Effect of Vibrotactile Feedback on the Control of the Interaction Force of a Supernumerary Robotic Arm

Abstract

:1. Introduction

2. Materials and Methods

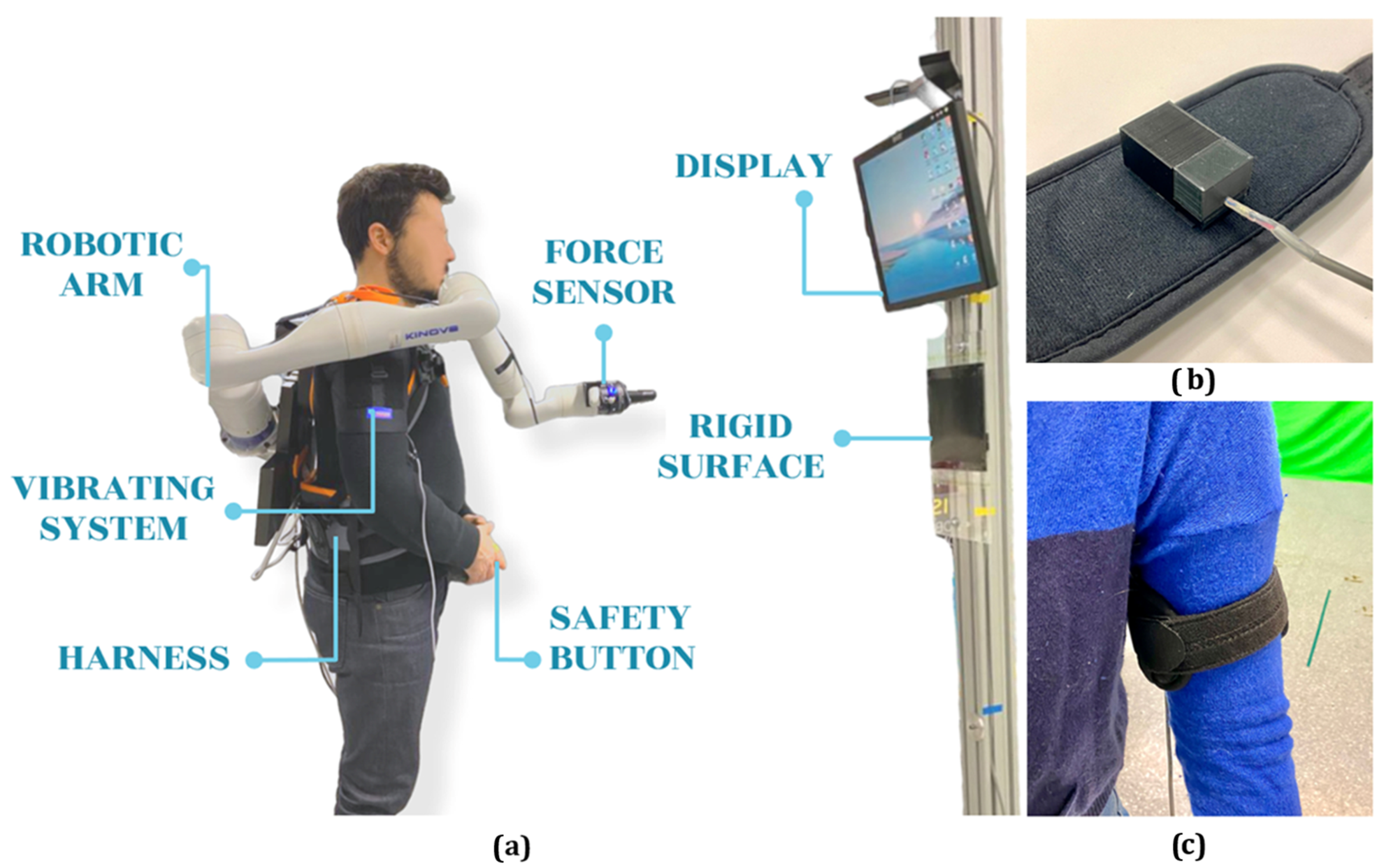

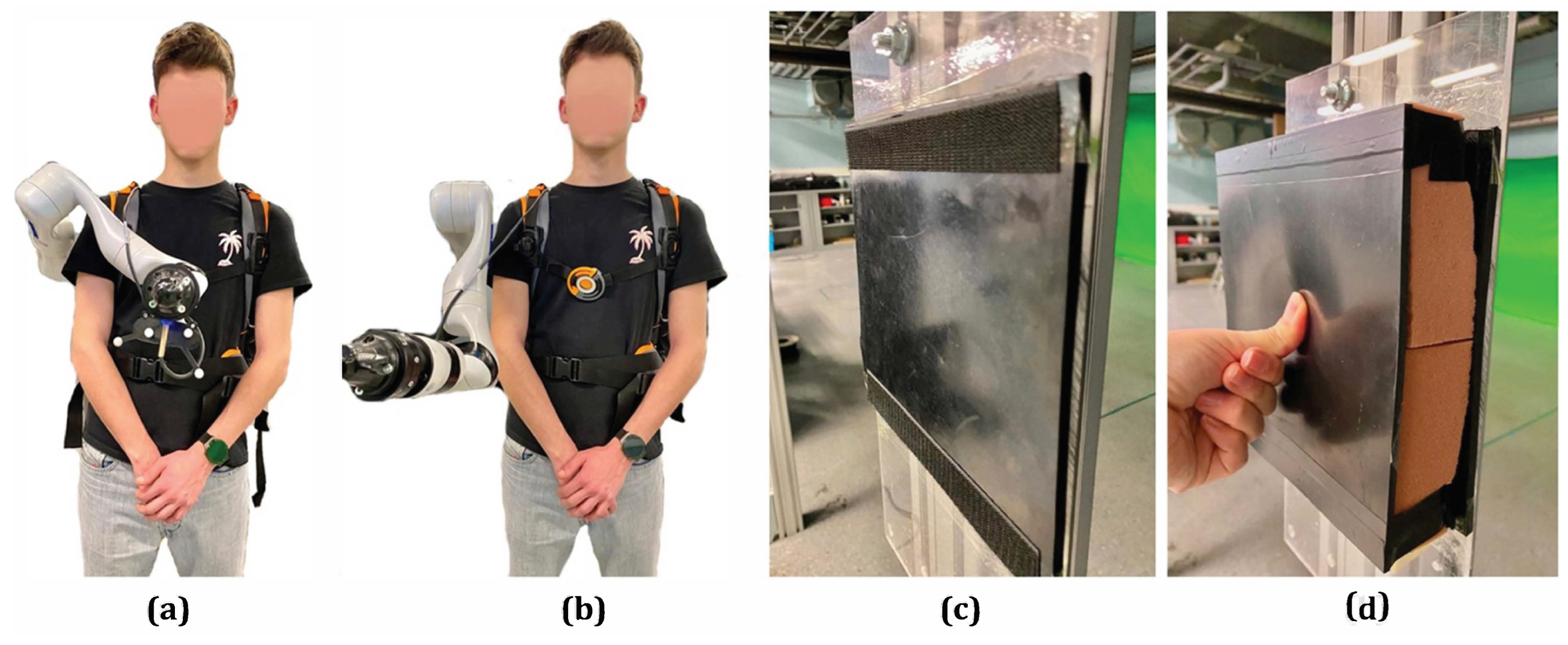

2.1. Experimental Setup

2.2. Vibrotactile Feedback and Data Processing

