Tacholess Time Synchronous Averaging for Gear Fault Diagnosis in Wind Turbine Gearboxes Using a Single Accelerometer

Abstract

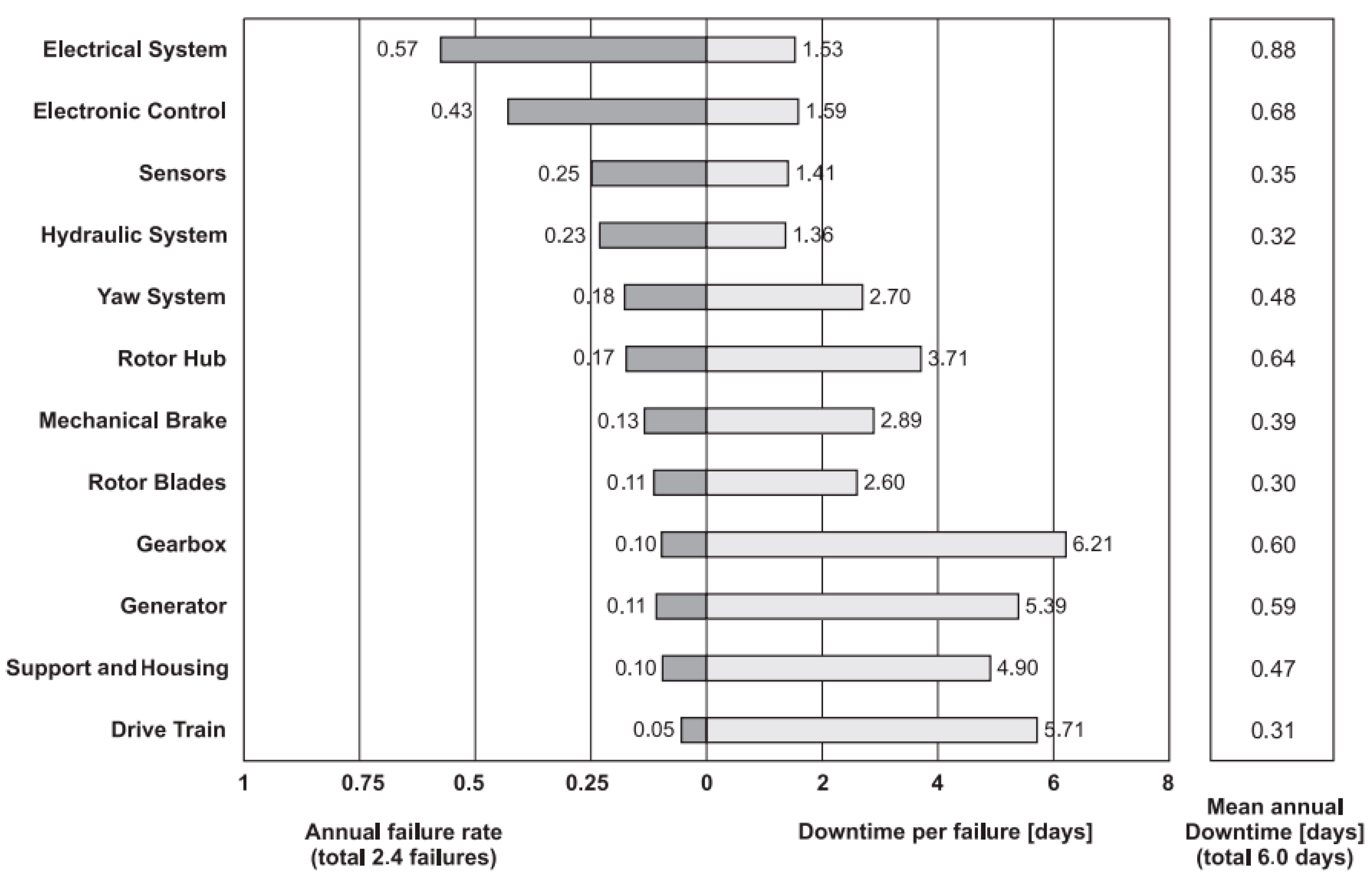

1. Introduction

2. Literature Review

2.1. Feature Extraction from TSA Based on Tacho Signal

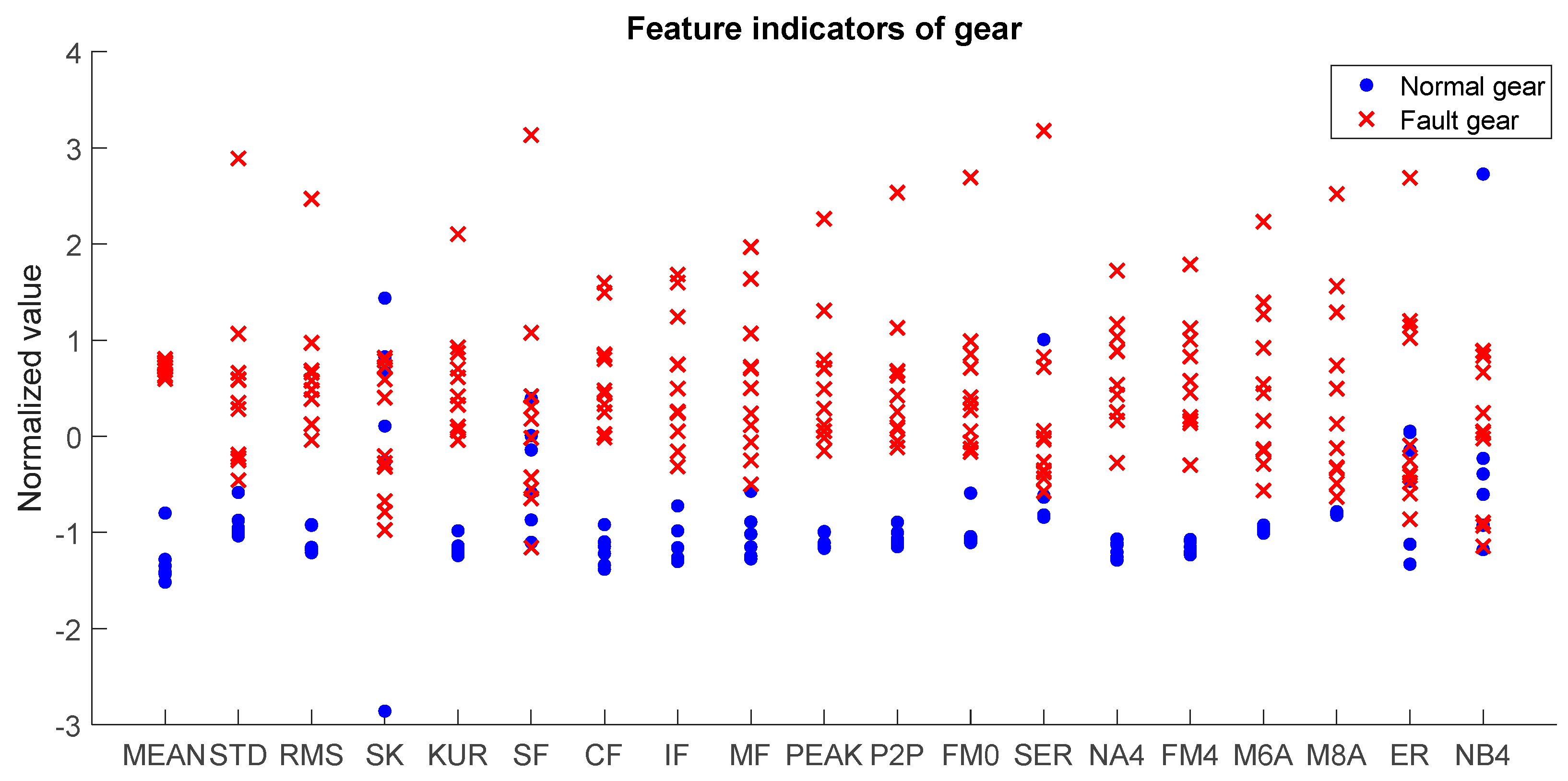

2.2. Selection Feature for Gear Fault Diagnostics

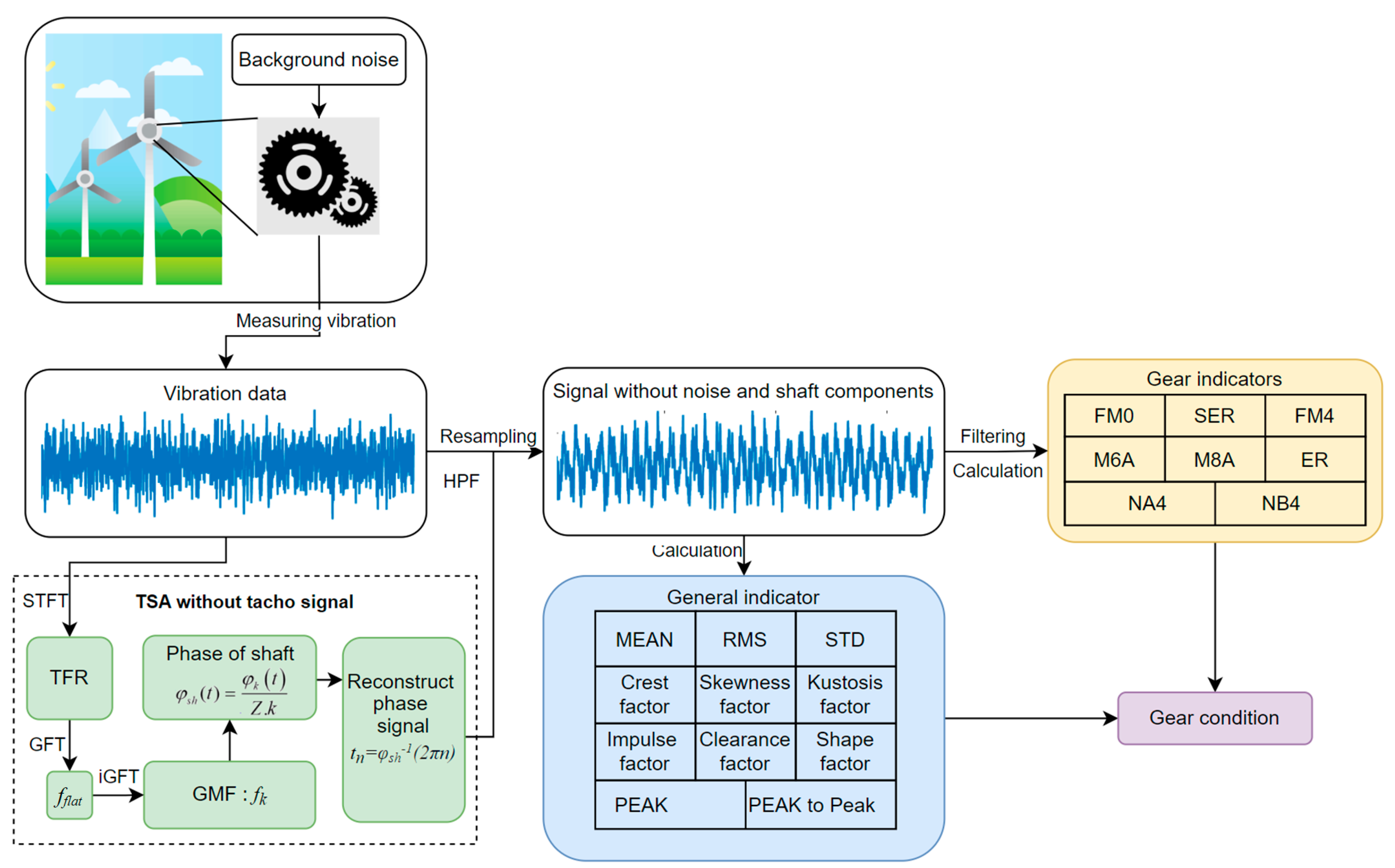

3. Feature Extraction from TSA without Using a Tacho Signal

3.1. Reconstruction Tacho Signal from Time–Frequency Representation (TFR)

3.2. Flowchart

- Phase signal reconstruction:

- Calculating characteristic values:

