Abstract

Upper limb exoskeleton robots, as highly integrated wearable devices with the human body structure, hold significant potential in rehabilitation medicine, human performance enhancement, and occupational safety and health. The rapid advancement of high-precision, low-noise acquisition devices and intelligent motion intention recognition algorithms has led to a growing demand for more rational and reliable control strategies. Consequently, the control systems and strategies of exoskeleton robots are becoming increasingly prominent. This paper innovatively takes the hierarchical control system of exoskeleton robots as the entry point and comprehensively compares the current control strategies and intelligent technologies for upper limb exoskeleton robots, analyzing their applicable scenarios and limitations. The current research still faces challenges such as the insufficient real-time performance of algorithms and limited individualized adaptation capabilities. It is recognized that no single traditional control algorithm can fully meet the intelligent interaction requirements between exoskeletons and the human body. The integration of many advanced artificial intelligence algorithms into intelligent control systems remains restricted. Meanwhile, the quality of control is closely related to the perception and decision-making system. Therefore, the combination of multi-source information fusion and cooperative control methods is expected to enhance efficient human–robot interaction and personalized rehabilitation. Transfer learning and edge computing technologies are expected to enable lightweight deployment, ultimately improving the work efficiency and quality of life of end-users.

1. Introduction

Upper exoskeleton robots are wearable robots designed based on bionics and ergonomics, integrating theories and technologies from fields such as mechanical engineering, control theory, computer science, electronics, biomedical engineering, and rehabilitation medicine. Exoskeleton robots can transfer the wearer’s load to the robot itself. They can also enhance the wearer’s strength and provide motion assistance based on the wearer’s intentions. They are one of the most promising approaches to addressing issues such as physical disabilities and assisting the elderly in walking [1]. Unlike intelligent prostheses, exoskeleton robots focus more on coupling and collaborating with the wearer’s body rather than simply replacing certain limbs. This will enable patients to complete certain movements to a greater extent according to their personal wishes.

Typically, exoskeleton robots can be classified into rehabilitation-assisted exoskeleton robots and enhanced exoskeleton robots in terms of application scenarios [2]. Rehabilitation upper limb exoskeleton robots mainly include mobility assistance, motor rehabilitation, and neuromotor rehabilitation. Regarding mobility assistance, the robotic exoskeleton acts as a functional support for the rehabilitation of injured people, congenital/acquired disabled people, and the elderly, enabling them to perform upper limb movements affected by pathology [3]. For motor rehabilitation, the restoration of motor function and the rehabilitation of the upper limb are the main medical motivations. It can improve and enhance patients’ motor abilities and also prevent muscle atrophy caused by sedentary behavior [4,5]. Research on neuromotor rehabilitation is relatively scarce yet more important. This type of exoskeleton can implement different rehabilitation programs for the elderly or patients with movement disorders related to nervous system diseases by monitoring human physiological signals, improving their ability to live independently and their safety protection capabilities. However, safety and accuracy need to be given special consideration [6].

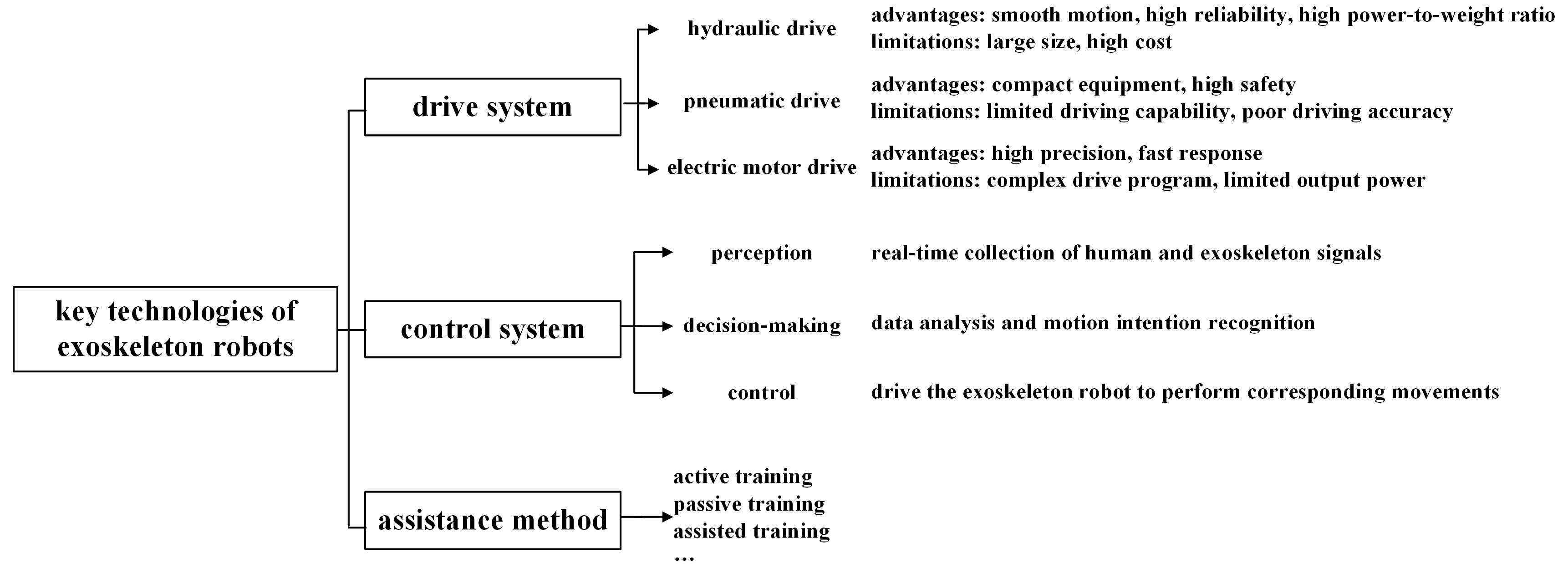

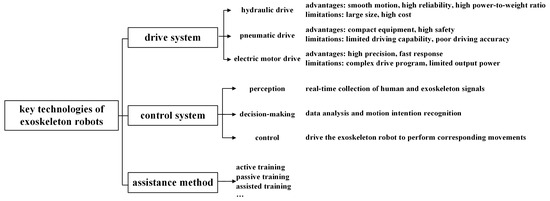

Enhancement-type exoskeleton robots are primarily used in special scenarios such as soldier combat, medical rescue, and heavy physical labor [7,8,9]. They are designed to enhance individual capabilities, improve mobility, and enhance performance. Therefore, the exploration and advancement of exoskeleton robots are significantly important for enhancing human health, strengthening medical services, and improving the operational capabilities and efficiency of workers in specific industries. The key technological architecture of exoskeleton robots, as depicted in Figure 1, is as follows: The driving part is the power source of the exoskeleton robot, providing assistance. Common types include motor-driven, pneumatic, hydraulic-driven, and cable-driven parts. The control system is the core of the exoskeleton robot, mainly responsible for predicting motion intentions, making decision commands, and then enabling the end controller to output corresponding control signals. For different driving methods and scene requirements, corresponding control strategies are needed, such as passive assistance, active rehabilitation, etc. The above-mentioned key technologies will be introduced in detail later.

Figure 1.

The key technical architecture of exoskeleton robots.

With the development of high-precision and low-noise sensor signal acquisition equipment and advanced intent recognition algorithms, exoskeleton robots urgently need corresponding control strategies to match. In the design process of exoskeleton robot control systems, various factors often need to be considered. First and foremost, the control system must ensure the safety and comfort of the user, with the capability to handle abnormal situations; secondly, the control system must possess a certain level of robustness to prevent user tremors and external disturbances from affecting the control effectiveness and precision; then, the control system needs to respond in advance or in a timely manner according to the user’s movement intentions, ensuring timeliness; and finally, it needs to have adaptability for users with different physiological or physical characteristics, making flexible adjustments as needed [10,11].

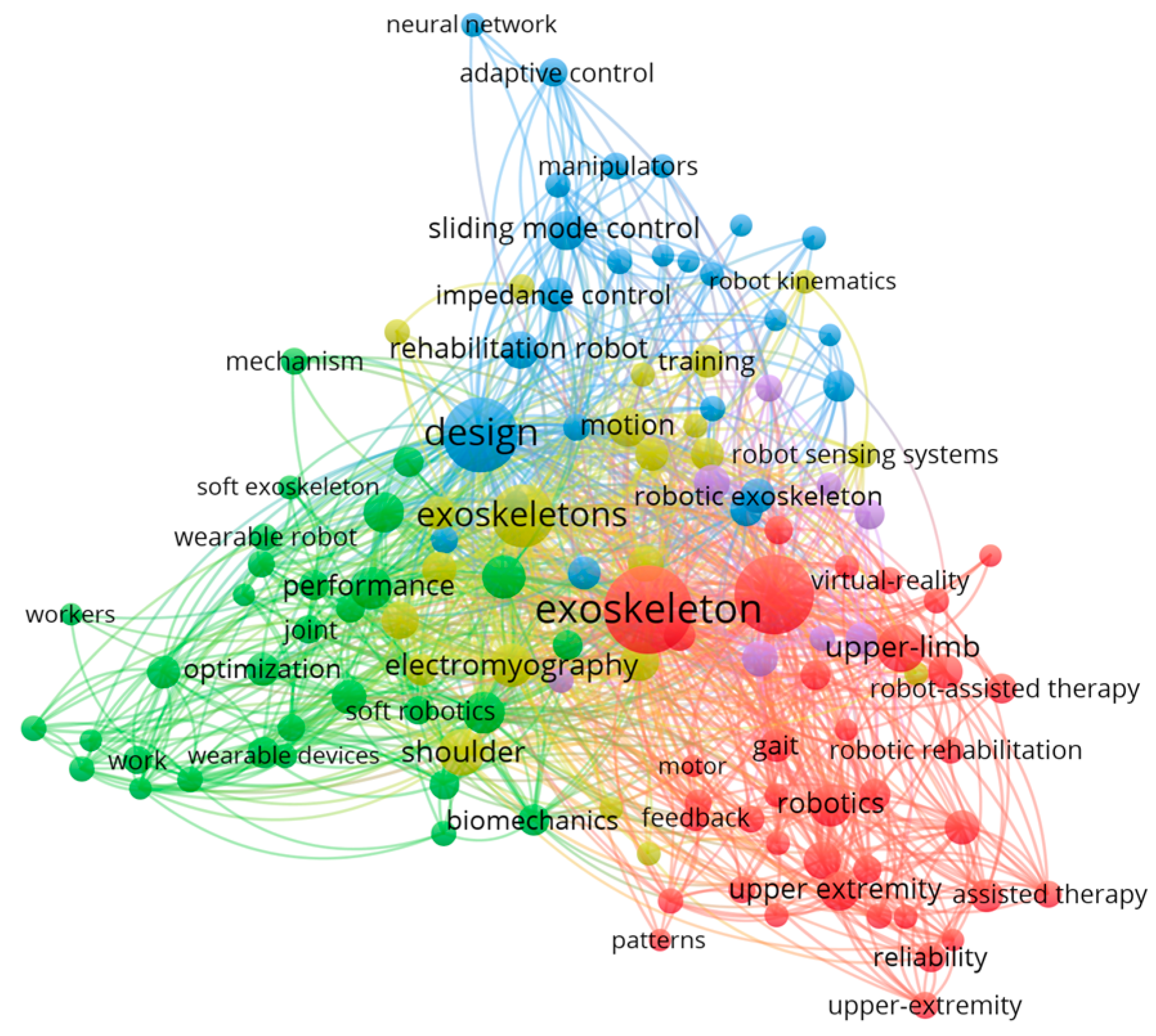

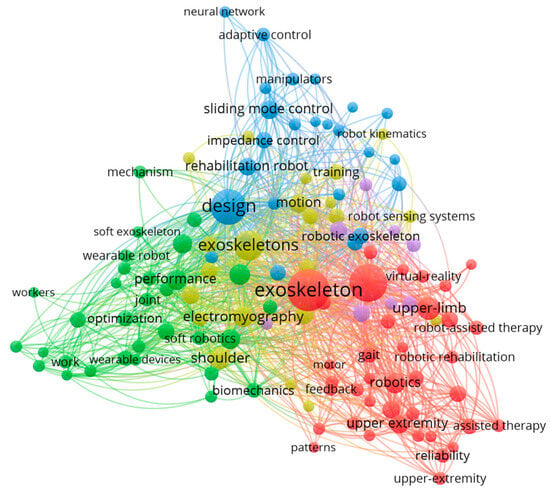

The core of control strategies in the control system is essentially to combine sensor data or intention recognition results to provide users with good and reliable human–robot interaction. Whether the choice of control strategies is appropriate directly determines the effect of human–robot interaction. Without advanced control strategies, exoskeletons may become rigid, inefficient, or even unsafe, thus limiting their potential in the medical and industrial fields. Therefore, the choice of control strategies is of crucial importance for the practical application effects of exoskeleton robots [12,13]. The literature with the themes of “exoskeleton control” and “upper limb” in the past five years (2020–2024) was screened in the Web of Science database. After data cleaning, 124 eligible keywords were selected. The association strength was statistically analyzed based on the number of co-occurrences among subject terms, keywords, etc., and a visual analysis of the key technologies for upper limb exoskeleton control was carried out, as shown in Figure 2. In the control strategy clustering (blue icons), there were a total of 25 branches, among which the main ones in the sequence were impedance control, adaptive control, and neural network control. This also coincides with the development of the exoskeleton product series. Other clusters represent other key technologies and development directions in the control of exoskeleton robots.

