1. Introduction

If watermills were invented during the Classical Age, their diffusion occurred mainly in the Medieval Age, as pointed out by M. Bloch [

1]. Especially in mountain and foothill areas, but apparently resistant to the cultural influence of main towns and courts, the systematic and widespread application of technical equipment connected to the principle of the water wheel contributed to the development of the capillary historical hydraulic landscape for at least eight centuries. This was possible thanks to a process of light infrastructure of the territory. The admirable water wheels were the “engines” of grain mills, hemp roller mills, sawmills, forges, foundries, and twisting and spinning machines, for a production that we could today call a short supply chain.

Similarly, the consolidation of professional figures that were already present within medieval communities—such as the miller and the blacksmith—on one side, played primary social roles, and on the other, were subject to specific regulations, burdens, and severe penalties for fraud, due to the primary importance of their activities for local communities.

Like much of the territory of southwestern Piedmont during the fourteenth and fifteenth centuries, the mountain area of the Maira Valley, of which Busca and Dronero represent the main centres, boasted a significant plan of canalization for irrigation and production purposes. That canalization system was possible through the construction of so called bealere (canals) which, once obtaining water from the Maira River, descend towards the plain, crossing Dronero and Busca.

These were pharaonic works for the times, carried out by the will of the religious orders or of the marquis himself, contracted to private builders with the help of the funds of the newly established municipalities. To mention just two examples: the Marchisa Canal, or

bealera cuniculorum, with most of the section was built under-ground, was “a wonderful work worthy of being counted among the most distinguished of this kind,” in the description that G. Casalis [

2] in his Dictionary of 1835. The Presidenta Canal, was supported by concession of the King of France and the noble property of the Este family until the nineteenth century.

It was this type of endeavour that give a significant boost to the organization of work in the craft sector, at least for this part of the plain, centralising the then many mills scattered everywhere in more aggregated centres, creating an almost proto-industrial plant capable of exploiting unique and large water heads, with constant water flow, for more productive machines. Otherwise, in the communities of the upper valley, the impervious orography and a more autarkic economy imposed a diffused, capillary micro-hydro, with minimal, punctual applications of a very short supply chain.

This period is also marked by the strong development of mining and metallurgy activities, promoted by the economic policy of the Marquis of Saluzzo. Iron, silver, copper, and alum were extracted from quarries in the valley (mostly owned by marquis and leased to private individuals) and processed in the forges of the valley floor, where they built furnaces and forges driven by external water wheels [

3,

4,

5]. In the sixteenth century, the forges and the water-powered trip hammers were among the apparatuses that had the greatest impact on these activities, due to local political tensions. According to the chronicles reconstructed by G. Manuel Di San Giovanni [

6], once the imperial troops commanded by Gonzaga were approaching the entrance into the marquisate, Giò Federico Saluzzo, lord of Montemale and governor of Dronero—appointed by the King of France—reinforced the defences of Dronero. In doing so, he ordered the fusion of new artillery pieces and required the community to manufacture all the tools necessary for the fortification works, such as shovels, spades, hoes, and blades, in the local forges.

