A Study on Micro-Pit Texture Parameter Optimization and Its Tribological Properties

Abstract

:1. Introduction

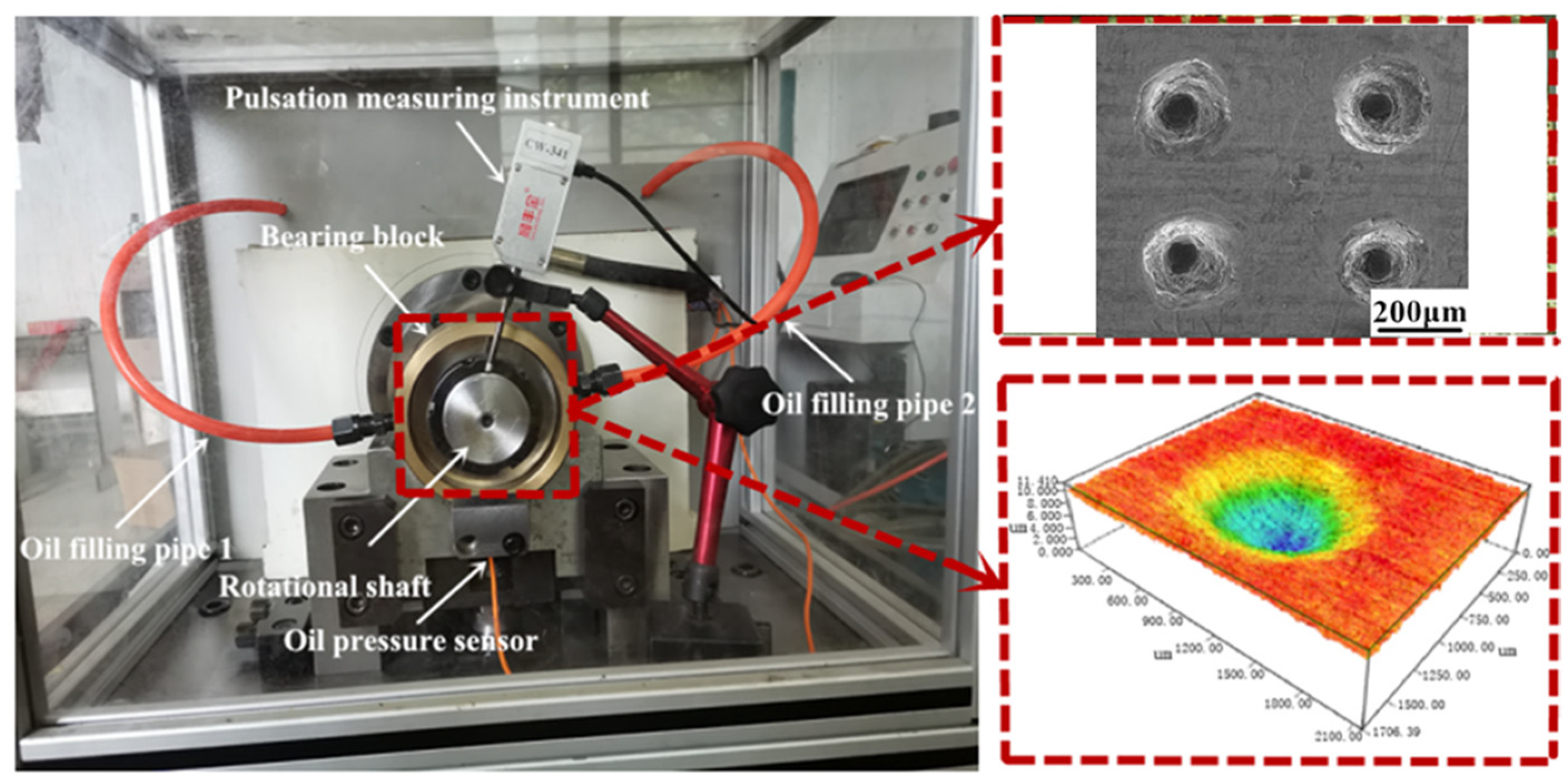

2. Experiments

2.1. Preparation

2.2. Friction and Wear Test

2.3. Design of the Orthogonal Experiment

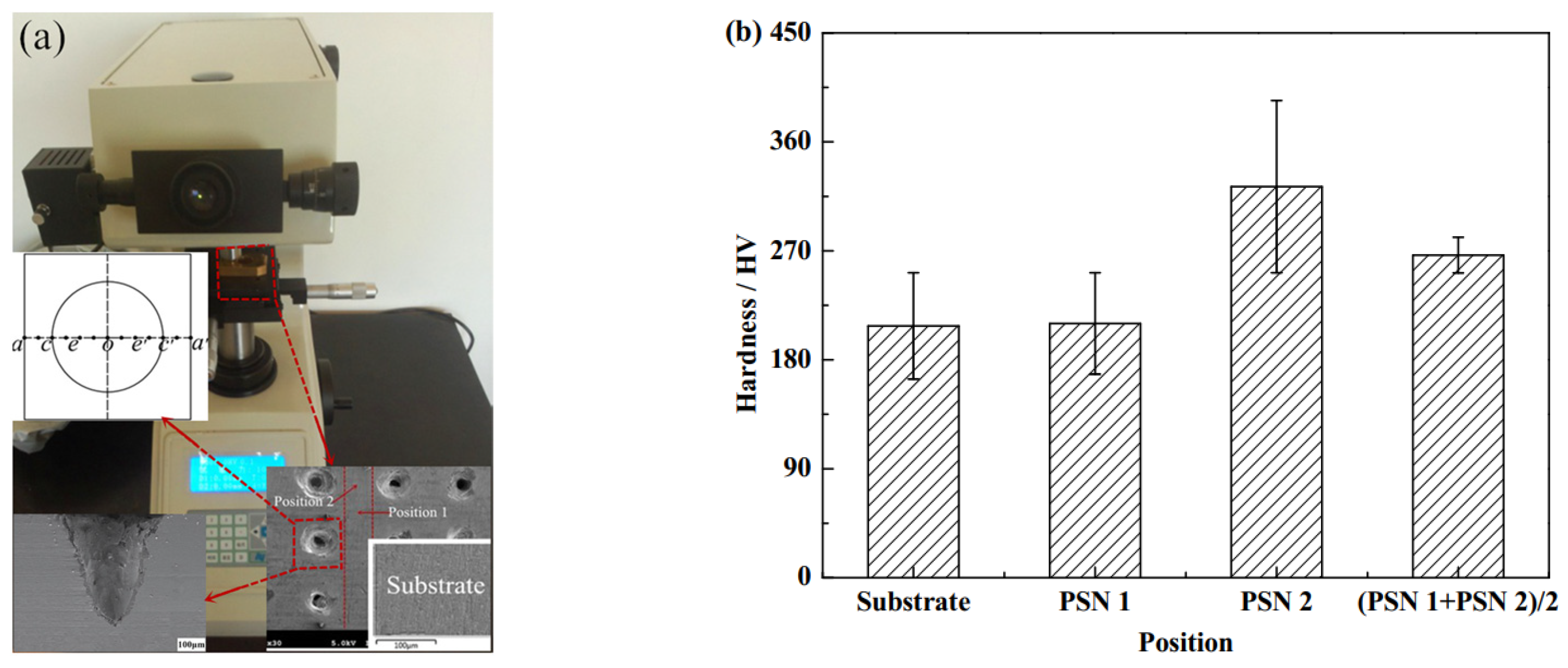

3. Hardness Analysis of Laser Machining

3.1. Analysis of the Surface Hardness

3.2. Effect of Energy on Microhardness

3.3. Effect of Repetition Times

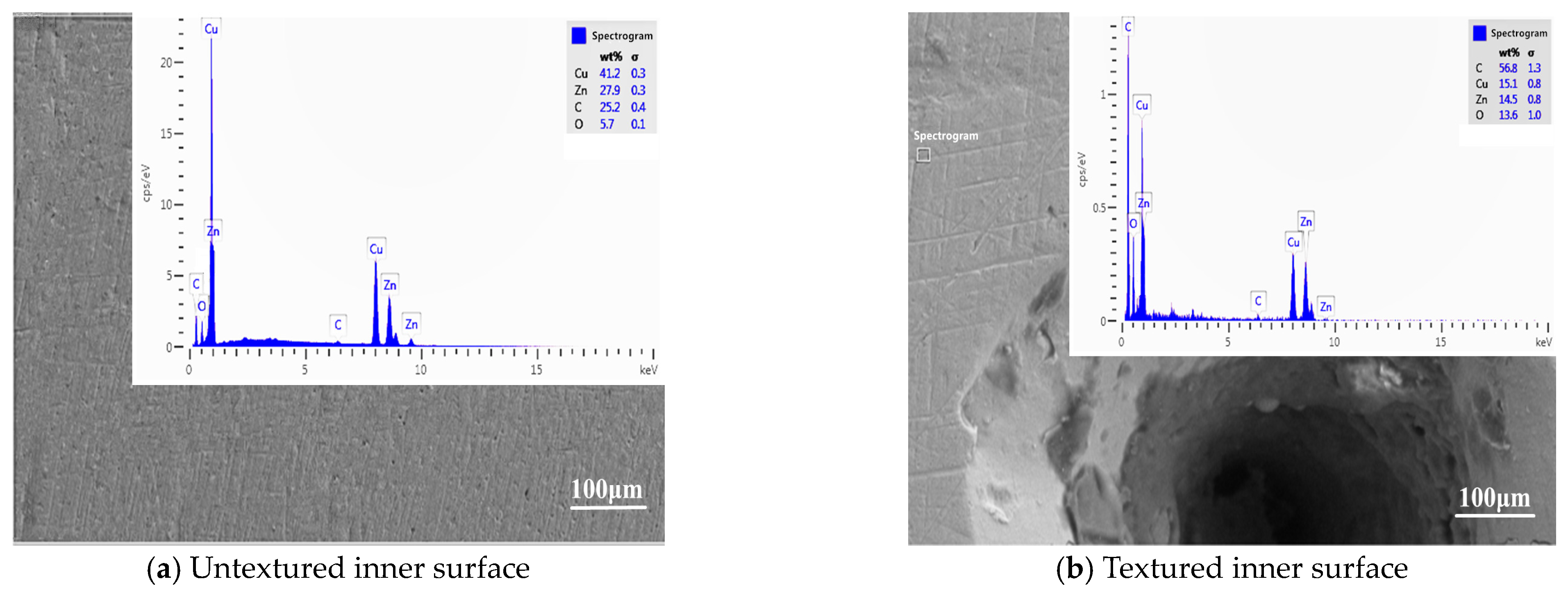