Figure 2.

Visual maps based on co-keyword analysis.

At present, for rehabilitative upper limb exoskeleton robots, the main control method is still impedance control. This is a feedback-based control approach that enables the robot to interact with humans in a sustainable and intuitive manner. Impedance control includes position control and force control [14], which allows the patient’s joints to move along a pre-set trajectory to complete certain actions, providing patients with a natural and intuitive experience and improving an individual’s mobility to a certain extent. However, this control strategy lacks flexibility and has limitations in terms of optimization and learning capabilities. The movement trajectory is fixed and cannot be adapted to different degrees of illness, body shapes, etc. Moreover, it cannot judge the human body’s movement intention. It has only achieved good application results in the initial stage of patient rehabilitation in the clinical field [15,16,17]. Although variable impedance control methods have emerged subsequently, essentially, the exoskeleton still follows passively and cannot achieve effective automatic control.

Traditional adaptive control often achieves self-tuning and the adaptation of parameters through algorithms to achieve compliant control effects. However, it lacks self-learning capabilities, relies on predefined mathematical models and parameter adjustment rules, has limited adaptability, and is relatively weak in adapting to unmodeled dynamics or sudden changes [18]. However, with users’ greater demand for the effect of human–robot interaction and complex and changeable usage scenarios, the automatic selection of control algorithms according to practical applications has shown a new development trend. In recent years, with the development of artificial intelligence, machine learning, and deep learning, many prediction, search, and self-learning algorithms have emerged, achieving excellent application effects in the fields of vision and image and also making significant progress in the field of human body movement intention recognition. How to combine artificial intelligence algorithms with upper limb exoskeleton control and use machine learning and deep learning to realize the search of exoskeleton control strategies and the automatic adjustment of controller parameters has become a research hotspot of intelligent control at present.

Most of the previously published review papers focused on intention recognition and did not thoroughly describe the end effectors and control strategies of exoskeleton robots. In addition, there are significant connections between adaptive control, intelligent control, sensing sensors, and decision-making algorithms. Optimizing the control effect of upper limb exoskeletons requires an organic integration of sensing and decision-making. Few of the previously published articles elaborated on the exoskeleton control system in a hierarchical manner to highlight its correlations. Therefore, the novelty and main contributions of this paper can be summarized as follows:

- (1)

- Taking the hierarchical control system of exoskeleton robots as the starting point, this paper not only horizontally reveals the connections among various components of the control system of upper limb exoskeleton robots but also vertically compares the current control strategies and intelligent technologies of upper limb exoskeleton robots.

- (2)

- It analyzes their applicable scenarios and limitations and points out that the key factors restricting the intelligent control of upper limb exoskeleton robots are related to perception and decision-making. The optimization of control effects and human–robot interaction is inseparable from the collaborative development among various levels of the control system. Multi-source information fusion and algorithm integration are expected to break through this problem.

The rest of the paper is organized as follows: Section 2 presents the overall control system of exoskeleton robots, covering perception, decision-making, and control. Section 3 discusses the typical control strategies of current upper limb exoskeleton robots, including traditional impedance control, adaptive control, and the latest intelligent control strategies and makes a comparison among different schemes. Section 4 summarizes the article, including the current technical difficulties, development trends, and future prospects.

2. Development Status of Upper Exoskeleton Robots

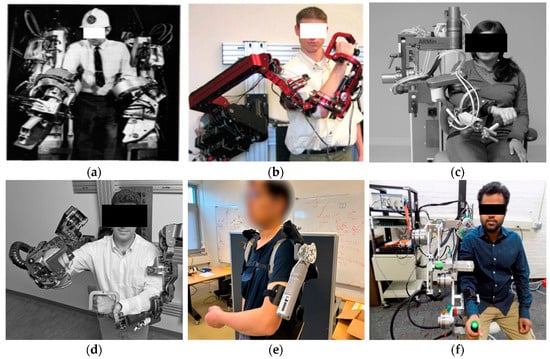

In the 1960s, General Electric developed the world’s first upper limb exoskeleton, known as the “Hardiman” exoskeleton [19]. It is driven by both hydraulic pressure and electricity and is divided into an upper body and a lower body, magnifying the wearer’s strength by 25 times, as shown in Figure 3a [20]. However, due to technical reasons, the prototype was too heavy and had slow response times, leading to low practical value, and the project ultimately did not succeed. Nevertheless, many design concepts from the project provided valuable experience for the subsequent research and design of exoskeletons.

Toward the end of the 20th century and the beginning of the 21st century, with the development of lightweight materials, actuation components, automation, and electronics, upper limb exoskeleton robots began to achieve significant breakthroughs. Two examples are the CADEN-7 robot developed by the University of Washington [21,22,23], as shown in Figure 3b. This exoskeleton robot adopts a multi-degree-of-freedom design, enabling a natural and smooth movement experience. It also features a human–robot interface module that can be adjusted according to user characteristics. The three-DOF (degree of freedom) mobile robot was developed by Saga University in Japan [24]. This exoskeleton innovatively applies surface electromyogram signals to intention recognition and actively controls based on human movement intentions. This optimizes the human–robot interaction effect and effectively assists users’ movements. With the development of lightweight materials, actuation components, control theory, and electronics, upper limb exoskeleton robots have rapidly advanced.

Most upper limb exoskeleton robots are driven by electric motors, which offer a simple, flexible, and precise control method capable of providing accurate assistance. In 2007, the University of Zurich in Switzerland developed an exoskeleton called ARMin for the treatment of stroke patients’ arms [22,25,26], as shown in Figure 3c. This exoskeleton has six DOFs, is equipped with force and position sensors, and primarily uses impedance control as its main control strategy.

In 2013, researchers at the University of California developed the UL-EXO7 exoskeleton robot for chronic stroke survivors [27,28], which has seven DOFs, as shown in Figure 3d. It drives neural reorganization, brain recovery, and functional recovery through task-specific repetitive training.

Grazi et al. developed a new semi-passive upper limb exoskeleton called H-PULSE for worker assistance [29]. This exoskeleton features an assistive level of electric adjustment. The robot is composed of several submodules, including a physical human–robot interface, a passive degree-of-freedom chain, an assistive actuation mechanism, and a control system. It can reduce the muscle activity of the user as well as the heart rate. However, this achievement has not been further verified among actual workers. Only the action of lifting heavy objects above the head has been tested. Felix Balser et al. [30,31] from Aalborg University in Denmark designed a novel three-DOF passive shoulder exoskeleton, as shown in Figure 3e. This exoskeleton mainly addresses the problems faced by workers during repetitive overhead tasks. By providing assistance, it effectively reduces the muscle effort of workers, thus reducing the risk of developing musculoskeletal disorders. Its core advantage lies in its ability to provide adjustable and adaptive assistance. The experimental results clearly show that this exoskeleton can significantly reduce the activation level of shoulder muscles, effectively alleviating the burden on shoulder muscles when workers are working.

The University of Wisconsin-Green Bay proposed an upper limb rehabilitation exoskeleton named U-Rob [32], which has seven DOFs, as shown in Figure 3f. It can improve human–robot interaction by monitoring the interaction forces between the robot and the wearer. It uses PID control technology to control joint motion and endpoint motion. This device can function both as an upper limb exoskeleton and as an end effector type of device.

Figure 3.

Exoskeleton robot product. (a) [20], (b) [23], (c) [26], (d) [28], (e) [31], (f) [32].

Figure 3.

Exoskeleton robot product. (a) [20], (b) [23], (c) [26], (d) [28], (e) [31], (f) [32].