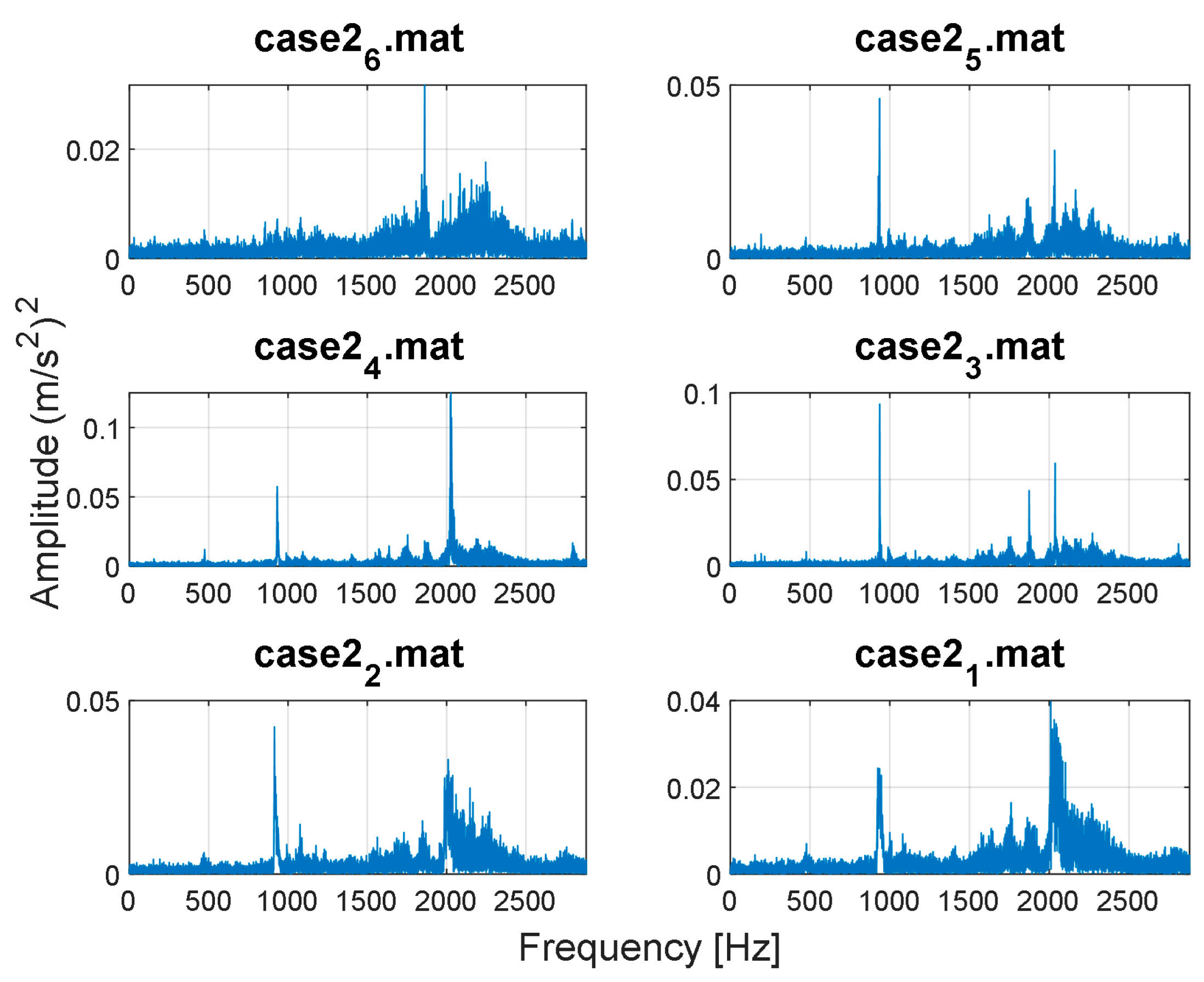

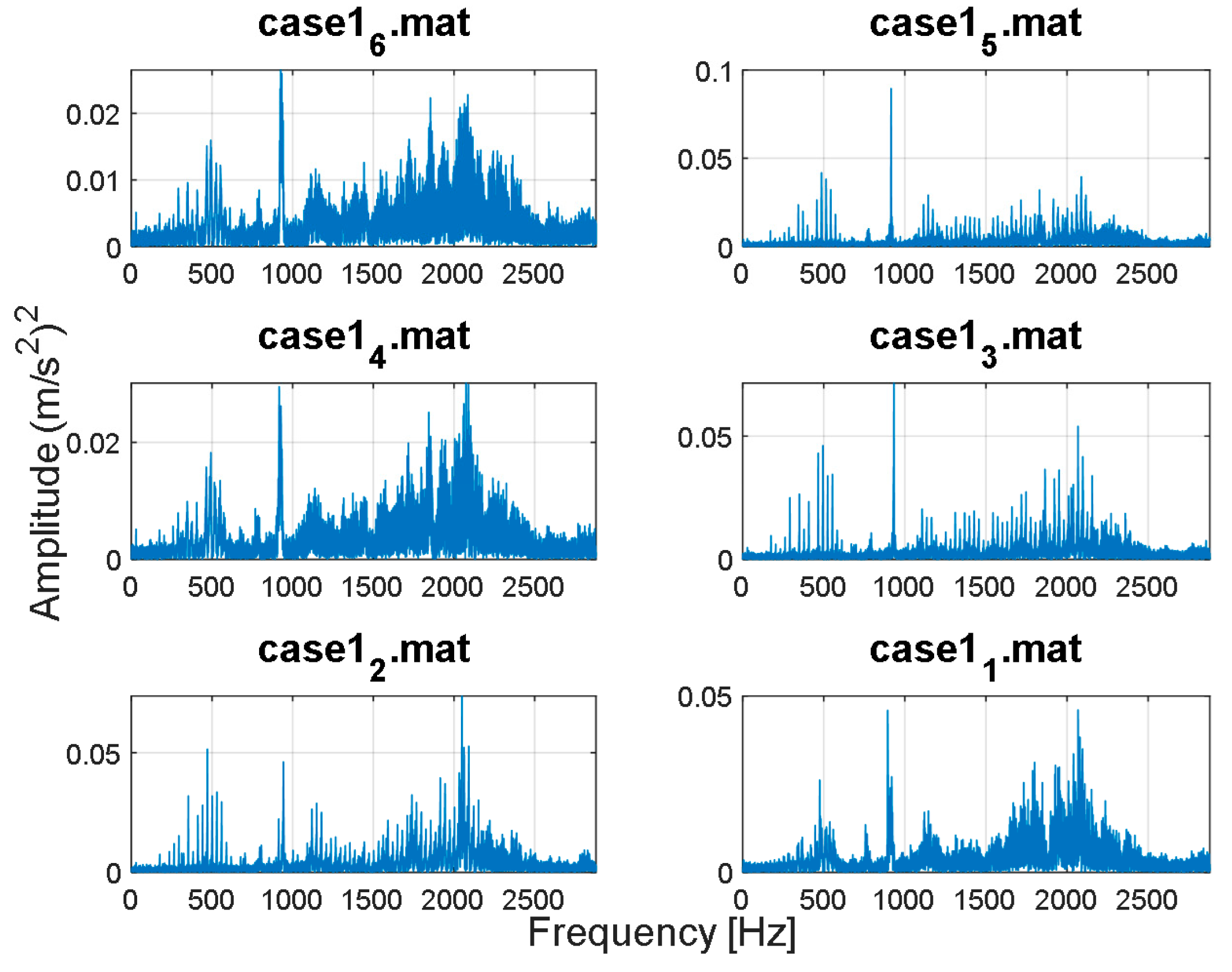

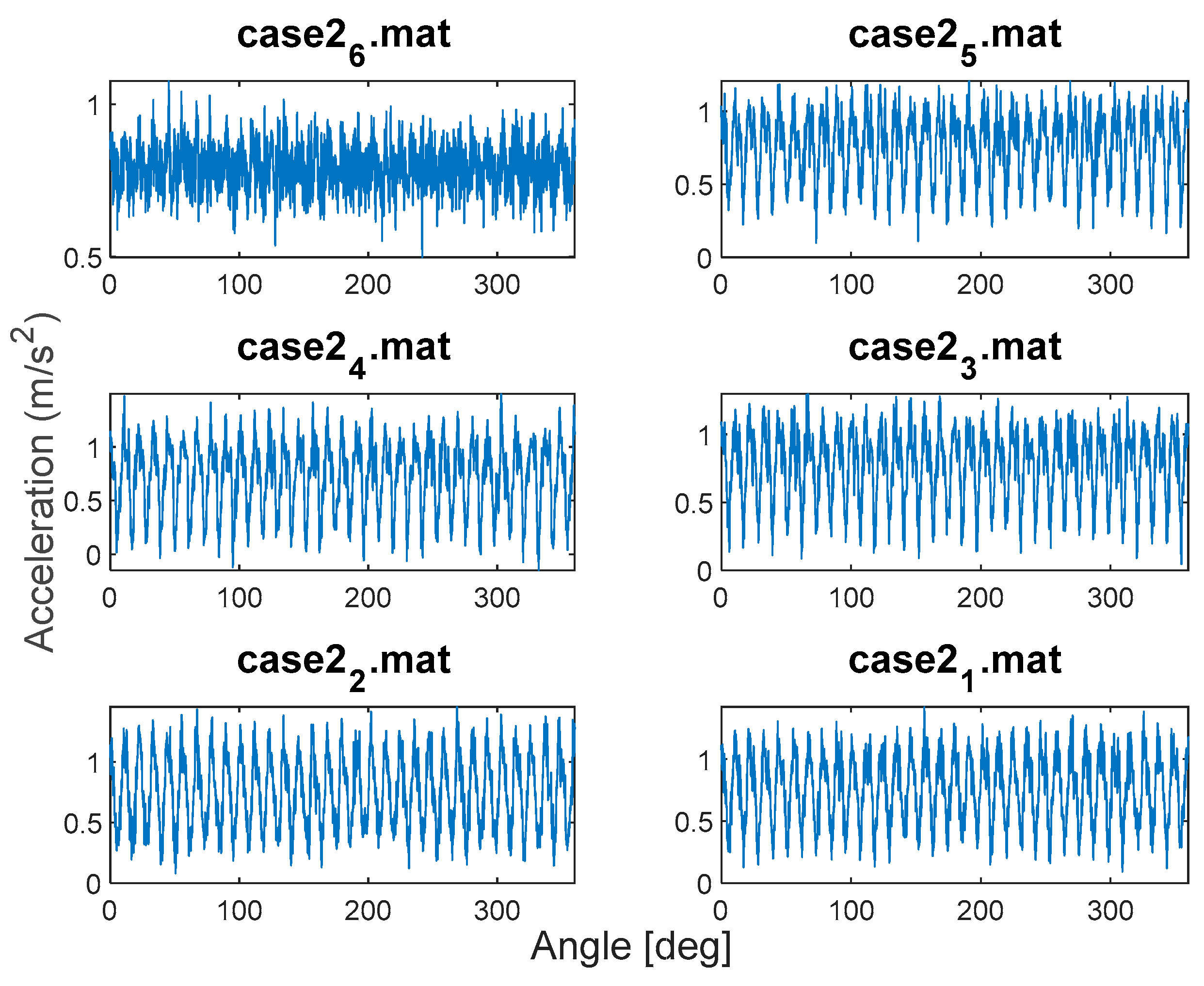

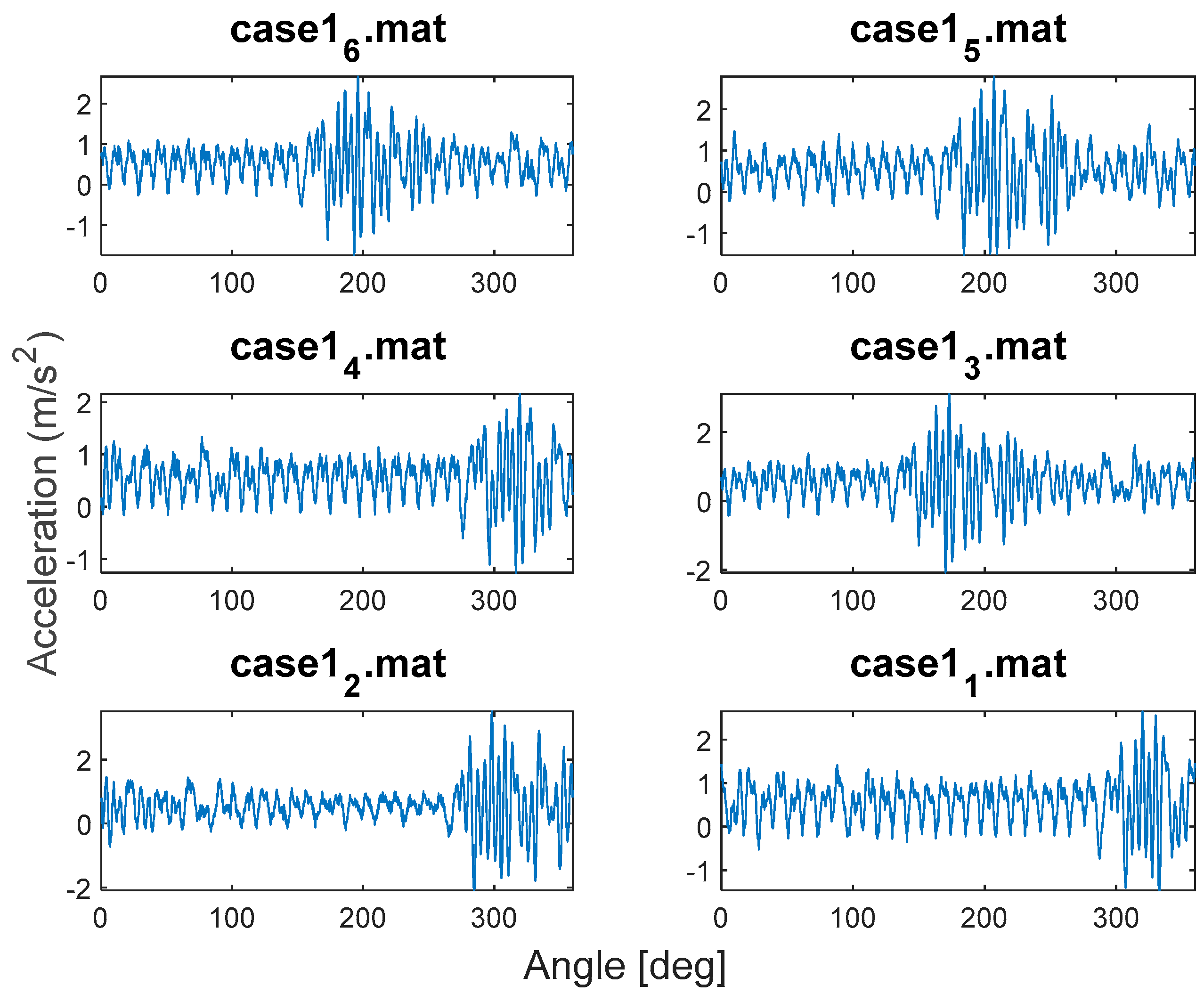

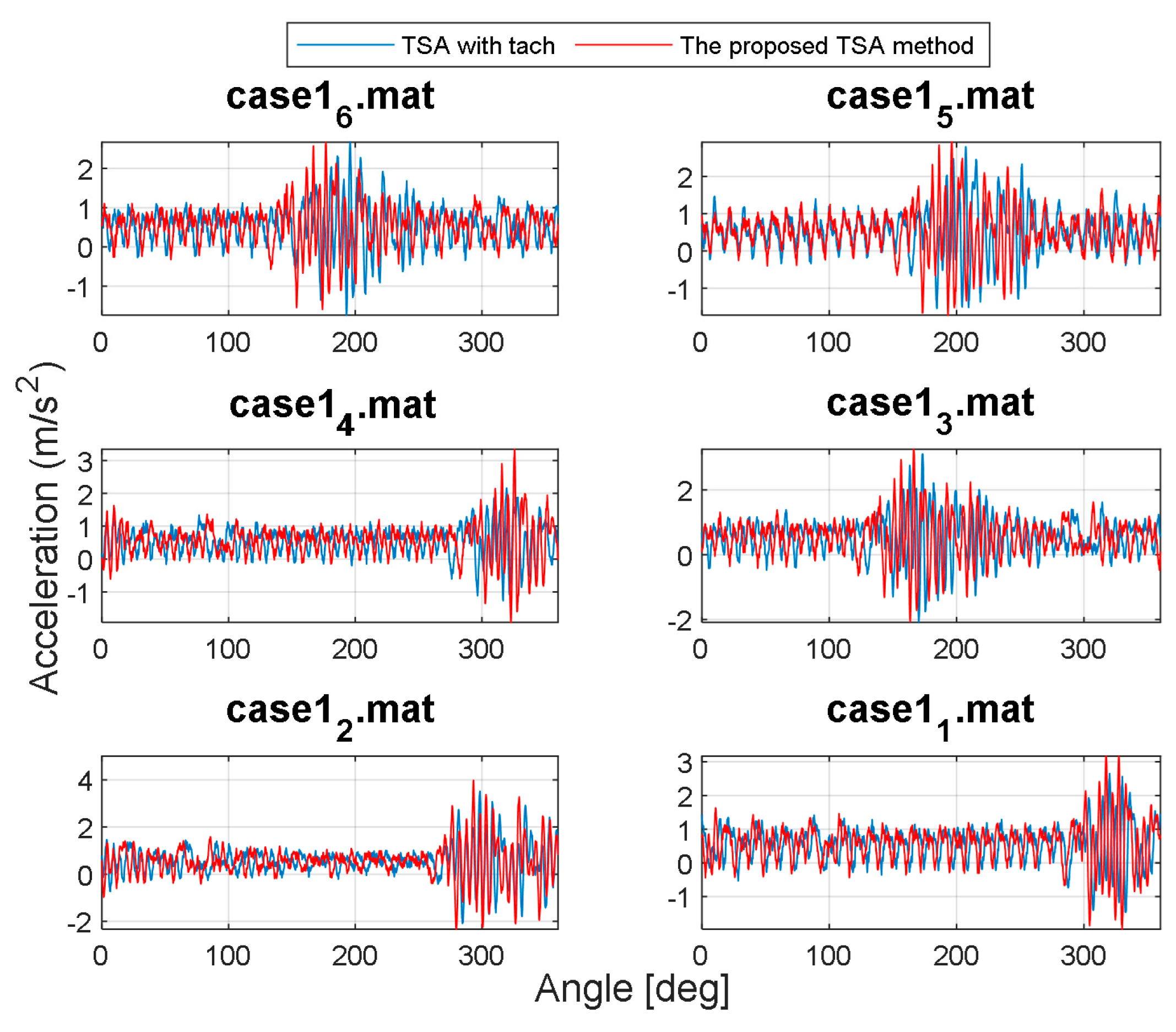

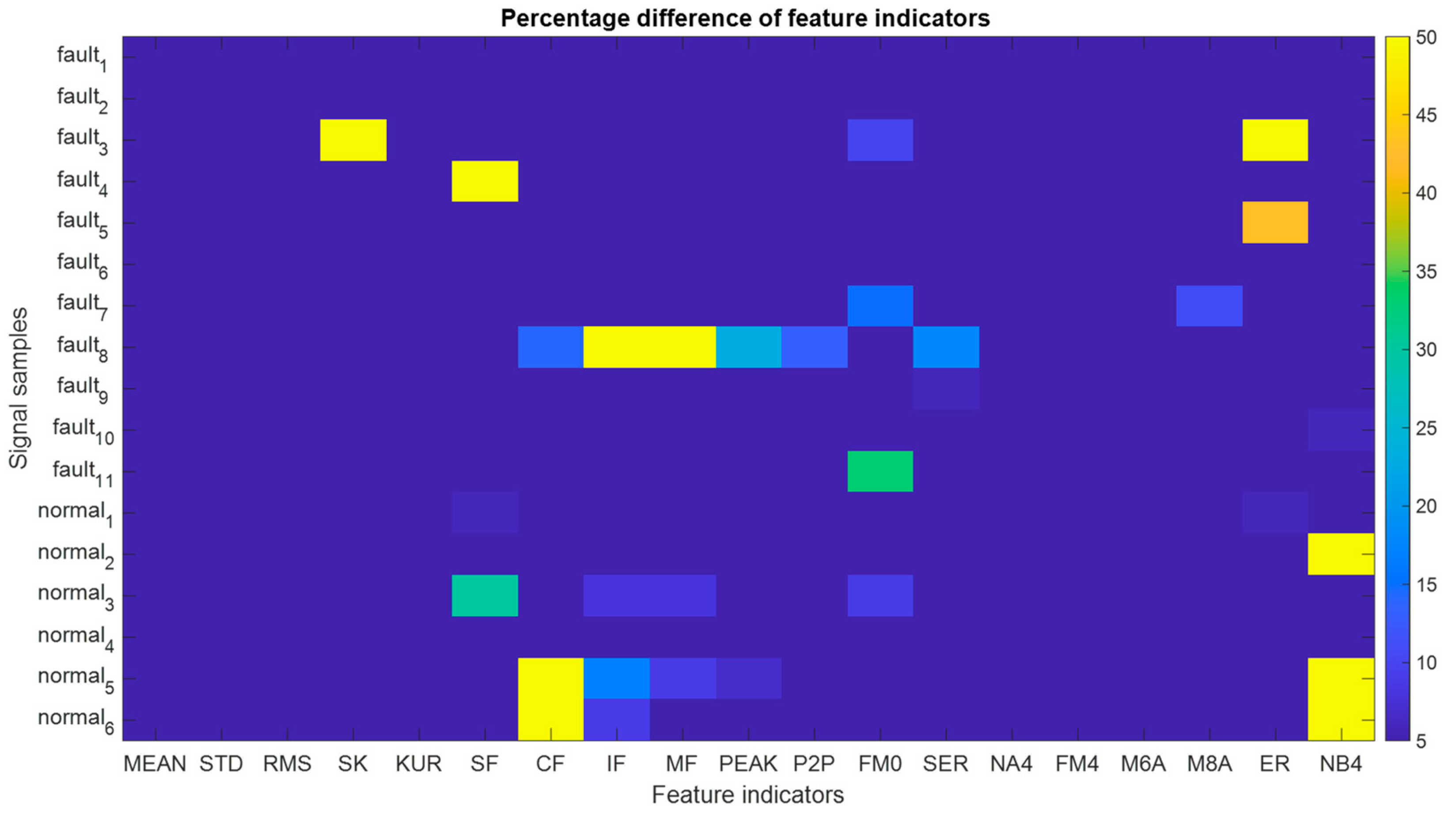

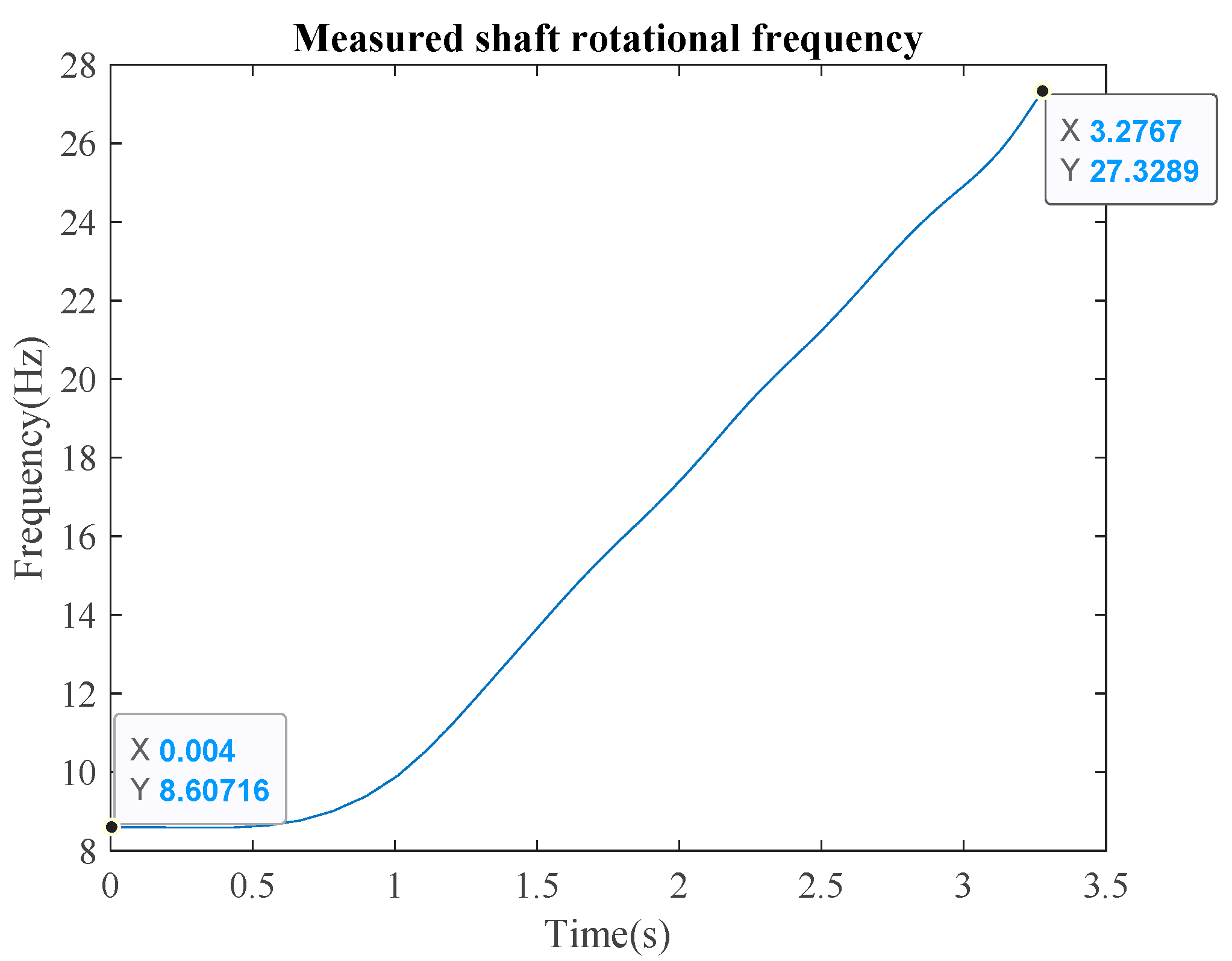

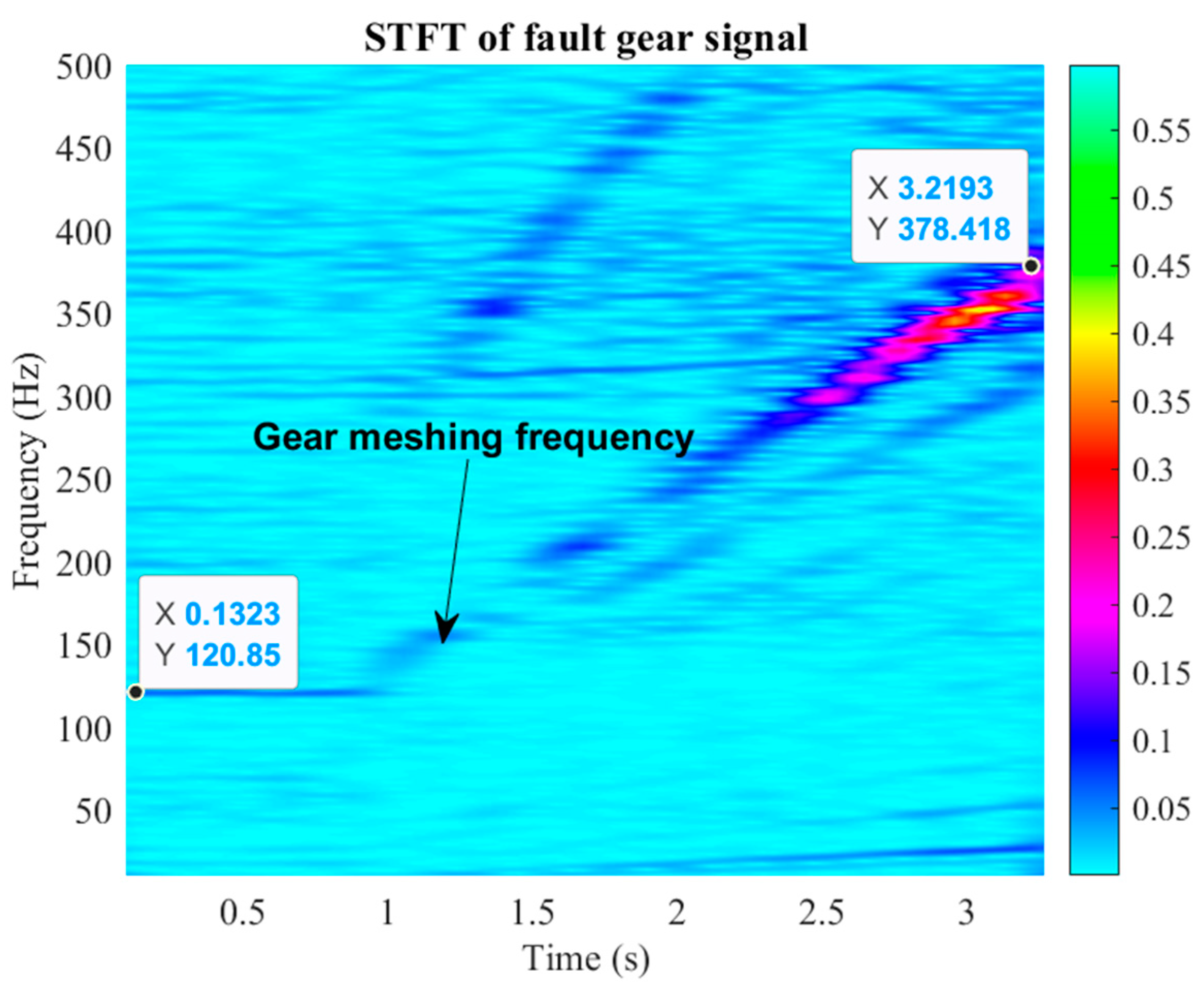

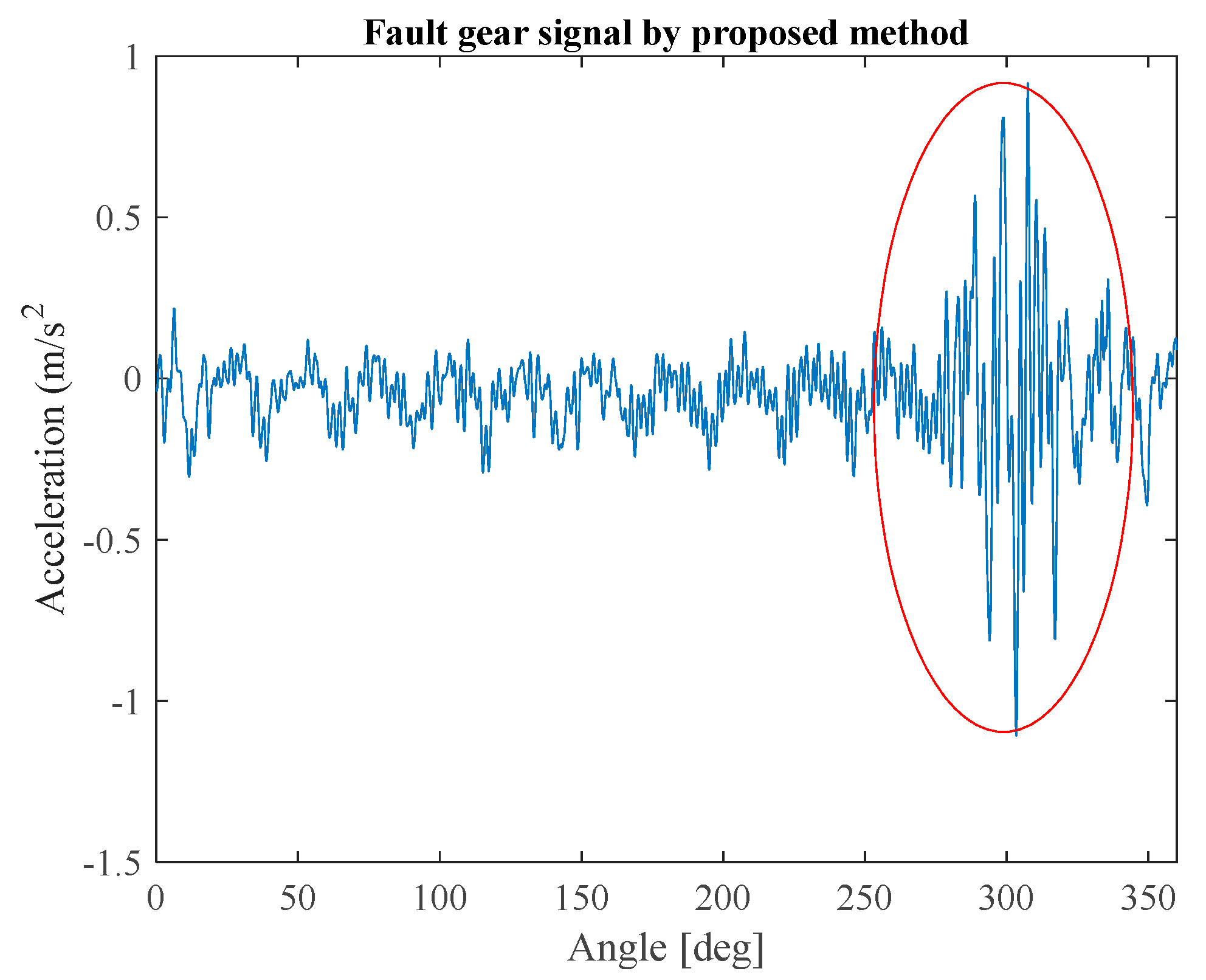