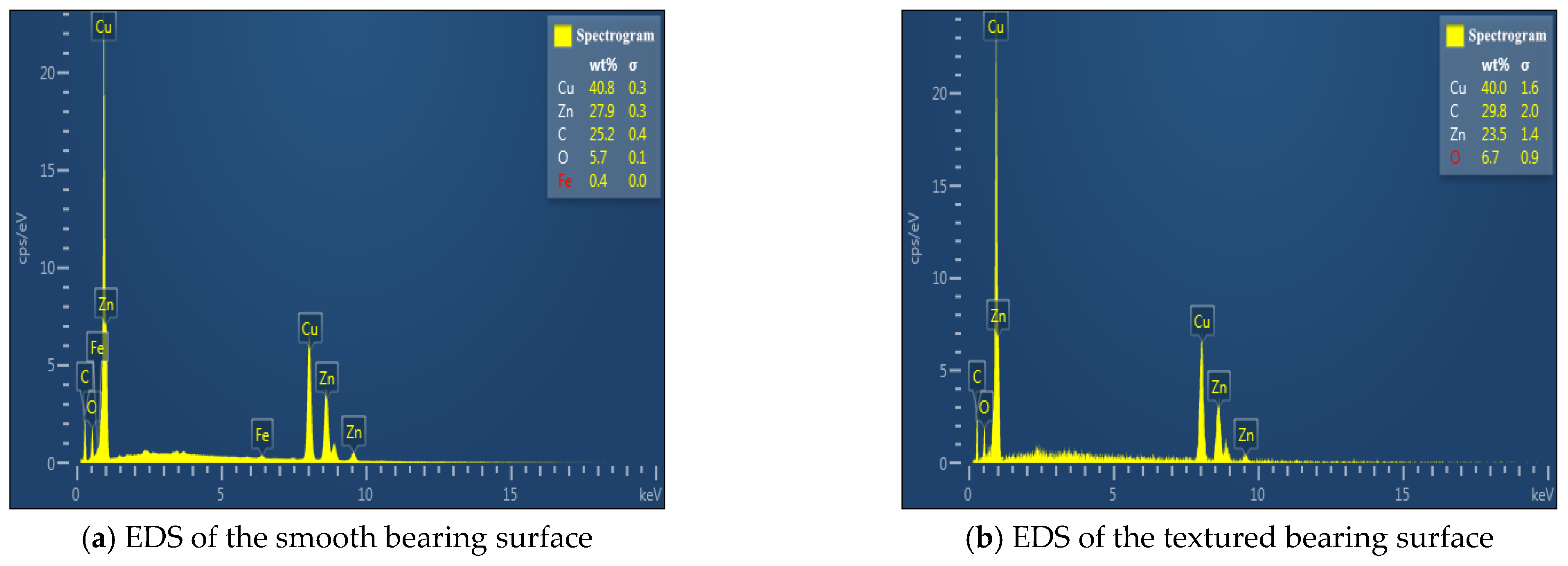

3.4. Surface Composition Analysis

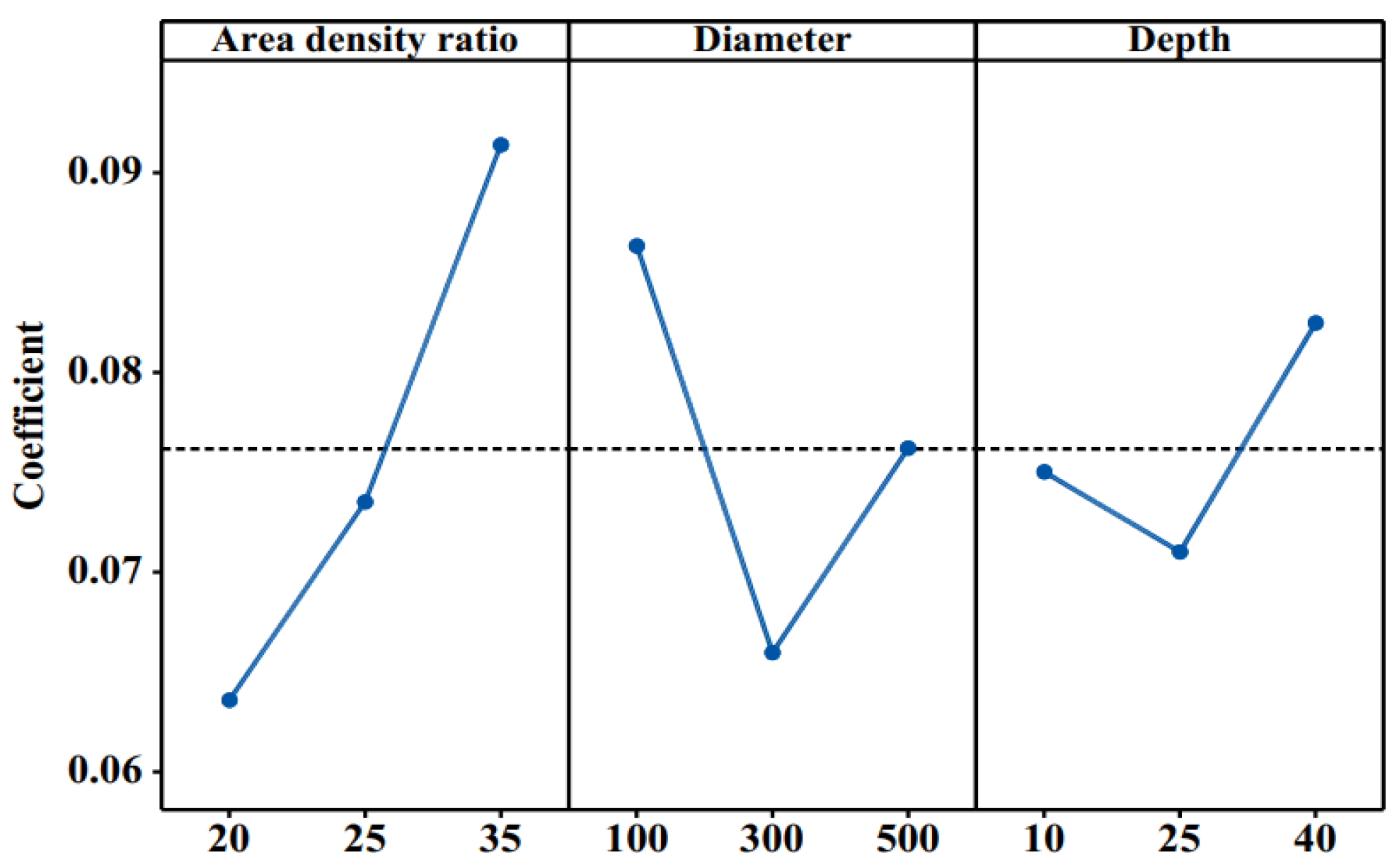

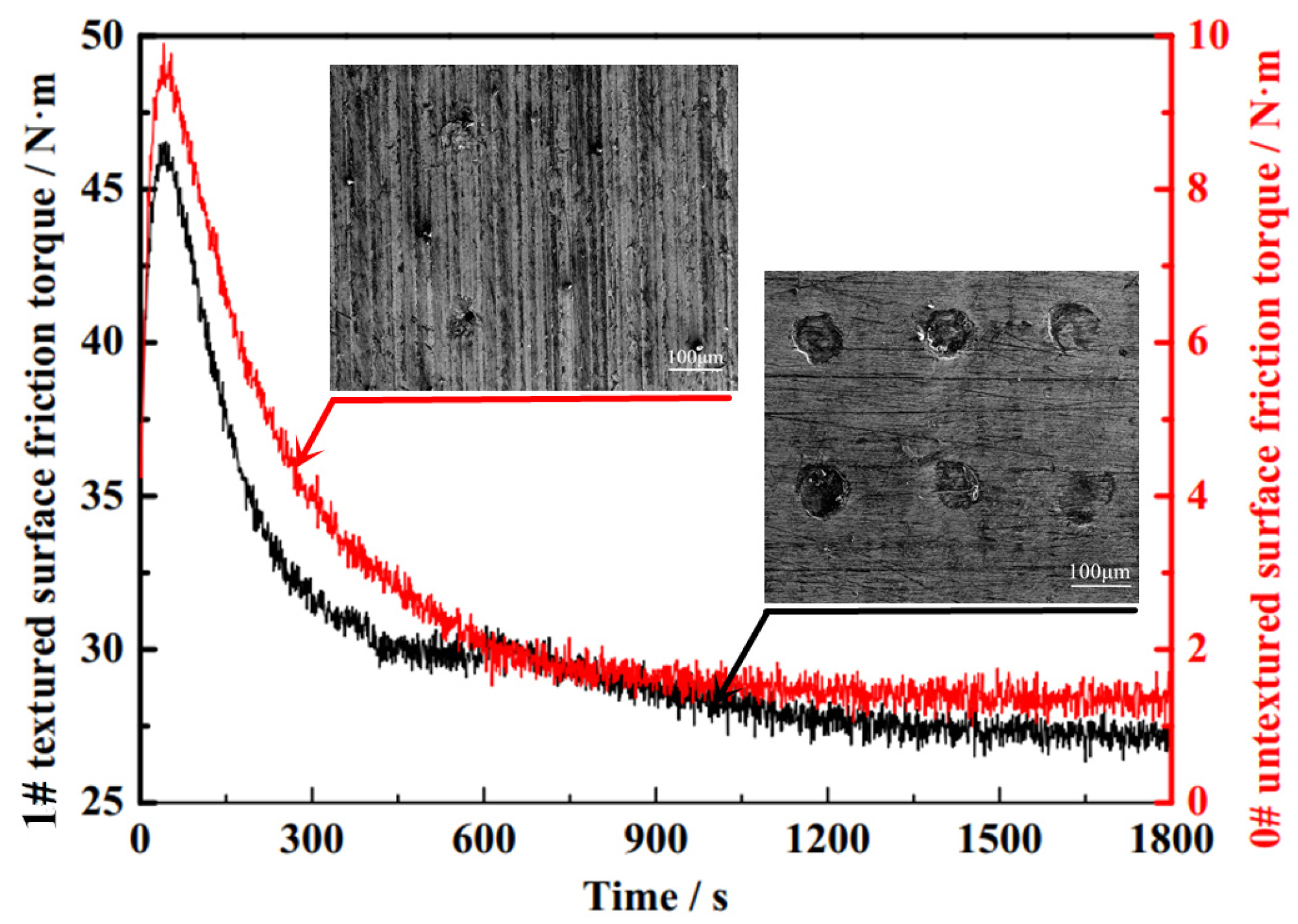

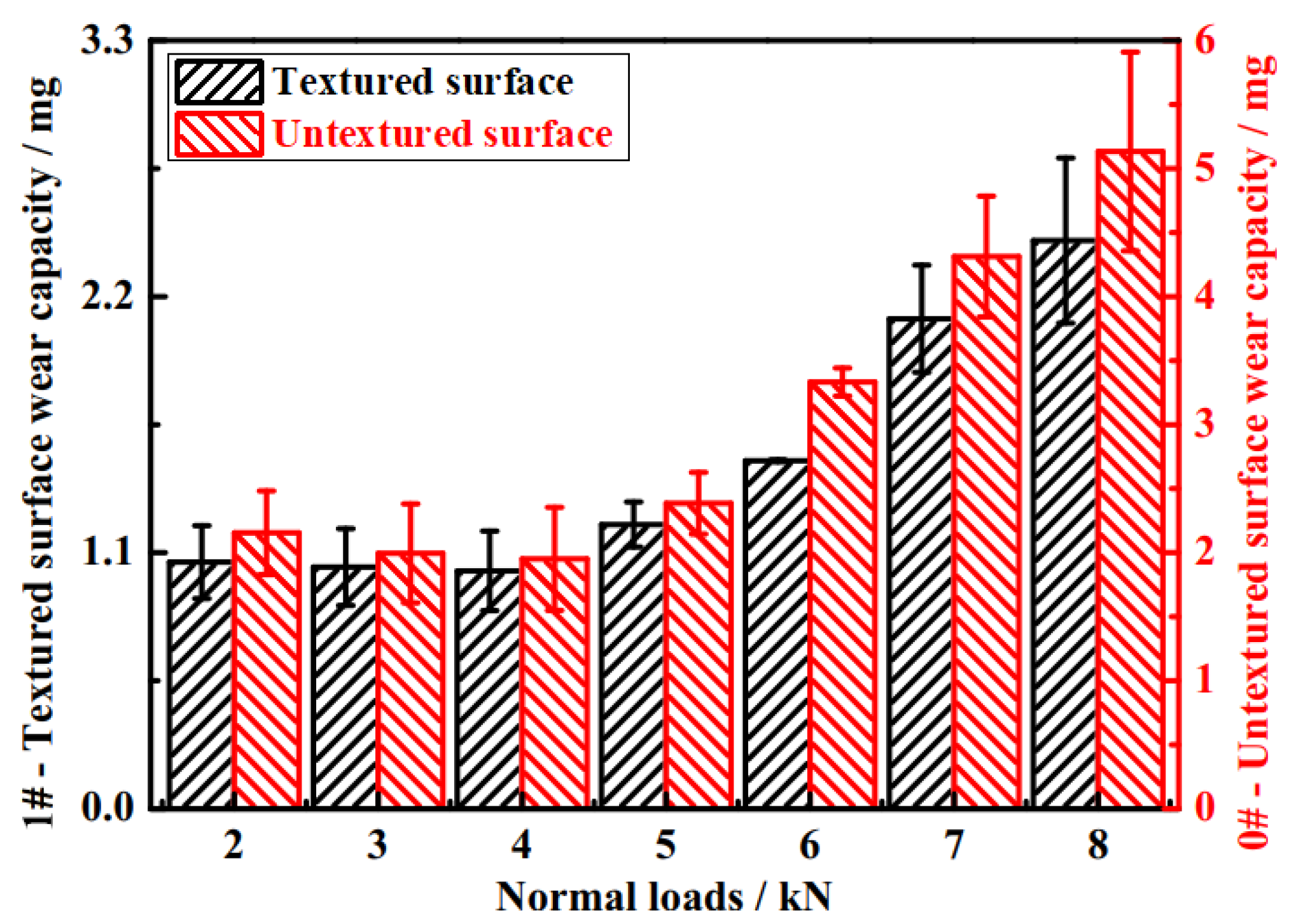

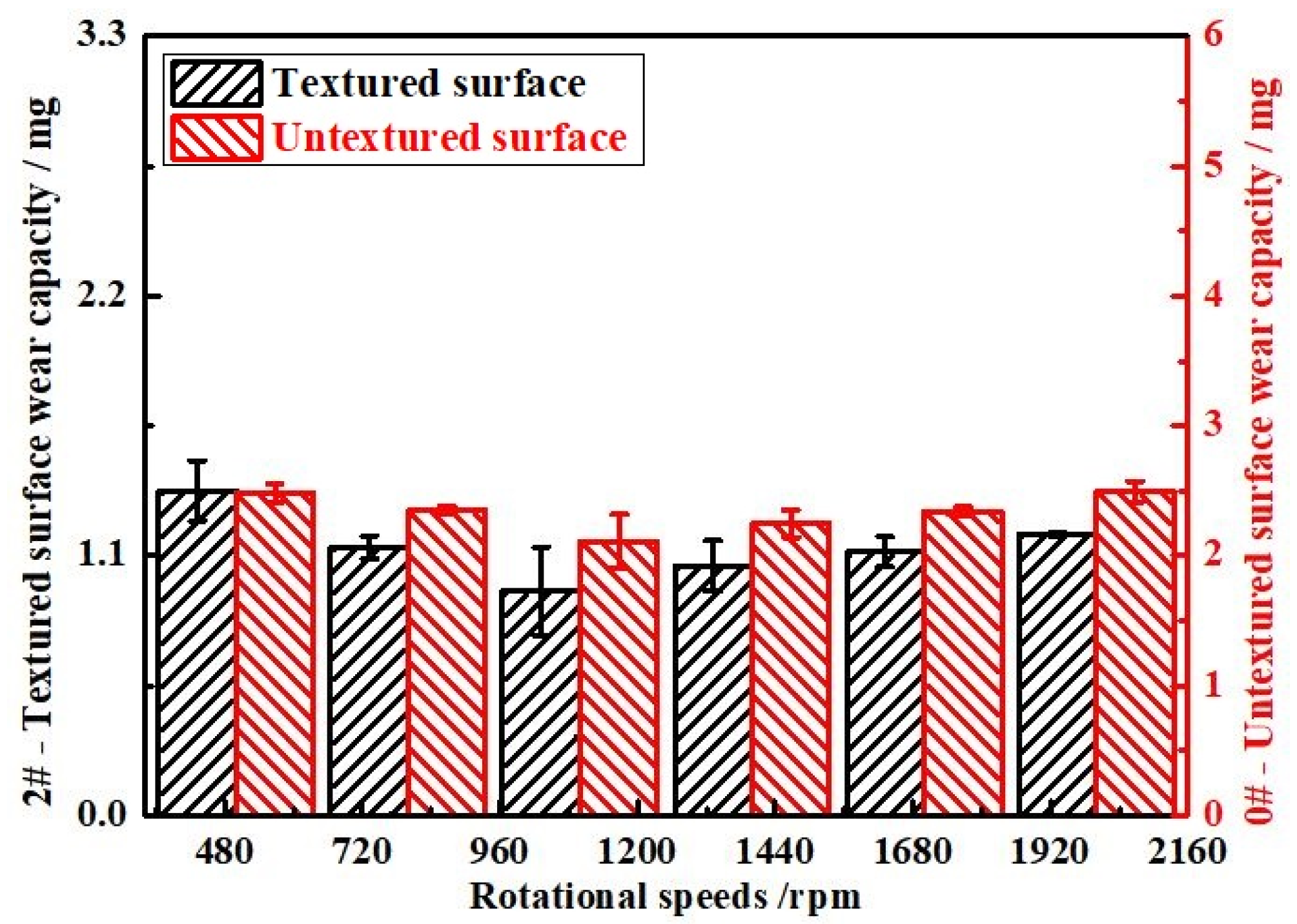

4. Tribological Characteristics

5. Conclusions

- (1)

- The laser texturing of surfaces induced hardening in some areas, and it resulted in increased concentrations of carbon (C) and oxygen (O) elements on the inner surfaces of