Assessment of Residual Useful Life of Sun Gear in a Planetary Gearbox Based on Dynamic Wear Behaviors Analyses

Abstract

:1. Introduction

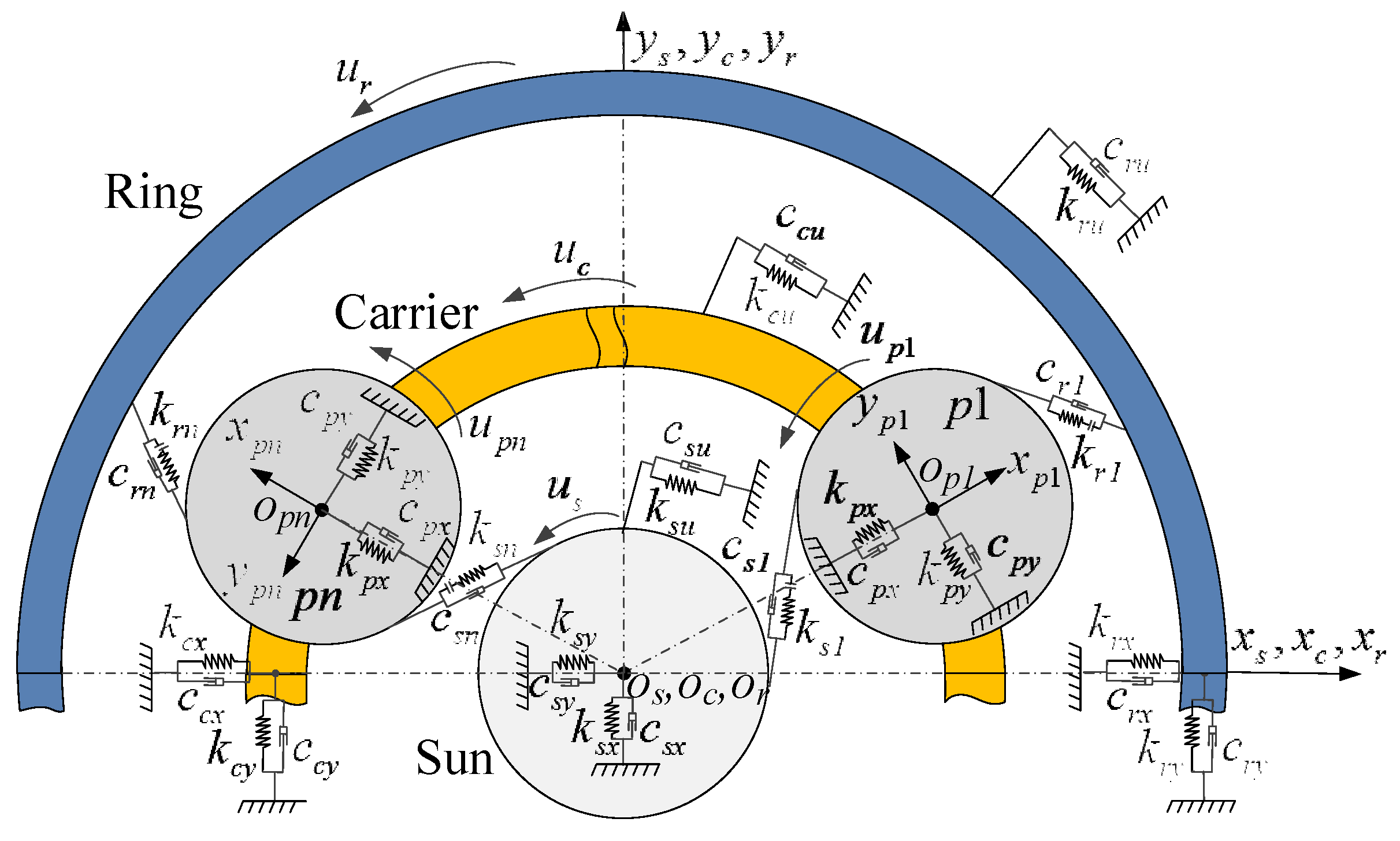

2. Dynamic Modeling for a Planetary Gear Train with Worn-Surface Gear

2.1. Description of the Nonlinear Dynamic Model

2.2. The Differential Equation of Motion for Planetary Gear Train

- (1)

- The differential equations of motion for the sun gear subsystemwhere ms and Is represent the mass and rotational inertia of the sun gear, respectively. represents the base circle radius of the sun gear. represents the input torque on the sun gear. ωc represents the rotation speed of the planet carrier.

