Analysis of the Causes of Damage to the Stabilisation Actuator of the Cap Piece of the Powered Roof Supports and a Proposal to Reduce the Effects

Abstract

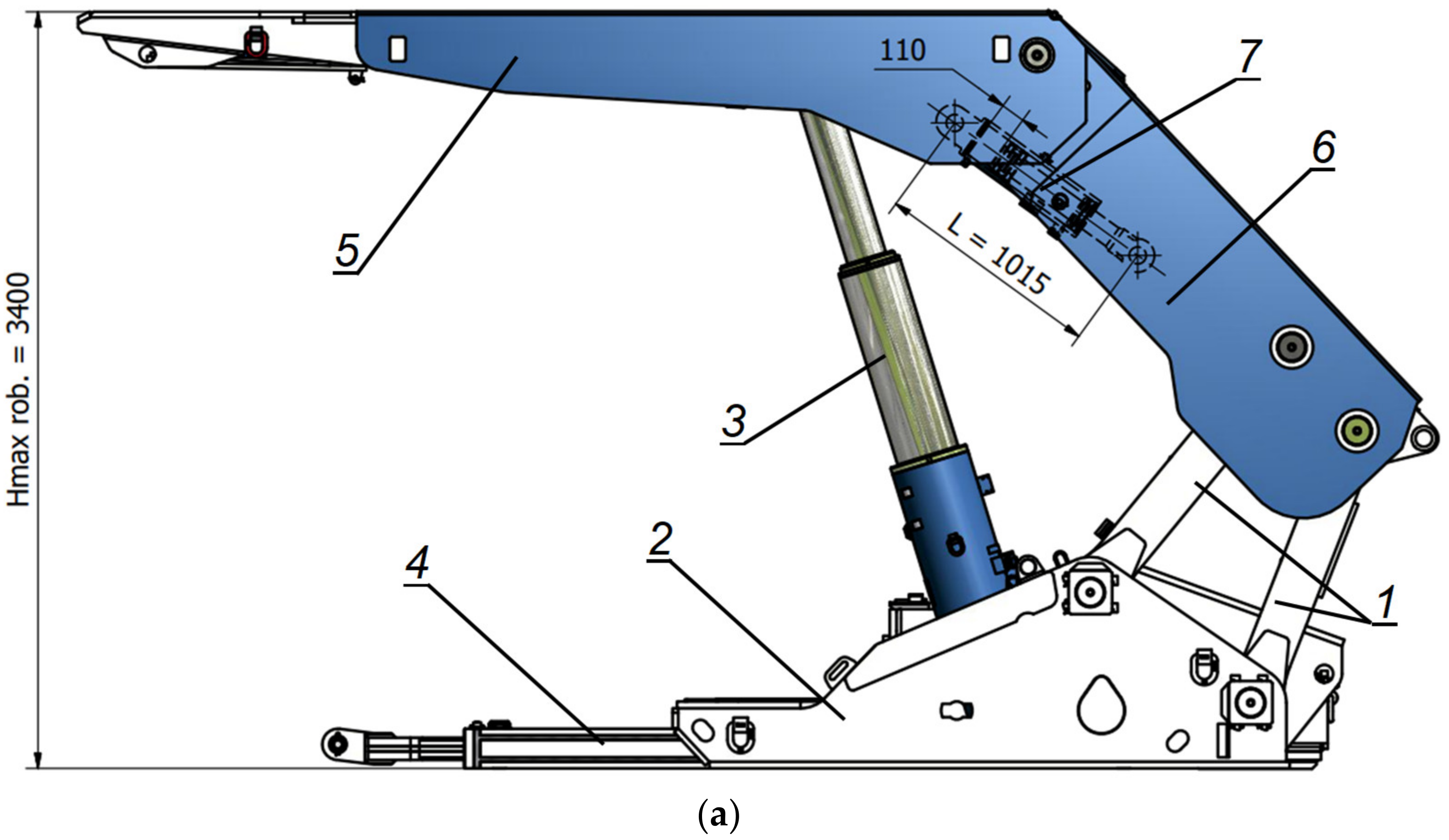

:1. Introduction

2. Materials and Methods

- where

- PN—over-piston operation of the cap piece’s support;

- PT—sub-piston operation of the cap piece’s support.

