Design of Soft Robots: A Review of Methods and Future Opportunities for Research

Abstract

1. Introduction

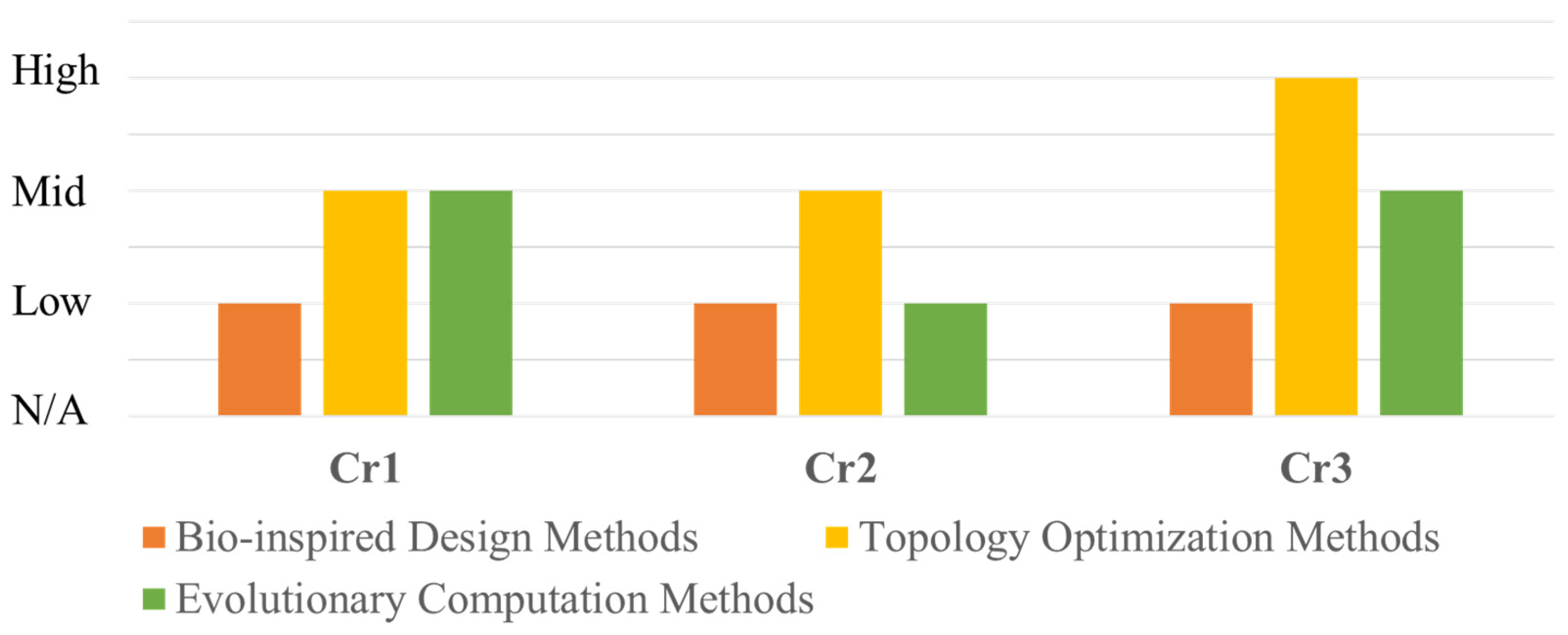

- The first criterion (Cr1): A design method that represents the design requirement for a soft robot as completely and explicitly as possible. By “completely”, it means that all three categories of requirements, namely function, performance, and condition, can be included [27]. By explicitly, it means that the design requirement can be expressed in an object model or schematic model rather than in a specific computational model, e.g., finite element model.

- The second criterion (Cr2): A design method that allows for creating the architecture or the concept of a soft robot as rationally as possible. By “rationally”, it means that the concept is created based on first principles.

- The third criterion (Cr3): A design method that allows for creating the final design as systematically as possible. By “Systematically”, it means that the design process follows the four steps outlined above (adapted from the one in [23]), which may also be called a white-box rather than a black-box process [28].