processed bearings by 31.1% and 7.9%, respectively. Moreover, it was found that the micro-pit surface hardness followed an approximate parabolic distribution and decreased along the micro-pit wall. This finding aids our understanding of hardness change during laser processing.

- (2)

- The optimal texture parameters to obtain the lowest friction coefficient were Sp = 20%, d = 300 μm, and hp = 25 μm. The antifriction properties of the investigated textured bearing could be improved by up to 48%. Suitable micro-pit texturing on the surface can effectively reduce friction, which provides a valuable approach for surface optimization design. In addition, it was found that the oil film boundary underwent a series of lubrication processes (from boundary lubrication to mixed lubrication and finally to dynamic lubrication) as the operating conditions changed.

- (3)

- The corresponding wear was abrasive wear, and the antifriction mechanism involved the synergistic effect of abrasive storage, a secondary hydrodynamic lubrication source, and a supplied lubricating medium to change the lubrication states. These outcomes provide valuable information for the optimization and control of bearing lubrication.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mao, Y.Z.; Yang, J.X.; Ji, J.C.; Xu, W.; Guo, Q. An analytical solution of Reynolds equation for evaluation the characteristics of surface textured bearing. Ind. Lubr. Tribol. 2020, 72, 1075–1085. [Google Scholar] [CrossRef]

- Mao, Y.Z.; Yang, J.X.; Xu, W.J.; Liu, Y. Study on the influence of round pits arrangement patterns on tribological properties of journal bearings. Ind. Lubr. Tribol. 2019, 71, 931–941. [Google Scholar] [CrossRef]

- Lin, C.G.; Yang, Y.N.; Chu, J.L.; Sima, C.; Liu, P.; Qi, L.-B.; Zou, M.-S. Study on nonlinear dynamic characteristics of propulsion shafting under friction contact of stern bearings. Tribol. Int. 2023, 183, 108391. [Google Scholar] [CrossRef]

