Influence of Check Gate Construction on Operation of Check Gate in Ship Lock

Abstract

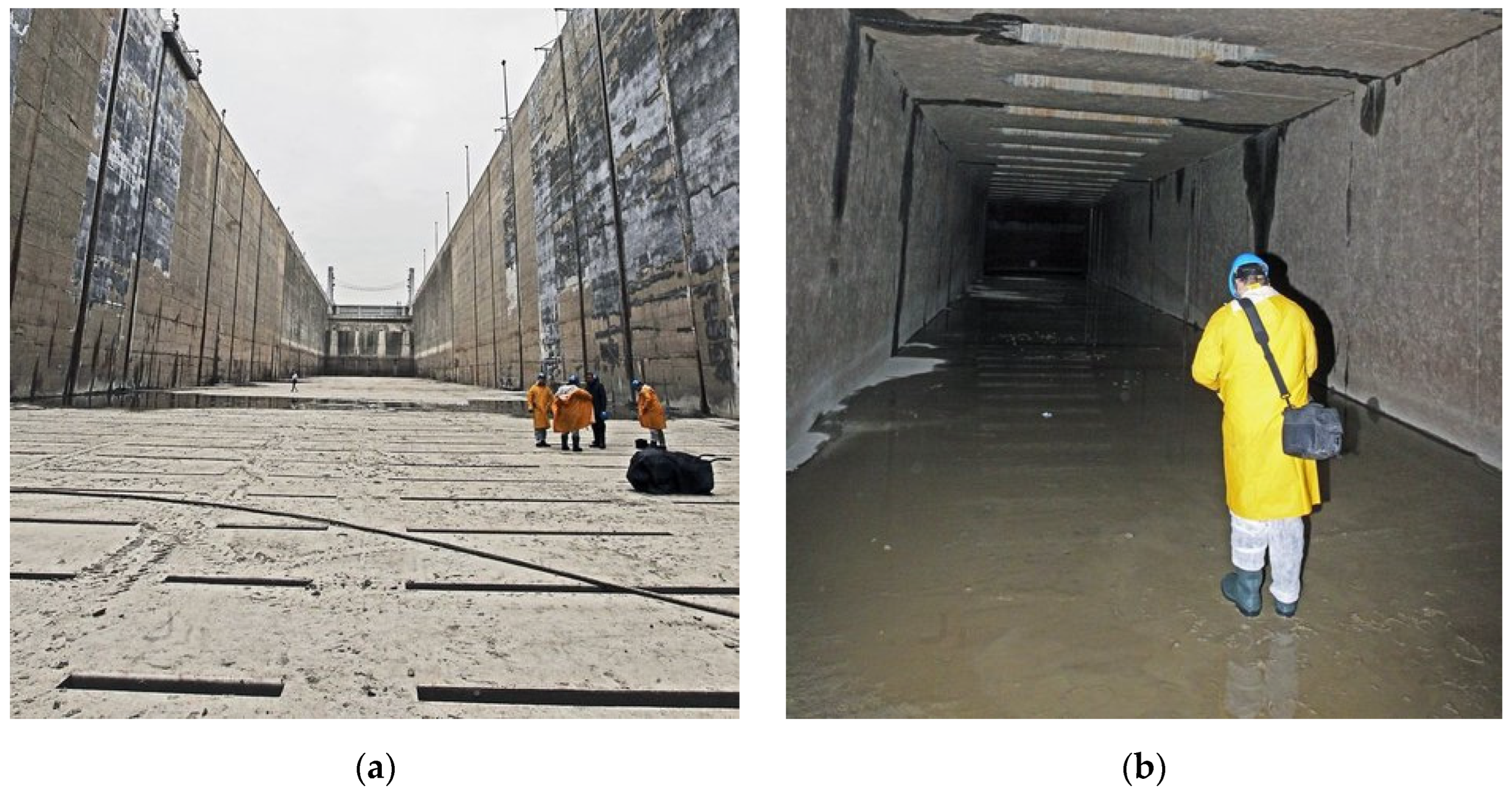

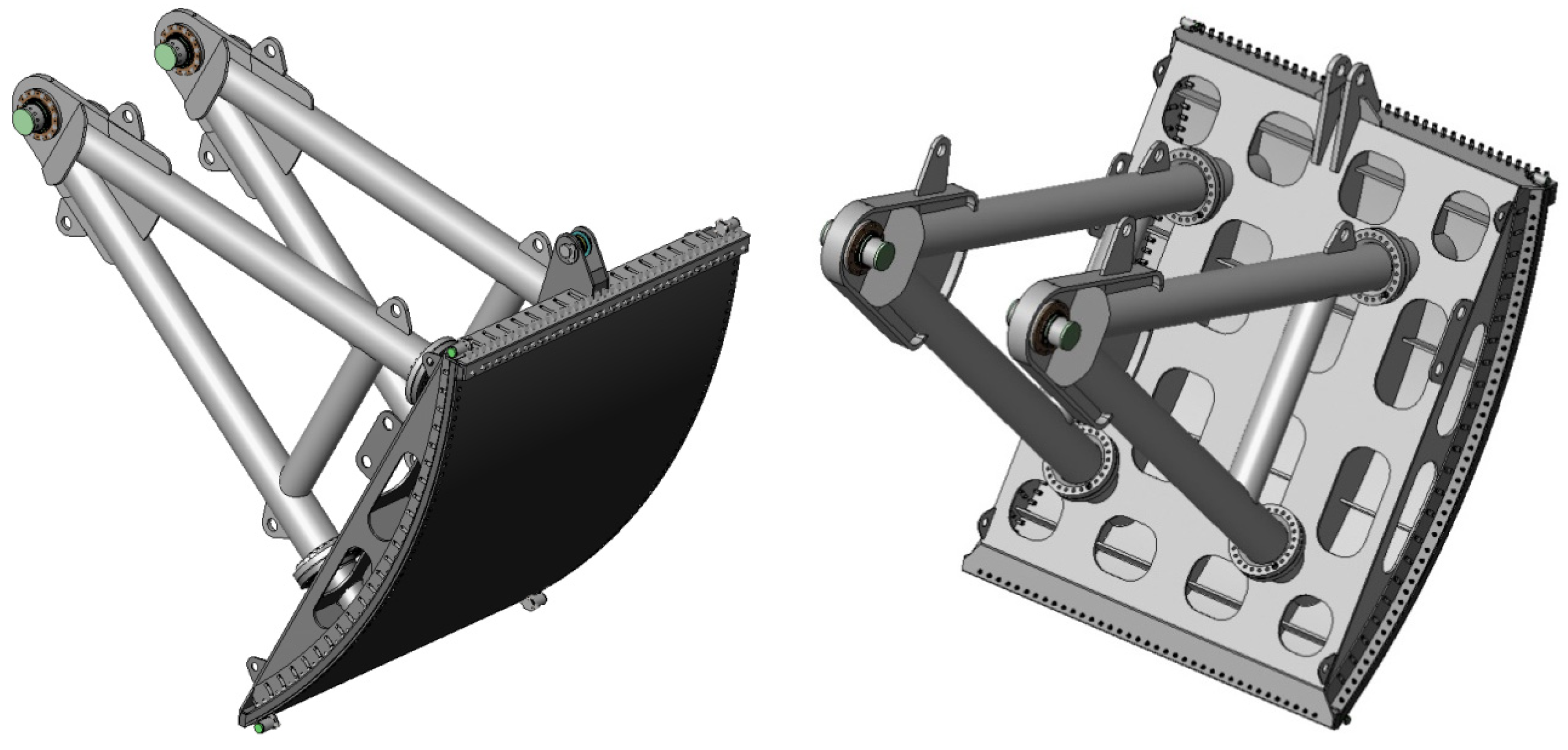

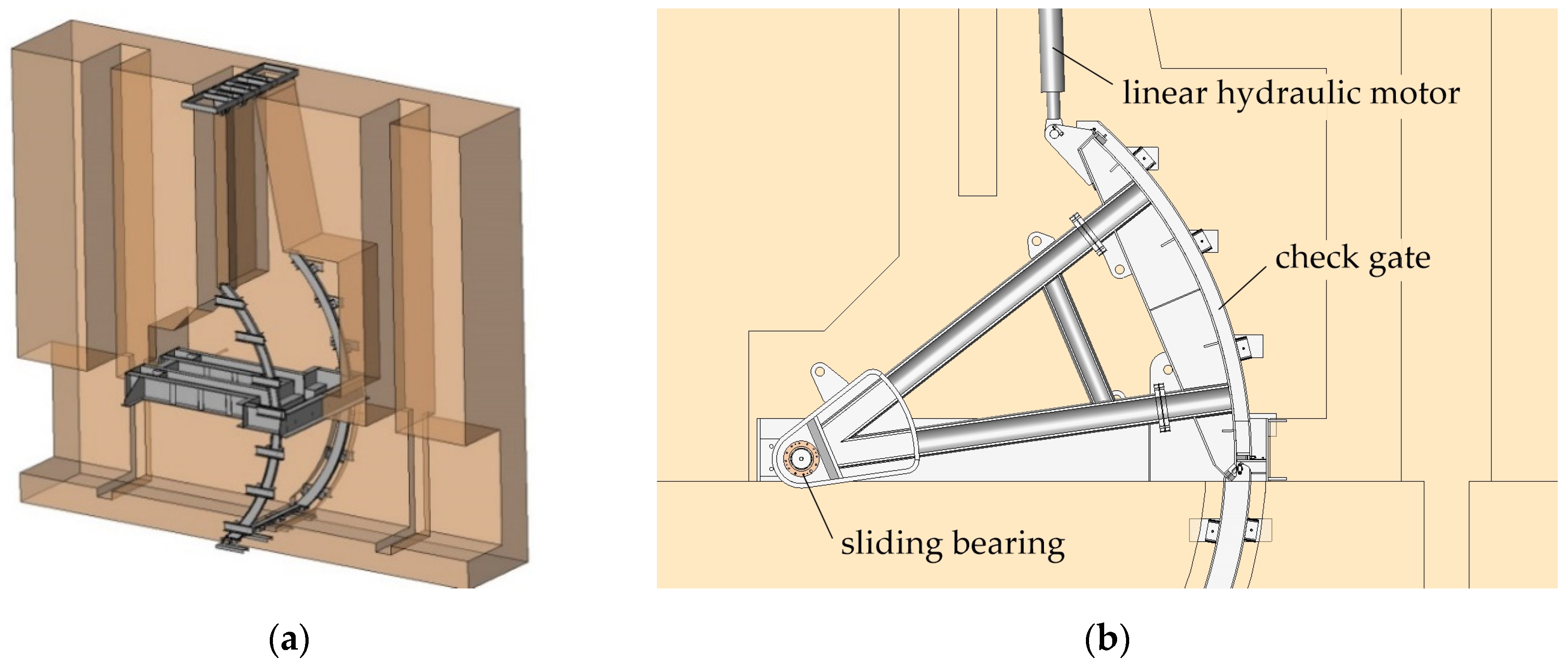