- where

- Prp—sub-piston working pressure, MPa;

- Sp = D2—sub-piston working surface, m2;

- Prn—over-piston working pressure, MPa;

- Sn = (D2–d2)—over-piston working surface, m2;

- D—cylinder’s diameter, m;

- d—piston rod’s diameter, m.

3. Results

- PW = PR = PN (1)

- where

- PW—initial suport,

- PR—operating support,

- PN—nominal support capacity.

4. Discussion

5. Conclusions

- (1)

- Under conditions in which a high adverse impact of the rock mass can be predicted, four props are used on the powered roof support with or without a shield.

- (2)

- The prop structure and the hydraulic support actuator should be adapted to carry an increased load.

- (3)

- Safety relief valves should be used as additional protection for the hydraulic prop and the cap piece’s support actuator.

- (4)

- The cap piece’s support actuator should have a safety relief valve protecting at least the over-piston space.

- (5)

- The capacity of the safety relief valve should be adjusted to the working surface of the cap piece’s support actuator.

- (6)

- Tests should be carried out with respect to the hydraulic power elements of powered roof supports in stations under static and dynamic load.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khayrutdinov, M.M.; Golik, V.I.; Aleksakhin, A.V.; Trushina, E.V.; Lazareva, N.V.; Aleksakhina, Y.V. Proposal of an Algorithm for Choice of a Development System for Operational and Environmental Safety in Mining. Resources 2022, 11, 88. [Google Scholar] [CrossRef]

- Gabov, V.V.; Zadkov, D.A.; Babyr, N.V.; Xie, F. Nonimpact rock pressure regulation with energy recovery into the hydraulic system of the longwall powered support. Eurasian Min. 2021, 36, 55–59. [Google Scholar] [CrossRef]

- Babyr, N.; Babyr, K. To improve the contact adaptability of mechanical roof support. E3S Web Conf. 2021, 266, 03015. [Google Scholar] [CrossRef]

- Babyr, N.V.; Korolev, A.I.; Neupokoeva, T.V. Enhancement of powered cleaning equipment with the view of mining and geological conditions. IOP Conf. Ser. Earth Environ. Sci. 2018, 194, 032004. [Google Scholar] [CrossRef]

- Buevich, V.V.; Gabov, V.V.; Zadkov, D.A.; Vasileva, P.A. Adaptation of the mechanized roof support to changeable rock pressure. Eurasian Min. 2015, 2, 11–14. [Google Scholar] [CrossRef]

- Gabov, V.V.; Zadkov, D.A.; Stebnev, A.V. Evaluation of structure and variables within performance rating of hydraulically powered roof sup-port legs with smooth roof control. Eurasian Min. 2016, 2, 37–40. [Google Scholar]

- Bortnowski, P.; Gładysiewicz, L.; Król, R.; Ozdoba, M. Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems. Energies 2021, 14, 1786. [Google Scholar] [CrossRef]

- Bardzinski, P.; Jurdziak, L.; Kawalec, W.; Król, R. Copper ore quality tracking in a belt conveyor system using simulation tools. Nat. Resour. Res. 2020, 29, 1031–1040. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, A.K.; Mishra, A.K.; Singh, R. Underground mining of thick coal seams. Int. J. Min. Sci. Technol. 2015, 25, 885–896. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Modified Rock Bolt Support for Mining Method with Controlled Roof Bending. Energies 2020, 13, 1868. [Google Scholar] [CrossRef]

- Prostański, D. Empirical Models of Zones Protecting Against Coal Dust Explosion. Arch. Min. Sci. 2017, 62, 611–619. [Google Scholar] [CrossRef] [Green Version]

- Adach-Pawelus, K.; Pawelus, D. Influence of Driving Direction on the Stability of a Group of Headings Located in a Field of High Horizontal Stresses in the Polish Underground Copper Mines. Energies 2021, 14, 5955. [Google Scholar] [CrossRef]

- Qiao, S.; Zhang, Z.; Zhu, Z.; Zhang, K. Influence of cutting angle on mechanical properties of rock cutting by conical pick based on finite element analysis. J. Min. Sci. 2021, 28, 161–173. [Google Scholar] [CrossRef]

- Ji, Y.; Ren, T.; Wynne, P.; Wan, Z.; Zhaoyang, M.; Wang, Z. A comparative study of dust control practices in Chinese and Australian longwall coal mines. Int. J. Min. Sci. Technol. 2016, 25, 687–706. [Google Scholar] [CrossRef]