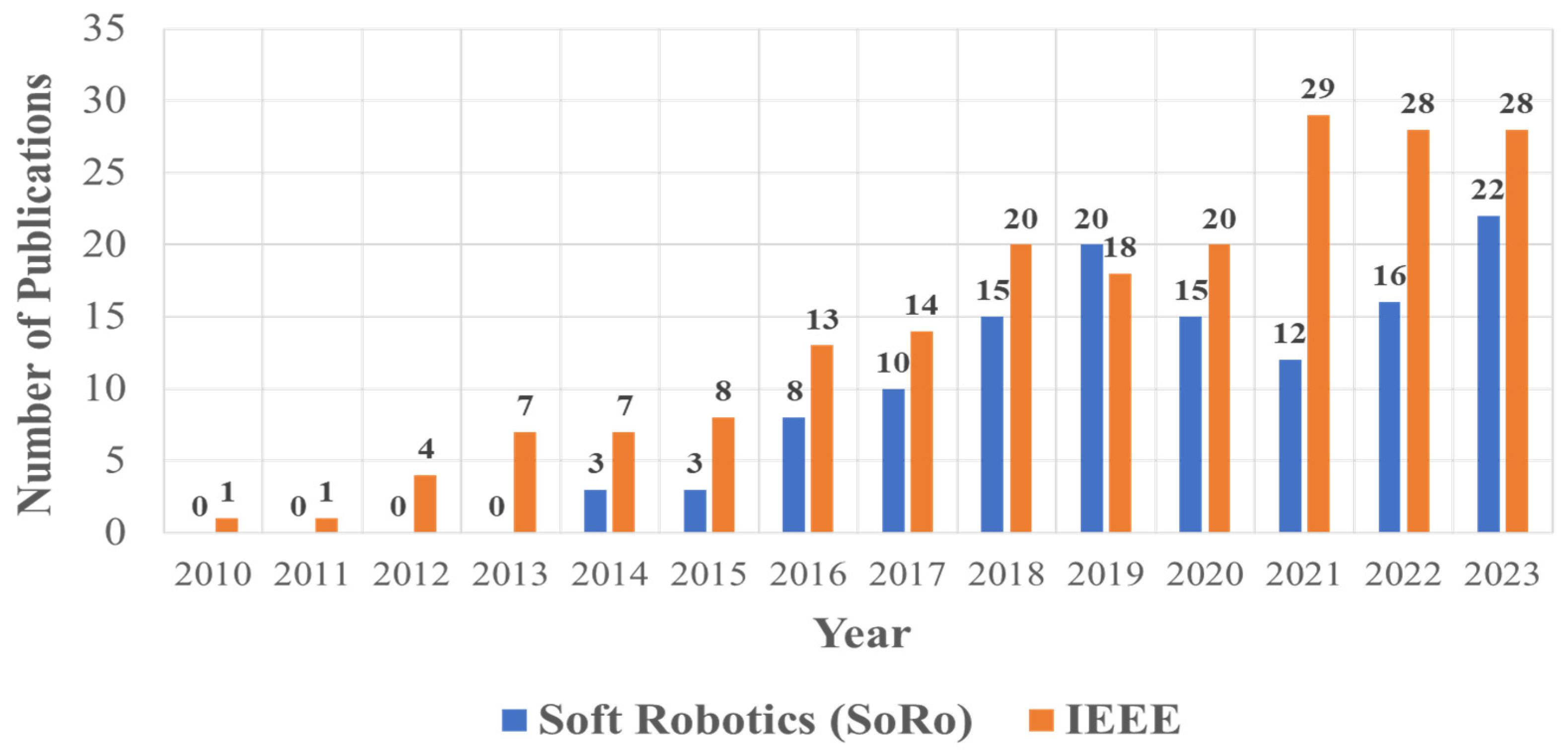

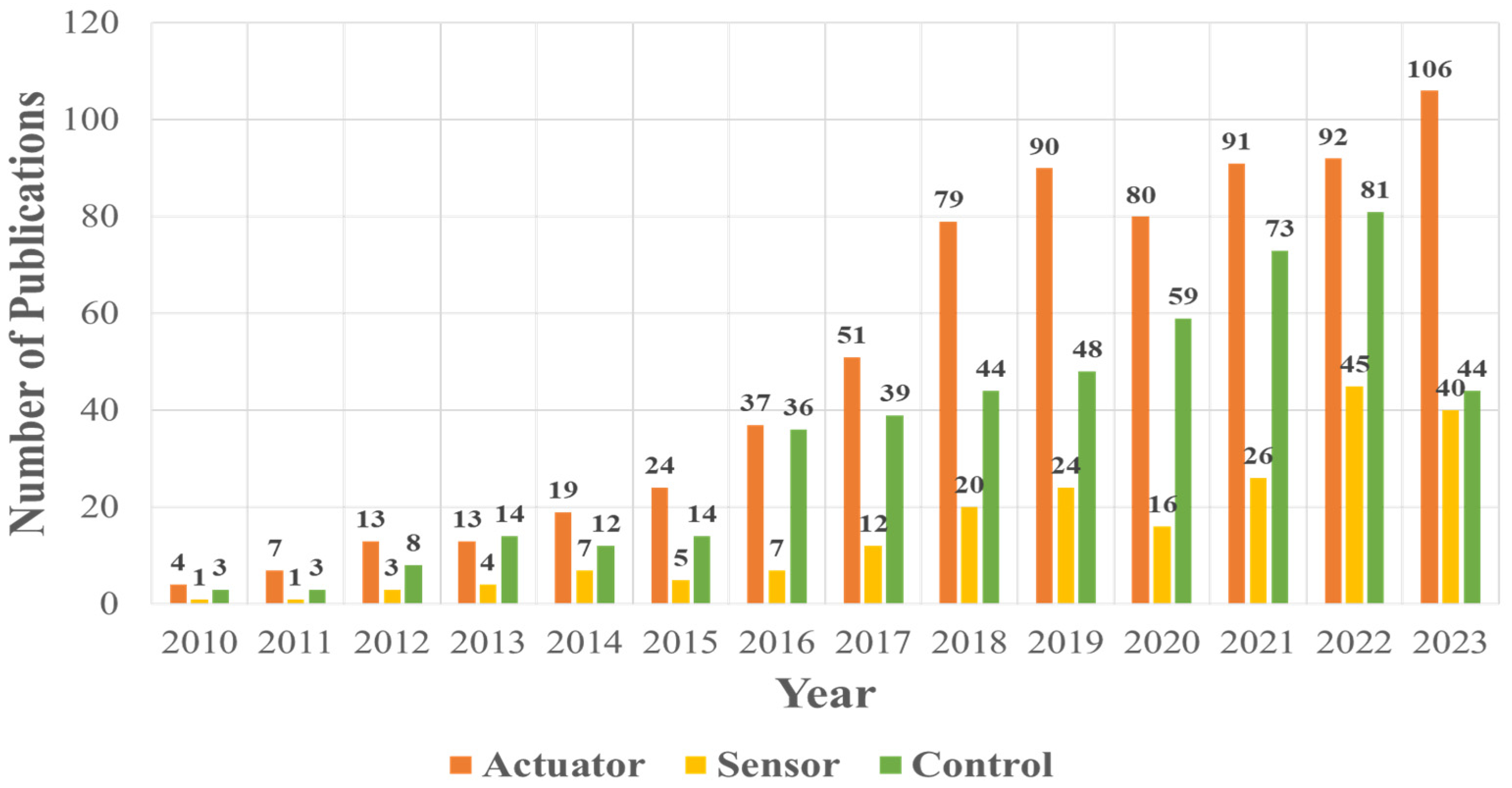

2. Searching and Selecting Papers: A Systematic Approach

2.1. Target Databases

2.2. Keywords Selection

- AND—Soft robot; Design.

- OR—Architecture; Actuator; Mathematical Model; Body; Mechanism.

2.3. Identification of Relevant Publications

3. Results and Discussion

3.1. Design Methods

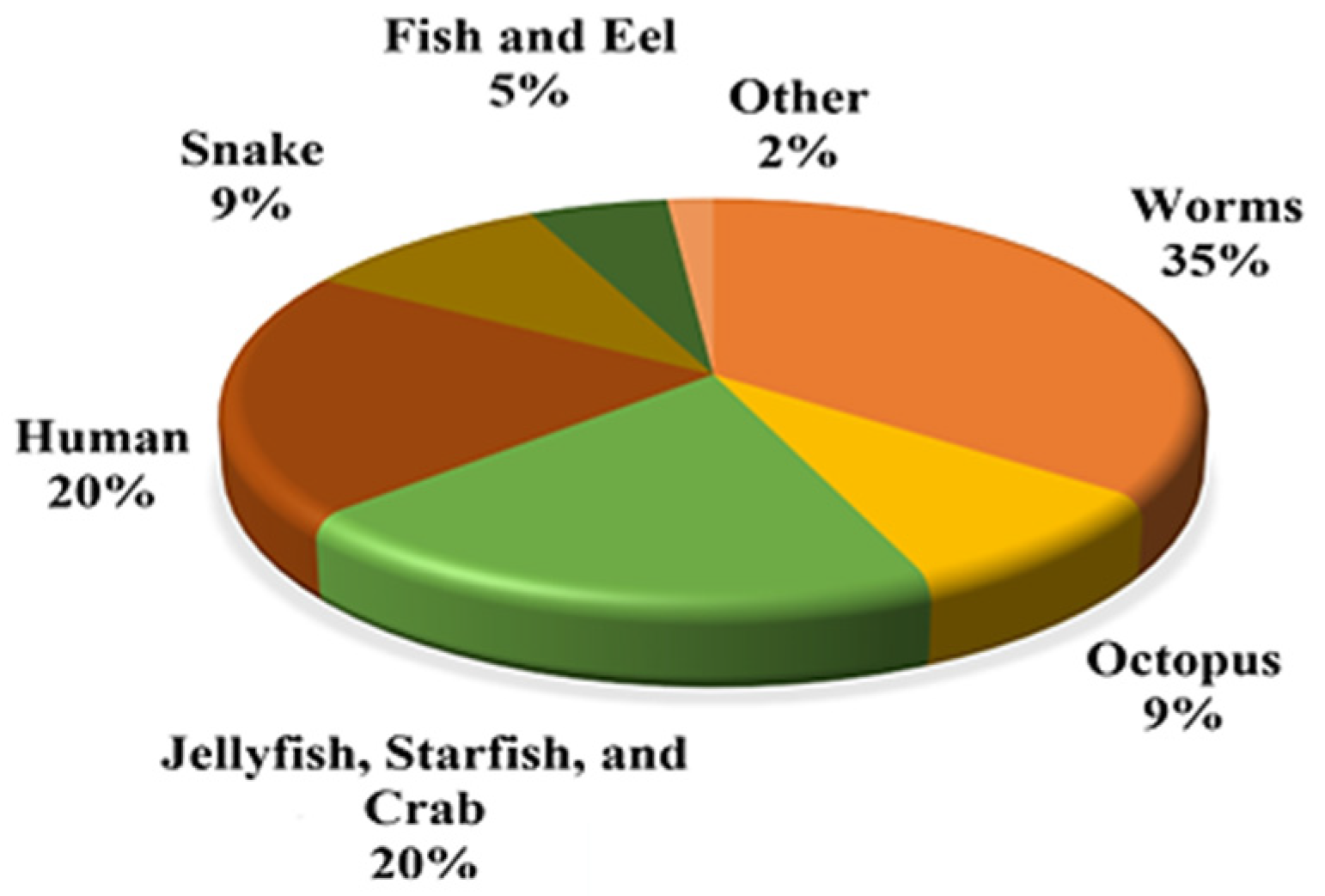

3.1.1. Bio-Inspired Design Methods

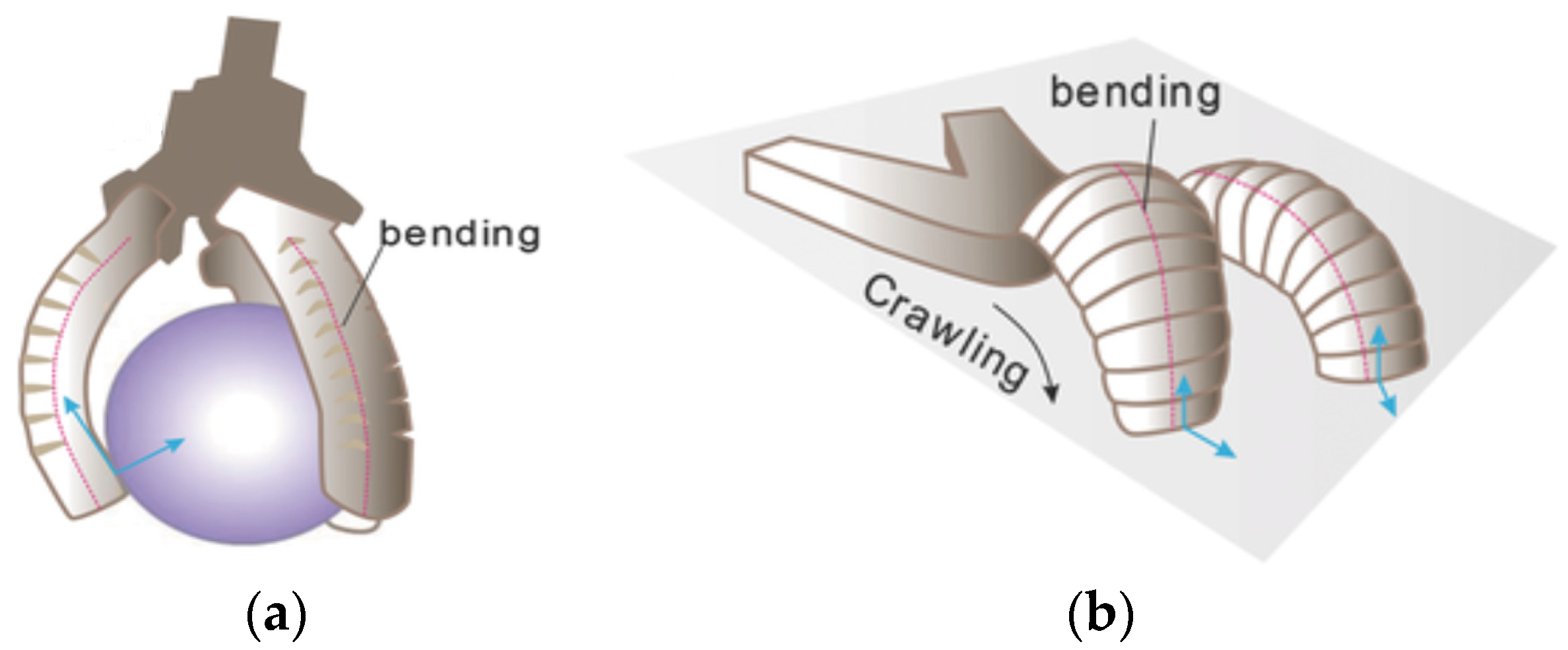

- Deformability: Creatures such as octopuses, worms, and caterpillars have flexible bodies with bending, stretching, and twisting abilities. This remarkable flexibility empowers them to adjust and navigate their surroundings; for instance, octopuses can bend their arms to catch prey and effortlessly squeeze them. By replicating these creatures, soft robots are built to possess such flexible and adaptive properties and behaviors [53,54,55]. The governing principle behind this is the deformability of the structure, including both elastic and plastic deformation.

- Variable-stiffness structure: Creatures such as starfish and worms possess distinctive structures capable of transitioning from soft to hard and vice versa, a phenomenon known as variable-stiffness structure. The variable stiffness property enables these creatures to adjust the stiffness of their body dynamically in response to changes in their environment and potential threats. Soft robots built by replicating the variable-structure property are referred to in [58,59,60]. The governing principle for the variable stiffness is that stiffness is a property of the structure, and a change in the structure will cause a change in the stiffness of the structure.

- Self-healing: Creatures such as starfish and salamanders can regenerate lost body parts, a phenomenon called resilience [61,62,63,64,65]. Soft robots built by replicating these creatures are referred to in [66,67]. The underlying governing principle is the self-repair or self-healing of the structure, the microstructure of the materials.