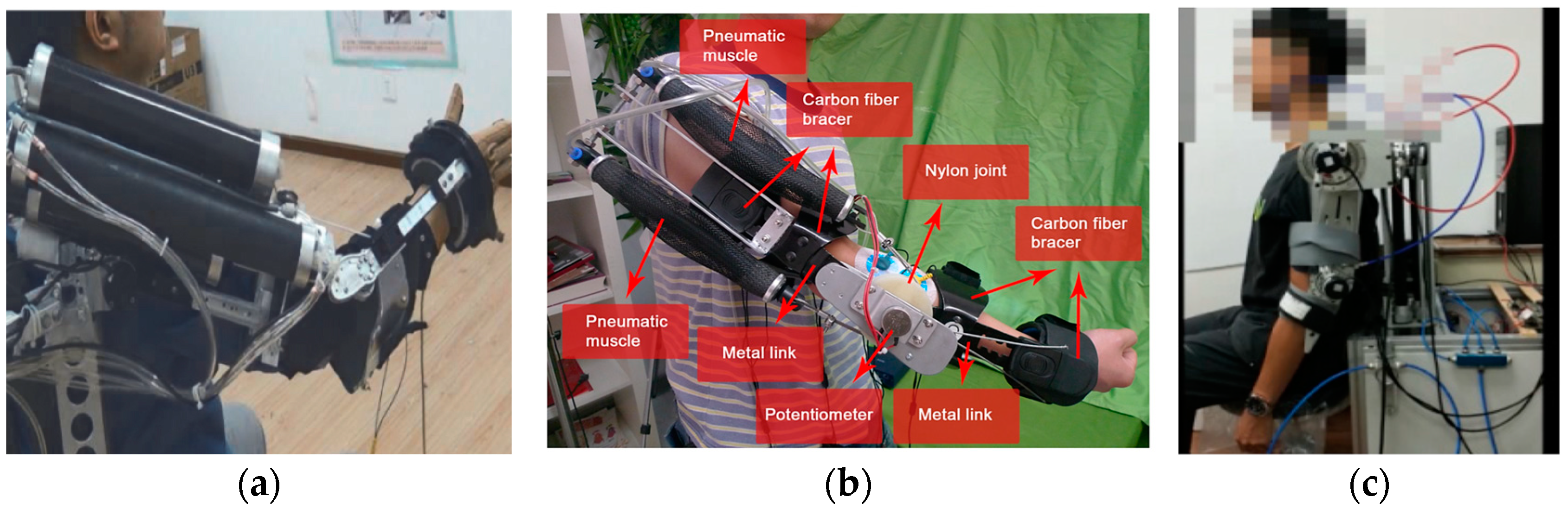

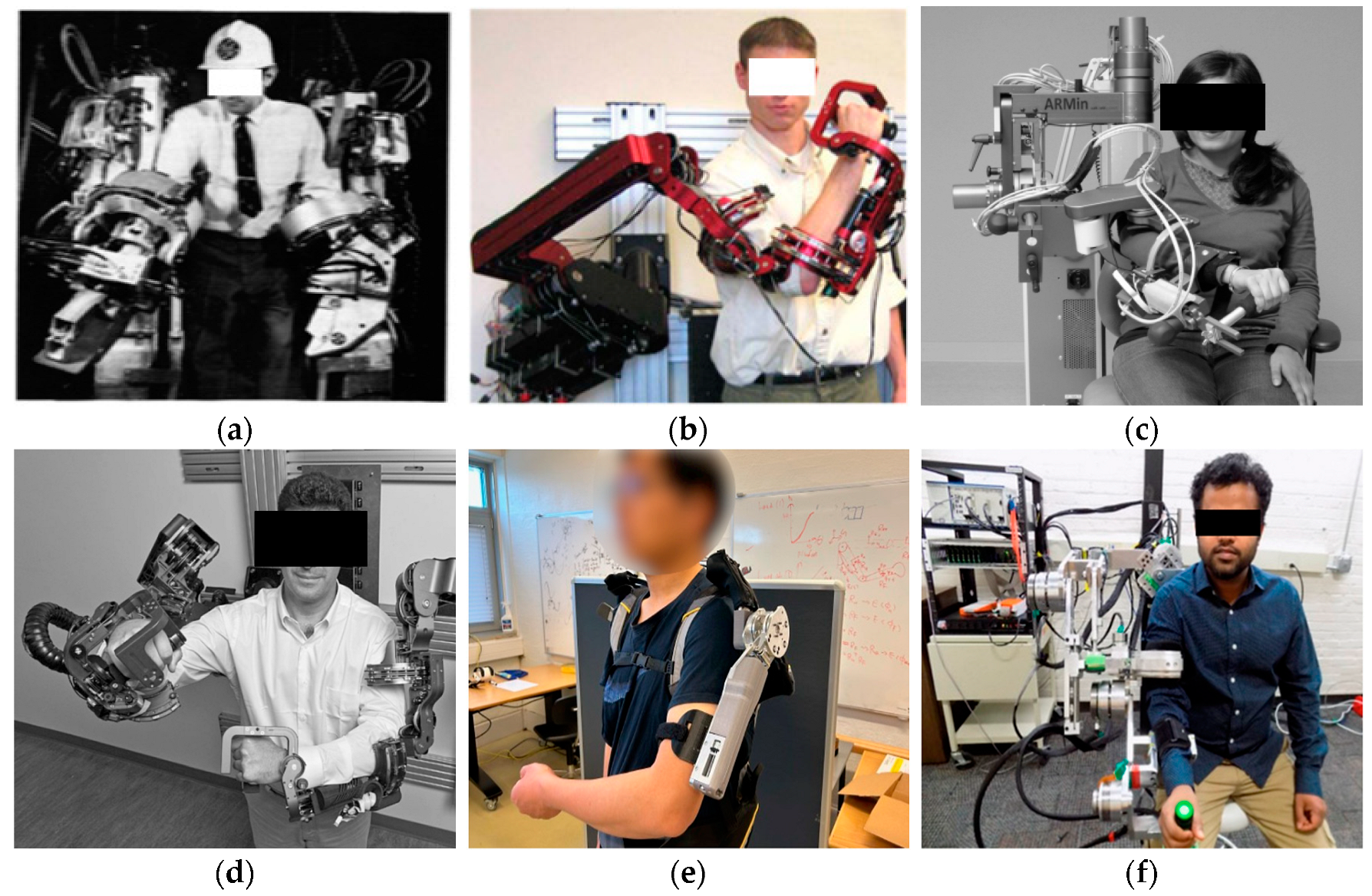

Upper limb exoskeleton robots driven by electric motors usually need to be equipped with multiple joint motors. To ensure that the torque meets the usage requirements, the motors and transmission devices usually have a relatively large weight, which causes inconvenience to the wearer. Therefore, pneumatic driving has emerged accordingly. Pneumatic devices are lightweight, have a long service life, and are environmentally friendly, but they are not suitable for high-power system transmission. The RUPERT exoskeleton driven by pneumatic artificial muscles, developed by Arizona State University in the United States [33,34], utilizes pneumatic artificial muscles (PAMs) to provide assistive force. This device is highly portable and easy to wear, as shown in Figure 4a. It has five DOFs and is used to assist with shoulder elevation, humeral external rotation, elbow extension, forearm supination, and wrist/hand extension.

Figure 4.

Pneumatic artificial muscle products. (a) [34], (b) [35], (c) [36].

Tang et al. [35] from Zhejiang University designed an upper limb exoskeleton driven by pneumatic muscles, as shown in Figure 4b. By integrating the proportional electromyogram control method, the exoskeleton can be controlled in real-time according to the users’ movement intentions. Experiments were conducted on six subjects to evaluate the reliability of the control scheme and the effectiveness of power assistance. This exoskeleton can be used to assist in elbow rehabilitation after nerve injury. Chen et al. [36] designed a lightweight four-DOF upper limb exoskeleton robot for rehabilitation, as shown in Figure 4c. It is driven by PMAs through steel cables. The use of a fuzzy sliding mode controller helps avoid possible sudden spasms and tremors of patients, which is of great significance for practical rehabilitation applications.

Wu Jun from the Huazhong University of Science and Technology has made improvements to the control strategies for pneumatic muscle exoskeletons, achieving excellent control effects even in situations where the model is unknown [37]. Liu et al. [38] designed a lightweight (3.1 kg) upper limb exoskeleton that can provide adaptive support forces for the upper limb based on a linkage mechanism and gas springs, as well as an adjustable maximum force (10–130 N) based on small motors and sensors. By combining the driving capacity of the motors and the lightweight mechanism of the gas springs, power consumption is reduced to achieve long-lasting battery life.

Meanwhile, to address the issue of the heavy weight of exoskeletons, some scholars have proposed cable-driven exoskeleton robots. There are many robot products driven by cables, such as the iCub robot developed by the Italian Institute of Technology. However, numerous difficulties have been encountered in the research on cable-driven robots [39,40], including the limitations of this driving method itself: the cable-driven system has a weak load-carrying capacity, and its pre-tension will change with the increase in the number of movements of the driven joint, resulting in significant differences in the initial positions of the driving motors. Moreover, it is highly difficult to maintain, and its reliability is not as good as that of traditional mechanical structures. As a result, none of the commercialized robotic manipulators have adopted the cable-driven transmission scheme.

However, in the field of exoskeletons, the upper limb rehabilitation exoskeleton with a cable-driven parallel structure has the advantages of a lightweight and large payload, enabling cable driving to achieve new development in exoskeleton products. Nevertheless, due to the non-rigid characteristics of the driving cables and the different body shapes of the wearers, there are relatively large errors in the geometric parameters of the exoskeleton, making the structural design and driving algorithm of the cable-driven exoskeleton of crucial importance.

Chen et al. [41] proposed a passively safe cable-driven upper limb exoskeleton that can perfectly simulate human body movements, but it has not been experimentally verified.

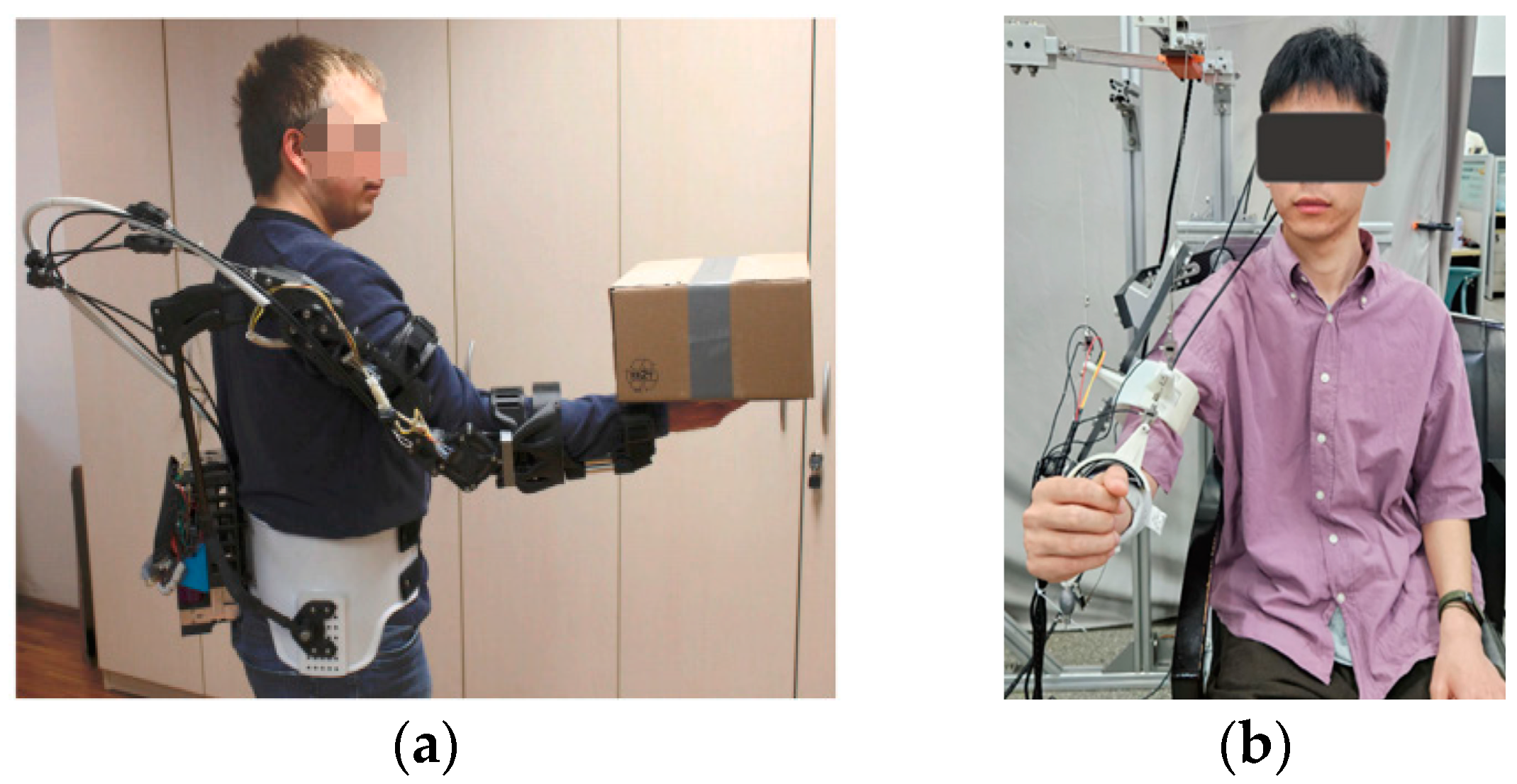

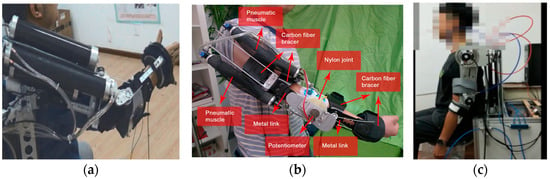

Xiao et al. [42] designed a seven-DOF cable-driven upper arm exoskeleton (CABXLexo-7). To achieve the compactness of the exoskeleton, two types of cable-driven differential mechanisms were designed. Meanwhile, to reduce the weight of the exoskeleton, the cable conduit mechanism transmits the power of the motors installed on the back panel to the corresponding joints, providing more comfortable assistance. Dezman et al. [43] proposed a lightweight, low-inertia, cable-driven upper limb exoskeleton, as shown in Figure 5a. They also modeled the friction characteristics, and the model can better capture the nonlinear behavior of the exoskeleton driving system, improving the overall performance by 15%. It is sufficient to meet the requirements of daily living activities.

Figure 5.

Cable-driven exoskeleton products. (a) [43], (b) [44].

Chen et al. [44] proposed a cable-driven exoskeleton system for upper limb rehabilitation, as shown in Figure 5b. It has three DOFs and weighs only 1.7 kg. This system can provide motion assistance for the shoulder and elbow. It adopts a PID-based position control strategy and an impedance control strategy to support rehabilitation training. Experiments were carried out on five subjects, achieving good results.

Meanwhile, many scholars are dedicated to research on cable driving or cable configuration. Zhang et al. [45] proposed a new cable configuration method in the shoulder joint rehabilitation exoskeleton, which solved the problem that cables can only pull but not push. Shi et al. [46] also proposed a dynamic adaptive structure aiming at the unidirectionality of cables. It significantly enlarges the working space and greatly improves tension efficiency. It will no longer affect human–computer interaction due to limited space and reduces potential dangers.

In addition, with the increase in application scenarios, full-body exoskeletons have emerged. Sarcos Corporation has developed the XOS series of full-body powered exoskeletons [47,48], as shown in Figure 6. These exoskeletons use hydraulic drive systems and are integrated with numerous sensors, hydraulic actuators, and controllers, which greatly enhance human capabilities. However, it is not possible to integrate the power supply and hydraulic pump station into the exoskeleton robot itself. The comparison of upper limb exoskeleton robot products is shown in Table 1. The comparison of different driving methods is shown in Table 2.