- Kajihara, M.; Ichikawa, R.; Nagaami, K.; Suzuki, H.; Yonezu, A. Micro-dimple textured surface produced by laser-induced particle impact test and improving tribological performance. Mater. Today Commun. 2024, 38, 108213. [Google Scholar] [CrossRef]

- Mao, Y.Z.; Li, D.Q.; Li, L.L.; Zheng, J. Effect of textured parameters on tribological properties of hydrodynamic journal bearing. Ind. Lubr. Tribol. 2024, 76, 102–109. [Google Scholar] [CrossRef]

- Su, B.B.; Zou, X.H.; Wang, Z.X.; Huang, L. Numerical analysis of lubrication properties on a bio-inspired parabolic textured surface. Meccanica 2024, 59, 987–1000. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.X.; Guo, Z.W.; Zhang, X.; Yin, H.; Xu, C.; Yuan, C. Anti-friction and self-repairing abilities of ultrafine serpentine, attapulgite and kaolin in oil for the cylinder liner-piston ring tribo-systems. Lubr. Sci. 2022, 34, 210–223. [Google Scholar] [CrossRef]

- Liu, Q.; Kouediatouka, A.N.; Jiang, S.; Yuan, H.; Li, J.; Dong, G. Laser com-texture on Ti6Al4V surface for lubricant transportation to improve tribological properties. J. Tribol. Trans. ASME 2023, 145, 031705. [Google Scholar] [CrossRef]

- Mishra, S.; Aggarwal, S. A review of performance of textured journal bearing. Tribol. Online 2023, 18, 494–507. [Google Scholar] [CrossRef]

- Jiao, B.W.; Liu, Y.Y.; Li, T.Y.; Lu, X.; Ma, X. Macro-texture in hydrodynamic lubrication: Effects of dimple parameter, density and distribution. Proc. Inst. Mech. Eng. Part C 2022, 236, 8703–8713. [Google Scholar] [CrossRef]

- Zhu, C.X.; Wang, X.Y.; Ma, W. Experimental study on the wear characteristics of textured joint surfaces under bionic lubrication. Key Eng. Mater. 2023, 945, 19–25. [Google Scholar] [CrossRef]

- Guo, Q.G.; Zheng, L.; Zhong, Y.H.; Wang, S.; Ren, L. Numerical simulation of hydrodynamic lubrication performance for continuous groove-textured surface. Tribol. Int. 2022, 167, 107411. [Google Scholar] [CrossRef]

- Lü, Y.J.; Kang, J.X.; Zhao, X.W.; Zhang, Y.; Yang, X.; Chen, R.; Xing, Z. Effects of different surface textures on tribological performances of the cylinder liner-piston ring: An experimental study. Int. J. Engine Res. 2023, 25, 545–556. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Dzierwa, A.; Pawlus, P. Effects of operating conditions and pit area ratio on the coefficient of friction of textured assemblies in lubricated reciprocating sliding. Materials 2022, 15, 7199. [Google Scholar] [CrossRef] [PubMed]

- Soltani-Kordshuli, F.; Harris, N.; Zou, M. Tribological behavior of polydopamine/polytetrafluoroethylene coating on laser textured stainless steel with hilbert Curves. Friction 2023, 11, 1307–1319. [Google Scholar] [CrossRef]

- Li, P.Y.; Zhang, F.; Zhang, H.; Wang, T.; Wang, Q.; Qiao, W. Lubrication performance of kite-shaped microtexture under hydrodynamic lubrication. Tribol. Int. 2023, 179, 108–144. [Google Scholar] [CrossRef]

- Schnell, G.; Studemund, H.; Thomas, R.; Seitz, H. Experimental investigations on the friction behavior of partially femtosecond laser textured journal bearing shells. Tribol. Int. 2023, 188, 108764. [Google Scholar] [CrossRef]

- Schnell, G.; Timon, M.; Hermann, S. Tribological effects of different scaled chevronshaped microstructures on the Stribeck curve of parallel contacts under unidirectional friction. Tribol. Int. 2022, 178, 108099. [Google Scholar] [CrossRef]

- Zhang, H.; Pei, X.; Jiang, X. Anti-wear property of laser textured 42CrMo steel surface. Lubricants 2023, 11, 353. [Google Scholar] [CrossRef]

- Annadi, R.R.; Syed, I. Impact of multi-scaled surface textures on tribological performance of parallel sliding contact under lubricated condition. Tribol. Int. 2023, 183, 108415. [Google Scholar] [CrossRef]

- Hu, E.; Zhi, J.; Wu, Y.; Yu, S. Fabrication and tribological properties of the laser textured SiC cylinders with diamond coating. Appl. Phys. A 2023, 129, 257. [Google Scholar] [CrossRef]

- Wozniak, A.; Bialas, O.; Adamiak, M.; Hadzima, B.; Szewczenko, J. The influence of laser texturing on the tribological behavior of titanium alloy Ti6Al4V in medical applications. Arch. Civ. Mech. Eng. 2024, 24, 146. [Google Scholar] [CrossRef]

- Guo, G.L.; Hu, T.; Li, Q.; Liu, Y. Nanosecond laser-induced dimple texturing of TB6 alloy surfaces: Tribological behavior under dry and starved-oil lubrication. Tribol. Int. 2024, 197, 109842. [Google Scholar] [CrossRef]