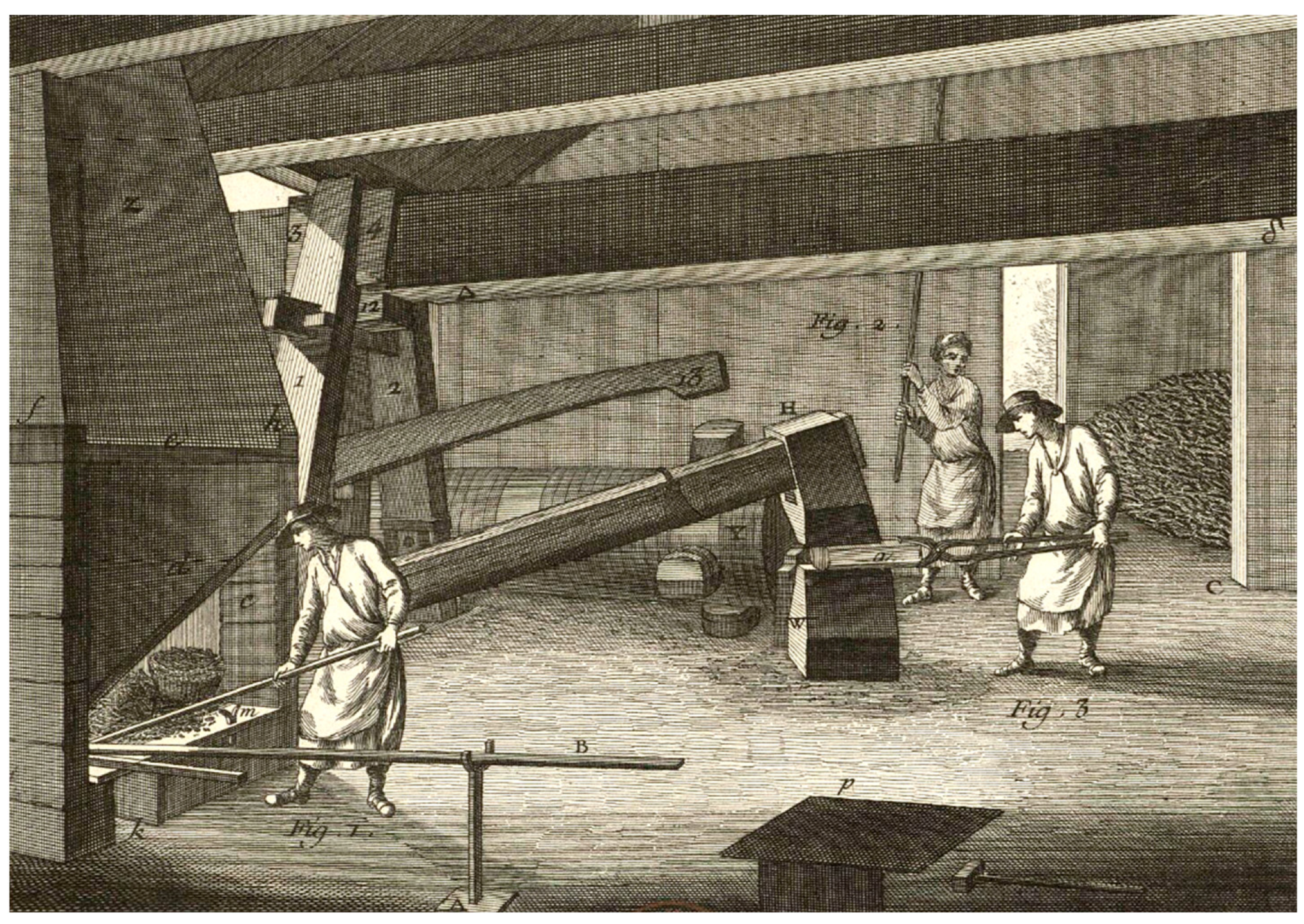

Among the most substantial documented sources of information, through which we can reconstruct the productive apparatus of the local communities, there are certainly detailed the vast reconnaissance campaigns carried out during the Napoleonic period in the occupied territories (the Maira Valley and Busca were headed by the Stura department, arrondissement of Cuneo). At the root is the interest of the French government in determining the productive potential of the territory, by virtue of the belligerent policy undertaken, with particular attention given to metalworking activities. In addition to allowing us to reconstruct a vast framework consisting of factories and mills located almost everywhere and articulated on precise plots of canalizations, the documents show that the use of the iron trip hammer was particularly widespread at that time (

Figure 1). This was a manifestation of a metal economy that, partially abandoning high-altitude mining, tended to move in the direction of the recovery of exhausted iron and its regeneration through its processing in workshops [

3,

4].

This was the motivation for this dynamic technological and architectural enhancement of the numerous workshops in the area, such as the La Pianca trip hammer and forge of Busca, and the renewal of their internal equipment with the adoption of new “donkey-headed” hammers, hydraulic trompes, stoves, ovens, and grinding wheels, all organized in larger and more spacious environments, in structures often generated by the accretion of building along the canal direction.

