A Novel Sleeve Design to Reduce the Eddy Current Loss of High-Speed Electrical Machines

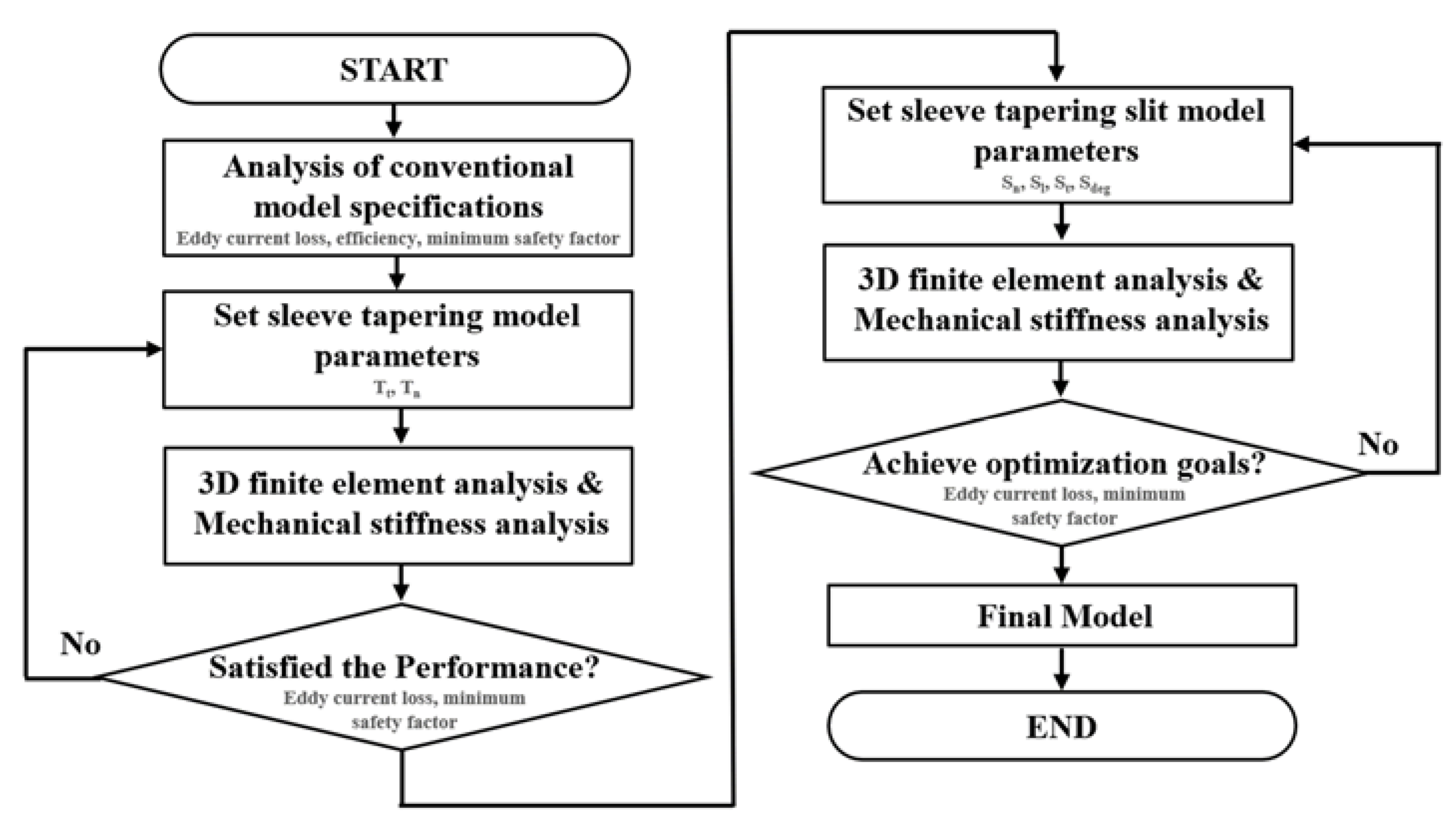

Abstract

1. Introduction

2. Conventional Model Specifications

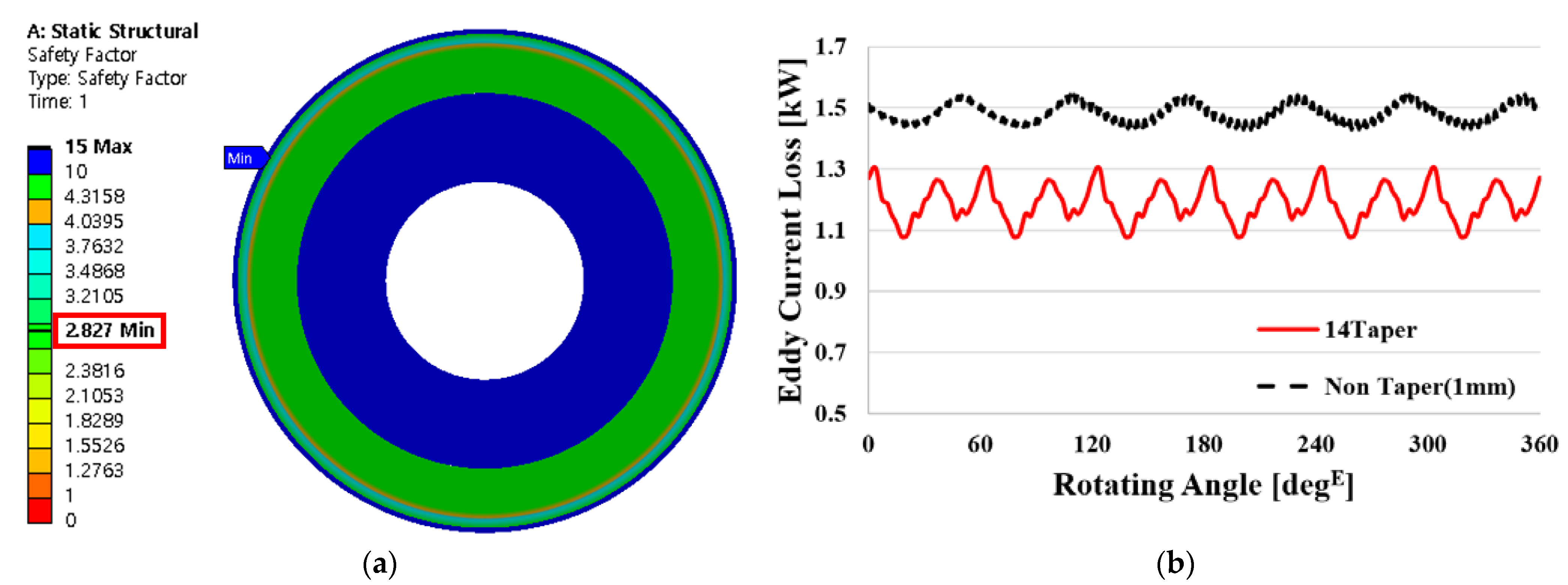

3. Theoretical Analysis

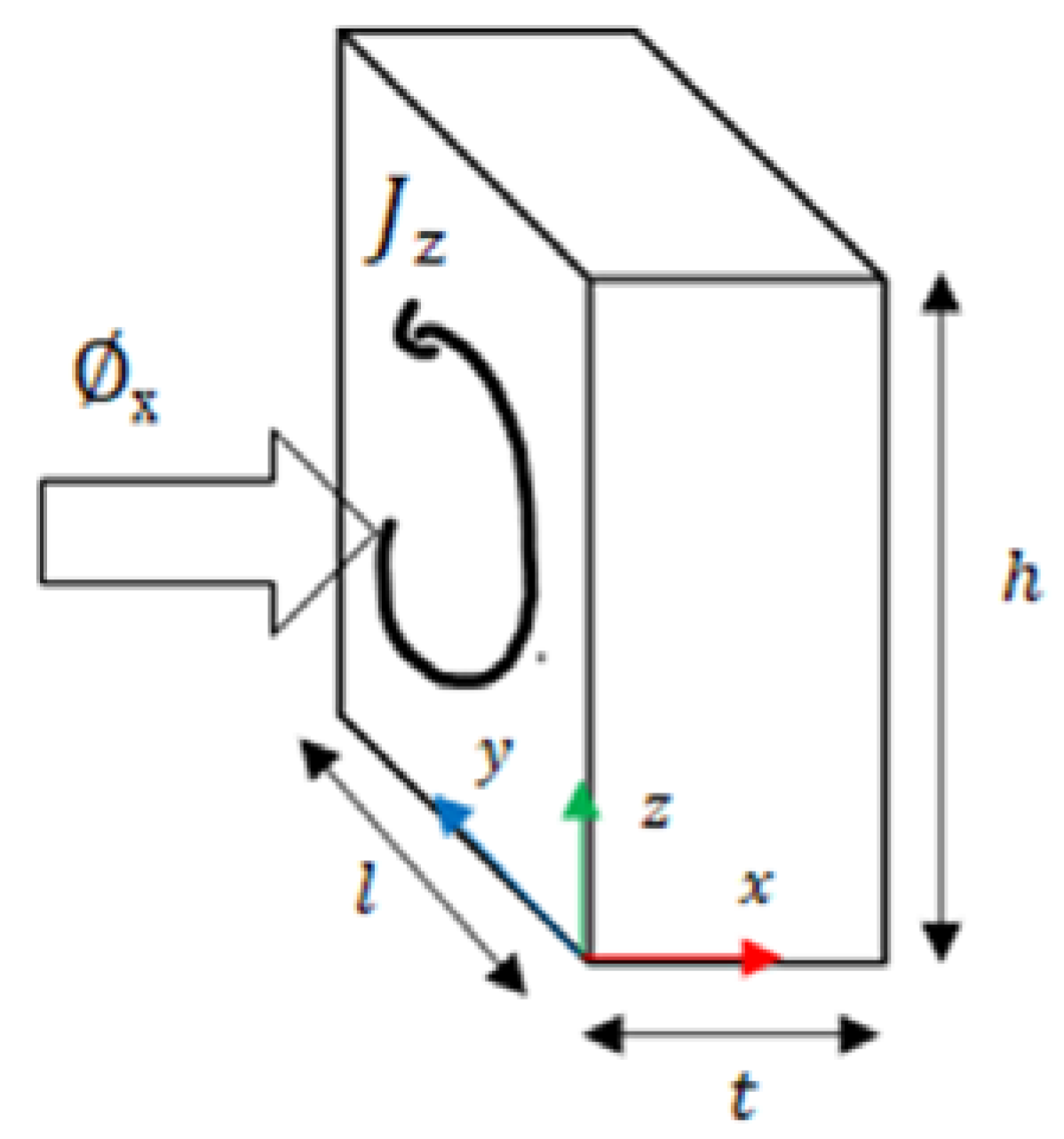

3.1. Eddy Current Loss

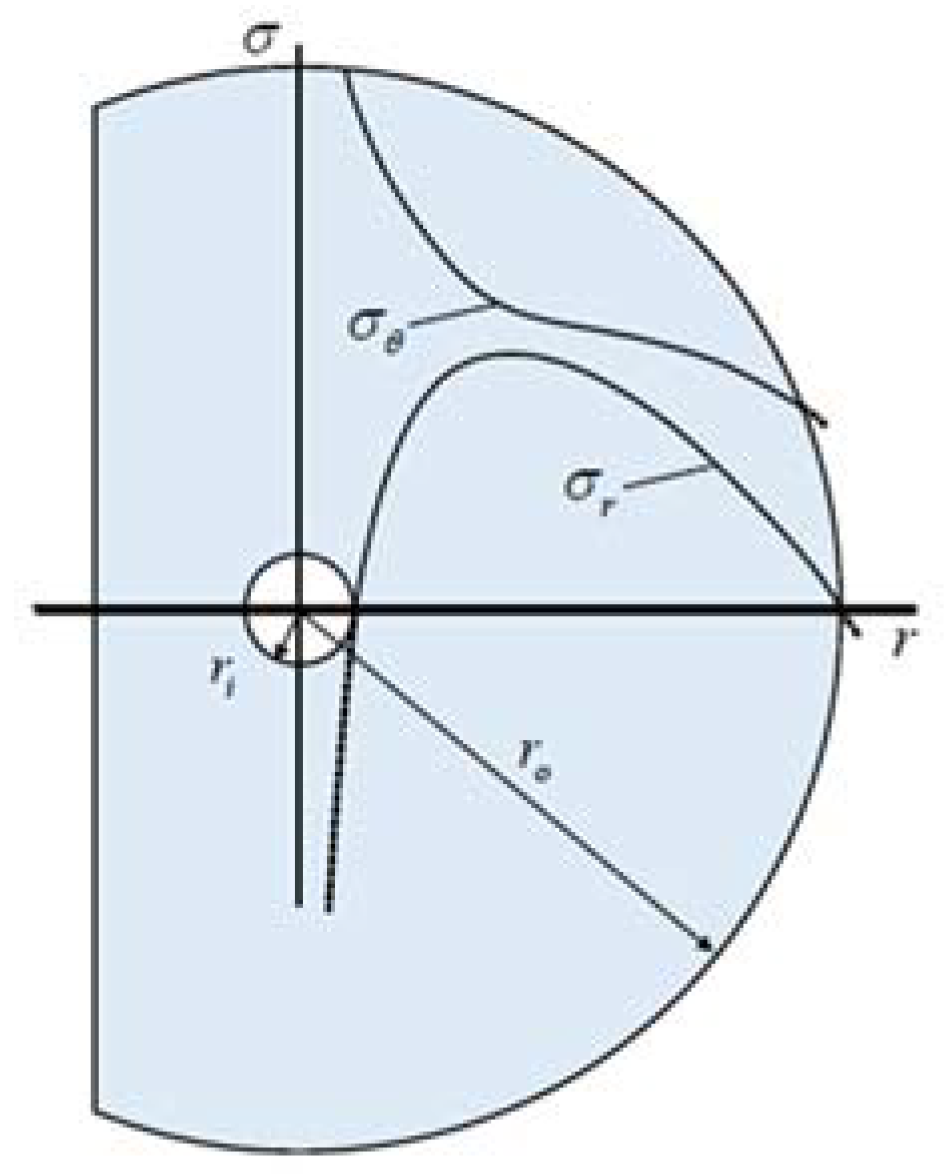

3.2. Rotor Stress and Minimum Safety Factor

- : conditions and stresses can be accurately calculated, the reliability of the material quality is high, and the volume of the structure is to be reduced.

- : for well-known materials that do not change load conditions and driving environments, stress can be easily calculated, and are generally applied in industry.

- : environment, load, and stress calculations are common, and for materials that are common or not commonly used.

- : when the operating environment fluctuates greatly, stress calculation is uncertain, or well-known materials are used.

- In this paper, the minimum safety factor for the maximum stress generated by the pressing and rotating effects on the permanent magnet and sleeve of the rotor is limited to 2 to 4.

