Cutting Performance and Tool Wear of AlCrN- and TiAlN-Coated Carbide Tools during Milling of Tantalum–Tungsten Alloy

Abstract

:1. Introduction

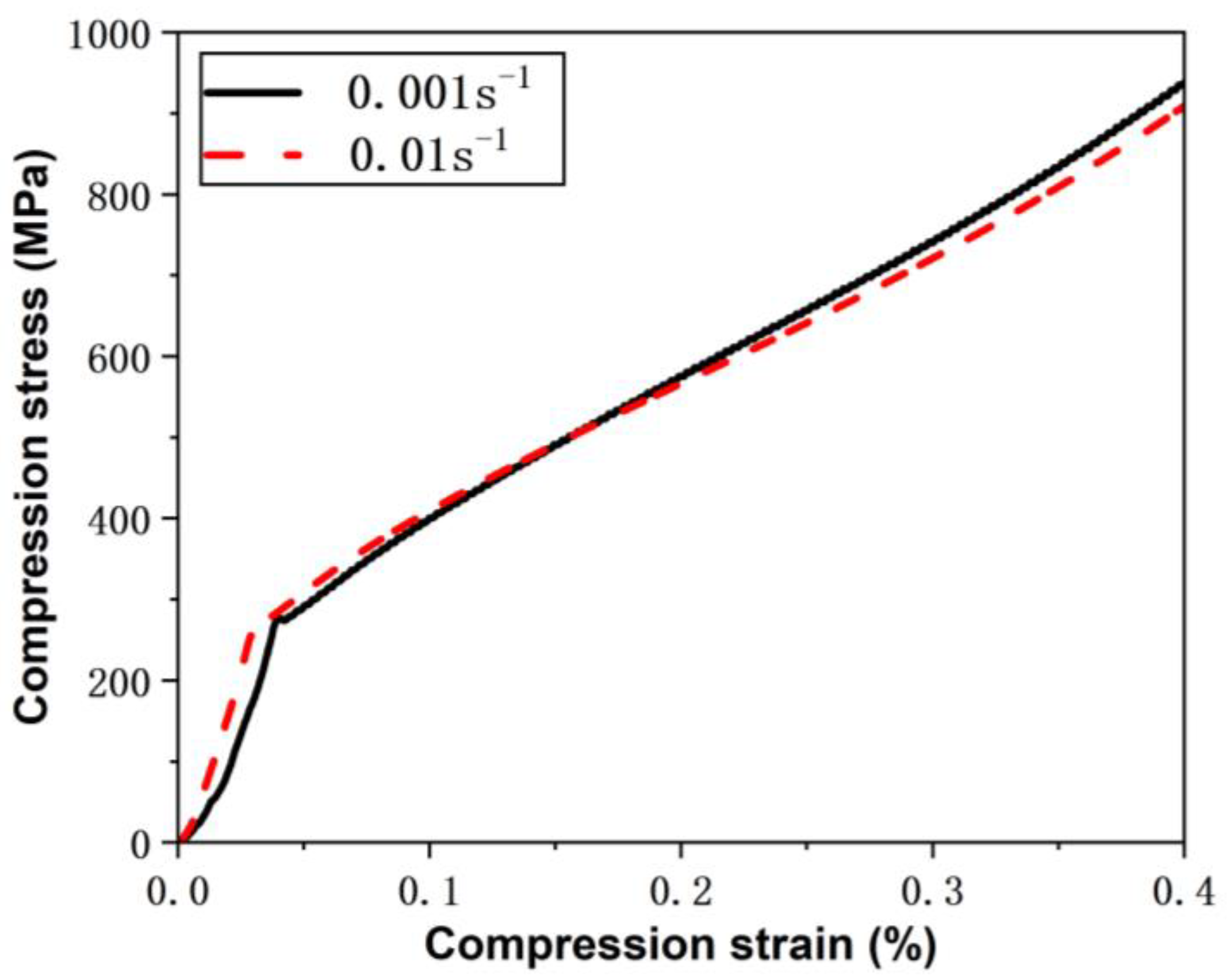

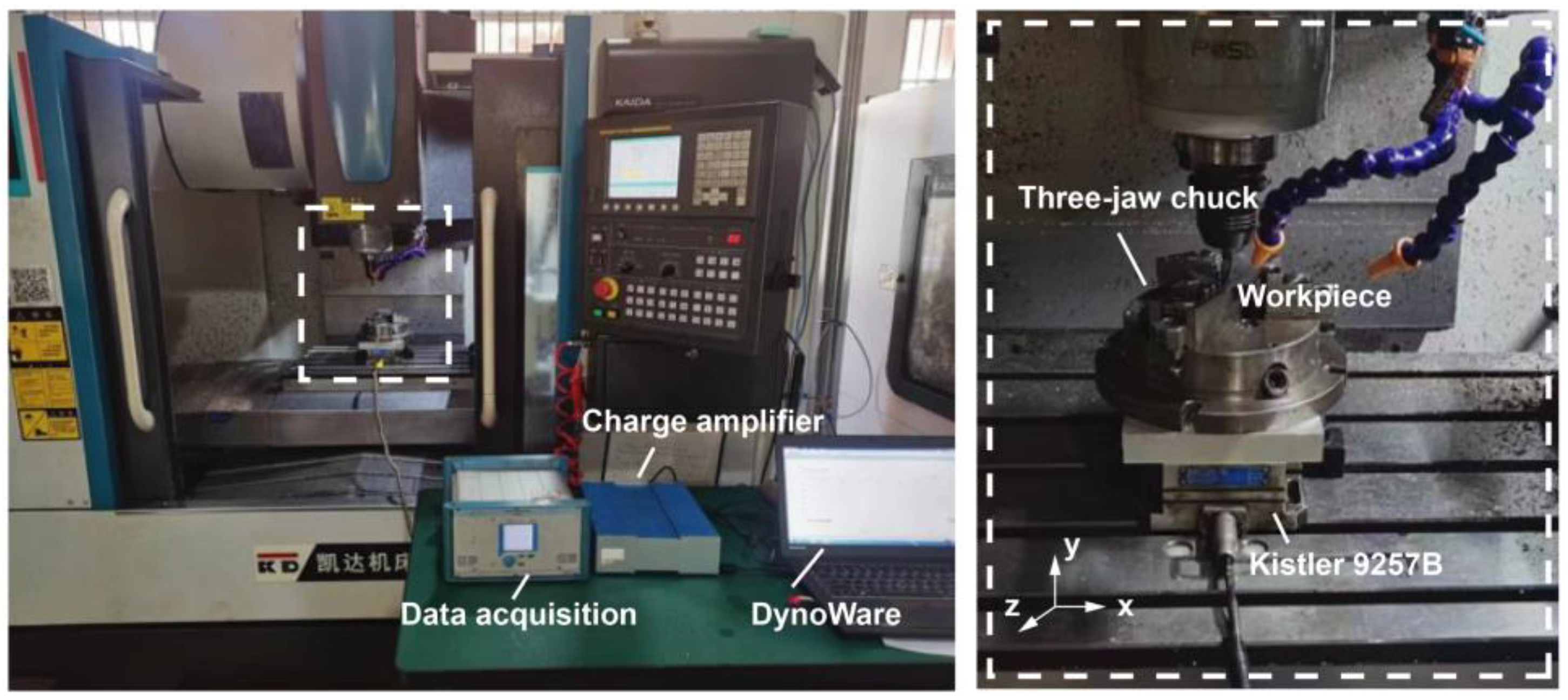