Rustic casings with mechanical hearts driven by hydraulic wheels were powered by the force of water, always downwards and never from above, to exploit its kinetic energy. They were housed in hazy and smoky environments, where the heat of the fire, the rhythmic and deafening gait of the mechanical hammers on the anvils, the hiss of the grinding wheels and transmission belts, together with the skilful artisan action (not by chance called

ars, in practical Latin etymology, as opposed to the more abstract Greek

tekhné), gave shape to a sample of ferrous trinkets and tools of all sorts and uses, with the most unusual forms—memories that today Corrado Ambrogio would reinvent in his famous artistic installations. Those tools were nonetheless essential for everyday life, agricultural activity, and building practices, sometimes represented with that realistic pictorial style in real signs ante litteram, painted in plain sight on the façade, the only ornaments of this severe architecture (

Figure 2).

The present work intends to establish a craft production panorama highlighting the trip hammers and workshops related to metalworking, today almost totally in the shadows, decayed over the course of a few decades, but which until the mid-twentieth century represented a significant production sector, both in numbers and quality. This intent was achieved through the in-depth investigation of the case study of the forge La Pianca of Busca, the detailed analysis of the functioning of its motion transmission apparatuses, from the water wheel to the hammers, and through the verification of the operations involved in the work of the workshop.

The numbers of iron machining centers linked to the exploitation of the water wheel are impressive. Even in the censuses of the early twentieth century, hammers and workshops in full activity were common almost everywhere in the territorial area surrounding the case study of La Pianca. As emerges in the most recent thematic works [

8,

9,

10], all the main centers of the valley, as well as the high altitude centers, possessed forges and hammers, where the water wheel used by the grain mill was also, in recent times, flanked by the wheel used by the hammer.

In particular, there are the numerous Dronero hammers—thirteen—later abandoned to concentrate the work in the Falci SpA industrial plant. Moreover, the Busca hammers, among which the forges located on the Morea canal (three including the case study of La Pianca), of remote origin but active until the second half of the twentieth century, stand out. Going up the Maira Valley, you will find hammers and forges in San Damiano Macra, the Vallà workshop, still complete with the trip hammer, grinding wheels and forges, slides, and concrete channels of modern construction, although now in progressive degradation. In Macra, the workshop on the path leading to Caricatori, is organized in a single large space, covered by a groundwater. In Stroppo, the Laugero Mill, also called Mulin du Piri, already mentioned in Napoleonic sources, was a forge that in the twentieth century was still quite active and equipped with a hammer activated by an external wooden wheel, to which two static vertical drills and two grinding wheels were also connected (the production of tools for agricultural processing, iron for animals, building products, and hardware, lasted until 1980). In the locality of San Michele Prazzo, a small iron hammer was active in the multipurpose nucleus consisting of the grain mule. In Acceglio, Pontemaria, a small “donkey-headed” hammer driven by a second external water wheel, and a forge with a chimney, anvils, and work tools constituted the equipment of a workshop mainly used for shoeing the animals and for the production of metal objects [

11,

12].

The present work is therefore a first important study on a specific example, the forge of La Pianca, of this complex and extensive production panorama, and follows a similar work done by some of the authors on flour water mills, also in Piedmont [

13,

14]. The presence in the territory of evident and numerous specimens of the work, often still intact both in reference to the equipment of the machinery and the buildings in which they are housed, as well as the clear recognizability of ancillary works such as canals and water supply canals (

bealere), which inevitably constitute significant linear infrastructures, justifies scientific interest and investigations such as the one presented here, in the immediate perspective of safeguarding the historical memory of the artefacts and their future complete readmission into the circuits of the local economies.

More ambitious objectives inherent in works such as this remain the prefiguration of effective scenarios for the conversion of production artefacts, and the prediction of the beneficial effects on the cultural, economic, and social aspects of the surrounding area by activating recovery processes with virtuous and sustainable dynamics, including but not limited to, an energy point of view in regards to the landscape and environmental enhancement plans.

