Optimizing Machining Efficiency in High-Speed Milling of Super Duplex Stainless Steel with SiAlON Ceramic Inserts

Abstract

:1. Introduction

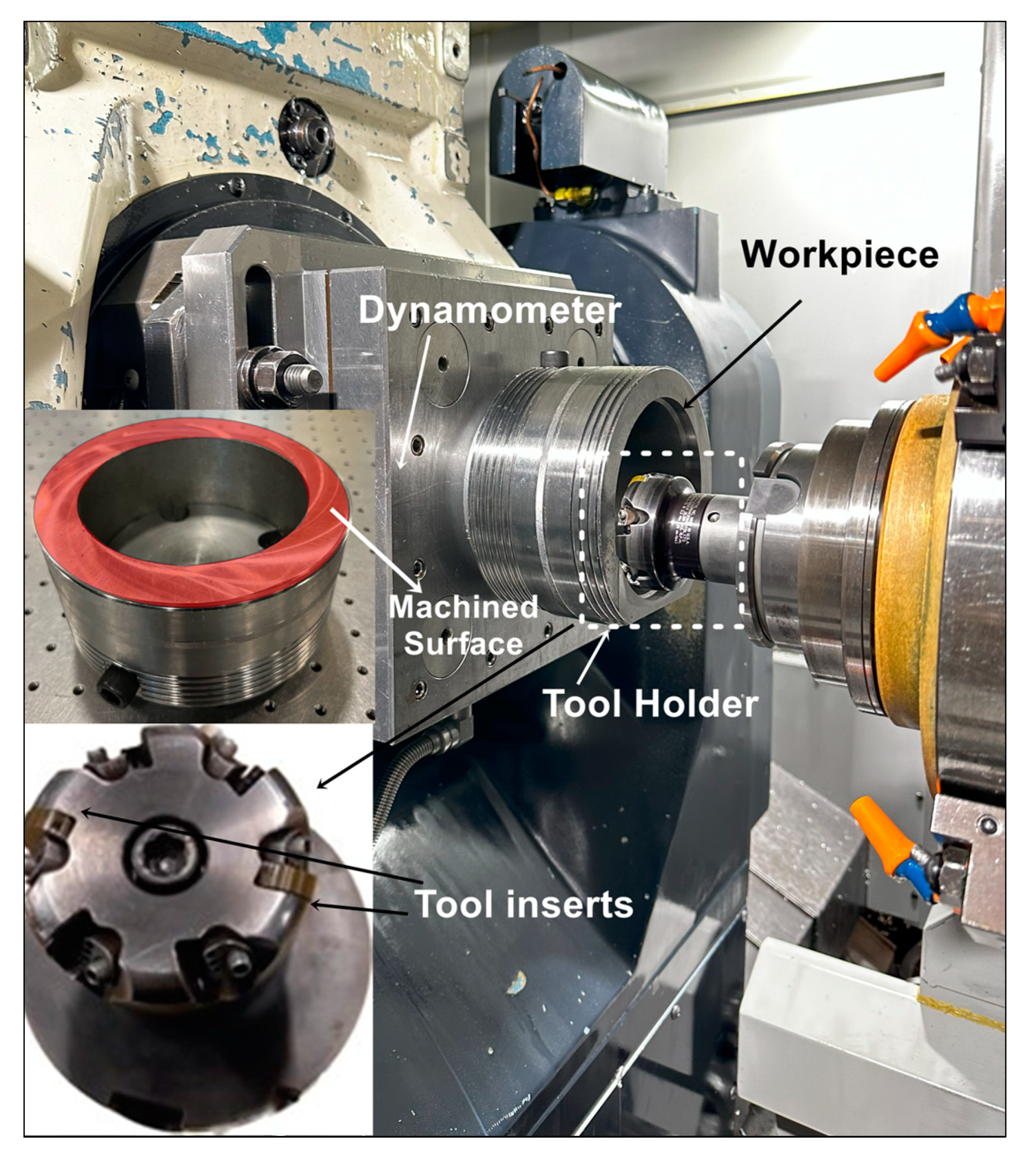

2. Methodology

