Manufacturing 4.0: Checking the Feasibility of a Work Cell Using Asset Administration Shell and Physics-Based Three-Dimensional Digital Twins

Abstract

1. Introduction

2. Related Works

3. Methodology for Engineering Heterogeneous Digital Twins: N-DTs

- Specification: This is in the N-DTs’ first phase. The five jobs in this step are (1) collecting and analyzing all datasheets and documents related to the use case, (2) determining all entities that require DTs and their DT types, (3) preparing all historical data related to the defined entities, (4) browsing and retrieving all DT prototypes related to the target DTs, and (5) defining a list that includes both functional and non-functional requirements of the use case. The first two jobs intensely impact all the other steps in the methodology since they directly decide the quantity and type of DT instances to develop. Then, they indirectly impact the direction and cost of the project. The third job only influences the DT validation step, and the fourth job can help to reduce labor in the design step by reusing the existing works. The fifth job provides a checklist for the N-DTs validation step.

- Design: This is in the N-DTs’ first phase. It is specified depending on the associated DT type and development experts. Generally, this step takes the information related to its target manufacturing entity in the specification step as input and produces a blueprint that models the entity as output. The developers can make the blueprint from scratch or design it from an existing DT prototype. The latter approach has more advantages in labor saving and error reduction. The encoding language used to make the blueprint varies based on the domain.

- DT Implementation: This is in the N-DTs’ first phase. It is specified depending on the associated DT type and development experts. Generally, this step takes the blueprint in the design step as input and produces a DT as output. Technically speaking, a DT can be a program or an executable object in a program. The encoding language used to implement it varies based on the domain.

- DT Validation: This is in the N-DTs’ first phase. It is specified depending on the associated DT type and development experts. Generally, this step tests the DT with the historical data collected in the specification step or directly with the physical twin. If the developers detect errors, they turn back to the design step.

- Aggregation: This is in the N-DTs’ second phase. This step selects DTs and groups them into different abstract groups based on developers’ strategies. Furthermore, developers aggregate the DTs and run each group separately as a subsystem. For example, developers group all DTs associated with a manufacturing entity into group A and, in another case, group all DTs with the same type into group B. Note that a DT can belong to both groups.

- Group Validation: This is in the N-DTs’ second phase. This step tests the subsystem corresponding to a group of DTs in the aggregation step with the DTs’ corresponding historical datasets or their physical twins. The validation of a group of DTs can detect errors at the use case level; then, developers must return to the specification step and make modifications. When errors relate only to a DT, the developers check only the design step related to the DT. The number of validations depends on the number of abstract groups in the aggregation step.

- N-DTs Implementation: This is in the N-DTs’ third phase. Developers deploy all DTs as a united N-DTs system. The system must be the result expected by the use case.

- N-DTs Validation: This is in the N-DTs’ third phase. Developers test the N-DTs system with historical data and the physical system. The N-DTs must satisfy functional and non-functional requirements defined in the specification phase. If developers detect errors, they return to the specification phase for adjustments.

4. Methodology for Engineering Feasibility-Checking Framework

4.1. AAS and Papyrus for Manufacturing

- P4M can model and create AAS DTs representing all products, processes, and resources of a target manufacturing system. The AAS DTs can exchange data and commands with their assets and, even more, communicate with other DTs and external applications when necessary.

- The capabilities of a resource can be modeled as the submodel elements of a submodel Capabilities. In other words, the AAS DT of a resource has a submodel Capabilities that includes the resource’s capabilities and related information.

- Due to the AAS’ flexibility, it is possible to add context and additional information to any AAS DT as a submodel. Another solution is to define an AAS DT for a use case or a manufacturing system that contains all the context information.

4.2. Physics-Based 3D and XDE Physics

4.3. Engineering a Feasibility-Checking Framework Using AAS and 3D DTs

- After the specification step, there are only two chains of the design, DT implementation, and DT validation steps. One chain is for AAS DTs, and another is for 3D DTs. Each manufacturing entity should have one AAS DT and one 3D DT, except for processes that can only be represented by AAS DTs. Note that the nAAS DT is not necessarily equal to the n3D DT.