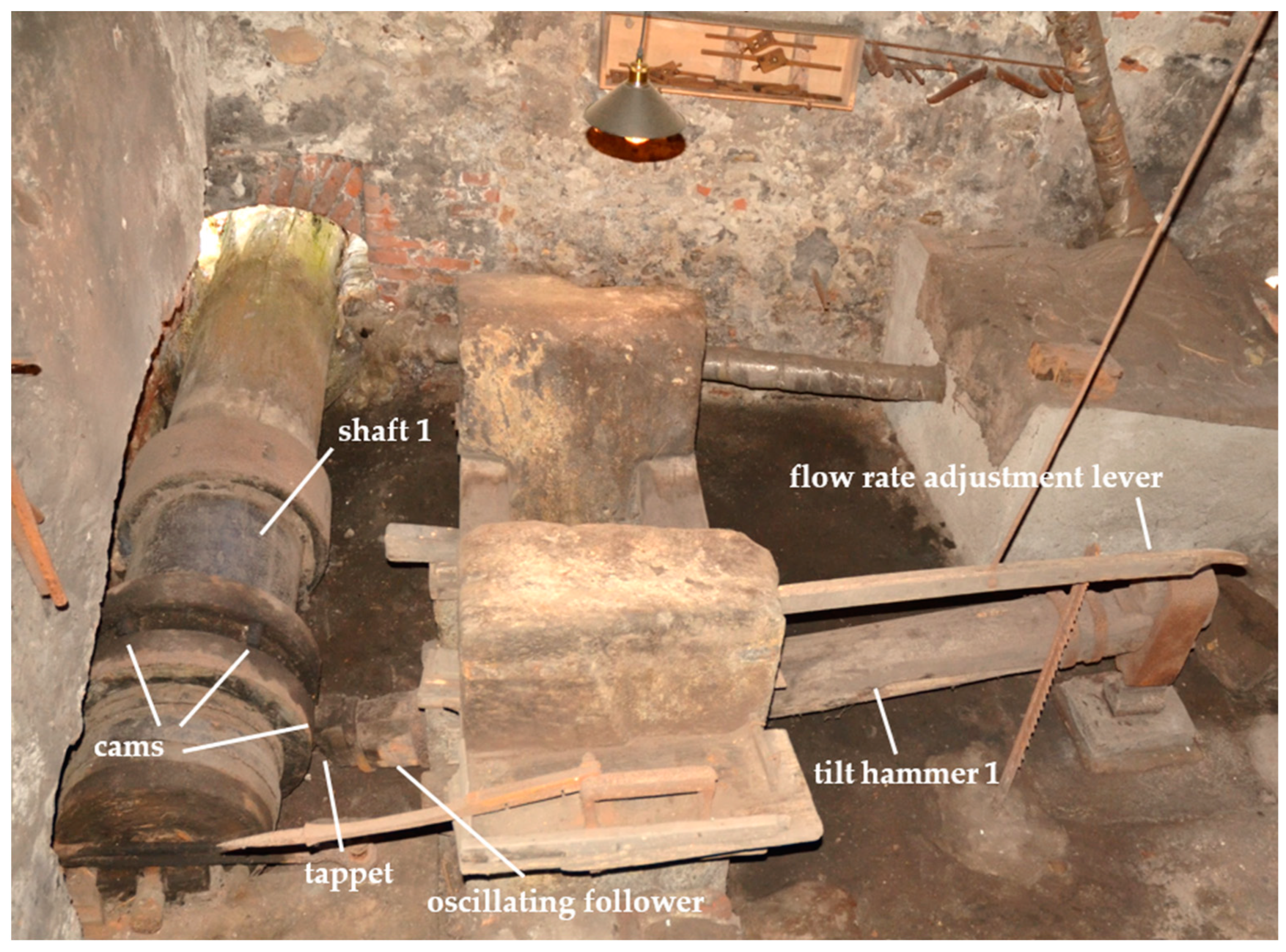

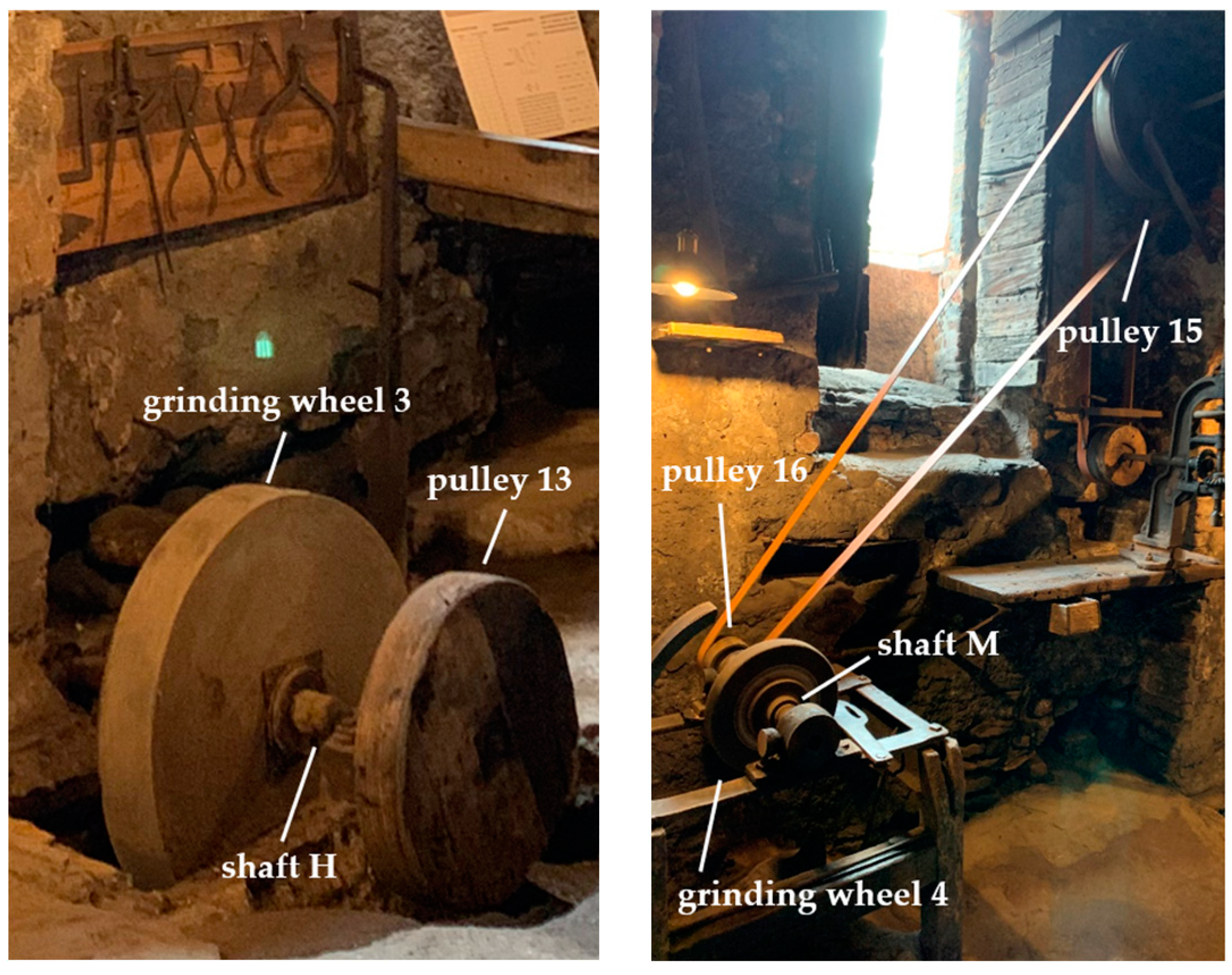

The present work is therefore structured with the first section as a description of the territorial context of the forge of La Pianca and the building hosting it. Historical information and direct testimonies, reported by the owner of the artefact itself, outline the scenario in which the workshop operated in the last period of activity. Its technical equipment, the activities that took place, and the economic and productive dynamics are still alive in the memory of those who, like Gianpiero Cavallo, lived (and grew up) in direct contact with those who worked here. Today, the La Pianca building, thanks to the care of the descendants of the last blacksmith, retains the completeness of the equipment in an environment crystallized at the time of disposal, maintaining its documentary value.

In a second section, the functioning of the machinery equipment is analyzed in detail, from the water wheels to the trip hammers, static drills, and grinding wheels, without neglecting the power transmissions. Models and images accompany the text in a meticulous descriptive path that unfolds between the individual devices, gears, and wheels, highlighting the solid combination of prefabricated artefacts with others made to measure, or even on site.

The rudimentary systems, elementary power transmissions, mechanisms, links, and weights, seem to be the result of a meticulously sought balance (and perhaps not totally empirical) by both the manufacturers and users themselves. The former certainly belong to groups of specialized workers (carpenters, metallurgical experts, mechanics, fitters), with uncommon knowledge and with the task of inventing—and adapting to the site—complex devices. The latter, artisans and blacksmiths, were called to the much more difficult daily task of drawing their livelihood from the power of water.

