1. Introduction

The operations of most industries and power plants rely significantly on rotating machinery, which makes the accurate detection of faults associated with this class of machines at early stages a vital objective. Typical rotating machines comprise several integrated components, including rotors, bearings, supporting structures, couplings, electric motors, etc. The dynamic conditions under which they operate and the manufacturing/installation imperfections make them vulnerable to various abnormalities, of which rotor and bearing-related faults are prevalent. The most common rotor faults that cause rotor vibration are rotor unbalance, rotor/coupling misalignment, and rotor-to-stator rubbing [

1].

The malfunctions in rotating machinery may cause damage to the critical components of the machine, such as bearings, or even lead to machine failure, which has safety and economic implications [

2]. Therefore, the early detection and reliable diagnosis of rotor and bearing faults in their preliminary stages have become essential in industries to enhance machine reliability and maintenance cost-effectiveness. Recently, manufacturing companies have made great efforts to implement effective machinery maintenance programs that can detect and diagnose rotor and bearing faults at their initial stages [

3,

4].

The vibration response of rotating machines is sensitive to any change in the structural parameters. Moreover, vibration behaviour due to rotor defects varies depending on the nature of the fault. Hence, analysing the vibration signals can reveal any faults in the rotating machines. Therefore, vibration-based condition monitoring (VCM) has been beneficial in detecting rotor and bearing-related faults. Generally, the VCM is done by installing several vibration sensors at individual bearing locations on the monitored machine. Over the years, VCM techniques have been successfully used to detect and diagnose rotor and bearing faults [

5,

6,

7]. A summary of the recent research in machine diagnosis and prognosis, as well as possible future trends, has been provided by Jardine et al. [

8]. Tama et al. [

9] and Kumar et al. [

10] have recently provided an overview of the VCM and presented a literature review on recent research in this field. Furthermore, they have built an experimental rig to simulate some rotor faults, namely rotor unbalance and shaft misalignment. A recent thorough review of vibration-based condition monitoring of rotating machinery is presented by Tiboni et al. [

11]. Yunusa-Kaltungo [

12] has provided a comprehensive literature review of the VCM in rotating machines.

Currently, many researchers have proposed VCM that employs artificial intelligence (AI) techniques in the rotor faults identification process, such as fuzzy logic methods and artificial neural networks (ANN) [

13,

14]. ANNs have shown, in many research studies in recent days, their effectiveness for accurately identifying the different rotating machine faults. Moreover, artificial intelligence methods can help accelerate decision-making with reduced human involvement.

Mubaraali et al. [

15] have introduced an intelligent diagnostic system method that employs a fuzzy neural network using the special bearing diagnostic symptom parameters (SSPs) in time and frequency domains to precisely and automatically determine the fault type of low-speed bearings. Khoualdia et al. [

16] have been able to diagnose faults in an induction motor under different operating conditions using a multi-layer perceptron (MLP) artificial neural network (ANN) with the Levenberg–Marquardt learning algorithm. The faults included in their study are broken rotor bars, bearing faults, and misalignment.

Sepulveda and Sinha [

17] have developed a machine fault diagnosis model that can be applied blindly to similar machines with high accuracy in the predictions. They have identified the healthy and faulty conditions of an experimental rig operating at various speeds using a smart vibration-based machine learning (SVML) model. Mei et al. [

18] achieved deep analysis and processing of large-scale data while selecting several feature combinations that effectively characterise state information. Their research proposes a machinery and equipment CM method combining the relative degree of contribution (RDoC)-based feature selection and deep residual network (DRN). They proposed an optimal feature combination selection strategy with high characterisation information density to meet the challenge of large numbers of sensors with mismatched sampling rates.

Espinoza-Sepulveda and Sinha [

19] have presented a vibration-based ML model (VML) with a multi-layered perceptron (MLP) network, four hidden layers, and each of them with a variable quantity of non-linear neurons. Their proposed method used vibration measurements from a laboratory-scaled rig and employed an artificial intelligence (AI)-based machine learning (ML) model. The research mainly focused on optimising vibration-based parameters for identifying rotor faults without including other rotating machinery components and used the artificial neural network (ANN) model for classification. However, there is a need to investigate these parameters’ effectiveness in identifying rotor and bearing faults.

The current study is further extended from the earlier study [

19]. The ANN model and the vibration parameters used in the earlier VML model [

19] for rotor fault detection are used again in the current study to standardise the earlier proposed method. However, the vibration parameters [

19] in both time and frequency domains are further revised by extending the frequency band so the revised parameters can cover the anti-frication bearing defects. The measured vibration data from a laboratory-scale rotating test rig with different experimentally simulated faults in the rotor and bearings are used in this study. The bearing supports for the rig are designed such that the rig can operate below and above the critical speeds. The proposed VML model is developed for both rotor and bearing defects at a rotor speed that is above the first critical speed. The proposed VML model is further tested at two different rotating speeds, one below the first critical speed and the other above the second critical speed. The dynamics of the machine are different at these speeds, but the proposed VML model provides encouraging results. The paper presents the methodology, the rig and measured vibration data, the optimised parameters, and the findings.