2.3. Experimental Protocol

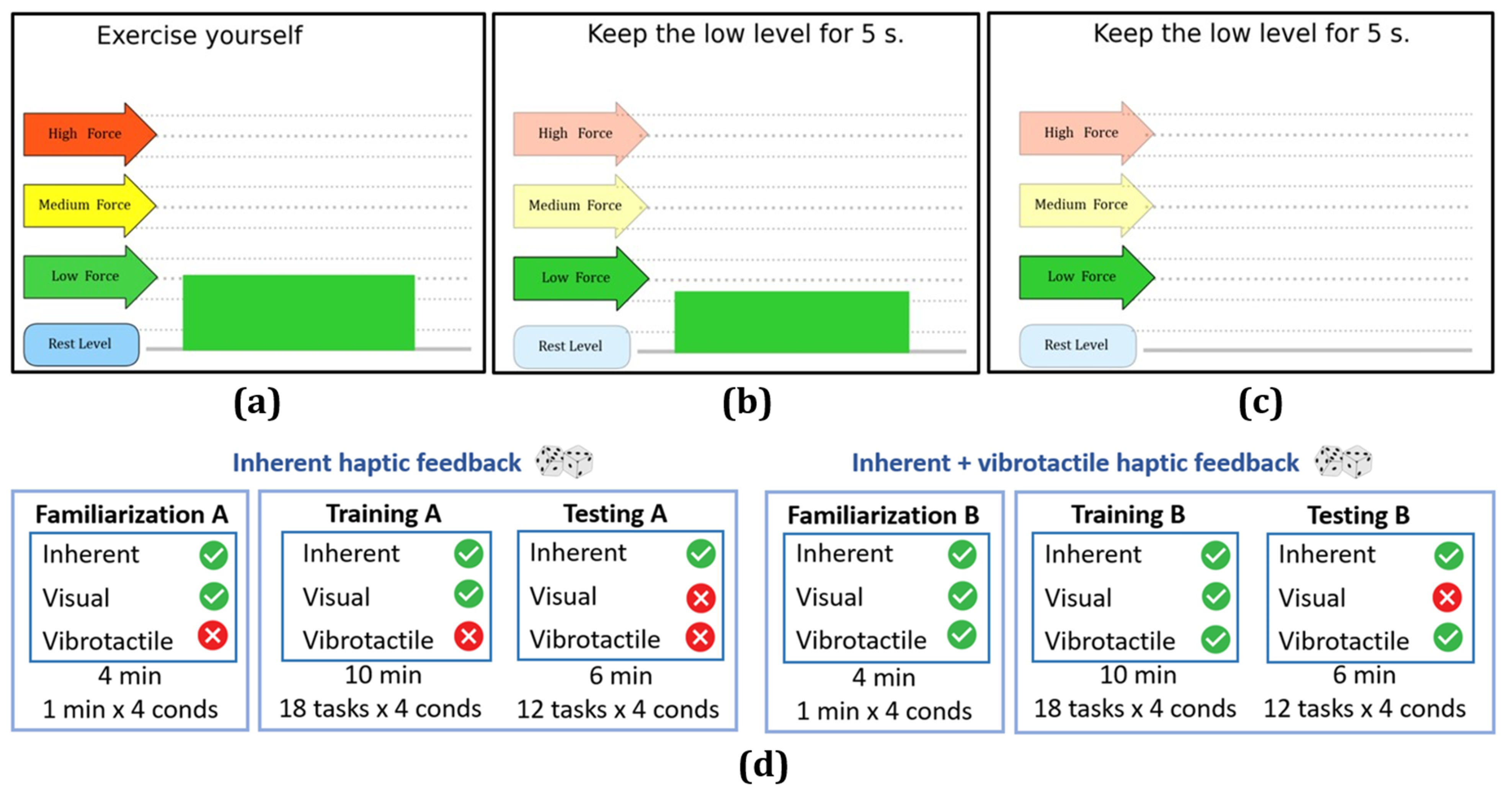

- Familiarization session:Participants experienced 1 min in each of the 4 combinations while controlling the SRA with their body to exert a force against the vertical surface and observe on the graphical interface the amount of force exerted (Figure 2a).

- Training session:Then, participants were asked to execute the task 18 times, 6 for each force level, for each of the 4 combinations of conditions. Thanks to the visual feedback provided through the GUI (Figure 2b), they were able to check the level of force exerted.