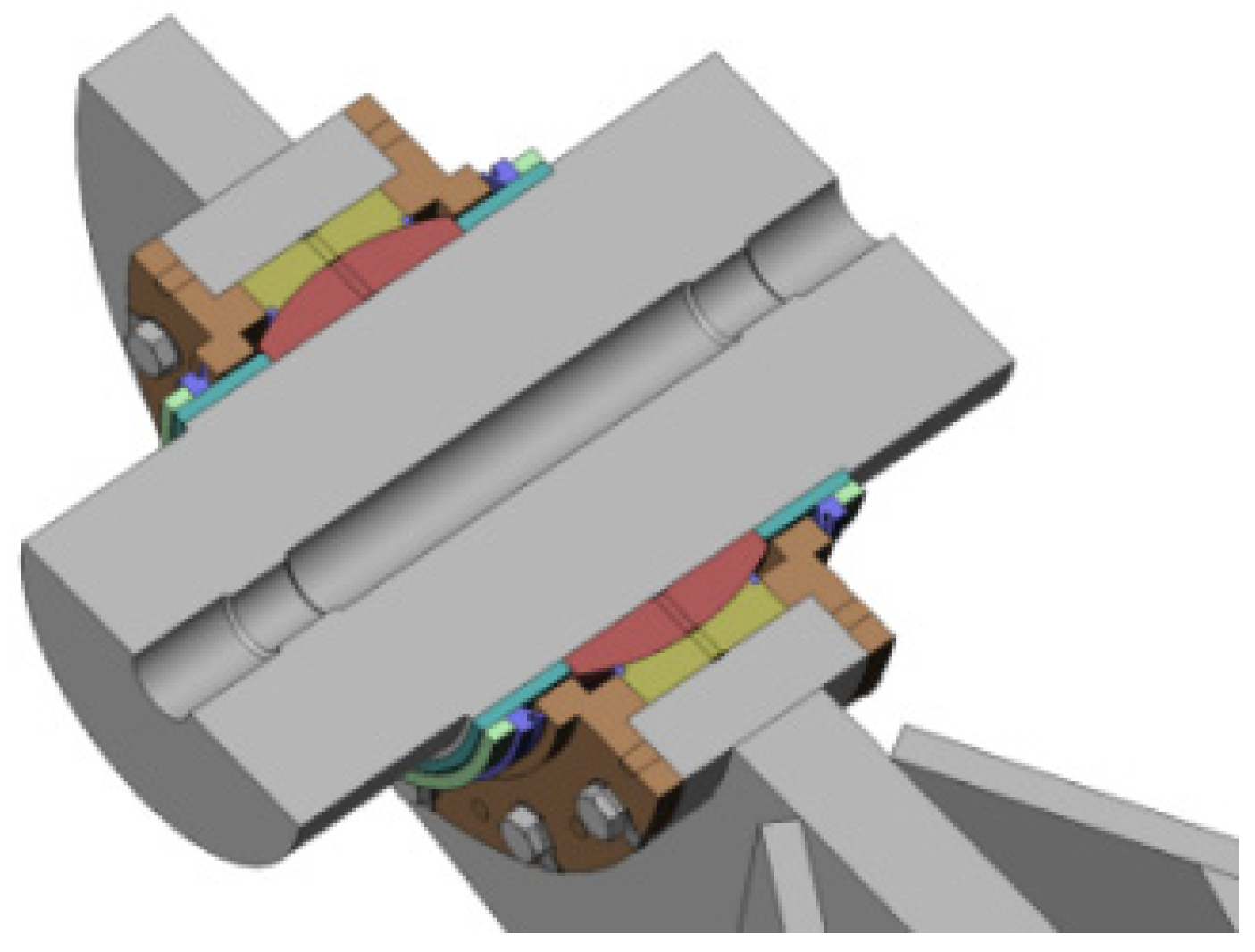

:1. Introduction

2. Characteristics of Gabčíkovo Waterworks and Its Ship Locks

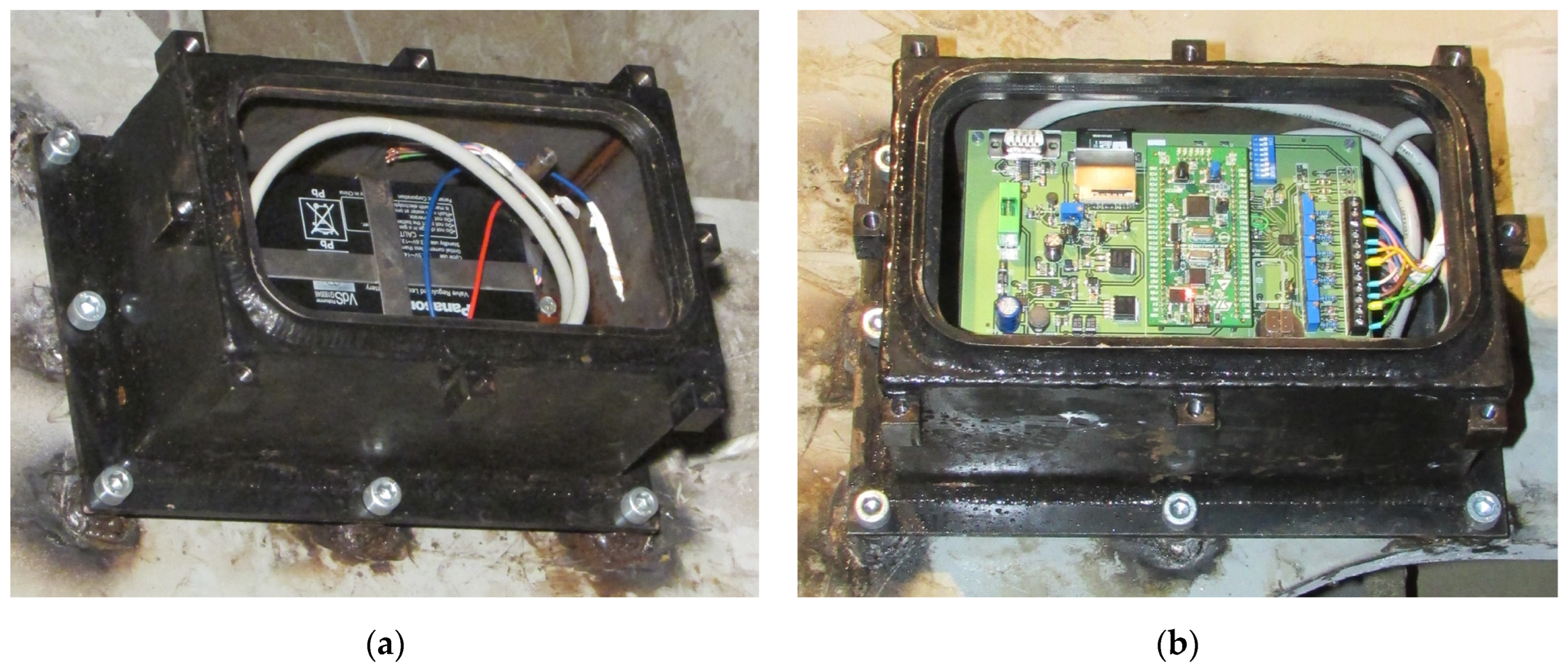