- One recommendation in the aggregation step is to aggregate the two DTs addressing a manufacturing entity into a group. For example, an AAS DT and a 3D DT of an AGV can be in one group so that the validation between these two DTs with the physic AGV or with the historical data can be more manageable. Suppose that k is the number of manufacturing entities defined in the specification step; thus, the number of group validation steps should be between 1 and k. During a group validation, developers may add an object to the group; for example, 3D DT developers create a wall in front of the 3D DT of an AGV in the physical simulation. The object should be considered a part of the group validation but not a new group with the 3D DT.

- In this case, the N-DTs implementation and N-DTs validation steps of N-DTs equal the feasibility-checking framework implementation and feasibility-checking framework validation steps. The output of the final step is a feasibility-checking framework ready for factory operators to operate feasibility-checking practices.

5. Production Assembly Line Case Study

5.1. Architecture of the PAL System and the Feasibility-Checking Framework

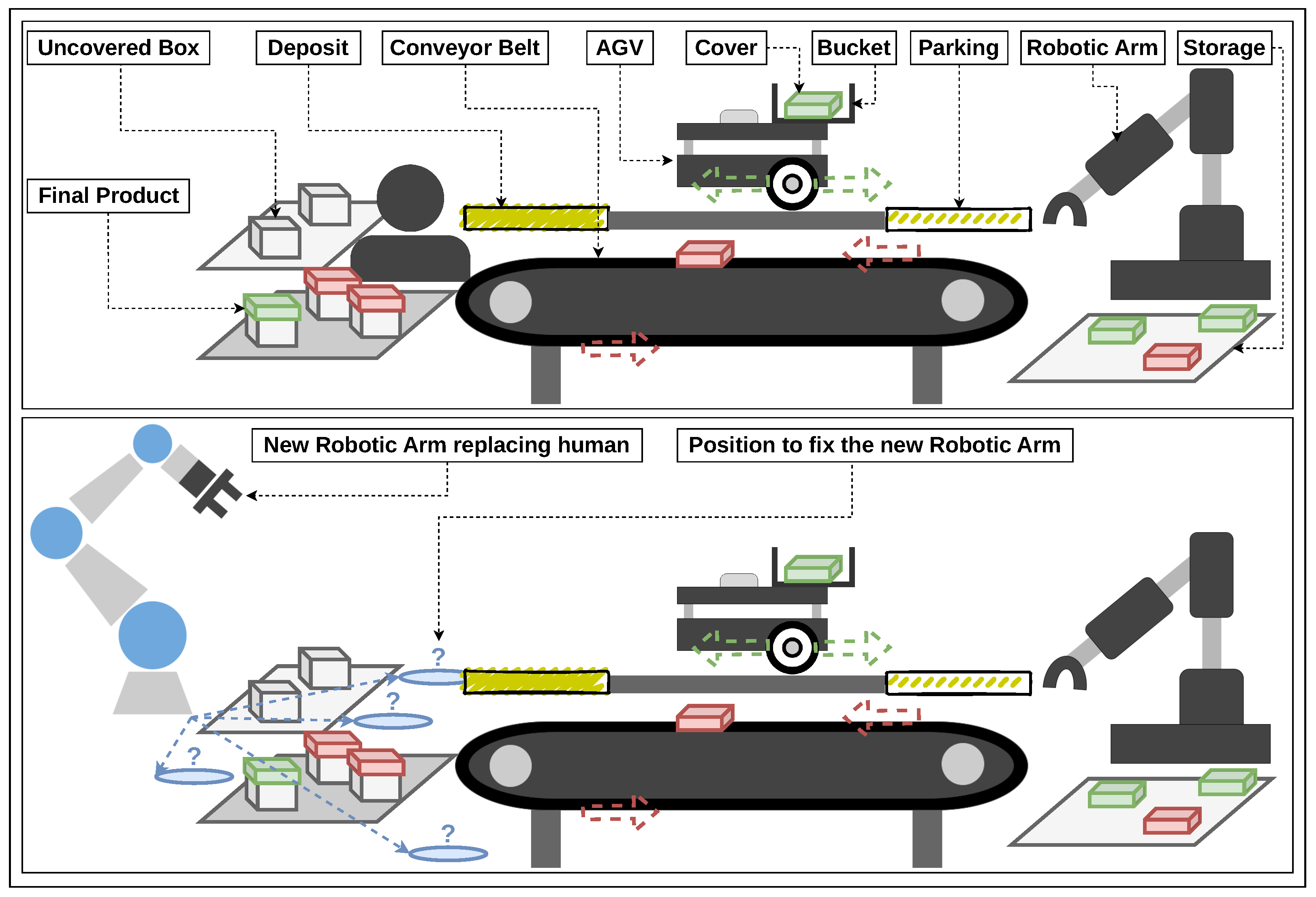

- Module 1—Work Cell: This includes physical devices of the original PAL system as in Figure 7. Note that the new robotic arm is not yet in this PAL system.

- Module 2—3D DTs: This includes 3D DTs running on the physical simulation generated by XDE Physics.

- Module 3—AAS DTs: This includes AAS DTs running on an AAS server generated by P4M.

- Module 4—Networking: This includes network hardware and software that guarantee the communication between Module 1, Module 2, and Module 3. Tag 4a in Figure 8 means that Module 1, Module 2, and Module 3 can connect and disconnect. For example, Module 1 can connect with Module 2, and they are disconnected when necessary. Tag 4b clarifies that the technologies behind Module 4 are OPC UA and TSN, and the infrastructures after them are an OPC UA server and TSN devices configured by NEON. In detail:

- ∘

- OPC UA is a multipart standard for deploying industrial systems [31]. It has two contributions to the architecture. The first contribution is the OPC UA address space running on the OPC UA server that represents resources of the PAL system. Second, OPC UA network protocols in two messaging patterns, PubSub (Publish/Subscribe) and ReqRes (Request/Response), enable the