- Testing session:Finally, participants performed the task 12 times, 4 for each force level, repeated for each of the 4 combinations, without any visual feedback of the level of force exerted (Figure 2c).

- How much did you find the vibration helpful?

- How much did you find the inherent sensation helpful?

- How much was the vibrotactile feedback useful to adapt to the different conditions?

- How much was the inherent sensation useful to adapt to the different conditions?

2.4. Data Analysis

- The average error (e): the difference between the requested and the actual force, computed and averaged for each trial from the moment the participant reached for the first time the requested force interval to the end of the trial;

- The normalized error (): the average error divided by the requested force level;

- The maintaining time (t): the sum of all the time intervals in which the participant maintained the exerted force within a band of ±2 N around the requested one;

- The settling time (): the time from the instant in which the participant overcame 10% of the requested force level until the moment when he/she maintained the requested level for at least 0.15 s.

3. Results

3.1. Overview of Force Profiles

3.2. Effect of the Variation of Environmental Parameters

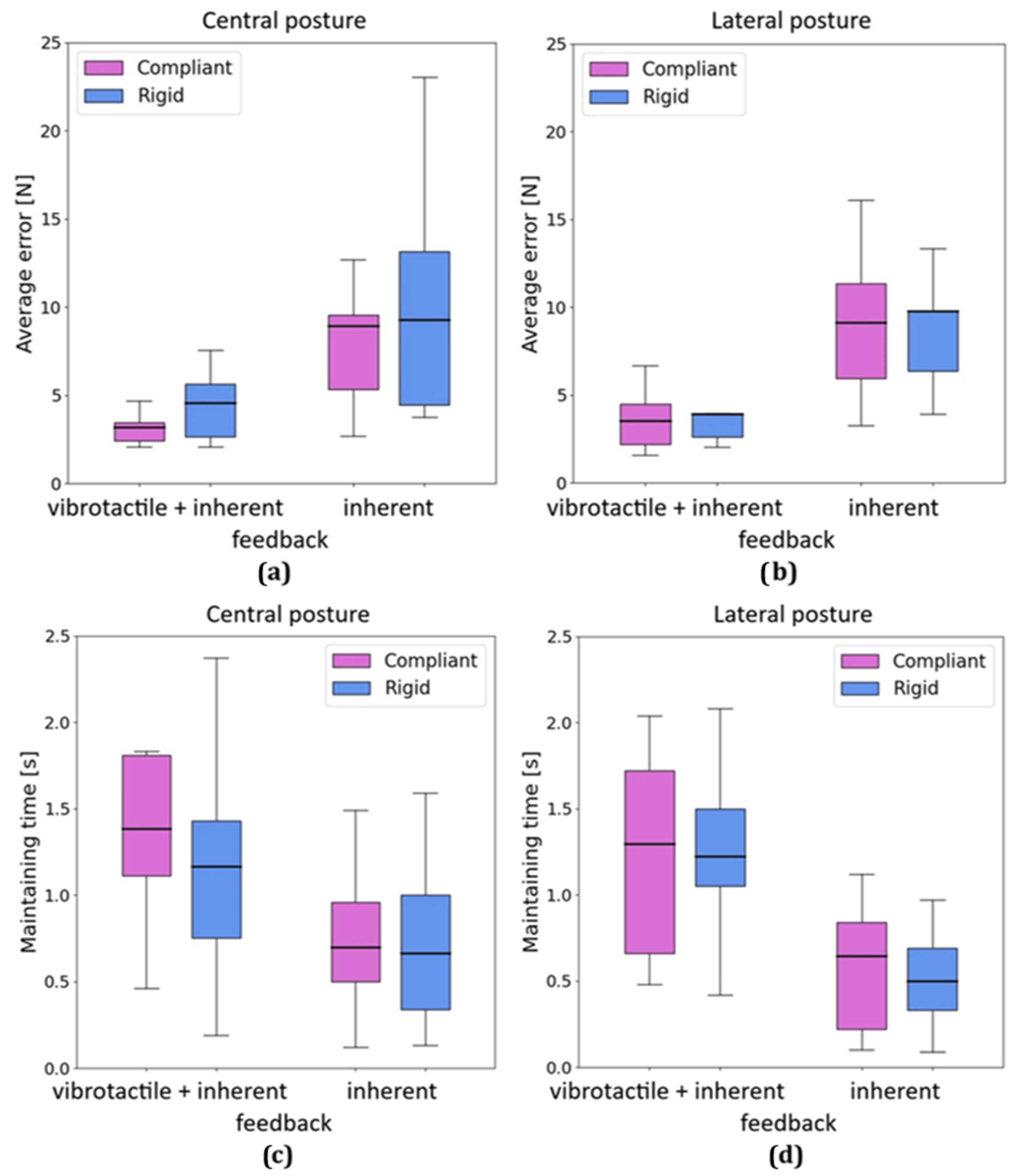

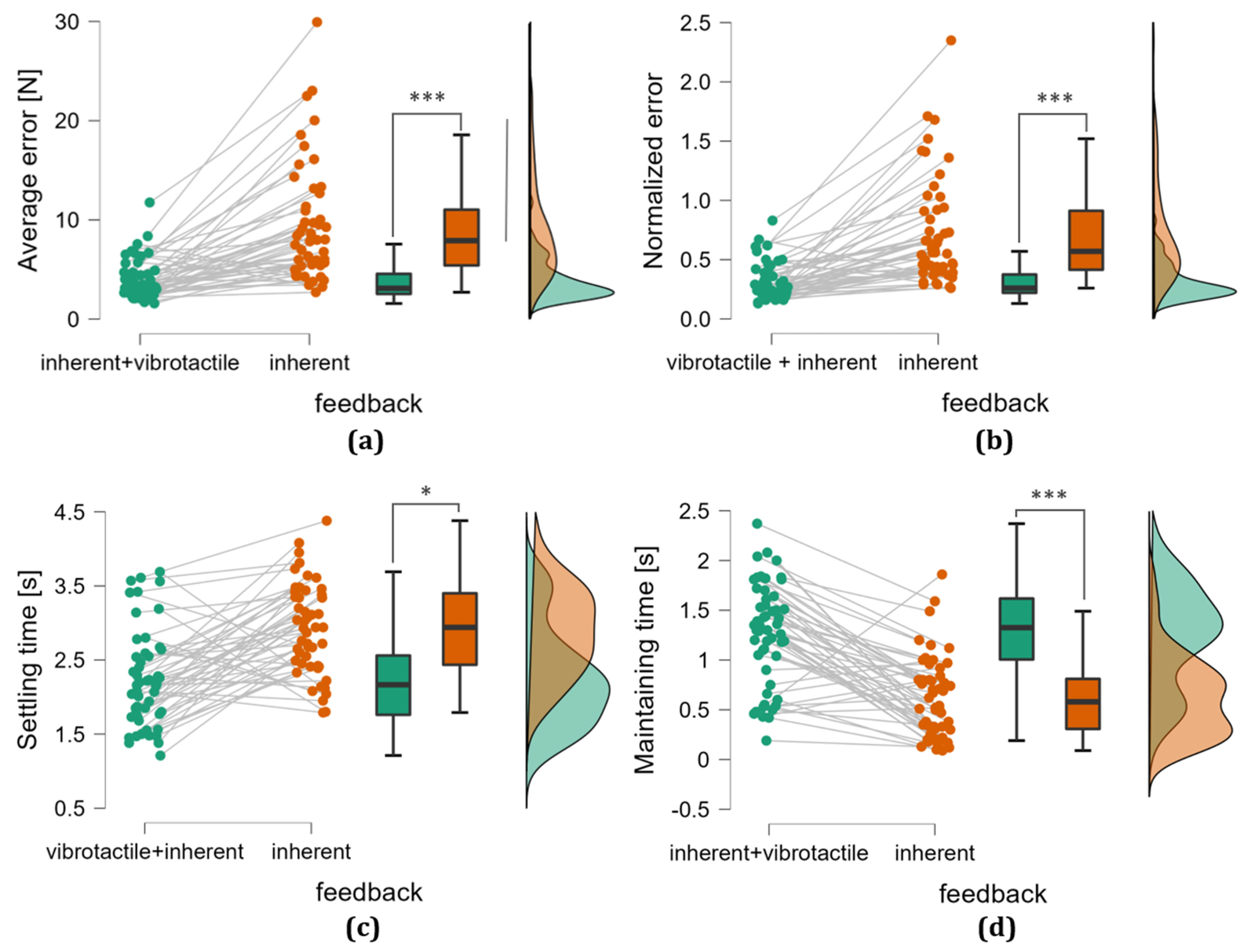

3.3. Effect of the Feedback

- Lower average errors (, , N, N);

- Lower normalized errors (, , , );

- Higher maintaining times (, , s, s);