4. Sleeve Tapering Model

4.1. Proposal Sleeve Tapering Model

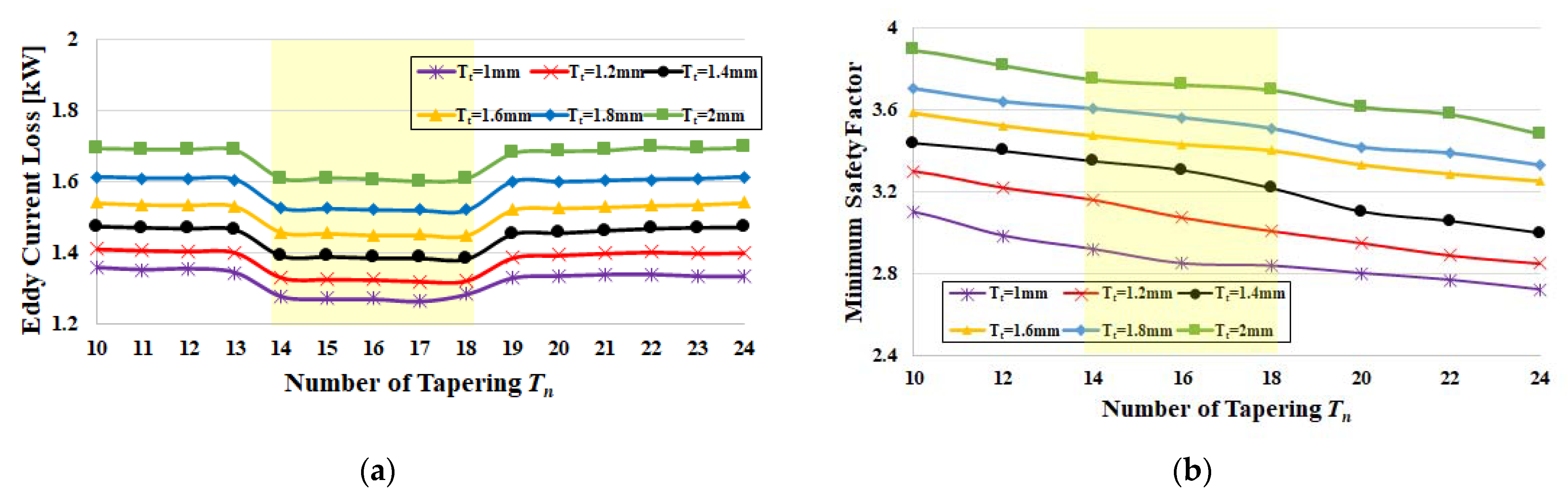

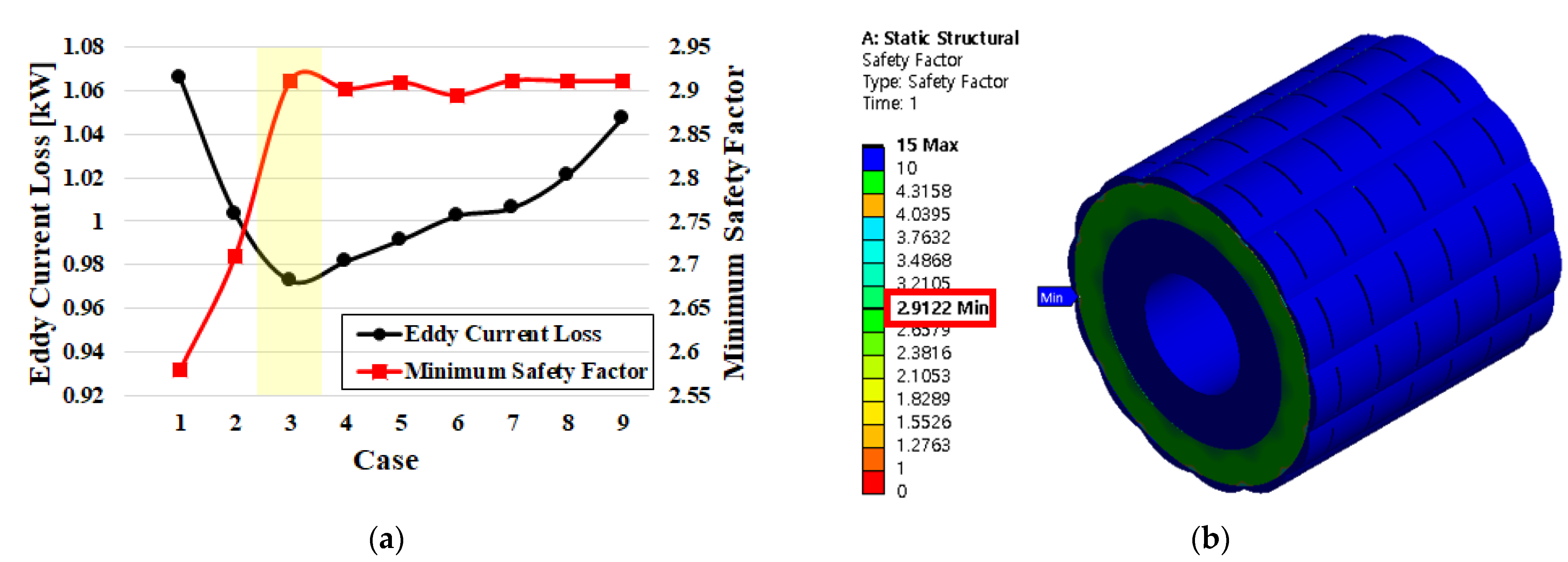

4.2. Selecting the Optimal Sleeve Tapering Model

5. Sleeve Tapering Slit Model

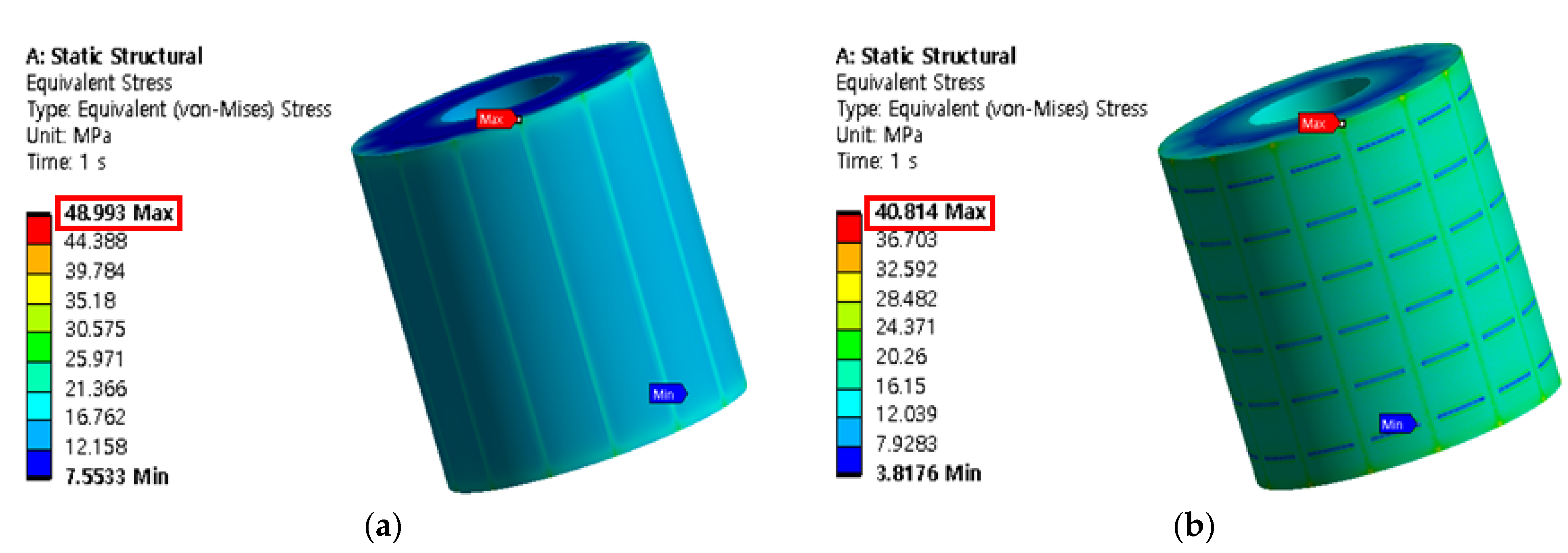

5.1. Proposal Sleeve Tapering Slit Model

5.2. Selecting the Optimal Sleeve Tapering Slit Model

5.2.1. Selection of Slit Length (), Number of Slit (

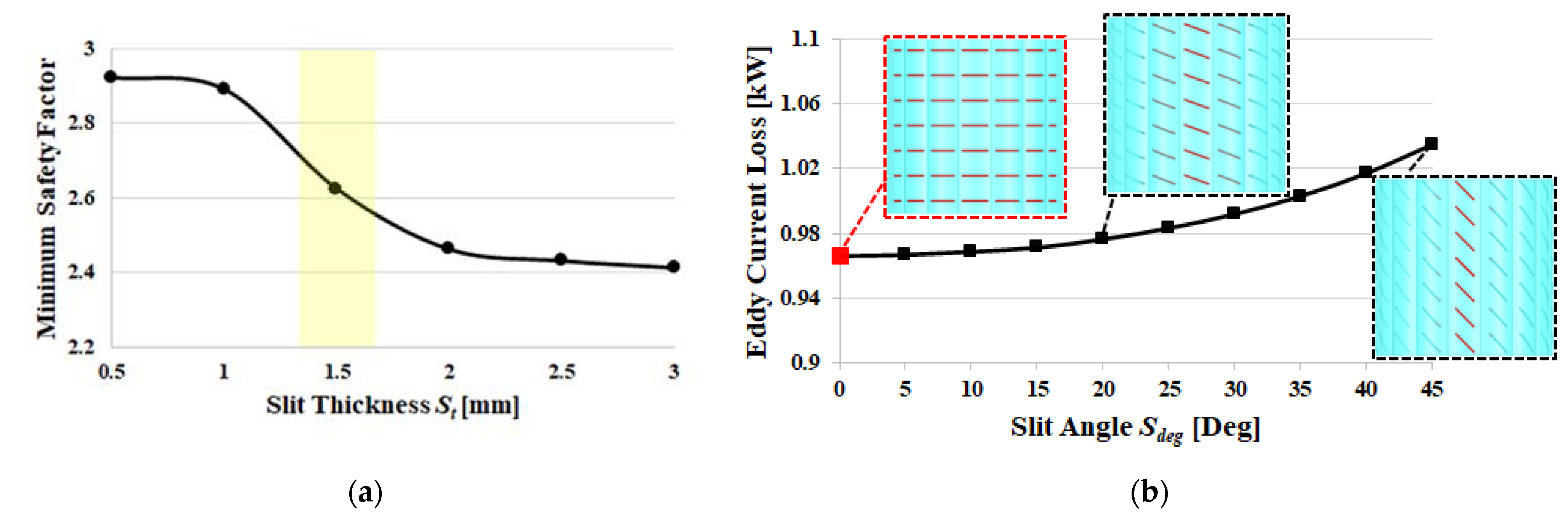

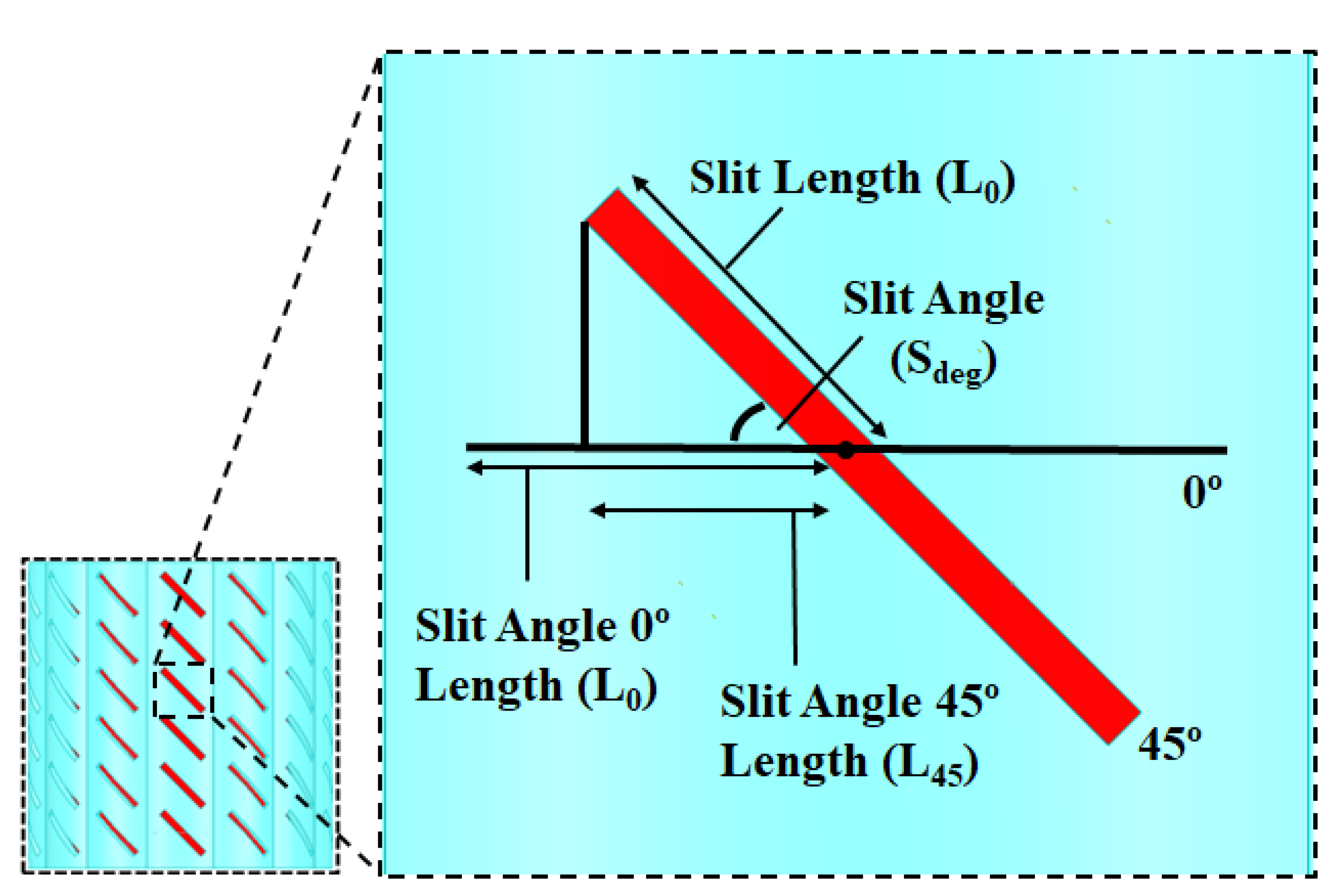

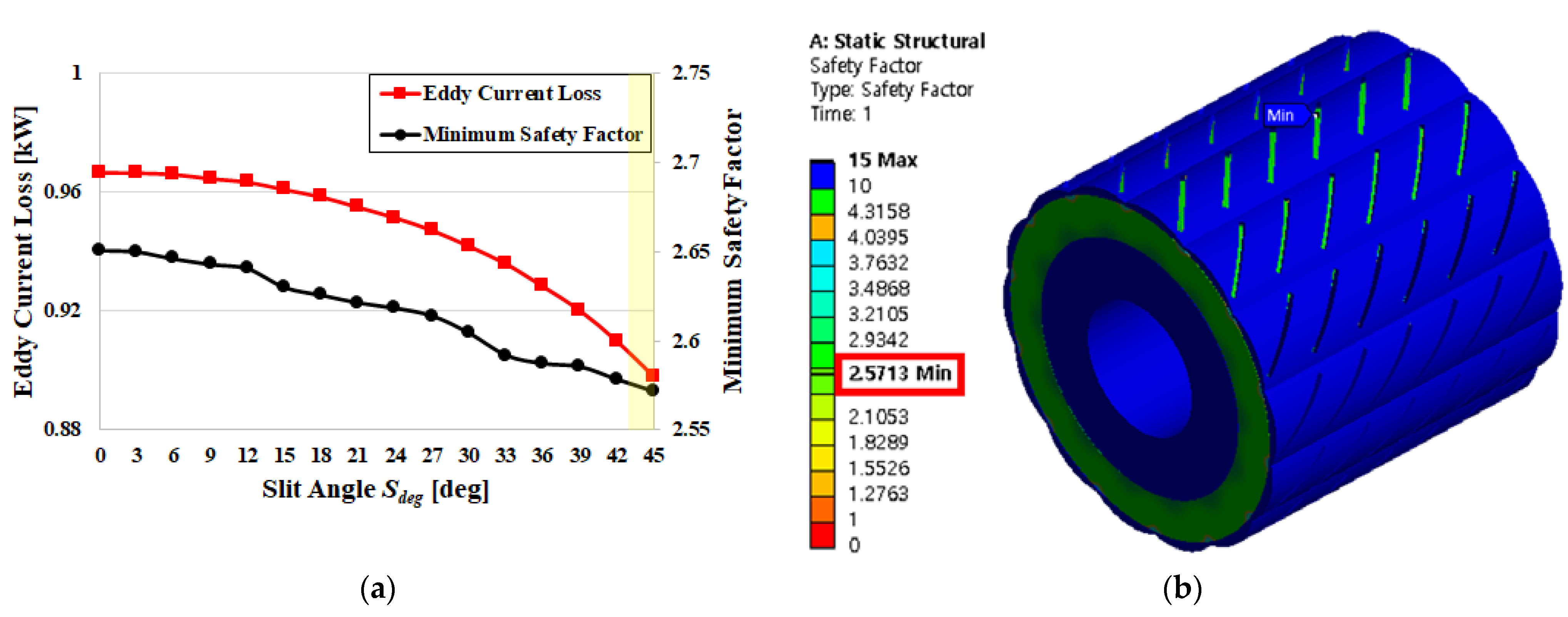

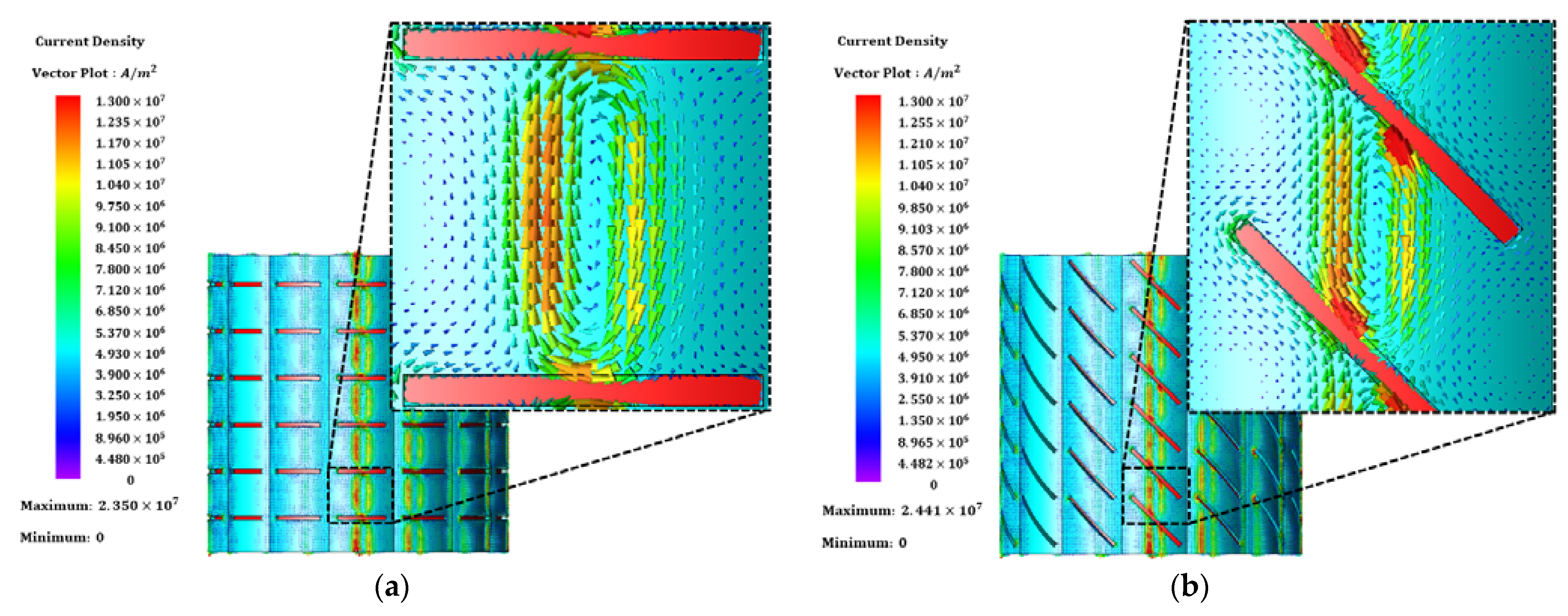

5.2.2. Selection of Slit Thickness (), Slit Angle (

5.2.3. Numerical Approach to Block Length

5.2.4. Selection of Same Block Length Model

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Du, G.; Tong, J.; Huang, N.; Hu, C.; Xu, W. Comparation of Different Rotor Sleeves of Highspeed Permanent Magnet Synchronous Motors Based on Multi-physics. In Proceedings of the 2021 IEEE 4th Student Conference on Electric Machines and Systems (SCEMS), Huzhou, China, 1–3 December 2021; pp. 1–5. [Google Scholar]