4. Experiment Test Results

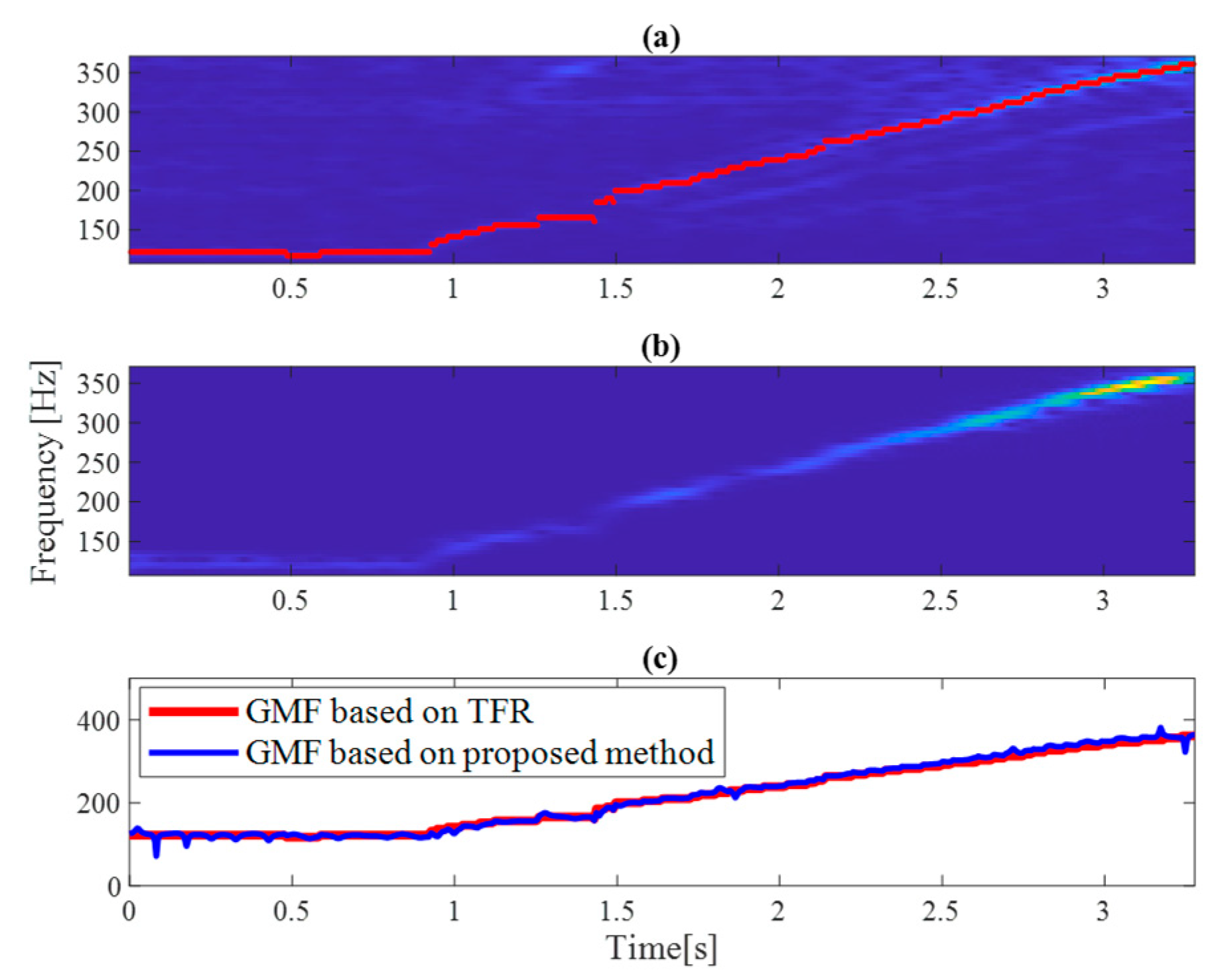

- (i)

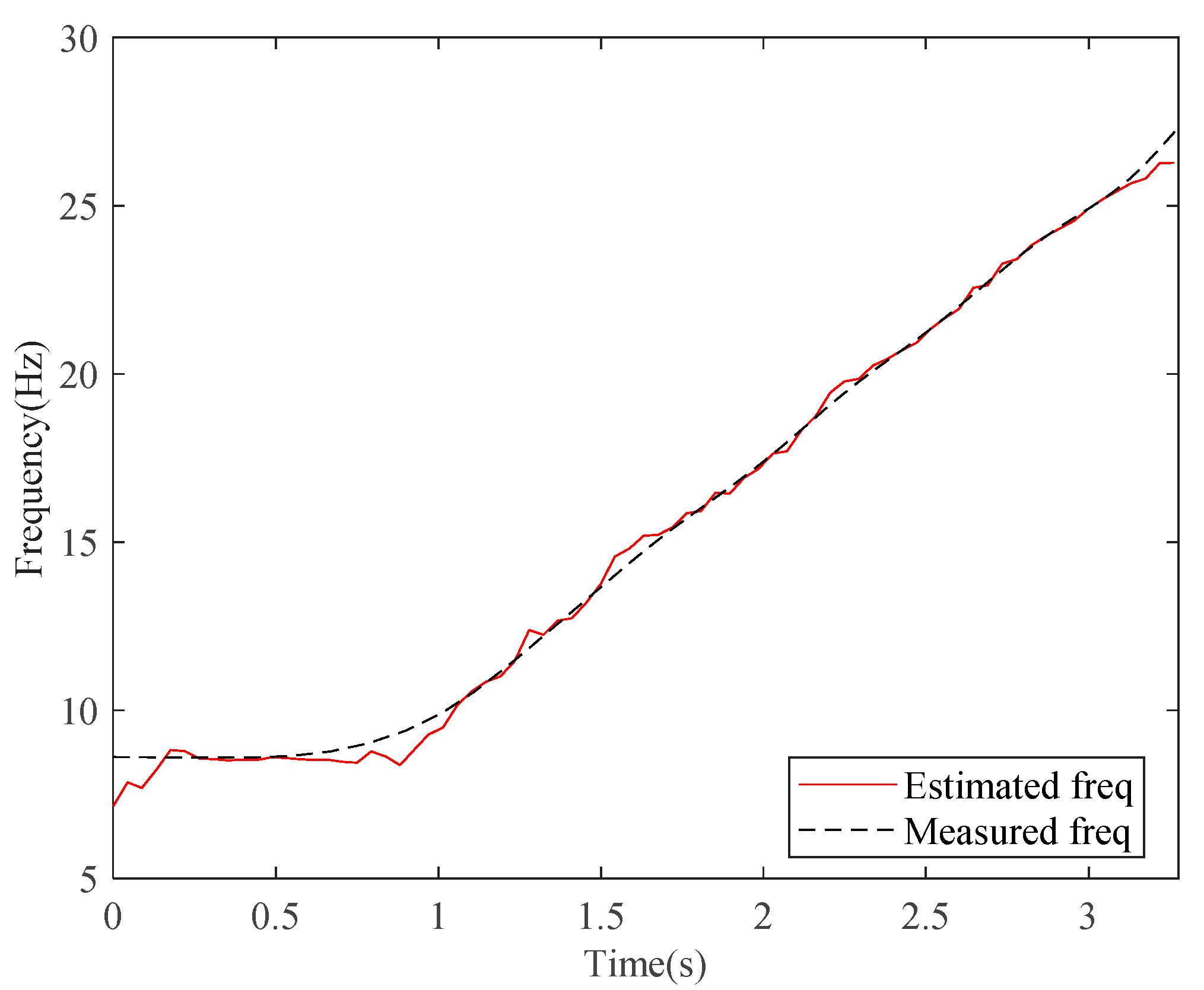

- The preliminary GMF estimate obtained from the spectrogram is a red instantaneous frequency curve, as shown in Figure 13a;

- (ii)

- The frequency components around the first-order meshing frequency are eliminated to obtain a clean first-order GMF, as shown in Figure 13b;

- (iii)

- The results in Figure 13c clearly indicate that the preliminary estimated GMF components almost fully overlap with the separated GMF components.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CWT | continuous wavelet transform |

| FDR | Fisher’s discriminant ratio |

| GFT | Generalized Fourier Transform |

| GMF | gear meshing frequency |

| IF | instantaneous frequency |

| STFT | Short-time Fourier Transform |

| TFR | time–frequency representation |

| TSA | time synchronous averaging |

References

- Liu, W.Y.; Tang, B.P.; Han, J.G.; Lu, X.N.; Hu, N.N.; He, Z.Z. The Structure Healthy Condition Monitoring and Fault Diagnosis Methods in Wind Turbines: A Review. Renew. Sustain. Energy Rev. 2015, 44, 466–472. [Google Scholar] [CrossRef]

- García Márquez, F.P.; Tobias, A.M.; Pinar Pérez, J.M.; Papaelias, M. Condition Monitoring of Wind Turbines: Techniques and Methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Sohoni, V.; Gupta, S.C.; Nema, R.K. A Critical Review on Wind Turbine Power Curve Modelling Techniques and Their Applications in Wind Based Energy Systems. J. Energy 2016, 2016, 8519785. [Google Scholar] [CrossRef]