Figure 6.

XOS series full-body power-assist exoskeleton [48].

Table 1.

Comparison of different exoskeleton robots.

Table 2.

Comparison of different driving methods.

3. Introduction to Upper Exoskeleton Robot Control Systems

Exoskeleton robots are the result of interdisciplinary research. With the advancement of modern artificial intelligence and rehabilitation technology, they have achieved further development. Key technologies for exoskeleton robots include actuation systems, control systems, and training modes.

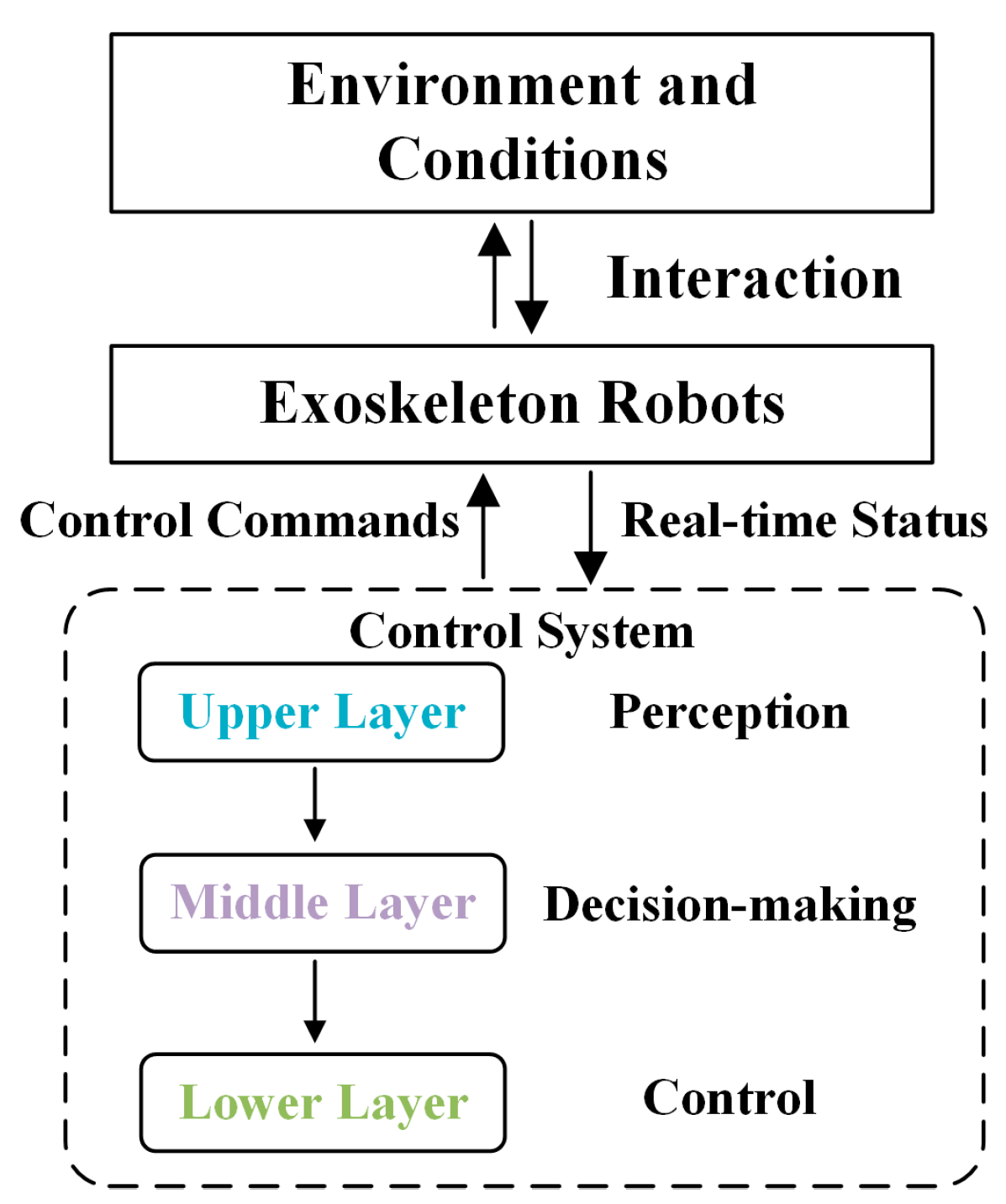

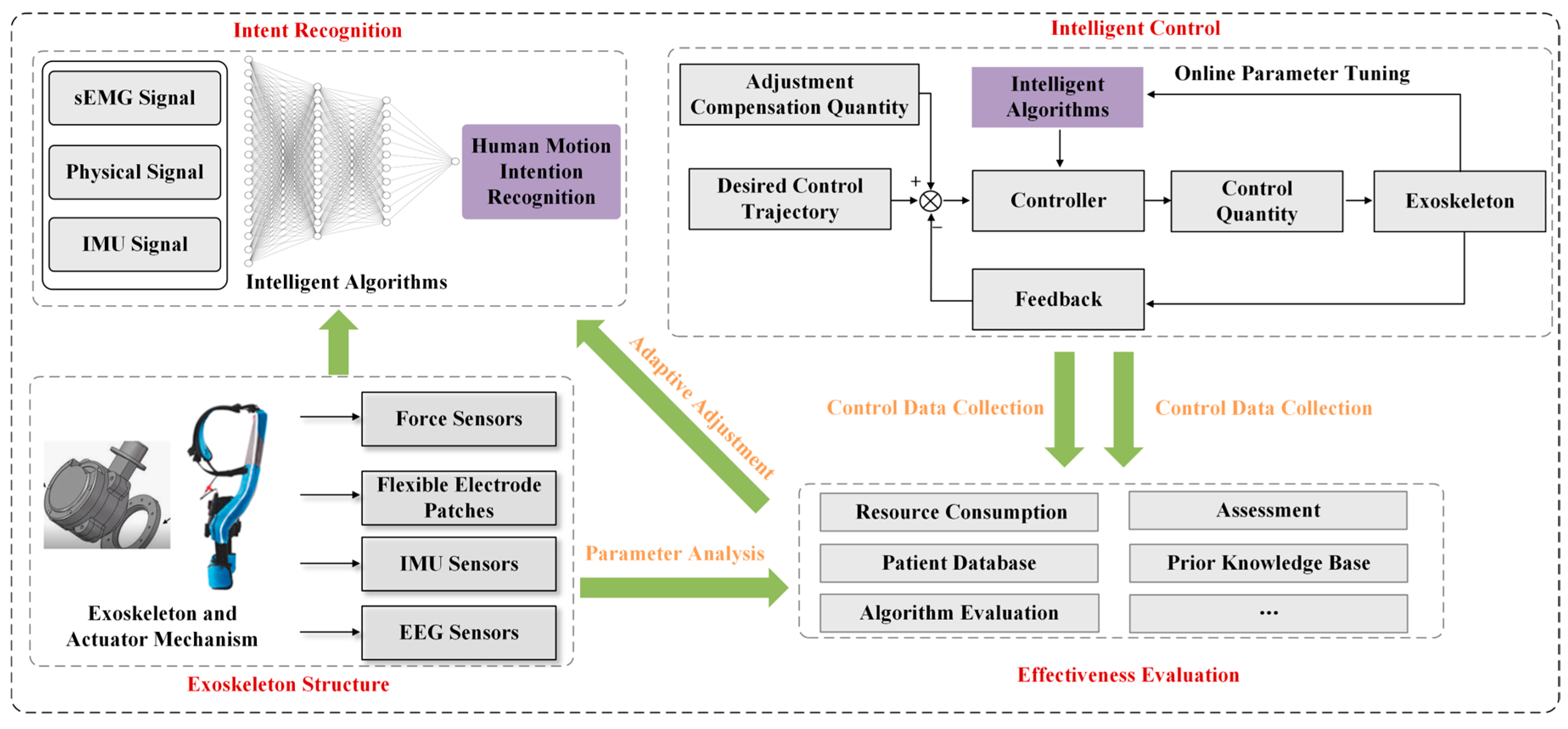

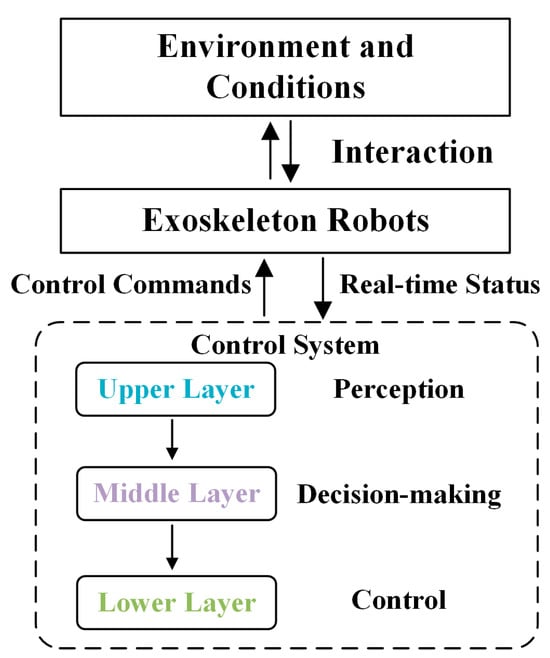

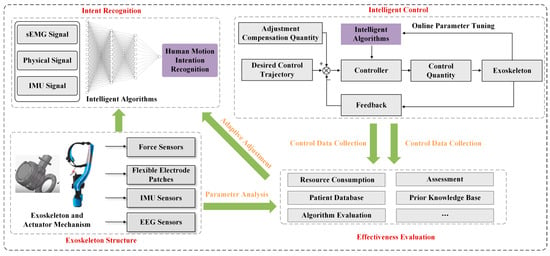

The control system, which is the key to the operation of exoskeleton robots, determines their functions and application effects. The control system can be divided into three levels, namely perception, decision-making, and execution [49]. In 1977, Saridis [50] et al. put forward a hierarchical approach that combined control theory analysis techniques with artificial intelligence heuristic techniques and divided the control system into three levels, comprising the organizational level, the coordination level, and the execution level. For the control of exoskeleton robots, there is also a similar hierarchical structure, as shown in Figure 7. The optimization of control effects and human–robot interaction is inseparable from the collaborative development among various levels of the control system. The focus of this article is to introduce control strategies for the underlying actuators.

Figure 7.

Hierarchical structure of exoskeleton robots.

3.1. Perception System

The perception system includes sensors and data acquisition systems, which monitor and record gait patterns, patient physiological status, and environmental variables during the motion process based on the sensors mounted on the exoskeleton robot. To obtain more accurate operational data, exoskeleton robots are typically equipped with a variety of sensors, including physiological signal sensors and physical signal sensors. The sensor data are not only voluminous but often accompanied by noise, increasing the complexity of information processing. To meet this challenge, the algorithms of the control system must possess efficient capabilities of data perception and preprocessing and transmit them to the next level of the system for intention discrimination.

Physiological signal sensors mainly include EEG (electroencephalography) sensors and EMG (electromyography) sensors; physical signal sensors include accelerometers, gyroscopes, angle sensors, plantar pressure sensors, etc. [51]. In practical applications, a combination of various sensors is often used to improve the accuracy of data analysis.

EEG signals truly reflect human intentions and contain more genuine information, but at the same time, decoding them is more difficult. Currently, electroencephalogram signals include non-invasive EEG, semi-invasive electrocorticogram (ECoG), invasive microelectrodes, etc. The brain–computer interface (BCI) is a device for collecting EEG signals. However, the EEG collection system has problems such as unstable data and low information content, and there are great difficulties in data processing and discrimination. Most of them are still in the laboratory testing stage. EEG-based exoskeleton robots are often used for stroke patients, because their upper limb muscle movement ability is severely impaired and a new way must be found to obtain movement intentions [52,53,54].

Wang et al. [55] designed a six-DOF upper limb rehabilitation robot controlled by EEG. They adopted the wavelet denoising method based on the Gaussian mixture model (GMM) for signal preprocessing. After extracting the feature vectors, they classified and recognized the electroencephalogram features to obtain the patients’ movement intentions, which confirmed the feasibility. However, only laboratory tests were carried out. Tang et al. [56] used EEG signals to decode users’ intentions and convert them into control commands for Bowden cables to operate external devices.