3. Results and Discussion

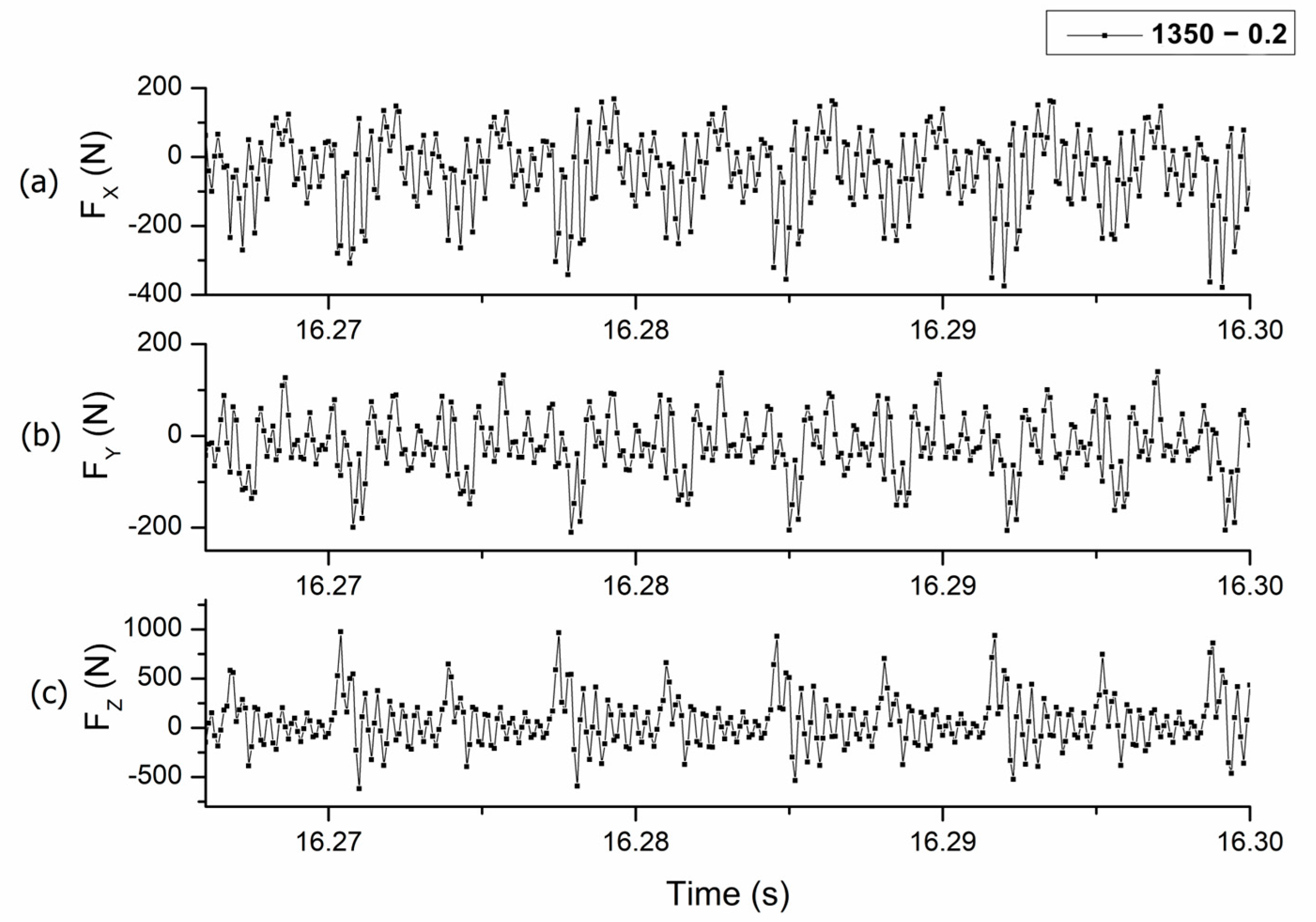

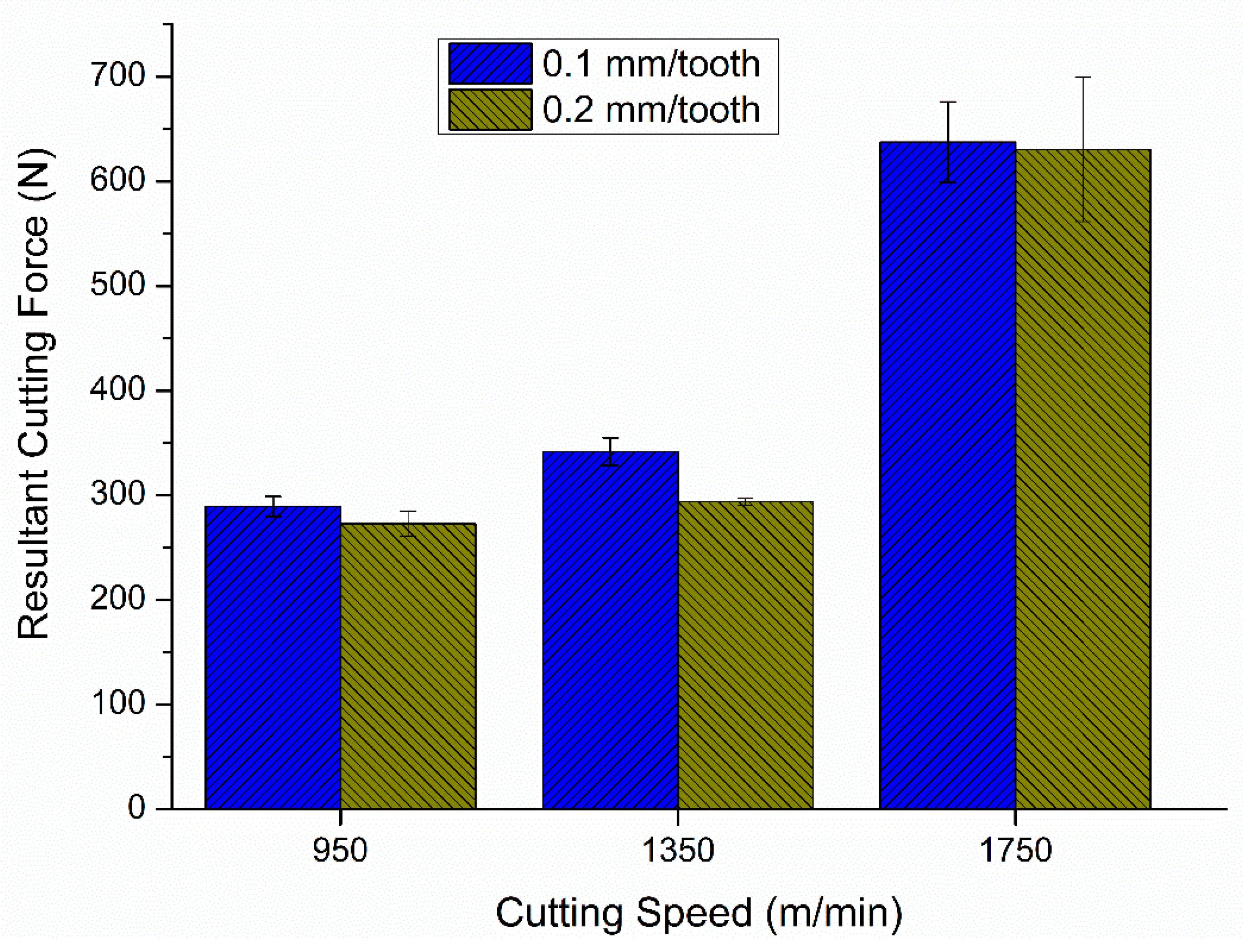

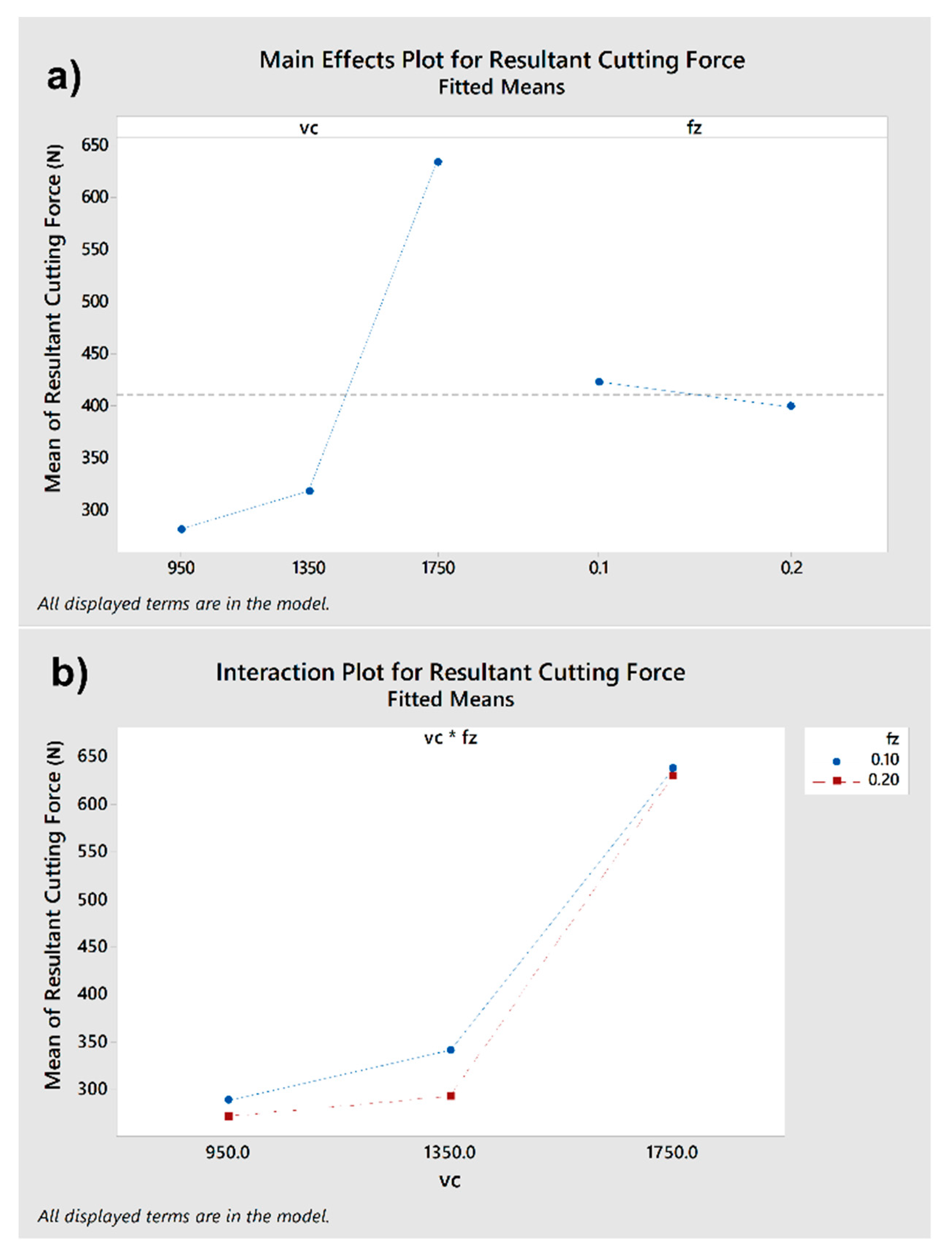

3.1. Cutting Forces

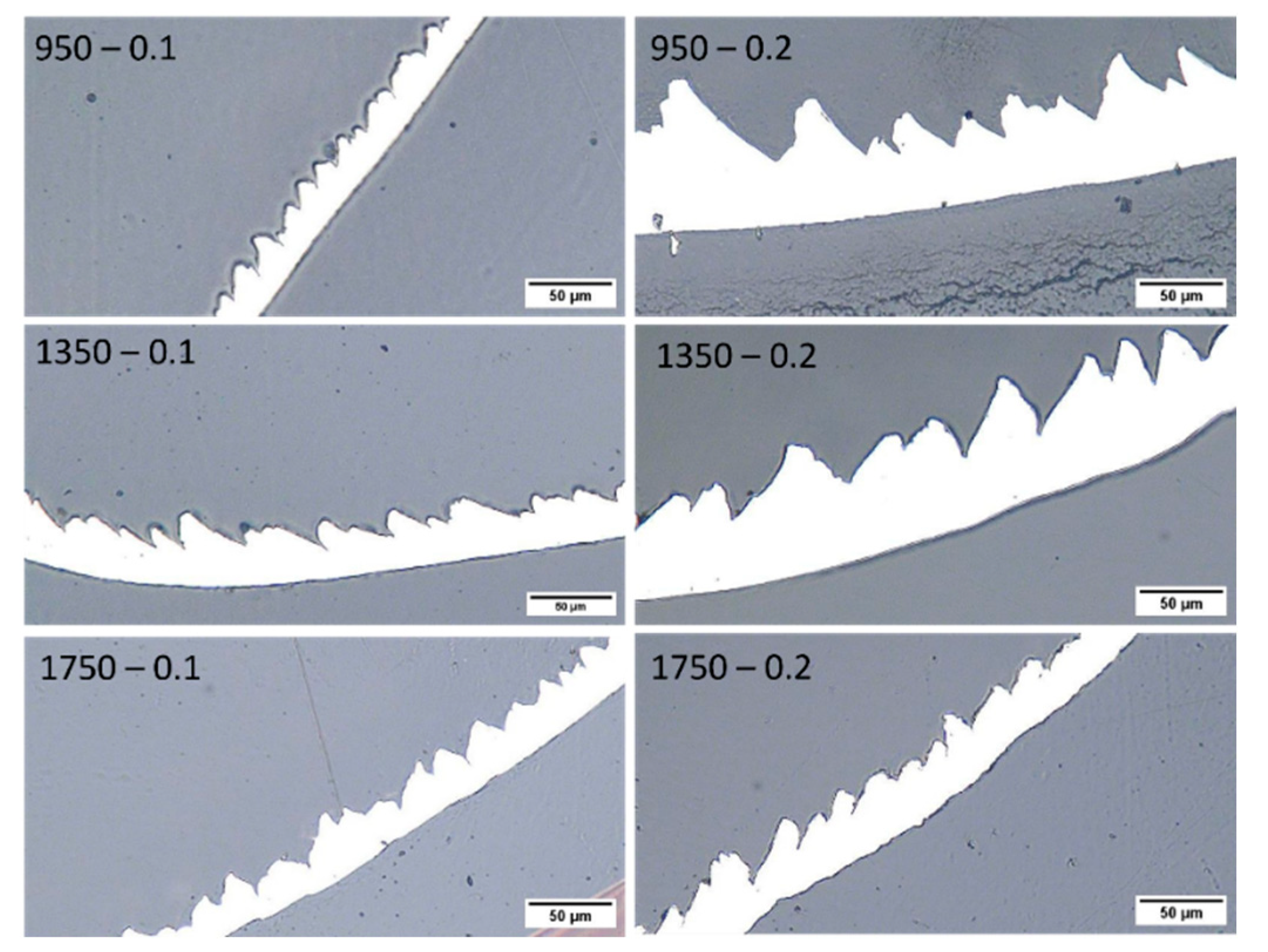