3. Placement of Sensors and Application of Measuring Boxes

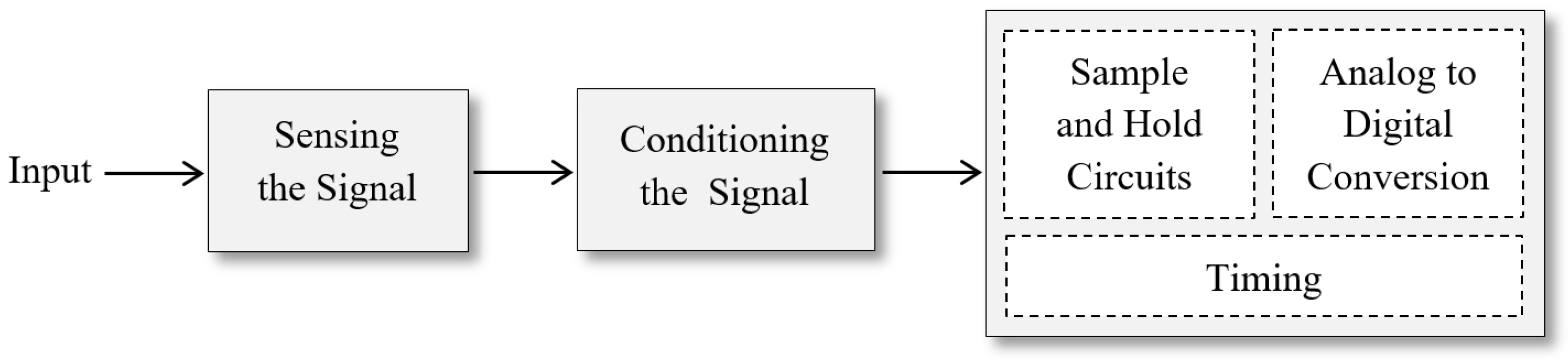

4. Data Accumulation and Processing System Structure

4.1. Measurement Chain and Its Organisation

