Investigation on Start-Up Characteristics of Large Axial Flow Pump Systems Considering the Influence of Auxiliary Safety Facilities

Abstract

1. Introduction

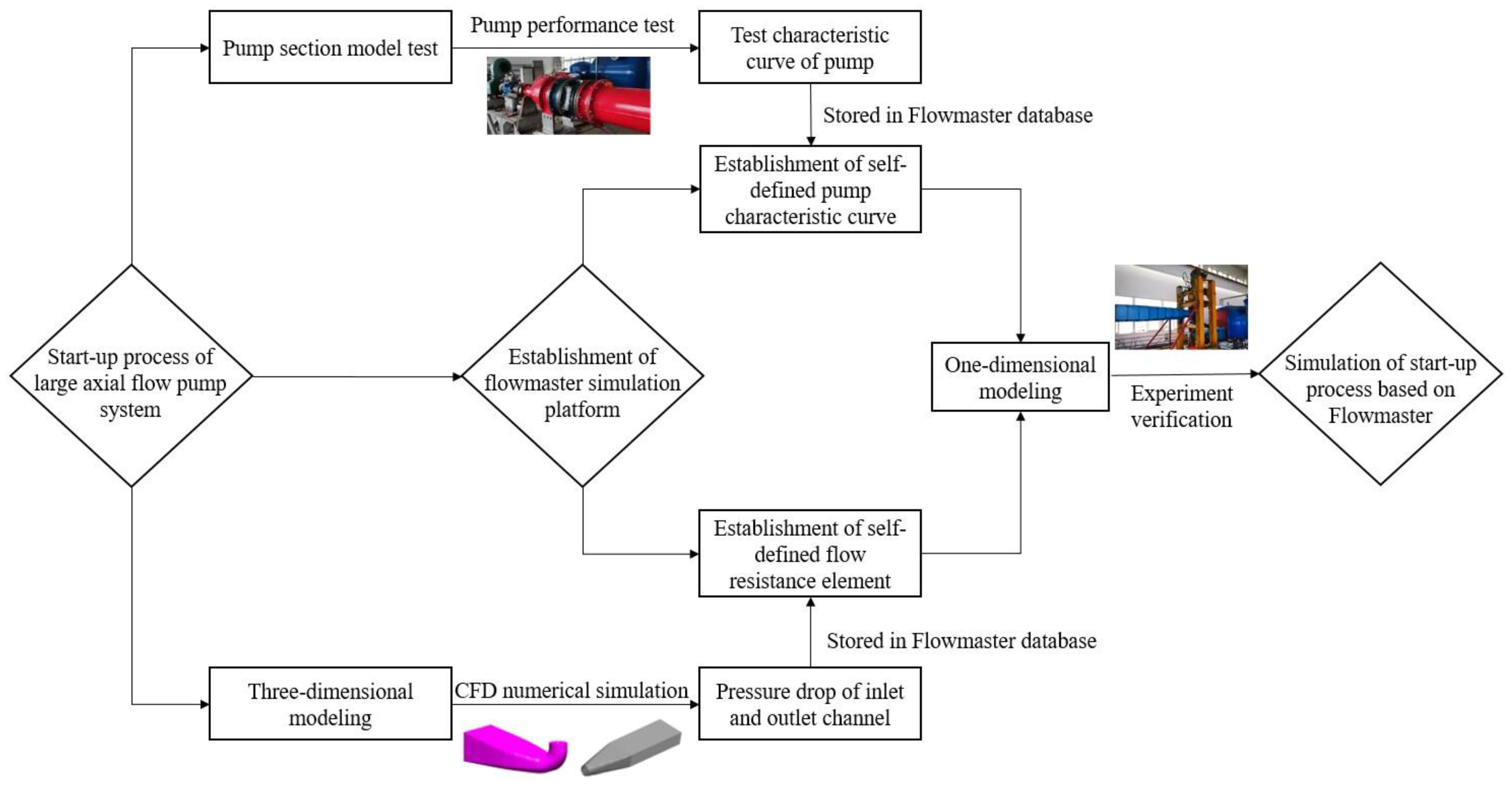

2. Numerical Simulation and Experimental Setup

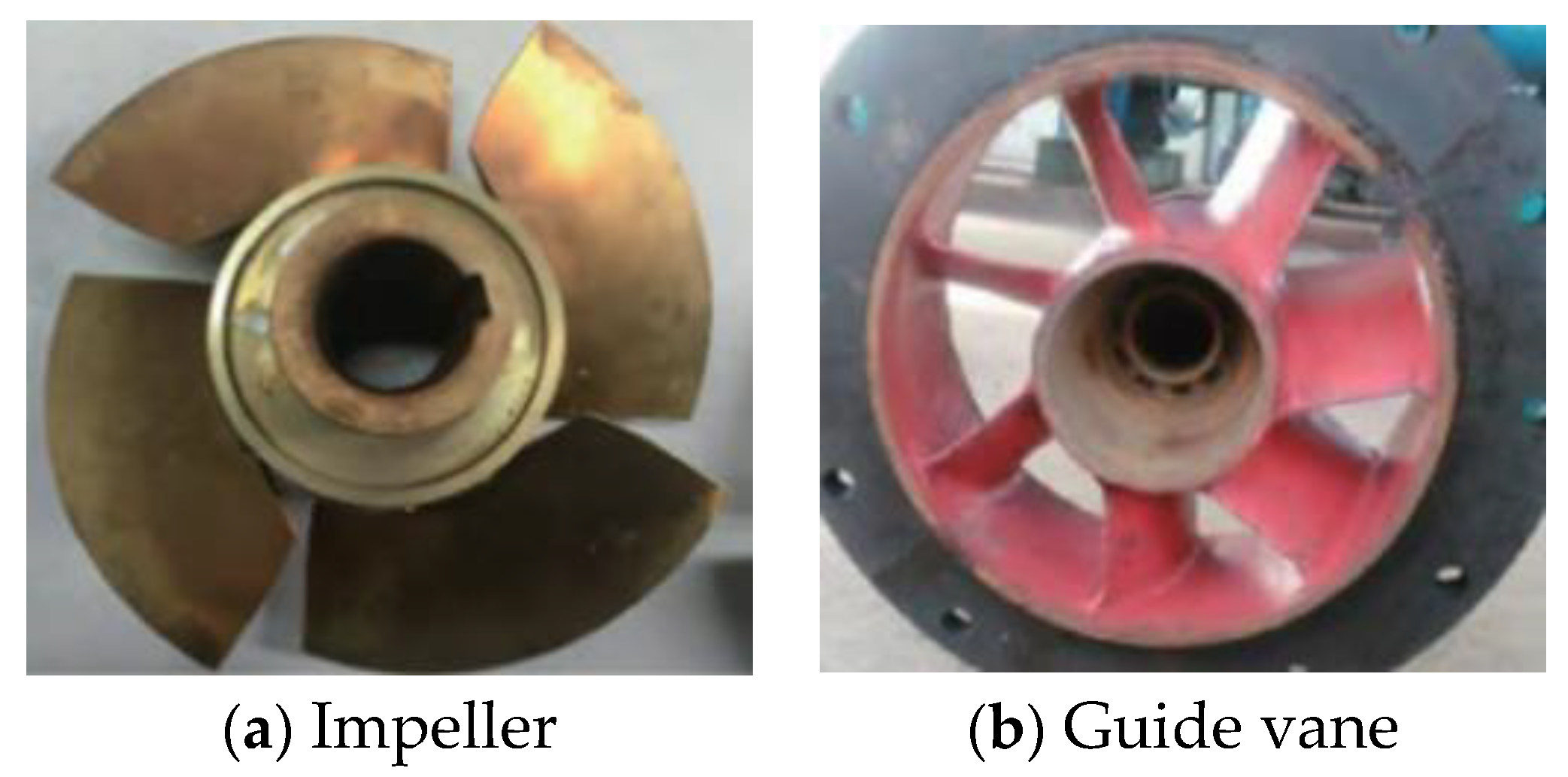

2.1. Physical Model

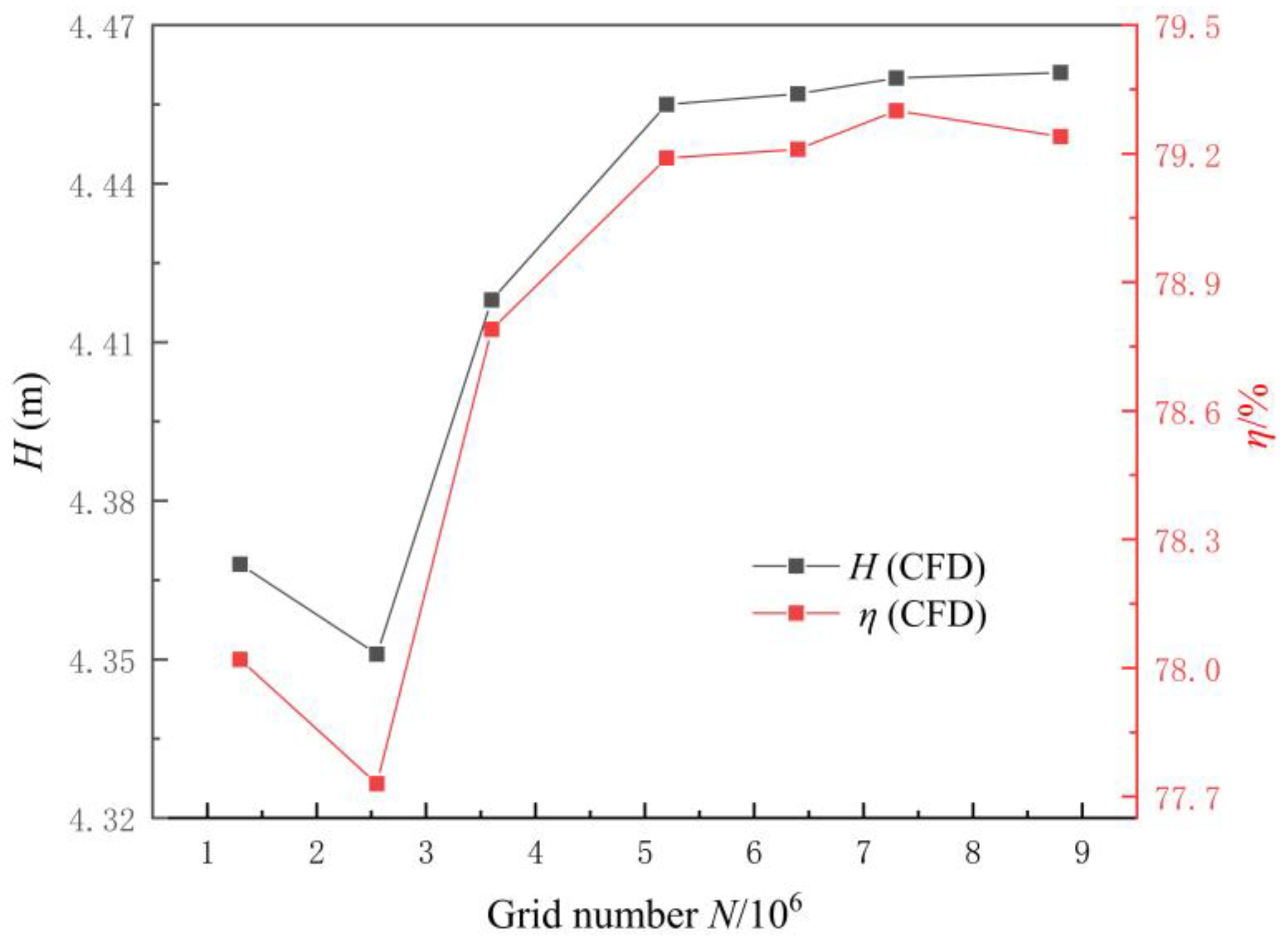

2.2. Simulation Process and Mathematical Model

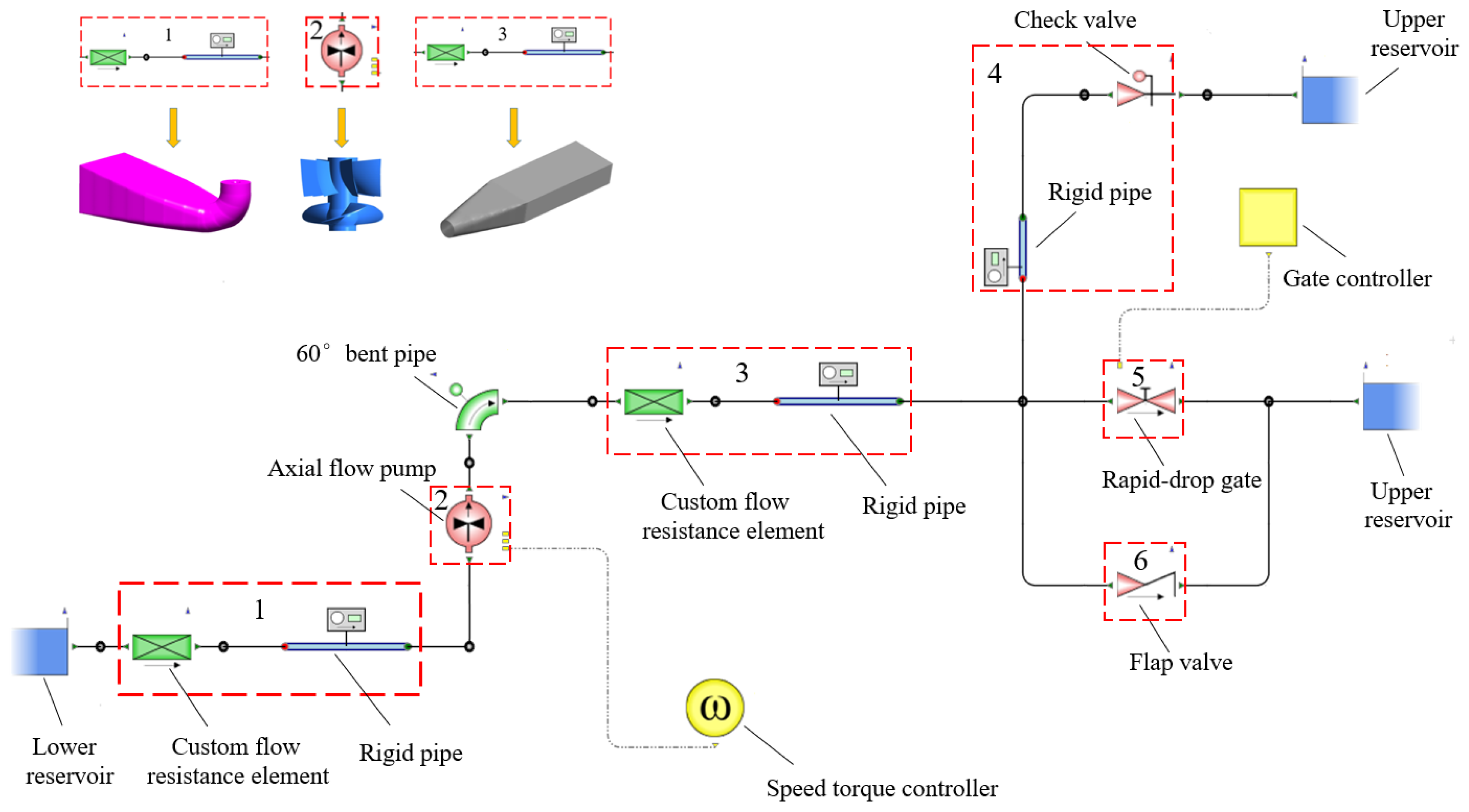

2.3. Simulation Model Construction and Boundary Conditions

2.4. Scheme and Its Specific Description

2.5. Experimental Setup

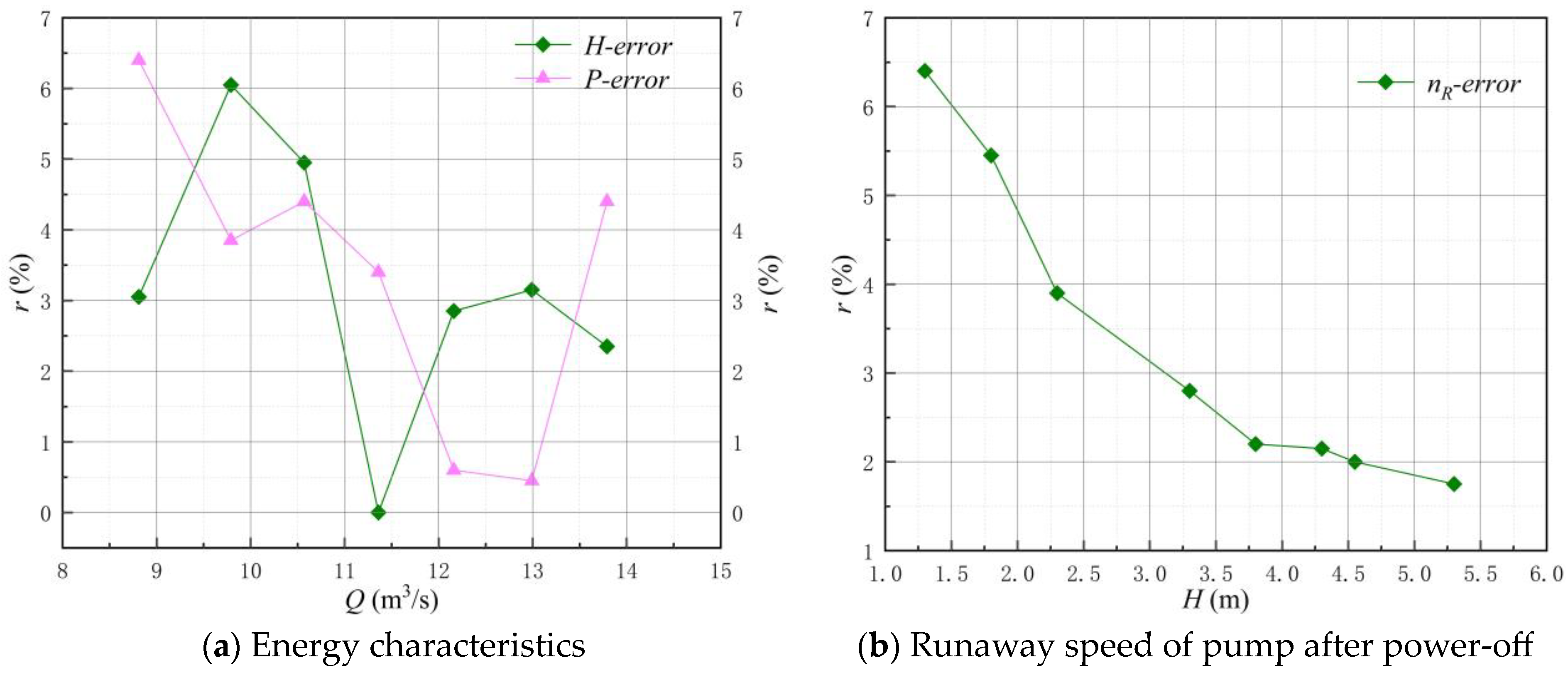

3. Model Validation

4. Results and Discussion

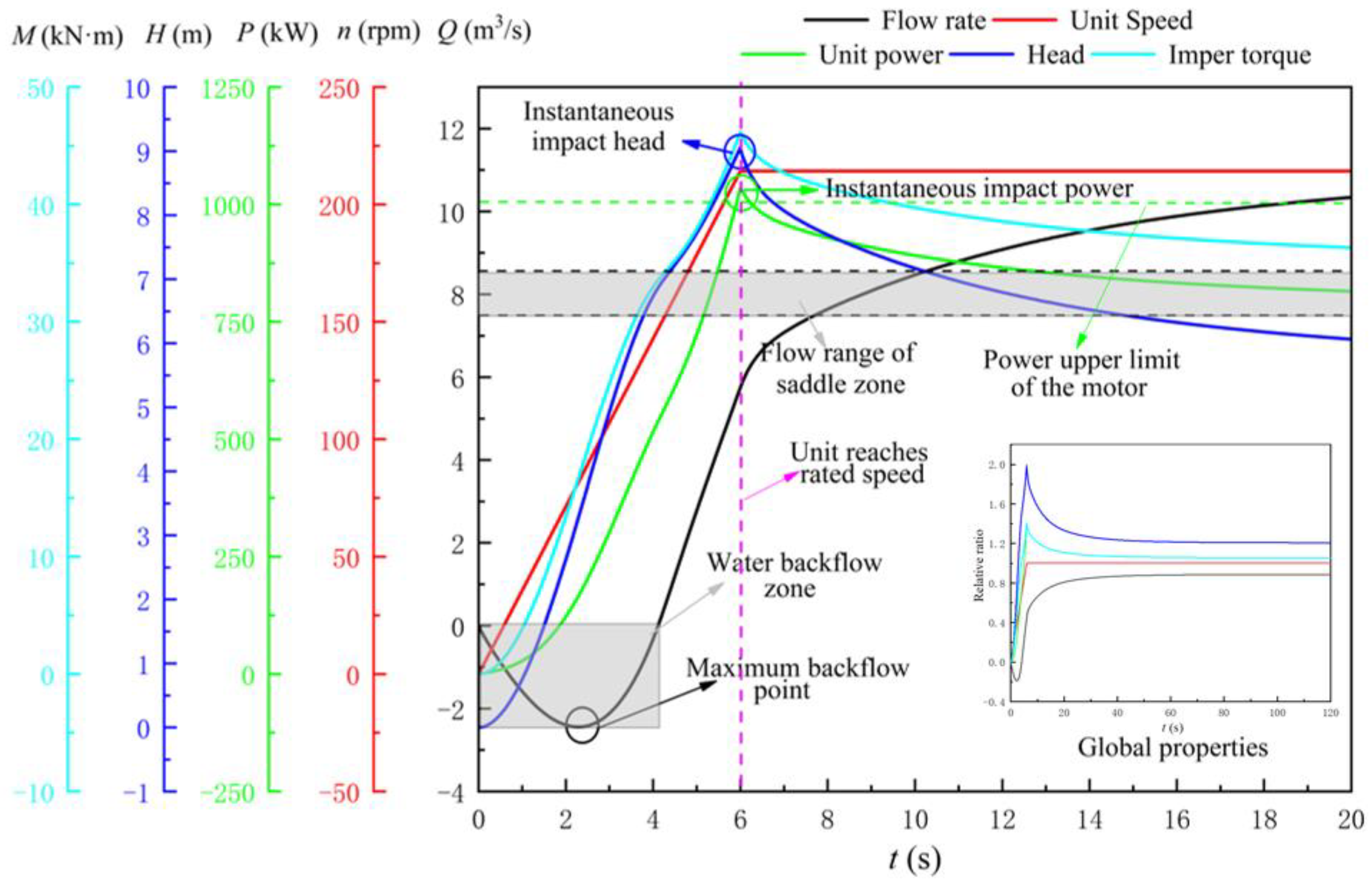

4.1. Influence of Opening Speed of Rapid-Drop Gate

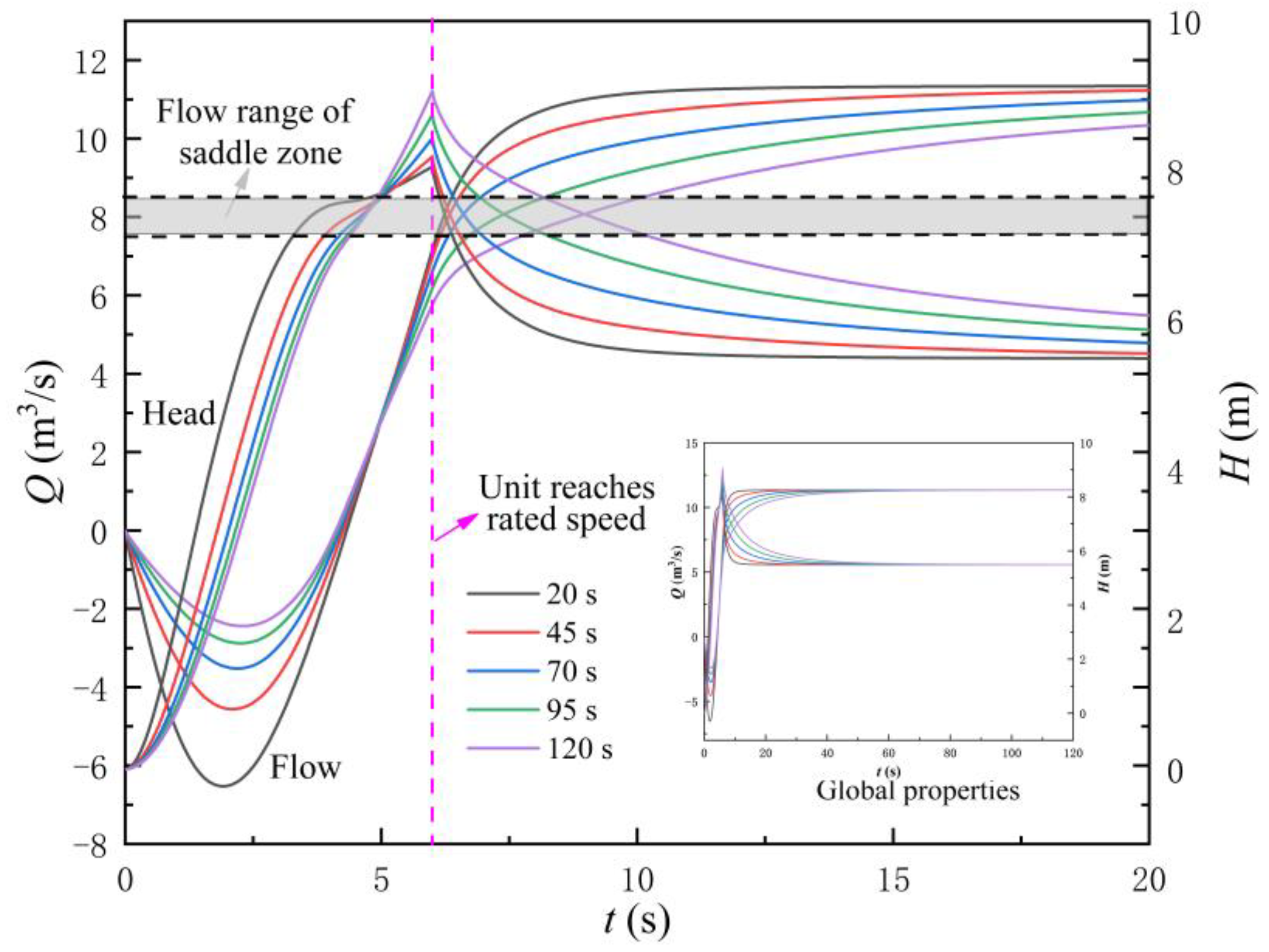

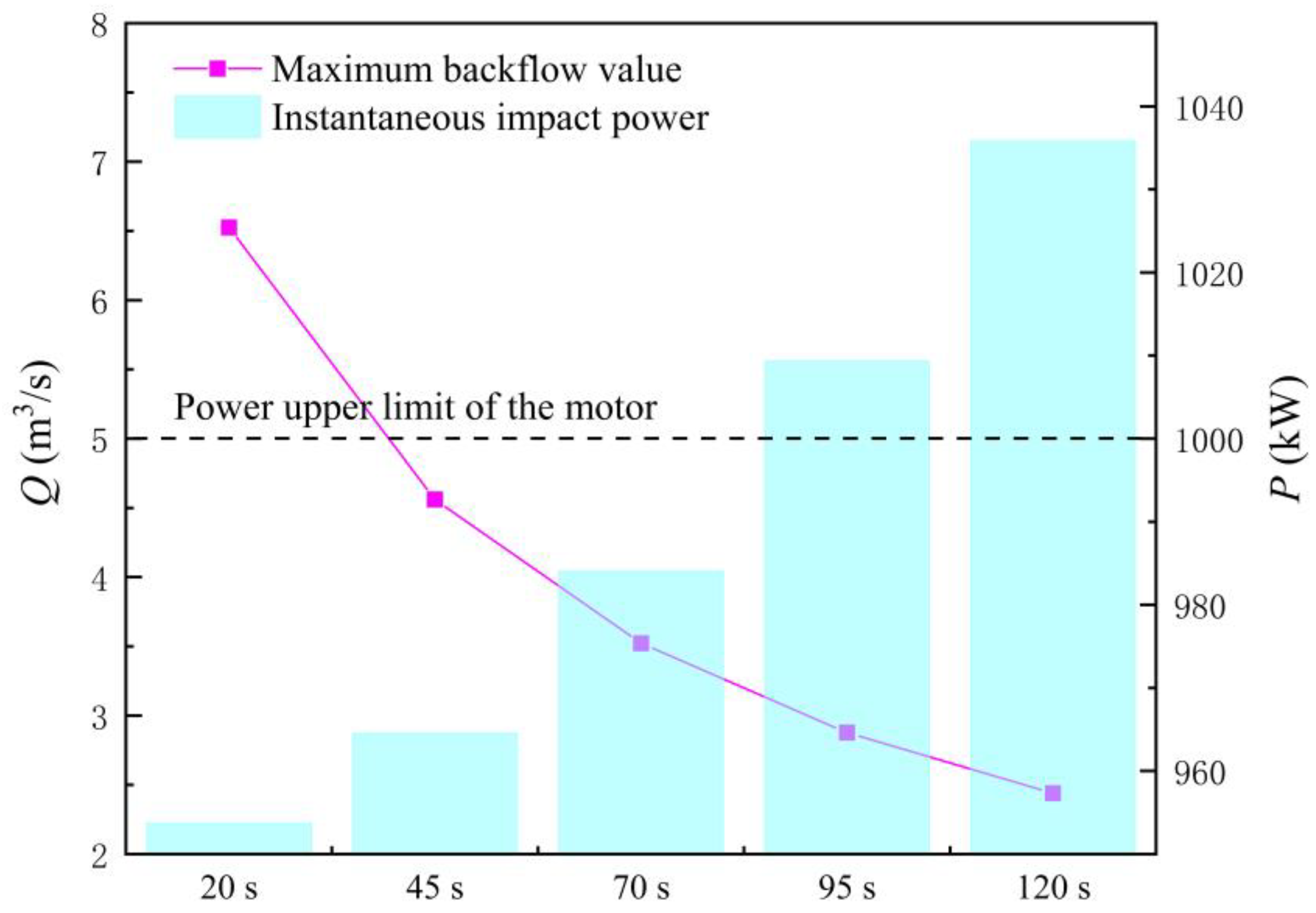

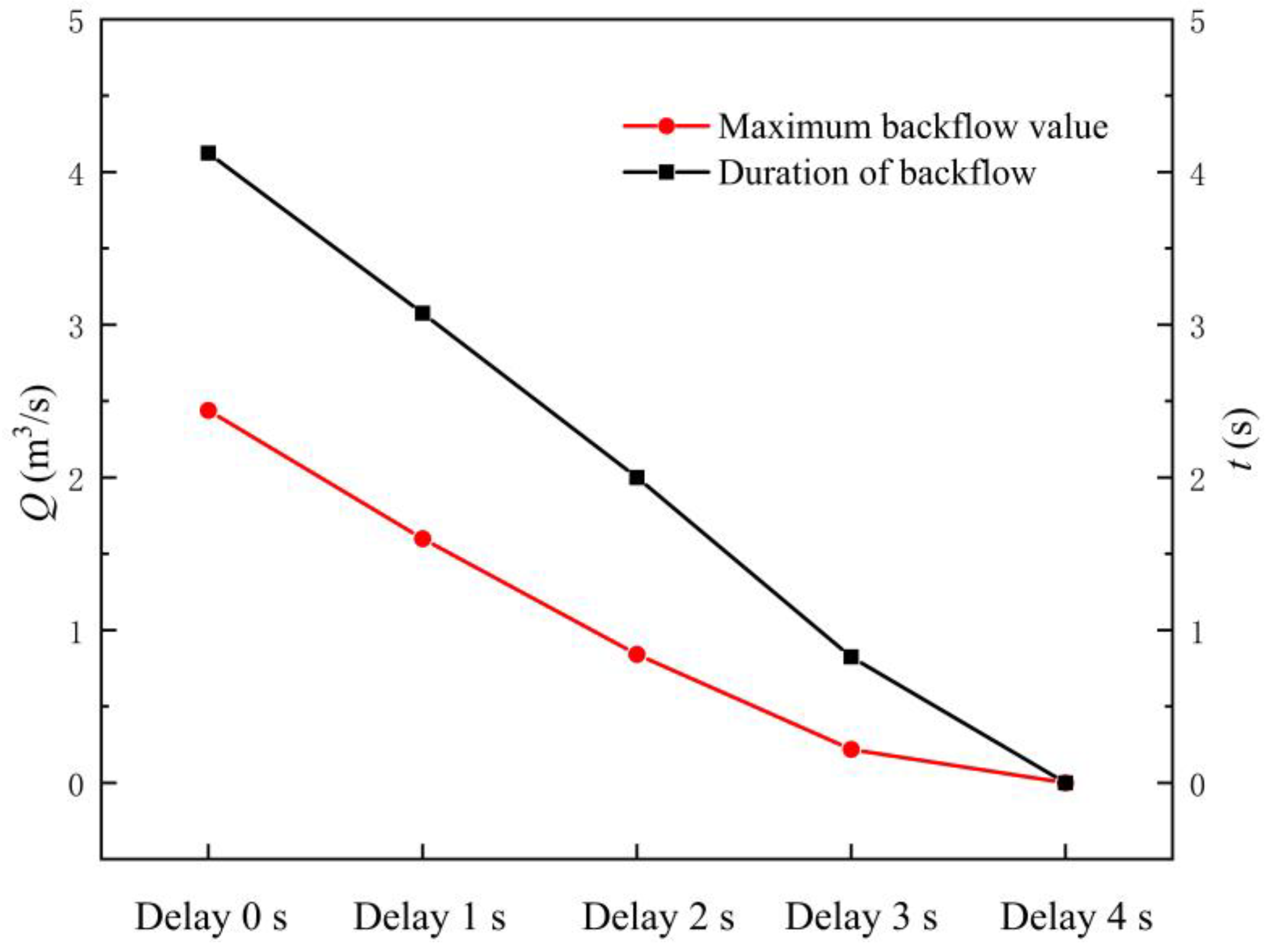

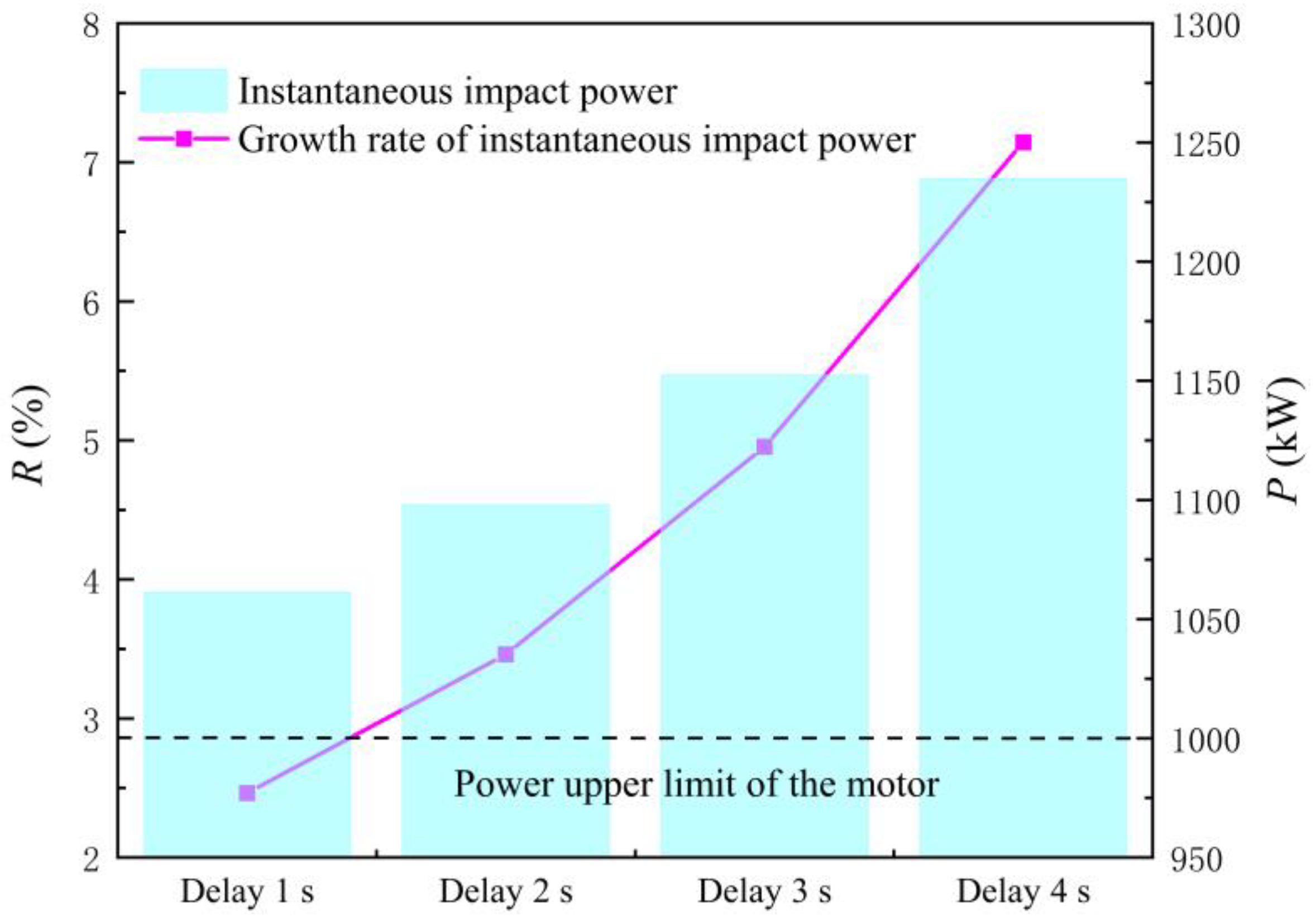

4.2. Influence of Delaying Opening Time of Rapid-Drop Gate

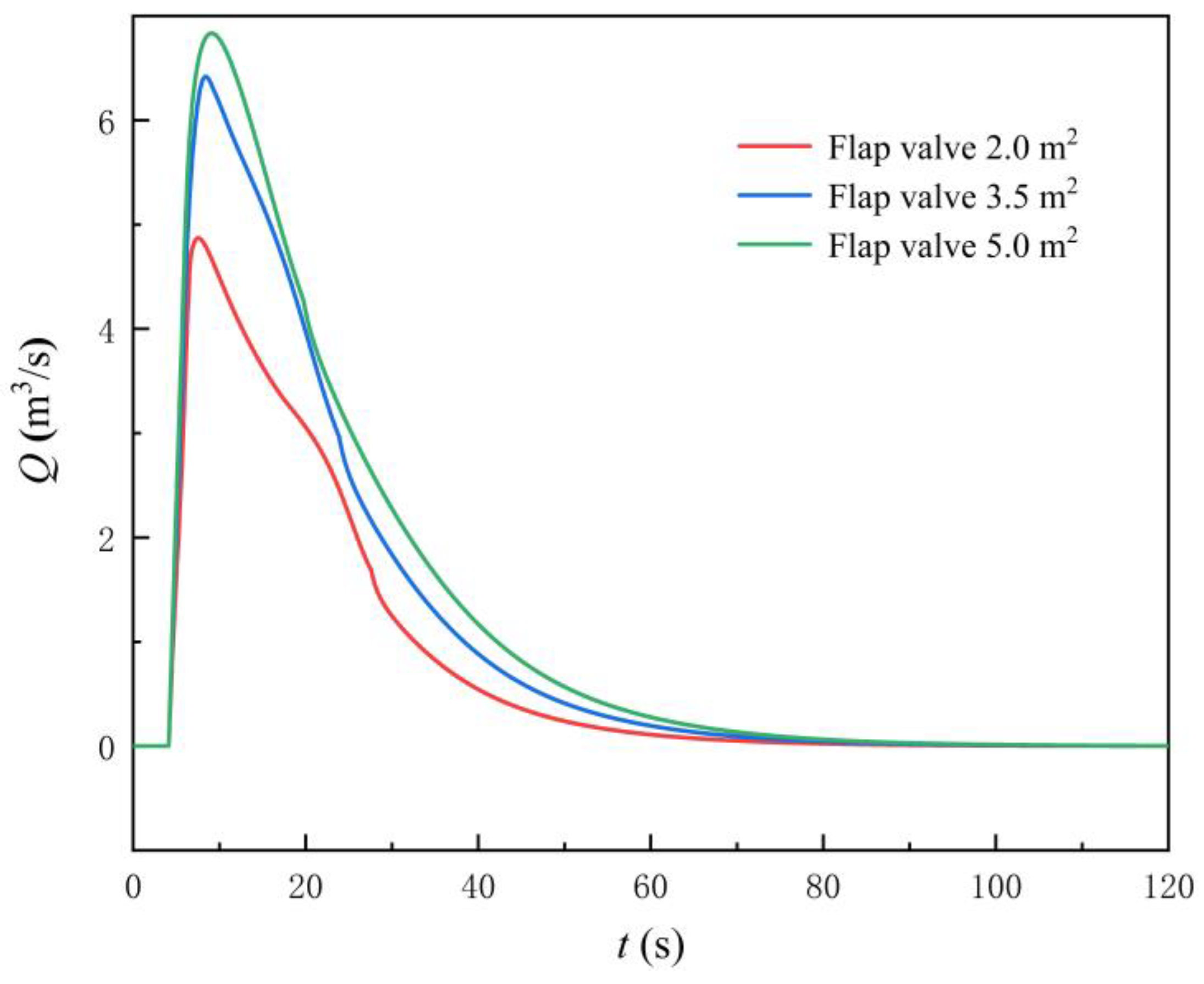

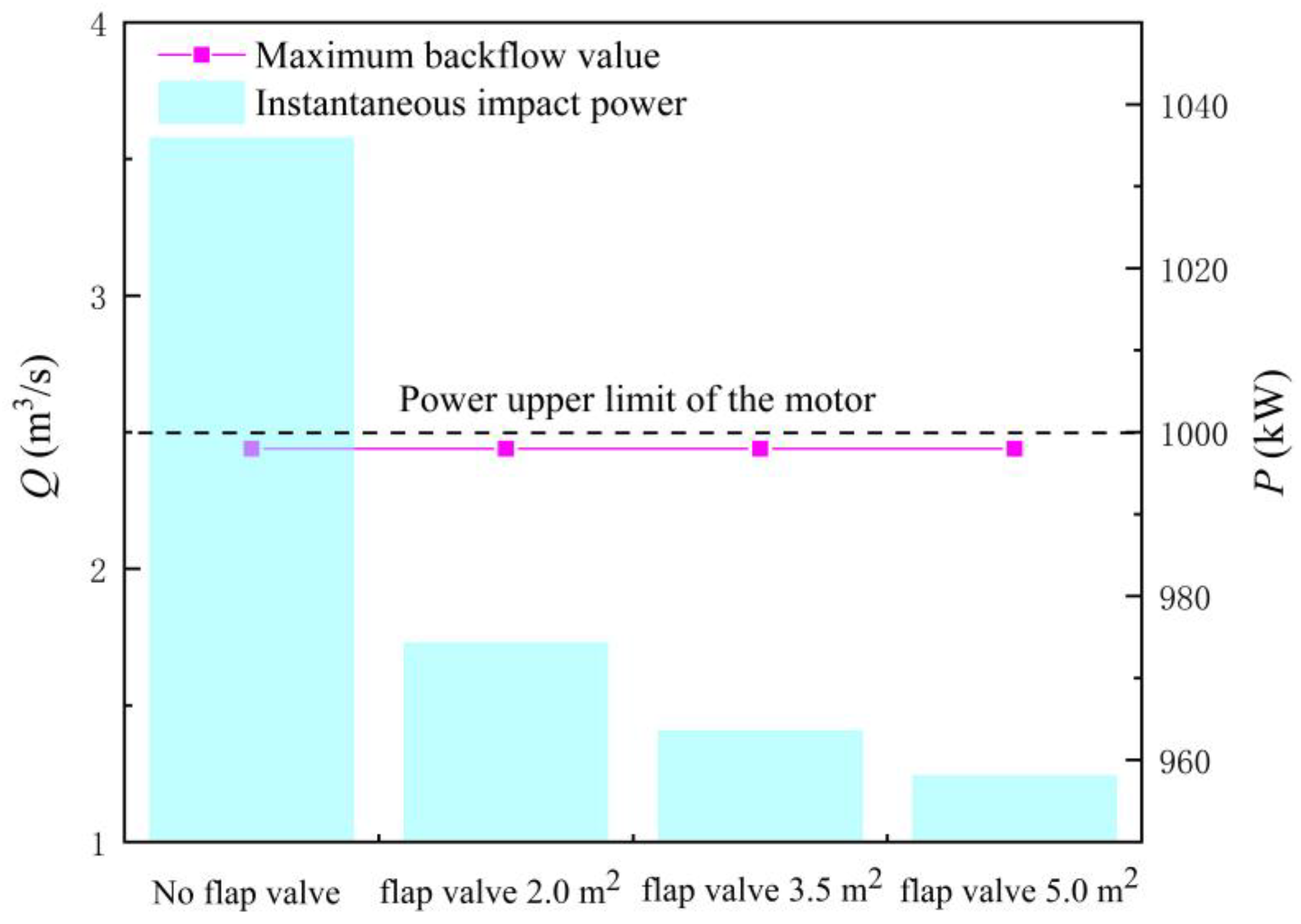

4.3. Influence of Adding the Flap Valve

