Pulsed Laser Ultrasonic Vibration-Assisted Cutting of SiCp/Al Composites through Finite Element Simulation and Experimental Research

Abstract

:1. Introduction

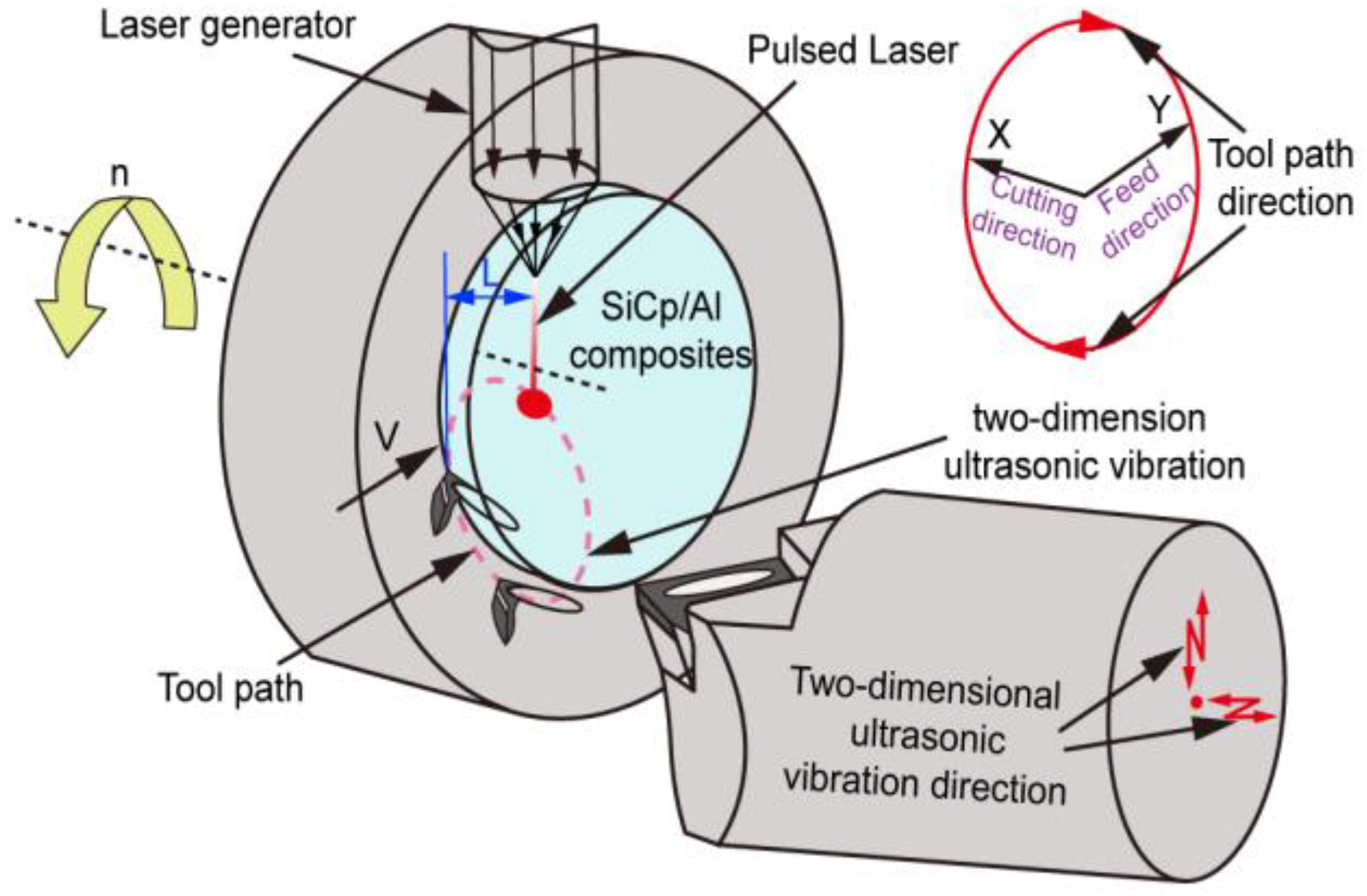

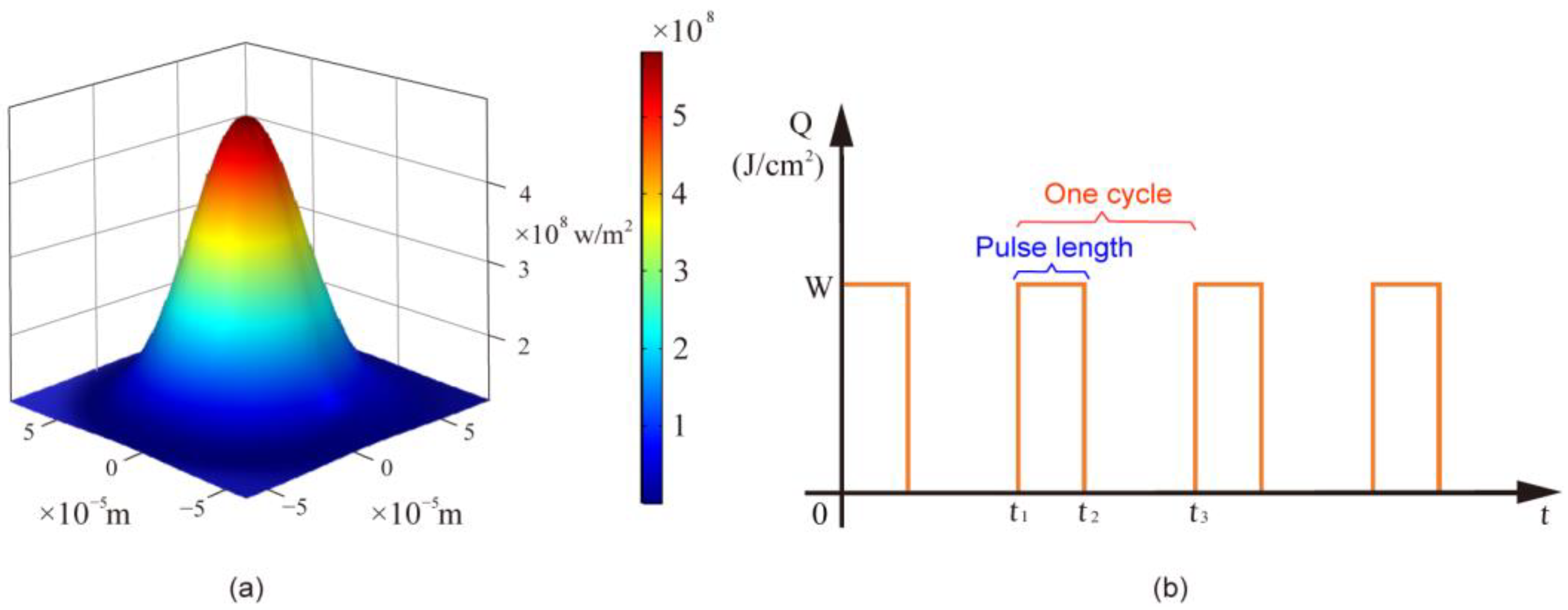

2. The Principle of PLUVAC

3. PLUVAC Finite Element Simulation of SiCp/Al