physical devices and DTs to connect to the AAS werver directly and communicate between them indirectly. In detail, AAS and 3D DTs communicate with the OPC UA server based on OPC UA ReqRes, and the physical devices in the work cell communicate with the OPC UA server relying on OPC UA PubSub. Note that the robots in the work cell are not natively compatible with OPC UA but use a solution that bridges ROS 1, ROS 2, and OPC UA PubSub [32].

- ∘

- TSN is a set of IEEE 802 standards that target low-latency and deterministic communications, especially for industrial systems [33]. In the architecture, TSN devices redistribute the bandwidth for communications between Module 1, Module 2, and Module 3. In other words, they can block/unblock or increase/decrease the bandwidth of any communication.

- Module 5—Application: This includes software programs that monitor the system. They may run on different computers. First, a BPMN orchestrator developed upon the Node-RED framework (https://nodered.org/, accessed on 1 March 2023) monitors and controls AAS DTs on the AAS server. Second, UaExpert (https://unified-automation.com/products/development-tools/uaexpert.html, accessed on 1 March 2023) works as an OPC UA client that browses the OPC UA address space of the OPC UA server to observe variables and their related information associated with the PAL system’s resources. Third, as NEON fully supports the centralized model of the TSN standard IEEE 802.1Qcc, its tool, centralized user configuration (CUC), can monitor and dynamically configure the data flows exchanged between modules.

- AAS DTs in Module 3 can connect to their corresponding physical devices in Module 1 for AAS DT validation, independently from Module 2. This feature can help AAS DT experts to test their AAS DTs without the appearance of 3D DT experts.

- 3D DTs in Module 2 can connect to their corresponding physical devices in Module 1 for 3D DT validation, independently from Module 3. This feature can help 3D DT experts test their 3D DTs without the appearance of AAS DT experts.

- AAS DTs in Module 3 can connect to their corresponding 3D DTs in Module 2 for group validation, independently from Module 1. This feature enables the remote testing of AAS and 3D DTs: the DT experts do not need to be available at the testbed.

- Module 1, Module 2, and Module 3 can collaborate simultaneously. It is practical for feasibility-checking framework validation.