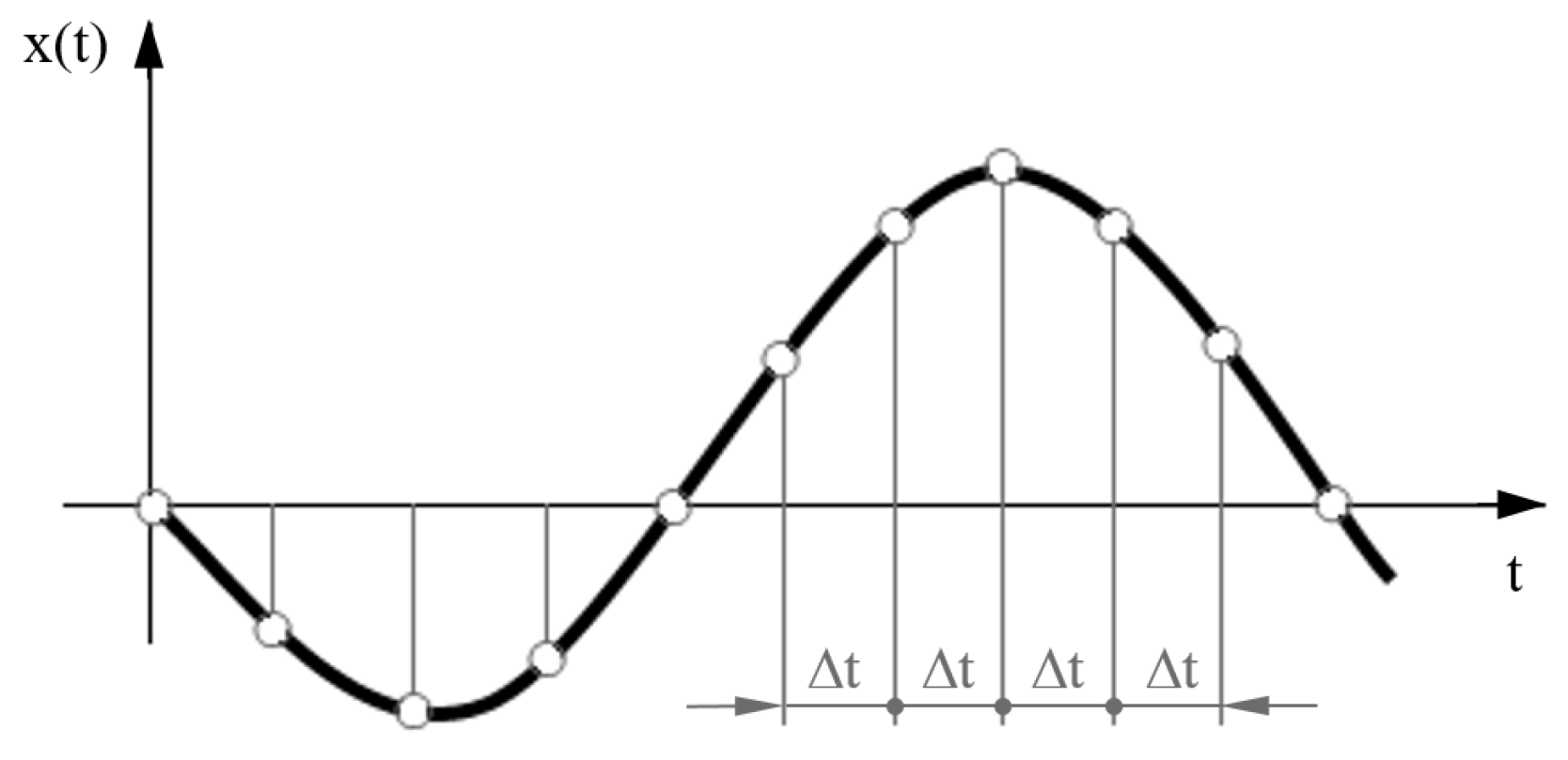

4.2. Signal Sampling

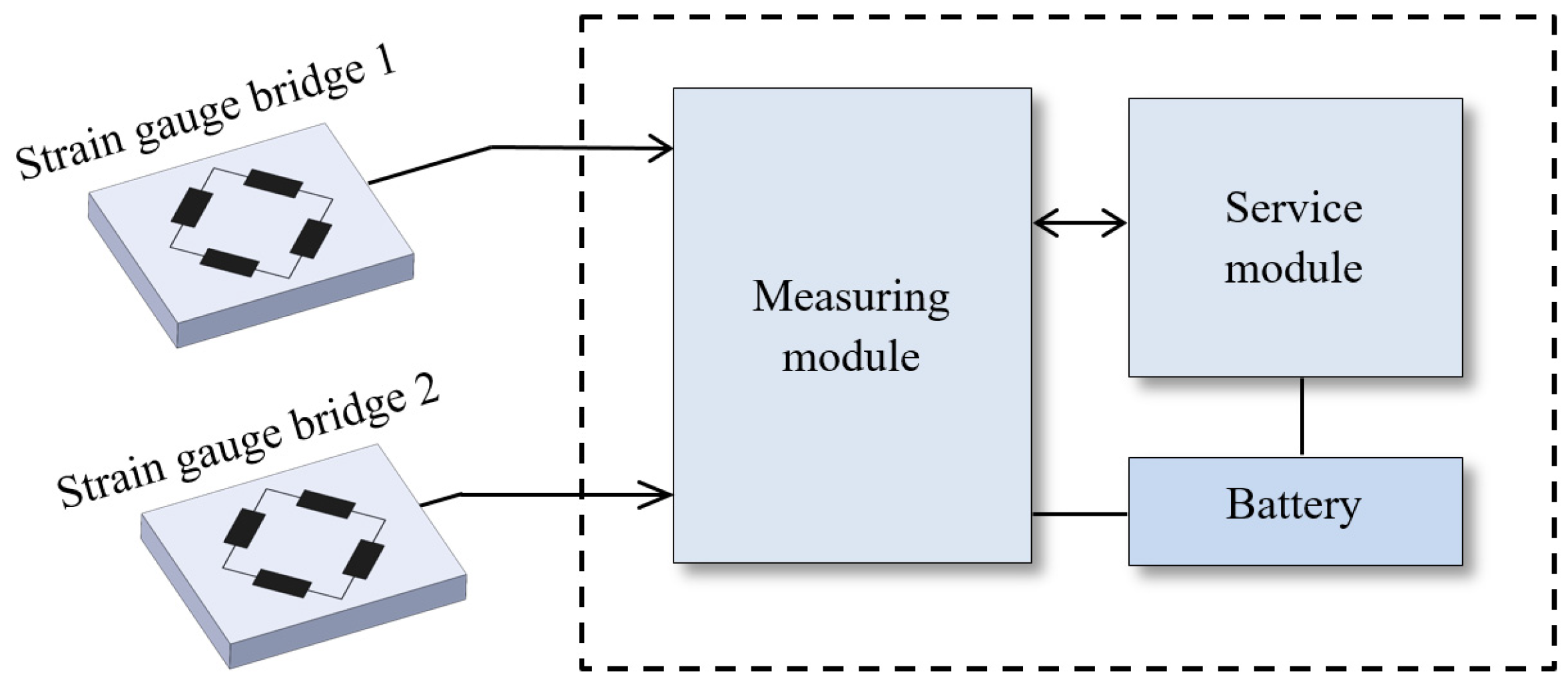

4.3. System Structure

4.4. Software

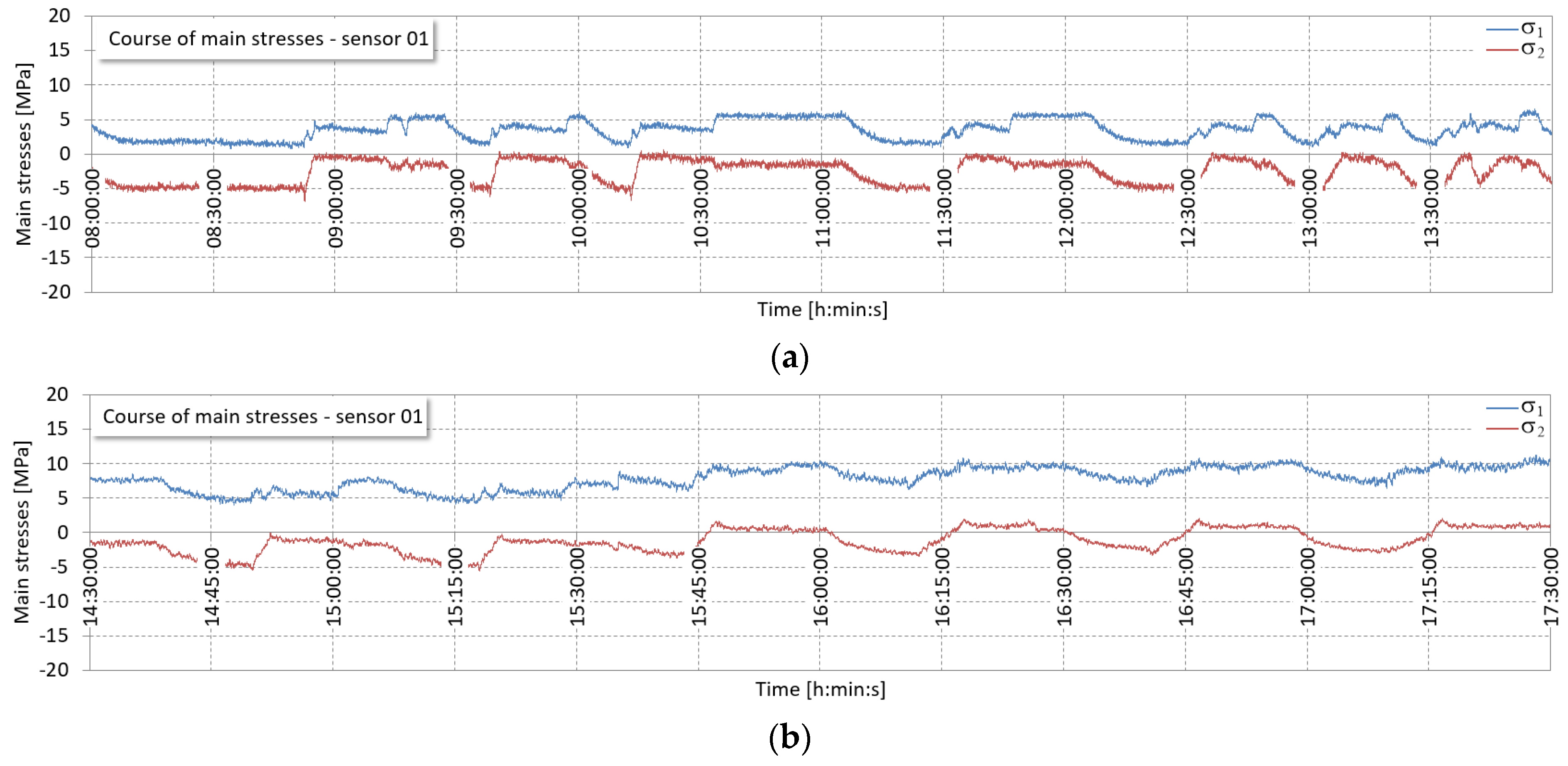

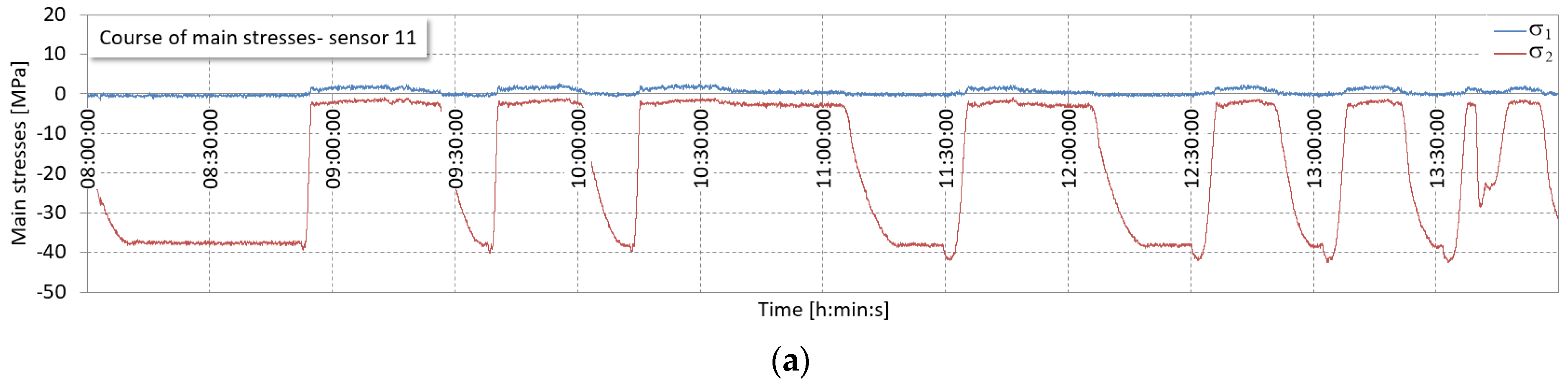