3.1.2. Topology Optimization Method

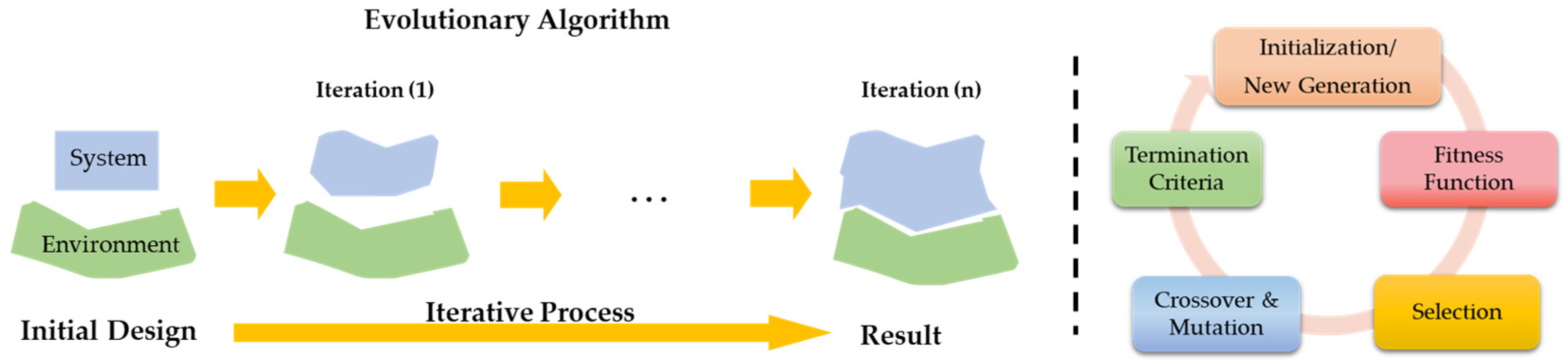

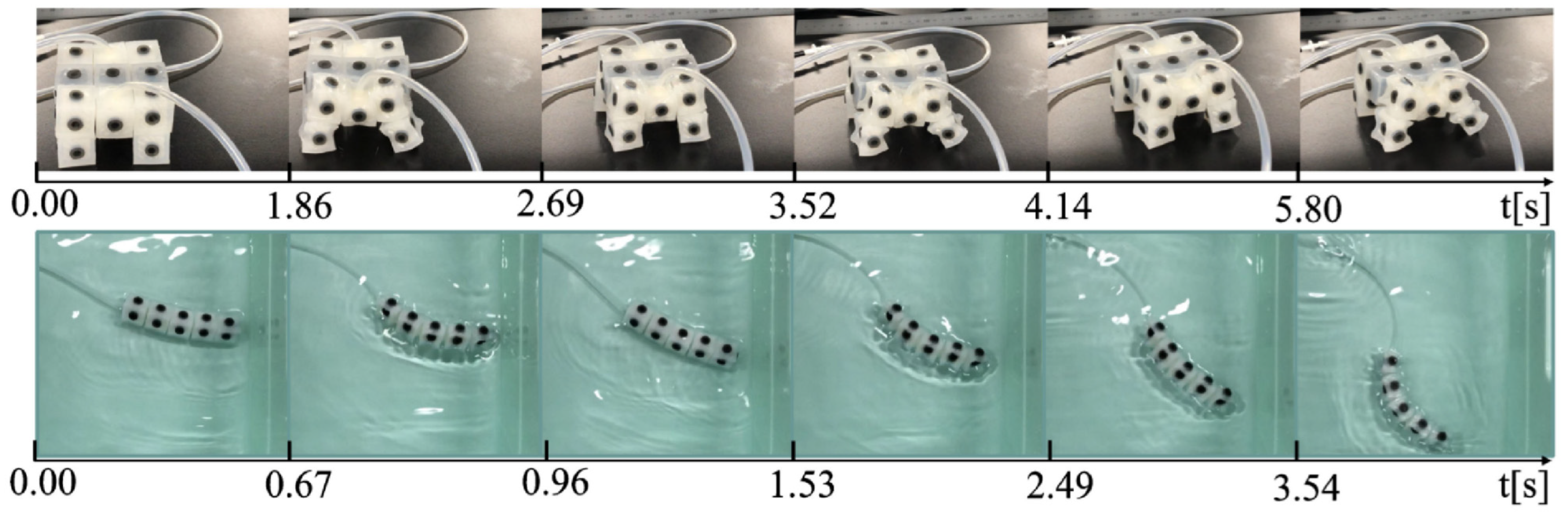

3.1.3. Evolutionary Computation Method

3.2. Analysis

3.2.1. Building Blocks

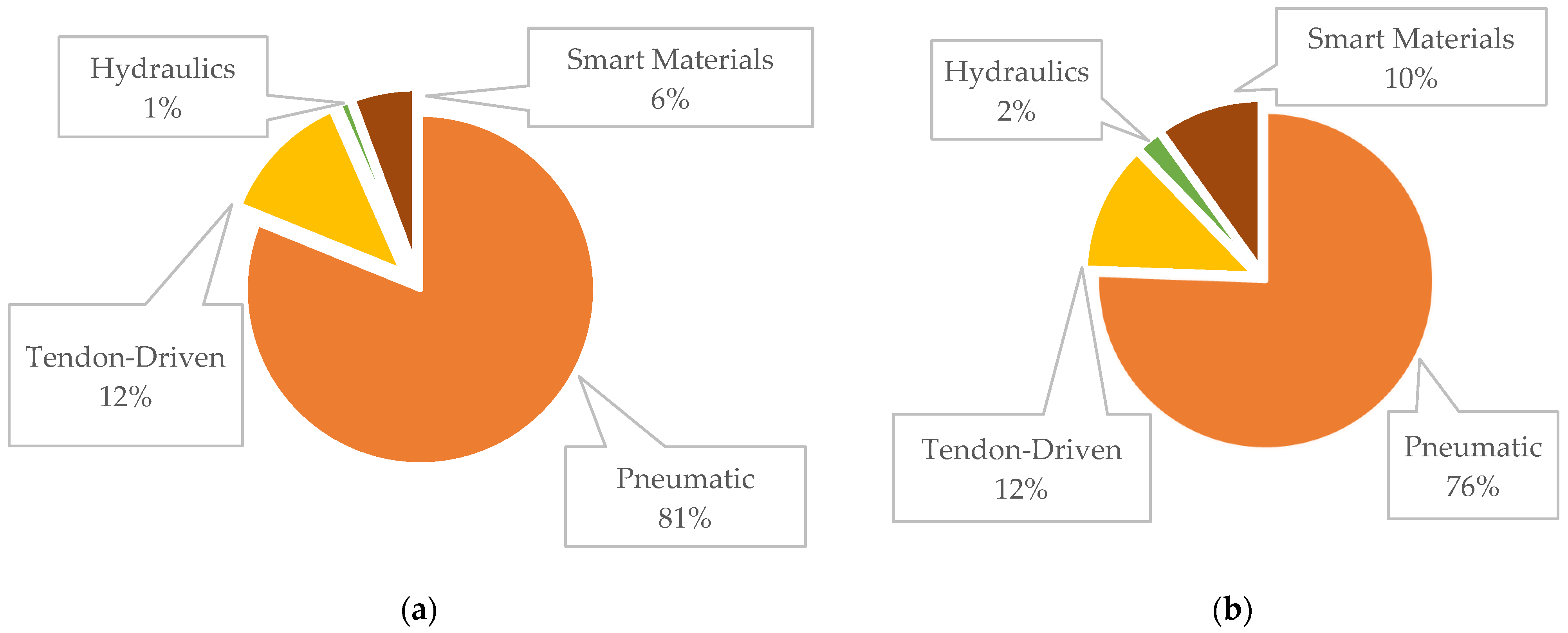

3.2.2. Actuation Methods

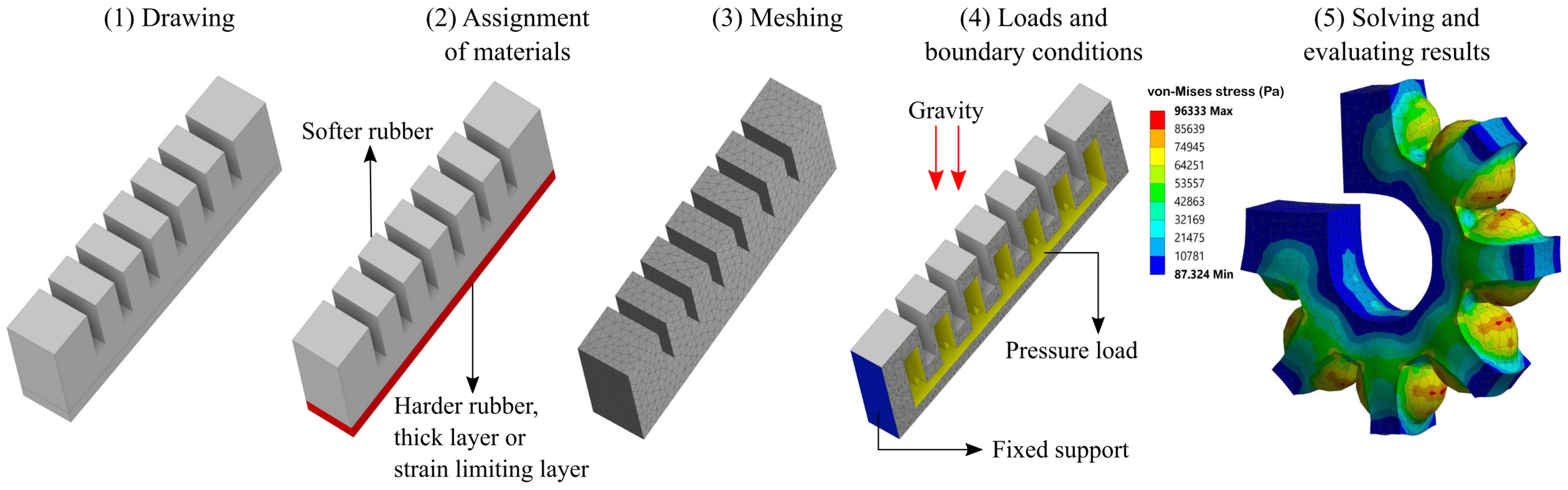

3.2.3. Mathematical Modeling

3.3. Knowledge Gaps

4. Future Directions of Research

5. Conclusions and Contributions of the Paper

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Asghar, A.; Iqbal, M.; Khaliq, A.; Rehman, S.U.; Iqbal, J. Performance comparison of structured H∞ based looptune and LQR for a 4-DOF robotic manipulator. PLoS ONE 2022, 17, e0266728. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.; Yin, R.; Cao, L.; Yuan, C.; Ding, H.K.; Zhang, W.J. Soft robotics: Definition and research issues. In Proceedings of the 24th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 21–23 November 2017; pp. 366–370. [CrossRef]