5.2. Engineering the Feasibility-Checking Framework of the PAL Case Study

- Datasheets of the four major resources were easily downloaded from the vendors’ websites. However, since no datasheets of the three minor resources were available, one member of the development team manually measured them and noted the measurements in a document. For example, the member measured the table’s length, width, and height with a ruler and then noted them down.

- The historical dataset related to the original PAL system was retrieved from a database of the work cell’s OPC UA server. The dataset includes many data instances generated by the NNED, T3WP, and CBELT while operating the manufacturing process. In detail, the data of NNED are its six joints’ actual position and speed values, the data of T3WP are its two wheels’ actual position and speed values, and the data of CBELT are its speed values.

- The AAS DT prototypes of robotic arms and AGVs in UML format were downloaded privately from an LSEA’s local server. Concerning the 3D DTs, the CAD prototypes in STEP (Standard for the Exchange of Product Data) or STL (Standard Triangle Language) format of NNED, T3WP, and UR3e were downloaded from the vendors’ websites. Their URDF files could also be found on the Internet.

- The specification document, including the functional and non-functional requirements, was produced after the kickoff meeting. The document indicates that the privilege of the project is the functional objective. The non-functional factors, such as performance or productivity, are optional.

- In the design steps, AAS DT models were designed in the P4M modeling environment using the modeling languages supported by this toolset. P4M especially proposes a new graphic modeling diagram called the AAS design diagram (ADD or add), which is compatible with the AAS specification version 3.0RC01 [34]. Figure 9 is a screenshot of the P4M modeling environment that allows users to input the information to fulfill an AAS model design. It is worth mentioning that the design content relies on the AAS DT experts’ experiences and the study at the specification step. In this case study, ADD and BPMN were used as follows.

- ∘

- Figure 10 illustrates the AAS T3WP modeled in ADD. This AAS DT has five submodels: Nameplate and TechnicalProperties describe the basic information of the AGV; Bucket has the property Loaded which indicates if the bucket on top of T3WP is carrying a box cover or not; Capabilities includes the only capability of T3WP, which is Transporting; Skills lists the operations that T3WP can operate (moving forward to the deposit position, moving backward to the storage position, and turning on/off), and two properties Mission and OperationStatus indicate the robot’s current operation and the status of the last operation. The capability Transporting links to the BPMN process diagram Transporting as in Figure 11. This BPMN diagram includes a chain of service tasks representing the subprocesses needed to fulfill the capability Transporting. Each subprocess occurs when calling its associated skill. For example, the BPMN service task CALL moveToDeposit represents the process that the T3WP moves to the deposit, which happens when calling the operation moveToDeposit of AAS T3WP.

- ∘

- Figure 12 illustrates the AAS PAL Process modeled in ADD. This AAS DT has three submodels: Configuration holds context information to set up the manufacturing process, which is the position of UR3e in this case; Counter contains a property that counts the number of delivered products; Service contains the BoxManufacturing service, which links to the BPMN process diagram Box Manufacturing as in Figure 13. This BPMN diagram includes a chain of three service tasks representing three capabilities required by the service BoxManufacturing. The required capability Transporting of AAS PAL Process matches with the offered capability Transporting of AAS T3WP, which means that the T3WP can work for this service.

- In the DT Implementation steps, AAS DT experts used the P4M’s generation code feature to generate Java codes automatically from the ADD models from the design step. It is easy to trigger this feature in the P4M modeling environment with only a few clicks. Then, the experts further specified the codes with network configurations, such as the port used to listen to external applications, and compiled them to produce AAS DT running instances. The running AAS T3WP listened at port 2023 for HTTP REST requests from external applications. It communicated with the physical T3WP through the OPC UA server using OPC UA communication protocols. The running AAS PAL Process listened at port 2020 also for HTTP REST requests from external applications. The external application in this case study is the BPMN orchestrator. It was developed manually based on the BPMN diagrams in the design steps.

- In the DT validation steps, networking experts temporarily disconnected Module 2, so the AAS DTs in Module 3 connected only with the physical devices in Module 1. AAS DT experts tested each property and operation of the AAS T3WP to verify if the response from the work cell is the same as the one in the AAS DT. For example, when calling the operation moveToDeposit, the physical T3WP must move to the deposit place; when the NNED drops a box cover into the bucket of T3WP, the property Loaded of AAS T3WP has a true value. The AAS PAL Process and other AAS DTs were tested with the same method.