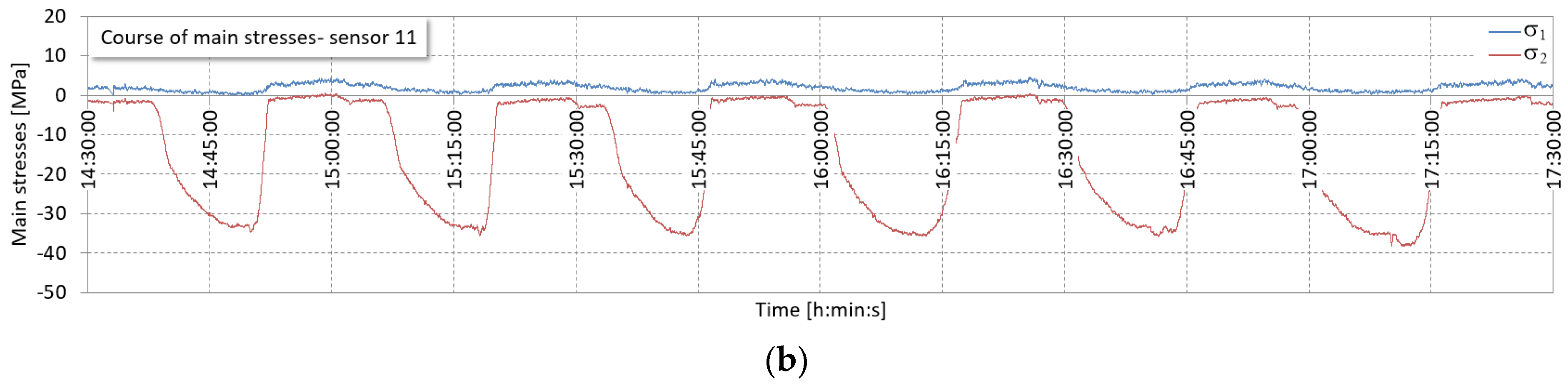

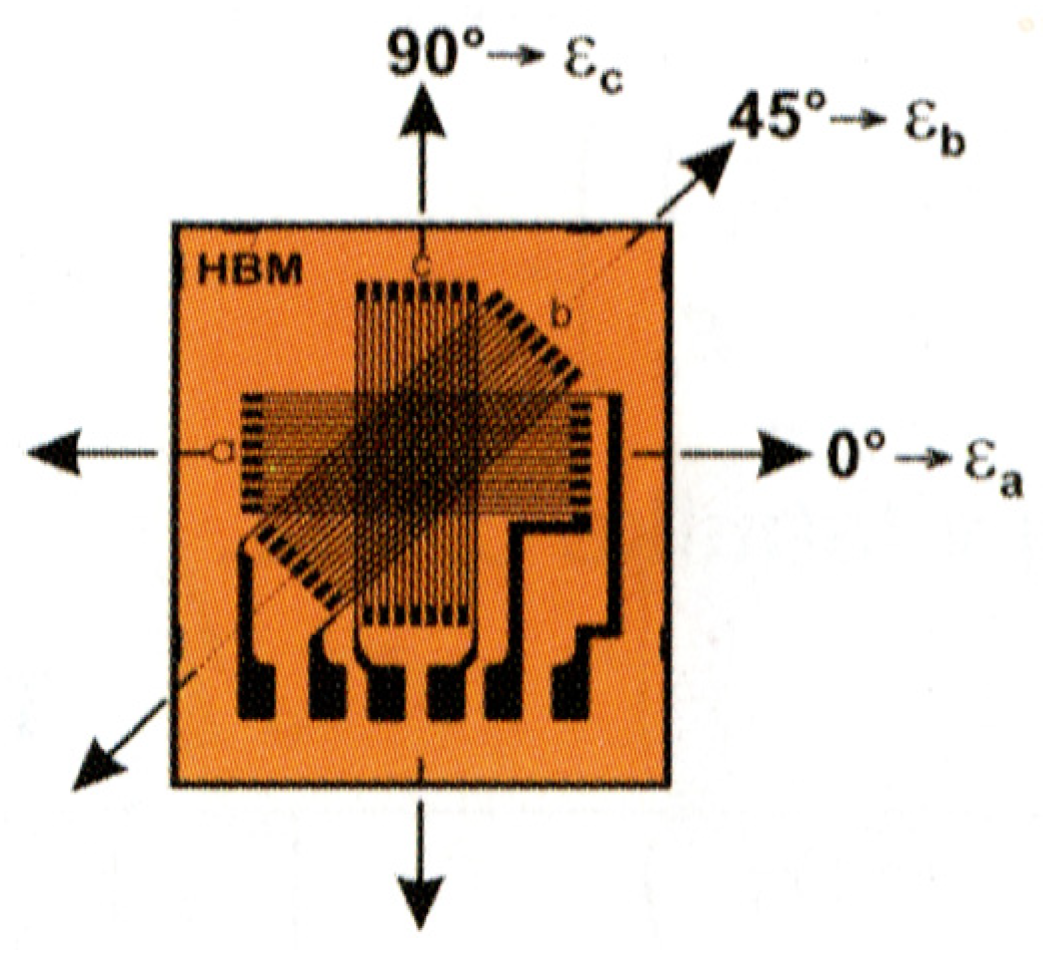

5. Strain Gauge Measurement of the Segment

6. Discussion

7. Conclusions

- -

- Installation applications of the strain gauge sensors were limited due to spatial, technological, and construction possibilities, which made it impossible to situate the sensors in places of maximum loading;