2. Materials and Methods

3. Results and Discussion

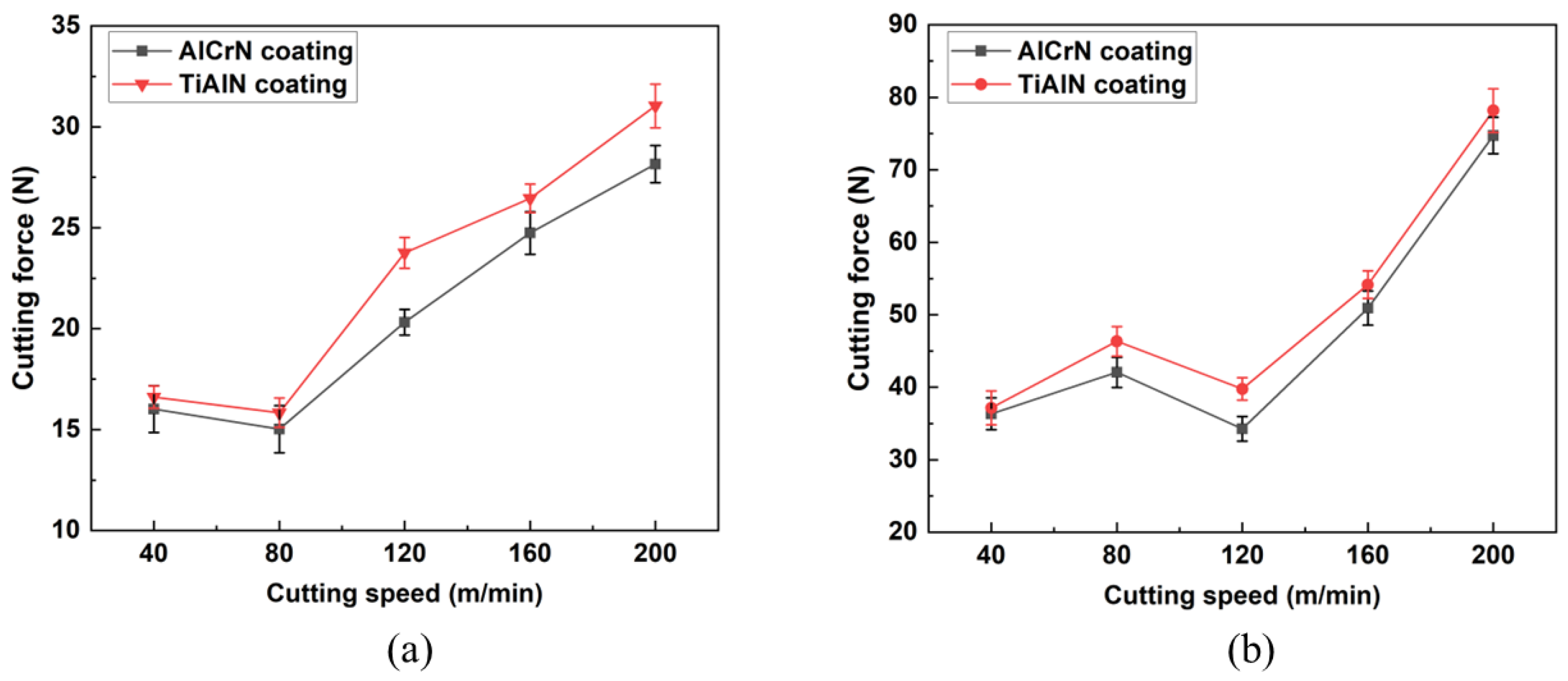

3.1. Cutting Forces

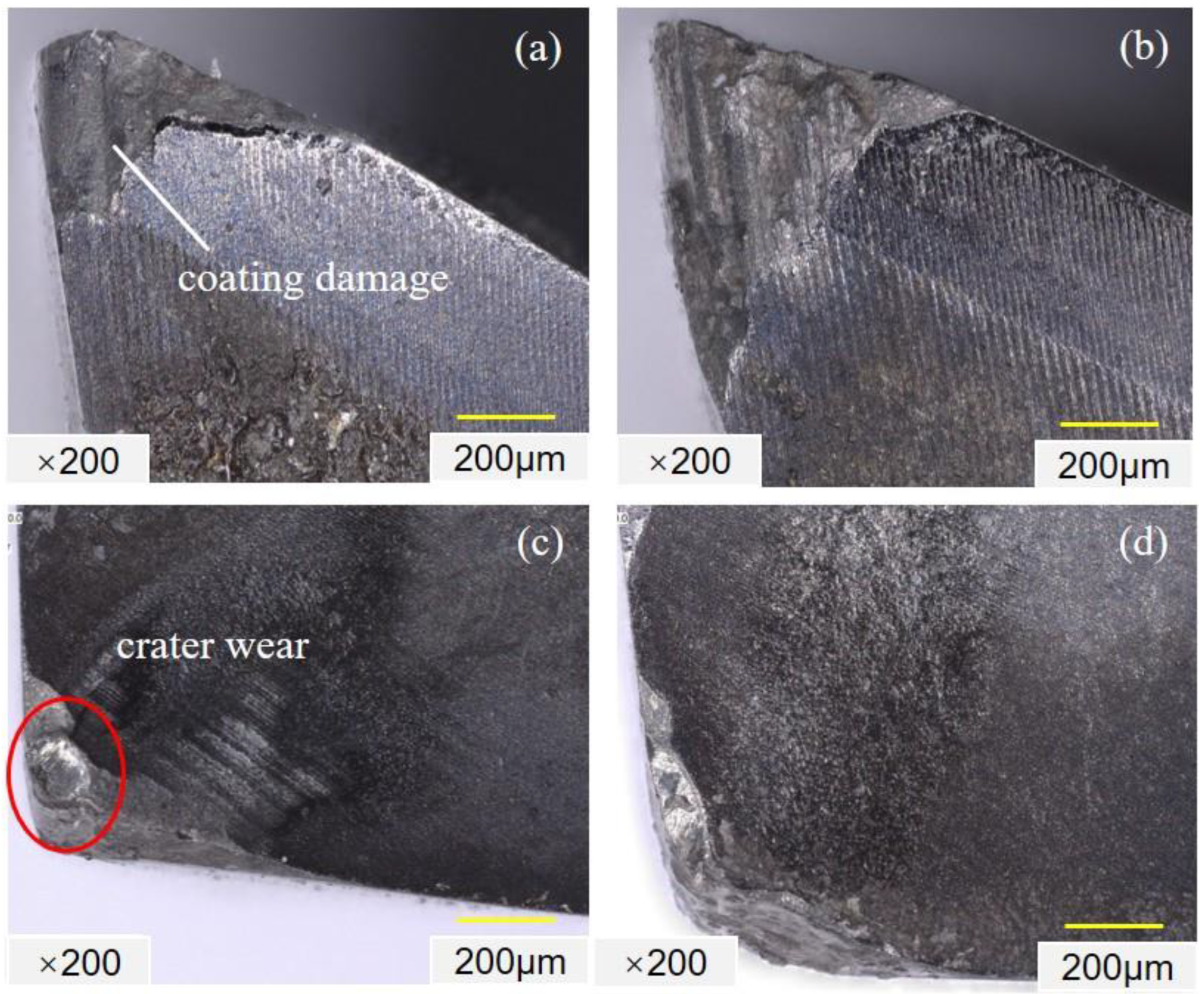

3.2. The Condition of the Tool’s Surface Wear

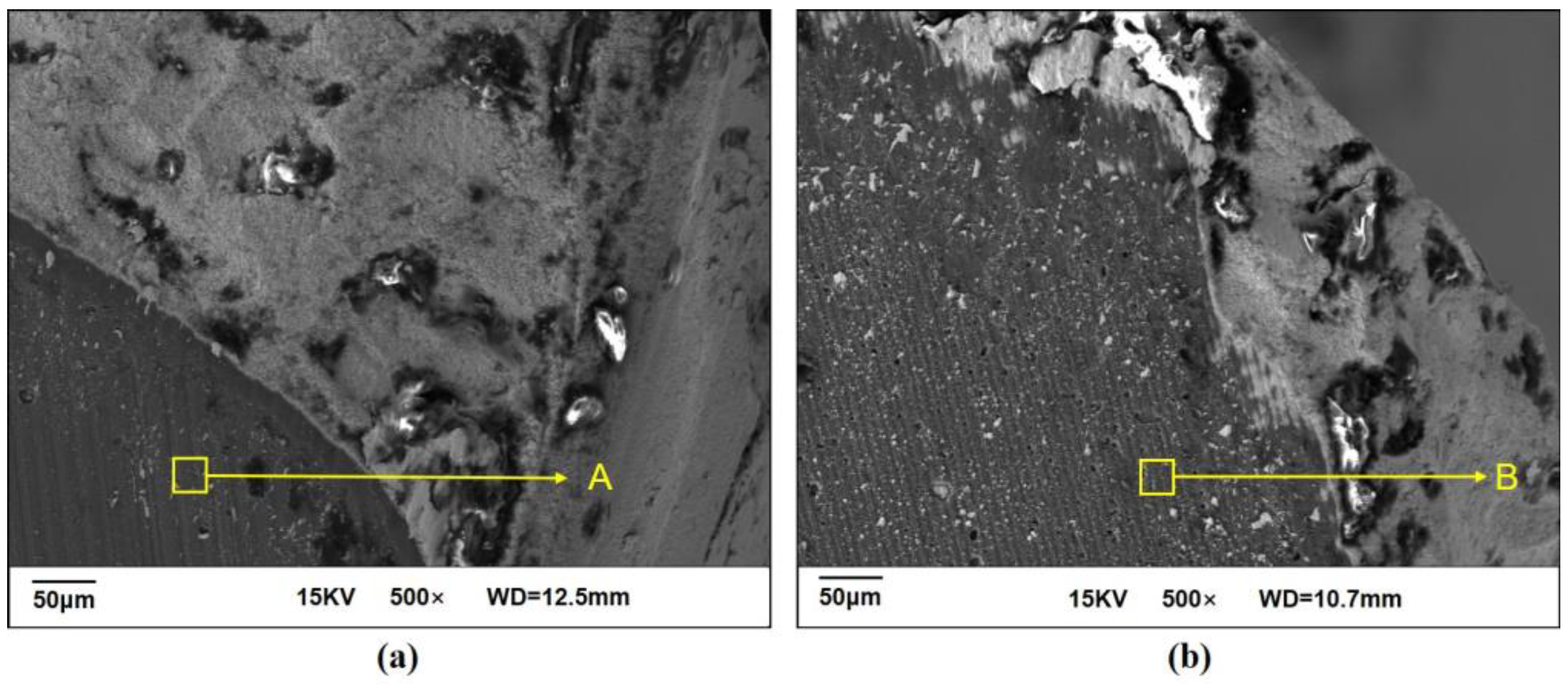