2. The La Pianca Mill

The La Pianca forge is located in the neighbourhood Borgo Biandonne, a real artisanal area of the Busca of the eighteenth-century. The village has developed along the Morea Canal (

Figure 3,

Figure 4 and

Figure 5), which takes its name from “beale domini” [

15], or the “canal of the lord”. The canal was built following a feudal act dated 5 March 1418, which also recognized the right to build a mill [

16].

In the following years, there was a real flourishing of activities along the canal itself, as reported in the “rights of the ‘Magnificent Community of Busca’: The men of Busca can take and have taken at their free will the water of the river Macra and make in it locks, mills, and beats and conduct said water in their prairies and mills as the men and communities of Busca are accustomed to take and do [

17]”.

There are no certain dates for the construction of the forge. The first mention of dates is found in the Land Registry of 1704, in which there are three forges noted for the processing of iron. One of these was located in Borgo Biandonne and was owned by the Prince of Carignano Emanuele Filiberto, Marquis of Busca [

16].

The next mention of dates is 1840, with the transfer act of ownership of the building by Mr. Zuccarelli to Mr. Bongioanni (for 7900 Lire, Italian currency of the time) and the subsequent act of 1919 (to a man named Cavallo) where it is expressly mentioned as a “building consisting of: hemp roller mill, forge, and various rooms on the upper floors” [

18] (

Figure 6 and

Figure 7).

The work carried out in the forge was closely linked to the agricultural world. The production mainly concerned pickaxes, spades, hoes, and axes, as well as some kitchen tools (small cleavers, chopping knives, etc.) (

Figure 8).

The work was produced with great skill, so that the blacksmith earned the inscription on the roll of honor of artisans (

Figure 9), and with great pride he engraved Cavallo’s last name on the artefact just made.

With the evolution of agricultural mechanization, the forge subsequently specialized in the restoration of ploughshares. This was, in fact, the most delicate part of the tool, an element that today is replaced carelessly, but that was once recovered several times, forging and reshaping it and then sharpening the blade, as well as the mowing bars used for the mechanical mowing of fodder.

The mill worked without interruption until the 1960s, when the change in the agricultural world, and in particular, the type and use of tools, decreed a slow closure that materialized at the end of the 1970s.

Next to the premises of the forge there is an additional room containing a hemp roller mill. It consisted of a stone wheel with a diameter of about 0.80 m powered by a vertical axis water wheel. The hemp, macerated in special locations (“nasors”) made along the irrigation ditches, dried for a fortnight, and was worked on by the action of the millstone, in order to separate the fibre from the canapulo (

Figure 10a). As evidence of the above, a photograph from the 1930s shows the vertical millstone in the background (

Figure 10b).

Fun fact: the forge La Pianca owes its name to the presence of a nearby iron walkway (

pianca, in Italian) placed to connect the two banks of the Maira stream (

Figure 11). The footbridge was built around 1890 by the blacksmith Bongiovanni Gio Battista and his son in order to shorten the route to Cuneo and last but not least, to attract customers heading to the other two forges, located on the other side of the Maira.

Another curiosity concerned the secret of tempering. Only the owner knew the right amount of soap to add to the water and above all, how to identify the precise colour reached by the iron in the forge to determine when immerse it in the solution. Moreover, the oil was expensive and was not easy to find, so once a year, Mr. Michele, the owner from 1919 to 1950, went with the cart pulled by the mule to the nearby city of Côte d’Azur to buy Marseille soap, soap that was macerated on the floor for a couple of years before being used for hardening.

4. Discussion

The case study of the La Pianca forge, here analysed with pleasure, not only due to its exquisite engineering, belongs—along with many other similar examples—to a world that since the second half of the twentieth century, for practical reasons and market economics, has disappeared. For decades, La Pianca has remained in a condition apparently without reason for existence, sometimes maintained almost entirely thanks to the commitment of volunteers or as a result of modest local investments, with the hope perhaps of preserving a memory (and that would be enough).

The proto-industrial fabric linked to iron processing, has previously (as well as currently) experienced very significant market fluctuations due to socio-political events, with a strong impact on the economic performance of the sector; therefore, it applied a long-term technology which remained almost unchanged for centuries in its technical principles (except for the numerous adaptations to the site, the building, the watercourse, and the specific territory). Despite this, by carrying out studies such as the one presented here, we realize how these few decades that separate us from the last production phase have been enough to create so many difficulties in understanding, specifically in relation to certain mechanisms, dynamics, functions, destinations, and values, precisely due to their character of liberation from the current purely consumerist and energy-consuming mindset. Therefore, on closer inspection, that world appears to us today rich in experiential opportunities, memories, logics, and new stimuli.