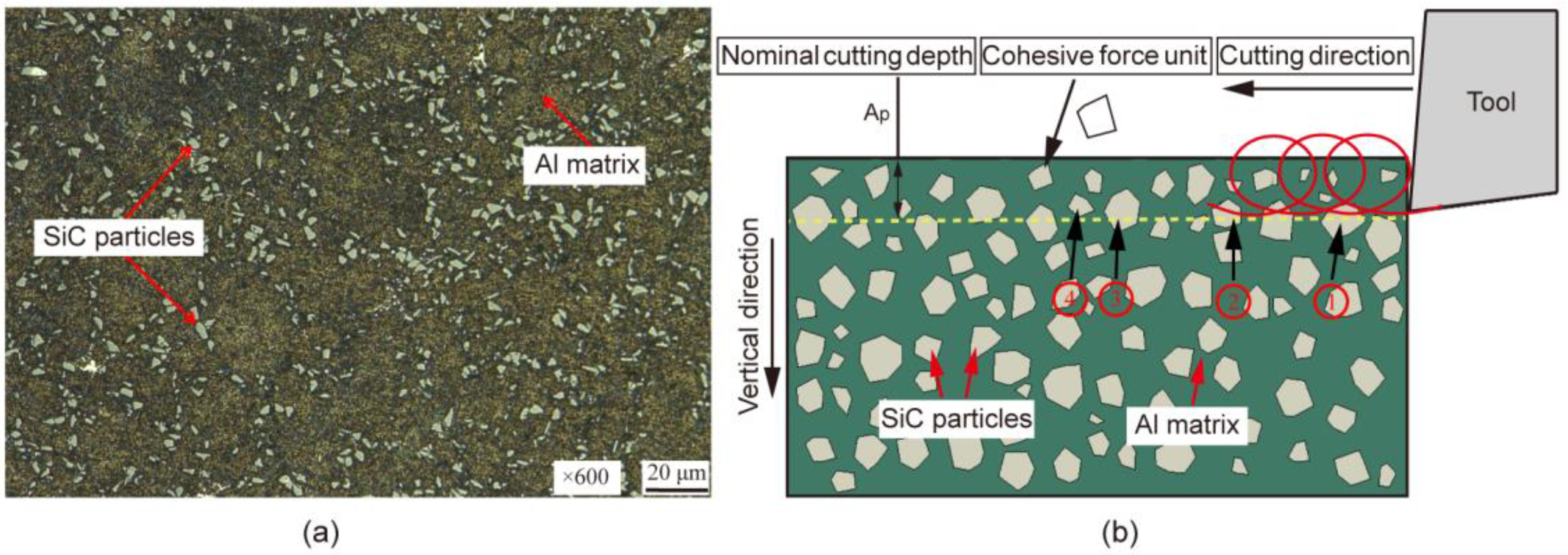

3.1. Finite Element Model

3.2. Material Properties

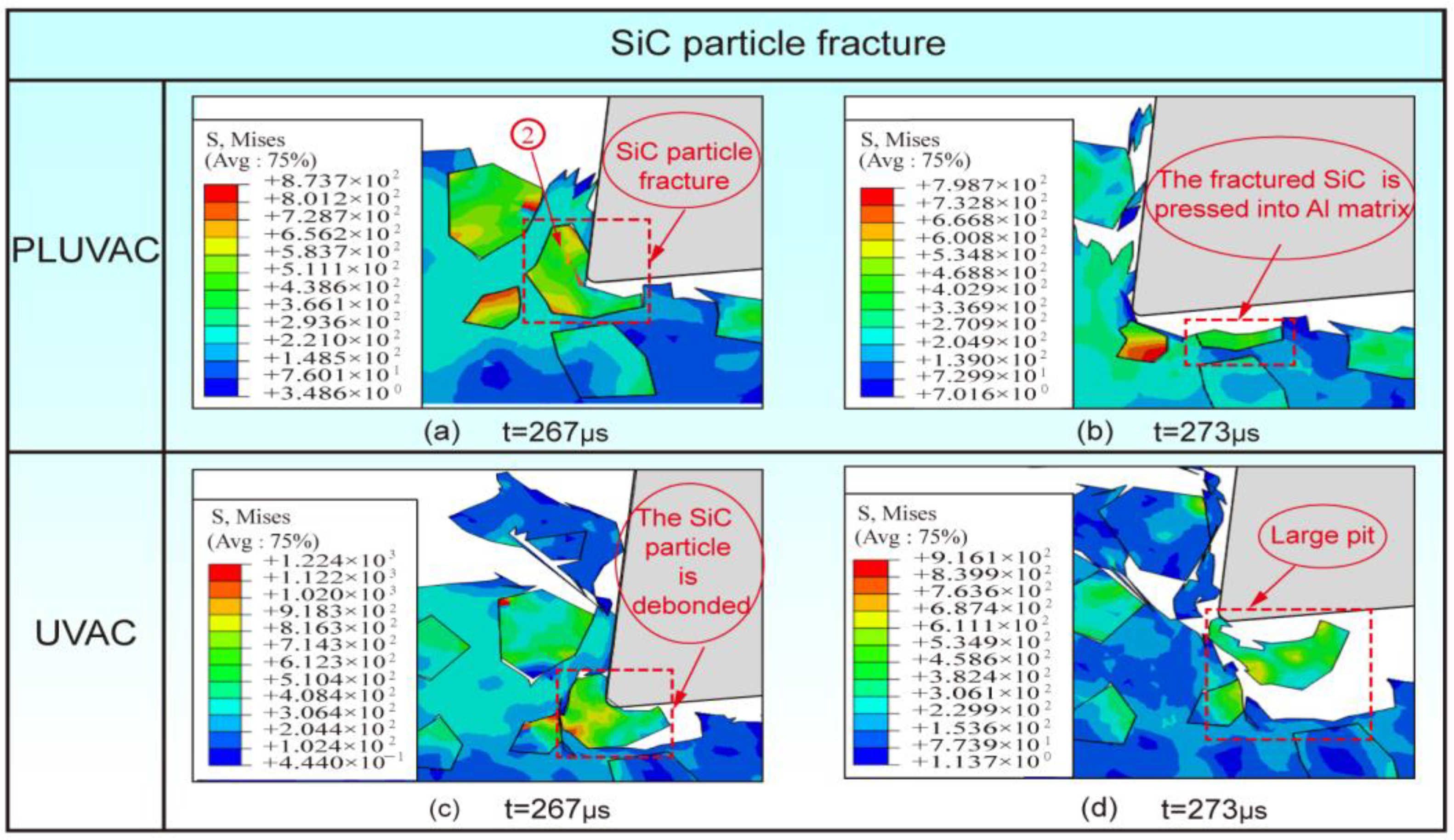

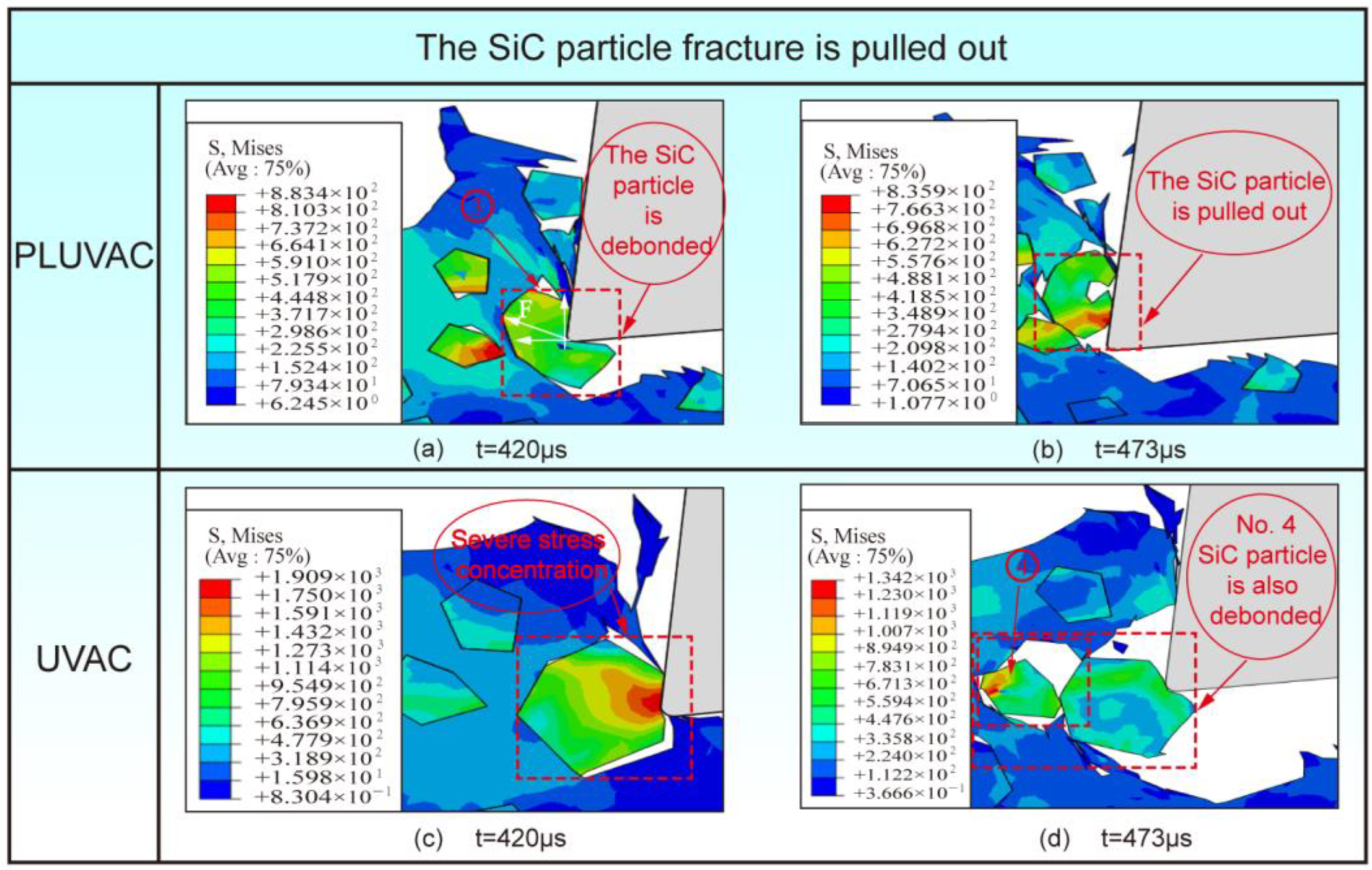

3.3. Damage Forms Analysis of SiC Particles

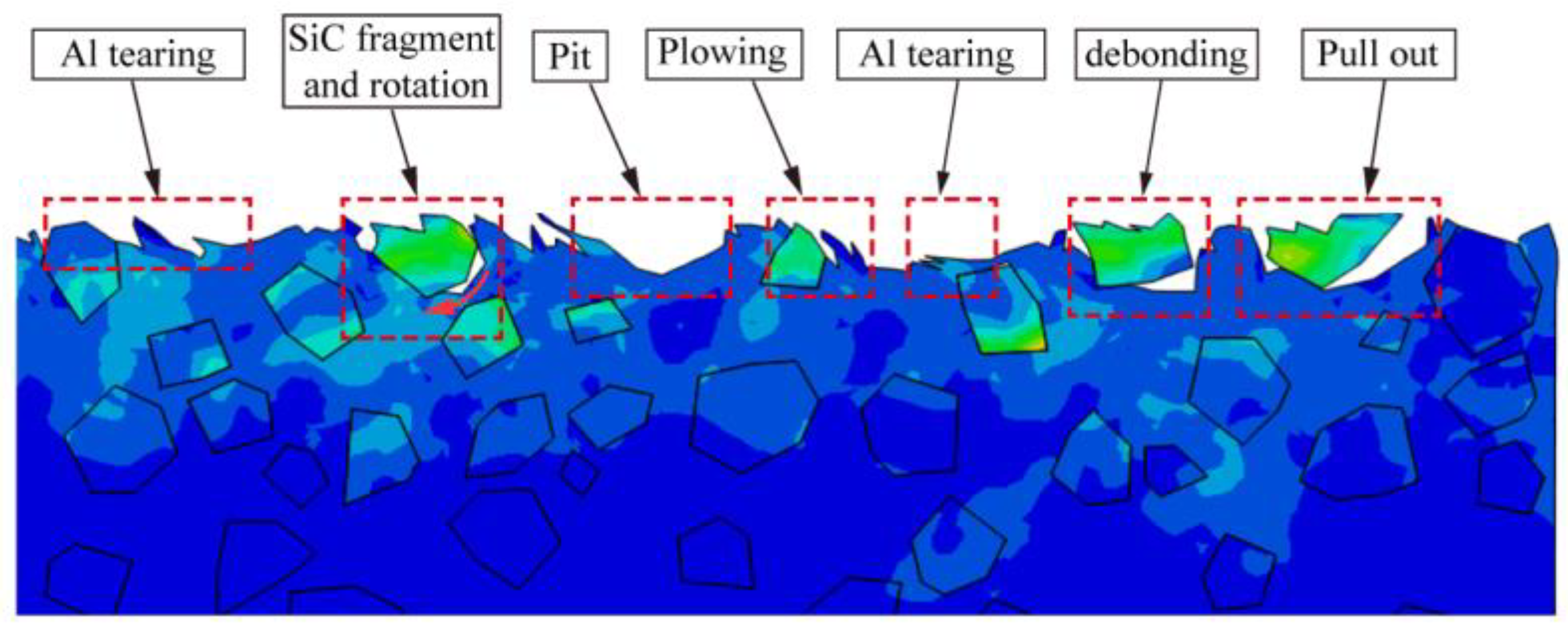

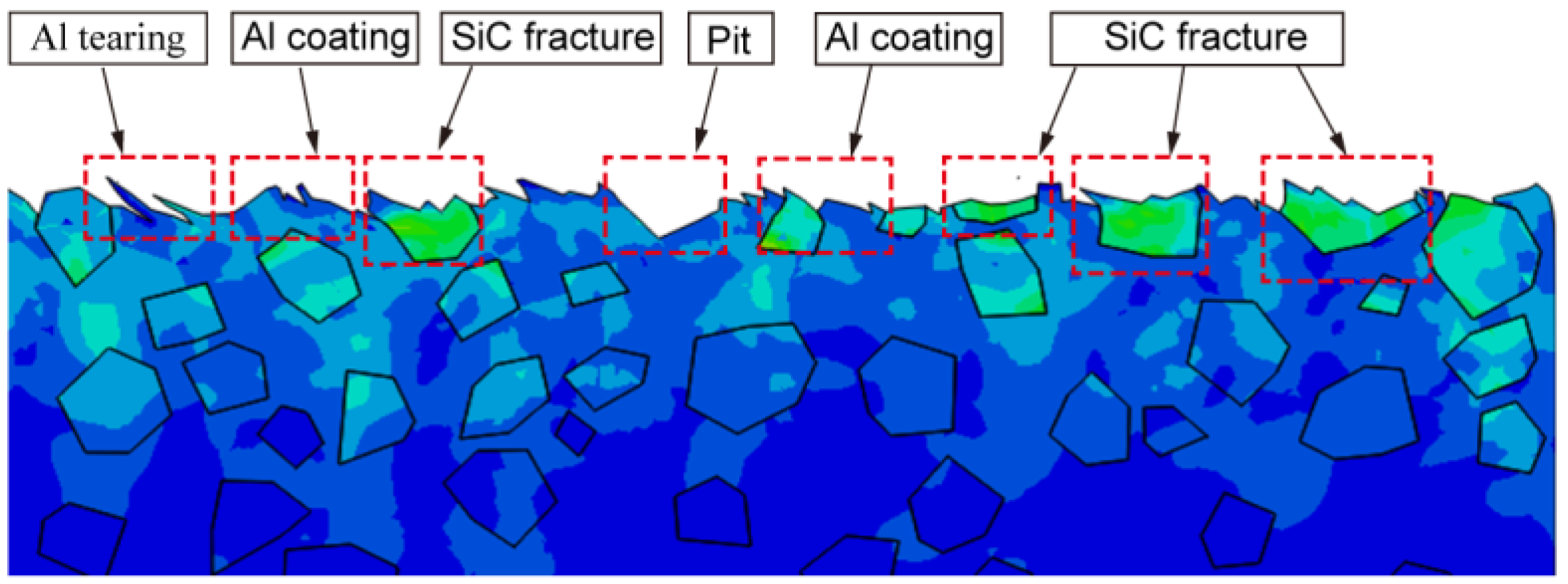