3. Machine Learning Model [19]

The earlier study by Sepulveda and Sinha [

19] used the ANN-based VML model for rotor fault identification. The VML model framework is kept exactly the same for further extension to bearing fault detection to standardise the model for any industrial application. This model is summarised here to aid understanding. The ANNs are knowledge-based systems developed through a training process that builds a connection between symptoms and the underlying causes of those symptoms [

26]. The study implements a multi-layered perceptron (MLP) network structure formed by four hidden layers of weight between the inputs and the outputs [

27]. The MLP is mainly employed for pattern recognition and extracting feature classifications as inputs. The network parameters, such as the number of layers, neurons, and types of functions utilised at the various stages, are established and modified through iterations. The output of these iterations is a feed-forward network with four hidden layers.

Figure 5 shows the four layers with a variable quantity of non-linear neurons, namely, 1000, 1000, 100, and 10, respectively. The ANN model used in this work is nearly the same as the one used by Espinoza-Sepulveda and Sinha [

19], with a slight modification in the output layer to include the effect of bearing faults.

The first function implemented in the ANN is the hidden neurons’ activation function, called the hyperbolic tangent sigmoid [

28]. The second selected function is the transfer function at the output neurons, namely, the normalised exponential function (SoftMax) [

29]. The third and fourth functions are the training function (i.e., scaled conjugate gradient back-propagation) and the performance function (i.e., cross-entropy). The functions mentioned above are presented in

Table 1.

The measured vibration data on machine conditions for each tested speed has been divided into three distinct groups (

Table 2). The first set, consisting of 70% of the samples, is used to train the ML model. Setting the parameters of the model or weights according to a learning rule to reduce the classification error on the training data constitutes the training process [

30]. The second group of data sets contains 15% of the collected samples. This data is used for the validation process, which includes testing the trained model on data not used during training. The validation process allows for a more unbiased assessment of the model’s performance than only looking at the training error. The validation process continues until the classification error on the validation data reaches an allowable limit, at which point the training process can be stopped. This method prevents overfitting, a common issue in machine learning in which the model becomes overly complex and performs well on training data but inadequately on new data [

31]. The third data set also comprised 15% of the samples. After the model has been trained and validated, these data are used to test the model’s generalisation ability. Testing on a distinct data set ensures that the model’s performance is robust and can classify new data reliably.

The model performance is calculated using Equation (8).

4. Experimental Rig and Measured Vibration Data

The laboratory-scaled rig is depicted in

Figure 6. The data being analysed in the current study have been measured previously by Luwei [

32]. A schematic diagram of the experimental rig is illustrated in

Figure 7. The laboratory rig includes two steel shafts with two different lengths and an identical diameter of 20 mm. The first shaft (SH1) has a length of 1 m, and the second shaft (SH2) has a length of 0.5 m. A rigid coupling connects both shafts. Two grease-lubricated ball bearings support each of the two shafts. Each bearing is secured flexibly with four springs to the rectangular bearing pedestal. The bearing pedestals are secured to a steel base bolted to the base structure. A flexible coupling connects the rotor-bearing-foundation system with a three-phase motor to drive the rotor at different speeds. The motor has a power of 0.75 kW, and the maximum speed is 3000 RPM. Two balancing discs are attached to shaft SH1, and a single balancing disc is attached to shaft SH2. The balancing discs have a diameter of 125 mm and a thickness of 14 mm. Single accelerometers with a sensitivity of 100 mV/g are installed on each of the four bearing housings.

The vibrational data have been measured at three different rotor speeds: 450 RPM (7.5 Hz), 900 RPM (15 Hz), and 1350 RPM (22.5 Hz). The machine conditions considered for each speed include healthy (only residual unbalance and misalignment), misalignment, a crack in the shaft, rotor rub, and a faulty bearing, B2. The acquired data comprise vibration acceleration responses from bearing housings (B1 to B4) at an angle of 45 degrees from the horizontal direction [

32]. The acceleration data are measured with a sampling frequency of 10,000 Hz. The number of machine runs at each rotor speed for the different conditions is presented in

Table 3.

