Test and Simulation Study on the Static Load and Pure Longitudinal Slip Characteristics of Non-Pneumatic Tire

Abstract

:1. Introduction

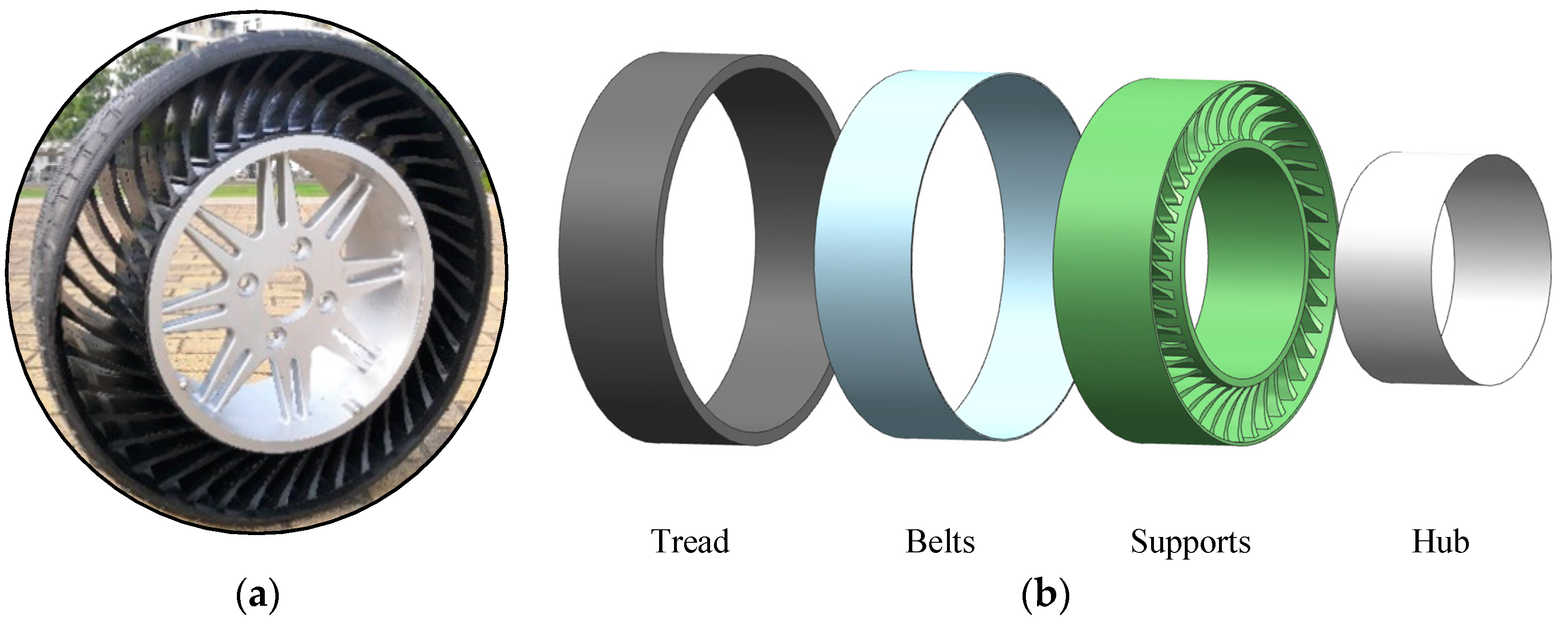

2. Design and Test Procedure

2.1. Geometric Design Dimensions

2.2. Material Properties

2.3. Test Program

2.3.1. Test Procedures

2.3.2. Test Results

3. FE Modeling and Validation

3.1. FE Modeling of NPT

3.1.1. Material Constitutive Model

3.1.2. FE Model

3.2. Validation of FE Models

4. Improved Design of NPT

4.1. Mechanism Analysis and Structural Design

4.2. Simulation Results and Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, K.W.; Kwark, C.W. Introduction to Technology Trends, Problems and Solutions of Non-Pneumatic. J. Korean Soc. Automot. Eng. 2019, 41, 26–31. [Google Scholar]

- Rugsaj, R.; Suvanjumrat, C. Proper radial spokes of non-pneumatic tire for vertical load supporting by finite element analysis. Int. J. Autom. Tech. 2019, 20, 801–812. [Google Scholar] [CrossRef]

- Żmuda, M.; Jackowski, J.; Hryciów, Z. Numerical research of selected features of the non-pneumatic tire. Comput. Technol. Eng. 2019, 2078, 020027. [Google Scholar] [CrossRef]