- -

- There were proposed certain constructional modifications on the check gate with regard to better access when applying measuring sensors (in our case, the strain gauges) as close as possible to the places with the highest loading;

- -

- The measuring equipment, specially developed for this measurement, was kept by the operator of the given waterworks for the next long-term monitoring of the newly installed check gate operation;

- -

- However, the courses of stress increments obtained from the measured points correspond to the values of the results obtained from the performed FEM analysis, but these are not the real maximum stress values acting in the check gate segment construction;

- -

- The measurements demonstrated the reliability of the proposed measuring procedure. At the same time, by analyzing the measured values of the stress increments in the individual measuring points, it was found that the measured welded construction of the check gate is suitable for the given operational conditions;

- -

- It was necessary to transform the measured values into the originally proposed measuring points, as mentioned above. The maximum stress values did not exceed the yield strength value of the base constructional material in no measuring point.

- -

- Due to doubts about the cause of accidental damage to the original check gate, it was decided that the new construction of the check gate will be made from material with higher resistance to notch influence at low temperatures compared to the originally applied material.

- -

- After analysis of the measurements performed on the new check gate construction, it is possible to summarize that the new constructional arrangement of the check gate, together with the system of seals, is an innovative solution that can be inspirational for producers of such devices.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dursun, B.; Gokcol, C. The role of hydroelectric power and contribution of small hydropower plants for sustainable development in Turkey. Renew. Energy 2011, 36, 1227–1235. [Google Scholar] [CrossRef]

- Singh, V.K.; Singal, S.K. Operation of hydro power plants—A review. Renew. Sustain. Energy Rev. 2017, 69, 610–619. [Google Scholar] [CrossRef]

- Sachdev, H.S.; Akella, A.K.; Kumar, N. Analysis and evaluation of small hydropower plants: A bibliographical survey. Renew. Sustain. Energy Rev. 2015, 51, 1013–1022. [Google Scholar] [CrossRef]

- Ven, V.D.; Loon, V. The interaction of a lock’s filling jet and the ship in the lock chamber, using scale model measurements. In Proceedings of the 7th IAHR International Symposium on Hydraulic Structures, Aachen, Germany, 15–18 May 2018; ISHS: Leuven, Belgium, 2018; pp. 402–410, ISBN 978-0-692-13277-7. [Google Scholar] [CrossRef]

- Van Der Hout, A.; Schotman, A.; Hoff, T.; Van Der Veen, J.W.; Quax, A. Innovative Mooring in Locks Using Shoretension: Density and Mooring Force Measurements in the North Lock Ijmuiden. In Proceedings of PIANC Smart Rivers 2022; Li, Y., Hu, Y., Rigo, P., Lefler, F.E., Zhao, G., Eds.; PIANC 2022; Lecture Notes in Civil Engineering; Springer: Singapore, 2023; Volume 264. [Google Scholar] [CrossRef]

- Wu, L.; Xiang, Z.; Shu, D.; Liu, M.; Yang, J.; Li, M. Dynamic Inversion Model of the Mooring Force on a Floating Bollard of a Sea Lock. J. Mar. Sci. Eng. 2023, 11, 1374. [Google Scholar] [CrossRef]

- Wan, Z.; Li, Y.; Wang, X.; An, J.; Cheng, L.; Liao, Y. Effect of ship-lock-induced surges on navigation safety in a branched lower approach channel system. J. Hydroinformatics 2022, 24, 481–496. [Google Scholar] [CrossRef]

- Gobbetti, L.E.C. Design of the filling and emptying system of the new Panama Canal Locks. J. Appl. Water Eng. Res. 2013, 1, 28–38. [Google Scholar] [CrossRef]

- Badano, N.D.; Menéndez, Á.N. Numerical modeling of Reynolds scale effects for filling/emptying system of Panama Canal Locks. Water Sci. Eng. 2021, 14, 237–245. [Google Scholar] [CrossRef]

- Menéndez, A.N.; Lecertua, E.A.; Badano, N.D. Optimización del diseño del sistema dellenado/vaciado del Tercer Juego de Esclusas del Canal de Panamá. RIBAGUA Rev. Iberoam. Agua 2014, 1, 4–13. [Google Scholar]

- Ooi, S.; Constantinescu, G.; Weber, L. Numerical simulations of lock-exchange compositional gravity current. J. Fluid Mech. 2009, 635, 361–388. [Google Scholar] [CrossRef]

- Jánosi, I.M.; Jan, D.; Szabó, K.G.; Tél, T. Turbulent drag reduction in dam-break flows. Exp. Fluids 2004, 37, 219–229. [Google Scholar] [CrossRef]

- Horváth, K.; Petreczky, M.; Rajaoarisoa, L.; Duviella, E.; Chuquet, K. MPC control of water level in a navigation canal—The Cuinchy-Fontinettes case study. In Proceedings of the European Control Conference (ECC), Strasbourg, France, 24–27 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1337–1342. [Google Scholar] [CrossRef]

- O’Mahoney, T.; Heinsbroek, A.; de Loor, A.; Kortlever, W.; Verelst, K. Numerical simulations of a longitudinal filling system for the New Lock at Terneuzen. In Proceedings of the 34th PIANC World Congress, Panama City, Panama, 7–12 May 2018. [Google Scholar]

- Verelst, K.; Vercruysse, J.; De Mulder, T. Hydraulic design of a filling emptying system for the new Royers lock in the port of Antwerp (Belgium). In Proceedings of the 36th IAHR World Congress: Deltas of the Future and What Happened Upstream, Delft, The Netherlands, 28 June–3 July 2015; pp. 4563–4574. [Google Scholar]

- Lama, G.F.C.; Giovannini, M.R.M.; Alessandro Errico, A.; Mirzaei, S.; Padulano, R.; Chirico, G.B.; Preti, F. Hydraulic Efficiency of Green-Blue Flood Control Scenarios for Vegetated Rivers: 1D and 2D Unsteady Simulations. Water 2021, 13, 2620. [Google Scholar] [CrossRef]