- Kotwica, K.; Stopka, G.; Kalita, M.; Bałaga, D.; Siegmund, M. Impact of Geometry of Toothed Segments of the Innovative KOMTRACK Longwall Shearer Haulage System on Load and Slip during the Travel of a Track Wheel. Energies 2021, 14, 2720. [Google Scholar] [CrossRef]

- Ralston, J.C.; Reid, D.C.; Dunn, M.T.; Hainsworth, D.W. Longwall automation: Delivering enabling technology to achieve safer and more productive underground mining. Int. J. Min. Sci. Technol. 2015, 25, 865–876. [Google Scholar] [CrossRef]

- Bajda, M.; Błażej, R.; Hardygóra, M. Optimizing splice geometry in multiply conveyor belts with respect to stress in adhesive bonds. Min. Sci. 2018, 25, 195–206. [Google Scholar]

- Wajs, J.; Trybała, P.; Górniak-Zimroz, J.; Krupa-Kurzynowska, J.; Kasza, D. Modern Solution for Fast and Accurate Inventorization of Open-Pit Mines by the Active Remote Sensing Technique—Case Study of Mikoszów Granite Mine (Lower Silesia, SW Poland). Energies 2021, 14, 6853. [Google Scholar] [CrossRef]

- Ziętek, B.; Banasiewicz, A.; Zimroz, R.; Szrek, J.; Gola, S. A Portable Environmental Data-Monitoring System for Air Hazard Evaluation in Deep Underground Mines. Energies 2020, 13, 6331. [Google Scholar] [CrossRef]

- Peng, S.S.; Feng, D.; Cheng, J.; Yang, L. Automation in U.S. longwall coal mining: A state-of-the-art review. Int. J. Min. Sci. Technol. 2019, 29, 151–159. [Google Scholar] [CrossRef]

- Hamříková, R.; Dlouhá, D. Video tutorials for students of the master’s program. In Open Education as a Way to a Knowledge Society; DisCo, Centre for Higher Education Studies: Praha, Czech Republic, 2017; pp. 446–451. [Google Scholar]

- Jixiong, Z.; Spearing, A.J.S.; Xiexing, M.; Shuai, G.; Qiang, S. Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int. J. Min. Sci. Technol. 2017, 27, 17–27. [Google Scholar]

- Juganda, A.; Strebinger, C.; Brune, J.F.; Bogin, G.E. Discrete modeling of a longwall coal mine gob for CFD simulation. Int. J. Min. Sci. Technol. 2020, 30, 463–469. [Google Scholar] [CrossRef]

- Toraño, J.; Diego, I.; Menéndez, M.; Gent, M. A finite element method (FEM)—Fuzzy logic (Soft Computing)—Virtual reality model approach in a coalface longwall mining simulation. Autom. Constr. 2008, 17, 413–424. [Google Scholar] [CrossRef]

- Huaiwei, R.; Desheng, Z.; Shixin, G.; Kai, Z.; Chenyang, X.; Ming, H.; Tijian, L. Dynamic impact experiment and response characteristics analysis for 1:2 reduced-scale model of hydraulic support. Int. J. Min. Sci. Technol. 2021, 3, 347–356. [Google Scholar]

- Hu, S.; Ma, L.; Guo, J.; Yang, P. Support-surrounding rock relationship and top-coal movement laws in large dip angle fully-mechanized caving face. Int. J. Min. Sci. Technol. 2018, 28, 533–539. [Google Scholar]

- Dlouhá, D.; Kozlová, K. Knowledge assessment of student’s high school mathematics. In Proceedings of the 18th Conference on Applied Mathematics, Bratislava, Slovakia, 5–7 February 2019; Volume 1, pp. 243–252. [Google Scholar]

- Dubovský, V.; Dlouhá, D.; Pospíšil, L. The calibration of evaporation models against the Penman-Monteith equation on lake Most. Sustainability 2021, 13, 313. [Google Scholar] [CrossRef]

- Bazaluk, O.; Velychkovych, A.; Ropyak, L.; Pashechko, M.; Pryhorovska, T.; Lozynskyi, V. Influence of Heavy Weight Drill Pipe Material and Drill Bit Manufacturing Errors on Stress State of Steel Blades. Energies 2021, 14, 4198. [Google Scholar] [CrossRef]