- Salameh, J.P.; Cauet, S.; Etien, E.; Sakout, A.; Rambault, L. Gearbox Condition Monitoring in Wind Turbines: A Review. Mech. Syst. Signal Process. 2018, 111, 251–264. [Google Scholar] [CrossRef]

- Moeini, R.; Entezami, M.; Ratkovac, M.; Tricoli, P.; Hemida, H.; Hoeffer, R.; Baniotopoulos, C. Perspectives on Condition Monitoring Techniques of Wind Turbines. Wind Eng. 2019, 43, 539–555. [Google Scholar] [CrossRef]

- El-Naggar, M.F.; Abdelhamid, A.S.; Elshahed, M.A.; Bekhet, M.E.S.M. Dynamic Reliability and Availability Allocation of Wind Turbine Subassemblies Through Importance Measures. IEEE Access 2022, 10, 99445–99459. [Google Scholar] [CrossRef]

- Faulstich, S.; Hahn, B.; Tavner, P.J. Wind Turbine Downtime and Its Importance for Offshore Deployment. Wind Energy 2011, 14, 327–337. [Google Scholar] [CrossRef]

- Blesa, J.; Jiménez, P.; Rotondo, D.; Nejjari, F.; Puig, V. An Interval NLPV Parity Equations Approach for Fault Detection and Isolation of a Wind Farm. IEEE Trans. Ind. Electron. 2015, 62, 3794–3805. [Google Scholar] [CrossRef]

- Mcfadden, P.D.; Toozhy, M.M. Application of Synchronous Averaging to Vibration Monitoring of Rolling Element Bearings. Mech. Syst. Signal Process. 2000, 14, 891–906. [Google Scholar] [CrossRef]

- McFadden, P.D. A Technique for Calculating the Time Domain Averages of the Vibration of the Individual Planet Gears and the Sun Gear in an Epicyclic Gearbox. J. Sound Vib. 1991, 144, 163–172. [Google Scholar] [CrossRef]

- McFadden, P.D. A Revised Model for the Extraction of Periodic Waveforms by Time Domain Averaging. Mech. Syst. Signal Process. 1987, 1, 83–95. [Google Scholar] [CrossRef]

- Halim, E.B.; Shoukat Choudhury, M.A.A.; Shah, S.L.; Zuo, M.J. Time Domain Averaging across All Scales: A Novel Method for Detection of Gearbox Faults. Mech. Syst. Signal Process. 2008, 22, 261–278. [Google Scholar] [CrossRef]

- Braun, S. The Synchronous (Time Domain) Average Revisited. Mech. Syst. Signal Process. 2011, 25, 1087–1102. [Google Scholar] [CrossRef]

- Du, N.T.; Dien, N.P. Advanced Signal Decomposition Methods for Vibration Diagnosis of Rotating Machines: A Case Study at Variable Speed. In Modern Mechanics and Applications, Proceedings of the International Conference on Modern Mechanics and Applications, Ho Chi Minh City, Vietnam, 2–4 December 2020; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2022. [Google Scholar]

- McFadden, P.D. Detecting Fatigue Cracks in Gears by Amplitude and Phase Demodulation of the Meshing Vibration. J. Vib. Acoust. 1986, 108, 165–170. [Google Scholar] [CrossRef]

- Boulahbal, D.; Golnaraghi, M.F.; Ismail, F. Amplitude and Phase Wavelet Maps for the Detection of Cracks in Geared Systems. Mech. Syst. Signal Process. 1999, 13, 423–436. [Google Scholar] [CrossRef]

- Zheng, H.; Li, Z.; Chen, X. Gear Fault Diagnosis Based on Continuous Wavelet Transform. Mech. Syst. Signal Process. 2002, 16, 447–457. [Google Scholar] [CrossRef]

- Urbanek, J.; Barszcz, T.; Antoni, J.; Samanta, B.; Al-Balushi, K.R. A Two-Step Procedure for Estimation of Instantaneous Rotational Speed with Large Fluctuations. Mech. Syst. Signal Process. 2013, 38, 96–102. [Google Scholar] [CrossRef]

- Lu, S.; Yan, R.; Liu, Y.; Wang, Q. Tacholess Speed Estimation in Order Tracking: A Review with Application to Rotating Machine Fault Diagnosis. IEEE Trans. Instrum. Meas. 2019, 68, 2315–2332. [Google Scholar] [CrossRef]

- Thirumala, K.; Umarikar, A.C.; Jain, T. Estimation of Single-Phase and Three-Phase Power-Quality Indices Using Empirical Wavelet Transform. Trans. Power Deliv. 2014, 30, 445–454. [Google Scholar] [CrossRef]

- Lin, R.; Liu, Z.; Jin, Y. Instantaneous Frequency Estimation for Wheelset Bearings Weak Fault Signals Using Second-Order Synchrosqueezing S-Transform with Optimally Weighted Sliding Window. ISA Trans. 2021, 115, 218–233. [Google Scholar] [CrossRef] [PubMed]

- Meignen, S.; Pham, D.H. Retrieval of the Modes of Multicomponent Signals from Downsampled Short-Time Fourier Transform. IEEE Trans. Signal Process. 2018, 66, 6204–6215. [Google Scholar] [CrossRef]

- Nguyen, T.-D.; Nguyen, P.-D. Improvements in the Wavelet Transform and Its Variations: Concepts and Applications in Diagnosing Gearbox in Non-Stationary Conditions. Appl. Sci. 2024, 14, 4642. [Google Scholar] [CrossRef]

- Dien, N.P.; Du, N.T. Fault Detection for Rotating Machines in Non-Stationary Operations Using Order Tracking and Cepstrum. In Advances in Engineering Research and Application, Proceedings of the International Conference on Engineering Research and Applications, Thai Nguyen, Vietnam, 1–2 December 2019; Sattler, K.-U., Nguyen, D.C., Vu, N.P., Tien Long, B., Puta, H., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 349–356. [Google Scholar]

- Dien, N.P.; Du, N.T. Gear Crack Detection under Variable Rotating Speed Conditions Using a Single Channel Accelerometer. Int. J. Mech. Prod. Eng. Res. Dev. 2020, 10, 127–136. [Google Scholar] [CrossRef]

- Du, N.T.; Dien, N.P.; Nga, N.T.T. Gear Fault Detection in Gearboxes Operated in Non-Stationary Conditions Based on Variable Sideband Analysis without a Tachometer. Front. Mech. Eng. 2022, 8, 1021222. [Google Scholar] [CrossRef]

- Schmidt, S.; Heyns, P.S.; de Villiers, J.P. A Novelty Detection Diagnostic Methodology for Gearboxes Operating under Fluctuating Operating Conditions Using Probabilistic Techniques. Mech. Syst. Signal Process. 2018, 100, 152–166. [Google Scholar] [CrossRef]

- Hamza, B.; Refassi, K. Novel Tacholess Order Tracking Method for Gear Fault Diagnosis under Speed-up and Speed-down Conditions. Insight-Non-Destr. Test. Cond. Monit. 2023, 65, 161–164. [Google Scholar] [CrossRef]

- Bonnardot, F.; El Badaoui, M.; Randall, R.B.; Danière, J.; Guillet, F. Use of the Acceleration Signal of a Gearbox in Order to Perform Angular Resampling (with Limited Speed Fluctuation). Mech. Syst. Signal Process. 2005, 19, 766–785. [Google Scholar] [CrossRef]

- Combet, F.; Gelman, L. An Automated Methodology for Performing Time Synchronous Averaging of a Gearbox Signal without Speed Sensor. Mech. Syst. Signal Process. 2007, 21, 2590–2606. [Google Scholar] [CrossRef]

- Coats, M.D.; Sawalhi, N.; Randall, R.B. Extraction of Tacho Information from a Vibration Signal for Improved Synchronous Averaging. In Proceedings of the Annual Conference of the Australian Acoustical Society 2009—Acoustics 2009: Research to Consulting, Adelaide, Australia, 23–25 November 2009. [Google Scholar]

- Urbanek, J.; Barszcz, T.; Sawalhi, N.; Randall, R.B. Comparison of Amplitude-Based and Phase-Based Methods for Speed Tracking in Application to Wind Turbines. Metrol. Meas. Syst. 2011, 18, 11. [Google Scholar] [CrossRef]

- Combet, F.; Zimroz, R. A New Method for the Estimation of the Instantaneous Speed Relative Fluctuation in a Vibration Signal Based on the Short Time Scale Transform. Mech. Syst. Signal Process. 2009, 23, 1382–1397. [Google Scholar] [CrossRef]

- Zhao, H.; Jiang, Y.; Niu, G. A Tacholess Order Tracking Method Based on Extended Intrinsic Chirp Component Decomposition for Gears under Large Speed Variation Conditions. J. Phys. 2022, 2184, 012052. [Google Scholar] [CrossRef]

- Etien, E.; Allouche, A.; Rambault, L.; Doget, T.; Cauet, S.; Sakout, A. A Tacholess Order Analysis Method for Pmsg Mechanical Fault Detection with Varying Speeds. Electronics 2021, 10, 418. [Google Scholar] [CrossRef]

- Jing, S.; Luo, Z.; Leng, J.; Wang, Z. Tacholess Order Tracking Method for Gearbox Based on Time-Varying Filter and Energy Centrobaric Correction Method. J. Vibroeng. 2019, 21, 1282–1295. [Google Scholar] [CrossRef]

