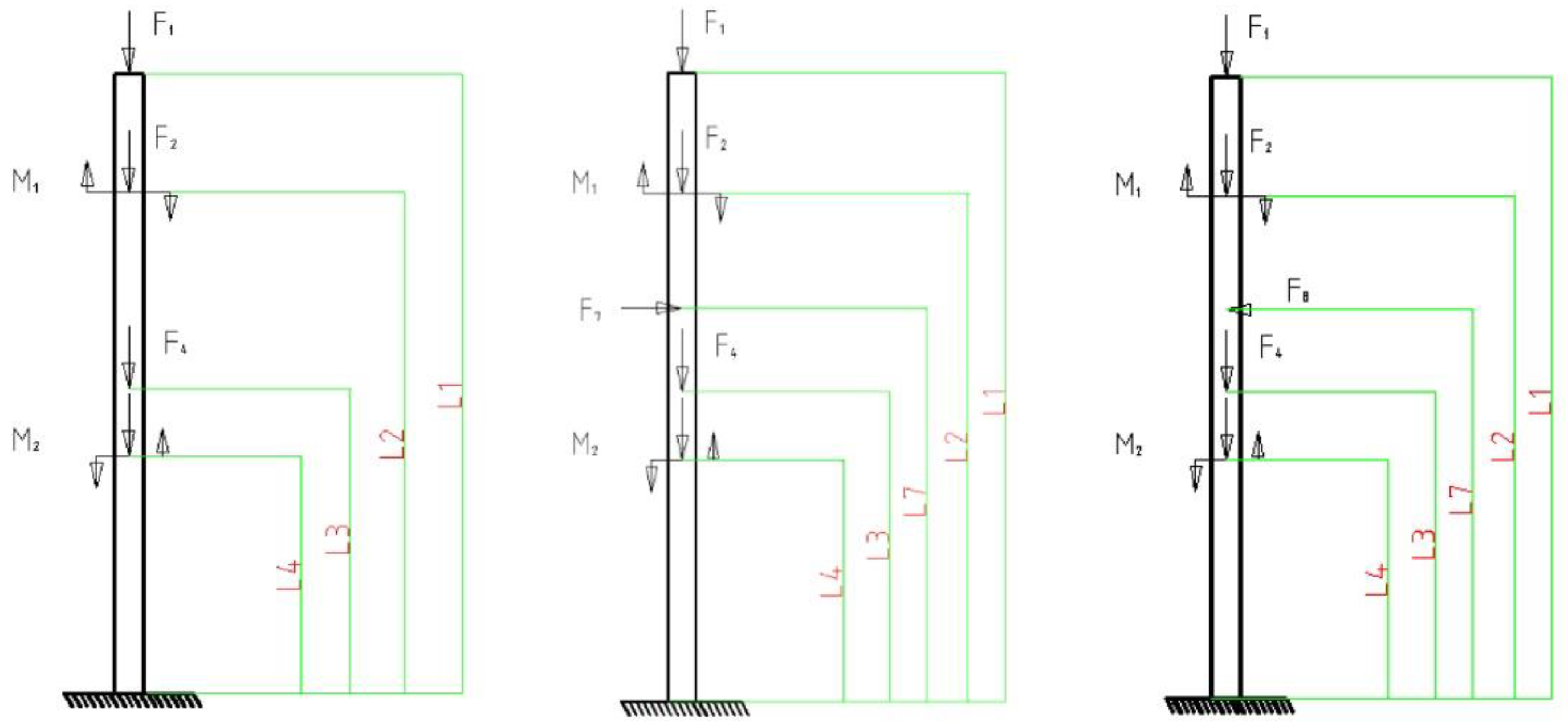

2.1. Safety Analysis Factors of Small Rail Roadway Stacker

2.2. Load Analysis of Small Rail Roadway Stacker

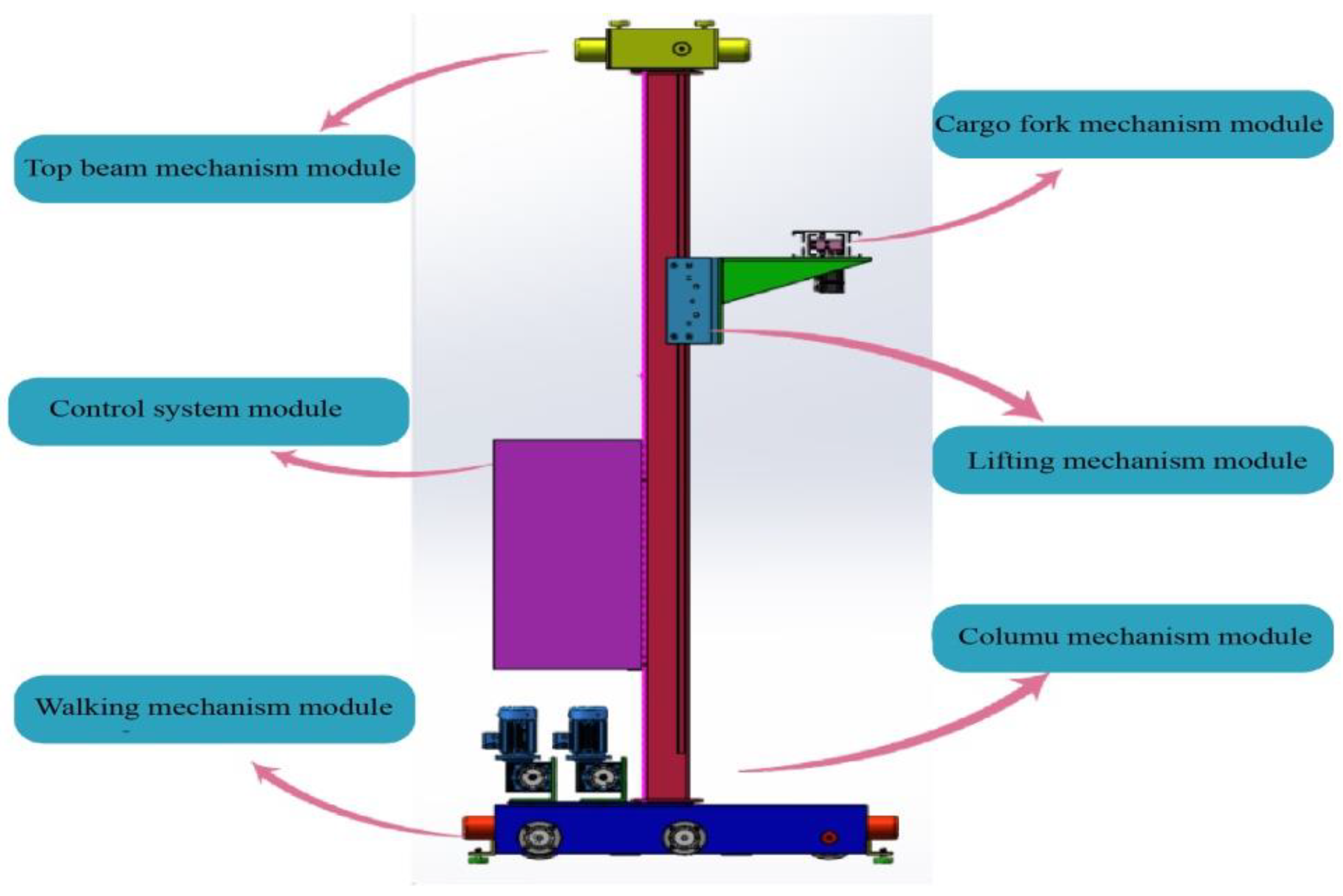

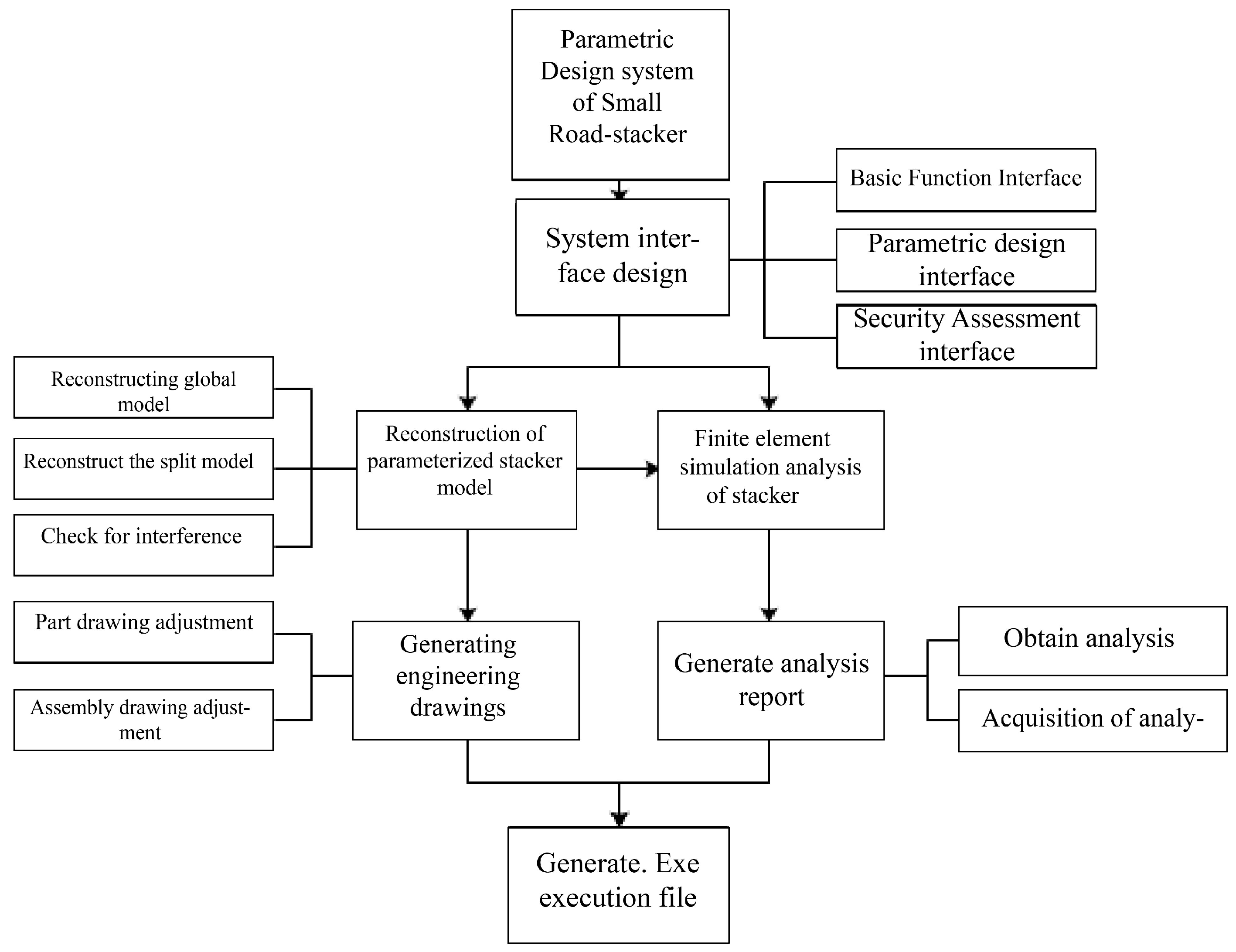

3. Modeling and Interface of Stacker Crane with Parameterized Operation

3.1. Modeling of Small Rail Roadway Stacker

- (1)

- When modeling the parts, their structural characteristics should be first analyzed in order to determine the modeling sequence. The features of the models should be as simple as possible, and without too many parameters. Constraints or functional relations should be added in order to restrict the models. Serialization parameters are then added to the parts related to performance parameters (column in the column mechanism module, machine body in the walking mechanism module, and lower fork plate in the cargo fork mechanism), and a part design table is established.