- (2)

- The differential equations of motion for the planet carrier subsystemwhere mc and Ic represent the mass and rotational inertia of the planet carrier, respectively. represents the radius of the pin circle at the planet carrier. represents the load torque on the planet carrier. δcnx, δcny and δcnu denote the relative displacement between the nth planet gear and the planet carrier along the direction of x, y and u, respectively. These can be calculated as

- (3)

- The differential equations of motion for the ring gear subsystemwhere mr and Ir represent the mass and rotational inertia of the ring gear, respectively. rbr represents the base circle radius of the ring gear.

- (4)

- The differential equations of motion for the nth planet gear subsystemwhere mp and Ip represent the mass and rotational inertia of the planet gear, respectively. rbp represents the base circle radius of the planet gear.

2.3. Internal Excitation with Tooth Surface Wear

3. Residual Useful Life Assessment Methodology for a Worn-Surface Sun Gear

3.1. Wear Prediction Method

3.2. Residual Useful Life Assessment Methodology

- (1)

- Input the basic parameters of the transmission system (as shown in Table 1), and the state parameters, such as input speed ns, load Tc and the initial depth of surface wear hw.

- (2)

- Based on the internal excitation model of TVMS and STE, and of every worn-surface meshing pair (i.e., the s-pn and the r-pn meshing pair) for q-th geometry update can be calculated.

- (3)

- Then, the dynamic meshing force (DMF) of the transmission system is obtained by introducing the stiffness excitation and displacement excitation with tooth surface wear into the dynamic model.

- (4)

- By inserting the DMF into Hertz’s contact model, the dynamic contact pressure p can be obtained.

- (5)

- Then, the depth of wear is calculated according to Archard’s formula with the parameters of k, p and s. (i = s, sp, pr, r) denotes the wear depth during the ζ-th wear cycle of q-th geometry update. Herein, the subscripts ‘s’ and ‘sp’ stand for the sun and planet gear of the s-pn meshing pair, respectively. Accordingly, the subscripts ‘pr’ and ‘r’ stand for the planet and ring gear of the r-pn meshing pair, respectively.

- (6)

- The wear depth of a single cycle was added to the total wear depth and the cumulative depth of the q-th geometry tooth surface update. Here, the wear depth of the sun gear is taken as an indicator of wear state because its wear is most serious in the planetary gear train. is the wear depth of accumulated the first ζ wear cycles of the q-th geometry update, and denotes the total depth of the first q-th geometry update wear.

- (7)

- When the wear depth reaches the preset wear threshold , the RUL of worn-surface gear is calculated and output. Otherwise, the wear process will continue to repeat.

- (8)

- Then, the accumulation wear depth needs to be compared with the q-th threshold . If ≥ , the accumulated life is calculated, and then the internal excitation and dynamic response are recalculated to carry out a new round of the tooth surface wear process. Otherwise, the wear cycle is repeated under the tooth profile reconstruction of the q-th.

4. Numerical Simulation and Discussions

4.1. Effect of Tooth Surface Wear on Internal Excitation

4.2. Effect of Tooth Surface Wear on DMF

4.3. Effect of Wear Depth on RUL

4.4. Effect of Working Condition on RUL

5. Conclusions

- (1)

- Based on the modified model of TVMS and STE considering tooth surface wear, the effect of wear depth on TVMS and STE was analyzed. The results show that the surface wear has little influence on the TVMS, but has obvious influence on the STE.