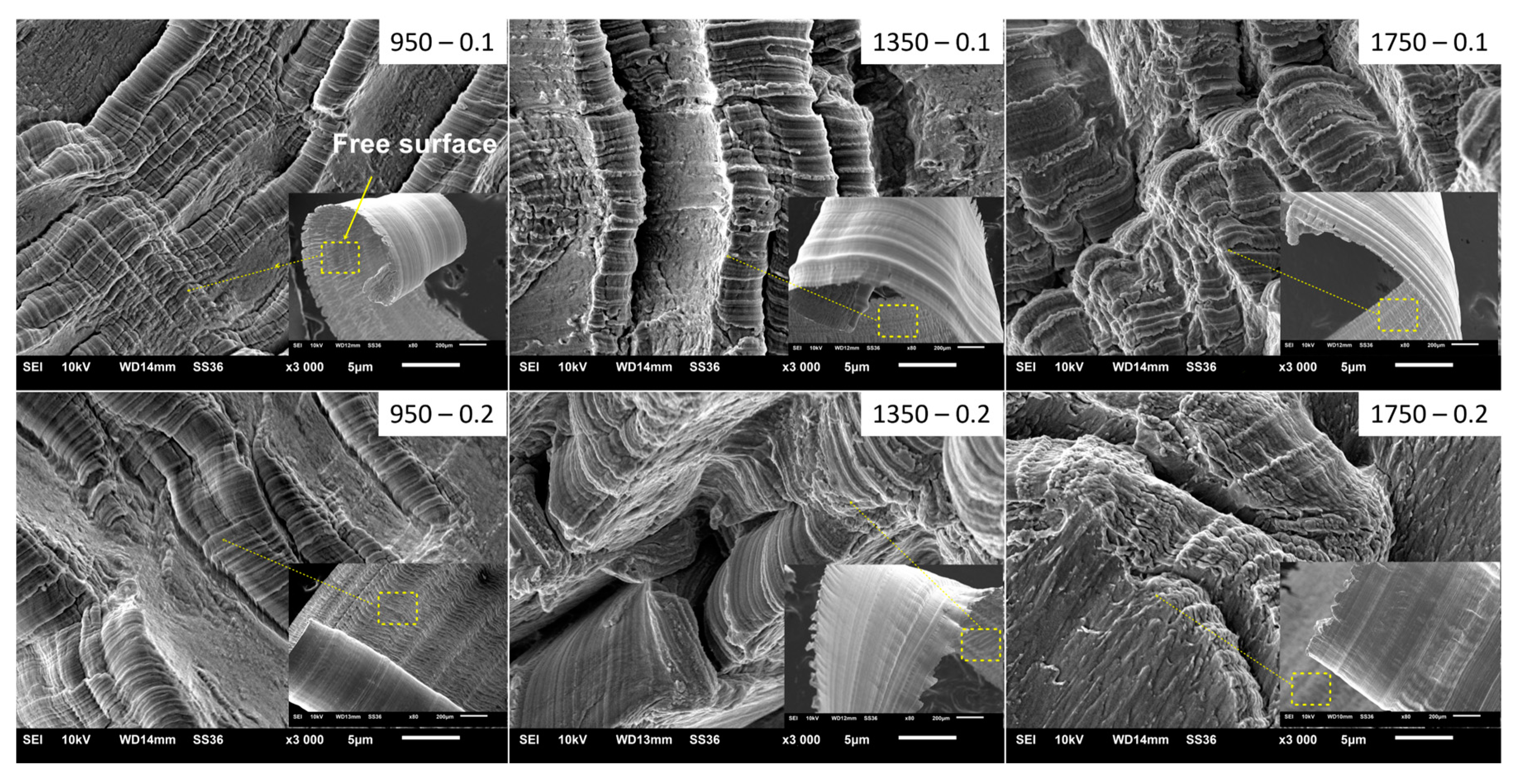

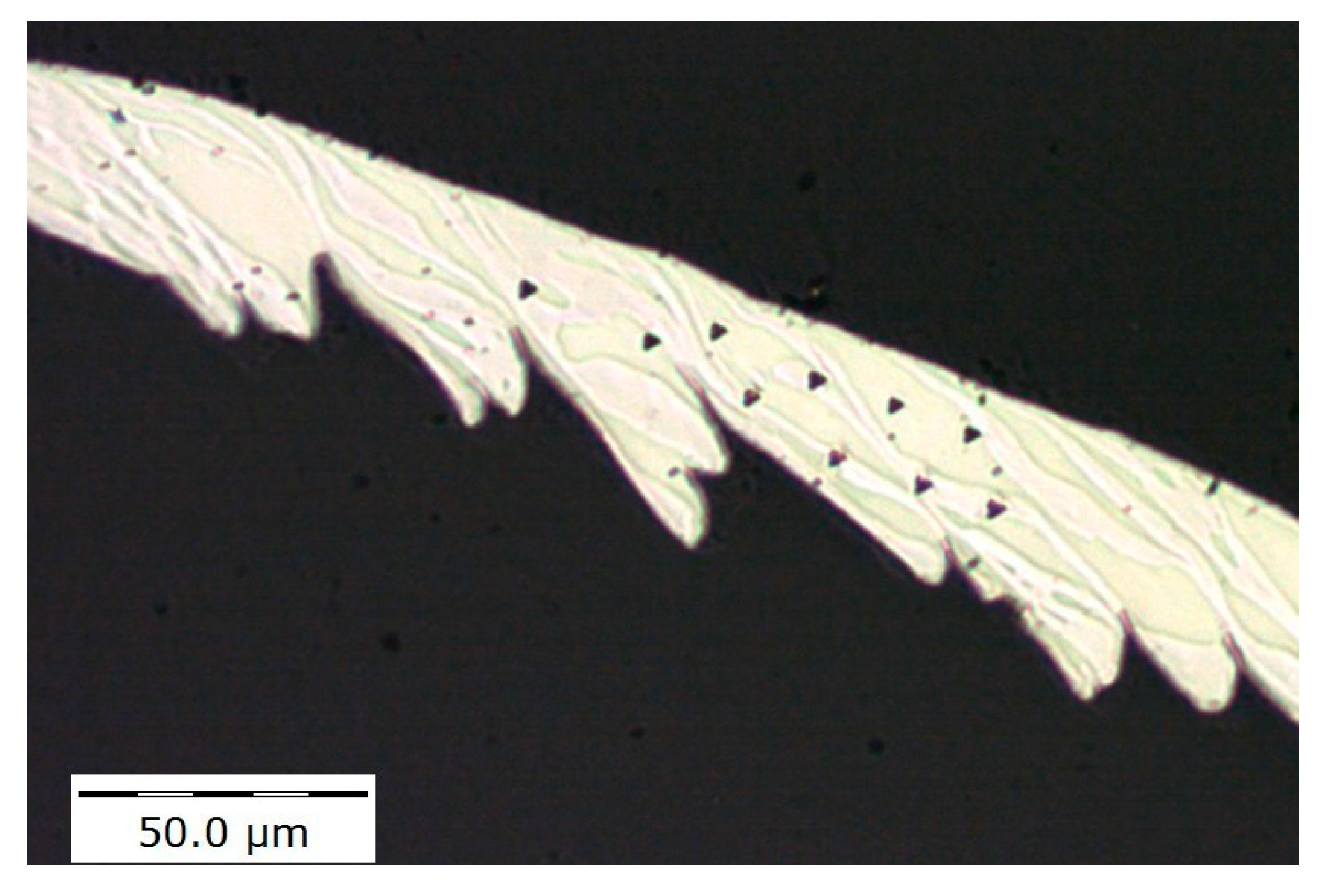

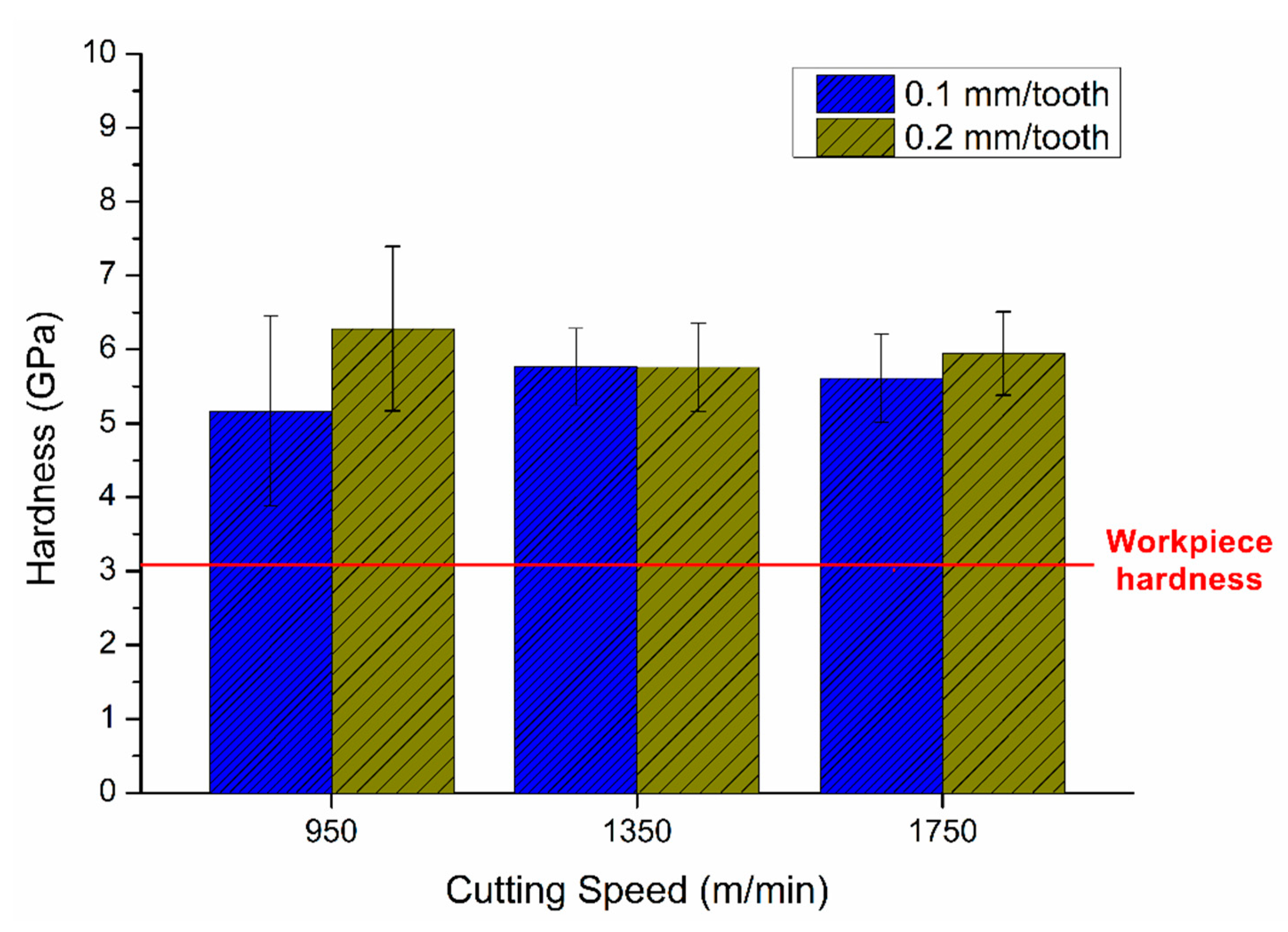

3.2. Chip Morphology and Friction Analysis

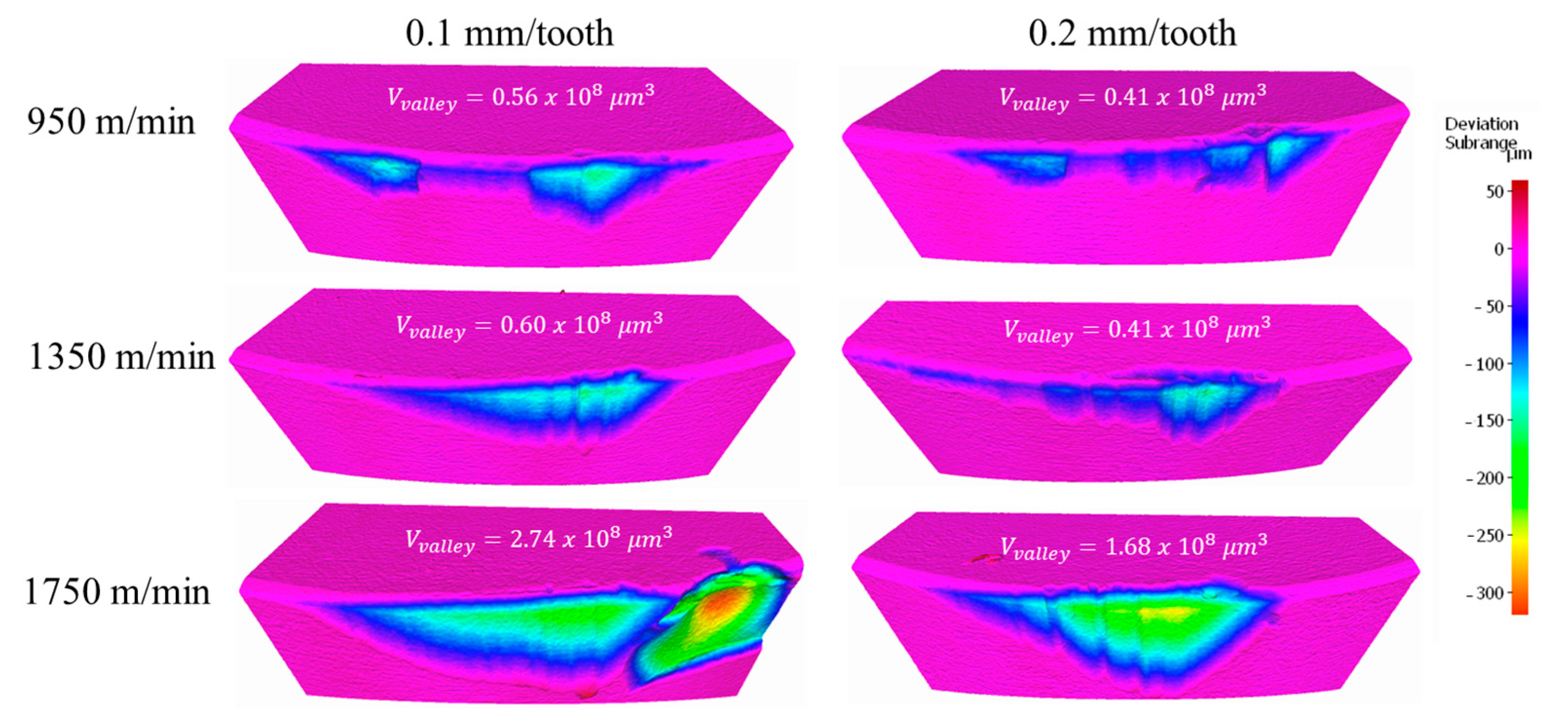