3.4. Surface Defects Analysis

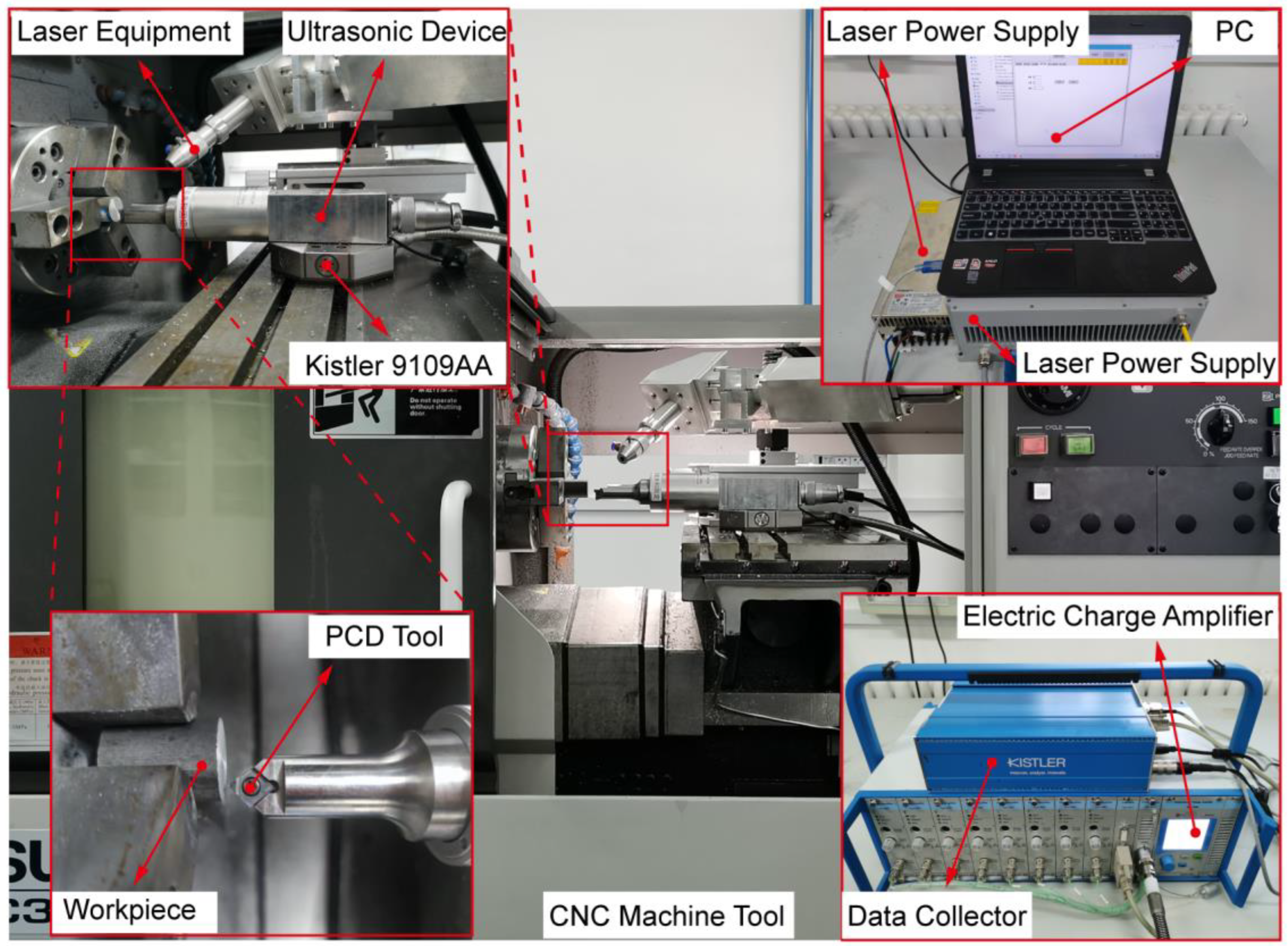

4. Experimental Setup

5. Results and Discussion

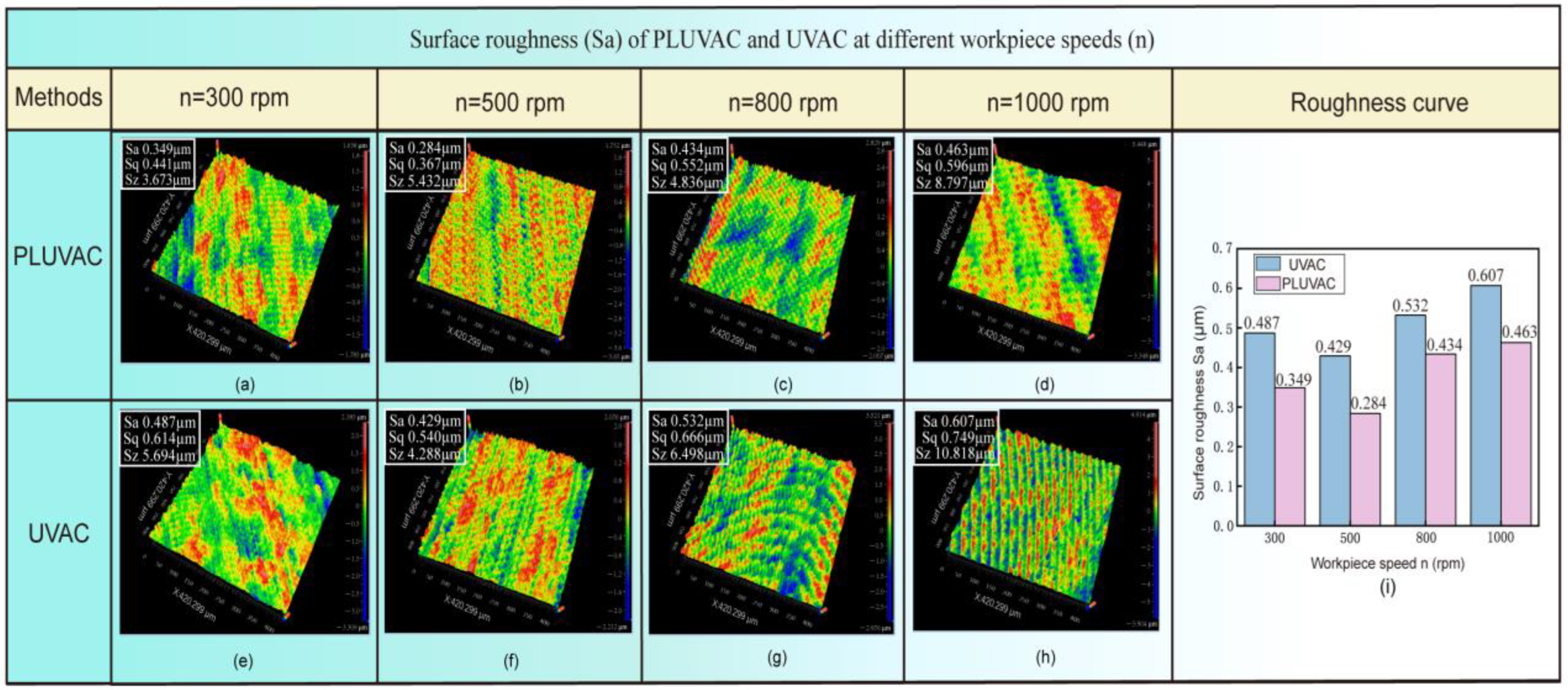

5.1. Effect of the Workpiece Speed (n) on the Sa

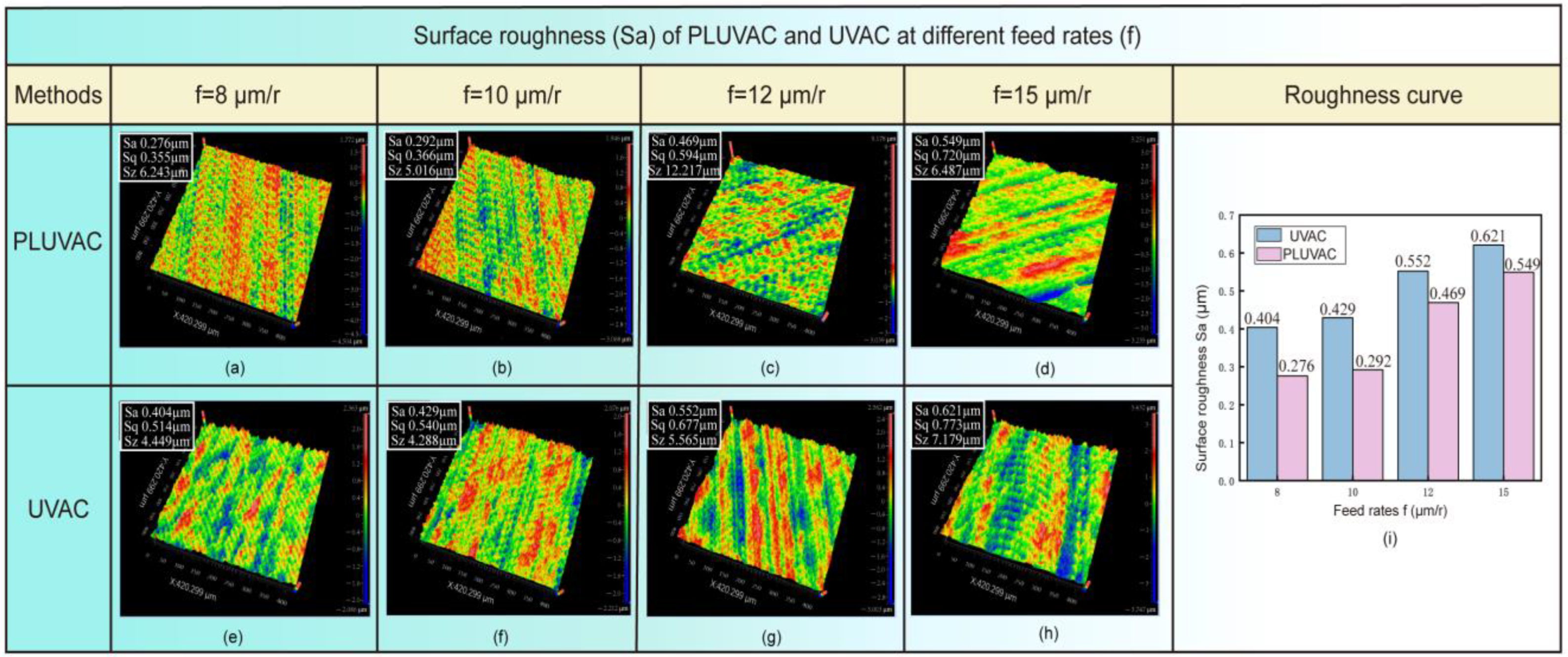

5.2. Effect of the Feed Rate (f) on the Sa