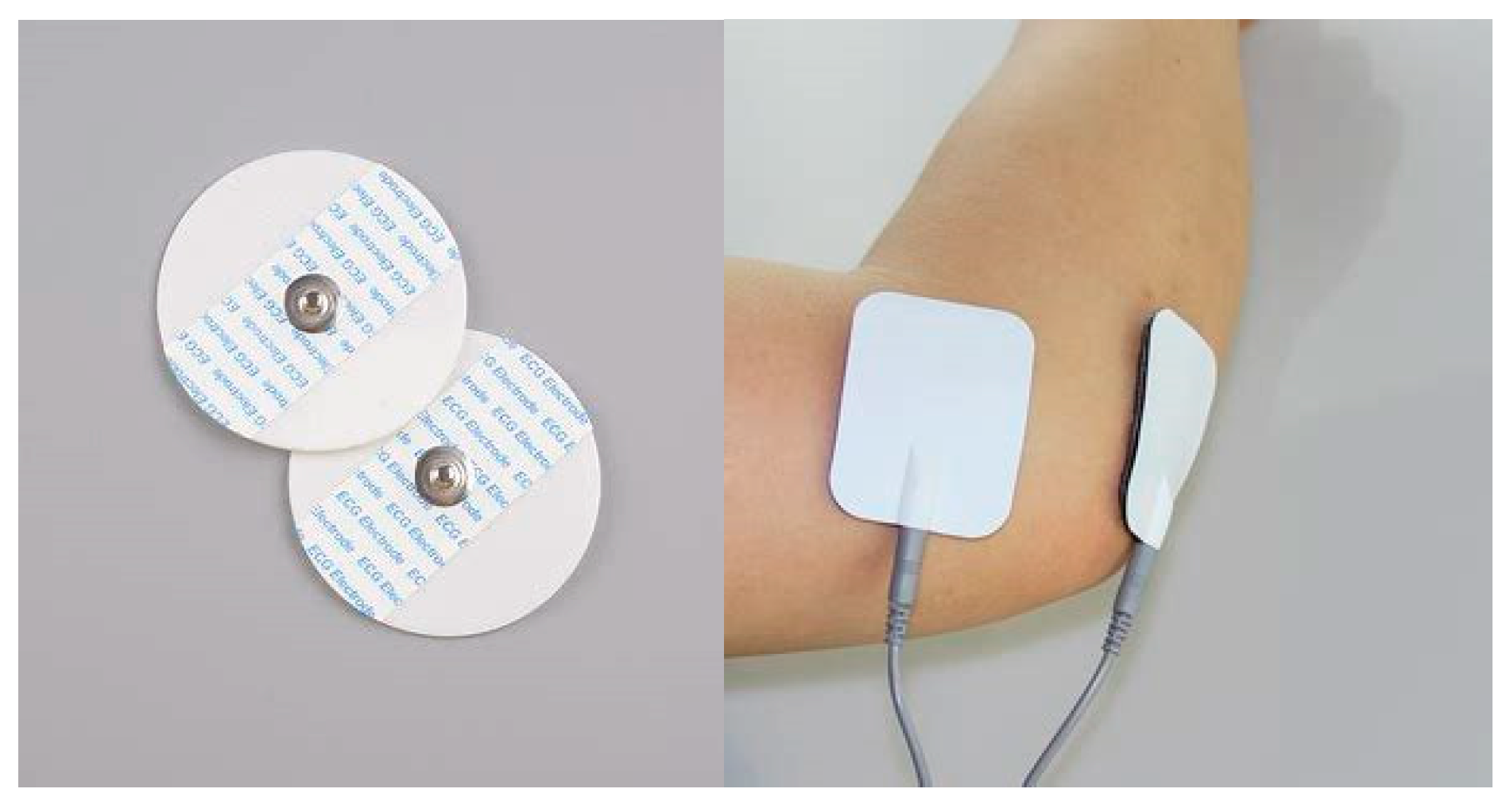

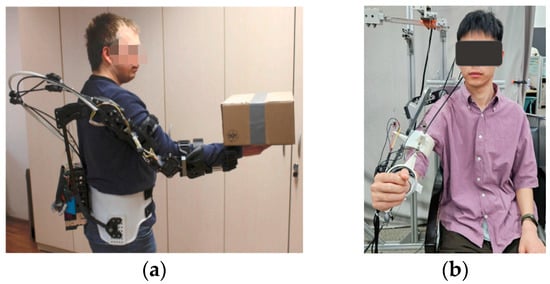

Compared to EEG signals, EMG signals are directly related to limb movement and have a higher signal-to-noise ratio, achieving better results in the current research on movement intention recognition. sEMG signals are captured using flexible electrodes attached to the skin’s surface, as shown in Figure 8. Compared to force sensors, sEMG signal acquisition is more convenient, does not require connection to mechanical structures, and can directly collect activity signals from the target muscle groups, enabling the precise monitoring of specific muscle activities, which occur about 30–150 ms before the movement is produced. However, it also has certain limitations.

Figure 8.

Flexible electrode patches.

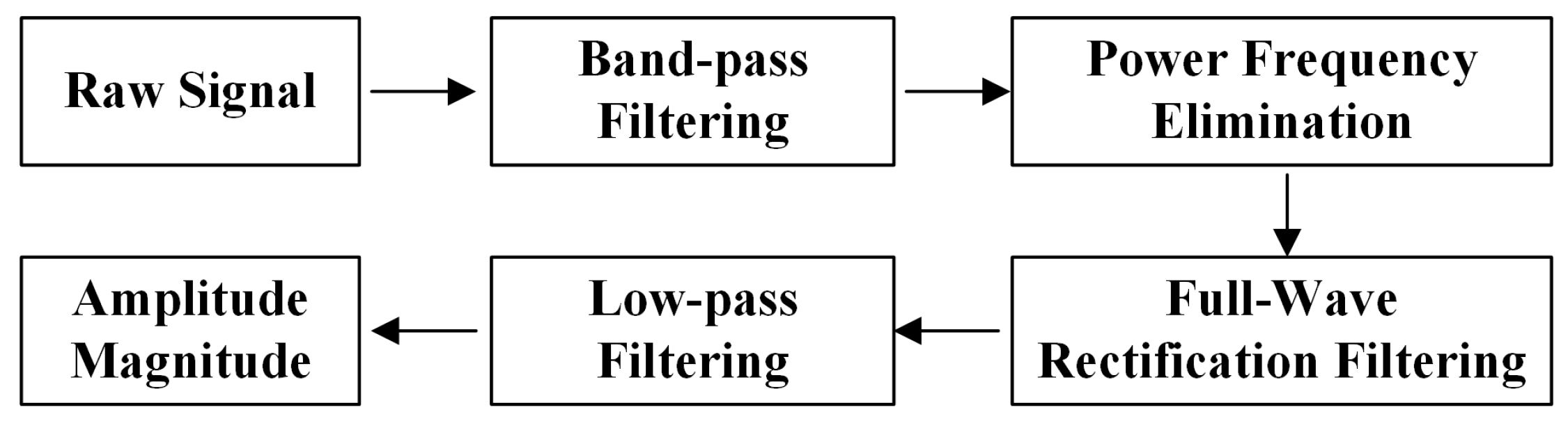

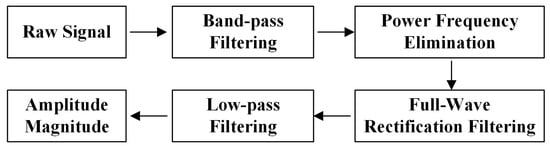

Under normal conditions, the amplitude of sEMG signals is below 10 mV. Due to reasons such as the non-fixed position of attachment or the presence of sweat on the body surface, the collected signals may have issues like high data noise and high randomness. Corresponding filtering algorithms are required to remove irrelevant signals such as electrocardiograms and power frequency interference, and it is impossible to overcome the effects brought about by muscle fatigue [57,58]. The signal processing workflow is shown in Figure 9.

Figure 9.

sEMG signal processing procedure.

Commonly used physical signal sensors include plantar pressure sensors, inertial measurement units (IMUs), encoders, and force/torque sensors, etc. These sensors can provide the decision-making layer with authentic physical signals for data processing and analysis, which are then used for human motion intention recognition and motion state estimation. Their advantage is a high signal-to-noise ratio, while their disadvantage is that the generation of signals lags behind human–robot interaction movements, leading to limitations in real-time performance.

No matter which type or multiple types of sensors are used to collect human body movement signals, the purpose is to predict the movement intentions of the human body through these signals so as to provide a more accurate assistance effect.

3.2. Decision-Making Solutions

Decision-making refers to the real-time analysis of data and the making of accurate judgments, which is the recognition of human movement intentions. This is an important part of the upper limb exoskeleton system. Due to the poor stability and high noise of the signals directly collected, it is common to classify discrete human intentions, estimate continuous human states, and combine these with mechanical sensors and system models for comprehensive analysis before inputting into the controller. This can improve the synchronization between the exoskeleton and the user, truly achieving the purpose of assistance or enhancement [59,60].

Motion intention recognition relies on sensor data from the perception layer. Since the perception layer sensors are divided into physiological signal sensors and mechanical sensors, motion intention recognition is also divided into two categories. Taking EMG signals and mechanical sensors as examples, this section introduces the recognition of human movement intentions based on EMG signals and the recognition of movement intentions based on mechanical sensors.

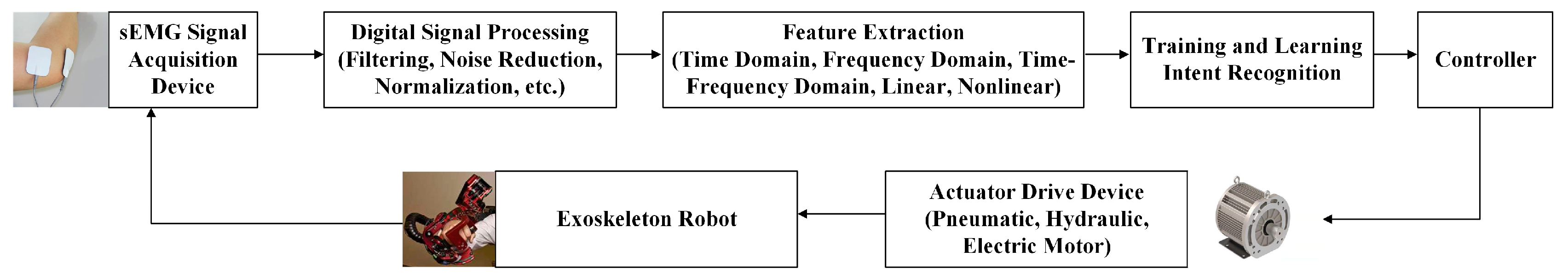

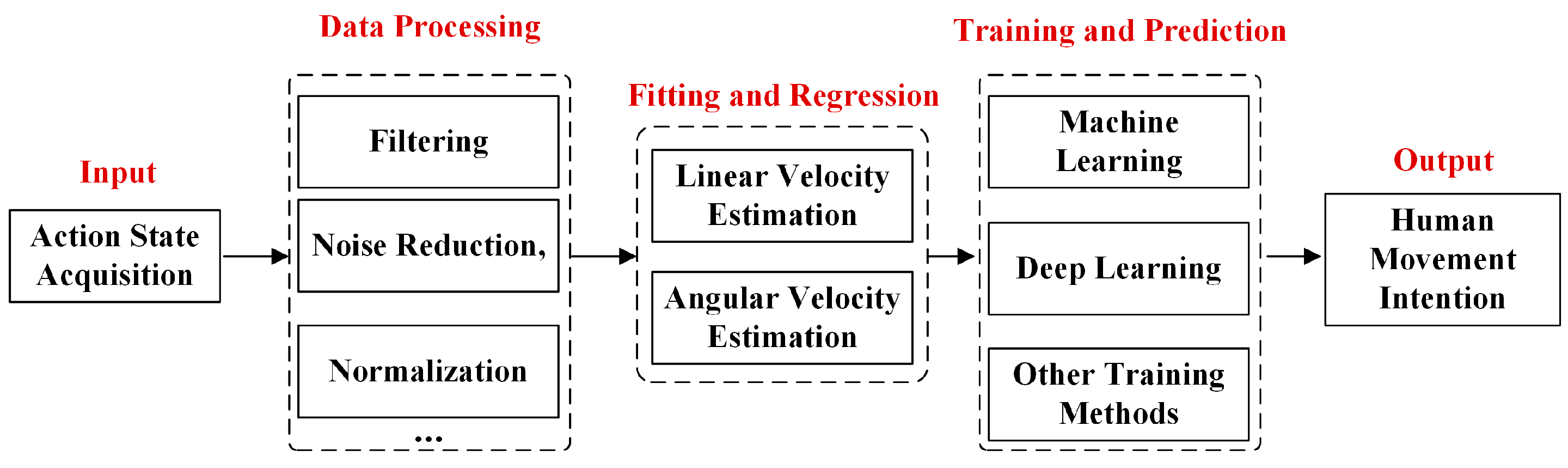

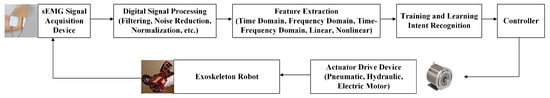

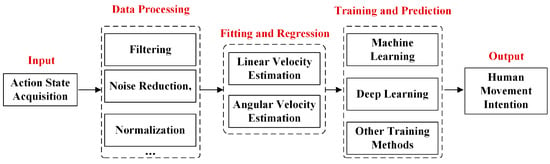

sEMG features include amplitude characteristics, time domain characteristics, frequency domain characteristics, time–frequency domain characteristics, nonlinear characteristics, etc. The process of upper limb movement intention recognition based on sEMG is shown in Figure 10, and the process of movement intention recognition based on IMU sensors is shown in Figure 11. Motion intention recognition first requires data processing, including amplification, normalization, filtering, etc., followed by data feature extraction, classification, prediction, etc., ultimately outputting the human movement intention.