- (2)

- In the assembly of parts, the assembly sequence and relative position relationship should be analyzed. The assembly of the internal parts of each module is first performed. Equations are then added to the sizes associated with the equation design, in order to form a corresponding relationship between the sizes. After the assembly of each module is completed, the whole assembly should be uniformly performed.

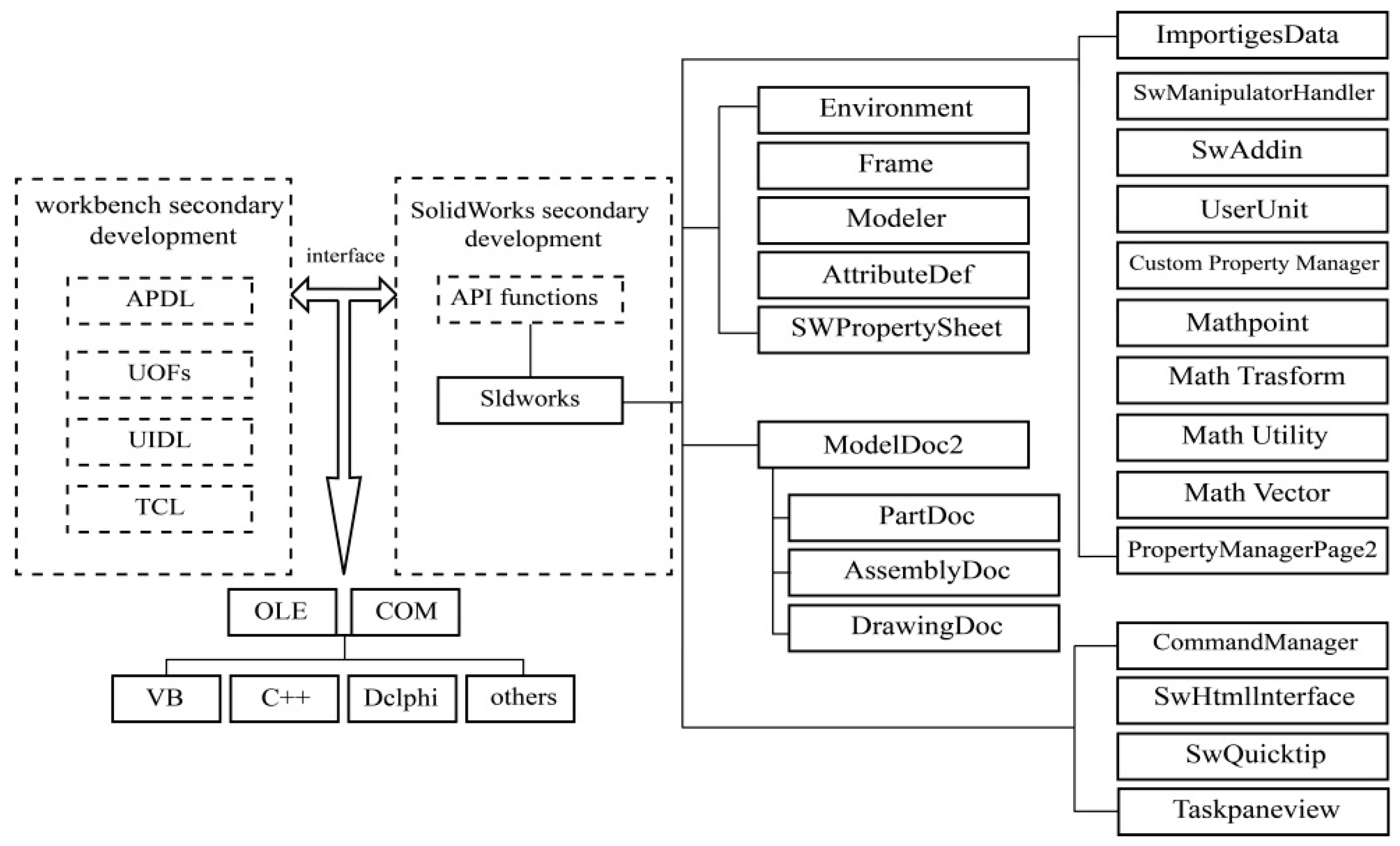

3.2. Software Development and Modeling Interface

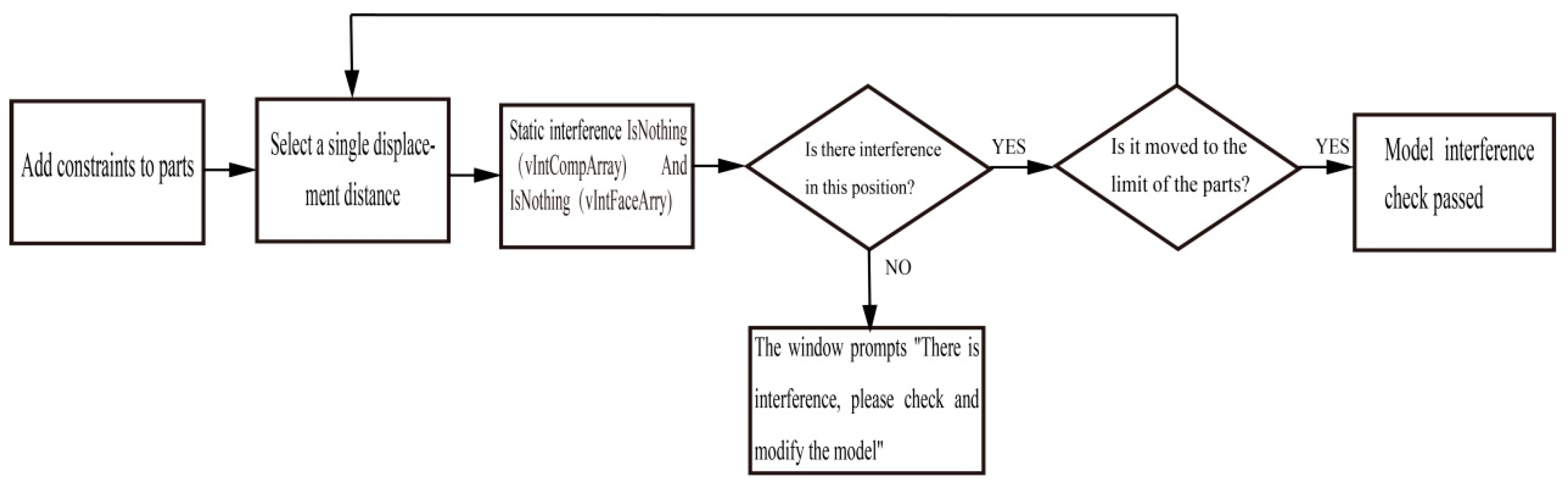

3.3. Interference Check of the Model

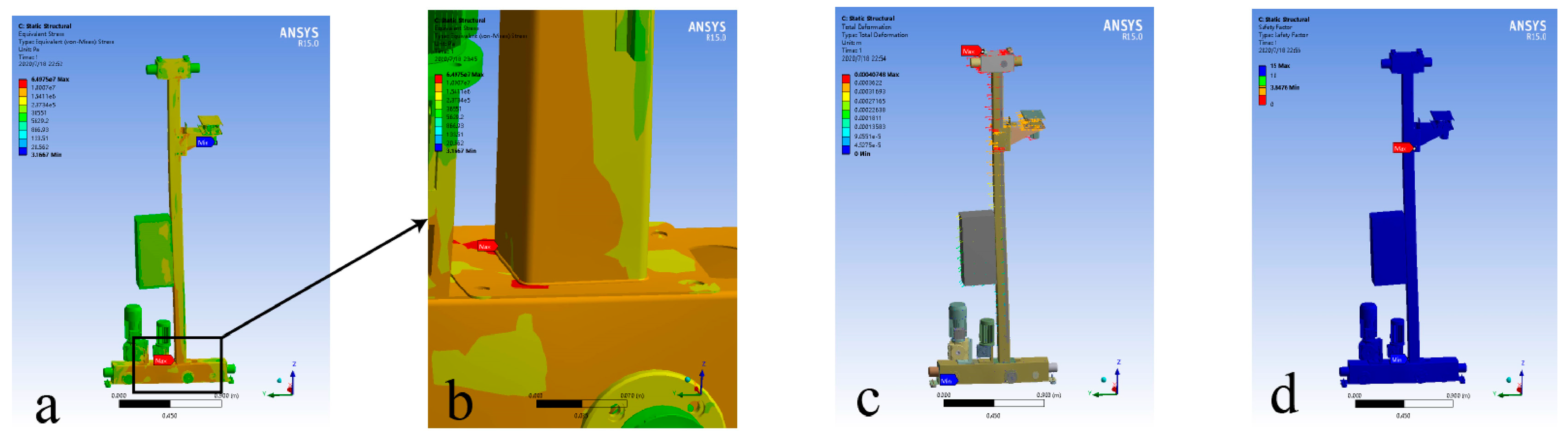

4. Safety Analysis of Small Rail Roadway Stacker

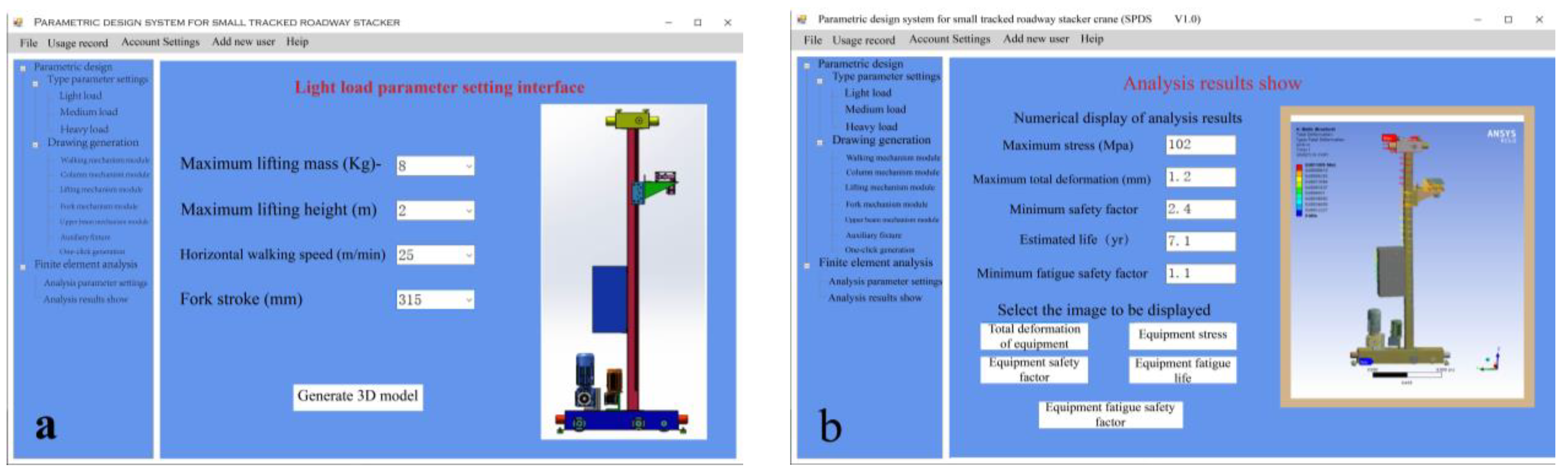

5. Software Development Example of Small Rail Roadway Stacker Design System

6. Results

7. Discussion