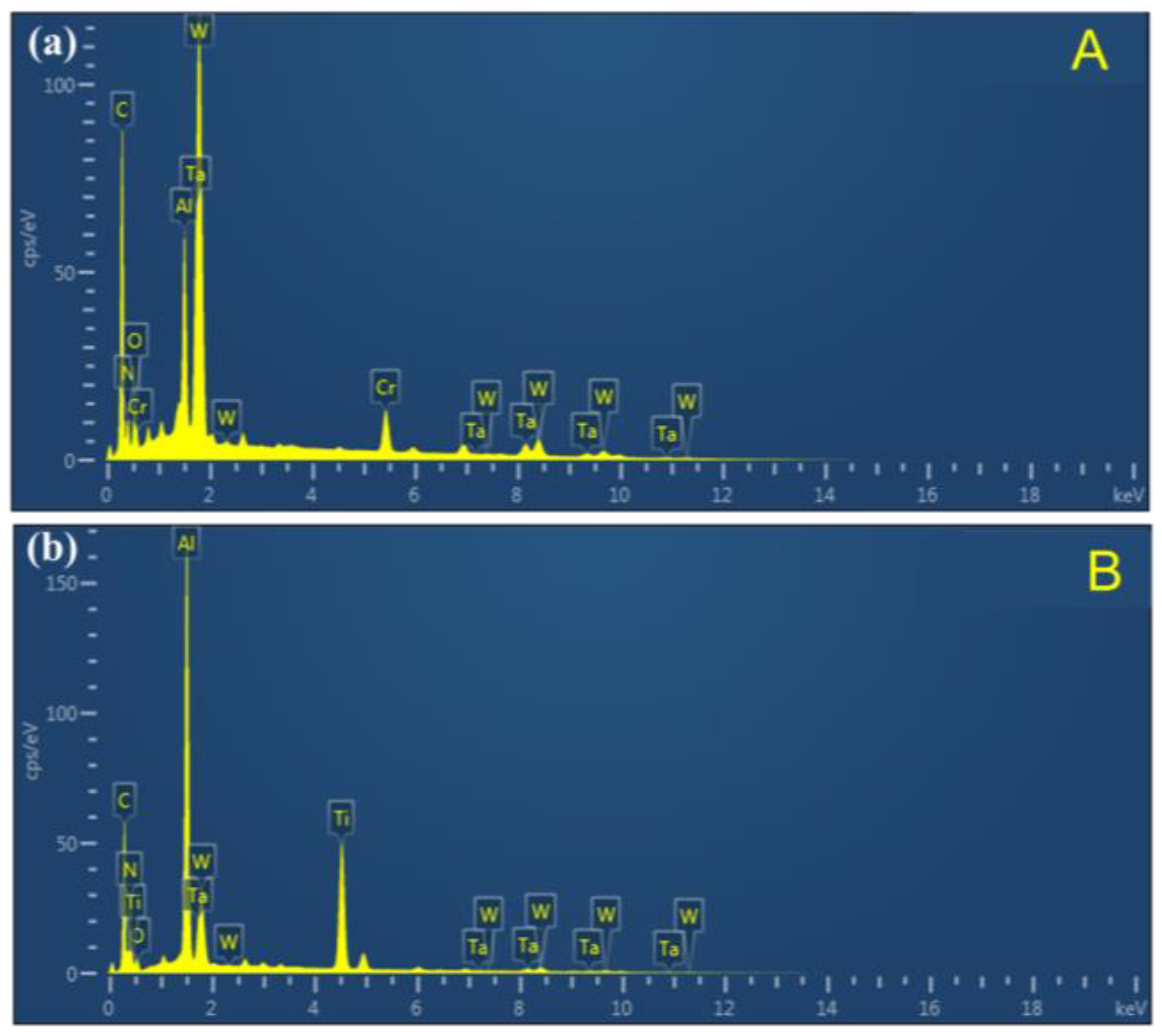

3.3. Tool Wear Behavior and Its Related Mechanism

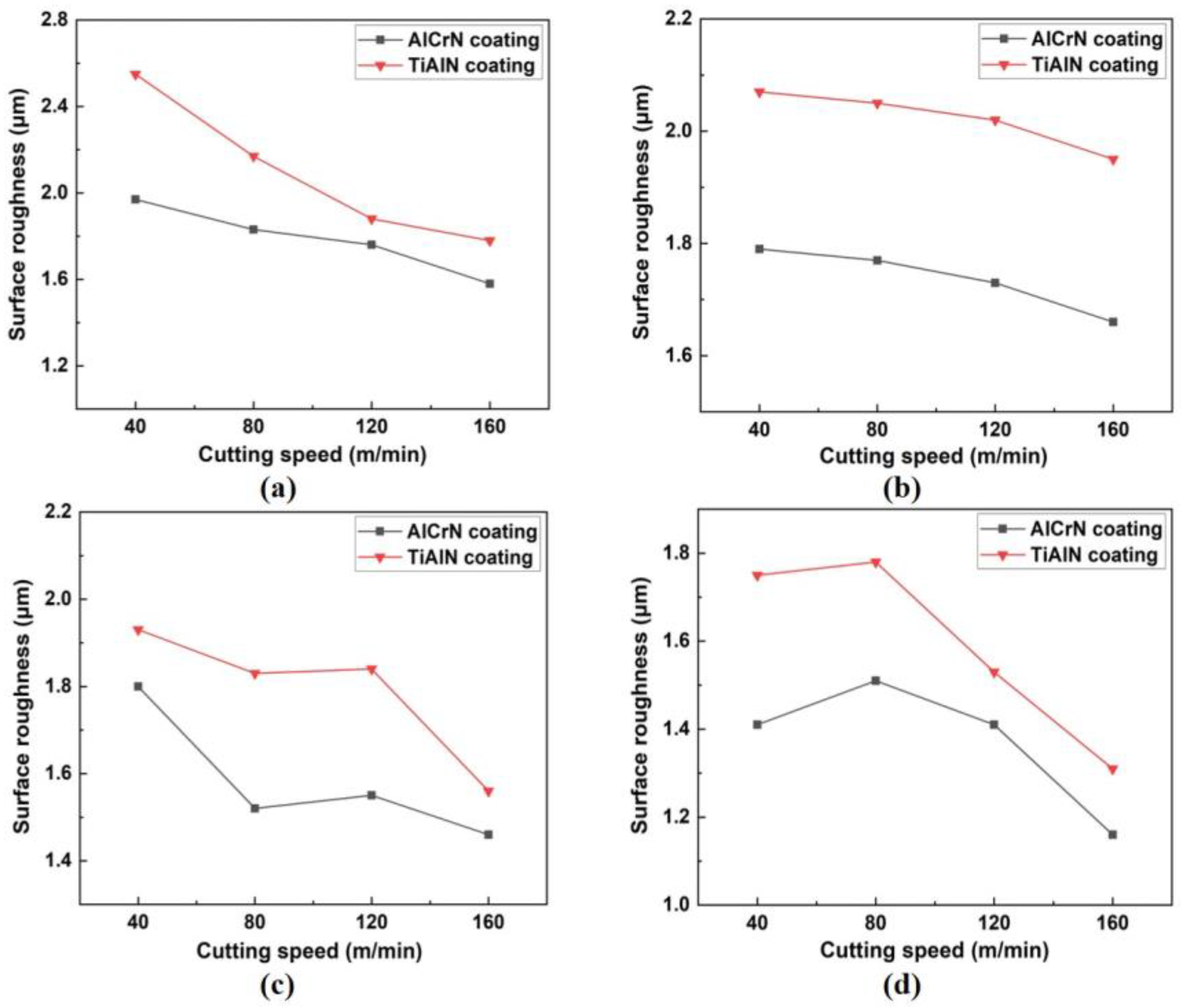

3.4. Surface Roughness

4. Conclusions

- (1).

- During the milling of tantalum–tungsten alloy Ta-2.5W at a low cutting speed, the high plasticity of the material frequently leads to the adherence of chips to the cutting tool, forming a BUE and deteriorating the surface roughness. As the cutting speed increases, the work-hardening effect intensifies, resulting in enhanced material strength and reduced plasticity, which in turn causes a rapid increase in the cutting forces and an improvement in surface roughness.

- (2).

- When machining tantalum–tungsten alloy Ta-2.5W, the superior hardness and exceptional wear resistance of AlCrN coatings stabilize the cutting edge more effectively than TiAlN-coated tools; this results in a reduction in cutting forces by 1% to 15% and a decrease in surface roughness by 6% to 20%.

- (3).