- Lower settling times (, , s, s).

3.4. Subjective Perception of Participants

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SRA | Supernumerary robotic arm |

| SRL | Supernumerary robotic limb |

| SRLG | Supernumerary robotic leg |

| SRF | Supernumerary robotic finger |

| DoF | Degree of freedom |

| MCU | Microcontroller unit |

| GUI | Graphical user interface |

| PWM | Pulse-width modulation |

References

- Yang, B.; Huang, J.; Chen, X.; Xiong, C.; Hasegawa, Y. Supernumerary robotic limbs: A review and future outlook. IEEE Trans. Med. Robot. Bionics 2021, 3, 623–639. [Google Scholar] [CrossRef]

- Davenport, C.; Parietti, F.; Asada, H.H. Design and biomechanical analysis of supernumerary robotic limbs. Dyn. Syst. Control Conf. 2012, 45295, 787–793. [Google Scholar]

- Llorens-Bonilla, B.; Parietti, F.; Asada, H.H. Demonstration-based control of supernumerary robotic limbs. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012. [Google Scholar]

- Llorens Bonilla, B.; Asada, H.H. A robot on the shoulder: Coor dinated human-wearable robot control using colored petri nets and partial least squares predictions. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 119–125. [Google Scholar]

- Luo, J.; Gong, Z.; Su, Y.; Ruan, L.; Zhao, Y.; Asada, H.H.; Fu, C. Modeling and balance control of supernumerary robotic limb for overhead tasks. IEEE Robot. Autom. Lett. 2021, 6, 4125–4132. [Google Scholar] [CrossRef]