- Trivedi, D.; Rahn, C.D.; Kier, W.M.; Walker, I.D. Soft robotics: Biological inspiration, state of the art, and future research. Appl. Bionics Biomech. 2008, 5, 99–117. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication, and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Kastor, N.; Vikas, V.; Cohen, E.; White, R.D. A Definition of Soft Materials for Use in the Design of Robots. Soft Robot. 2017, 4, 181–182. [Google Scholar] [CrossRef]

- Li, G.; Qiu, W.; Wang, M.; Zhu, Y.; Liu, F. Development of an earthworm-based soft robot for colon sampling. Front. Robot. AI 2024, 11, 1309220. [Google Scholar] [CrossRef] [PubMed]

- Lindenroth, L.; Bano, S.; Stilli, A.; Manjaly, J.G.; Stoyanov, D. A fluidic soft robot for needle guidance and motion compensation in intratympanic steroid injections. IEEE Robot. Autom. Lett. 2021, 6, 871–878. [Google Scholar] [CrossRef]

- Mohammadi, A.; Lavranos, J.; Tan, Y.; Choong, P.; Oetomo, D. A paediatric 3D-printed soft robotic hand prosthesis for children with upper limb loss. In Proceedings of the 2020 42nd Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC) in Conjunction with the 43rd Annual Conference of the Canadian Medical and Biological Engineering Society, Montreal, QC, Canada, 20–24 July 2020; pp. 3310–3313. [Google Scholar] [CrossRef]

- Zheng, Y.; Cao, L.; Qian, Z.; Chen, A.; Zhang, W. Topology optimization of a fully compliant prosthetic finger: Design and testing. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 1029–1103. [Google Scholar] [CrossRef]

- Liu, S.Q.; Zhang, H.B.; Yin, R.X.; Chen, A.; Zhang, W.J. Flexure Hinge Based Fully Compliant Prosthetic Finger. Proc. SAI Intell. Syst. Conf. (IntelliSys) 2016, 2, 839–849. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, H.; Yin, R.; Chen, A.; Zhang, W. Finite Element Analysis and Application of a Flexure Hinge Based Fully Compliant Prosthetic Finger. In Advanced Computational Methods in Life System Modeling and Simulation, Proceedings of International Conference on Life System Modeling and Simulation, LSMS 2017 and International Conference on Intelligent Computing for Sustainable Energy and Environment, ICSEE 2017, Nanjing, China, 22–24 September 2017; Communications in Computer and Information Science; Springer: Berlin/Heidelberg, Germany, 2017; pp. 191–198. [Google Scholar] [CrossRef]

- Song, K.Y.; Behzadfar, M.; Zhang, W.J. A Dynamic Pole Motion Approach for Control of Nonlinear Hybrid Soft Legs: A Preliminary Study. Machines 2022, 10, 875. [Google Scholar] [CrossRef]

- Zhou, X.; Ma, Z.; Wang, K.; Zhang, G.; Ren, D.; Zhang, W.; Zhang, B.; Yin, R. Motion Control of Magnetic-Controlled Spiral Microrobots for In-vitro Plaque Removal. IEEE Robot. Autom. Lett. 2024, 9, 5671–5678. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, Z.; Huang, H.; Liang, X. Pioneering Healthcare with Soft Robotic Devices: A Review. Smart Med. 2024, 3, e20230045. [Google Scholar] [CrossRef]

- Horvath, A.S.; Jochum, E.; Löchtefeld, M.; Vissonova, K.; Merritt, T. Soft robotics workshops: Supporting experiential learning about design, movement, and sustainability. In Cultural Robotics: Social Robots and Their Emergent Cultural Ecologies; Dunstan, B.J., Koh, J.T.K.V., Turnbull Tillman, D., Brown, S.A., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 189–218. [Google Scholar] [CrossRef]

- Lin, Y.; Xu, Y.X.; Juang, J.Y. Single-actuator soft robot for in-pipe crawling. Soft Robot. 2023, 10, 174–186. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.; Feng, Y.; Song, K.Y.; Zhang, W.J. 3D Printable Micro/Macro Dual Driving Multipede Millirobot and Its Characterization for Multi-Locomotory Modes. IEEE/ASME Trans. Mechatron. 2023, 28, 1–10. [Google Scholar] [CrossRef]

- Giordano, G.; Murali Babu, S.P.; Mazzolai, B. Soft robotics towards sustainable development goals and climate actions. Front. Robot. AI 2023, 10, 1116005. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.J.; Dijk Van, A. On developing an intelligent editor system for machine conceptual design: Application of database technology. In Computer-Aided Conceptual Design; Sharpe, J., Ho, V., Eds.; LooseLeaf Co.: Brecon, UK, 1994; pp. 221–240. [Google Scholar]

- Tony, A.; Badea, I.; Yang, C.; Liu, Y.; Wells, G.; Wang, K.; Yin, R.; Zhang, H.; Zhang, W. The Additive Manufacturing Approach to Polydimethylsiloxane (PDMS) Microfluidic Devices: Review and Future Directions. Polymers 2023, 15, 1926. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.M.; An, Q.; Li, J.W.; Zhang, W.J. Piezoelectric friction–inertia actuator—A critical review and future perspective. Int. J. Adv. Manuf. Technol. 2012, 62, 669–685. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, D.; Zhou, F.; Song, J.; Zhang, W. An Axiomatic Design Theory for Design of Apparel Products. J. Eng. Fibers Fabr. 2022, 17, 15589250221134350. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W. Engineering design: A systematic approach. Nasa Sti/Recon Tech. Rep. A 1988, 89, 47350. [Google Scholar]

- Fan, L.X.; Cai, M.Y.; Lin, Y.; Zhang, W.J. Axiomatic design theory: Further notes and its guideline to applications. Int. J. Mater. Prod. Technol. 2015, 51, 359–374. [Google Scholar] [CrossRef]

- Zhang, W.J.; Wang, J.W. Design Theory and Methodology for Enterprise Systems. Ent. Inf. Syst. 2016, 10, 245–248. [Google Scholar] [CrossRef]

- Bi, Z.; Lin, Y.; Zhang, W.J. The general architecture of adaptive robotic systems for manufacturing applications. Robot. Comput.-Integr. Manuf. 2010, 26, 461–470. [Google Scholar] [CrossRef]

- Dai, Z. Improvement of General Design Theory and Methodology with Its Application to Design of a Retractor for Ventral Hernia Repair Surgery. Doctoral Dissertation, University of Saskatchewan, Saskatoon, SK, Canada, March 2019. [Google Scholar]

- Wu, Z.F.; Li, J.; Cai, M.Y.; Lin, Y.; Zhang, W.J. On membership of black-box or white-box of artificial neural network models. In Proceedings of the IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016; pp. 1400–1404. [Google Scholar] [CrossRef]

- Zhang, W.J. An Integrated Environment for CAD/CAM of Mechanical Systems. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1994. [Google Scholar]

- Bi, Z.; Zhang, W. Modularity Technology in Manufacturing: Taxonomy and Issues. Int. J. Adv. Manuf. Technol. 2001, 18, 381–390. [Google Scholar] [CrossRef]

- Zhang, W.J.; van der Werff, K.; van Luttervelt, C.A. A generic mechanism model for use in a CIM environment for the development of mechanized production machines. Ann. CIRP 1993, 42, 135–138. [Google Scholar] [CrossRef]

- Zhang, W.J.; van der Werff, K. Automatic communication from a neutral object model of mechanisms to mechanism analysis program system based on a finite element approach. Finite Elem. Anal. Des. 1997, 28, 209–240. [Google Scholar] [CrossRef]

- Liu, W.; Jing, Z.; Huang, J.; Dun, X.; Qiao, L.; Leung, H.; Chen, W. An Inchworm-snake Inspired Flexible Robotic Manipulator with Multi-section SMA Actuators for Object Grasping. IEEE Trans. Ind. Electron. 2023, 70, 12616–12625. [Google Scholar] [CrossRef]

- Ma, K.; Chen, X.; Zhang, J.; Xie, Z.; Wu, J.; Zhang, J. Inspired by Physical Intelligence of an Elephant Trunk: Biomimetic Soft Robot with Pre-programmable Localized Stiffness. IEEE Robot. Autom. Lett. 2023, 8, 2898–2905. [Google Scholar] [CrossRef]

- Miao, Z.; Liang, J.; Chen, H.; Lu, J.; Sun, X.; Liu, Y.; Tang, F.; Zhang, M. Power Autonomy and Agility Control of an Untethered Insect-Scale Soft Robot. Soft Robot. 2023, 10, 749–759. [Google Scholar] [CrossRef] [PubMed]

- Qiu, J.; Ji, A.; Zhu, K.; Han, Q.; Wang, W.; Qi, Q.; Chen, G. A Gecko-Inspired Robot with a Flexible Spine Driven by Shape Memory Alloy Springs. Soft Robot. 2023, 10, 713–723. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Li, W.; Xu, J.; Dong, J.; Xiang, C.; Guan, Y.; Zhang, T. Design, and Implementation of a Miniature Jellyfish-Inspired Robot. IEEE Robot. Autom. Lett. 2023, 8, 3134–3141. [Google Scholar] [CrossRef]