5.3. Effect of the Cutting Depth (Ap) on the Sa

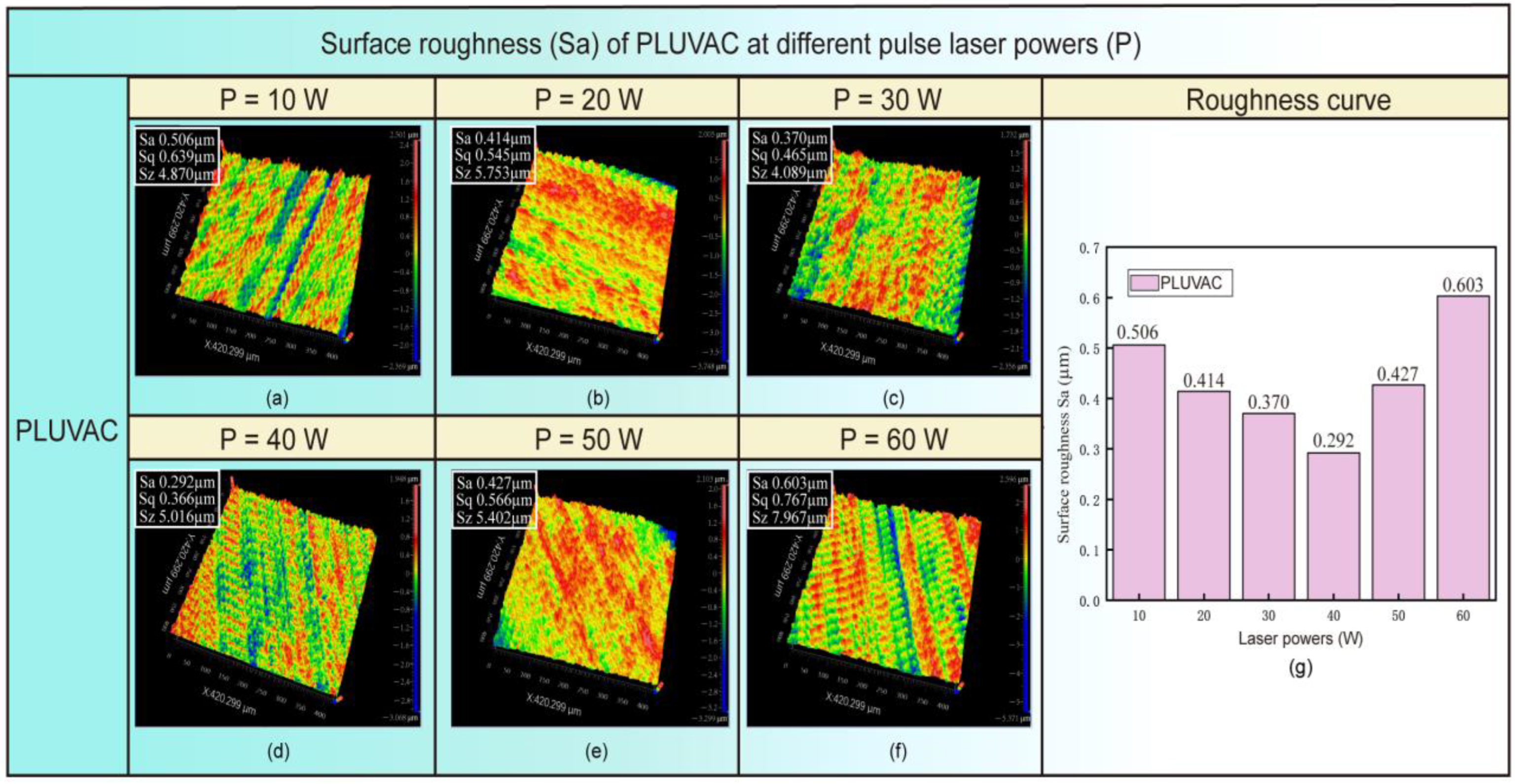

5.4. Effect of the Pulsed Laser Power (P) on the Sa

5.5. Effect of the Pulsed Laser Power (P) on the Average Cutting Forces

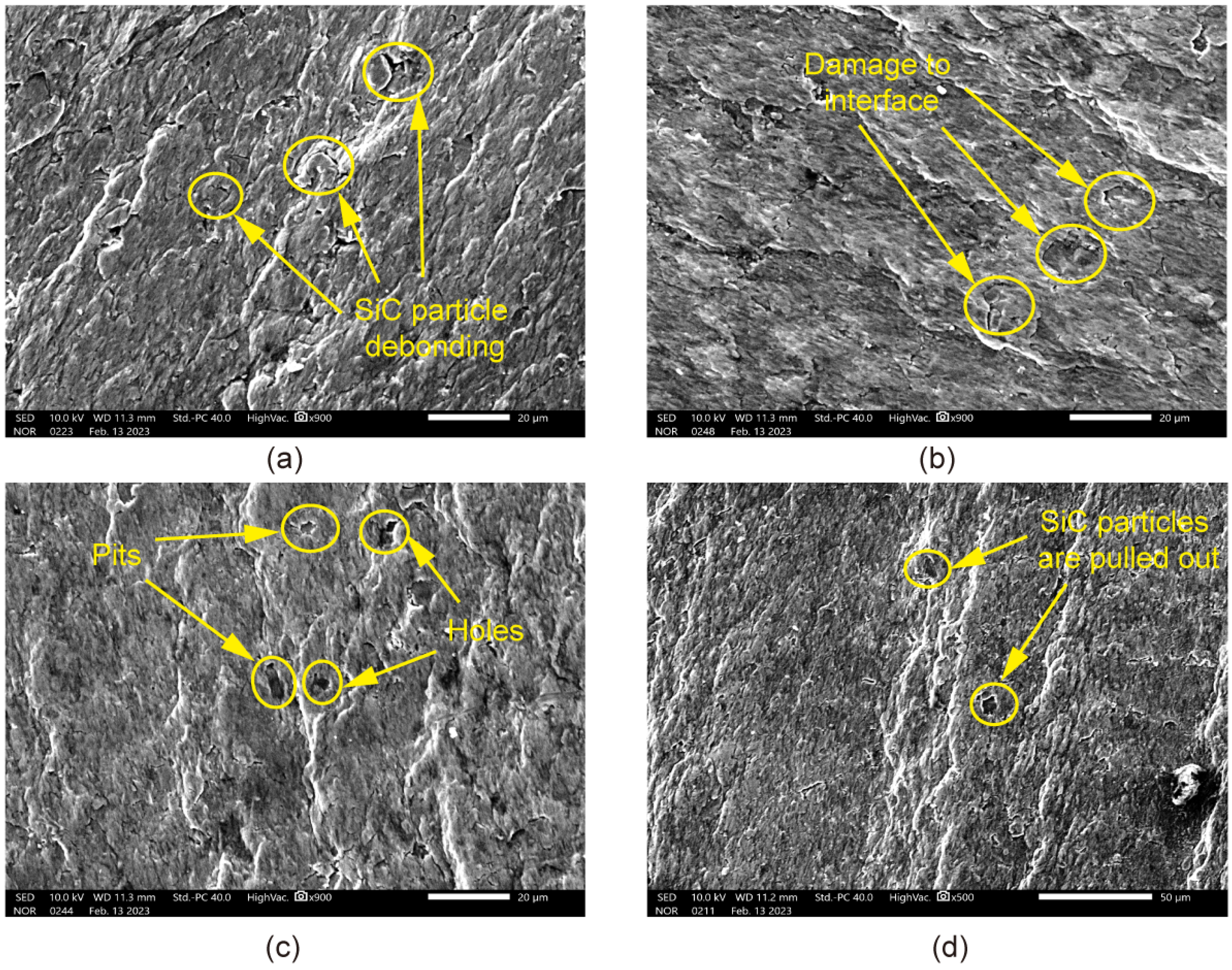