- Dlouhá, D.; Pokorný, J.; Dlouhá, K. Necessity of knowledge about math in safety engineering. In E-Learning: Unlocking the Gate to Education around the Globe; DisCo, Center for Higher Education Studies: Praha, Czech Republic, 2019; pp. 380–386. [Google Scholar]

- Dlouhá, D.; Dubovský, V.; Pospíšil, L. Optimal calibration of evaporation models against Penman-Monteith equatíon. Water 2021, 13, 1484. [Google Scholar] [CrossRef]

- Doroszuk, B.; Król, R. Analysis of conveyor belt wear caused by material acceleration in transfer station. Min. Sci. 2019, 26, 189–201. [Google Scholar] [CrossRef]

- Buyalich, G.; Byakov, M.; Buyalich, K.; Shtenin, E. Development of Powered Support Hydraulic Legs with Improved Performance. E3S Web Conf. 2019, 105, 3025. [Google Scholar] [CrossRef]

- Uth, F.; Polnik, B.; Kurpiel, W.; Baltes, R.; Kriegsch, P.; Clause, E. An innovate person detection system based on thermal imaging cameras dedicate for underground belt conveyors. Min. Sci. 2019, 26, 263–276. [Google Scholar]

- Dlouhá, D.; Hamříková, R. Our experience with the involvement of students in the creation of study materials. In Proceedings of the 17th Conference on Applied Mathematics, Bratislava, Slovakia, 6–8 February 2018; Volume 1, pp. 301–308. [Google Scholar]

- Zimroz, P.; Trybała, P.; Wróblewski, A.; Góralczyk, M.; Szrek, J.; Wójcik, A.; Zimroz, R. Application of UAV in Search and Rescue Actions in Underground Mine—A Specific Sound Detection in Noisy Acoustic Signal. Energies 2021, 14, 3725. [Google Scholar] [CrossRef]

- Dlouhá, D.; Hamříková, R. Interactive distance materials of mathematics for VŠB-TU Ostrava. In Overcoming the Challenges and the Barriers in Open Education; DisCo, Centre for Higher Education Studies: Praha, Czech Republic, 2018; pp. 67–72. [Google Scholar]

- Pokorny, J.; Dlouhá, D.; Kucera, P. Study of the necessity of use virtual origin in assessment of selected fire plume characteristics. MM Sci. J. 2016, 5, 1424–1428. [Google Scholar] [CrossRef]

- Pokorny, J.; Mozer, V.; Malerova, L.; Dlouhá, D.; Wilkinson, P. A simplified method for establishing safe available evacuation time based on a descending smoke layer. Commun. Sci. Lett. Univ. Zilina 2018, 20, 28–34. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z. Systematic principles of surrounding rock control in longwall mining within thick coal seams. Int. J. Min. Sci. Technol. 2019, 29, 591–598. [Google Scholar] [CrossRef]

- Stoiński, K. Mining Roof Support in Hazardous Conditions of Mining Tremors. Collective Work for Editing Kazimierza Stoińskiego; The Central Mining Institute: Katowice, Poland, 2018. [Google Scholar]

- Dlouhá, D.; Dubovský, V. The improvement of the lake Most evaporation estimates. Inżynieria Miner. 2019, 21, 159–164. [Google Scholar]

- Świątek, J.; Janoszek, T.; Cichy, T.; Stoiński, K. Computational Fluid Dynamics Simulations for Investigation of the Damage Causes in Safety Elements of Powered Roof Supports—A Case Study. Energies 2021, 14, 1027. [Google Scholar] [CrossRef]

- Rajwa, S.; Janoszek, T.; Prusek, S. Influence of canopy ratio of powered roof support on longwall working stability—A case study. Int. J. Min. Sci. Technol. 2019, 29, 591–598. [Google Scholar] [CrossRef]

- Buyalich, G.; Buyalich, K.; Byakov, M. Factors Determining the Size of Sealing Clearance in Hydraulic Legs of Powered Supports. E3S Web Conf. 2017, 21, 3018. [Google Scholar] [CrossRef]

- Huang, P.; Spearing, S.; Ju, F.; Jessu, K.V.; Wang, Z.; Ning, P. Control Effects of Five Common Solid Waste Backfilling Materials on In Situ Strata of Gob. Energies 2019, 12, 154. [Google Scholar] [CrossRef]