Modal tests were performed by Luwei and Sinha [

32] to dynamically characterise the test rig. The first five bending natural frequencies identified by the modal tests are 11.52 Hz, 18.62 Hz, 30.75 Hz, 49.13 Hz, and 85.83 Hz [

32]. Taking natural frequencies into account, the three operational speeds are chosen in this study: one below the first critical speed and two above the critical speeds. These speeds are set at 450 RPM (7.5 Hz), which is lower than the first critical speed; 900 RPM (15 Hz), which is higher than the first critical speed; and 1350 RPM (22.5 Hz), which is higher than the second critical speed. The rotating rig dynamics are significantly different at these three speeds.

The ball bearing specifications that are used in the experimental rig are represented in

Table 4. The calculated frequencies related to the ball, inner race, outer race, and cage of the bearings that support the experimental rig of the rotating machine for different rotation speeds are concluded in

Table 5.

5. Data Analysis at 900 RPM Rotating Speed

This section analyses vibration data obtained from the experimental rotating machine operating at 900 RPM (15 Hz) under four conditions: misalignment, shaft crack, rubbing, and a fault in bearing 2. The analysis examines the acceleration time domain, velocity frequency, and envelope spectrum.

Figure 8 shows various factors like fault type and severity influencing measured vibrations. However, it is not easy to distinguish between different conditions where the vibration response of the machine generates complex waveforms. Thus, further analysis, like frequency spectrum analysis, is required for fault diagnosis.

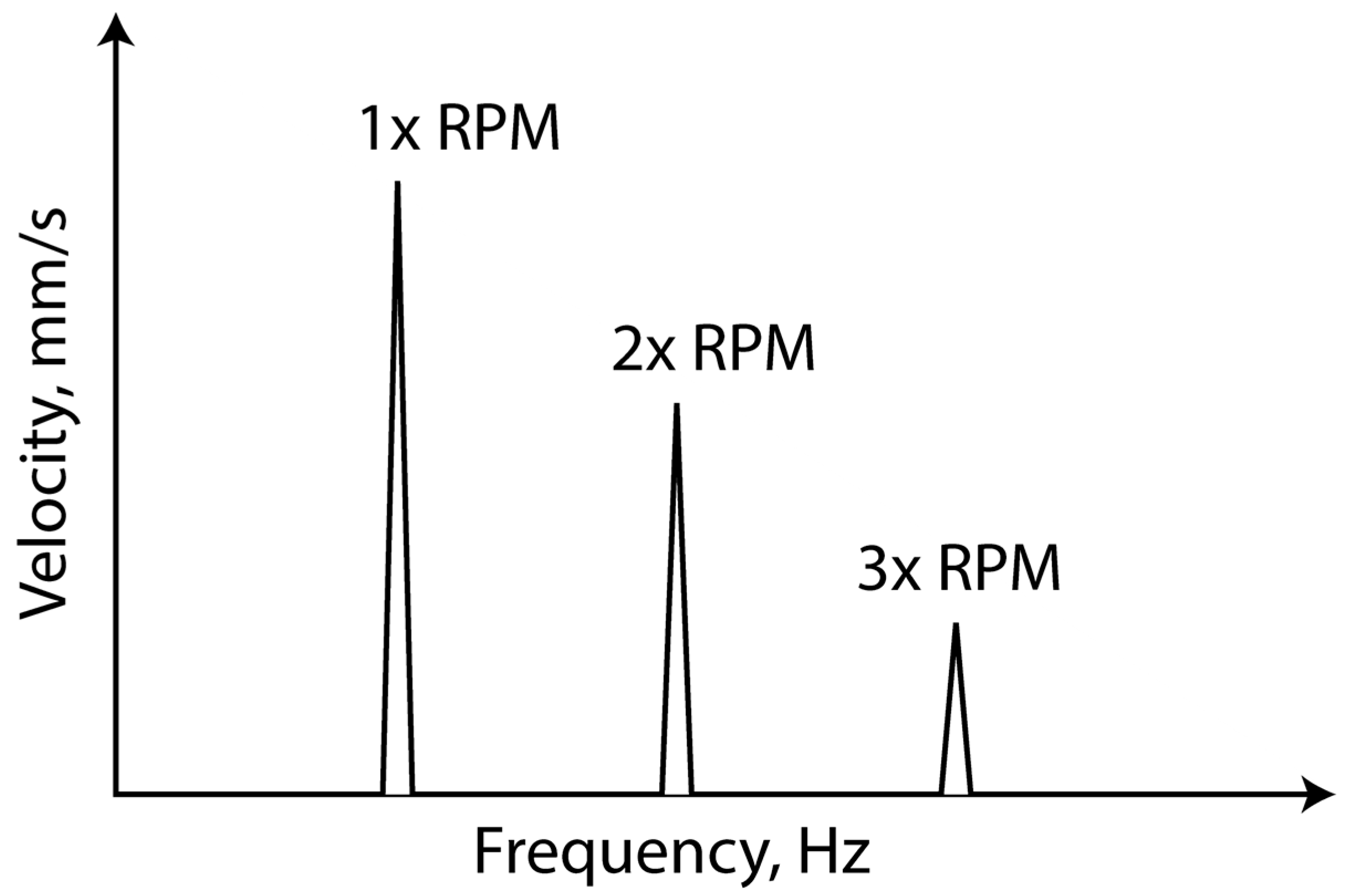

The velocity spectra in

Figure 9a–d correspond to rotor faults and exhibit peaks at 1x, 2x, and 3x the rotating frequency. These harmonics indicate rotor defects, requiring expert analysis for diagnosis.