- (2)

- The effect of surface wear on the DMF was analyzed by introducing the stiffness and displacement excitation with wear into the translational–torsional dynamic model of the planetary gear train. The results indicate that at the primary stage of tooth surface wear, the fluctuation range of DMF decreases gradually, presenting a state of “wearing-in”. Subsequently, the contact condition of tooth surface deteriorates gradually, and the fluctuation range of DMF will increase.

- (3)

- An assessment model of RUL for worn-surface gear under varying working conditions was proposed, and the influence of initial wear depth and varying working conditions on RUL was analyzed based on the model. The results show that the torque load has the greatest influence on the RUL, followed by the initial wear depth, and the input speed has the least influence.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ryali, L.; Talbot, D. A dynamic load distribution model of planetary gear sets. Mech. Mach. Theory 2021, 158, 104229. [Google Scholar] [CrossRef]

- Kahnamouei, J.T.; Yang, J. Development and verification of a computationally efficient stochastically linearized planetary gear train model with ring elasticity. Mech. Mach. Theory 2021, 155, 104061. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X. Effects of misalignment on surface wear of spur gears. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 1145–1158. [Google Scholar] [CrossRef]

- Park, D.; Kolivand, M.; Kahraman, A. Prediction of surface wear of hypoid gears using a semi-analytical contact model. Mech. Mach. Theory 2012, 52, 180–194. [Google Scholar] [CrossRef]

- Grabovic, E.; Artoni, A.; Gabiccini, M.; Guiggiani, M.; Mattei, L.; Di Puccio, F.; Ciulli, E. Friction-Induced Efficiency Losses and Wear Evolution in Hypoid Gears. Machines 2022, 10, 748. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, C.; Lei, Y.; Liu, Z. An adhesive wear model for helical gears in line-contact mixed elastohydrodynamic lu-brication. Wear 2019, 426, 896–909. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Zhang, J. Investigation on coupling effects between surface wear and dynamics in a spur gear system. Tribol. Int. 2016, 101, 383–394. [Google Scholar] [CrossRef]

- He, Z.; Hu, Y.; Zheng, X.; Yu, Y. A Calculation Method for Tooth Wear Depth Based on the Finite Element Method That Considers the Dynamic Mesh Force. Machines 2022, 10, 69. [Google Scholar] [CrossRef]

- Huangfu, Y.; Zhao, Z.; Ma, H.; Han, H.; Chen, K. Effects of tooth modifications on the dynamic characteristics of thin-rimmed gears under surface wear. Mech. Mach. Theory 2020, 150, 103870. [Google Scholar] [CrossRef]

- Li, X.; Olofsson, U. A study on friction and wear reduction due to porosity in powder metallurgic gear materials. Tribol. Int. 2017, 110, 86–95. [Google Scholar] [CrossRef]

- Huangfu, Y.; Chen, K.; Ma, H.; Li, X.; Yu, X.; Zhao, B.; Wen, B. Investigation on meshing and dynamic characteristics of spur gears with tip relief under wear fault. Sci. China Technol. Sci. 2019, 62, 1948–1960. [Google Scholar] [CrossRef]

- Akbarzadeh, S.; Khonsari, M.M. Prediction of Steady State Adhesive Wear in Spur Gears Using the EHL Load Sharing Concept. J. Tribol. 2009, 131, 024503. [Google Scholar] [CrossRef]

- Zhang, J.-G.; Liu, S.-J.; Fang, T. On the prediction of friction coefficient and wear in spiral bevel gears with mixed TEHL. Tribol. Int. 2017, 115, 535–545. [Google Scholar] [CrossRef]

- Brandão, J.A.; Cerqueira, P.; Seabra, J.H.; Castro, M.J. Measurement of mean wear coefficient during gear tests under various operating conditions. Tribol. Int. 2016, 102, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Kahraman, A.; Bajpai, P.; Anderson, N.E. Influence of Tooth Profile Deviations on Helical Gear Wear. J. Mech. Des. 2005, 127, 656–663. [Google Scholar] [CrossRef]