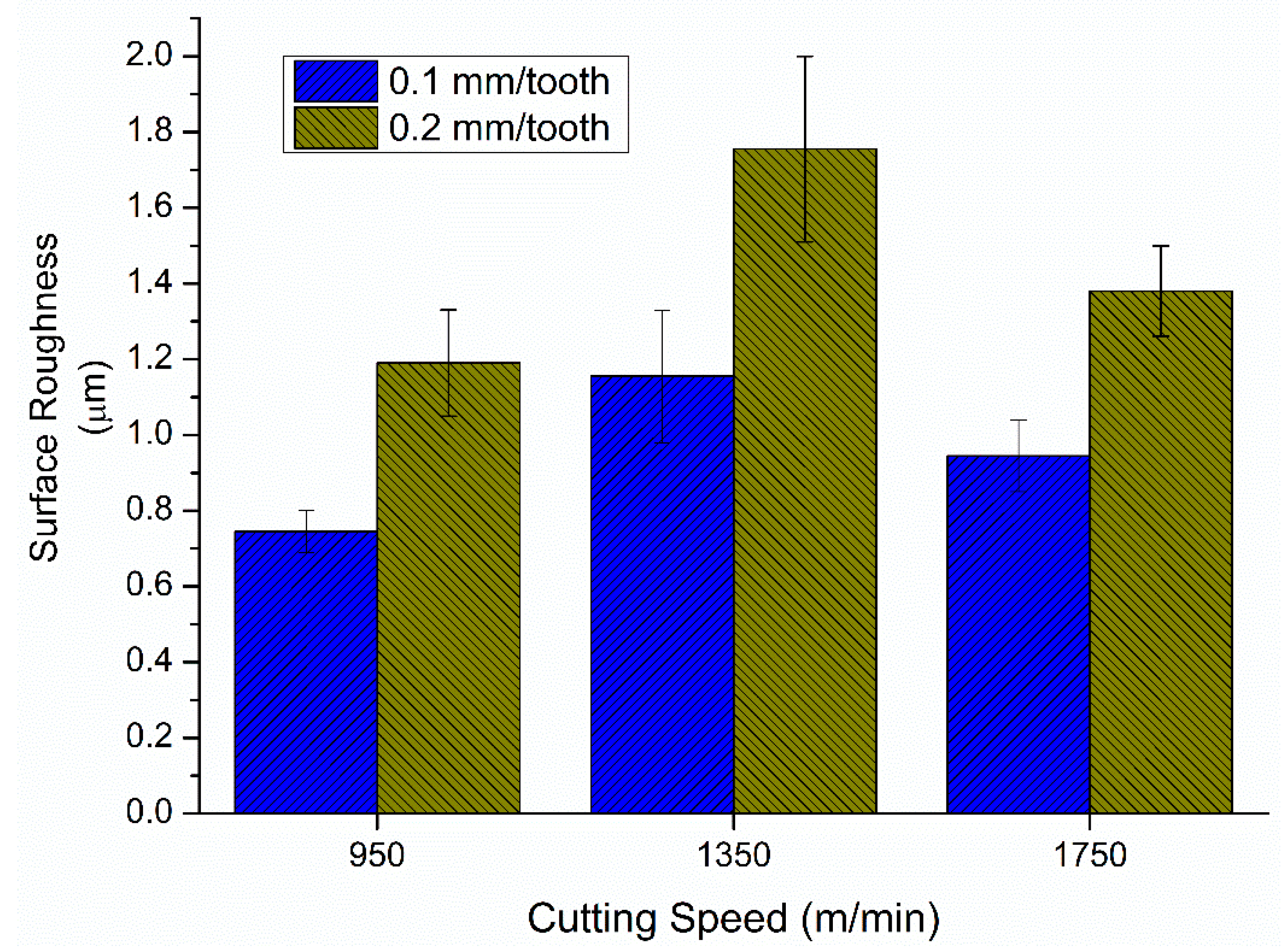

3.3. Workpiece Surface Roughness

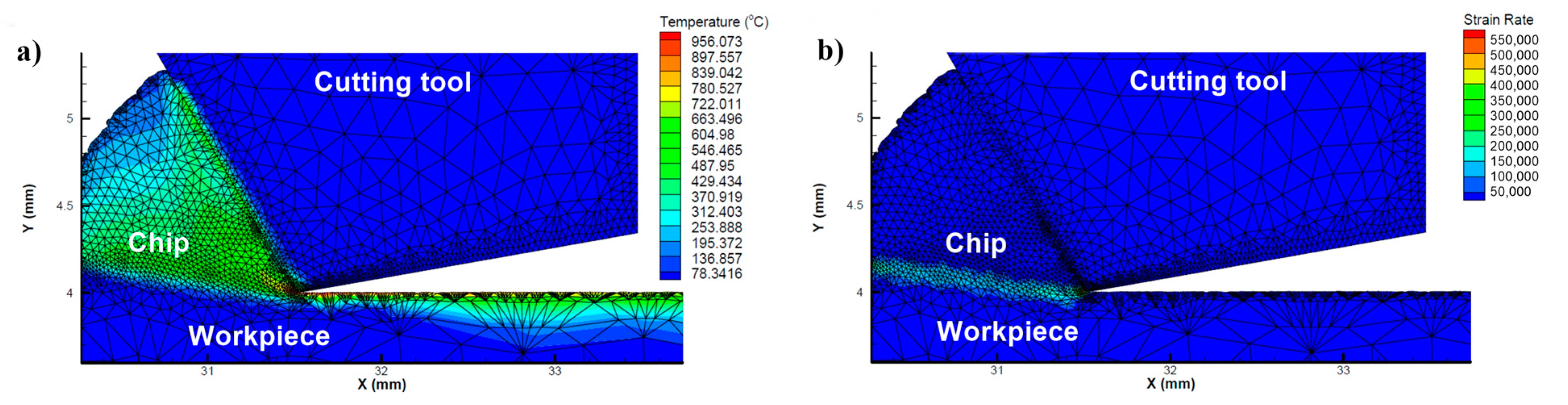

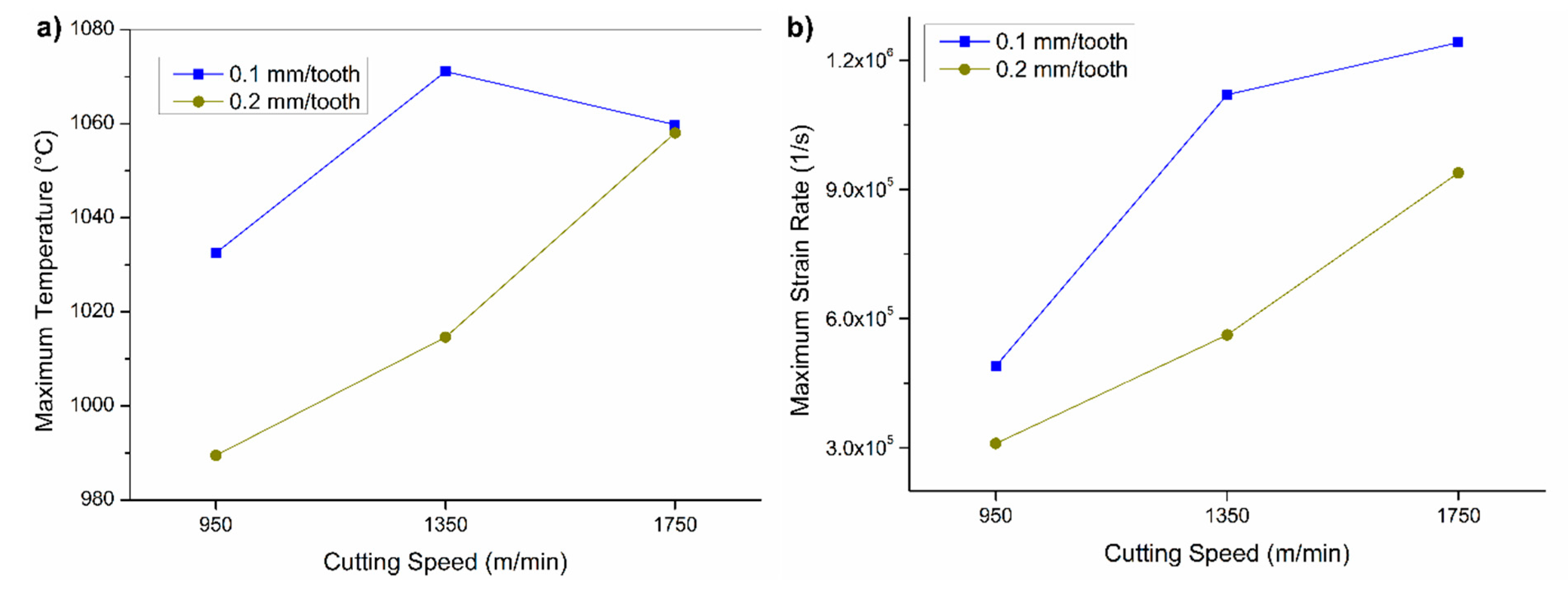

3.4. Finite Element Analysis

3.5. Implications and Future Prospects

4. Conclusions

- The analysis of cutting forces exposed a significant influence on cutting speed, with lower forces obtained at cutting speeds of 950 and 1350 m/min. However, with an even higher cutting speed (1750 m/min) the cutting forces were intensified, particularly when severe tool wear was present. Moreover, increased flank wear affected the cutting forces due to reduced tool clearance angle and increased friction.