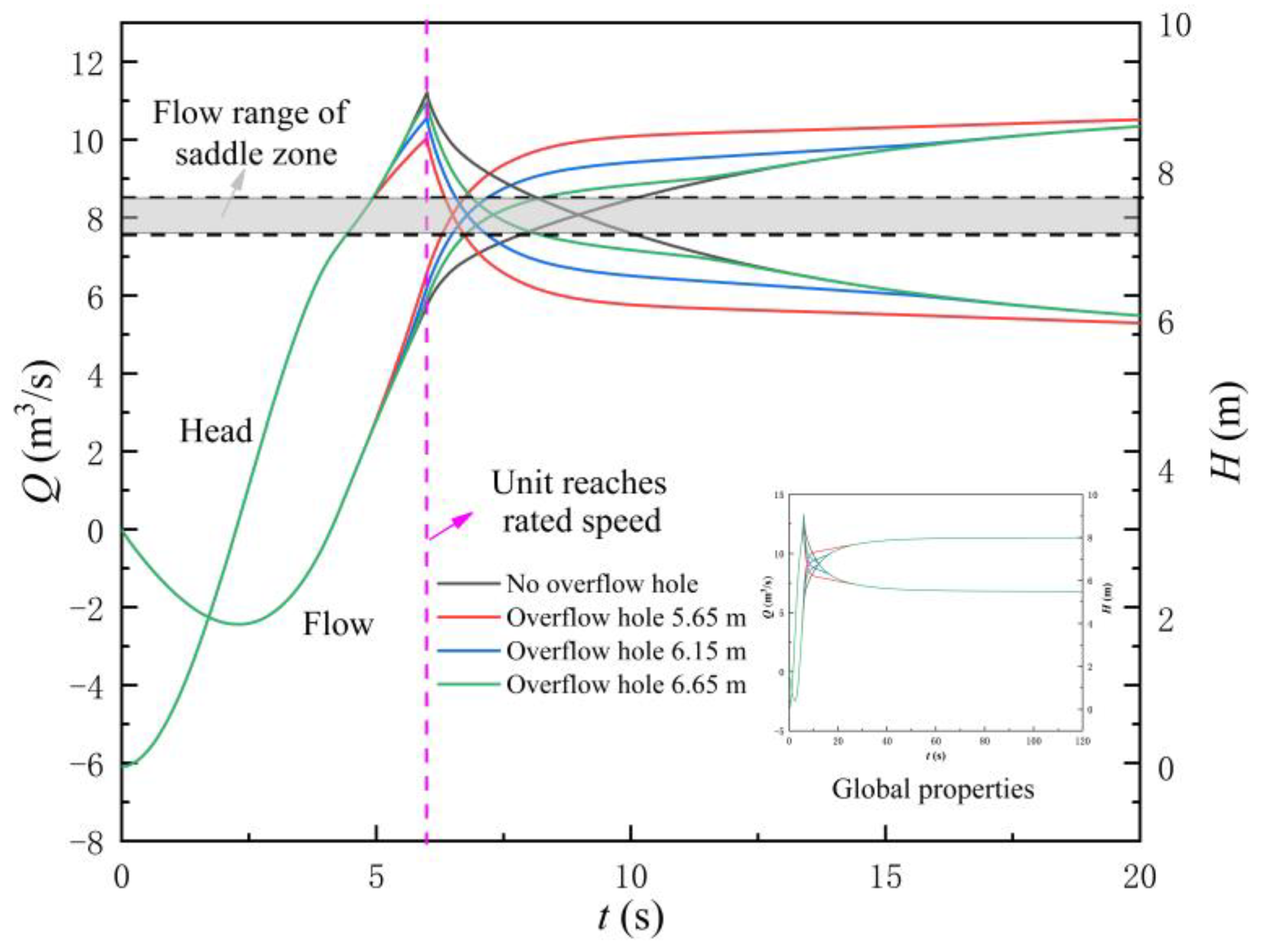

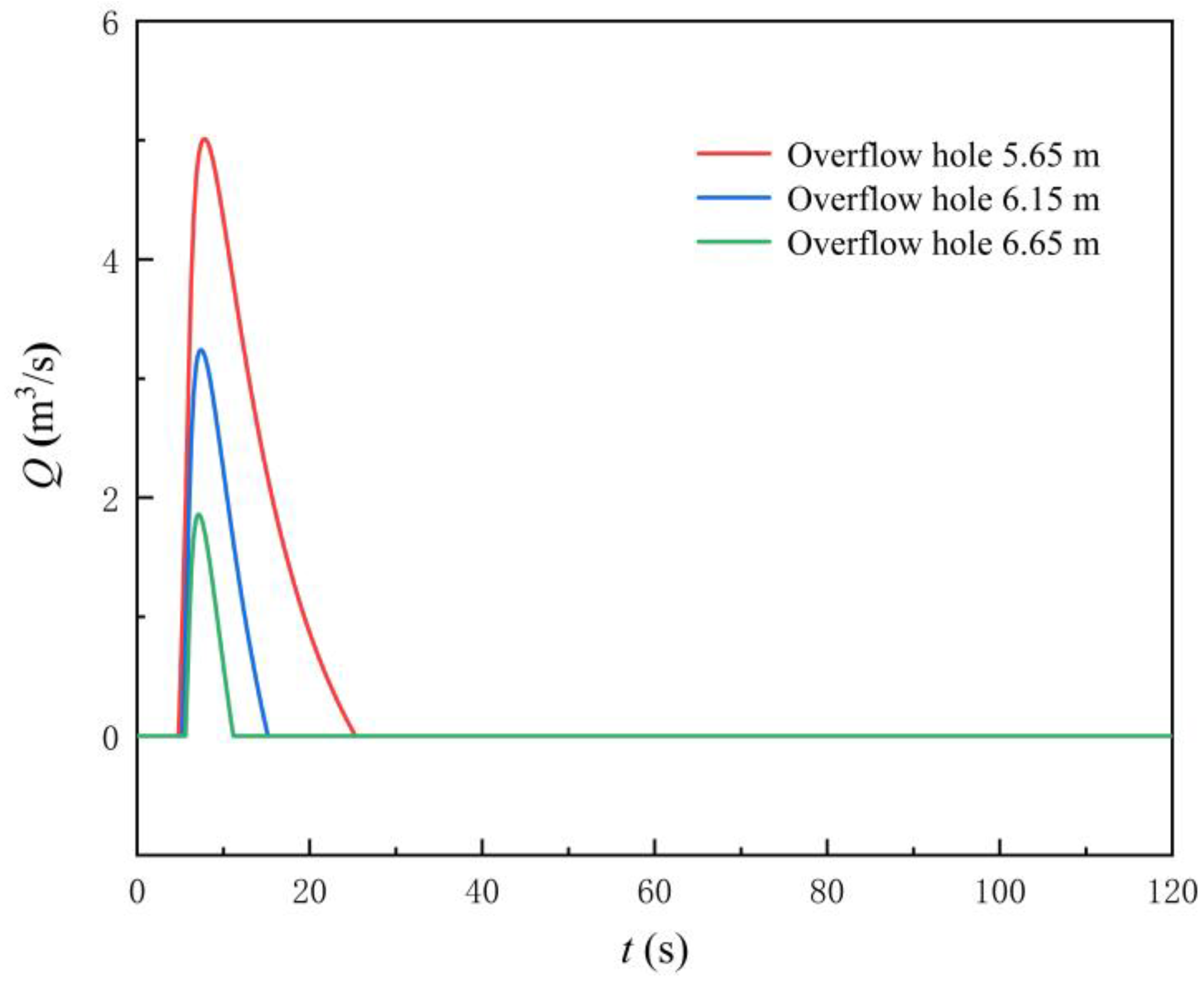

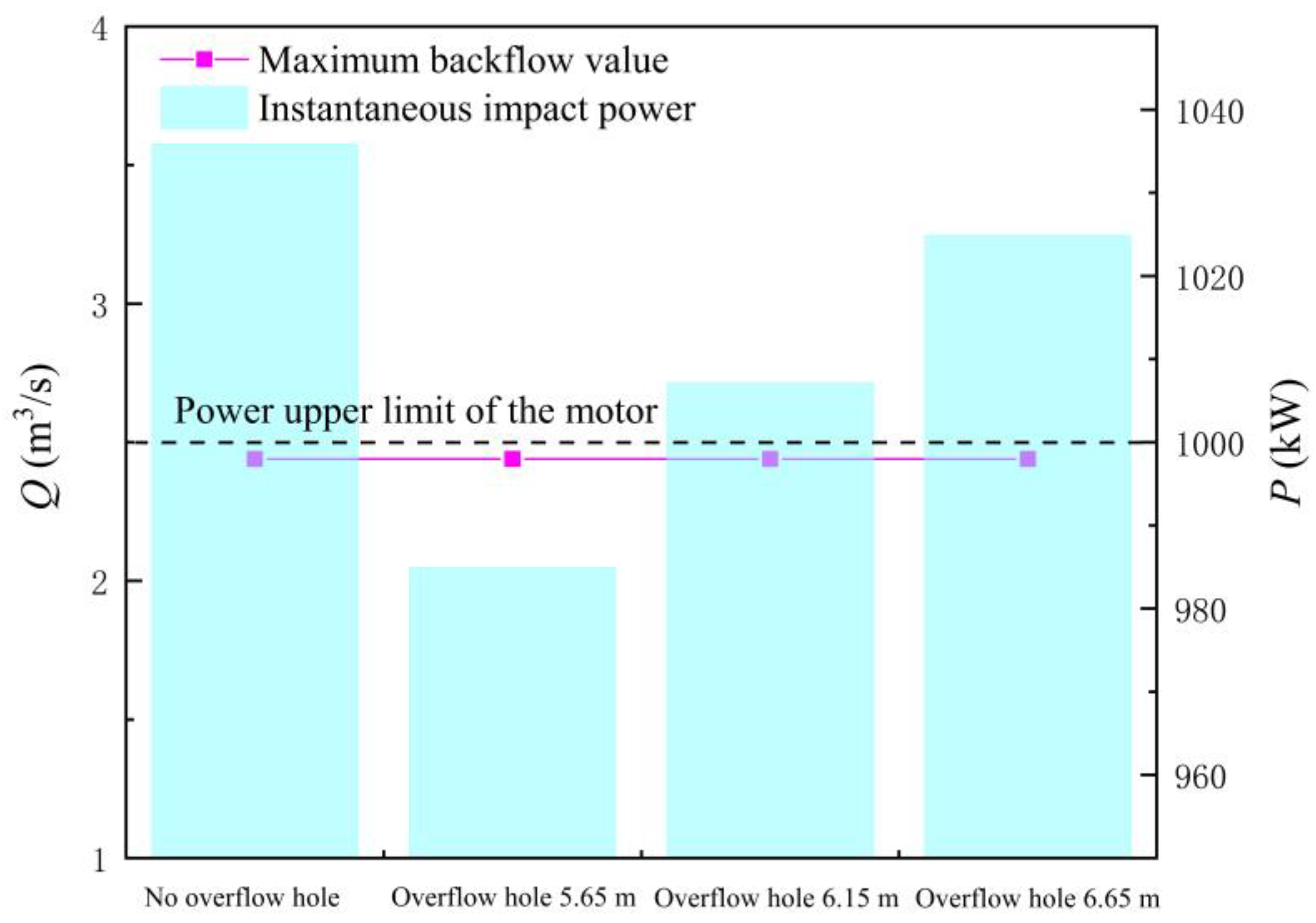

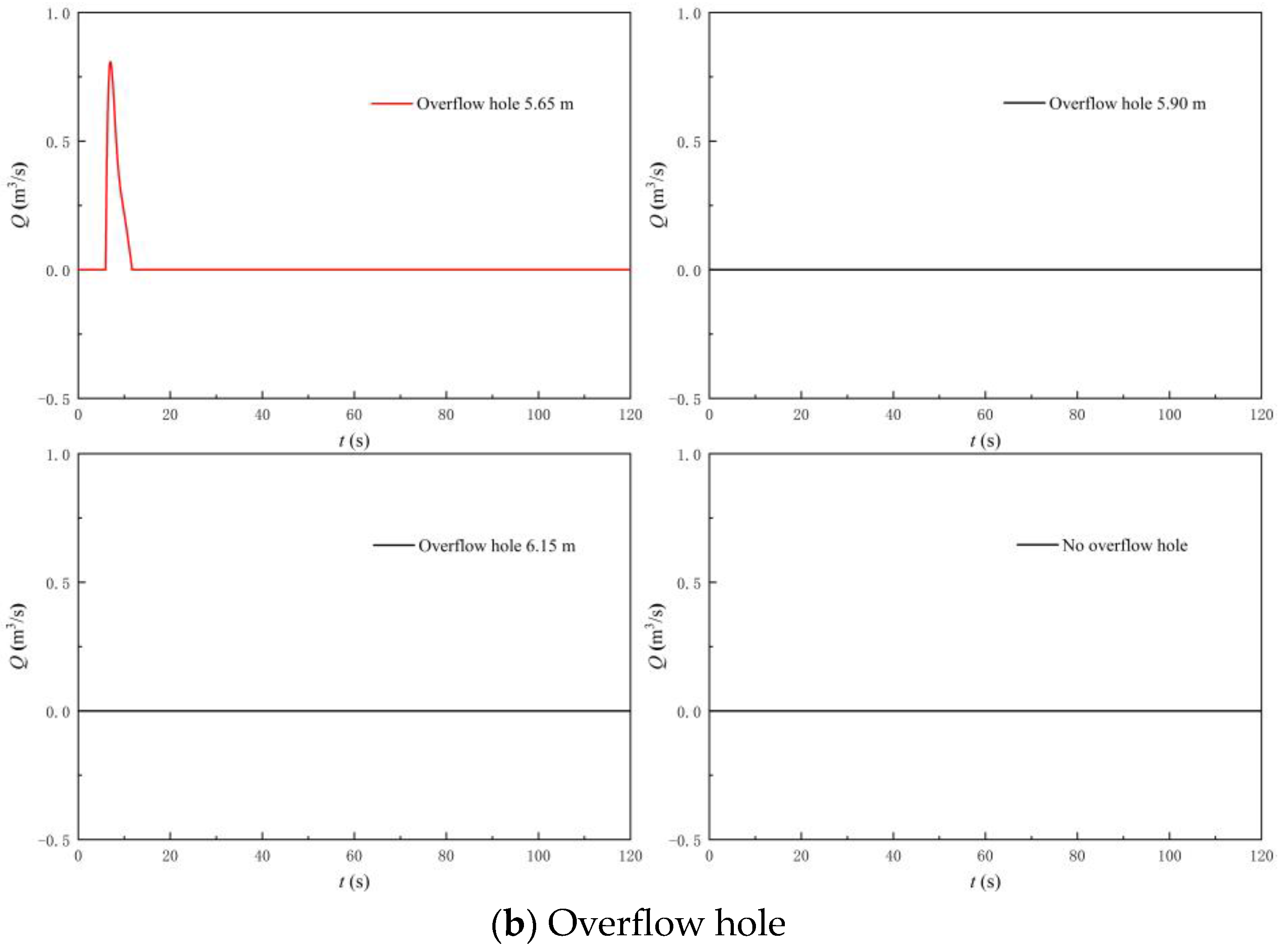

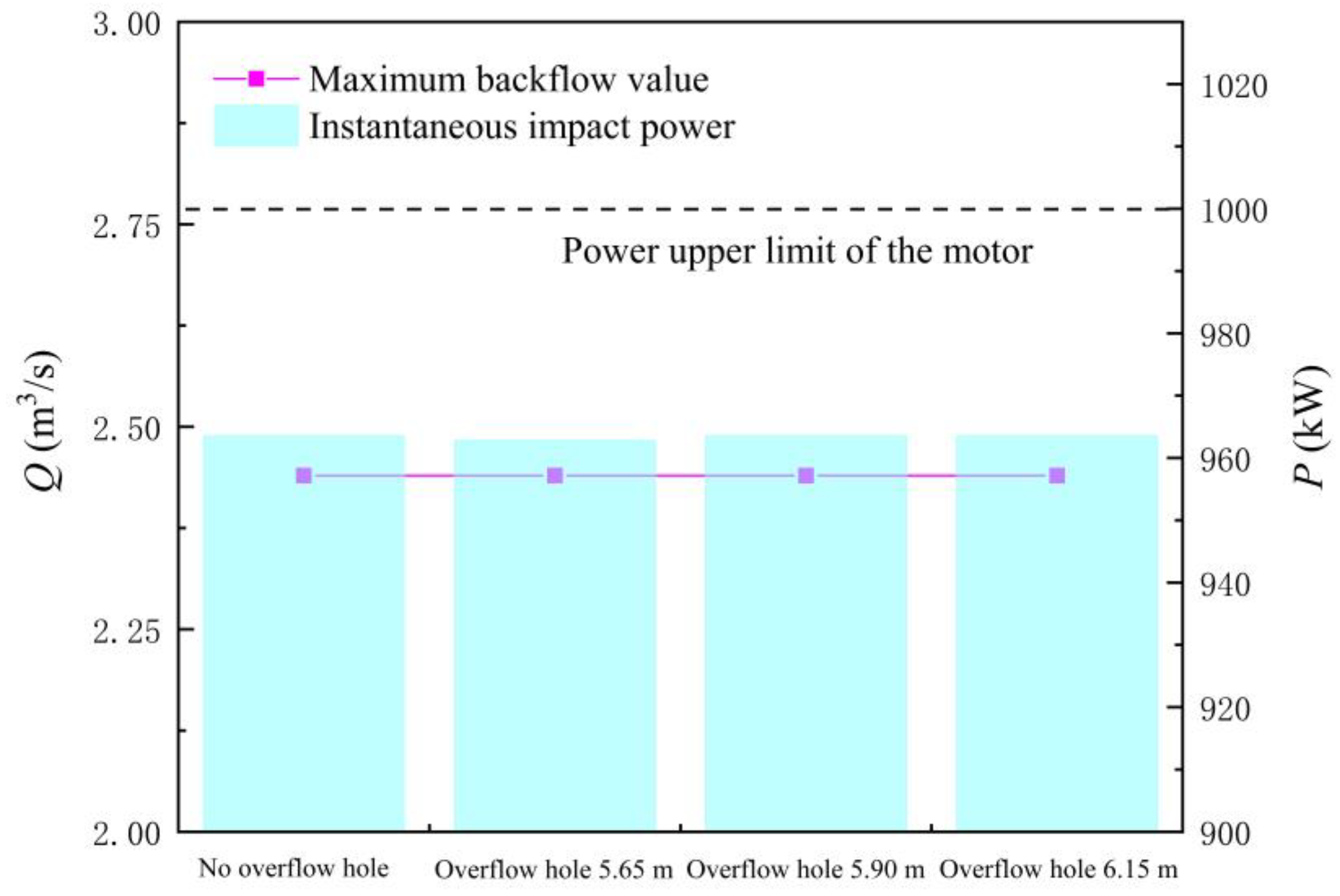

4.4. Influence of Adding the Overflow Hole

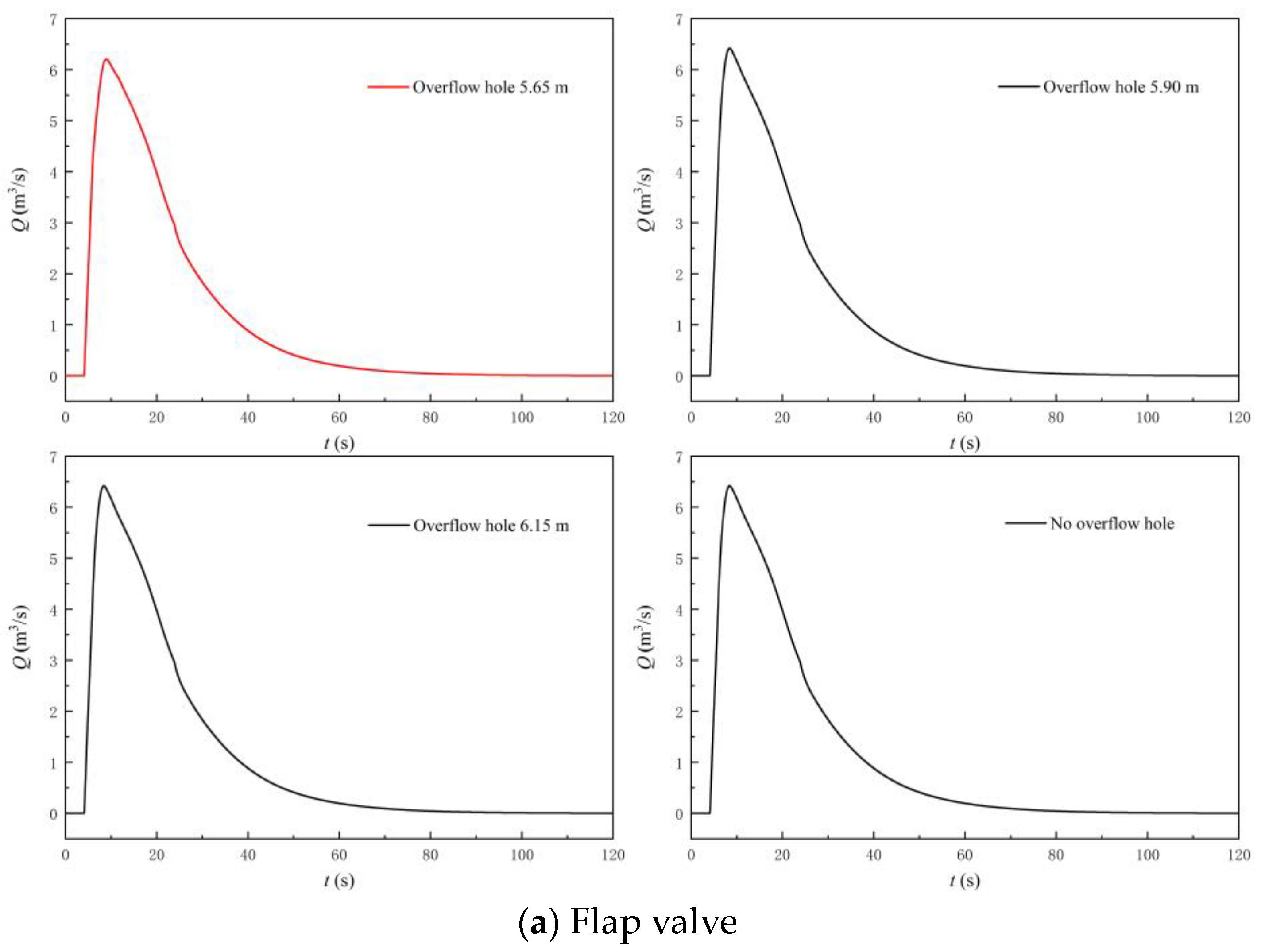

4.5. Influence of Adding Both the Flap Valve and Overflow Hole

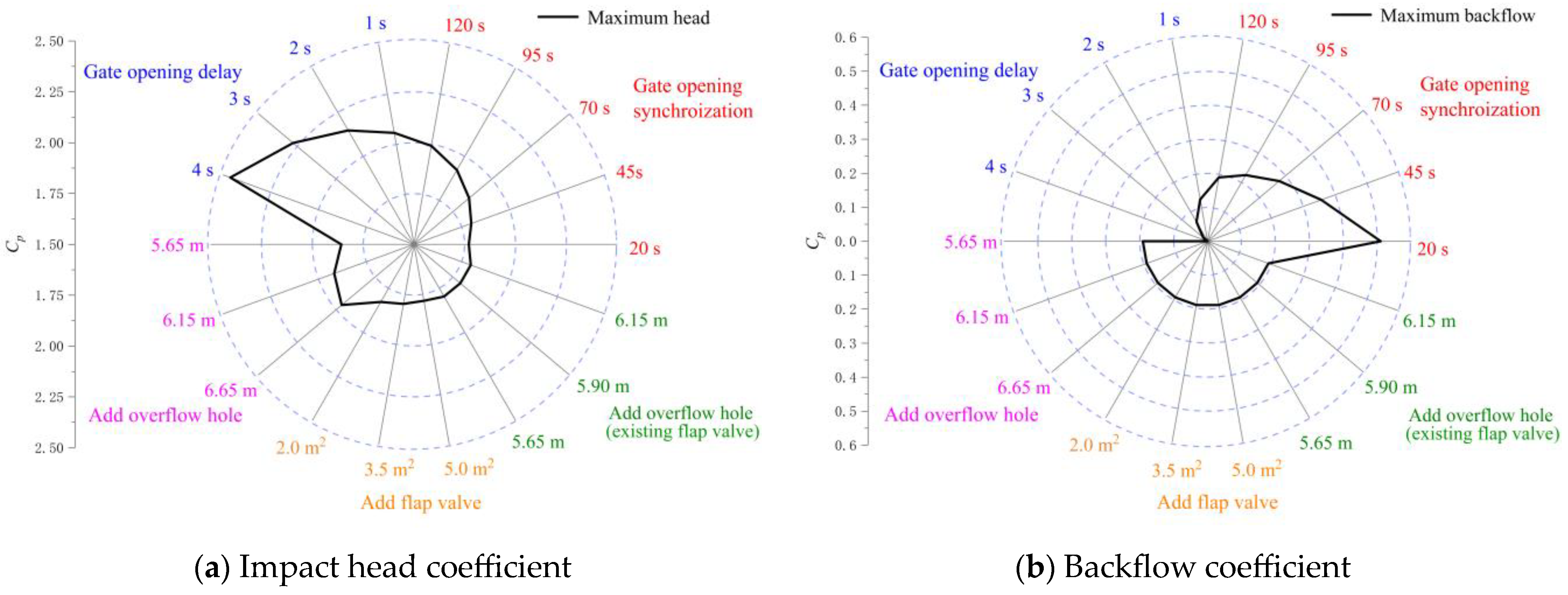

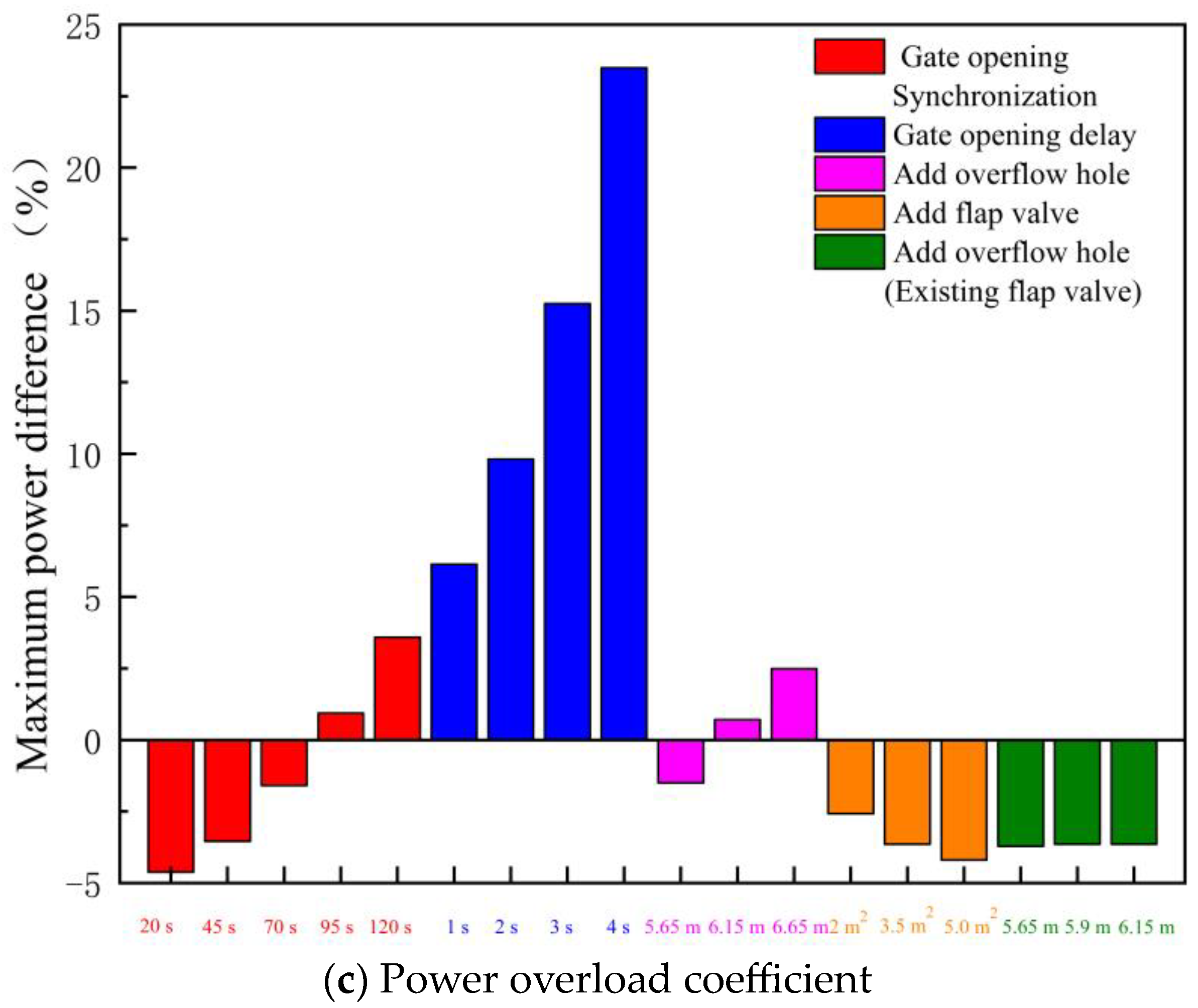

4.6. Comparison of the Influence of Different Safety Auxiliary Measures

5. Conclusions

- (1)

- During the start-up transition process, if only the opening speed of the rapid-drop gate is adjusted without any safety auxiliary facilities, it will be difficult to give consideration to the index of backflow coefficient and the index of impact head coefficient. Once the gate opening speed is too fast, it will cause a sharp increase in backflow, while if the gate opening speed is too slow, it will cause a sharp increase in the instantaneous impact head and the instantaneous impact power.

- (2)