- In the design step, the CAD model and URDF file of T3WP are imported into XDE Physics via Unity3D. Figure 14 illustrates T3WP’s CAD model proposed by Robotis. This model has then been completed by adding a bucket onto the T3WP.

- In the DT implementation step, additional high-level methods are added to allow for simulating the motion and behaviors of the 3D T3WP. The 3D T3WP is then integrated into the physical simulation of the complete scene. Figure 15 is a screenshot of the physical simulation.

- In the DT validation step, the behavior of the 3D T3WP was first tested with historical data: the 3D T3WP consumed historical data corresponding to the desired position of the robot and moved adequately in the physical simulation. Second, it was validated with the real devices. Networking experts temporarily disconnected Module 3, so the 3D DTs in Module 2 are only connected with the physical devices in Module 1 in order to validate that the motion of the the real T3WP is mimicked in real time by the 3D T3WP in the physical simulation. The development members validated the 3D DT manually by eyes.

5.3. Feasibility-Checking Practices and Results

6. Discussion

7. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, S.J. Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef]

- Cutting-Decelle, A.; Young, R.; Michel, J.; Grangel, R.; Le Cardinal, J.; Bourey, J. ISO 15531 MANDATE: A Product-process-resource based Approach for Managing Modularity in Production Management. Concurr. Eng. 2007, 15, 217–235. [Google Scholar] [CrossRef]

- Pfrommer, J.; Schleipen, M.; Beyerer, J. PPRS: Production skills and their relation to product, process, and resource. In Proceedings of the 2013 IEEE 18th Conference on Emerging Technologies & Factory Automation (ETFA), Cagliari, Italy, 10–13 September 2013; pp. 1–4. [Google Scholar] [CrossRef]

- Koren, Y. The Global Manufacturing Revolution: Product-Process-Business Integration and Reconfigurable Systems, 1st ed.; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Höse, K.; Amaral, A.; Götze, U.; Peças, P. Manufacturing Flexibility through Industry 4.0 Technological Concepts—Impact and Assessment. Glob. J. Flex. Syst. Manag. 2023, 24, 271–289. [Google Scholar] [CrossRef]

- Bayha, A.; Bock, J.; Boss, B.; Diedrich, C.; Malakuti, S. Describing Capabilities of Industrie 4.0 Components; White Paper, Plattfrom Industrie 4.0; BMWi: Berlin, Germany, 2020. [Google Scholar]

- Diedrich, C.; Belyaev, A.; Blumenfeld, R.; Bock, J.; Grimm, S.; Hermann, J.; Klausmann, T.; Köcher, A.; Maurmaier, M.; Meixner, K.; et al. Information Model for Capabilities, Skills & Services; Discussion Paper; Plattform Industrie 4.0; BMWi: Berlin, Germany, 2022. [Google Scholar]

- ISO/IEC 30173:2023-11; Digital twin—Concepts and Terminology. International Organization for Standardization: Geneva, Switzerland, 2023.

- Industrial Digital Twin Association. Asset Administration Shell Specification—Part 1: Metamodel Schema; Specification IDTA Number: 01001-3-0; Industrial Digital Twin Association: Frankfurt am Main, Germany, 2023. [Google Scholar]

- ANSI/ISA-95.00.01-2010; Enterprise-Control System Integration—Part 1: Models and Terminology. American National Standards Institute: Research Triangle Park, NC, USA, 2010.