- Shin, C.; Bae, J.; Hong, D. Ceiling work scenario based hardware design and control algorithm of supernumerary robotic limbs. In Proceedings of the 2015 15th International Conference on Control, Automation and Systems (ICCAS), Busan, Republic of Korea, 13–16 October 2015; pp. 1228–1230. [Google Scholar]

- Parietti, F.; Chan, K.; Asada, H.H. Bracing the human body with supernumerary robotic limbs for physical assistance and load reduction. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 141–148. [Google Scholar]

- Parietti, F.; Asada, H.H. Supernumerary robotic limbs for aircraft fuselage assembly: Body stabilization and guidance by bracing. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 1176–1183. [Google Scholar]

- Parietti, F.; Chan, K.C.; Hunter, B.; Asada, H.H. Design and control of supernumerary robotic limbs for balance augmentation. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 5010–5017. [Google Scholar]

- Parietti, F.; Asada, H. Supernumerary robotic limbs for human body support. IEEE Trans. Robot. 2016, 32, 301–311. [Google Scholar] [CrossRef]

- Guggenheim, J.; Asada, H.H. Inherent haptic feedback from supernumerary robotic limbs. IEEE Trans. Haptics 2020, 14, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Sobajima, M.; Sato, Y.; Xufeng, W.; Hasegawa, Y. Improvement of operability of extra robotic thumb using tactile feedback by electrical stimulation. In Proceedings of the 2015 International Symposium on Micro-NanoMechatronics and Human Science (MHS), Nagoya, Japan, 23–25 November 2015; pp. 1–3. [Google Scholar]