- It is a very dangerous start-up mode to delay the opening of the rapid-drop gate to reduce the maximum backflow value and the duration of backflow at the initial start-up of the pump system. When the opening of the rapid-drop gate lags behind the start of the motor, the instantaneous impact power of the unit will increase rapidly, and the possibility of start-up failure of the pump station will be greatly increased.

- (3)

- The method of adding the flap valve to the rapid-drop gate has no obvious benefit in shortening the backflow state at the initial stage of the pump start-up, but it will significantly weaken the instantaneous impact power of the unit and prevent overload of the unit. When the safety auxiliary facilities of an additional flap valve on the rapid-drop gate are adopted, the backflow coefficient is within 0.2, the impact head coefficient is within 2, and the power overload coefficient is less than 0. Synthesizing the three key characteristic indexes in the start-up process evaluation, the method of adding a flap valve on the rapid-drop gate can obtain a higher quality of the start-up transition process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| g | Local acceleration of gravity (m/s2) |

| H | Head (m) |

| M | The impeller torque (kN·m) |

| n | Rated speed (r/min) |

| H | the maximum net head (m) |

| D | Impeller diameter |

| Ip | The inertia moment of the LAPS (kg·m2) |

| Im | The motor rotation inertia (m3/s) |

| Ar | The area of the rapid-drop gate (m2) |

| t | Time (s) |

| ρ | The density of flow (kg/m3) |

| ω | The angular velocity of the impeller (rad/s) |

| η | Efficiency (%) |

| ηexp | Experimental efficiency (%) |

| ηsim | Simulated efficiency (%) |

| Qb | The maximum backflow |

| Qd | Designed flow |

| Hexp | Experimental head (m) |

| Hsim | Simulated head (m) |

| Hi | Maximum instantaneous impact head |

| Hd | The design head of the pump system |

| KH | The impact head coefficient |

| KQ | The backflow coefficient |

| Kp | The power overload coefficient |

| Pi | The maximum IIP |

| Pu | The upper limit of motor power |

Abbreviations

| CFD | Computational fluid dynamics |

| LAPS | Large axial flow pump station system |