- Xu, L.; Chatterton, S.; Pennacchi, P.; Liu, C. A Tacholess Order Tracking Method Based on Inverse Short Time Fourier Transform and Singular Value Decomposition for Bearing Fault Diagnosis. Sensors 2020, 20, 6924. [Google Scholar] [CrossRef]

- Peeters, C.; Leclère, Q.; Antoni, J.; Lindahl, P.; Donnal, J.; Leeb, S.; Helsen, J. Review and Comparison of Tacholess Instantaneous Speed Estimation Methods on Experimental Vibration Data. Mech. Syst. Signal Process. 2019, 129, 407–436. [Google Scholar] [CrossRef]

- Schmidt, S.; Heyns, P.S.; de Villiers, J.P. A Tacholess Order Tracking Methodology Based on a Probabilistic Approach to Incorporate Angular Acceleration Information into the Maxima Tracking Process. Mech. Syst. Signal Process. 2018, 100, 630–646. [Google Scholar] [CrossRef]

- Han, J.; Gao, H.; Guo, L.; Liu, X.; Wu, T.; Li, S. Bearing Fault Diagnosis Method Based on Order Tracking without Rotational Speed. Xinan Jiaotong Daxue Xuebao/J. Southwest Jiaotong Univ. 2024, 59, 220–228. [Google Scholar] [CrossRef]

- Duan, R.; Liao, Y.; Yang, L. Adaptive Tacholess Order Tracking Method Based on Generalized Linear Chirplet Transform and Its Application for Bearing Fault Diagnosis. ISA Trans. 2022, 127, 324–341. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, K.; Zhang, X.; Xu, Y. A Tacholess Order Tracking Method Based on Spectral Amplitude Modulation for Variable Speed Bearing Fault Diagnosis. IEEE Trans. Instrum. Meas. 2023, 72, 3518708. [Google Scholar] [CrossRef]

- Hu, Y.; Tu, X.; Li, F.; Li, H.; Meng, G. An Adaptive and Tacholess Order Analysis Method Based on Enhanced Empirical Wavelet Transform for Fault Detection of Bearings with Varying Speeds. J. Sound Vib. 2017, 409, 241–255. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, G.; Luo, A.; Liang, L.; Jiang, K. An Online Tacholess Order Tracking Technique Based on Generalized Demodulation for Rolling Bearing Fault Detection. J. Sound Vib. 2016, 367, 233–249. [Google Scholar] [CrossRef]

- Zhao, M.; Lin, J.; Xu, X.; Lei, Y. Tacholess Envelope Order Analysis and Its Application to Fault Detection of Rolling Element Bearings with Varying Speeds. Sensors 2013, 13, 10856. [Google Scholar] [CrossRef] [PubMed]

- Du, N.T.; Trung, P.T.; Cuong, N.H.; Dien, N.P. Automatic Rolling Bearings Fault Classification: A Case Study at Varying Speed Conditions. Front. Mech. Eng. 2024, 10, 1341466. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, W.; Wu, C. A Fast Tacho-Less Order Tracking Method for Gear Fault Diagnosis Under Large Rotational Speed Variation Conditions Based on Multi-Stage Generalized Demodulation. In Advances in Mechanical Design: Proceedings of the 2019 International Conference on Mechanical Design, Huzhou, China, 12–14 August 2020; Springer: Singapore, 2020; Volume 77, p. 77. [Google Scholar]

- Sun, B.; Li, H.; Wang, C.; Zhang, K.; Chen, S. Current-Aided Dynamic Time Warping for Planetary Gearbox Fault Detection at Time-Varying Speeds. IEEE Sens. J. 2024, 24, 390–402. [Google Scholar] [CrossRef]

- Qu, Y.; Zhu, J.; He, D.; Qiu, B.; Bechhoefer, E. Development of a New Acoustic Emission Based Fault Diagnosis Tool for Gearbox. In Proceedings of the PHM 2013—2013 IEEE International Conference on Prognostics and Health Management, Gaithersburg, MD, USA, 24–27 June 2013. [Google Scholar]

- Coats, M.D.; Randall, R.B. Compensating for Speed Variation by Order Tracking with and without a Tacho Signal. In Proceedings of the Institution of Mechanical Engineers—10th International Conference on Vibrations in Rotating Machinery, London, UK, 1–13 September 2012. [Google Scholar]

- Gerber, T.; Martin, N.; Mailhes, C. Monitoring Based on Time-Frequency Tracking of Estimated Harmonic Series and Modulation Sidebands. In Advances in Condition Monitoring of Machinery in Non-Stationary Operations, Proceedings of the Fourth International Conference on Condition Monitoring of Machinery in Non-Stationary Operations, CMMNO’2014, Lyon, France, 15–17 December 2014; Chaari, F., Zimroz, R., Bartelmus, W., Haddar, M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 87–98. [Google Scholar]

- Sim, J.; Kim, S.; Park, H.J.; Choi, J.H. A Tutorial for Feature Engineering in the Prognostics and Health Management of Gears and Bearings. Appl. Sci. 2020, 10, 5639. [Google Scholar] [CrossRef]

- Olhede, S.; Walden, A.T. A Generalized Demodulation Approach to Time-Frequency Projections for Multicomponent Signals. Proc. R. Soc. A 2005, 461, 2159–2179. [Google Scholar] [CrossRef]

- Bechhoefer, E.; Kingsley, M.; Menon, P. Bearing Envelope Analysis Window Selection Using Spectral Kurtosis Techniques. In Proceedings of the Prognostics and Health Management (PHM), Denver, CO, USA, 20–23 June 2011; IEEE: Montreal, QC, Canada, 2011; pp. 1–6. [Google Scholar]

- Bechhoefer, E.; Van Hecke, B.; He, D. Processing for Improved Spectral Analysis. In Proceedings of the Annual Conference of Prognostics and Health Management Society 2013, New Orleans, LA, USA, 14–17 October 2013. [Google Scholar]

- Meltzer, G.; Dien, N.P. Fault Diagnosis in Gears Operating under Non-Stationary Rotational Speed Using Polar Wavelet Amplitude Maps. Mech. Syst. Signal Process. 2004, 18, 985–992. [Google Scholar] [CrossRef]

| Value | Equation |

|---|---|

| Mean | |

| Root mean square | |

| Standard deviation | |

| Peak value | |

| Skewness factor | |

| Kurtosis factor | |

| Crest factor | |

| Clearance factor | |

| Shape factor | |

| Impulse factor | |

| Peak to peak |

| Value Description | Equation |

|---|---|

| The figure of merits zero | |

| Sideband energy ratio | |

| The ratio of the fourth moment to the squared average variance of the residual signal | |

| The ratio of the fourth moment to the squared average variance of the GMF-centered filtered signal envelope | |

| Fault detection on a few gear teeth | |

| Surface fault detection on machinery components | |

| Surface fault detection on machinery components with higher sensitivity | |

| Energy ratio |

| Reference Results | The Proposed Scheme Results | ||

|---|---|---|---|

| Feature | FDR Value | Feature | FDR Value |

| MEAN | 57.02 | MEAN | 56.98 |

| CF | 12.13 | CF | 10.61 |

| NA4 | 9.88 | NA4 | 10.25 |

| FM4 | 8.96 | FM4 | 9.25 |

| KUR | 8.63 | KUR | 8.75 |

| IF | 6.32 | RMS | 5.76 |

| PEAK | 5.98 | PEAK | 5.74 |

| RMS | 5.80 | IF | 5.71 |

| P2P | 4.77 | P2P | 4.64 |

| MF | 4.14 | MF | 3.79 |

| FM0 | 3.58 | FM0 | 3.37 |

| M6A | 3.05 | M6A | 3.11 |

| STD | 2.12 | STD | 2.11 |

| M8A | 1.48 | M8A | 1.54 |

| ER | 0.38 | ER | 0.38 |

| SER | 0.28 | SER | 0.30 |

| SF | 0.23 | SF | 0.22 |

| NB4 | 0.01 | NB4 | 0.01 |

| SK | 0.00 | SK | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.-D.; Nguyen, H.-C.; Nguyen, V.-M.-H.; Nguyen, P.-D. Tacholess Time Synchronous Averaging for Gear Fault Diagnosis in Wind Turbine Gearboxes Using a Single Accelerometer. Machines 2024, 12, 424. https://doi.org/10.3390/machines12060424

Nguyen T-D, Nguyen H-C, Nguyen V-M-H, Nguyen P-D. Tacholess Time Synchronous Averaging for Gear Fault Diagnosis in Wind Turbine Gearboxes Using a Single Accelerometer. Machines. 2024; 12(6):424. https://doi.org/10.3390/machines12060424

Chicago/Turabian StyleNguyen, Trong-Du, Huu-Cuong Nguyen, Van-Minh-Hoang Nguyen, and Phong-Dien Nguyen. 2024. "Tacholess Time Synchronous Averaging for Gear Fault Diagnosis in Wind Turbine Gearboxes Using a Single Accelerometer" Machines 12, no. 6: 424. https://doi.org/10.3390/machines12060424

APA StyleNguyen, T.-D., Nguyen, H.-C., Nguyen, V.-M.-H., & Nguyen, P.-D. (2024). Tacholess Time Synchronous Averaging for Gear Fault Diagnosis in Wind Turbine Gearboxes Using a Single Accelerometer. Machines, 12(6), 424. https://doi.org/10.3390/machines12060424