- Pareto chart analysis identifies cutting speed as the crucial factor for machining outcomes, particularly with low thermal conductivity and strain-hardening alloys.

- Chip morphology analysis revealed that smoother chip surfaces reduced deformation and lower coefficients of friction were achieved at cutting speeds of 950 and 1350 m/min, combined with a feed rate of 0.2 mm/tooth. These conditions significantly enhanced machining efficiency.

- SEM images of the chip reveal stick–slip phenomena at 1750 m/min and 0.2 mm/tooth, indicating thermoplastic instability through lamellar patterns.

- The combination of a 0.2 mm/tooth feed rate and 1350 m/min cutting speed yields the most pronounced surface roughness. Elevated cutting speeds from 950 to 1350 m/min result in higher surface roughness levels possibly due to increased temperatures and lateral material flow.

- Finite element analysis confirmed the experimental findings, emphasizing the critical role of cutting speed and feed rate in controlling temperature and strain rate during the machining process.

- The optimal combination for maximizing material removal rate, minimizing tool wear, and reducing forces is a cutting speed of 1350 m/min and a feed rate of 0.2 mm/tooth. However, this leads to higher surface roughness, prompting a decision between surface quality and tool life. In machining super duplex stainless steel, prioritizing surface integrity is crucial for corrosion and fatigue resistance. Finding the right balance between tool wear and surface integrity is vital for long-term performance and reliability in demanding applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Strubbia, R.; Hereñú, S.; Marinelli, M.C.; Alvarez-Armas, I. Fatigue damage in coarse-grained lean duplex stainless steels. Mater. Sci. Eng. A 2016, 659, 47–54. [Google Scholar] [CrossRef]

- Cvijović, Z.; Radenković, G. Microstructure and pitting corrosion resistance of annealed duplex stainless steel. Corros. Sci. 2006, 48, 3887–3906. [Google Scholar] [CrossRef]

- Gowthaman, P.S.; Jeyakumar, S.; Saravanan, B.A. Machinability and tool wear mechanism of Duplex stainless steel—A review. Mater. Today Proc. 2020, 26, 1423–1429. [Google Scholar] [CrossRef]

- Tucker, J.D.; Miller, M.K.; Young, G.A. Assessment of thermal embrittlement in duplex stainless steels 2003 and 2205 for nuclear power applications. Acta Mater. 2015, 87, 15–24. [Google Scholar] [CrossRef]

- Gamarra, J.R.; Diniz, A.E. Taper turning of super duplex stainless steel: Tool life, tool wear and workpiece surface roughness. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 39. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Engin, S.; Sim, W.-M. High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann. 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Martinho, R.P.; Silva, F.J.G.; Martins, C.; Lopes, H. Comparative study of PVD and CVD cutting tools performance in milling of duplex stainless steel. Int. J. Adv. Manuf. Technol. 2019, 102, 2423–2439. [Google Scholar] [CrossRef]

- Nagy, A.I.; Fábián, E.R.; Horváth, R.; Terek, P. Difficulties in the Machining Super Duplex Stainless Steels. Műszaki Tudományos Közlemények 2019, 11, 141–144. [Google Scholar] [CrossRef]

- Patra, S.; Agrawal, A.; Mandal, A.; Podder, A.S. Characteristics and Manufacturability of Duplex Stainless Steel: A Review. Trans. Indian Inst. Met. 2021, 74, 1089–1098. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, X.; Hu, Y.; Wang, S. Quantitative Studies of Machining-Induced Microstructure Alteration and Plastic Deformation in AISI 316 Stainless Steel Using EBSD. J. Mater. Eng. Perform. 2018, 27, 434–446. [Google Scholar] [CrossRef]

- Sharman, A.R.C.R.C.; Hughes, J.I.I.; Ridgway, K. The effect of tool nose radius on surface integrity and residual stresses when turning Inconel 718TM. J. Mater. Process. Technol. 2015, 216, 123–132. [Google Scholar] [CrossRef]

- A240/A240M—24; Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications. ASTM Internacional: West Conshohocken, PA, USA, 2024.

- Ciftci, I. Machining of austenitic stainless steels using CVD multi-layer coated cemented carbide tools. Tribol. Int. 2006, 39, 565–569. [Google Scholar] [CrossRef]

- Parsi, P.K.; Kotha, R.S.; Routhu, T.; Pandey, S.; Dwivedy, M. Machinability evaluation of coated carbide inserts in turning of super-duplex stainless steel. SN Appl. Sci. 2020, 2, 1933. [Google Scholar] [CrossRef]

- Mativenga, P.T.; Abukhshim, N.A.; Sheikh, M.A.; Hon, B.K.K. An Investigation of Tool Chip Contact Phenomena in High-Speed Turning Using Coated Tools. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 657–667. [Google Scholar] [CrossRef]

- Ning, Y.; Rahman, M.; Wong, Y.S. Investigation of chip formation in high speed end milling. J. Mater. Process. Technol. 2001, 113, 360–367. [Google Scholar] [CrossRef]

- Zhang, H.; Dang, J.; Ming, W.; Xu, X.; Chen, M.; An, Q. Cutting responses of additive manufactured Ti6Al4V with solid ceramic tool under dry high-speed milling processes. Ceram. Int. 2020, 46, 14536–14547. [Google Scholar] [CrossRef]

- Hotta, M.; Hojo, J.; Komeya, K.; Tatami, J.; Meguro, T.; Masuda, H.; Morinaga, K.; Cheng, Y.-B. Preparation of Ca-α SiAlON hollow spheres by carbothermal reduction–nitridation of CaO–Al2O3–SiO2 glass. Mater. Lett. 2011, 65, 116–118. [Google Scholar] [CrossRef]

- Dong, P.; Wang, X.; Zhang, M.; Guo, M.; Seetharaman, S. The preparation and characterization of β-SiAlON nanostructure whiskers. J. Nanomater. 2008, 2008, 282187. [Google Scholar] [CrossRef]

- Deng, W.J.; Lin, P.; Xie, C.; Li, Q. Analysis of Large-Strain Extrusion Machining with Different Chip Compression Ratios. J. Nanomater. 2012, 2012, 12. [Google Scholar] [CrossRef]

- Shaw, M.C. Metal Cutting Principles, 2nd ed.; Oxford University Press: New York, NY, USA, 2005; ISBN 0-19-514206-3. [Google Scholar]

- Molaiekiya, F.; Stolf, P.; Paiva, J.M.; Bose, B.; Goldsmith, J.; Gey, C.; Engin, S.; Fox-Rabinovich, G.; Veldhuis, S.C. Influence of process parameters on the cutting performance of SiAlON ceramic tools during high-speed dry face milling of hardened Inconel 718. Int. J. Adv. Manuf. Technol. 2019, 105, 1083–1098. [Google Scholar] [CrossRef]

- Man, X.; Ren, D.; Usui, S.; Johnson, C.; Marusich, T.D. Validation of Finite Element Cutting Force Prediction for End Milling. Procedia CIRP 2012, 1, 663–668. [Google Scholar] [CrossRef]