| IIP | Instantaneous impact power |

| TRRO | Time required for gate opening |

| TOOD | Time of gate opening delay |

| AOF | Area of flap valve |

| EOOH | Elevation of overflow hole |

| MBF | Maximum backflow flow |

References

- Ge, X.F.; Zhang, J.; Zhang, J.; Liu, D.; Zheng, Y.; Chen, H.X. Review of Research on the Three-Dimensional Transition Process of Large-Scale Low-Lift Pump. Energies 2022, 15, 8338. [Google Scholar] [CrossRef]

- Xu, H.; Gong, Y.; Cao, C.J.; Chen, H.X.; Kan, K.; Feng, J.G. Research on the three-dimensional transition process of the full discharge system of the axial extension tubular pump station. J. Agric. Mach. 2021, 52, 143–151. [Google Scholar]

- Zhang, X.X.; Cheng, Y.G.; Yang, J.D.; Xia, L.S.; Lai, X. Simulation of the load rejection transient process of a francis turbine by using a 1-D-3-D coupling approach. J. Hydrodyn. 2014, 26, 715–724. [Google Scholar] [CrossRef]

- Thanapandi, P.; Prasad, R. Centrifugal pump transient characteristics and analysis using the method of characteristics. Int. J. Mech. Sci. 1995, 37, 77–89. [Google Scholar] [CrossRef]