- Xing, J.; Jin, W.; Yang, K.; Howard, I. A Bionic Piezoelectric Robotic Jellyfish with a Large Deformation Flexure Hinge. IEEE Trans. Ind. Electron. 2023, 70, 12596–12605. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, J. Dynamic Research on Nonlinear Locomotion of Inchworm-Inspired Soft Crawling Robot. Soft Robot. 2023, 10, 660–672. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Ngo, T.D.; La, H.M.; Ho, V.A. Soft Robotic Hand for Sushi Grasping and Handling. In Proceedings of the 2023 IEEE/SICE International Symposium on System Integration (SII), Atlanta, GA, USA, 17–20 January 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Zheng, Z.; Kumar, P.; Chen, Y.; Cheng, H.; Wagner, S.; Chen, M.; Verma, N.; Sturm, J.C. Model-Based Control of Planar Piezoelectric Inchworm Soft Robot for Crawling in Constrained Environments. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022; pp. 693–698. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Zhang, Y.; Ma, P.; Nava, E.; Du, T.; Arm, P.; Matusik, W.; Katzschmann, R.K. Sim2Real for Soft Robotic Fish via Differentiable Simulation. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; pp. 12598–12605. [Google Scholar] [CrossRef]

- Yuanzhong, L.; Takanishi, A.; Ishii, H. Design of a Soft Rat Robot Based on Pneumatic Actuator. In Proceedings of the 2022 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Sapporo, Japan, 11–15 July 2022; pp. 926–931. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, P.; Huang, H.; Zhu, J. Bio-Inspired Transparent Soft Jellyfish Robot. Soft Robot. 2023, 10, 590–600. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Puranam, V.R.; Misra, S.; Venkiteswaran, V.K. A Snake-Inspired Multi-Segmented Magnetic Soft Robot Towards Medical Applications. IEEE Robot. Autom. Lett. 2022, 7, 5795–5802. [Google Scholar] [CrossRef]

- Villani, A.; Ciucci, G.; Colliva, A.; Marullo, S.; Zacchigna, S.; Prattichizzo, D. RobHeart: Soft Robot for Heart-Like Volumetric Stress on Seeded Cardiac Cells. In Proceedings of the 2022 9th IEEE RAS/EMBS International Conference for Biomedical Robotics and Biomechatronics (BioRob), Seoul, Republic of Korea, 21–24 August 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Rezaei, M.H.; Reza Kolani, M.; Mirhaghgoo Jalali, S.A.; Zareinejad, M. Earthworm-Inspired In-pipe Soft Robot (ESR): Design, Modeling, and Implementation. In Proceedings of the 2022 10th RSI International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 22–24 November 2022; pp. 125–131. [Google Scholar] [CrossRef]

- Bell, M.A.; Weaver, J.C.; Wood, R.J. An Ambidextrous STarfish-Inspired Exploration and Reconnaissance Robot (The ASTER-bot). Soft Robot. 2022, 9, 991–1000. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Tan, R.; Lu, H.; Shen, Y. Starfish Inspired Milli Soft Robot with Omnidirectional Adaptive Locomotion Ability. IEEE Robot. Autom. Lett. 2021, 6, 3325–3332. [Google Scholar] [CrossRef]

- Tang, C.; Huang, H.; Li, B. Design and Control of a Magnetic Driven Worm-like Micro-robot. In Proceedings of the 2021 IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 27–31 December 2021; pp. 1304–1308. [Google Scholar]

- Xie, Z.; Domel, A.G.; An, N.; Green, C.; Gong, Z.; Wang, T.; Knubben, E.M.; Weaver, J.C.; Bertoldi, K.; Wen, L. Octopus Arm-Inspired Tapered Soft Actuators with Suckers for Improved Grasping. Soft Robot. 2020, 7, 639–648. [Google Scholar] [CrossRef] [PubMed]

- Ishige, M.; Umedachi, T.; Taniguchi, T.; Kawahara, Y. Exploring Behaviors of Caterpillar-Like Soft Robots with a Central Pattern Generator-Based Controller and Reinforcement Learning. Soft Robot. 2019, 6, 579–594. [Google Scholar] [CrossRef] [PubMed]

- Seok, S.; Onal, C.D.; Cho, K.J.; Wood, R.J.; Rus, D.; Kim, S. Meshworm: A peristaltic soft robot with antagonistic nickel titanium coil actuators. IEEE/ASME Trans. Mechatron. 2013, 18, 1485–1497. [Google Scholar] [CrossRef]

- Laschi, C.; Cianchetti, M.; Mazzolai, B.; Margheri, L.; Follador, M.; Dario, P. Soft robot arm inspired by the octopus. Adv. Robot. 2012, 26, 709–727. [Google Scholar] [CrossRef]

- Lin, H.T.; Leisk, G.G.; Trimmer, B. GoQBot: A caterpillar-inspired soft-bodied rolling robot. Bioinspir. Biomim. 2011, 6, 026007. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Fu, Y.; Deng, J.; Sun, J.; Liu, Y. A Bistable Jumping Robot with Pure Soft Body Actuated by Twisted Artificial Muscle. In Proceedings of the 2021 27th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Shanghai, China, 26–28 November 2021; pp. 388–393. [Google Scholar]

- Liu, Y. Soft robot review: Actuation and application. In Proceedings of the 2022 International Conference on Electronics and Devices, Computational Science (ICEDCS), Marseille, France, 20–22 September 2022; pp. 23–26. [Google Scholar] [CrossRef]

- Lloyd, P.; Thomas, T.L.; Venkiteswaran, V.K.; Pittiglio, G.; Chandler, J.H.; Valdastri, P.; Misra, S. A Magnetically Actuated Coiling Soft Robot with Variable Stiffness. IEEE Robot. Autom. Lett. 2023, 8, 3262–3269. [Google Scholar] [CrossRef]

- Wockenfuß, W.R.; Brandt, V.; Weisheit, L.; Drossel, W.G. Design, Modeling and Validation of a Tendon-Driven Soft Continuum Robot for Planar Motion Based on Variable Stiffness Structures. IEEE Robot. Autom. Lett. 2022, 7, 3985–3991. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, J.; Zhao, J. A Gas–Ribbon-Hybrid Actuated Soft Finger with Active Variable Stiffness. Soft Robot. 2022, 9, 250–265. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Zhang, W.; Gupta, M.M. Resilient Robots: Concept, Review, and Future Directions. Robotics 2017, 6, 22. [Google Scholar] [CrossRef]

- Zhang, W.J.; Van Luttervelt, C.A. Toward a Resilient Manufacturing System. CIRP Ann. 2011, 60, 469–472. [Google Scholar] [CrossRef]

- Zhang, W.J.; Lin, Y. On the Principle of Design of Resilient Systems—Application to Enterprise Information Systems. Ent. Inf. Syst. 2010, 4, 99–110. [Google Scholar] [CrossRef]

- Sun, Z.H.; Yang, G.S.; Zhang, B.; Zhang, W.J. On the Concept of the Resilient Machine. In Proceedings of the 2011 6th IEEE Conference on Industrial Electronics and Applications (ICIEA), Beijing, China, 21–23 June 2011; pp. 357–360. [Google Scholar] [CrossRef]

- Wang, F.; Qian, Z.; Yan, Z.; Yuan, C.; Zhang, W. A Novel Resilient Robot: Kinematic Analysis and Experimentation. IEEE Access 2019, 8, 2885–2892. [Google Scholar] [CrossRef]

- Orozco, F.; Horvat, D.; Miola, M.; Moreno-Villoslada, I.; Picchioni, F.; Bose, R.K. Electroactive Thermo-Pneumatic Soft Actuator with Self-Healing Features: A Critical Evaluation. Soft Robot. 2023, 10, 852–859. [Google Scholar] [CrossRef] [PubMed]

- Jiang, F.; Zhang, Z.; Wang, X.; Cheng, G.; Zhang, Z.; Ding, J. Pneumatically Actuated Self-Healing Bionic Crawling Soft Robot. J. Intell. Robot. Syst. 2020, 100, 445–454. [Google Scholar] [CrossRef]

- Annabestani, M.; Kamare, B.; Shabani, M.; Magalhaes, S.V.; Mondini, A.; Mazzolai, B. A Bioinspired Multifunctional Soft Gripper with Embedded Sensing Ability: A potential way for sustainable agricultural harvesting. In Proceedings of the 2023 IEEE International Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Pisa, Italy, 6–8 November 2023; pp. 182–187. [Google Scholar] [CrossRef]

- Hashanjana, L.; Senanayaka, P.; Madushan, I.; Himaruwan, H.D.S.; Kulasekera, A.L.; Dassanayake, P.C. Design and Development of a Soft Gripper System for Difficult-to-Handle Food Items. In Proceedings of the 2023 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 9–11 November 2023; pp. 678–683. [Google Scholar] [CrossRef]

- Banerjee, A. The Impact of Soft Robotics in Today’s World: Applications, Challenges Faced, And Future Outlook. In Proceedings of the 2022 International Conference on Smart Generation Computing, Communication and Networking (SMART GENCON), Bangalore, India, 23–25 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de-Santos, P. Soft Gripper for Robotic Harvesting in Precision Agriculture Applications. In Proceedings of the 2021 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Santa Maria da Feira, Portugal, 28–29 April 2021; pp. 167–172. [Google Scholar] [CrossRef]

- Cheng, W.B.; Di, Y.Y.; Zhang, E.M.; Moser, M.A.; Kanagaratnam, S.; Korman, L.Y.; Zhang, W.J. Modeling and In Vitro Experimental Validation for Kinetics of the Colonoscope in Colonoscopy. Ann. Biomed. Eng. 2013, 41, 1084–1093. [Google Scholar] [CrossRef]

- Cheng, W.B.; Moser, M.; Kanagaratnam, S.; Zhang, W.J. Development of Autonomous Microrobotics in Endoscopy. J. Med. Eng. Technol. 2011, 35, 391–401. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Cao, L.; Luo, Y.; Chen, A.; Zhang, E.; Zhang, W.J. A Novel Methodology for Comprehensive Modeling of the Kinetic Behavior of Steerable Catheters. IEEE/ASME Trans. Mechatron. 2019, 24, 1785–1797. [Google Scholar] [CrossRef]

- Hu, X.; Chen, A.; Luo, Y.; Zhang, C.; Zhang, E. Steerable Catheters for Minimally Invasive Surgery: A Review and Future Directions. Comput. Assist. Surg. 2018, 23, 21–41. [Google Scholar] [CrossRef] [PubMed]