- Shen, Z.; Qiao, B.; Yang, L.; Luo, W.; Yang, Z.; Chen, X. Fault mechanism and dynamic modeling of planetary gear with gear wear. Mech. Mach. Theory 2021, 155, 104098. [Google Scholar] [CrossRef]

- Shen, Z.; Qiao, B.; Yang, L.; Luo, W.; Chen, X. Evaluating the influence of tooth surface wear on TVMS of planetary gear set. Mech. Mach. Theory 2019, 136, 206–223. [Google Scholar] [CrossRef]

- Chen, Z.; Ji, P. Research on the variation of mesh stiffness and transmission error for spur gear with tooth profile modification and wear fault. Eng. Fail. Anal. 2021, 122, 105184. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, H.; Wang, X.; Peng, Z.; Yang, K.; Zhu, W. Influence of the backlash generated by tooth accumulated wear on dynamic behavior of compound planetary gear set. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 2025–2041. [Google Scholar] [CrossRef]

- Atanasiu, V.; Oprişan, C.; Leohchi, D. The Effect of Tooth Wear on the Dynamic Transmission Error of Helical Gears with Smaller Number of Pinion Teeth. Appl. Mech. Mater. 2014, 657, 649–653. [Google Scholar] [CrossRef]

- Yuksel, C.; Kahraman, A. Dynamic tooth loads of planetary gear sets having tooth profile wear. Mech. Mach. Theory 2004, 39, 695–715. [Google Scholar] [CrossRef]

- Yang, J.; Sun, R.; Yao, D.; Wang, J.; Liu, C. Nonlinear Dynamic Analysis of high speed multiple units Gear Transmission System with Wear Fault. Mech. Sci. 2019, 10, 187–197. [Google Scholar] [CrossRef] [Green Version]

- Geng, Z.; Xiao, K.; Li, J.; Wang, J. Bifurcation and Chaos of a Spur Gear Transmission System with Non-Uniform Wear. J. Vib. Acoust. 2021, 143, 031004. [Google Scholar] [CrossRef]

- Chang, H.; Borghesani, P.; Smith, W.A.; Peng, Z. Application of surface replication combined with image analysis to inves-tigate wear evolution on gear teeth–A case study. Wear 2019, 430, 355–368. [Google Scholar] [CrossRef]

- Zhang, R.; Gu, F.; Mansaf, H.; Wang, T.; Ball, A.D. Gear wear monitoring by modulation signal bispectrum based on motor current signal analysis. Mech. Syst. Signal Process. 2017, 94, 202–213. [Google Scholar] [CrossRef]

- Feng, S.; Fan, B.; Mao, J.; Xie, Y. Prediction on wear of a spur gearbox by on-line wear debris concentration monitoring. Wear 2015, 336–337, 1–8. [Google Scholar] [CrossRef]

- Feng, K.; Smith, W.A.; Borghesani, P.; Randall, R.B.; Peng, Z. Use of cyclostationary properties of vibration signals to identify gear wear mechanisms and track wear evolution. Mech. Syst. Signal Process. 2021, 150, 107258. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.; Li, Y.; Ni, Q.; Wu, H.; Zheng, J. A novel cyclic-correntropy based indicator for gear wear monitoring. Tribol. Int. 2022, 171, 107528. [Google Scholar] [CrossRef]

- Laval, X.; Mailhes, C.; Martin, N.; Bellemain, P.; Pachaud, C. Amplitude and phase interaction in Hilbert demodulation of vibration signals: Natural gear wear modeling and time tracking for condition monitoring. Mech. Syst. Signal Process. 2021, 150, 107321. [Google Scholar] [CrossRef]

- Hu, C.; Smith, W.A.; Randall, R.B.; Peng, Z. Development of a gear vibration indicator and its application in gear wear monitoring. Mech. Syst. Signal Process. 2016, 76–77, 319–336. [Google Scholar] [CrossRef]