- Gerada, D.; Mebarki, A.; Brown, N.; Gerada, C.; Cavagnino, A.; Boglietti, A. High-speed electrical machines: Technologies, trends, and developments. IEEE Trans. Ind. Electron. 2014, 61, 2946–2959. [Google Scholar] [CrossRef]

- Lee, S.-H.; Song, S.-W.; Kim, D.-H.; Min, J.-Y.; Kim, W.-H. Performance comparison analysis and process suggestion through slotless SPMSM during high-speed operation. AIP Adv. 2023, 13, 025039. [Google Scholar] [CrossRef]

- Honda, Y.; Yokote, S.; Higaki, T.; Takeda, Y. Using the Halbach magnet array to develop an ultrahigh-speed spindle machine for machine tools. In Proceedings of the IEEE Industry Applications Conference Thirty-Second IAS Annual Meeting, New Orleans, LA, USA, 5–9 October 1997; Volume 1, pp. 56–60. [Google Scholar]

- Zhang, J.; Chen, W.; Huang, X.; Fang, Y.; Zhang, J.; Ma, J.; Cao, W. Evaluation of applying retaining shield rotor for high-speed interior permanent magnet machines. IEEE Trans. Magn. 2015, 51, 8108504. [Google Scholar]

- Mirzaei, M.; Binder, A. Permanent magnet savings in high speed electrical machines. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Ischia, Italy, 11–13 June 2008; pp. 1276–1281. [Google Scholar]