5.6. Comparative Analysis of Surface Defects between PLUVAC and UVAC Methods

5.6.1. Complete Fragment and Partial Fracture of SiC Particles in UVAC

5.6.2. Debonding and Pull-Out of SiC Particles in UVAC

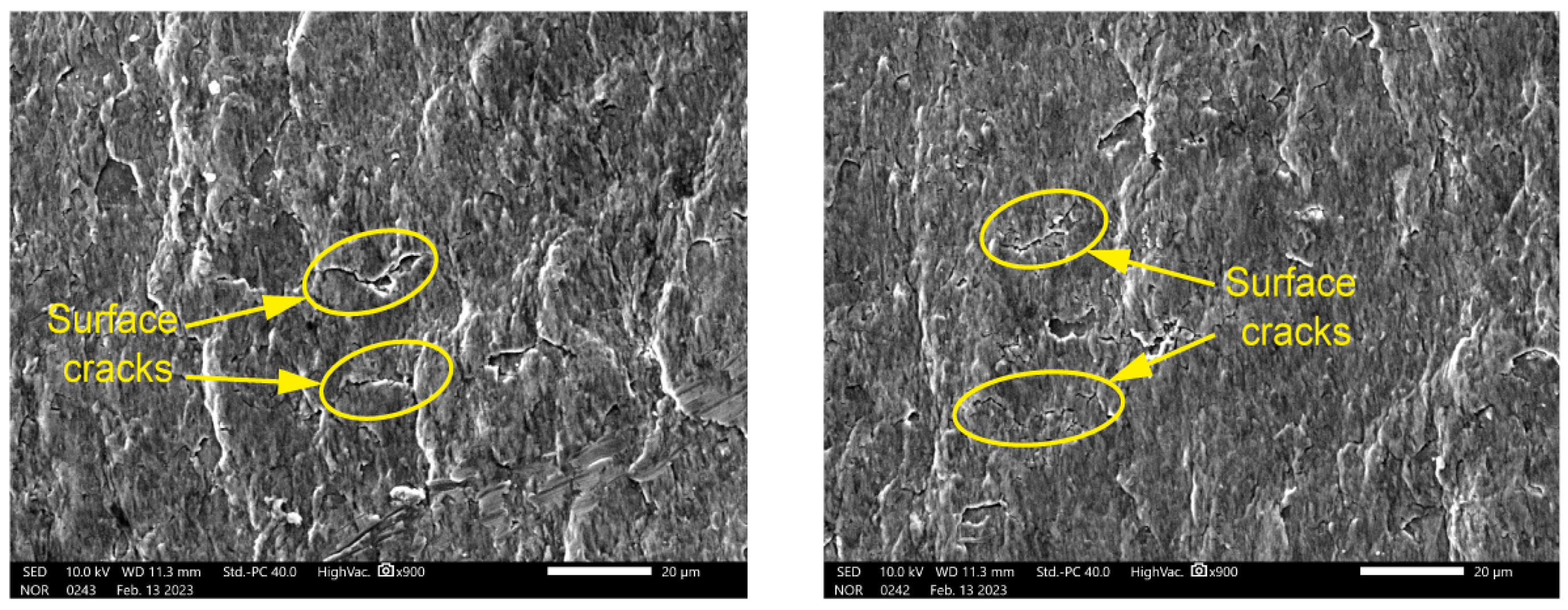

5.6.3. Surface Cracks of Workpiece in UVAC

5.6.4. Surface Defects Analysis of PLUVAC

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peng, P.; Xiang, D.; Lei, X.; Shi, Z.; Li, B.; Liu, G.; Zhao, B.; Gao, G. Study on the edge defects of high volume fraction 70% SiCp/Al composites in ultrasonic-assisted milling. Int. J. Adv. Manuf. Technol. 2022, 122, 485–498. [Google Scholar] [CrossRef]