- Hu, N.; Ding, L.; Liu, Y.; Wang, K.; Zhang, B.; Yin, R.; Zhang, W. Development of 3D-Printed Magnetic Micro-Nanorobots for Targeted Therapeutics: The State of Art. Adv. NanoBiomed Res. 2023, 3, 2300018. [Google Scholar] [CrossRef]

- Chen, M.; Wang, D.; Zou, J.; Sun, L.; Sun, J.; Jin, G. A Multi-Module Soft Robotic Arm with Soft End Effector for Minimally Invasive Surgery. In Proceedings of the 2nd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Shanghai, China, 22–24 November 2019; pp. 461–465. [Google Scholar] [CrossRef]

- Kwok, K.W.; Wurdemann, H.; Arezzo, A.; Menciassi, A.; Althoefer, K. Soft Ro-bot-Assisted Minimally Invasive Surgery and Interventions: Advances and Outlook. Proc. IEEE 2022, 110, 871–892. [Google Scholar] [CrossRef]

- Ren, H.; Gu, X.; Tan, K.L. Human-compliant body-attached soft robots towards automatic cooperative ultrasound imaging. In Proceedings of the IEEE 20th International Conference on Computer Supported Cooperative Work in Design (CSCWD), Nanchang, China, 4–6 May 2016; pp. 653–658. [Google Scholar] [CrossRef]

- Wang, H.; Totaro, M.; Beccai, L. Toward perceptive soft robots: Progress and challenges. Adv. Sci. 2018, 5, 1800541. [Google Scholar] [CrossRef] [PubMed]

- Li, W.B.; Guo, X.Y.; Zhang, W.M. SomBot: A Bio-inspired Dynamic Somersaulting Soft Robot. IEEE Robot. Autom. Lett. 2021, 6, 1654–1661. [Google Scholar] [CrossRef]

- Dalklint, A.; Wallin, M.; Tortorelli, D. Simultaneous shape and topology optimization of inflatable soft robots. Comput. Methods Appl. Mech. Eng. 2024, 420, 116751. [Google Scholar] [CrossRef]

- Liu, C.H.; Chung, F.M.; Chen, Y.; Chiu, C.H.; Chen, T.L. Optimal Design of a Motor-Driven Three-Finger Soft Robotic Gripper. IEEE/ASME Trans. Mechatron. 2020, 25, 1830–1840. [Google Scholar] [CrossRef]

- Caasenbrood, B.; Pogromsky, A.; Nijmeijer, H. A computational design framework for pressure-driven soft robots through nonlinear topology optimization. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020; pp. 633–638. [Google Scholar] [CrossRef]

- Lipson, H. Challenges and opportunities for design, simulation, and fabrication of soft robots. Soft Robot. 2014, 1, 21–27. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, G.; Li, D.; Song, Z.; Chen, F. Soft robotic joints with anisotropic stiffness by multi objective topology optimization. IEEE/ASME Trans. Mechatron. 2024, 29, 1064–1075. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Z.; Pancheri, F.; Lueth, T.C. Toqro: A flexible quadruped walking robot with topology optimized soft legs. In Proceedings of the 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft), San Diego, CA, USA, 14–17 April 2024; pp. 61–66. [Google Scholar] [CrossRef]

- Srinivas, G.L.; Mohammad, A.; Brandstötter, M. Design and development of fin-ray finger using topology optimization with multiple load cases. In Proceedings of the 2024 International Conference on Cognitive Robotics and Intelligent Systems (ICC-ROBINS), Coimbatore, India, 17–19 April 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Srinivas, G.L.; Javed, A.; Faller, L.M. Versatile 3D-printed fin-ray effect soft robotic fingers: Lightweight optimization and performance analysis. J Braz. Soc. Mech. Sci. Eng. 2024, 46, 382. [Google Scholar] [CrossRef]

- Wang, X.; Wang, B.; Pinskier, J.; Xie, Y.; Brett, J.; Scalzo, R.; Howard, D. Fin-bayes: A multi-objective Bayesian optimization framework for soft robotic fingers. Soft Robot. 2024. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Liu, Z.; Wang, B.; Ma, Z.; Ma, D.; Deng, X. A versatile topology-optimized compliant actuator for soft robotic gripper and walking robot. Soft Robot. 2024, 11, 157–170. [Google Scholar] [CrossRef] [PubMed]

- Jain, S.; Dontu, S.; Teoh, J.E.M.; Alvarado, P.V.Y. A multimodal, reconfigurable workspace soft gripper for advanced grasping tasks. Soft Robot. 2023, 10, 527–544. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.-H.; Chen, L.-J.; Chi, J.-C.; Wu, J.-Y. Topology optimization design and experiment of a soft pneumatic bending actuator for grasping applications. IEEE Robot. Autom. Lett. 2022, 7, 2086–2093. [Google Scholar] [CrossRef]

- Suder, J.; Bobovský, Z.; Mlotek, J.; Vocetka, M.; Oščádal, P.; Zeman, Z. Structural optimization method of a FinRay finger for the best wrapping of object. Appl. Sci. 2021, 11, 3858. [Google Scholar] [CrossRef]

- Tian, J.; Zhao, X.; Gu, X.D.; Chen, S. Designing Ferromagnetic Soft Robots (FerroSoRo) with level-set-based multiphysics topology optimization. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 10067–10074. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Denk, M.; Bodaghi, M.; Kouzani, A.Z.; Kaynak, A. Topology-optimized 4D printing of a soft actuator. Acta Mech. Solida Sin. 2020, 33, 418–430. [Google Scholar] [CrossRef]

- Cao, L.; Dolovich, A.T.; Chen, A.; Zhang, W. Topology optimization of efficient and strong hybrid compliant mechanisms using a mixed mesh of beams and flexure hinges with strength control. Mech. Mach. Theory 2018, 121, 213–227. [Google Scholar] [CrossRef]

- Cao, L.; Dolovich, A.T.; Schwab, A.L.; Herder, J.L.; Zhang, W. Toward a Unified Design Approach for Both Compliant Mechanisms and Rigid-Body Mechanisms: Module Optimization. ASME J. Mech. Des. 2015, 137, 122301. [Google Scholar] [CrossRef]

- Cao, L.; Dolovich, A.; and Zhang, W.J. On the understanding of design problem formulation for compliant mechanisms through topology optimization. Mech. Sci. 2013, 4, 357–369. [Google Scholar] [CrossRef][Green Version]

- Zhang, H.; Kumar, A.S.; Chen, F.; Fuh, J.Y.H.; Wang, M.Y. Topology Optimized Multimaterial Soft Fingers for Applications on Grippers, Rehabilitation, and Artificial Hands. IEEE/ASME Trans. Mechatron. 2019, 24, 120–131. [Google Scholar] [CrossRef]

- Zhang, H.; Kumar, A.S.; Fuh, J.Y.H.; Wang, M.Y. Design and Development of a Topology-Optimized Three-Dimensional Printed Soft Gripper. Soft Robot. 2018, 5, 650–661. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Kumar, A.S.; Fuh, J.Y.H.; Wang, M.Y. Investigation on Developing a Topology Optimized and 3D Printable Multi-material Soft Gripper. In Proceedings of the 2018 IEEE 14th International Conference on Control and Automation (ICCA), Anchorage, AK, USA, 12–15 June 2018; pp. 692–697. [Google Scholar] [CrossRef]

- Liu, C.H.; Chen, T.L.; Chiu, C.H.; Hsu, M.C.; Chen, Y.; Pai, T.Y.; Peng, W.G.; Chiang, Y.P. Optimal design of a soft robotic gripper for grasping unknown objects. Soft Robot. 2018, 5, 452–465. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, M.Y.; Chen, F.; Wang, Y.; Kumar, A.S.; Fuh, J.Y.H. Design and development of a soft gripper with topology optimization. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 6239–6244. [Google Scholar] [CrossRef]

- Pinskier, J.; Wang, X.; Liow, L.; Xie, Y.; Kumar, P.; Langelaar, M.; Howard, D. Diversity-Based Topology Optimization of Soft Robotic Grippers. Adv. Intell. Syst. 2024, 6, 2300505. [Google Scholar] [CrossRef]

- Zhang, H.; Kumar, A.S.; Fuh, J.Y.H.; Wang, M.Y. Topology optimized design, fabrication, and evaluation of a multimaterial soft gripper. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; pp. 424–430. [Google Scholar] [CrossRef]

- Chen, S.; Chen, F.; Cao, Z.; Wang, Y.; Miao, Y.; Gu, G.; Zhu, X. Topology optimization of skeleton-reinforced soft pneumatic actuators for desired motions. IEEE/ASME Trans. Mechatron. 2021, 26, 1745–1753. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Zhou, N.; Lueth, T.C. A MATLAB-Based Framework for Designing 3D Topology Optimized Soft Robotic Grippers. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Delft, The Netherlands, 12–16 July 2021; pp. 1283–1289. [Google Scholar] [CrossRef]

- Lehman, J.; Clune, J.; Misevic, D.; Adami, C.; Altenberg, L.; Beaulieu, J.; Bentley, P.J.; Bernard, S.; Beslon, G.; Bryson, D.M.; et al. The surprising creativity of digital evolution: A collection of anecdotes from the evolutionary computation and artificial life research communities. Artif. Life 2020, 26, 274–306. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, J. Evolutionary multi-objective optimization for evolving soft robots in different environments. In Bio-Inspired Information and Communication Technologies: 11th EAI International Conference; Springer International Publishing: Cham, Switzerland, 2019; Volume 11, pp. 112–131. [Google Scholar]

- Nematollahi, M.A.; Hasanshahi, B.; Eftekhari, M.; Safavi, A.A. Material properties identification of a piezoelectric beam using inverse method. In Bio-Inspired Information and Communication Technologies: 11th EAI International Conference; Springer International Publishing: Cham, Switzerland, 2020; Volume 234, pp. 1351–1365. [Google Scholar] [CrossRef]