- Zhang, J.P. The Study on Characteristics of Starting Transient Process of Shaft Tubular Pumping Station; Yangzhou University: Yangzhou, China, 2015. [Google Scholar]

- Fu, S.F.; Zheng, Y.; Kan, K.; Chen, H.X.; Han, X.X.; Liang, X.L.; Liu, H.W.; Tian, X.Q. Numerical simulation and experimental study of transient characteristics in an axial flow pump during start-up. Renew. Energy 2020, 146, 1879–1887. [Google Scholar] [CrossRef]

- Long, Y.; Lin, B.; Fang, J.; Zhu, R.S.; Fu, Q. Research on the Transient Hydraulic Characteristics of Multistage Centrifugal Pump During Start-Up Process. Front. Energy Res. 2020, 8, 76. [Google Scholar] [CrossRef]

- Li, T.X.; Li, Y.C.; He, Z.S.; Luo, W. Application of the Energy-saving Flap Valve in Pumping Station Rebuild. Fluid Mach 2008, 8, 48–49, 65. [Google Scholar]

- Liang, X.; Zhang, J.K.; Li, Z.H.; Xiao, B.C.; Chen, S. Optimizing protection scheme for accident shutdown of axial flow pumping station under super hump conditions. J. Drain. Irrig. Mach. Eng. 2020, 38, 1010–1015. [Google Scholar]