- Rugsaj, R.; Suvanjumrat, C. Development of a Transient Dynamic Finite Clement Model for the Drum Testing of a Non-Pneumatic Tire. IOP Conf. Ser. Mater. Sci. Eng. 2020, 886, 012056. [Google Scholar] [CrossRef]

- Sim, J.; Hong, J.; Cho, I.; Lee, J. Analysis of Vertical Stiffness Characteristics Based on Spoke Shape of Non-Pneumatic Tire. Appl. Sci. 2021, 11, 2369. [Google Scholar] [CrossRef]

- Jang, I.G.; Sung, Y.H.; Yoo, E.J.; Kwak, B.M. Pattern design of a non-pneumatic tyre for stiffness using topology optimization. Eng. Optimiz. 2012, 44, 119–131. [Google Scholar] [CrossRef]

- Kumar, A.S.; Kumar, R.K. Force and moment characteristics of a rhombi tessellated non-pneumatic tire. Tire Sci. Tech. 2016, 44, 130–148. [Google Scholar] [CrossRef]

- Meng, F.; Lu, D.; Yu, J. Flexible Cellular Structures of a Non-Pneumatic Tire. In Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016. [Google Scholar] [CrossRef]

- Wang, Q.; Xiao, Z.; Zhu, M.; Zhao, Y.; Deng, Y. Comparative Analysis of Static Loading Performance of Rigid and Flexible Road Wheel based on Finite Element Method. Def. Sci. J. 2020, 70, 41–46. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, Y.; Lin, F.; Xiao, Z.; Zhu, M.; Li, H. Simulation of steady-state rolling non-pneumatic mechanical elastic wheel using finite element method. Simul. Model. Pract. Theory 2018, 85, 60–79. [Google Scholar] [CrossRef]

- Zhao, Y.; Du, X.; Lin, F.; Wang, Q.; Fu, H. Static stiffness characteristics of a new non-pneumatic tire with different hinge structure and distribution. J. Mech. Sci. Tech. 2018, 32, 3057–3064. [Google Scholar] [CrossRef]

- Du, X.; Zhao, Y.; Lin, F.; Fu, H.; Wang, Q. Numerical and experimental investigation on the camber performance of a non-pneumatic mechanical elastic wheel. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3315–3327. [Google Scholar] [CrossRef]

- Du, X.; Zhao, Y.; Wang, Q.; Fu, H. Numerical analysis of the dynamic interaction between a non-pneumatic mechanical elastic wheel and soil containing an obstacle. Proc. Inst. Mech. Eng. Part D 2016, 231, 731–742. [Google Scholar] [CrossRef]

- Zhao, Y.; Zang, L.; Chen, Y.; Li, B.; Wang, J. Non-pneumatic mechanical elastic wheel natural dynamic characteristics and influencing factors. J. Cent. South Univ. 2015, 22, 1707–1715. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, Y.; Du, X.; Zhu, M.; Fu, H. Equivalent stiffness and dynamic response of new mechanical elastic wheel. J. Vibroeng. 2015, 18, 431–445. [Google Scholar]

- Du, X.; Zhao, Y.; Wang, Q.; Fu, H.; Lin, F. Grounding Characteristics of a Non-Pneumatic Mechanical Elastic Tire in a Rolling State with a Camber Angle. J. Mech. Eng. 2019, 5, 287–296. [Google Scholar] [CrossRef] [Green Version]

- Stowe, D.; Conger, K.; Summers, J.D.; Joseph, P.; Thompson, B.; Matthews, J. Designing a Lunar Wheel. Int. Des. Eng. Tech. Conf. 2008, 43291, 627–639. [Google Scholar] [CrossRef]

- Ganniari-Papageorgiou, E.; Chatzistergos, P.; Wang, X. The Influence of the Honeycomb Design Parameters on the Mechanical Behavior of Non-Pneumatic Tires. Int. J. Appl. Mech. 2020, 12, 15. [Google Scholar] [CrossRef]

- Kucewicz, M.; Baranowski, P.; Małachowski, J. Airless Tire Conceptions Modeling and Simulations. In Proceedings of the 13th International Scientific Conference; Springer: Cham, Switzerland, 2017; pp. 293–301. [Google Scholar] [CrossRef]

- Ju, J.; Kim, D.-M.; Kim, K. Flexible cellular solid spokes of a non-pneumatic tire. Compos. Struct. 2012, 94, 2285–2295. [Google Scholar] [CrossRef]