While it is not always possible to accurately model the performance of the entire transmission of these mills, since water wheels and wooden and iron gears exhibit an intrinsically non-linear behaviour, which aggravates the uncertainty in determining total efficiency, conducting research, and carrying out in-depth investigations, it is evident that the scientific understanding of technologies if often applied in a more or less empirical way, and their correct framing in a broader socio-economic context can detect interesting implications, not only in a documentary manner. Hydraulic landscapes and the proto-industry have a long historical heritage that seems to be characterized by elements of absolute contemporaneity, such as a high level of production quality (in the agricultural and craft field) obtainable with a “zero impact” from an energy point of view. As Daniele Regis says [

11], “the current interest in mini and micro hydroelectric, for smaller and more sustainable structures (against the construction of large reservoirs and dams always with a strong impact on the territory and its ecosystem), sometimes also characterized by a predominantly engineering ap-plication of new technologies, can innovate, regenerate, refine in the palimpsest of history and landscape”.

Moreover, through the regeneration of the historical productive heritage linked to water exploitation, the prospects desired by the new international approach could be applied. Eco-museology and the themes of active (and not passive, as often happens in the numerous ethnographic museums) enhancement can be combined (as the net of political strategies on the use of water resources) with tourist dynamics linked to the attractiveness generated by waterways, as well as with the exploration of “cultural routes,” teaching, and practical and theoretical training in synergy with study and research centres, providing re-activated plants, which is effective both for documentation and production.

Through the circular economy of recovery, with a low environmental footprint and the establishment of land associations (to compact the extensions of often excessively fragmented agricultural land), or through building associations (in terms of the architectural recovery of buildings now abandoned and multiple), all framed under a broader local policy of enhancement of short supply chains, without the exclusion of innovative and light technological applications, the conditions for a more systematic recirculation of historical production buildings as testimonies (not only material) of work could be created.

The conservation of the technical apparatus and the building of the La Pianca forge and the integrity of external accessory elements related to the flow of water, together with the interest aroused locally by institutions and associations regarding the research presented here, entitle the forge entitled to a possible inclusion in an eco-museum proposal focused on hydraulic landscapes.

Today, the La Pianca forge presents the best surrounding conditions for preservation and revaluation. Therefore, it is up to all of us to oversee its future.

5. Conclusions

In this study, we analysed in detail the water-powered trip hammer and La Pianca forge, taken as a case study of a typical mill in the Piedmont region (Italy) dedicated to the forging of metals. These types of production settlements were widespread throughout the Piedmont territory, and some of them remained productive until the middle of the 20th century. Many are still in a good state of conservation, and we believe that it is therefore necessary to undertake a recovery process.

In the first section, the socio-economic and territorial context in which the mill was established was studied, both through the consultation of archives and historical texts, and with the collection of testimonies from those who saw the forge in operation up to its definitive closure in the late 1970s. Then, the architecture of the machinery plant was analysed in detail, from the water wheels to the various users, in particular trip hammers, grinding wheels, and drills, passing through power transmissions.

Beyond the historical value of the work, both for aspects closer to the history of the territory and of the architecture of the productive buildings, and in regards to the history of the mechanisms and machines, the authors hope that the detailed study can make a contribution to the recovery, redevelopment or conversion processes of these artefacts, both for museum, testimony, and production purposes.

As far as this last aspect is concerned, the contextual study and the functional reconstruction of the fleet of machines must be understood as a first input to be able to evaluate in the future which type of intervention can eventually be put into practice.

Due to widespread dissemination, previously realized water channels, concessions for the use of water, integration into the landscape, and acceptance by the population, water wheels are in fact an interesting prime low-power mover. They could be put back into operation, both as a mechanical power take-off for driving refurbished machinery for artisanal activities, as well as for the generation of electric energy to be used locally, i.e., in energy communities.

The detailed analysis of the La Pianca mill has allowed us to highlight these potentialities, which will be explored in a future work.