- Xu, Z.; Zheng, Y.; Kan, K.; Chen, H.X.; Lu, Y.; Dai, J. Accelerated starting transition process of rapid gate in large tubular pumping station. J. Drain. Irrig. Mach. Eng. 2020, 38, 1016–1022. [Google Scholar]

- Li, Q.; Ma, X.; Wu, P.; Yang, S.; Huang, B.; Wu, D.Z. Study on the Transient Characteristics of the Centrifugal Pump during the Startup Period with Assisted Valve. Processes 2020, 8, 1241. [Google Scholar] [CrossRef]

- Lu, W. Studies on the Mechanical Characteristics of Flap Valve Cutoff Device in Pumping Stations; Shanghai University: Shanghai, China, 2009. [Google Scholar]

- Wang, Z.X.; Du, Y.T. Opening Angle and Impact Force Analysis of Different Types Flap Valve in Pumping Stations. IOP Conf. Ser. Earth Environ. Sci. 2019, 371, 022067. [Google Scholar] [CrossRef]

- Tsukamoto, H.; Ohashi, H. Transient Characteristics of a Centrifugal Pump during Starting Period. J. Fluids Eng. 1982, 104, 6–13. [Google Scholar] [CrossRef]

- Li, Z.F.; Wu, P.; Wu, D.Z.; Wang, L.Q. Experimental and numerical study of transient flow in a centrifugal pump during startup. J. Mech. Sci. Technol. 2011, 25, 749–757. [Google Scholar] [CrossRef]