- Under dry milling conditions of Ta-2.5W at a cutting speed of 120 m/min, feed rate of 0.2 mm/r, cutting depth of 0.4 mm, and cutting width of 2 mm, the primary wear observed on both coatings was concentrated on the flank face, with similar wear magnitudes observed. However, at the rake face, AlCrN coatings demonstrated superior wear resistance. Furthermore, the main wear mechanisms of AlCrN-coated and TiAlN-coated tools were crater wear, adhesive wear, and diffusion wear.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, G.; Wei, Z.; Wu, G.; Mao, X. The microstructure and strength of a tantalum alloy: Influence of temperature. Mater. Sci. Eng. A 2023, 880, 145312. [Google Scholar] [CrossRef]

- Agrawal, M.; Jha, R.; Singh, K.K.; Singh, R. Optimization of Leaching Parameters for Recovery of Tantalum from Waste Tantalum Capacitors. In Springer Proceedings in Physics: Proceedings of the 3rd International Conference on Advances in Materials Processing: Challenges and Opportunities, Roorkee, India, 17–19 October 2023; Springer Nature Singapore: Singapore, 2023; Volume 293, pp. 213–218. [Google Scholar] [CrossRef]

- Stelmakh, V.; Rinnerbauer, V.; Chan, W.R.; Senkevich, J.J.; Joannopoulos, J.D.; Soljacic, M.; Celanovic, I. Tantalum-tungsten alloy photonic crystals for high-temperature energy conversion systems. Conf. Photonic Cryst. Mater. Devices 2014, 9127, 116–124. [Google Scholar] [CrossRef]

- Liu, G.; Gu, X.; Heng, F.; Men, J. Microstructure evolution and deformation mechanism with comparison of Ta-2.5 W and Cu under detonation load. Mater. Today Commun. 2024, 38, 107737. [Google Scholar] [CrossRef]

- Cheng, C.; Fu, Y.; Du, C.; Du, Z.; Jiang, Z.; Zhou, F.; Zhong, K.; Wang, X. Experimental and numerical study of tantalum-tungsten alloy rod penetrator impacting thick armor plate. Int. J. Refract. Met. Hard Mater. 2022, 107, 105873. [Google Scholar] [CrossRef]

- Chen, S.R.; Gray, G.T. Constitutive behavior of tantalum and tantalum-tungsten alloys. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 1996, 27, 2994–3006. [Google Scholar] [CrossRef]

- Davis, J.M.; Saei, M.; Mohanty, D.P.; Udupa, A.; Sugihara, T.; Chandrasekar, S. Cutting of tantalum: Why it is so difficult and what can be done about it. Int. J. Mach. Tools Manuf. 2020, 157, 103607. [Google Scholar] [CrossRef]

- Burgess, J.W. Wear of Nanostructured Tool Coatings Bonded to Turning Inserts Dry Turning a Tantalum Tungsten Alloy; Purdue University: West Lafayette, IN, USA, 2009; p. 145. [Google Scholar]

- Li, W.J.; Zhou, B.W.; Xing, L.J.; He, H.; Ni, X.J.; Li, M.J.; Gong, Z.H. Influence of cutting parameters and tool nose radius on the wear behavior of coated carbide tool when turning austenitic stainless steel. Mater. Today Commun. 2023, 37, 107349. [Google Scholar] [CrossRef]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat generation and temperature prediction in metal cutting: A review and implications for high speed machining. Int. J. Mach. Tools Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Fei, G.; Zhang, X.; Ahmad, S.; Wang, M.Y.; Li, L.; Xiong, W.; Zhang, J. Dynamic Behavior and Constitutive Model for Two Tantalum-Tungsten Alloys under Elevated Strain Rates. Rare Met. Mater. Eng. 2017, 46, 2753–2762. [Google Scholar] [CrossRef]

- Gourdin, W.H.; Lassila, D.H.; Leblanc, M.M.; Shields, A.L. The influence of tungsten alloying on the mechanical-properties of tantalum. J. De Phys. LV 1994, 4, 207–212. [Google Scholar] [CrossRef]

- Khan, A.S.; Liang, R. Behaviors of Three BCC Metal Over a Wide Range of Strain Ratesand Temperatures Experiments and Modeling. Int. J. Plast. 1999, 15, 1089–1109. [Google Scholar] [CrossRef]

- Zhou, J.; Khan, A.S.; Cai, R.; Chen, L. Comparative study on constitutive modeling of tantalum and tantalum tungsten alloy. J. Iron Steel Res. Int. 2006, 13, 68–74. [Google Scholar] [CrossRef]

- Wang, Z.; Rajurkar, K.P.; Fan, J.; Petrescu, G. Cryogenic machining of tantalum. J. Manuf. Process. 2002, 4, 122–127. [Google Scholar] [CrossRef]