- Dong, J.; Huang, Y.; Jin, L.; Lin, H. Comparative study of surface-mounted and interior permanent-magnet machines for high-speed applications. IEEE Trans. Appl. Supercond. 2016, 26, 5200304. [Google Scholar] [CrossRef]

- Binder, A.; Schneider, T.; Klohr, M. Fixation of buried and surface-mounted magnets in high-speed permanent-magnet synchronous machines. IEEE Trans. Ind. Appl. 2006, 42, 1031–1037. [Google Scholar] [CrossRef]

- Li, W.; Qiu, H.; Zhang, X.; Cao, J.; Yi, R. Analyses on electromagnetic and temperature fields of super high-speed permanentmagnet generator with different sleeve materials. IEEE Trans. Ind. Electron. 2014, 61, 3056–3063. [Google Scholar] [CrossRef]

- Shen, J.X.; Hao, H.; Jin, M.J.; Yuan, C. Reduction of rotor eddy current loss in high speed PM brushless machines by grooving retaining sleeve. IEEE Trans. Magn. 2013, 49, 3973–3976. [Google Scholar] [CrossRef]

- Zhang, F.; Du, G.; Wang, T.; Wang, F.; Cao, W.; Kirtley, J.L. Electromagnetic design and loss calculations of a 1.12-MW high-speed permanent-magnet machine for compressor applications. IEEE Trans. Energy Convers. 2016, 31, 132–140. [Google Scholar] [CrossRef]

- Zhang, F.; Du, G.; Wang, T.; Liu, G.; Cao, W. Rotor retaining sleeve design for a 1.12-MW high-speed PM machine. IEEE Trans. Ind. Applicat. 2015, 51, 3675–3685. [Google Scholar] [CrossRef]

- Zhou, F.Z.; Shen, J.X.; Fei, W.; Lin, R. Study of retaining sleeve and conductive shield and their influence on rotor loss in high-speed PM BLDC machines. IEEE Trans. Magn. 2006, 42, 3398–3400. [Google Scholar] [CrossRef]

- Shah, M.R.; El-Refaie, A.M. Eddy-current loss minimization in conducting sleeves of surface PM machine rotors with fractionalslot concentrated armature windings by optimal axial segmentation and copper cladding. IEEE Trans. Ind. Applicat. 2009, 45, 720–728. [Google Scholar] [CrossRef]

- Benlamine, R.; Hamiti, T.; Vangraefschepe, F.; Lhotellier, D. Electromagnetic, structural and thermal analyses of high-speed PM machines for aircraft application. In Proceedings of the International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 212–217. [Google Scholar]