- Zhao, T.; Wang, Y.Q.; He, Y.; Zhu, Y.; Li, M. Numerical Simulation and Experimental Investigation on Tribological Properties of Gear Alloy Surface Biomimetic Texture. Tribol. Trans. 2023, 66, 610–622. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Zhao, F.F.; Wei, X.; Gao, F.; Li, P.; Dong, G. Effect of texture parameters on the tribological properties of spheroidal graphite cast iron groove-textured surface under sand-containing oil lubrication conditions. Wear 2019, 428–429, 470–480. [Google Scholar] [CrossRef]

- Hu, T.C.; Hu, L.T. The study of tribological properties of laser-textured surface of 2024 aluminium alloy under boundary lubrication. Lubr. Sci. 2012, 24, 84–93. [Google Scholar] [CrossRef]

- Xu, Y.F.; Peng, Y.B.; Dearn, K.D.; You, T.; Geng, J.; Hu, X. Fabrication and tribological characterization of laser textured boron cast iron surfaces. Surf. Coat. Technol. 2017, 313, 391–401. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovith, A.; Perfiliev, V.; Lapsker, I.; Halperin, G.; Itovich, Y.; Etsion, I. Friction and wear of MoS2 films on laser textured steel surfaces. Surf. Coat. Technol. 2008, 202, 3332–3340. [Google Scholar] [CrossRef]

- Arslan, A.; Masuki, H.H.; Varman, M.; Kalam, A.; Quazi, M.; Al Mahmud, K.; Gulzar, M.; Habibullah, M. Effect of texture diameter and depth on the tribological performance of DLC coating under lubricated sliding condition. Appl. Surf. Sci. 2015, 356, 1135–1149. [Google Scholar] [CrossRef]

- Saeid, F.; Parlinska-Wojtan, M.; Hoffmann, P.; Wasmer, K. Effects of laser surface texturing on the wear and failure mechanism of grey cast iron reciprocating against steel under starved lubrication conditions. Wear 2017, 386–387, 29–38. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, D.Y.; Hua, M.; Dong, G.N.; Chin, K.S. A study on the tribological behavior of surface texturing on the babbitt alloy under mixed or starved lubrication. Tribol. Lett. 2014, 56, 305–315. [Google Scholar] [CrossRef]

| Parameters | Units | Values |

|---|---|---|

| Flash point | °C | 230 |

| Viscosity in 100 °C | 10−6 m2/s | 15.66 |

| Density | kg/m3 | 900 |

| Pour point | °C | −39 |

| Viscosity grade | - | 40 |

| Level | Factors | ||

|---|---|---|---|

| A | B | C | |

| 1 | 20 | 100 | 10 |

| 2 | 25 | 300 | 25 |

| 3 | 35 | 500 | 40 |

| No. | Factors | COF | ||

|---|---|---|---|---|

| A | B | C | ||

| 0 | 0 | 0 | 0 | 0.12760 |

| 1 | 20 | 100 | 10 | 0.07050 |

| 2 | 20 | 300 | 25 | 0.05320 |

| 3 | 20 | 500 | 40 | 0.07012 |

| 4 | 25 | 100 | 25 | 0.07870 |

| 5 | 25 | 300 | 40 | 0.06451 |

| 6 | 25 | 500 | 10 | 0.07736 |

| 7 | 35 | 100 | 40 | 0.11280 |

| 8 | 35 | 300 | 10 | 0.08023 |

| 9 | 35 | 500 | 25 | 0.08115 |

| K1 | 0.087 | 0.0760 | 0.0721 | |

| K2 | 0.066 | 0.0710 | 0.0811 | |

| K3 | 0.076 | 0.0825 | 0.0764 | |

| R | 0.010 | 0.0050 | 0.0043 | |

| Rank | A > B > C | |||

| Optimum | Sp = 20%, d = 300 μm, hp = 25 μm | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Y.; Zhang, Y.; Zheng, J.; Li, L.; Huang, Y.; Shi, S.; Wang, L.; Pei, J.; Li, Z. A Study on Micro-Pit Texture Parameter Optimization and Its Tribological Properties. Machines 2024, 12, 475. https://doi.org/10.3390/machines12070475

Mao Y, Zhang Y, Zheng J, Li L, Huang Y, Shi S, Wang L, Pei J, Li Z. A Study on Micro-Pit Texture Parameter Optimization and Its Tribological Properties. Machines. 2024; 12(7):475. https://doi.org/10.3390/machines12070475

Chicago/Turabian StyleMao, Yazhou, Yuxuan Zhang, Jingyang Zheng, Lilin Li, Yuchun Huang, Shaolin Shi, Linyuan Wang, Jiaming Pei, and Zichen Li. 2024. "A Study on Micro-Pit Texture Parameter Optimization and Its Tribological Properties" Machines 12, no. 7: 475. https://doi.org/10.3390/machines12070475

APA StyleMao, Y., Zhang, Y., Zheng, J., Li, L., Huang, Y., Shi, S., Wang, L., Pei, J., & Li, Z. (2024). A Study on Micro-Pit Texture Parameter Optimization and Its Tribological Properties. Machines, 12(7), 475. https://doi.org/10.3390/machines12070475