- Aoyama, T.; Shikida, H.; Schatz, R.; Hasegawa, Y. Operational learning with sensory feedback for controlling a robotic thumb using the posterior auricular muscle. Adv. Robot. 2019, 33, 243–253. [Google Scholar] [CrossRef]

- Shikida, H.; Noel, S.; Hasegawa, Y. Somatosensory Feedback Improves Operability of Extra Robotic Thumb Controlled by Vestigial Muscles. In Proceedings of the 2017 International Symposium on Micro-NanoMechatronics and Human Science (MHS), Nagoya, Japan, 3–6 December 2017; pp. 1–4. [Google Scholar]

- Hussain, I.; Meli, L.; Pacchierotti, C.; Salvietti, G.; Prattichizzo, D. Vibrotactile haptic feedback for intuitive control of robotic extra fingers. In Proceedings of the 2015 IEEE World Haptics Conference (WHC), Evanston, IL, USA, 22–26 June 2015; pp. 394–399. [Google Scholar]

- Hussain, I.; Salvietti, G.; Meli, L.; Pacchierotti, C. Using the Robotic Sixth Finger and Vibrotactile Feedbackfor Grasp Compensation in Chronic Stroke Patients. In Proceedings of the 2015 IEEE International Conference on Rehabilitation Robotics (ICORR), Singapore, 11–14 August 2015. [Google Scholar]

- Christiansen, R.; Contreras-Vidal, J.L.; Gillespie, R.B.; Shewokis, P.A.; O’Malley, M.K. Vibrotactile feedback of pose error enhances myoelectric control of a prosthetic hand. In Proceedings of the 2013 World Haptics Conference (WHC), Daejeon, Republic of Korea, 14–17 April 2013; pp. 531–536. [Google Scholar]

- Fröhner, J.; Salvietti, G.; Beckerle, P.; Prattichizzo, D. Can wearable haptic devices foster the embodiment of virtual limbs? IEEE Trans. Haptics 2018, 12, 339–349. [Google Scholar] [CrossRef] [PubMed]

- Witteveen, H.J.; Droog, E.A.; Rietman, J.S.; Veltink, P.H. Vibro-and electrotactile user feedback on hand opening for myoelectric forearm prostheses. IEEE Trans. Biomed. Eng. 2012, 59, 2219–2226. [Google Scholar] [CrossRef] [PubMed]

- Wheeler, J.; Bark, K.; Savall, J.; Cutkosky, M. Investigation of rotational skin stretch for proprioceptive feedback with application to myoelectric systems. IEEE Trans. Neural Syst. Rehabil. Eng. 2010, 18, 58–66. [Google Scholar] [CrossRef] [PubMed]

- Clemente, F.; Valle, G.; Controzzi, M.; Strauss, I.; Iberite, F.; Stieglitz, T.; Cipriani, C. Intraneural sensory feedback restores grip force control and motor coordination while using a prosthetic hand. J. Neural Eng. 2019, 16, 026034. [Google Scholar] [CrossRef] [PubMed]

- Zollo, L.; Di Pino, G.; Ciancio, A.L.; Ranieri, F.; Cordella, F.; Gentile, C.; Guglielmelli, E. Restoring tactile sensations via neural interfaces for real-time force-and-slippage closed-loop control of bionic hands. Sci. Rob. 2019, 4, 27. [Google Scholar] [CrossRef] [PubMed]

- Markovic, M.; Schweisfurth, M.A.; Engels, L.F.; Bentz, T.; Wüstefeld, D.; Farina, D.; Dosen, S. The clinical relevance of advanced artificial feedback in the control of a multi-functional myoelectric prosthesis. J. Neuroeng. Rehabil. 2018, 15, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Saraiji, M.; Sasaki, T.; Kunze, K.; Minamizawa, K.; Inami, M. Metaarms: Body remapping using feet-controlled artificial arms. In Proceedings of the UIST’18: The 31st Annual ACM Symposium on User Interface Software and Technology, Berlin, Germany, 14 October 2018; pp. 65–74. [Google Scholar]