Figure 10.

Upper limb movement intention recognition process based on sEMG.

Figure 11.

Motion intent recognition process based on IMU sensors.

With the development of machine learning, a variety of intelligent algorithms have been applied to the classification and recognition of movement intentions, such as support vector machines [61,62,63,64,65,66], random forests [67,68,69], neural networks [70,71,72,73,74,75], and reinforcement learning [76,77,78,79,80]. Both EMG signal-based and IMU signal-based movement intention recognition has seen rapid development. Among these, neural networks and reinforcement learning algorithms have achieved better classification results. However, the same algorithm applied to different datasets can also result in significant classification differences [81,82]. Researching classification algorithms with stronger universality is also one of the current focuses of technological research.

3.3. Control Systems

In the industrial field, traditional control methods (such as PID control) have been widely applied. However, the control algorithms for exoskeleton robots must not only meet the needs of the actuation devices but also achieve interactive control between the robot and the user, providing efficient assistance. There are significant differences in the kinematic and dynamic models of different users, and the structure is complex. Therefore, during the operation of exoskeleton robots, the choice of control strategy is crucial. The quality of the control strategy directly affects the safety, applicability, and assistance efficiency of the exoskeleton robots. Many factors need to be considered in the design of the control strategy for exoskeletons.

- In terms of safety, the operation of the exoskeleton must ensure the individual safety of the user, and any control decision must be made under the premise of ensuring safety. Since there are many uncertain factors in the human–robot interaction process, and a large amount of noise can be easily introduced during the signal collection process, the exoskeleton robot control system and control strategy must have the ability to properly handle abnormal situations.

- In terms of human–robot coordination, the control strategy of the exoskeleton needs to be consistent with the user’s body structure, movement habits, and movement trends, and the timeliness must meet the requirements of the usage scenario, ensuring that the exoskeleton robot can improve the user’s work efficiency and achieve smooth and compliant human–robot coordination.

Exoskeleton control strategies are generally divided into two types, which are active control and passive control. These two control methods have distinct differences in functionality and application scenarios, as shown in Table 3.

Table 3.

Comparison of active and passive control.

Passive control focuses on positional control and typically allows movement only along a predetermined trajectory. It is suitable for users who have specific target joint motion training needs or those who have difficulty moving naturally. When adjusting the movement trajectory, it is essential to ensure the user’s safety. If the patient attempts to resist or deviate from the predetermined movement path, a passive control system may not be able to adapt, which could lead to poor training outcomes or safety issues. Traditional control schemes are commonly used in such cases.

In active control mode, the exoskeleton robot continuously judges and responds to the user’s movements in real time. This control method requires the exoskeleton robot to have strong capabilities for judging human movement intentions and rapid control response [83,84]. By collecting human body data from sensors installed at different locations and combining it with classification and prediction algorithms to discern movement intentions, the robot can then make correct and appropriately scaled movements to assist or enhance natural human motion. The advantage of this control method is its ability to effectively cooperate with the user to complete tasks and its high level of human–robot coordination, making it suitable for situations that require a high degree of coordination and precise cooperation, such as rehabilitation training and sports assistance. However, it demands a high level of control system performance, including signal processing speed, model accuracy, control output, and actuation methods.

In short, the control method and control strategy need to be determined according to the actual situation. Different perception models determine the differences in control principles. For example, the exoskeleton control based on electromyographic (EMG) signals requires the use of EMG sensors at the sensing end, and the intention recognition method and control scheme based on EMG signals are output to the controller and actuator. After changing to the perception prediction model based on physical sensor signals, the control strategy should also be changed accordingly to match the exoskeleton control system and achieve precise control. The next section provides a categorized description of the control strategies for upper limb exoskeleton robots.

3.4. Kinematic Modeling and Dynamic Modeling

Kinematics describes the geometric relationships between the end effector and the positions of various joints of a robot, including forward kinematics and inverse kinematics. In forward kinematics, given the joint variables of the robot, the position and orientation of the robot’s end effector are calculated. Inverse kinematics, on the other hand, involves calculating all the joint variables corresponding to a known position and orientation of the robot’s end effector. A commonly used modeling method is the Denavit-Hartenberg (D-H) parameter method [85]. The basic principle of the D-H method is to regard each joint as a combination of rotation and translation. Then, by describing these combinations, the position, orientation, and kinematic characteristics of the end effector can be determined. Specifically, each joint is regarded as a coordinate system transformation. By describing the coordinate systems, the overall coordinate system of the robotic exoskeleton can be obtained, thus determining its position, orientation, and kinematic characteristics.

Dynamic modeling is a crucial foundation for implementing real-time control algorithms. Calculating joint driving torques through dynamic methods is of great guiding significance for the research on the stability of robot control systems. Currently, there are several mature methods for robot dynamic modeling, including the Lagrangian method, the Newton–Euler method, the Kane’s method, and the Gauss’s method.

The Lagrangian method is based on the principle of energy conservation. It constructs the Lagrangian energy function through the kinetic and potential energies of the system and takes the derivative of the generalized coordinate variables to establish a mathematical relationship between the generalized external force input and the change in generalized coordinates. This method simplifies the modeling process. However, in a multi-degree-of-freedom system, due to a large number of integration and differentiation operations, the computational burden is relatively large [86].

The Newton–Euler method combines Newtonian mechanics and Eulerian mechanics. By describing the relationships between the external force, mass, and centroid acceleration of a rigid body, as well as the external torque, angular acceleration, angular velocity, and inertia tensor, it establishes dynamic equations. However, as the number of rigid bodies increases, the number of equations also increases significantly, and the constraint forces need to be eliminated, resulting in relatively high computational complexity. In particular, when applied to complex multi-body systems, the derivation process is rather cumbersome [87].

Kane’s equations are based on analytical mechanics. Using generalized velocity as the independent variable and introducing the concepts of partial velocity, partial angular velocity, generalized active force, and generalized inertial force, it establishes dynamic equations in algebraic form. This method is suitable for complex systems with multiple degrees of freedom, which can reduce the number of calculation steps and improve computational efficiency [88].

Since exoskeleton robots with different joints and degrees of freedom have different dynamic models, this paper focuses on discussing the control strategies of the end effector controller. Therefore, this section takes a single joint as an example to introduce its Lagrangian dynamic modeling. The Lagrangian equation is as follows:

Here, represents the joint angle and represents the joint torque. K and P are the kinetic energy and potential energy of the elbow joint system, respectively, and L = K − P is the Lagrangian function. Subsequently, the dynamic parameters will be derived in combination with the mechanical structure design of the joint part, and the system characteristics will be analyzed.

4. Research on Control Strategy Technology for Upper Exoskeleton Robots

4.1. Impedance Control Method

When an exoskeleton is used to assist users with motion recovery, the user’s own movement intentions may not be apparent, making it difficult for the perception layer of the exoskeleton robot control system to capture signal changes. This requires the exoskeleton robot to guide the user through joint movements, gradually improving the user’s motor performance, and impedance control is commonly used for this purpose.

Impedance control refers to a real-time dynamic control of both force and position [89]. In 1985, Hogan proposed adjusting the parameters of the end effector to achieve the desired state of force and position, that is, controlling the exoskeleton robot by varying the output impedance. Additionally, when the force feedback signal is translated into a position adjustment, this type of force control is known as stiffness control. When the force feedback signal is converted into a velocity correction, this type of force control is called damping control. This method does not rely on prior motion constraint knowledge required for pre-modeling.

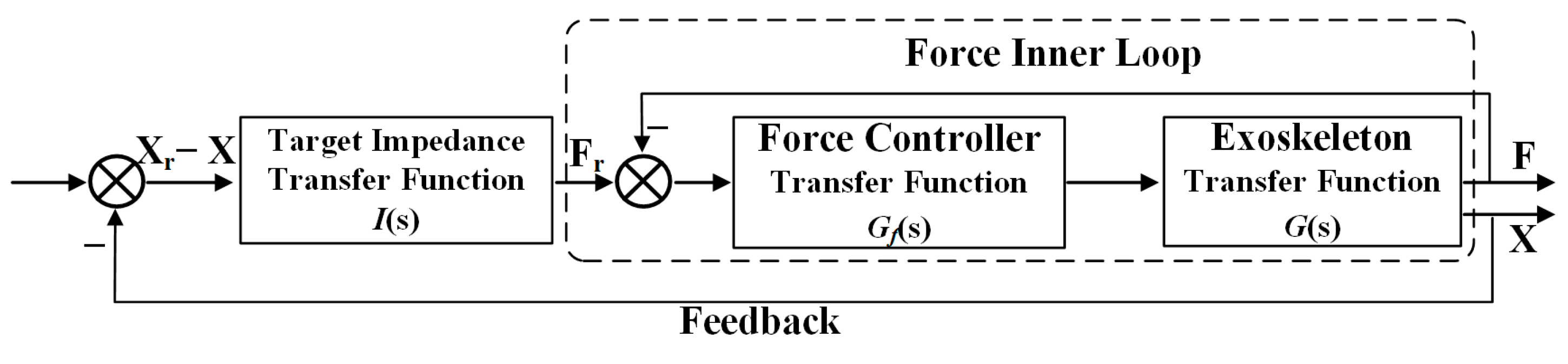

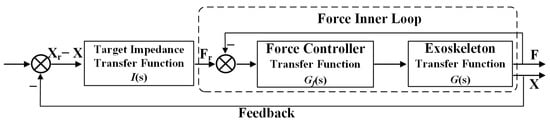

There are two ways to implement impedance control. One is the force-based impedance control method, and the other is the position-based impedance control method. The force-based impedance control method consists of an inner loop force controller and an outer loop impedance operator, as shown in Figure 12. Here, X and Xr represent the actual and desired positions, respectively, F and Fr represent the actual and desired forces, respectively, I(s) is the target impedance transfer function, Gf(s) is the force controller transfer function, and G(s) is the robot’s transfer function. The position feeds the robot’s dynamics model as a feedforward input, calculating the force magnitude based on the target motion state, actual motion state, and target impedance parameters and using the inner loop controller to output to the actuator to achieve the desired dynamic characteristics. However, the control effect is closely related to the robot’s dynamics model, and errors in model parameters can lead to significant deviations during operation.

Figure 12.

Schematic diagram of force-based impedance control.