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, X.Y.; Chen, Y.; Wang, P. Application of Genetic Algorithm in Path Optimazition of Stacker. J. Anhui Polytech. Univ. 2019, 34, 33–38. [Google Scholar]

- Li, L. The composition of modern logistics and automated warehouse systems. Autom. Instrum. 2017, 1, 152–154. [Google Scholar]

- Xie, Y.M.; Yan, X.Q.; Zou, Y. The principle and application of stackers in automated warehouses. Pop. Util. Electr. 2018, 3, 22–23. [Google Scholar]

- Tsujimoto, K.; Li, G.H. The development history of automatic three-dimensional warehouse roadway stacker technology. Logist. Mater. Handl. 2006, 8, 92–95. [Google Scholar]

- Jabi, W.; Soe, S.; Theobald, P.; Aish, R.; Lannon, S. Enhancing parametric design through non-manifold topology. Des. Stud. 2017, 9, 96–114. [Google Scholar] [CrossRef]

- Wang, D.S. Parameterized design of stacker crane. Logist. Mater. Handl. 2007, 5, 94–95. [Google Scholar]

- Gan, Z.P.; Jin, G.F.; Fang, J.M. Research on modular design of stacker cranes. Hoisting Conveying Mach. 2007, 4, 85–88. [Google Scholar]

- Song, Z.L.; Shen, M.D.; Zhang, H.X. Serial design of small railroad roadway stacker. Constr. Mach. Equip. 2007, 10, 63–66+144. [Google Scholar]

- Wei, F.; Wang, Z.Y.; Wu, S.F. Intelligent design platform for mechanical products based on CBR. Mach. Des. Manuf. 2010, 11, 253–255. [Google Scholar]

- Wang, S.T.; Wang, Z.Y.; Wu, S.F. Roadway stacker rapid design system based on SolidWorks. Mach. Des. Manuf. 2011, 1, 53–55. [Google Scholar]

- Chen, J.; Tang, X.L.; Ding, L. Workbench-based mechanical analysis for fork of double-column stacker. Hoisting Conveying Mach. 2016, 7, 69–72. [Google Scholar]

- Zheng, Y.Q.; Huang, J.G.; Zhao, R.Z. Based on the Finite Element Analysis of Single Mast Stack-crane Structure Optimazition and Improvement. Modul. Mach. Tool Autom. Manuf. Tech. 2010, 9, 83–85. [Google Scholar]

- Huang, C.; Hu, Y.J.; Dong, Y.H. Mechanical Analysis and Structural Optimization of Single Column Stacker Frame. J. Tianjin Univ. Sci. Technol. 2018, 33, 61–66. [Google Scholar]

- Fu, C.Y.; Ding, S.H.; Wang, Z.J. Single Mast Stacker Crane Speed Control and Stand Column Dynamic Flexure Derformation Structure. Mach. Des. Manuf. 2019, 6, 247–251. [Google Scholar]

- Zhang, L.; Zhang, F.; Qin, Y.T. Research and Simulation on Vibro-impact of Double-Mast Stacker Crane. J. Vib. Meas. Diagn. 2018, 38, 1143–1147+1290. [Google Scholar]

- Ma, W.; Lu, J. Review on Carburizing Case Quality of Carburizing and Hardening Gear. J. Mech. Transm. 2015, 39, 170–175. [Google Scholar]