- Rajaguru, J.; Dwivedi, M.; Natarajan, S.; Krishnaswamy, H.; Arunachalam, N. Machining induced residual stress prediction during orthogonal cutting of super duplex stainless steel using CEL approach. J. Manuf. Process. 2022, 82, 474–487. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Sengupta, D.; Mukhopadhyay, S. Cutting force-based real-time estimation of tool wear in face milling using a combination of signal processing techniques. Mech. Syst. Signal Process. 2007, 21, 2665–2683. [Google Scholar] [CrossRef]

- Ming, W.; Huang, X.; Ji, M.; Xu, J.; Zou, F.; Chen, M. Analysis of cutting responses of Sialon ceramic tools in high-speed milling of FGH96 superalloys. Ceram. Int. 2021, 47, 149–156. [Google Scholar] [CrossRef]

- Zheng, G.; Zhao, J.; Cheng, X.; Xu, R.; Zhao, G. Experimental Investigation on Sialon Ceramic Inserts for Ultra-high-speed Milling of Inconel 718. Mater. Manuf. Process. 2016, 31, 633–640. [Google Scholar] [CrossRef]

- Wei, M.; Wu, M.; Xu, J.; Cheng, Y. Influence of Flank Wear on the Microstructure Characteristics of the GH4169 Metamorphic Layer under High-Pressure Cooling. Materials 2023, 16, 2944. [Google Scholar] [CrossRef]

- Molaiekiya, F.; Aramesh, M.; Veldhuis, S.C. Chip formation and tribological behavior in high-speed milling of IN718 with ceramic tools. Wear 2020, 446–447, 203191. [Google Scholar] [CrossRef]

- Fernández-Abia, A.I.; Barreiro, J.; López De Lacalle, L.N.; Martínez, S.; Martínez, S.; López De Lacalle, L.N.; Barreiro, J.; De Lacalle, L.N.L.; Martínez, S.; Barreiro, J.; et al. Effect of very high cutting speeds on shearing, cutting forces and roughness in dry turning of austenitic stainless steels. Int. J. Adv. Manuf. Technol. 2011, 57, 61–71. [Google Scholar] [CrossRef]

- Trent, E.M.; Wright, P.K. Metal Cutting, 4th ed.; Butterworth-Heinemann: Boston, MA, USA, 2000; ISBN 0-7506-7069-X. [Google Scholar]

- Molinari, A.; Musquar, C.; Sutter, G. Adiabatic shear banding in high speed machining of Ti–6Al–4V: Experiments and modeling. Int. J. Plast. 2002, 18, 443–459. [Google Scholar] [CrossRef]

- Hokka, M.; Gomon, D.; Shrot, A.; Leemet, T.; Bäker, M.; Kuokkala, V.-T. Dynamic Behavior and High Speed Machining of Ti-6246 and Alloy 625 Superalloys: Experimental and Modeling Approaches. Exp. Mech. 2014, 54, 199–210. [Google Scholar] [CrossRef]

- Houchuan, Y.; Zhitong, C.; ZiTong, Z. Influence of cutting speed and tool wear on the surface integrity of the titanium alloy Ti-1023 during milling. Int. J. Adv. Manuf. Technol. 2015, 78, 1113–1126. [Google Scholar] [CrossRef]

- Jafarian, F.; Umbrello, D.; Golpayegani, S.; Darake, Z. Experimental Investigation to Optimize Tool Life and Surface Roughness in Inconel 718 Machining. Mater. Manuf. Process. 2016, 31, 1683–1691. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, K.; Zhou, Q.; Zhou, H.; Liu, B.; Zheng, G. Numerical investigations on the effect of ultra-high cutting speed on the cutting heat and rock-breaking performance of a single cutter. J. Pet. Sci. Eng. 2020, 190, 107120. [Google Scholar] [CrossRef]

| Element Weight Composition (%) | C | Cr | Ni | Mo | N | Mn | Cu | P | S | Si |

| 0.2 | 25 | 7 | 4 | 0.27 | 1.2 | 0.5 | 0.02 | 0.01 | 0.8 | |

| Mechanical and Thermal Properties | ||||||||||

| Yield Strength (MPA) | Tensile Strength (MPa) | Elongation (%) | Thermal Conductivity (W/m.K) | |||||||

| 550 | 800 | 25 | 14 | |||||||

| Test | Cutting Speed (m/min) | Feed Rate (mm/tooth) | Depth of Cut (mm) |

|---|---|---|---|

| 1 | 950 | 0.1 | 0.25 |

| 2 | 950 | 0.2 | |

| 3 | 1350 | 0.1 | |

| 4 | 1350 | 0.2 | |

| 5 | 1750 | 0.1 | |

| 6 | 1750 | 0.2 |

| Total number of elements | 24,000 |

| Maximum element size | 0.01 |

| Minimum element size | 0.02 |

| UNS S32750 Properties | |

| Thermal conductivity | 14 (W/m.°C) |

| Thermal capacity | 425 (J/kg.°C) |

| Density | 7.8 (g/cm3) |

| Thermal expansion | 13 (µm/m/K) |

| Cutting Speed (m/min)—Feed Rate (mm/tooth) | Chip Compression Ratio (CCR) | Φ—Shear Angle (°) | Friction Coefficient (µ) | Resultant Cutting Force, Average (N) |

|---|---|---|---|---|

| 950—0.10 | 0.83 | 50.6 | 0.34 | 289 ± 9 |

| 950—0.20 | 0.88 | 53.4 | 0.23 | 273 ± 12 |

| 1350—0.10 | 0.86 | 52.7 | 0.26 | 342 ± 13 |

| 1350—0.20 | 0.88 | 53.4 | 0.23 | 294 ± 3 |

| 1750—0.10 | N/A | N/A | N/A | 637 ± 39 |

| 1750—0.20 | N/A | N/A | N/A | 630 ± 69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guimarães, M.; Saciotto, V.; He, Q.; DePaiva, J.M.; Diniz, A.; Veldhuis, S. Optimizing Machining Efficiency in High-Speed Milling of Super Duplex Stainless Steel with SiAlON Ceramic Inserts. Machines 2024, 12, 349. https://doi.org/10.3390/machines12050349

Guimarães M, Saciotto V, He Q, DePaiva JM, Diniz A, Veldhuis S. Optimizing Machining Efficiency in High-Speed Milling of Super Duplex Stainless Steel with SiAlON Ceramic Inserts. Machines. 2024; 12(5):349. https://doi.org/10.3390/machines12050349

Chicago/Turabian StyleGuimarães, Monica, Victor Saciotto, Qianxi He, Jose M. DePaiva, Anselmo Diniz, and Stephen Veldhuis. 2024. "Optimizing Machining Efficiency in High-Speed Milling of Super Duplex Stainless Steel with SiAlON Ceramic Inserts" Machines 12, no. 5: 349. https://doi.org/10.3390/machines12050349

APA StyleGuimarães, M., Saciotto, V., He, Q., DePaiva, J. M., Diniz, A., & Veldhuis, S. (2024). Optimizing Machining Efficiency in High-Speed Milling of Super Duplex Stainless Steel with SiAlON Ceramic Inserts. Machines, 12(5), 349. https://doi.org/10.3390/machines12050349