- Han, T.; Wang, Y.; Shen, J.-X. Analysis and Experiment Method of Influence of Retaining Sleeve Structures and Materials on Rotor Eddy Current Loss in High-Speed PM Motors. IEEE Trans. Ind. Applicat. 2020, 56, 4889–4895. [Google Scholar] [CrossRef]

- Jun, H.-W.; Lee, J.; Lee, H.-W.; Kim, W.-H. Study on the Optimal Rotor Retaining Sleeve Structure for the Reduction of Eddy-Current Loss in High-Speed SPMSM. IEEE Trans. Magn. 2015, 51, 8103004. [Google Scholar]

- Jung, D.-H.; Lee, J.-K.; Kim, J.-Y.; Jang, I.S.; Lee, J.; Lee, H.-J. Design Method of an Ultrahigh Speed PM Motor/Generator for Electric-Turbo Compounding System. IEEE Trans. Appl. Superconduct. 2018, 28, 5202804. [Google Scholar]

- Lee, T.-W.; Hong, D.-K. Rotor Design, Analysis and Experimental Validation of a High-Speed Permanent Magnet Synchronous Motor for Electric Turbocharger. IEEE Access 2022, 10, 21955–21969. [Google Scholar] [CrossRef]

- Damiano, A.; Floris, A.; Fois, G.; Porru, M.; Serpi, A. Modelling and design of PM retention sleeves for High-Speed PM Synchronous Machines. In Proceedings of the 2016 6th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 30 November–1 December 2016; pp. 118–125. [Google Scholar]

- Pan, B.; Tao, D.; Ge, B.; Wang, L.; Hou, P. Analysis of Eddy Current Loss of 120-kW High-Speed Permanent Magnet Synchronous Motor. Machines 2022, 10, 346. [Google Scholar] [CrossRef]

- Song, S.W.; Jeong, M.J.; Kim, K.S.; Lee, J.; Kim, W.H. A study on reducing eddy current loss of sleeve and improving torque density using ferrofluid of a surface permanent magnet synchronous motor. IET Electr. Power Appl. 2022, 16, 463–471. [Google Scholar] [CrossRef]

- Yamazaki, K.; Kanou, Y.; Fukushima, Y.; Ohki, S.; Nezu, A.; Ikemi, T.; Mizokami, R. Reduction of Magnet Eddy-Current Loss in Interior Permanent-Magnet Motors with Concentrated Windings. IEEE Trans. Ind. Applicat. 2010, 46, 2434–2441. [Google Scholar] [CrossRef]

- Hou, P.; Ge, B.; Tao, D.; Pan, B.; Wang, Y. Rotor Strength Analysis of FeCo-Based Permanent Magnet High Speed Motor. Machines 2022, 10, 462. [Google Scholar] [CrossRef]

- Ade, A.P.M.; Putri, F.; Arifin, F. Analisis Fatigue Menggunakan Autodesk Inventor Terhadap konstruksi Mesin Pencacah sabut Kelapa. MACHINERY J. Teknol. Terapan 2022, 3, 17–22. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Stator outer diameter | 250 | mm |

| Stator inner diameter | 108 | mm |

| Staking length | 104 | mm |

| Air gap length | 1 | mm |

| Rotor outer diameter | 106 | mm |

| Sleeve thickness | 3 | mm |

| Number of turns per slot | 7 | - |

| Number of parallel branches | 2 | - |

| Wire diameter | 4.8 | mm |

| Fill factor | 42.28 | % |

| Parameter | Value | Unit |

|---|---|---|

| Current | 120 | Arms |

| Phase resistance | 9.63 | mΩ |

| Torque | 50.4 | N·m |

| Shaft torque | 50 | N·m |

| Torque ripple rate | 1.6 | % |

| Line voltage | 771.6 | Vpeak |

| Line voltage THD | 1.1 | % |

| Copper loss | 208.1 | W |

| Core loss | 765.6 | W |

| Eddy current loss | 2218 | W |

| Power | 102.6 | kW |

| Efficiency | 96.9 | % |

| Parameter | Inconel 718 | NdFeB 42 | 35PN230 |

|---|---|---|---|

| Mass density [kg/m3] | 8220 | 7500 | 7600 |

| Young’s modulus [Gpa] | 165 | 160 | 161.4 |

| Poisson’s ratio | 0.29 | 0.24 | 0.33 |

| Yield tensile strength [Mpa] | 648 | 78.4 | 440 |

| Case | ||

|---|---|---|

| 1 | 4 | 22 |

| 2 | 5 | 20 |

| 3 | 6 | 17 |

| 4 | 7 | 14 |

| 5 | 8 | 12 |

| 6 | 9 | 11 |

| 7 | 10 | 10 |

| 8 | 11 | 9 |

| 9 | 12 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-H.; Song, S.-W.; Jeong, M.-J.; Kim, W.-H.; Jung, D.-H. A Novel Sleeve Design to Reduce the Eddy Current Loss of High-Speed Electrical Machines. Machines 2023, 11, 756. https://doi.org/10.3390/machines11070756

Lee S-H, Song S-W, Jeong M-J, Kim W-H, Jung D-H. A Novel Sleeve Design to Reduce the Eddy Current Loss of High-Speed Electrical Machines. Machines. 2023; 11(7):756. https://doi.org/10.3390/machines11070756

Chicago/Turabian StyleLee, Seung-Heon, Si-Woo Song, Min-Jae Jeong, Won-Ho Kim, and Dong-Hoon Jung. 2023. "A Novel Sleeve Design to Reduce the Eddy Current Loss of High-Speed Electrical Machines" Machines 11, no. 7: 756. https://doi.org/10.3390/machines11070756

APA StyleLee, S.-H., Song, S.-W., Jeong, M.-J., Kim, W.-H., & Jung, D.-H. (2023). A Novel Sleeve Design to Reduce the Eddy Current Loss of High-Speed Electrical Machines. Machines, 11(7), 756. https://doi.org/10.3390/machines11070756