- Mizutani, M.; Naruse, T.; Kameyama, Y.; Koma, Y.; Ohmori, H.; Sasaki, C. Fabrication of cutting tools for ultraprecision machining of tantalum and their cutting characteristics. J. Vac. Sci. Technol. B 2009, 27, 1367–1369. [Google Scholar] [CrossRef]

- Wang, R.; Wang, X.; Yan, P.; Zhou, T.; Jiao, L.; Teng, L.; Zhao, B. The effects of cryogenic cooling on tool wear and chip morphology in turning of tantalum-tungsten alloys Ta-2.5W. J. Manuf. Process. 2023, 86, 152–162. [Google Scholar] [CrossRef]

- Umut, K.; Erhan, B. Investigating effects of milling conditions on cutting temperatures through analytical and experimental methods. J. Mater. Process. Technol. 2017, 262, 532–580. [Google Scholar] [CrossRef]

- He, H.B.; Li, H.Y.; Zhang, X.Y.; Yue, Q.B.; Zhang, J.; Ma, L.; Li, Y.M. Research on the Cutting Performances and Wear Mechanisms of TiAlCrN Coated Tools During Dry Turning. Int. J. Precis. Eng. Manuf. 2019, 20, 201–207. [Google Scholar] [CrossRef]

- Das, S.; Dhupal, D.; Kumar, A. Experimental investigation into machinability of hardened AISI 4140 steel using TiN coated ceramic tool. Measurement 2015, 62, 108–126. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Effect of chip sliding velocity and temperature on the wear behaviour of PVD AlCrN and AlTiN coated mixed alumina cutting tools during turning of hardened steel. Surf. Coat. Technol. 2018, 334, 509–525. [Google Scholar] [CrossRef]

- Lazarus, L.J. Topical report: Tantalum-2.5% tungsten machinability testing. Honeywell Fed. Manuf. Technol. 2009, 12–13. [Google Scholar] [CrossRef]

- Iram, S.; Cai, F.; Wang, J.; Zhang, J.; Liang, J.; Ahmad, F.; Zhang, S. Effect of Addition of Mo or V on the Structure and Cutting Performance of AlCrN-Based Coatings. Coatings 2020, 10, 298. [Google Scholar] [CrossRef]

| Elements | W | C | N | H | O | Fe | Ti | Nb | Ta |

|---|---|---|---|---|---|---|---|---|---|

| Wt (%) | 2.75 | 0.01 | 0.01 | 0.0015 | 0.015 | 0.01 | 0.01 | 0.5 | BAL |

| Factors | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Cutting speed (m/min) | 40 | 80 | 120 | 160 | 200 |

| Feed per tooth (mm/r) | 0.1 | 0.2 | — | — | — |

| Axial depth of cut (mm) | 0.2 | 0.4 | — | — | — |

| Radial depth of cut (mm) | 1 | 2 | — | — | — |

| Element | Weight Percentage (%) |

|---|---|

| C | 34.73 |

| O | 4.14 |

| Al | 4.71 |

| Cr | 6.24 |

| Ta | 14.18 |

| W | 28.90 |

| N | 7.09 |

| Element | Weight Percentage (%) |

|---|---|

| C | 27.12 |

| O | 3.00 |

| Al | 16.81 |

| Ti | 20.60 |

| Ta | 5.25 |

| W | 8.60 |

| N | 18.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Liu, Z.; Wu, Y.; Wang, Q.; Shu, D. Cutting Performance and Tool Wear of AlCrN- and TiAlN-Coated Carbide Tools during Milling of Tantalum–Tungsten Alloy. Machines 2024, 12, 170. https://doi.org/10.3390/machines12030170

Wang J, Liu Z, Wu Y, Wang Q, Shu D. Cutting Performance and Tool Wear of AlCrN- and TiAlN-Coated Carbide Tools during Milling of Tantalum–Tungsten Alloy. Machines. 2024; 12(3):170. https://doi.org/10.3390/machines12030170

Chicago/Turabian StyleWang, Jiahao, Zhengqing Liu, Yang Wu, Qiucheng Wang, and Dayu Shu. 2024. "Cutting Performance and Tool Wear of AlCrN- and TiAlN-Coated Carbide Tools during Milling of Tantalum–Tungsten Alloy" Machines 12, no. 3: 170. https://doi.org/10.3390/machines12030170

APA StyleWang, J., Liu, Z., Wu, Y., Wang, Q., & Shu, D. (2024). Cutting Performance and Tool Wear of AlCrN- and TiAlN-Coated Carbide Tools during Milling of Tantalum–Tungsten Alloy. Machines, 12(3), 170. https://doi.org/10.3390/machines12030170