In contrast,

Figure 9e lacks harmonic indicators of a bearing defect, typically occurring at higher frequencies. Thus, envelope analysis is applied to detect better-bearing faults. The vibrations are band-pass filtered from 2000–5000 Hz so that the filtered data contains the bearing-related vibration response. The Hilbert transform and the FFT analysis are performed on the envelope time-domain data to compute the envelope spectrum (

Figure 10).

Figure 10a–d show no peaks, indicating no bearing faults present with the rotor faults. However,

Figure 10e shows peaks at the 1x and 2x harmonics of the bearing cage frequency from

Table 2, indicating a fault in bearing B2’s cage.

6. The VML Model

Sepulveda and Sinha [

19] have used both time- and frequency-domain features to develop an ANN-based VML model to diagnose rotor-related faults. The study suggested six parameters (

Table 6)—two in the time domain (acceleration RMS and kurtosis) and four in the frequency-domain parameters (1x, 2x, and 3x amplitudes of the velocity spectra and spectrum energy). These parameters were found to be robust parameters to detect rotor faults in the earlier study.

This study is also attempting to keep exactly the same ANN-based VML and the parameters to make this model as the standard VML model for both the rotor and anti-friction bearing fault detection. However, the following three essential modifications are implemented to include bearing-related vibration responses.

- i.

The RMS values are calculated from the measured vibration data, which contain a frequency range up to 5000 Hz. Hence, the RMS values have rotor and bearing responses.

- ii.

The bearing assembly and housing resonance frequency is likely to be in the band of 2000–5000 Hz for this bearing used in the rig. It is also known that the bearing defect frequencies (in the case of the bearing fault) are generally modulated around the bearing resonance frequency. Hence the kurtosis (FK) calculated on the band-pass filtered acceleration signals in the 2000 Hz to 5000 Hz frequency range so that kurtosis can reflect the bearing condition.

- iii.

Similarly, like RMS, the frequency range for the spectrum energy (SE) calculation is expanded from 0.3 times the rotational speed to 5000 Hz. This adjustment accommodates the effects of subharmonics related to the rotor faults and the high band frequency range for the anti-friction bearing faults.

These time- and frequency-domain parameters are extracted from all measured vibration signals of the collected samples and all tested experimental conditions.

Table 7 provides the list of total data and the arrangement of their use within the ANN-based VML model.

The databank of the ANN’s input for each tested speed,

Data, is constructed as follows:

In this context, ‘

‘ refers to the databank for the healthy condition, ‘

’ corresponds to the databank for the misalignment fault condition, ‘

DataC’ represents the databank for the cracked shaft fault condition, ‘

‘ is associated with the databank for the rotor rub fault condition, and ‘

‘ denotes the databank for the bearing fault condition. Each of these databanks comprises parameters from individual runs. Each databank is arranged as per Equation (10).

The subscripts 1, 2, 3, and so on denote the machine run or sample numbers, as detailed in

Table 2. For the healthy machine condition, the parameters for each run, which consist of 24 elements (calculated as 6 parameters per bearing times 4 bearings), are organised according to the structure provided in Equation (11).

where

z is the healthy machine condition’s run number (sample number). Similarly, the databanks can be arranged for other machine fault conditions. Once the databanks are prepared, the VML model is applied, as discussed in

Section 3.

7. Application of the ANN-Based VML Model and Results

The bearing fault is now included in the ANN-based VML used earlier [

19]. The model in this study is designed to classify the state of the rotor and bearing system into five distinct conditions: healthy, misalignment, crack, rub, and bearing faults. Selected input parameters of the ANN are representative of the machine’s dynamic characteristics, including the RMS and FK of acceleration in the time domain, as well as the 1x, 2x, and 3x velocity spectra and the SE of velocity in the frequency domain. For a balanced learning process, we structured the dataset with 70% dedicated to training and the remaining 30% equally divided for validation and testing.

Upon developing the system at 900 RPM, the ANN-based VML model shows excellent performance, achieving 100% accuracy in identifying the healthy condition, rotor faults, and bearing faults (

Table 8).