- Furtado, G.C.A.; Mesquita, A.L.A.; Morabito, A.; Hendrick, P.; Hunt, J.D. Using hydropower waterway locks for energy storage and renewable energies integration. Appl. Energy 2020, 275, 115361. [Google Scholar] [CrossRef]

- Yang, Q.; Zhai, J.; Jiang, Z. Numerical simulation of saltwater intrusion in a lock with long canal adopting coupled box model and three-dimensional model. In Proceedings of the 36th IAHR World Congress: Deltas of the Future and What Happened Upstream, Delft, The Netherlands, 28 June–3 July 2015; pp. 181–190. [Google Scholar]

- Liu, J.; Hu, Y.; Li, Z.; Xue, S. Risk Analysis and Optimization of Water Surface Deviation from Shafts in the Filling–Emptying System of a Mega-Scale Hydro-Floating Ship Lift. Water 2021, 13, 1377. [Google Scholar] [CrossRef]

- Zhang, J.; Leontidis, V.; Dazin, A.; Tounzi, A.; Delarue, P.; Caignaert, G.; Piriou, F.; Libaux, A. Canal lock variable speed hydropower turbine design and control. IET Renew. Power Gener. 2018, 12, 1698–1707. [Google Scholar] [CrossRef]

- Daniel, R.; Paulus, T. Lock gates and other closures in hydraulic projects. In Butterworth-Heinemann, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Thorenz, C.; Strybny, J. On the numerical modelling of filling-emptying system for locks. In Proceedings of the 10th International Conference on Hydroinformatics: HIC; Understanding Changing Climate and Environment and Finding Solutions, Hamburg, Germany, 14–18 July 2012; Hinkelmann, R., Ed.; TuTech. Innovation: Hamburg, Germany, 2012. [Google Scholar]

- Gapeev, A.; Morgunov, K.; Karacheva, M. Quality Assessment of the System of Filling a Shipping Lock Chamber from under the Segmental Guillotine Gate. In Proceedings of the International Scientific Conference Energy Management of Municipal Facilities and Sustainable Energy Technologies EMMFT 2019; Murgul, V., Pukhkal, V., Eds.; EMMFT 2019; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2020; Volume 1258. [Google Scholar] [CrossRef]

- Yucel, M.; Yucel, M. The measurement of strain of a prototype pulley system using a Brillouin optical time domain analysis. Microw. Opt. Technol. Lett. 2022, 64, 190–198. [Google Scholar] [CrossRef]

- Hrabovsky, L.; Cepica, D.; Frydrysek, K. Detection of mechanical stress in the steel structure of a bridge crane. Theor. Appl. Mech. Lett. 2021, 11, 100299. [Google Scholar] [CrossRef]

- Aytaç Onur, Y.; Gelen, H. Design and deflection evaluation of a portal crane subjected to traction load. Mater. Test. 2020, 62, 1131–1137. [Google Scholar] [CrossRef]

- Anand, L.D.V.; Hepsiba, D.; Palaniappan, S.; Sumathy, B.; Vijayakumar, P.; Rani, S.S. Automatic strain sensing measurement on steel beam using strain gauge. Mater. Today Proc. 2021, 45 Pt 2, 2578–2580, ISSN 2214-7853. [Google Scholar] [CrossRef]

- Gorbushin, A.R.; Bolshakova, A.A. Unsteady axial force measurement by the strain gauge balance. Measurement 2020, 152, 107381, ISSN 0263-2241. [Google Scholar] [CrossRef]

- Wang, Y.J.; Chi, P.K.; Lin, Y.H.; Lu, T.F.; Sue, C.Y. A six-axis force and torque sensor consisting of compliant mechanisms and full-bridge strain gauges. Measurement 2024, 226, 114151, ISSN 0263-2241. [Google Scholar] [CrossRef]

- Cui, H.; Du, H.; Zhao, F.; Hong, M. Damage identification in a plate structure based on a cross-direction strain measurement method. Measurement 2020, 158, 107714, ISSN 0263-2241. [Google Scholar] [CrossRef]

- Sinay, J.; Bigoš, P.; Bugár, T. Experimental Methods and Machine Testing; Alfa: Bratislava, Slovakia, 1989; 232p, ISBN 082-737-89. [Google Scholar]

- Kulka, J.; Mantič, M.; Faltinová, E.; Kopas, M. Autonomous online system for evaluating steel structure durability. Diagnostyka 2016, 17, 15–20, ISSN 1641-6414. [Google Scholar]

- Sága, M.; Vaško, M.; Pecháč, P. Chosen Numerical Algorithms for Interval Finite Element Analysis. Procedia Eng. 2014, 96, 400–409, ISSN 1877–7058. [Google Scholar] [CrossRef]

- Lindgren, G.; Rychlik, I. Rain Flow Cycle Distributions for Fatigue Life Prediction under Gaussian Load Processes. Fatigue Fract. Eng. Mater. Struct. 1987, 10, 251–260. [Google Scholar] [CrossRef]

- Rychlik, I.; Gupta, S. Rain-flow fatigue damage for transformed Gaussian loads. Int. J. Fatigue 2007, 29, 406–420. [Google Scholar] [CrossRef]

- Tovo, R. Damage-based evaluation of probability density distribution for rain-flow ranges from random processes. Int. J. Fatigue 2000, 22, 425–429. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulka, J.; Mantič, M.; Kopas, M.; Fabian, M.; Grega, R.; Kaššay, P.; Siman, M. Influence of Check Gate Construction on Operation of Check Gate in Ship Lock. Machines 2024, 12, 641. https://doi.org/10.3390/machines12090641

Kulka J, Mantič M, Kopas M, Fabian M, Grega R, Kaššay P, Siman M. Influence of Check Gate Construction on Operation of Check Gate in Ship Lock. Machines. 2024; 12(9):641. https://doi.org/10.3390/machines12090641

Chicago/Turabian StyleKulka, Jozef, Martin Mantič, Melichar Kopas, Michal Fabian, Robert Grega, Peter Kaššay, and Marián Siman. 2024. "Influence of Check Gate Construction on Operation of Check Gate in Ship Lock" Machines 12, no. 9: 641. https://doi.org/10.3390/machines12090641

APA StyleKulka, J., Mantič, M., Kopas, M., Fabian, M., Grega, R., Kaššay, P., & Siman, M. (2024). Influence of Check Gate Construction on Operation of Check Gate in Ship Lock. Machines, 12(9), 641. https://doi.org/10.3390/machines12090641