- Chelladurai, S.J.S.; Kumar, S.S.; Venugopal, N.; Ray, A.P.; Manjunath, T.C.; Gnanasekaran, S. A review on mechanical properties and wear behaviour of aluminium based metal matrix composites. Mater. Today Proc. 2021, 37, 908–916. [Google Scholar] [CrossRef]

- Monaca, A.; Murray, J.W.; Liao, Z.; Speidel, A.; Robles-Linares, J.A.; Axinte, D.A.; Hardy, M.C.; Clare, A.T. Surface integrity in metal machining-Part II: Functional performance. Int. J. Mach. Tool. Manufact. 2021, 164, 103718. [Google Scholar] [CrossRef]

- Liao, Z.; Abdelhafeez, A.; Li, H.; Yang, Y.; Diaz, O.G.; Axinte, D. State-of-the-art of surface integrity in machining of metal matrix composites. Int. J. Mach. Tool. Manufact. 2019, 143, 63–91. [Google Scholar]

- Zhao, J.; Ge, J.; Khudoley, A.; Chen, H. Numerical and experimental investigation on the material removal profile during polishing of inner surfaces using an abrasive rotating jet. Tribol. Int. 2024, 191, 109125. [Google Scholar] [CrossRef]

- Zhu, C.; Gu, P.; Wu, Y.; Liu, D.; Wang, X. Surface roughness prediction model of SiCp/Al composite in grinding. Int. J. Mech. Sci. 2019, 155, 98–109. [Google Scholar] [CrossRef]

- Sun, W.; Duan, C.; Yin, W. Chip formation mechanism in machining of Al/SiCp composites based on analysis of particle damage. J. Manuf. Process. 2021, 64, 861–877. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Z.; Lin, J.; Zhou, X.; Xu, Z.; Zhou, W.; Zhang, S.; Gao, Y. Enhanced machinability of aluminium-based silicon carbide by non-resonant vibration-assisted magnetorheological finishing. J. Mater. Process. Technol. 2023, 324, 118223. [Google Scholar]

- Gu, Y.; Kang, M.; Lin, J.; Liu, A.; Fu, B.; Wan, P. Non-resonant vibration-assisted magnetorheological finishing. Precis. Eng. 2021, 71, 263–281. [Google Scholar]

- You, K.; Yan, G.; Luo, X.; Gilchrist, M.D.; Fang, F. Advances in laser assisted machining of hard and brittle materials. J. Manuf. Process. 2020, 58, 677–692. [Google Scholar]

- Kang, M.; Gu, Y.; Lin, J.; Zhou, X.; Zhang, S.; Zhao, H.; Li, Z.; Yu, B.; Fu, B. Material removal mechanism of non-resonant vibration-assisted magnetorheological finishing of silicon carbide ceramics. Int. J. Mech. Sci. 2024, 242, 107986. [Google Scholar]

- Zhao, J.; Huang, J.; Xiang, Y.; Wang, R.; Xu, X.; Ji, S.; Hang, W. Effect of a protective coating on the surface integrity of a microchannel produced by microultrasonic machining. J. Manuf. Process. 2021, 61, 280–295. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, R.; Huang, J.; Hu, B.; Ji, S. Micro ultrasonic machining hemispherical mold for MEMS resonator gyroscope using a novel ultraprecise ceramic entire-ball tool. J. Micromech. Microeng. 2020, 30, 075007. [Google Scholar]

- Liu, G.; Xiang, D.; Peng, P.; Li, Y.; Yuan, Z.; Zhang, Z.; Gao, G.; Zhao, B. Establishment of scratching force model for micro-removal of SiCp/Al composites by ultrasonic vibration. J. Mater. Process. Technol. 2022, 307, 117677. [Google Scholar] [CrossRef]

- Huang, W.; Yu, D.; Zhang, X.; Zhang, M.; Chen, D. Ductile-regime machining model for ultrasonic elliptical vibration cutting of brittle materials. J. Manuf. Process. 2018, 36, 68–76. [Google Scholar]

- Zha, H.; Feng, P.; Zhang, J.; Yu, D.; Wu, Z. Material removal mechanism in rotary ultrasonic machining of high-volume fraction SiCp/Al composites. Int. J. Adv. Manuf. Technol. 2018, 97, 2099–2109. [Google Scholar] [CrossRef]

- Zhou, Y.; Gu, Y.; Lin, J.; Zhao, H.; Liu, S.; Xu, Z.; Yu, H.; Fu, X. Finite element analysis and experimental study on the cutting mechanism of SiCp/Al composites by ultrasonic vibration-assisted cutting. Ceram. Int. 2022, 48, 35406–35421. [Google Scholar] [CrossRef]

- Shi, Z.; Xiang, D.; Feng, H.; Wu, B.; Zhang, Z.; Gao, G.; Zhao, B. Finite element and experimental analysis of ultrasonic vibration milling of high-volume fraction SiCp/Al composites. Int. J. Precis. Eng. Manuf. 2021, 22, 1777–1789. [Google Scholar]

- Zheng, W.; Wang, Y.; Zhou, M.; Wang, Q.; Ling, L. Material deformation and removal mechanism of SiCp/Al composites in ultrasonic vibration assisted scratch test. Ceram. Int. 2018, 44, 15133–15144. [Google Scholar] [CrossRef]

- Bai, W.; Roy, A.; Sun, R.; Silberschmidt, V.V. Enhanced machinability of SiC-reinforced metal-matrix composite with hybrid turning. J. Mater. Process. Technol. 2019, 268, 149–161. [Google Scholar] [CrossRef]

- Li, Q.; Yuan, S.; Gao, X.; Zhang, Z.; Chen, B.; Li, Z.; Batako, A.D.L. Surface and subsurface formation mechanism of SiCp/Al composites under ultrasonic scratching. Ceram. Int. 2023, 49, 817–833. [Google Scholar] [CrossRef]

- Sahu, A.K.; Malhotra, J.; Jha, S. Laser-based hybrid micromachining processes: A review. Opt. Laser. Technol. 2022, 146, 107554. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, C.M. Experimental Investigation on Machinability of Titanium Alloy by Laser-Assisted End Milling. Metals 2021, 11, 1552. [Google Scholar]

- Wang, M.; Zheng, Z.; Wu, Z.; Zhang, J.; Chen, X.; Xiao, J.; Xu, J. Investigation on the machinability of SiCp/Al composite by in-situ laser assisted diamond cutting. J. Mater. Process. Technol. 2023, 318, 118044. [Google Scholar] [CrossRef]

- Hao, X.; Xu, W.; Chen, M.; Wang, C.; Han, J.; Li, L.; He, N. Laser hybridizing with micro-milling for fabrication of high aspect ratio micro-groove on oxygen-free copper. Precis. Eng. 2021, 70, 15–25. [Google Scholar]