- Wu, T.; Li, M.; Zhu, X.; Lu, X. Research on non-pneumatic tire with gradient anti-tetrachiral structures. Mech. Adv. Mater. Struct. 2020, 28, 2351–2359. [Google Scholar] [CrossRef]

- Czech, C.; Guarneri, P.; Thyagaraja, N.; Fadel, G. Systematic Design Optimization of the Metamaterial Shear Beam of a Nonpneumatic Wheel for Low Rolling Resistance. J. Mech. Design 2015, 137, 041404. [Google Scholar] [CrossRef]

- Thyagaraja, N.; Shankar, P.; Fadel, G.; Guarneri, P. Optimizing the shear beam of a non-pneumatic wheel for low rolling resistance. ASME 2011, 54822, 33–42. [Google Scholar] [CrossRef]

- Gasmi, A.; Joseph, P.F.; Rhyne, T.B.; Cron, S.M. Closed-form solution of a shear deformable, extensional ring in contact between two rigid surfaces. Int. J. Solids Struct. 2011, 48, 843–853. [Google Scholar] [CrossRef] [Green Version]

- Gasmi, A.; Joseph, P.F.; Rhyne, T.B.; Cron, S.M. Development of a two-dimensional model of a compliant non-pneumatic tire. Int. J. Solids Struct. 2012, 49, 1723–1740. [Google Scholar] [CrossRef] [Green Version]

- Aboul-Yazid, A.M.; Emam, M.A.A.; Shaaban, S.; El-Nashar, M.A. Effect of Spokes Structures on Characteristics Performance of Non-Pneumatic Tires. Int. J. Auto. Mech. Eng. 2015, 11, 2212–2223. [Google Scholar] [CrossRef]

- Wang, S.; Chester, S.A. Experimental characterization and continuum modeling of inelasticity in filled rubber-like materials. Int. J. Solids Struct. 2018, 136, 125–136. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, T.; Wang, H.; Huang, Y.; Chen, G. Vertical Tire Forces Estimation of Multi-Axle Trucks Based on an Adaptive Treble Extend Kalman Filter. Chin. J. Mech. Eng. 2021, 34, 55. [Google Scholar] [CrossRef]

- Rhyne, T.B.; Cron, S.M. Development of a non-pneumatic wheel. Tire Sci. Tech. 2006, 34, 150–169. [Google Scholar] [CrossRef]

| Component | Density (kg/m3) | Young’s Modulus (MPa) | Poisson’s Ratio | C10 | C01 |

|---|---|---|---|---|---|

| PU | 1200 | - | 0.49 | - | - |

| Rubber | 920 | - | 0.49 | 0.88 | −0.18 |

| Steel | 7850 | 2.05 × 105 | 0.29 | - | - |

| Structures | Secant Radial Stiffness (N/mm) | Tangent Radial Stiffness (N/mm) | Longitudinal Stiffness (N/mm) |

|---|---|---|---|

| Original | 221.7 | 61.3 | 465.6 |

| Optimized I | 294.8 | 145.3 | 142.6 |

| Optimized II | 352.0 | 242.9 | 533.9 |

| Structures | Bearing Coefficient α | Linearity R-Square | Anti-Symmetric Ratio β |

|---|---|---|---|

| Original | 1.1% | 0.9625 | 642.9 |

| Optimized I | 11.1% | 0.9818 | - |

| Optimized II | 8.2% | 0.9932 | 379.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; Xu, T.; Liu, X.; Wu, M.; Zhou, X.; Gao, F. Test and Simulation Study on the Static Load and Pure Longitudinal Slip Characteristics of Non-Pneumatic Tire. Machines 2023, 11, 86. https://doi.org/10.3390/machines11010086

Zhu L, Xu T, Liu X, Wu M, Zhou X, Gao F. Test and Simulation Study on the Static Load and Pure Longitudinal Slip Characteristics of Non-Pneumatic Tire. Machines. 2023; 11(1):86. https://doi.org/10.3390/machines11010086

Chicago/Turabian StyleZhu, Liangliang, Ting Xu, Xiaoyu Liu, Mengqi Wu, Xuehan Zhou, and Fei Gao. 2023. "Test and Simulation Study on the Static Load and Pure Longitudinal Slip Characteristics of Non-Pneumatic Tire" Machines 11, no. 1: 86. https://doi.org/10.3390/machines11010086