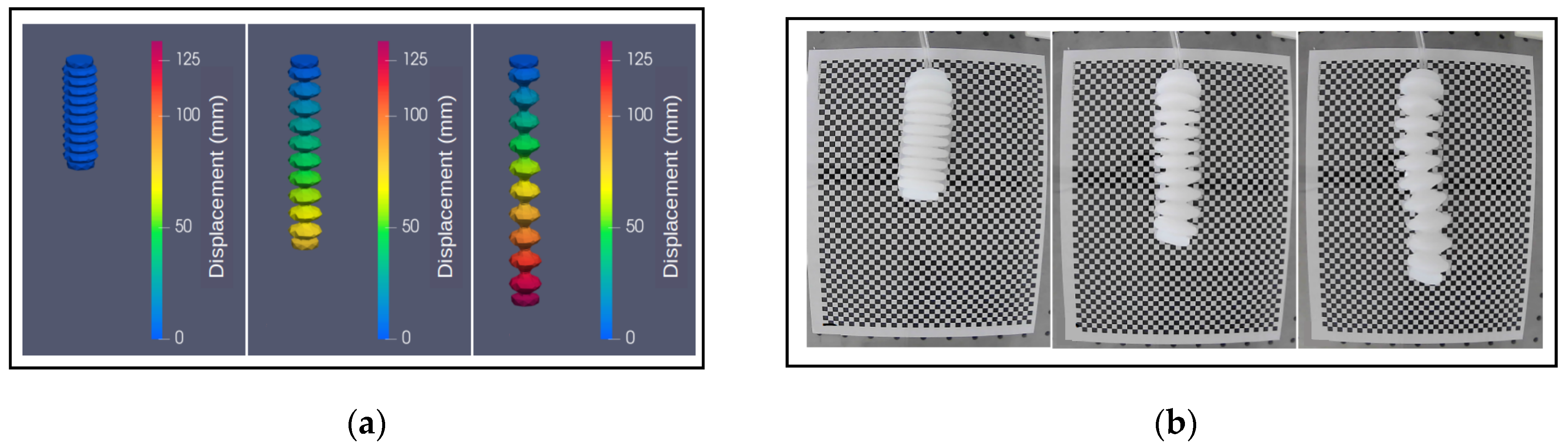

- Ogawa, J.; Mori, T.; Watanabe, Y.; Kawakami, M.; Shiblee, M.N.I.; Furukawa, H. MORI-A: Soft vacuum-actuated module with 3D-printable deformation structure. IEEE Robot. Autom. Lett. 2022, 7, 2495–2502. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, W.B.; Choi, W.Y.; Cho, K.J. Soft robotic blocks: Introducing SoBL, a fast-build modularized design block. IEEE Robot. Autom. Mag. 2016, 23, 30–41. [Google Scholar] [CrossRef]

- Kriegman, S.; Nasab, A.M.; Shah, D.; Steele, H.; Branin, G.; Levin, M.; Bongard, J.; Kramer-Bottiglio, R. Scalable sim-to-real transfer of soft robot designs. In Proceedings of the 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020; pp. 359–366. [Google Scholar]

- Legrand, J.; Terryn, S.; Roels, E.; Vanderborght, B. Reconfigurable, multi-material, voxel-based soft robots. IEEE Robot. Autom. Lett. 2023, 8, 1255–1262. [Google Scholar] [CrossRef]

- Lee, J.Y.; Eom, J.; Choi, W.Y.; Cho, K.J. Soft LEGO: Bottom-up design platform for soft robotics. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 7513–7520. [Google Scholar] [CrossRef]

- Chiou, S.J.; Sridhar, K. Automated conceptual design of mechanisms. Mech. Mach. Theory 1999, 34, 467–495. [Google Scholar] [CrossRef]

- Miao, Y.; Chen, F. Shape Optimization of Soft Pneumatic Bellows for High Energy Density. In Proceedings of the 27th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Shanghai, China, 26–28 November 2021; pp. 480–485. [Google Scholar] [CrossRef]

- Lyu, F.; Li, M.; Guo, J.; Guo, S. A New Fabrication Method for Soft Pneumatic Actuators based on Paraffin. In Proceedings of the IEEE International Conference on Mechatronics and Automation (ICMA), Guilin, China, 7–10 August 2022; pp. 340–344. [Google Scholar] [CrossRef]

- Scharff, R.B.N.; Fang, G.; Tian, Y.; Wu, J.; Geraedts, J.M.P.; Wang, C.C.L. Sensing and Reconstruction of 3-D Deformation on Pneumatic Soft Robots. IEEE/ASME Trans. Mechatron. 2021, 26, 1877–1885. [Google Scholar] [CrossRef]

- Tirado, J.; Jørgensen, J.; Rafsanjani, A. Earthworm-inspired multimodal soft actuators. In Proceedings of the IEEE International Conference on Soft Robotics (RoboSoft), Singapore, 3–7 April 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, P.; Tang, Z.; Xin, W.; Xie, Z.; Guo, S.; Laschi, C. Design and Experimental Characterization of a Push-Pull Flexible Rod-Driven Soft-Bodied Robot. IEEE Robot. Autom. Lett. 2022, 7, 8933–8940. [Google Scholar] [CrossRef]

- Park, Y.J.; Ko, M.G.; Jamil, B.; Shin, J.; Rodrigue, H. Simple and Scalable Soft Actuation Through Coupled Inflatable Tubes. IEEE Access 2022, 10, 41993–42003. [Google Scholar] [CrossRef]

- Koh, J.-S.; Lee, D.-Y.; Cho, K.-J. Design of the shape memory alloy coil spring actuator for the soft deformable wheel robot. In Proceedings of the 9th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Daejeon, Republic of Korea, 26–28 November 2012; pp. 641–642. [Google Scholar] [CrossRef]

- Kanada, A.; Mashimo, T. Design and Experiments of Flexible Ultrasonic Motor Using a Coil Spring Slider. IEEE/ASME Trans. Mechatron. 2020, 25, 468–476. [Google Scholar] [CrossRef]

- Chaichaowarat, R.; Nishimura, S.; Krebs, H.I. Design and Modeling of a Variable-Stiffness Spring Mechanism for Impedance Modulation in Physical Human–Robot Interaction. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 7052–7057. [Google Scholar] [CrossRef]

- Sun, Y.; Lueth, T.C. Design of 3D-Printed Continuum Robots Using Topology Optimized Compliant Joints. In Proceedings of the IEEE International Conference on Soft Robotics (RoboSoft), Singapore, 3–7 April 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Garcia, M.; Pena, P.; Tekes, A.; Amiri Moghadam, A.A. Development of Novel Three-Dimensional Soft Parallel Robot. In Proceedings of the SoutheastCon, Atlanta, GA, USA, 10–13 March 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Yongrou, Z.; Da, W.; Xuefeng, Z.; Taobo, C.; Dan, H. A Kinematic Model for Soft Robot Based on Double Laminate Plate Theory. In Proceedings of the IEEE International Conference on Robotics and Biomimetics (ROBIO), Kuala Lumpur, Malaysia, 12–15 December 2018; pp. 600–605. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, F.; Aukes, D.M. Tunable Dynamic Walking via Soft Twisted Beam Vibration. IEEE Robot. Autom. Lett. 2023, 8, 1967–1974. [Google Scholar] [CrossRef]

- Li, S.; Stampfli, J.; Xu, H.; Malkin, E.; Diaz, E.V.; Rus, D.; Wood, R.J. A Vacuum-driven Origami “Magic-ball” Soft Gripper. In Proceedings of the International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 7401–7408. [Google Scholar] [CrossRef]

- Karimi, M.A.; Alizadehyazdi, V.; Jaeger, H.M.; Spenko, M. A Self-Reconfigurable Variable-Stiffness Soft Robot Based on Boundary-Constrained Modular Units. IEEE Trans. Robot. 2022, 38, 810–821. [Google Scholar] [CrossRef]

- Kremer, P.; Nohooji, H.R.; Sanchez-Lopez, J.L.; Voos, H. TRIGGER: A Lightweight Universal Jamming Gripper for Aerial Grasping. IEEE Access 2023, 11, 50098–50115. [Google Scholar] [CrossRef]

- Gariya, N.; Kumar, P.; Makkar, M. Experimental Study of a Soft Pneumatic Actuator for the Application of Robotic Gripper. In Proceedings of the 5th International Conference on Power, Control & Embedded Systems (ICPCES), Allahabad, India, 6–8 January 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Glick, P.; Suresh, S.A.; Ruffatto, D.; Cutkosky, M.; Tolley, M.T.; Parness, A. A Soft Robotic Gripper with Gecko-Inspired Adhesive. IEEE Robot. Autom. Lett. 2018, 3, 903–910. [Google Scholar] [CrossRef]

- Drotman, D.; Ishida, M.; Jadhav, S.; Tolley, M.T. Application-Driven Design of Soft, 3-D Printed, Pneumatic Actuators with Bellows. IEEE/ASME Trans. Mechatron. 2019, 24, 78–87. [Google Scholar] [CrossRef]

- Lu, Q.; Mahtab, B.; Zhao, F.; Song, K.-Y.; Feng, Y. Bioinspiration to Robot Locomotion implementing 3D printed Foxtail Grass. In Proceedings of the IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 27–31 December 2021; pp. 69–73. [Google Scholar] [CrossRef]

- Oh, N.; Lee, J.-G.; Rodrigue, H. Torsional Pneumatic Actuator Based on Pre-Twisted Pneumatic Tubes for Soft Robotic Manipulators. IEEE/ASME Trans. Mechatron. 2023, 28, 3191–3201. [Google Scholar] [CrossRef]

- Dewapura, J.I.; Hemachandra, P.S.; Dananjaya, T.; Awantha, W.V.I.; Wanasinghe, A.T.; Kulasekera, A.L.; Chathuranga, D.S.; Dassanayake, V.P.C. Design and Development of a Novel Bio-inspired Worm-type Soft Robot for In-pipe Locomotion. In Proceedings of the 20th International Conference on Control, Automation and Systems (ICCAS), Busan, Republic of Korea, 13–16 October 2020; pp. 586–591. [Google Scholar] [CrossRef]

- Golgouneh, A.; Dunne, L.E. A review in on-body compression using soft actuators and sensors: Applications, mechanisms, and challenges. IEEE Rev. Biomed. Eng. 2024, 17, 166–179. [Google Scholar] [CrossRef] [PubMed]