- Kim, J.; Zani, L.; Abdul-Kadir, A.; Roy, A.; Baxevanakis, K.P.; Jones, L.C.R.; Silberschmidt, V.V. Hybrid-hybrid turning of micro-SiCp/AA2124 composites: A comparative study of laser-and-ultrasonic vibration-assisted machining. J. Manuf. Process. 2023, 86, 109–125. [Google Scholar] [CrossRef]

- Zhao, G.; Mao, P.; Li, L.; Iqbal, A.; He, N. Micro-milling of 65 vol% SiCp/Al composites with a novel laser-assisted hybrid process. Ceram. Int. 2020, 46, 26121–26128. [Google Scholar] [CrossRef]

- Zhai, C.; Xu, J.; Li, Y.; Hou, Y.; Yuan, S.; Liu, Q.; Wang, X. The study on surface integrity on laser-assisted turning of SiCp/2024Al. Int. J. Optomechatron. 2020, 14, 29–43. [Google Scholar] [CrossRef]

- Xu, D.; Liao, Z.; Axinte, D.; Sarasua, J.A.; M’Saoubi, R.; Wretland, A. Investigation of surface integrity on laser-assisted machining of nickel based superalloy. Mater. Des. 2020, 194, 108851. [Google Scholar]

- Azarhoushang, B.; Soltani, B.; Zahedi, A. Laser-assisted grinding of silicon nitride by picosecond laser. Int. J. Adv. Manuf. Technol. 2017, 93, 2517–2529. [Google Scholar] [CrossRef]

- Xiao, G.; Liu, Z.; Geng, Y.; He, Y.; Li, C.; Lin, O.; Zhu, S. Enhancing machinability of Ti6Al4V by ultrashort-pulse laser-induced modification assisted grinding. Int. J. Adv. Manuf. Technol. 2023, 125, 4601–4620. [Google Scholar] [CrossRef]

- Longo, W.P.; Reed-Hill, R.E. An analysis of work softening in polycrystalline nickel. Metallography 1974, 7, 181–201. [Google Scholar] [CrossRef]

- Blaha, F.; Langenecker, B. Plastizitätsuntersuchungen von metallkristallen in ultraschallfeld. Acta Metall. Sin. 1959, 7, 93–100. [Google Scholar] [CrossRef]

- Peng, P.; Xiang, D.; Li, Y.; Yuan, Z.; Lei, X.; Li, B.; Liu, G.; Zhao, B.; Gao, G. Experimental study on laser assisted ultrasonic elliptical vibration turning (LA-UEVT) of 70% SiCp/Al composites. Ceram. Int. 2022, 48, 33538–33552. [Google Scholar] [CrossRef]

- Yu, W.; Chen, J.; Ming, W.; An, Q.; Chen, M. Experimental and FEM study of cutting mechanism and damage behavior of ceramic particles in orthogonal cutting SiCp/Al composites. Ceram. Int. 2021, 47, 7183–7194. [Google Scholar] [CrossRef]

- Li, B.; Xiang, D.; Peng, P.; Li, Y.; Liu, G.; Gao, G.; Zhao, B. Experimental and FEM study of surface formation and deformation mechanism of SiCp/Al composites in Laser-ultrasonic vibration assisted turning. Ceram. Int. 2023, 49, 13510–13519. [Google Scholar] [CrossRef]

- Zhang, J.; Han, L.; Zhang, J.; Liu, H.; Yan, Y.; Sun, T. Brittle-to-ductile transition in elliptical vibration-assisted diamond cutting of reaction-bonded silicon carbide. J. Manuf. Process. 2019, 45, 670–681. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, H.; Liu, F.; Wang, L. Investigation on femtosecond laser ablative processing of SiCp/AA2024 composites. J. Manuf. Process. 2020, 49, 227–233. [Google Scholar]

- Zhang, H.; Kong, X.; Yang, L.; Wang, Y.; Chi, G. High temperature deformation mechanisms and constitutive modeling for Al/SiCp/45 metal matrix composites undergoing laser-assisted machining. Mater. Sci. Eng. A 2015, 642, 330–339. [Google Scholar] [CrossRef]

| Cutting Parameters | Numerical Value | Unit |

|---|---|---|

| Cutting speed V | 654 | mm/s |

| Cutting depth Ap | 10 | μm |

| Longitudinal amplitude | 10 | μm |

| Bending amplitude | 4 | μm |

| Tool front angle | 5 | angle |

| Tool back angle | 7 | angle |

| Parameters | Al Phase | SiC Phase |

|---|---|---|

| Density (ton/mm3) | 2.7 × 10−9 | 3.2 × 10−9 |

| Young’s modulus (MPa) | 70,000 | 408,000 |

| Poisson’s ratio | 0.3 | 0.2 |

| Thermal conductivity (W/(m·K)) | 189 | 81 |

| Specific heat capacity (J/(kg·K)) | 2.3 × 10−5 | 4.9 × 10−6 |

| Yield stress (MPa) | / | 1500 |

| Melting point (K) | 873.15 | 2973.15 |

| A (MPa) | 270 | / |

| B (MPa) | 134 | / |

| n | 0.514 | / |

| m | 0.703 | / |

| C | 0.0082 | / |

| D1 | 0.06 | / |

| D2 | 0.497 | / |

| D3 | −1.551 | / |

| D4 | 0.0286 | / |

| D5 | 6.8 | / |

| Processing Parameters | Workpiece Speed (n)/(rpm) | Feed Rate (f)/(μm/r) | Cutting Depth (Ap)/(μm) | Pulsed Laser Power (P)/(W) | Pulsed Frequency /KHz |

|---|---|---|---|---|---|

| Section 5.1 | 300, 500, 800, 1000 | 10 | 8 | 40 | 200 |

| Section 5.2 | 500 | 8, 10, 12, 15 | 8 | 40 | 200 |

| Section 5.3 | 500 | 10 | 6, 8, 10, 12 | 40 | 200 |

| Section 5.4 | 500 | 10 | 8 | 10, 20, 30, 40, 50, 60 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Gu, Y.; Lin, J.; Ye, Q.; Liu, S.; Xi, Y.; Gao, Y.; Gao, T.; Liang, G.; Xie, L. Pulsed Laser Ultrasonic Vibration-Assisted Cutting of SiCp/Al Composites through Finite Element Simulation and Experimental Research. Machines 2024, 12, 71. https://doi.org/10.3390/machines12010071

Zhou W, Gu Y, Lin J, Ye Q, Liu S, Xi Y, Gao Y, Gao T, Liang G, Xie L. Pulsed Laser Ultrasonic Vibration-Assisted Cutting of SiCp/Al Composites through Finite Element Simulation and Experimental Research. Machines. 2024; 12(1):71. https://doi.org/10.3390/machines12010071

Chicago/Turabian StyleZhou, Weidong, Yan Gu, Jieqiong Lin, Qingsong Ye, Siyang Liu, Yuan Xi, Yinghuan Gao, Tianyu Gao, Guangyu Liang, and Lue Xie. 2024. "Pulsed Laser Ultrasonic Vibration-Assisted Cutting of SiCp/Al Composites through Finite Element Simulation and Experimental Research" Machines 12, no. 1: 71. https://doi.org/10.3390/machines12010071

APA StyleZhou, W., Gu, Y., Lin, J., Ye, Q., Liu, S., Xi, Y., Gao, Y., Gao, T., Liang, G., & Xie, L. (2024). Pulsed Laser Ultrasonic Vibration-Assisted Cutting of SiCp/Al Composites through Finite Element Simulation and Experimental Research. Machines, 12(1), 71. https://doi.org/10.3390/machines12010071