- Zhang, X.W.; Tang, F.P.; Liu, C.; Shi, L.J.; Liu, H.Y.; Sun, Z.Z.; Hu, W.Z. Numerical Simulation of Transient Characteristics of Start-Up Transition Process of Large Vertical Siphon Axial Flow Pump Station. Front. Energy Res. 2021, 9, 706975. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, L.; Chen, J.; Liu, H.L.; Luo, K.K.; Zhang, Z.L.; Cao, M.H. Experimental study on transient startup characteristics of a super low specific speed centrifugal pump. J. Chem. Eng. Jpn. 2019, 52, 743–750. [Google Scholar] [CrossRef]

- Liu, Y.F.; Zhou, D.Q.; Zheng, Y.; Zhang, H.S.; Xu, J.Y. Numerical simulation of starting process of axial flow pump with quick-stop gate. South North Water Transf. Water Sci. Technol. 2017, 15, 167–172. [Google Scholar]

- Ge, Q.E.; Duan, X.H.; Xu, L.L.; Ma, B.; Chen, S.S.; Yan, D.F. Experimental Study of the Transition Course on the Starts of Synchronous Motor in South-North Water Diversion Project. Large Electric Machine and Hydraulic Turbine 2006, 5, 1–5. [Google Scholar]

- Sun, Y.M.; Yu, G.P.; Liu, C. Research on Closing Control of the Sluice Gate for Sudden Power Off of Large Pump. Adv. Sci. Lett. 2011, 4, 2316–2320. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Wang, W.J.; Pei, J.; Yuan, S.Q. Numerical simulation of unsteady flow characteristics in a centrifugal pump during runaway process caused by power failure. J. Phys. Conf. Ser. 2022, 2217, 0212047. [Google Scholar] [CrossRef]

- Kan, K.; Zheng, Y.; Chen, H.X.; Zhou, D.Q.; Dai, J.; Binama, M.; Yu, A. Numerical simulation of transient flow in a shaft extension tubular pump unit during runaway process caused by power failure. Renew. Energy 2020, 154, 1153–1164. [Google Scholar] [CrossRef]

- Kan, K.; Chen, H.X.; Zheng, Y.; Zhou, D.Q.; Binama, M.; Dai, J. Transient Characteristics during Power-Off Process in a Shaft Extension Tubular Pump by Using a Suitable Numerical Model. Renew. Energy 2021, 164, 109–121. [Google Scholar] [CrossRef]

- Zhang, X.W.; Tang, F.P. Investigation on hydrodynamic characteristics of coastal axial flow pump system model under full working condition of forward rotation based on experiment and CFD method. Ocean Eng. 2022, 253, 0029–8018. [Google Scholar] [CrossRef]

- Feng, J.J.; Ge, Z.G.; Zhang, Y.; Zhu, G.; Wu, G.J.; Lu, J.L.; Luo, X.Q. Numerical investigation on characteristics of transient process in centrifugal pumps during power failure. Renew. Energy 2021, 170, 267–276. [Google Scholar] [CrossRef]

- Gou, D.M.; Guo, P.C.; Luo, X.Q.; Zhan, L.G.; Guo, Y.F. 3-D combined simulation of power-off runaway transient process of pumped storage power station under pump condition. Chin. J. Hydrodyn. 2018, 33, 28–39. [Google Scholar]

- Yang, Z.Y.; Liu, Z.R.; Cheng, Y.G.; Zhang, X.X.; Liu, K.; Xia, L.S. Differences of Flow Patterns and Pressure Pulsations in Four Prototype Pump-Turbines during Runaway Transient Processes. Energies 2020, 13, 5269. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Zhang, X.X.; Liu, D.M.; Cheng, Y.G.; Zhao, M.D. CFD simulation of the pump trip runaway transient process of a pumped-storage power plant with head 700 m. IOP Conf. Ser. Earth Environ. Sci. 2021, 774, 012102. [Google Scholar] [CrossRef]

- Song, X.J.; Liu, C. Experimental study of the floor-attached vortices in pump sump using V3V. Renew. Energy 2021, 164, 0960–1481. [Google Scholar]

- Song, X.J.; Luo, Y.Y.; Wang, Z.W. Numerical prediction of the influence of free surface vortex air-entrainment on pump unit performance. Ocean Eng. 2022, 256, 111503. [Google Scholar] [CrossRef]

- Yang, F.; Li, Z.B.; Yuan, Y.; Lin, Z.K.; Zhou, G.X.; Ji, Q.W. Study on vortex flow and pressure fluctuation in dustpan-shaped conduit of a low head axial-flow pump as turbine. Renew. Energy 2022, 196, 856–869. [Google Scholar] [CrossRef]

- Rohani, M.; Afshar, M. Simulation of transient flow caused by pump failure: Point-Implicit Method of Characteristics. Ann. Nucl. Energy 2010, 37, 1742–1750. [Google Scholar] [CrossRef]

- Wang, F.J.; Bai, M.M.; Xiao R., F. Application of Flowmaster in the analysis of pump station transition process. J. Drain. Irrig. Mech. Eng. 2010, 28, 144–148. [Google Scholar]

- Hu, X.Y. Research on Hydraulic Transition Process in Pump Station System Based on Flowmaster; Xihua University: Chengdu, China, 2012. [Google Scholar]

- Geng, T.H. Numerical Simulation of Hydraulic Transient Process of Francis Turbine Generator Unit based on Flowmaster; Xihua University: Chengdu, China, 2020. [Google Scholar]

- Yang, F.; Li, Z.B.; Fu, J.G.; Lv, Y.T.; Ji, Q.W.; Jian, H.F. Numerical and experimental analysis of transient flow field and pressure pulsations of an axial-flow pump considering the pump-pipeline interaction. J. Mar. Sci. Eng. 2022, 10, 258. [Google Scholar] [CrossRef]

- He, Z.; Bao, H.; Gao, C.; Shu, L. Research of runaway transition process in the full flow system of tubular shaft-extension pump. Fluid Mach 2021, 49, 57–64. [Google Scholar]

- Yang, Z.Y.; Cheng, Y.G.; Xia, L.S.; Meng, W.W.; Liu, K.; Zhang, X.X. Evolutions of flow patterns and pressure fluctuations in a prototype pump-turbine during the runaway transient process after pump-trip. Renew. Energy 2020, 152, 1149–1159. [Google Scholar] [CrossRef]

- Wang, L.; Tang, F.P.; Chen, Y.; Liu, H.Y. Evolution Characteristics of Suction-Side-Perpendicular Cavitating Vortex in Axial Flow Pump under Low Flow Condition. J. Mar. Sci. Eng. 2021, 9, 1058. [Google Scholar] [CrossRef]

- Song, X.J.; Liu, C.; Wang, Z.W. Prediction on the pressure pulsation induced by the free surface vortex based on experimental investigation and Biot-Savart Law. Ocean Eng. 2022, 250, 0029–8018. [Google Scholar] [CrossRef]

- Yang, F.; Li, Z.B.; Hu, W.Z.; Liu, C.; Jiang, D.J.; Liu, D.S.; Nasr, A. Analysis of flow loss characteristics of slanted axial-flow pump device based on entropy production theory. R. Soc. Open Sci. 2022, 9, 211208. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.Y.; Cheng, Y.G.; Xia, L.S.; Meng, W.W.; Gao, L.W.; Dai, Y.X. Evolutions of guide vane moment of a pump-turbine during runaway transient process after pump trip. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 072033. [Google Scholar] [CrossRef]

- Liu, J.T.; Li, Z.; Wang, L.; Jiao, L. Numerical Simulation of the Transient Flow in a Radial Flow Pump during Stopping Period. J. Fluids Eng. 2011, 133, 111101. [Google Scholar] [CrossRef]

- Zhang, R.T.; Zhu, H.G.; Li C., X.; Yao, L.B. Shut-down Transient of Bulb Tubular Pumping Station with VFD. Trans. Chin. Soc. Agric. Mach. 2013, 44, 45–49. [Google Scholar]

| Flow Passage Component | Number of Grids | Number of Nodes |

|---|---|---|

| Inlet channel | 1,083,798 | 191,421 |

| Impeller | 1,296,256 | 1,373,248 |

| Guide vane | 1,438,255 | 1,538,250 |

| Outlet elbow | 432,533 | 78,380 |

| Outlet channel | 910,224 | 158,193 |

| Total | 5,161,066 | 3,339,492 |

| Start-Up Control Simulation | Safety Auxiliary Facility Components | Time for Pump to Reach Rated Speed | Time Required for Gate Opening | Relation between Motor Starting and Gate Opening | Scheme Design | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Influence of opening speed of rapid-drop gate (Section 4.1) | Rapid-drop gate | 6 s | Synchronization | Time required for gate opening (TRRO) | ||||||||||

| 20 s | 45 s | 70 s | 95 s | 120 s | ||||||||||

| Influence of delaying opening of rapid-drop gate (Section 4.2) | Rapid-drop gate | 6 s | 120 s | Asynchronization | Time of gate opening delay (TOOD) | |||||||||

| 1 s | 2 s | 3 s | 4 s | |||||||||||

| Influence of adding the flap valve (Section 4.3) | Rapid-drop gate and flap valve | 6 s | 120 s | Synchronization | Area of flap valve (AOF) | |||||||||

| 2.0 m2 | 3.5 m2 | 5.0 m2 | ||||||||||||

| Influence of adding the overflow hole (Section 4.4) | Rapid-drop gate and overflow hole | 6 s | 120 s | Synchronization | Elevation of overflow hole (EOOH) | |||||||||

| 5.65 m | 6.15 m | 6.65 m | ||||||||||||

| Influence of adding both the flap valve and overflow hole (Section 4.5) | Rapid-drop gate, flap valve and overflow hole | 6 s | 120 s | Synchronization | Elevation of overflow hole (AOF =3.5 m2) | |||||||||

| 5.65 m | 5.90 m | 6.15 m | ||||||||||||

| Flap valve opening angle α | 20 | 30 | 40 | 50 | 60 |

| Loss coefficients ζ | 6.3 | 4 | 3.2 | 2.8 | 2.5 |

| Measuring Items | Instrument Name | Instrument Types | Instrument Range | Calibration Accuracy |

|---|---|---|---|---|

| Head | Difference pressure transmitter | EJA 110A | 0~200 kPa | ±0.1% |

| Flow | Electromagnetic flowmeter | E-mag type | DN400 mm | ±0.20% |

| Torque | Speed and torque sensor | ZJ | 200 N·m | ±0.15% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Jiang, Y.; Tang, F.; Song, X.; Liu, Y.; Yang, F.; Shi, L. Investigation on Start-Up Characteristics of Large Axial Flow Pump Systems Considering the Influence of Auxiliary Safety Facilities. Machines 2023, 11, 182. https://doi.org/10.3390/machines11020182

Zhang X, Jiang Y, Tang F, Song X, Liu Y, Yang F, Shi L. Investigation on Start-Up Characteristics of Large Axial Flow Pump Systems Considering the Influence of Auxiliary Safety Facilities. Machines. 2023; 11(2):182. https://doi.org/10.3390/machines11020182

Chicago/Turabian StyleZhang, Xiaowen, Yuhang Jiang, Fangping Tang, Xijie Song, Yuxi Liu, Fan Yang, and Lijian Shi. 2023. "Investigation on Start-Up Characteristics of Large Axial Flow Pump Systems Considering the Influence of Auxiliary Safety Facilities" Machines 11, no. 2: 182. https://doi.org/10.3390/machines11020182

APA StyleZhang, X., Jiang, Y., Tang, F., Song, X., Liu, Y., Yang, F., & Shi, L. (2023). Investigation on Start-Up Characteristics of Large Axial Flow Pump Systems Considering the Influence of Auxiliary Safety Facilities. Machines, 11(2), 182. https://doi.org/10.3390/machines11020182