- Buyalich, G.; Byakov, M.; Buyalich, K. Factors Determining Operation of Lip Seal in the Sealed Gap of the Hydraulic Props of Powered Supports. E3S Web Conf. 2017, 41, 1045. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Zhu, W.; Li, Y. Roof pre-blasting to prevent support crushing and water inrush accidents. Int. J. Min. Sci. Technol. 2012, 22, 379–384. [Google Scholar]

- Juárez-Ferreras, R.; González-Nicieza, C.; Menéndez-Díaz, A.; Álvarez-Vigil, A.E.; Álvarez-Fernández, M.I. Measurement and analysis of the roof pressure on hydraulic props in longwall. Int. J. Coal Geol. 2008, 75, 49–62. [Google Scholar] [CrossRef]

- Klishin, V.I.; Klishin, S.V. Coal Extraction from Thick Flat and Steep Beds. J. Min. Sci. 2010, 46, 149–159. [Google Scholar] [CrossRef]

- Ralston, J.C.; Hargrave, C.O.; Dunn, M.T. Longwall automation: Trends, challenges and opportunities. Int. J. Min. Sci. Technol. 2017, 27, 733–739. [Google Scholar] [CrossRef]

- Stoiński, K.; Mika, M. Dynamics of Hydraulic Leg of Powered Longwall Support. J. Min. Sci. 2003, 39, 72–77. [Google Scholar] [CrossRef]

- Frith, R.C. A holistic examination of the load rating design of longwall shields after more than half a century of mechanised longwall mining. Int. J. Min. Sci. Technol. 2015, 26, 199–208. [Google Scholar] [CrossRef]

- Zhao, X.; Li, F.; Li, Y.; Fan, Y. Fatigue Behavior of a Box-Type Welded Structure of Hydraulic Support Used in Coal Mine. Materials 2015, 8, 6609–6622. [Google Scholar] [CrossRef] [Green Version]

| Technical Specifications | |

|---|---|

| Diameter of the cylinder | 160 mm |

| Internal diameter | 80 mm |

| Minimum length | 840 mm |

| Maximum length | 1300 mm |

| Jump | 460 mm |

| Supply pressure | 250–320 MPa r |

| Operating pressure | 380 MPa |

| Push force at supply pressure | 502–643 kN |

| Push force at operating pressure | 764 kN |

| Pulling force at supply pressure | 377–482 kN |

| Pulling force at operating pressure | 573 kN |

| Sn (m2) | Sp (m2) | Prp (MPa) | Prn (MPa) | PN (N) | PT (N) |

|---|---|---|---|---|---|

| 0.5 | 0.2 | 45 | 31 | 90 | 155 |

| 0.5 | 0.2 | 40 | 30 | 80 | 150 |

| 0.5 | 0.2 | 38 | 29 | 76 | 145 |

| 0.5 | 0.2 | 36 | 28 | 72 | 140 |

| 0.5 | 0.2 | 35 | 27 | 70 | 135 |

| 0.5 | 0.2 | 34 | 26 | 68 | 130 |

| 0.5 | 0.2 | 32 | 25 | 64 | 125 |

| 0.5 | 0.2 | 31 | 24 | 62 | 120 |

| 0.5 | 0.2 | 30 | 23 | 60 | 115 |

| 0.5 | 0.2 | 29 | 22 | 58 | 110 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szurgacz, D. Analysis of the Causes of Damage to the Stabilisation Actuator of the Cap Piece of the Powered Roof Supports and a Proposal to Reduce the Effects. Machines 2023, 11, 194. https://doi.org/10.3390/machines11020194

Szurgacz D. Analysis of the Causes of Damage to the Stabilisation Actuator of the Cap Piece of the Powered Roof Supports and a Proposal to Reduce the Effects. Machines. 2023; 11(2):194. https://doi.org/10.3390/machines11020194

Chicago/Turabian StyleSzurgacz, Dawid. 2023. "Analysis of the Causes of Damage to the Stabilisation Actuator of the Cap Piece of the Powered Roof Supports and a Proposal to Reduce the Effects" Machines 11, no. 2: 194. https://doi.org/10.3390/machines11020194

APA StyleSzurgacz, D. (2023). Analysis of the Causes of Damage to the Stabilisation Actuator of the Cap Piece of the Powered Roof Supports and a Proposal to Reduce the Effects. Machines, 11(2), 194. https://doi.org/10.3390/machines11020194