- Zeng, X.G.; Zhang, L.L. Secondary development of SolidWorks based on VB. Mech. Eng. 2006, 3, 131–132. [Google Scholar]

- Liu, J.F.; Zhang, X.G. Parametric design of Engine Piston Based on Secondary Development of SolidWorks. Automob. Appl. Technol. 2019, 16, 62–65. [Google Scholar]

- Wang, X.G.; Guo, X.L.; Zhang, X.P. Using Thermography To Obtain The Fatigue Limit And S-N Curve Of Q235 Steel Rapidly. In Proceedings of the 2010 Cross-Strait Material Failure/Fracture Academic Conference and the Tenth Destruction Science Symposium/The Eighth National Proceedings of MTS Material Testing Conference, Tainan, China, 21 September 2010; pp. 964–968. [Google Scholar]

- Sun, R.; Wang, C.J.; Liu, P. Research on Automatic Design of Extendable TrussBased on CAD Software. Appl. Mech. Mater. 2012, 163, 172–175. [Google Scholar]

| / | Maximum Bending Stress σ (MPa) | Maximum Deformation ω (mm) |

|---|---|---|

| Static state | 9.5 | 0.78 |

| Under acceleration | 10.3 | 1.48 |

| Under deceleration | 8.6 | 0.65 |

| Object | Structure of Hierarchy | Function |

|---|---|---|

| SldWorks | The object at the top | Provides methods to access all other SolidWorks API |

| ModelDoc | Child object of SldWorks | Properties and methods of different document models |

| PartDoc | Child objects of ModelDoc | Part model file |

| AssemblyDoc | Child objects of ModelDoc | Assembly model file |

| DrawingDoc | Child objects of ModelDoc | Project drawing document |

| Feature | Child object of DrawingDoc | Feature of representation |

| Sketch | Child object of DrawingDoc | Sketch of representation |

| Environment | Child object of SldWorks | Representing the environment |

| AttributeDef | Child object of SldWorks | Attribute definition |

| Modeler | Child object of SldWorks | Model Management |

| / | The Acceleration (m/s2) | Maximum Stress (Mpa) | Maximum Deformation Displacement (mm) | Minimum Stress Safety Factor | Minimum Fatigue Life (Times) | Minimum Fatigue Safety Factor |

|---|---|---|---|---|---|---|

| The static situation | 0 | 65 | 0.4 | 3.8 | / | / |

| The accelerator | 1 | 102 | 1.1 | 2.4 | 3.1 × 106 | 1.1 |

| State of deceleration | −1 | 61 | 0.3 | 4.1 | / | 1.2 |

| / | Maximum Stress (Mpa) | Minimum Stress Safety Factor | Maximum Deformation Displacement (mm) | Minimum Fatigue Life (Times) | Minimum Fatigue Safety Factor |

|---|---|---|---|---|---|

| Stacker parameters | 102 | 2.4 | 1.2 | 3.1 × 106 | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Chen, Z.; Wu, J.; Wang, Y. Safety Analysis of Small Rail Roadway Stacker Based on Parametric Design. Machines 2023, 11, 8. https://doi.org/10.3390/machines11010008

Wu W, Chen Z, Wu J, Wang Y. Safety Analysis of Small Rail Roadway Stacker Based on Parametric Design. Machines. 2023; 11(1):8. https://doi.org/10.3390/machines11010008

Chicago/Turabian StyleWu, Wendong, Zhaoqiang Chen, Jun Wu, and Yudong Wang. 2023. "Safety Analysis of Small Rail Roadway Stacker Based on Parametric Design" Machines 11, no. 1: 8. https://doi.org/10.3390/machines11010008

APA StyleWu, W., Chen, Z., Wu, J., & Wang, Y. (2023). Safety Analysis of Small Rail Roadway Stacker Based on Parametric Design. Machines, 11(1), 8. https://doi.org/10.3390/machines11010008