- Huang, Y.; Dhouib, S.; Malenfant, J. An AAS Modeling Tool for Capability-Based Engineering of Flexible Production Lines. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021; pp. 1–6, ISSN 2577-1647. [Google Scholar] [CrossRef]

- Drath, R.; Weber, P.; Mauser, N. An evolutionary approach for the industrial introduction of virtual commissioning. In Proceedings of the 2008 IEEE International Conference on Emerging Technologies and Factory Automation, Hamburg, Germany, 15–18 September 2008; pp. 5–8. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication; White Paper; Dassault Systèmes: Vélizy-Villacoublay, France, 2014. [Google Scholar]

- Damrath, F.; Strahilov, A.; Bär, T.; Vielhaber, M. Establishing Energy Efficiency as Criterion for Virtual Commissioning of Automated Assembly Systems. Procedia CIRP 2014, 23, 137–142. [Google Scholar] [CrossRef]

- Sub, S.; Magnus, S.; Thron, M.; Zipper, H.; Odefey, U.; Fassler, V.; Strahilov, A.; Klodowski, A.; Bar, T.; Diedrich, C. Test methodology for virtual commissioning based on behaviour simulation of production systems. In Proceedings of the 2016 IEEE 21st International Conference on Emerging Technologies and Factory Automation (ETFA), Berlin, Germany, 6–9 September 2016; pp. 1–9. [Google Scholar] [CrossRef]

- Bedenbender, H.; Bentkus, A.; Epple, U.; Hadlich, T.; Heidel, R.; Hiller-meier, O.; Hoffmeister, M.; Huhle, H.; Kiele-Dunsche, M.; Koziolek, H.; et al. Industrie 4.0 Plug-and-Produce for Adaptable Factories: Example Use Case Definition, Models, and Implementation; Working Paper; Plattform Industrie 4.0; BMWi: Berlin, Germany, 2017. [Google Scholar]

- Lechler, T.; Fischer, E.; Metzner, M.; Mayr, A.; Franke, J. Virtual Commissioning – Scientific review and exploratory use cases in advanced production systems. Procedia CIRP 2019, 81, 1125–1130. [Google Scholar] [CrossRef]

- Li, W.; Gu, S.; Zhang, X.; Chen, T. Pattern Matching and Active Simulation Method for Process Fault Diagnosis. Ind. Eng. Chem. Res. 2020, 59, 12525–12535. [Google Scholar] [CrossRef]

- Wagner, A.; Lamoth, S.; Volkmann, M.; Hermann, J.; Ruskowski, M. Interaction between FeasibilityCheck, PreconditionCheck and SkillExecution in skill-based machining. In Proceedings of the 2023 IEEE 28th International Conference on Emerging Technologies and Factory Automation (ETFA), Sinaia, Romania, 12–15 September 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Volkmann, M.; Sidorenko, A.; Wagner, A.; Hermann, J.; Legler, T.; Ruskowski, M. Integration of a feasibility and context check into an OPC UA skill. IFAC-Pap. 2021, 54, 276–281. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Muller, P.A.; Gaertner, N. Modélisation Objet Avec UML; Eyrolles: Paris, France, 2004. [Google Scholar]

- Srivastava, A.; Bhardwaj, S.; Saraswat, S. SCRUM model for agile methodology. In Proceedings of the 2017 International Conference on Computing, Communication and Automation (ICCCA), Greater Noida, 5–6 May 2017; pp. 864–869. [Google Scholar] [CrossRef]

- Dhouib, S.; Huang, Y.; Smaoui, A.; Bhanja, T.; Gezer, V. Papyrus4Manufacturing: A Model-Based Systems Engineering approach to AAS Digital Twins. In Proceedings of the 2023 IEEE 28th International Conference on Emerging Technologies and Factory Automation (ETFA), Sinaia, Romania, 12–15 September 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Lanusse, A.; Tanguy, Y.; Espinoza, H.; Mraidha, C.; Gerard, S.; Tessier, P.; Schnekenburger, R.; Dubois, H.; Terrier, F. Papyrus UML: An open source toolset for MDA. In Proceedings of the ECMDA-FA ’09: Model Driven Architecture— Foundations and Applications: 5th European Conference, ECMDA-FA 2009, Enschede, The Netherlands, 23–26 June 2009; pp. 1–4. [Google Scholar]

- Platform Industrie 4.0. Details of the Asset Administration Shell—Part 2:— Interoperability at Runtime—Exchanging Information via Application Programming Interfaces; Specification Version 1.0RC02; BMWi: Berlin, Germany, 2021. [Google Scholar]