- Pinardi, M.; Raiano, L.; Noccaro, A.; Formica, D.; Di Pino, G. Cartesian Space Feedback for Real Time Tracking of a Supernumerary Robotic Limb: A Pilot Study. In Proceedings of the 2021 10th International IEEE/EMBS Conference on Neural Engineering (NER), Virtual Event, 4–6 May 2021; pp. 889–892. [Google Scholar]

- Pinardi, M.; Noccaro, A.; Raiano, L.; Formica, D.; Di Pino, G. Comparing end-effector position and joint angle feedback for online robotic limb tracking. PLoS ONE 2023, 18, e0286566. [Google Scholar] [CrossRef] [PubMed]

- Noccaro, A.; Raiano, L.; Pinardi, M.; Formica, D.; Di Pino, G. A novel proprioceptive feedback system for supernumerary robotic limb. In Proceedings of the 2020 8th IEEE RAS/EMBS International Conference for Biomedical Robotics and Biomechatronics (BioRob), New York, NY, USA, 29 November–1 December 2020; pp. 1024–1029. [Google Scholar]

- Sanchez, J.H.; Amanhoud, W.; Haget, A.; Bleuler, H.; Billard, A.; Bouri, M. Four-arm manipulation via feet interfaces. arXiv 2019, arXiv:1909.04993. [Google Scholar]

- Pinardi, M.; Longo, M.R.; Formica, D.; Strbac, M.; Mehring, C.; Burdet, E.; Di Pino, G. Impact of supplementary sensory feedback on the control and embodiment in human movement augmentation. Commun. Eng. 2023, 2, 64. [Google Scholar] [CrossRef]

- Available online: https://store.pellenc.com/batteries/357-harnais-confort.html (accessed on 12 December 2023).

- Khoramshahi, M.; Poignant, A.; Morel, G.; Jarrassé, N. A Practical Control Approach for Safe Collaborative Supernumerary Robotic Arms. In Proceedings of the 2023 IEEE International Conference on Advanced Robotics and Its Social Impacts (ARSO), Berlin, Germany, 5–7 June 2023. [Google Scholar]

- Al-Sada, M.; Jiang, K.; Ranade, S.; Piao, X.; Höglund, T.; Nakajima, T. HapticSerpent: A wearable haptic feedback robot for VR. In Proceedings of the CHI’18: CHI Conference on Human Factors in Computing Systems, Montreal, QC, Canada, 21–26 April 2018; pp. 1–6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buratti, S.; Deiana, D.; Noccaro, A.; Pinardi, M.; Di Pino, G.; Formica, D.; Jarrassé, N. Effect of Vibrotactile Feedback on the Control of the Interaction Force of a Supernumerary Robotic Arm. Machines 2023, 11, 1085. https://doi.org/10.3390/machines11121085

Buratti S, Deiana D, Noccaro A, Pinardi M, Di Pino G, Formica D, Jarrassé N. Effect of Vibrotactile Feedback on the Control of the Interaction Force of a Supernumerary Robotic Arm. Machines. 2023; 11(12):1085. https://doi.org/10.3390/machines11121085

Chicago/Turabian StyleBuratti, Silvia, Davide Deiana, Alessia Noccaro, Mattia Pinardi, Giovanni Di Pino, Domenico Formica, and Nathanaël Jarrassé. 2023. "Effect of Vibrotactile Feedback on the Control of the Interaction Force of a Supernumerary Robotic Arm" Machines 11, no. 12: 1085. https://doi.org/10.3390/machines11121085

APA StyleBuratti, S., Deiana, D., Noccaro, A., Pinardi, M., Di Pino, G., Formica, D., & Jarrassé, N. (2023). Effect of Vibrotactile Feedback on the Control of the Interaction Force of a Supernumerary Robotic Arm. Machines, 11(12), 1085. https://doi.org/10.3390/machines11121085