- Zhao, F.; Tian, Z.; Liang, X.; Xie, M. An Integrated Prognostics Method for Failure Time Prediction of Gears Subject to the Surface Wear Failure Mode. IEEE Trans. Reliab. 2018, 67, 316–327. [Google Scholar] [CrossRef]

- Liu, X. Vibration modelling and fault evolution symptom analysis of a planetary gear train for sun gear wear status as-sessment. Mech. Syst. Signal Pr. 2022, 166, 108403. [Google Scholar] [CrossRef]

- Beinstingel, A.; Parker, R.G.; Marburg, S. Experimental measurement and numerical computation of parametric instabilities in a planetary gearbox. J. Sound Vib. 2022, 536. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J. Effects of random interval parameters on spur gear vibration. J. Vib. Control. 2021, 27, 2332–2344. [Google Scholar] [CrossRef]

- Sainsot, P.; Velex, P.; Duverger, O. Contribution of Gear Body to Tooth Deflections—A New Bidimensional Analytical Formula. J. Mech. Des. 2004, 126, 748–752. [Google Scholar] [CrossRef]

- Kahnamouei, J.T.; Yang, J. Develop and verify Energy-Based Statistical Linearization Technique to Analysis Nonlinear Stochastic Vibration of A Spur Gear Pair. J. Vib. Acoust. 2023, 145, 1–29. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, Z.; Chen, S. Coupling of the 2D microtopography of tooth surface and transmission error. J. Mech. Sci. Technol. 2018, 32, 723–730. [Google Scholar] [CrossRef]

- Pei, J.; Han, X.; Tao, Y.; Feng, S. Study on Wear Dynamic Reliability of Gear System Based on Markov Diffusive Process. J. Tribol. 2022, 144, 021202. [Google Scholar] [CrossRef]

- Janakiraman, V.; Li, S.; Kahraman, A. An Investigation of the Impacts of Contact Parameters on Wear Coefficient. J. Tribol. 2014, 136, 031602. [Google Scholar] [CrossRef]

- Ding, H.; Kahraman, A. Interactions between nonlinear spur gear dynamics and surface wear. J. Sound Vib. 2007, 307, 662–679. [Google Scholar] [CrossRef]

| Parameters | Sun | Planet | Ring | Carrier |

|---|---|---|---|---|

| Number of tooth z | 20 | 29 | 79 | — |

| Module mn (mm) | 2.25 | 2.25 | 2.25 | 2.25 |

| Mass m (kg) | 0.53 | 0.35 | 1.85 | 4.5 |

| Inertia I (kg·mm2) | 146 | 297 | 17,440 | 11,178 |

| Diameter of basic circle db (mm) | 42.29 | 61.31 | 167.03 | 113 |

| Tooth width B (mm) | 25 | 28 | 25 | — |

| Bearing stiffness (N·μm −1) | 10 | 58 | 1000 | 195 |

| Torsional bearing stiffness (N·μm−1) | 10 | — | 57.6 | 10 |

| Pressure angle (°) | αs = 20°, αr = 20° | |||

| Damping coefficient of bearing | chx = chy = 0.03 | |||

| Damping coefficient of meshing | csn = crn = 0.07 | |||

| Backlash bc (μm) | 110 | |||

| Rated torque Tc (Nm) | 134 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, J. Assessment of Residual Useful Life of Sun Gear in a Planetary Gearbox Based on Dynamic Wear Behaviors Analyses. Machines 2023, 11, 149. https://doi.org/10.3390/machines11020149

Wang J, Zhang J. Assessment of Residual Useful Life of Sun Gear in a Planetary Gearbox Based on Dynamic Wear Behaviors Analyses. Machines. 2023; 11(2):149. https://doi.org/10.3390/machines11020149

Chicago/Turabian StyleWang, Jian, and Jun Zhang. 2023. "Assessment of Residual Useful Life of Sun Gear in a Planetary Gearbox Based on Dynamic Wear Behaviors Analyses" Machines 11, no. 2: 149. https://doi.org/10.3390/machines11020149