- Hasanshahi, B.; Azadi, M. Active vibration control of a functionally graded carbon nanotube-reinforced composite beam subjected to follower force. Iran. J. Sci. Technol. Trans. Mech. Eng. 2019, 43 (Suppl. S1), 25–35. [Google Scholar] [CrossRef]

- Shu, J.; Wang, J.; Su, Y.; Liu, H.; Li, Z.; Tong, R.K.-Y. An end-to-end posture perception method for soft bending actuators based on kirigami-inspired piezoresistive sensors. In Proceedings of the IEEE-EMBS International Conference on Wearable and Implantable Body Sensor Networks (BSN), Ioannina, Greece, 27–30 September 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, 20400–20403. [Google Scholar] [CrossRef] [PubMed]

- Chirikjian, G.S.; Burdick, J.W. The kinematics of hyper-redundant robot locomotion. IEEE Trans. Robot. Autom. 1995, 11, 781–793. [Google Scholar] [CrossRef]

- Zheng, T.; Branson, D.T.; Kang, R.; Cianchetti, M.; Guglielmino, E.; Follador, M.; Medrano-Cerda, G.A.; Godage, I.S.; Caldwell, D.G. Dynamic continuum arm model for use with underwater robotic manipulators inspired by octopus vulgaris. In Proceedings of the IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 5289–5294. [Google Scholar] [CrossRef]

- Rucker, D.C.; Jones, B.A.; Webster, R.J., III. A Geometrically Exact Model for Externally Loaded Concentric-Tube Continuum Robots. IEEE Trans. Robot. 2010, 26, 769–780. [Google Scholar] [CrossRef] [PubMed]

- Ferrentino, P.; Roels, E.; Brancart, J.; Terryn, S.; Van Assche, G.; Vanderborght, B. Finite Element Analysis-Based Soft Robotic Modeling: Simulating a Soft Actuator in SOFA. IEEE Robot. Autom. Mag. 2023, 2–12. [Google Scholar] [CrossRef]

- Schegg, P.; Ménager, E.; Khairallah, E.; Marchal, D.; Dequidt, J.; Preux, P.; Duriez, C. SofaGym: An Open Platform for Reinforcement Learning Based on Soft Robot Simulations. Soft Robot. 2023, 10, 410–430. [Google Scholar] [CrossRef] [PubMed]

- Duriez, C.; Coevoet, E.; Largilliere, F.; Morales-Bieze, T.; Zhang, Z.; Sanz-Lopez, M.; Carrez, B.; Marchal, D.; Goury, O.; Dequidt, J. Framework for online simulation of soft robots with optimization-based inverse model. In Proceedings of the IEEE International Conference on Simulation, Modeling, and Programming for Autonomous Robots (SIMPAR), San Francisco, CA, USA, 13–16 December 2016; pp. 111–118. [Google Scholar] [CrossRef]

- Ferigo, A.; Iacca, G.; Medvet, E.; Pigozzi, F. Evolving Hebbian Learning Rules in Voxel-Based Soft Robots. IEEE Trans. Cogn. Dev. Syst. 2023, 15, 1536–1546. [Google Scholar] [CrossRef]

- Khodambashi, R.; Berman, S.; He, X.; Aukes, D.M. Miniaturized Untethered Soft Robots Using Hydrogel-based Soft Voxel Actuators. In Proceedings of the IEEE 4th International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 12–16 April 2021; pp. 571–574. [Google Scholar] [CrossRef]

- Hiller, J.; Lipson, H. Automatic Design and Manufacture of Soft Robots. IEEE Trans. Robot. 2012, 28, 457–466. [Google Scholar] [CrossRef]

- Liang, L.; Meng, L.; Ma, H. Design, Characterization, and Optimization of the Soft Bellows Pneumatic Actuator. In Proceedings of the IEEE International Conference on Mechatronics and Automation (ICMA), Harbin, China, 6–9 August 2023; pp. 331–335. [Google Scholar] [CrossRef]

- Barreto, P.S.; Pinto, M.F.; Pereira, G.D.; Batista, J.L.; Carneiro, D.M.M.O.; Dias, J.T.; Almeida, L.F. Low-Cost Fish-Based Soft Robot Development for Underwater Environment. In Proceedings of the 15th IEEE International Conference on Industry Applications (INDUSCON), São Bernardo do Campo, Brazil, 22–24 November 2023; pp. 1672–1677. [Google Scholar] [CrossRef]

- Cabrera, M.; Van Liew, J.; Turoski, N.; Baysa, M.; Han, Y.-L. Utilizing Computational Modeling to Aid the Development of a Wearable Soft Robot for Finger Rehabilitation. In Proceedings of the International Conference on Advanced Mechatronic Systems (ICAMechS), Toyama, Japan, 17–20 December 2022; pp. 10–15. [Google Scholar] [CrossRef]

- Fahim, J.K.; Faried, A.M.; Shehata, O.M.; Morgan, E.I. Development and Control of an Enhanced Active Compliance based Soft Pneumatically Actuated Robotic Hand. In Proceedings of the 8th International Conference on Control, Mechatronics and Automation (ICCMA), Moscow, Russia, 6–8 November 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Salem, M.E.M.; Wang, Q.; Wen, R.; Xiang, M. Design and Characterization of Soft Pneumatic Actuator for Universal Robot Gripper. In Proceedings of the International Conference on Control and Robots (ICCR), Hong Kong, China, 15–17 September 2018; pp. 6–10. [Google Scholar] [CrossRef]

- Amala, E.G.; Lal Priya, P.S. Bending Deformation Relation with Various Materials for a Soft Pneumatic Actuator. In Proceedings of the Emerging Trends in Industry 4.0 (ETI 4.0), Raigarh, India, 19–21 May 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Xavier, M.S.; Tawk, C.D.; Zolfagharian, A.; Pinskier, J.; Howard, D.; Young, T.; Lai, J.; Harrison, S.M.; Yong, Y.K.; Bodaghi, M.; et al. Soft Pneumatic Actuators: A Review of Design, Fabrication, Modeling, Sensing, Control and Applications. IEEE Access 2022, 10, 59442–59485. [Google Scholar] [CrossRef]

- Wandke, K.; Z., Y. MOOSE-Based Finite Element Hyper Elastic Modeling for Soft Robot Simulations. IEEE Access 2021, 9, 139627–139635. [Google Scholar] [CrossRef]

- Tony, A.; Rasouli, A.; Farahinia, A.; Wells, G.; Zhang, H.; Achenbach, S.; Yang, S.M.; Sun, W.; Zhang, W. Toward a Soft Microfluidic System: Concept and Preliminary Developments. In Proceedings of the 27th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Shanghai, China, 26–28 November 2021; pp. 755–759. [Google Scholar] [CrossRef]

- Alam, W.; Mehmood, A.; Ali, K.; Javaid, U.; Alharbi, S.; Iqbal, J. Nonlinear Control of a Flexible Joint Robotic Manipulator with Experimental Validation. Stroj. Vestn. J. Mech. Eng. 2018, 64, 47–55. [Google Scholar] [CrossRef]

- Alam, W.; Ahmad, S.; Mehmood, A.; Iqbal, J. Robust sliding mode control for flexible joint robotic manipulator via disturbance observer. Interdiscip. Descrip. Comp. Syst. 2019, 17, 85–97. [Google Scholar] [CrossRef]

| Criterion | Rating Description |

|---|---|

| Cr1 | High: If a design method allows the designer to specify the design requirements “naturally”, including functions, performances, and constraints, this design method will be rated ‘high’ in terms of Cr1. Naturally, it means that the specification of design requirements is not dependent on any computational model but on a semantic template or data model [31,32]. Medium: If a design method allows the designer to specify the design requirements (function, performance, and constraint) in a computational model, for example, a particular evolutional computational model, this design method will be rated ‘medium’ in terms of Cr1. Low: If a design method does not allow the designer to specify the design requirements but directly allows the designer to specify a design object, a soft robot in this case, by mimicking a creature along with its behavior or property, this design method will be rated ‘low’ in terms of Cr1. It is noted that such a design method for soft robots is also called the bio-inspired design method, coined in this paper. |

| Cr2 | High: If a design method allows for generating the architecture of a soft robot based on first principles, it will be rated ‘high’ in terms of Cr2. In this case, the first principle refers to knowledge from basic sciences (e.g., physics, chemistry, biology) upon which to account for the behavior of a design object, such as a soft robot, in an explainable manner. Medium: If a design method combines the first principles and experiences of the designer in the design process, it will be rated ‘medium’ in terms of Cr2. For example, in a particular design method, the architecture of a product is proposed based on the designer’s experience, but the follow-up design activities, such as embodiment design, are conducted with an optimization principle; this design method will be rated ‘medium’ in Cr2. Low: If a design method requires the designer to determine the architecture or concept of a design object, such as a soft robot, using the designer’s intuition, experience, or bio-inspiration, this design method will be rated ‘low’ in terms of Cr2. |

| Cr3 | High: A design method follows a step-by-step flow with clear and distinct phases, and thus this design method will be rated ‘high’ in terms of Cr3. Medium: A design method may miss one or two design phases, e.g., technical specification of design requirements. This design method will be rated ‘medium’ in terms of Cr2. Low: If a design method does not have distinct design phases or steps for the designer to follow, this design method will be rated ‘low’ in terms of Cr3. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasanshahi, B.; Cao, L.; Song, K.-Y.; Zhang, W. Design of Soft Robots: A Review of Methods and Future Opportunities for Research. Machines 2024, 12, 527. https://doi.org/10.3390/machines12080527

Hasanshahi B, Cao L, Song K-Y, Zhang W. Design of Soft Robots: A Review of Methods and Future Opportunities for Research. Machines. 2024; 12(8):527. https://doi.org/10.3390/machines12080527

Chicago/Turabian StyleHasanshahi, Behzad, Lin Cao, Ki-Young Song, and Wenjun Zhang. 2024. "Design of Soft Robots: A Review of Methods and Future Opportunities for Research" Machines 12, no. 8: 527. https://doi.org/10.3390/machines12080527

APA StyleHasanshahi, B., Cao, L., Song, K.-Y., & Zhang, W. (2024). Design of Soft Robots: A Review of Methods and Future Opportunities for Research. Machines, 12(8), 527. https://doi.org/10.3390/machines12080527