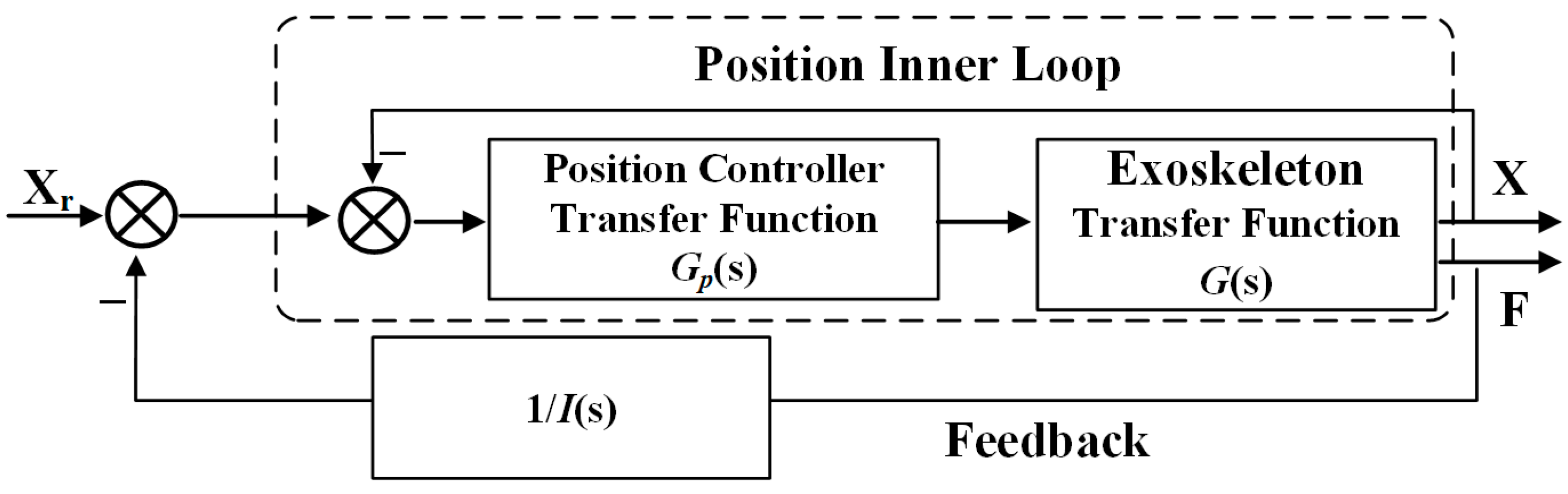

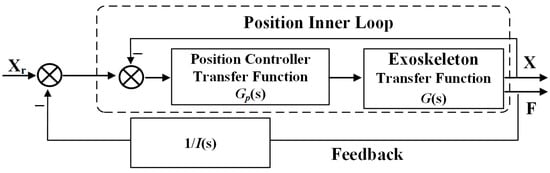

Position-based impedance control is similar to the aforementioned control method, as shown in Figure 13, where Gp(s) is the position controller transfer function. It also uses a dual-loop control structure, with the inner loop being the position control. Based on the output from the outer loop calculations, it controls the position by acting on the actuator, ultimately achieving the desired dynamic characteristics of the exoskeleton robot. Position control theory is well established, and commercial position controllers offer high precision and robustness.

Figure 13.

Schematic diagram of position-based impedance control.

Abane et al. [90] implemented the torque control of a five-DOF exoskeleton using the fuzzy PID algorithm. They adopted a model-free controller, which made it unnecessary to consider the adverse effects of noise and environmental factors, thereby achieving stable and safe control. However, traditional impedance control can only be applied to a certain set environment or scenario, making the user passively follow the movement. Li et al. [91] proposed an iterative learning impedance controller for a rehabilitation robot driven by series elastic actuators (SEAs), aiming for a desired impedance model. Through iterative optimization to gradually approach the desired impedance model, the position error and impedance error can converge to zero. The Lyapunov method is used to prove the stability of the control system, and this control strategy has good transient characteristics.

Human body movements are highly complex, making it difficult to achieve single or limited impedance control. In 2023, Liao et al. [92] proposed a control algorithm for upper limb rehabilitation exoskeleton robots with regional variable impedance. By dividing regions and setting different impedance coefficients, variable impedance control in different regions was realized. The simulation results showed that the exoskeleton could move freely in the low-impedance region, while the impedance force was larger in the high-impedance region, effectively meeting the different needs of users and achieving personalized assistance. With the development of artificial intelligence and machine learning, combining neural network algorithms with impedance control can improve the experience of human–computer interaction on the premise of improving control accuracy [93].

Although impedance control can achieve the adjustment of control effects, such adjustments, these are made offline and still require prior manual settings, making it difficult to achieve precise human–robot interaction. However, from the perspective of safety, as long as the set trajectory matches the laws of human kinematics, the safety of users can be ensured to a great extent, which is also one of the advantages that make impedance control widely used in exoskeleton products.

4.2. Adaptive Control Method

The core objective of the control strategy is to achieve effective control of both force and position. Impedance control has laid the foundation for the development of robotic control technology, but it still has some limitations in terms of application scope and control effectiveness.

- Complexity of multiple degrees of freedom: Exoskeleton robots typically have multiple degrees of freedom, which increases the complexity of control, making it difficult for traditional control strategies to cope comprehensively.

- Pose uncertainty: There may be uncertainty in the pose of the robot during actual operations, which requires control strategies to have higher adaptability and robustness.

- Strong coupling of force and position: Force and position are often highly coupled in robotic control, and traditional control strategies may struggle to effectively decouple these two variables, thereby affecting control accuracy.

- Ambiguity of the external environment: The uncertainty and ambiguity of the external environment pose higher demands on robotic control, and traditional control strategies may find it difficult to adapt to such changes.

The core problem corresponding to the above limitations is that impedance control cannot be automatically adjusted and cannot adapt to the current motion state. In response to this, Sun et al. [94] applied a self-learning strategy and proposed an adaptive control strategy based on impedance control. They used a command filter to reduce computational complexity and estimated environmental impedance and uncertainties in robot parameters through adaptive learning. However, the control design still depends on the robot dynamics model. Peng et al. [95] aimed at the time-varying environmental interaction model and automatically adjusted the parameters of the impedance controller with the combination of human–robot interaction force and robot motion control as the cost function. However, the selection of parameters has a significant impact on the control performance, which requires further research and optimization. Omrani et al. [96] proposed a model reference adaptive impedance controller based on time delay estimation for nonlinear time delay estimation, which was used to estimate unknown system dynamics and uncertainties and adaptively correct the controller gain. Nevertheless, in practical applications, the uncertainty of the model may still affect the control effect.

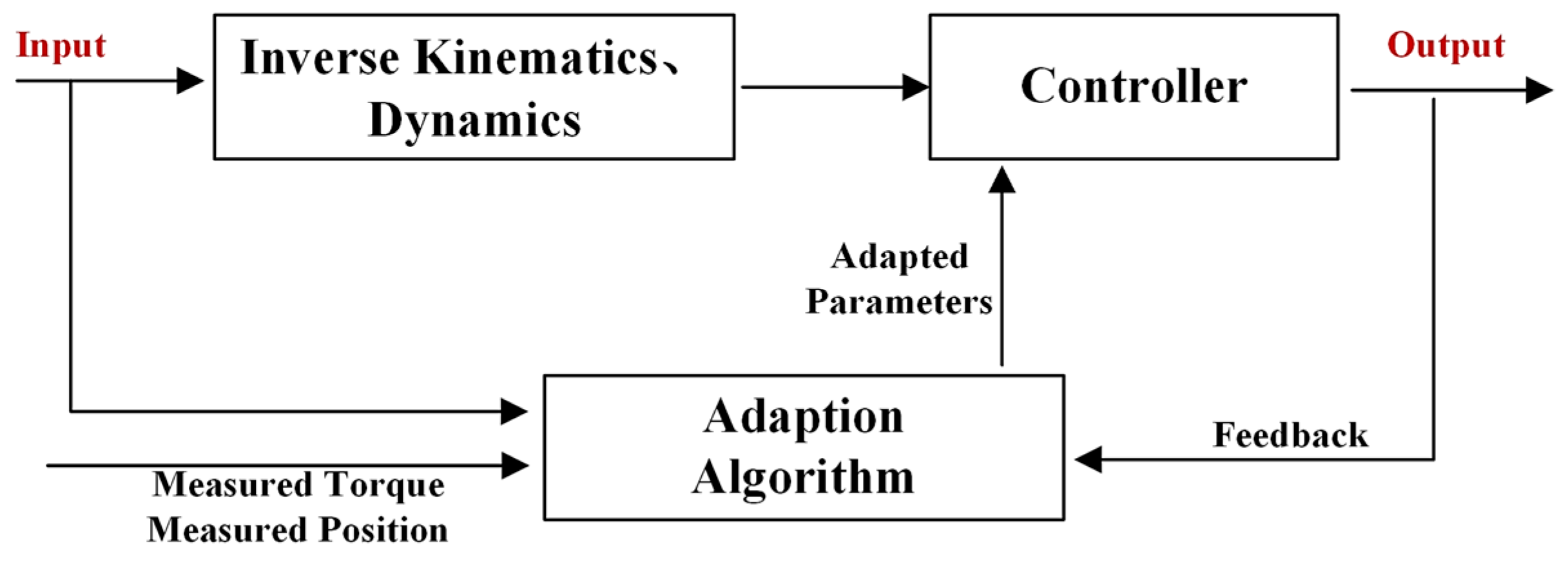

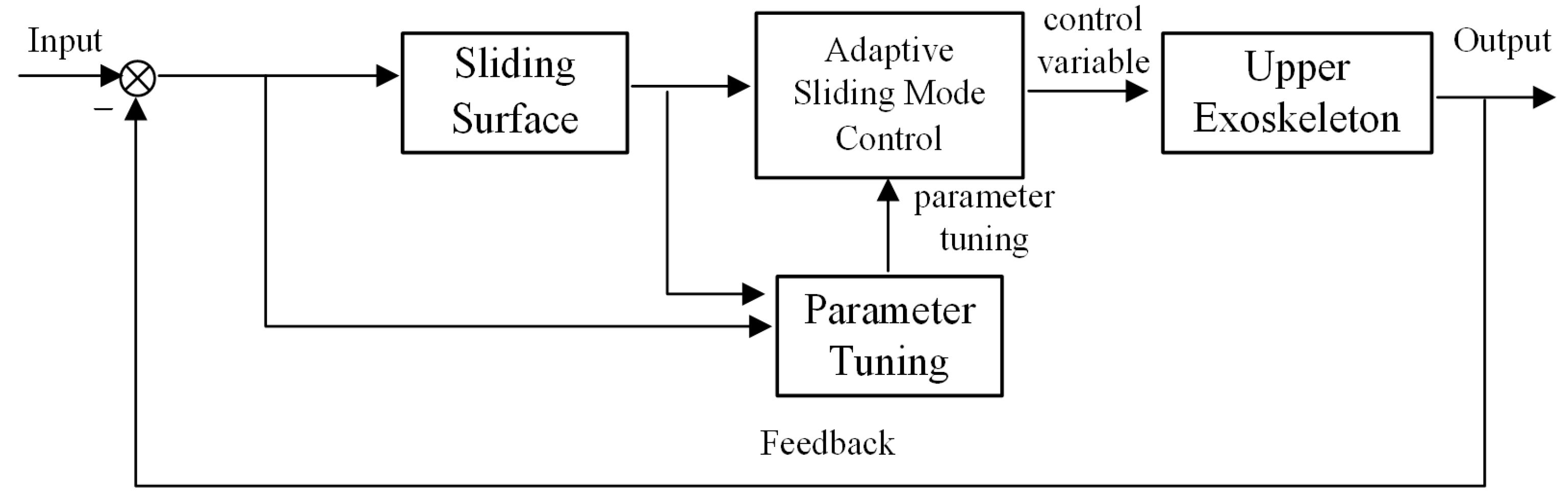

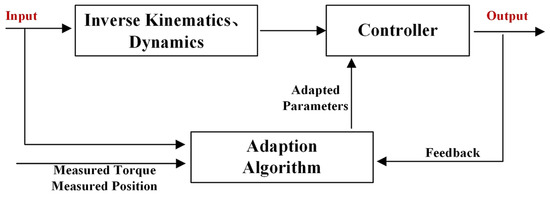

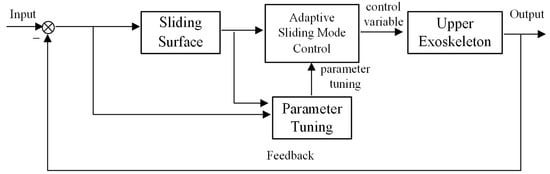

With the development of adaptive algorithms, an increasing number of scholars have applied adaptive control algorithms to the control process of upper limb exoskeleton robots, automatically adjusting the controller output to achieve compliant and precise control. The structure diagram of an adaptive control system is shown in Figure 14. Adaptive algorithms are also commonly used in other control schemes, such as PID or sliding mode control (SMC). Fuzzy control is often combined with adaptive control and is used for systems that are difficult to define with mathematical models.