- Merlhiot, X.; Garrec, J.L.; Saupin, G.; Andriot, C. The XDE mechanical kernel: Efficient and robust simulation of multibody dynamics with intermittent nonsmooth contacts. In Proceedings of the 2nd Joint International Conference on Multibody System Dynamics, Stuttgart, Germany, 29 May–1 June 2012; p. 84. [Google Scholar]

- Weistroffer, V.; Keith, F.; Bisiaux, A.; Andriot, C.; Lasnier, A. Using Physics-Based Digital Twins and Extended Reality for the Safety and Ergonomics Evaluation of Cobotic Workstations. Front. Virtual Real. 2022, 3, 781830. [Google Scholar] [CrossRef]

- Thomopoulos, N.T. Assembly Line Planning and Control; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Thi, M.T.; Ben Hadj Said, S.; Boc, M. SDN-Based Management Solution for Time Synchronization in TSN Networks. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 361–368. [Google Scholar] [CrossRef]

- Industry Standard Specification OPC 10000-1 R1.05.2; OPC Unified Architecture—Part 1: Overview and Concepts. OPC Foundation: Scottsdale, AZ, USA, 2023.

- Nguyen, Q.D.; Dhouib, S.; Huang, Y.; Bellot, P. An Approach to Bridge ROS 1 and ROS 2 Devices into an OPC UA-based Testbed for Industry 4.0. In Proceedings of the 2022 IEEE 1st Industrial Electronics Society Annual On-Line Conference (ONCON), kharagpur, India, 9–11 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- IEEE Std 802.1Q-2011/Cor 2-2012 (Corrigendum to IEEE Std 802.1Q-2011); IEEE Standard for Local and Metropolitan Area Networks–Media Access Control (MAC) Bridges and Virtual Bridged Local Area Networks–Corrigendum 2: Technical and Editorial Corrections. IEEE: Piscataway, NJ, USA, 2012; pp. 1–96. [CrossRef]

- Plattform Industrie 4.0. Details of the Asset Administration Shell—Part 1:— The Exchange of Information between Partners in the Value Chain of Industrie 4.0; Specification Version 3.0RC01; BMWi: Berlin, Germany, 2021. [Google Scholar]

| [12] | [13] | [14] | [15] | [16] | [17] | [18] | [19] | |

|---|---|---|---|---|---|---|---|---|

| Engineering Stage | ● | ● | ● | |||||

| Production Stage | ● | ● | ● | ● | ● | ● | ||

| Graphical Simulation | ● | ● | ● | ● | ● | |||

| Pattern Matching | ● | ● | ||||||

| Mathematical–Physical Calculation | ● | ● | ○ | |||||

| Digital Twin | ● | ● | ○ |

where

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, Q.-D.; Huang, Y.; Keith, F.; Leroy, C.; Thi, M.-T.; Dhouib, S. Manufacturing 4.0: Checking the Feasibility of a Work Cell Using Asset Administration Shell and Physics-Based Three-Dimensional Digital Twins. Machines 2024, 12, 95. https://doi.org/10.3390/machines12020095

Nguyen Q-D, Huang Y, Keith F, Leroy C, Thi M-T, Dhouib S. Manufacturing 4.0: Checking the Feasibility of a Work Cell Using Asset Administration Shell and Physics-Based Three-Dimensional Digital Twins. Machines. 2024; 12(2):95. https://doi.org/10.3390/machines12020095

Chicago/Turabian StyleNguyen, Quang-Duy, Yining Huang, François Keith, Christophe Leroy, Minh-Thuyen Thi, and Saadia Dhouib. 2024. "Manufacturing 4.0: Checking the Feasibility of a Work Cell Using Asset Administration Shell and Physics-Based Three-Dimensional Digital Twins" Machines 12, no. 2: 95. https://doi.org/10.3390/machines12020095

APA StyleNguyen, Q.-D., Huang, Y., Keith, F., Leroy, C., Thi, M.-T., & Dhouib, S. (2024). Manufacturing 4.0: Checking the Feasibility of a Work Cell Using Asset Administration Shell and Physics-Based Three-Dimensional Digital Twins. Machines, 12(2), 95. https://doi.org/10.3390/machines12020095