Figure 14.

Adaptive control system structure.

Adaptive control continuously evaluates the current state during execution and constantly adjusts system parameters. After verifying the system’s stability with a Lyapunov-like function, the model possesses advantages such as dynamic environmental adaptability, model correction, disturbance and noise suppression, and fault detection.

Mushage et al. [97] proposed an adaptive nonlinear control scheme using a new sliding mode control strategy based on the reaching law. This includes a high-gain state observer for the system dynamics and a fuzzy neural network for the estimation of nonlinear state vectors. They applied this scheme to a five-DOF upper limb exoskeleton robot model. The scheme has a faster response, fewer oscillations during the transition phase, good tracking accuracy, and control torque that is free of jitter and has a lower amplitude. To some extent, it solves problems in robot control such as uncertain nonlinear dynamics, unavailable full-state measurements, the occurrence of disturbance torques, and different types of drive faults.

Wang et al. [98], aiming to overcome the uncertainty of human and robotic limb parameters, designed an adaptive controller. The tracking error between the actual trajectory and the desired trajectory was within the ±1° range, demonstrating the effectiveness of the controller. Nunes et al. [99] developed an adaptive controller based on motion primitives. By analyzing the movement data of healthy individuals to extract motion primitives, these primitives were used to guide the exoskeleton robot in assisting post-stroke patients with gait recovery training. The control system calculates the torque generated during the patient’s actual movement and compares it with the movement patterns of healthy individuals, automatically adjusting the assistance provided by the exoskeleton to supplement the patient’s movement deficiencies, achieving customized rehabilitation support.

Similarly, Zhu et al. [100] proposed a nonlinear iterative learning control method for a five-DOF upper limb exoskeleton robot, which, combined with the dynamic model, achieved asymptotic stability tracking under periodic reference input, suitable for exoskeleton robots performing repetitive tasks.

At the same time, during the use of exoskeletons, sudden jitters or abnormal movements are inevitable, which requires the exoskeleton control system to not only have adaptive capabilities for the model but also to have the robustness to handle such situations, ensuring the stability and safety of the equipment [101]. In robustness research, SMC is one of the effective means to deal with bounded disturbances and uncertainties [102]. When the instantaneous output has a large error from the target value, the sliding mode controller can smooth the data or use an over-damped control approach to converge the output to the desired value, achieving stable control. The process of SMC is shown in Figure 15.

Figure 15.

The process of SMC.

SMC is essentially a nonlinear control strategy. The control input is not directly proportional to the response system state but is designed based on the position of the “sliding surface”. Sliding mode control is usually combined with adaptive control to enhance the overall performance of the control system. For different driving components, the SMC has a relatively good application effect.

For exoskeleton robots driven by electric motors, the inherent nonlinearity and uncertainties of linear motors, as well as the modeling errors of exoskeletons, are the main factors affecting their control accuracy. Regarding the high-precision trajectory tracking problem of rigid robot systems driven by servo motors, in 2019, Ba et al. [103] proposed a direct robust non-singular terminal sliding mode controller based on adaptive time delay estimation. By automatically adjusting the input gain through a self-learning mechanism, with the optimization goal of minimizing time delay estimation error, the terminal sliding mode control scheme quickly and accurately drives the control error to zero. Similarly, Li et al. [104] proposed a control method called a saturated sliding mode control scheme to deal with the precision control issue of motor-driven exoskeleton robots. Structurally, four motors drive piston push rods to provide assistance. Due to the inherent torque limitations of the motors, the control output should also be restricted. Thus, a saturated sliding mode controller was designed to drive the push rods, achieving more accurate control.

For the wrist part where the joint differences are even greater, the motor drive is required to have appropriate torque and speed and comply with the range of human body movements. Garcia-Leal et al. [105] designed a three-DOF wrist exoskeleton robot named “Biomech-Wrist”. By using first-order sliding mode control, high-precision trajectory tracking was realized, with the maximum RMSE being only 0.556 rad.

The sliding mode control is also applicable to the upper limb rehabilitation exoskeletons driven by pneumatic muscle actuators (PMAs). Liu et al. [106] proposed a nonsingular fast terminal sliding mode control method based on a nonlinear disturbance observer in view of the kinetic model errors and load disturbances at the joints. This method can not only achieve high-precision motion control of the joints but also provide reconfigurable assistance for patients. Due to the hysteresis, time-varying characteristics of PMAs, and the nonlinear motion between joint flexion and extension, it is difficult to accurately identify the model parameters, resulting in unmeasurable uncertainties and disturbances in the upper limb exoskeleton robots. Chu et al. [107] proposed an improved agent-based sliding mode controller. This control method can slow down the underdamped dynamic recovery motion to approach the target trajectory without overshooting due to large tracking errors that cause actuator saturation, greatly enhancing the stability of the controller in emergency situations.

For the high-precision trajectory tracking control of cable-driven exoskeleton robots, Wang et al. [108] proposed an “adaptive super-twisting nonsingular fast terminal sliding mode controller” based on time delay estimation. This scheme combines time delay estimation, the super-twisting algorithm, and the nonsingular fast terminal sliding mode. It is model-independent, ensuring rapid convergence, high accuracy, and strong robustness. Experiments have been carried out on a two-DOF exoskeleton robot for verification.

Applying sliding mode control to exoskeleton control has the advantages of high accuracy, strong robustness, and rapid response, which can significantly enhance the control performance and stability of exoskeleton robots in complex or changing environments. Since the core idea of sliding mode control is to establish a “sliding surface”, pulling the controlled system onto the “sliding surface” and making the system move along the “sliding surface”, in traditional sliding mode control, the control quantity only appears in the first-order derivative of the constraint equation, and high-frequency oscillations can easily occur. This has led to the extension of first-order sliding mode control, namely higher-order and fractional-order sliding mode control [109].

Yi et al. [110] proposed an adaptive non-oscillatory sliding mode controller for the trajectory tracking of robotic arms. They designed an adaptive second-order fast nonsingular terminal sliding mode controller that integrates the benefits of linear sliding mode control and terminal sliding mode control. This controller ensures system performance and robust stability while achieving rapid convergence and ideal tracking accuracy. It also incorporates adaptive techniques to compensate for uncertainties.

Fellag et al. [111] proposed a uniform continuous sliding mode control scheme based on finite-time stability for upper limb exoskeleton robots used in rehabilitation. This strategy, based on the homogeneity principle and the super-spiral algorithm, designed a continuous high-order sliding mode controller. It was tested on a five-DOF upper limb exoskeleton robot model, and the results showed superior tracking performance compared to traditional sliding mode controllers. It also achieved robust motion control in the face of parameter variations, uncertainties, and external disturbances.

Islam et al. [112] proposed a fractional-order sliding mode control (FSMC) algorithm to control a seven-DOF exoskeleton robot. They demonstrated the effectiveness of FSMC in handling unmodeled dynamics and resisting interference through simulation experiments. Compared to traditional SMC, FSMC performed better in tracking performance and reducing chatter phenomena.

With the progress of artificial intelligence technology, intelligent sliding mode control has emerged accordingly. Combining algorithms such as neural networks and adaptive learning, it can compensate for the external disturbances existing in the upper limb exoskeleton robot system and improve the performance of sliding mode control. Rahmani et al. [113] proposed a novel “adaptive neural network fast fractional-order terminal sliding mode control” strategy for the trajectory tracking control of a seven-DOF exoskeleton robot “ETS-MARSE”. By combining fast fractional-order integral terminal sliding mode control with adaptive radial basis function neural networks, it achieved precise tracking of the robot’s dynamics and reduced chatter phenomena. Wu et al. [114] combined the “radial basis function network” with the “neuro-fuzzy adaptive controller”, which not only ensured the tracking accuracy under the condition of parameter uncertainty but also obtained better frequency response characteristics. However, in order to achieve a faster response speed, usually the system will generate a relatively large overshoot, which is dangerous in the application for patients. Therefore, Brahmi et al. [115] proposed a new “integral nonsingular terminal sliding mode control” method, which reduced the chattering problem and enhanced the compliance of the control. Meanwhile, the radial basis function neural network was utilized to update the weights in real time to accurately predict the patients’ movement intentions without the need for pre-training.

Although adaptive control has made some progress in the precise control of the upper limb exoskeleton, adaptive control strategies require the real-time monitoring and processing of a large amount of sensor data, which poses challenges for the real-time accuracy of the system. There are differences in the body structure and rehabilitation needs of different users, and how to design adaptive control strategies that can adapt to individual differences is also an important issue.

4.3. Intelligent Control Method

The aforementioned control methods all require the construction of complex mathematical models. However, exoskeleton robots are inherently nonlinear and strongly coupled systems, and there are many uncertainties during their operation, which further increases the difficulty of modeling.

Jingxun Fu first proposed the concept of intelligent control in the scientific literature in 1971 [116] and gave a clear definition. He believed that the organic combination of artificial intelligence and control engineering would inevitably lead to the natural extension and development from learning control to intelligent control. The overall architecture of the intelligent control system is shown in Figure 16.

Figure 16.

The overall architecture of intelligent control systems.

Intelligent control systems are suitable for more complex systems and scenarios that require adaptability and self-learning capabilities. The architecture of intelligent control systems is hierarchical, consisting of organizational, coordination, and execution levels from top to bottom. The organizational level makes decisions and plans tasks based on existing knowledge; the coordination level receives instructions from the organizational level and coordinates the actions of the execution level; the execution level is responsible for the implementation of specific control tasks.

The intelligent control algorithms for exoskeleton robots mainly include machine learning, neural network control, deep learning, reinforcement learning, assist as needed, etc. These are all subsets of artificial intelligence. For example, machine learning can learn from data and make decisions about the future based on the data. Deep learning can handle more complex tasks, enabling the model to gain a deeper understanding of the data. Essentially, these intelligent algorithms are human-set and goal-oriented. They train on data according to a certain reward function, learn from the data, predict unknown future conditions, better adapt to dynamic environments and unknown robot models, and then seek corresponding control strategies. This helps improve the effectiveness of robot-assisted rehabilitation.

4.3.1. Intelligent Control of Neural Networks

Neural networks can fully approximate any complex nonlinear relationships and are capable of learning and experiencing the dynamic characteristics of systems with severe uncertainties. They can also estimate the dynamic models with uncertain factors. Combining neural networks with sliding mode control and adaptive control is a typical intelligent control strategy. Generally, in order to effectively handle unknown external disturbances, an observer needs to be introduced into the control design procedure to provide estimates of the unknown perturbations. However, traditional model-based feedback estimation requires a large amount of prior knowledge [117]. To solve this problem, He et al. [118] developed a disturbance observer designed based on the structure of neural networks. By using adaptive neural networks to approximate the unknown neural networks, it can approximate the unknown external disturbances online to eliminate the impact of the unknown external disturbances.

Zhang et al. [70] proposed a sliding mode control method compensated by the recurrent wavelet neural network (RWNN). The RWNN was utilized to approximate the uncertain factors in the system, such as parameter errors and external disturbances. The stability of the closed-loop control system was verified through the Lyapunov stability principle. The results showed that the errors of the sliding mode control compensated for by the recurrent wavelet neural network and the PID control were 9.22° and 5.51°, respectively. The dynamic performance and robustness of the control system were both superior to those of the PID control. However, the absolute error angle was still not satisfactory, and it was difficult to achieve practical application effects on rehabilitation exoskeleton robots.

To obtain a better tracking effect and enable the exoskeleton to truly understand human intentions and provide assistance, Liu et al. [119] used the radial basis function (RBF) neural network to estimate the dynamic model and designed an adaptive sliding mode control based on the estimated values. Even in the case of an uncertain dynamic model, the proposed control strategy could achieve excellent control effects. The error between the actual joint angle and the desired joint angle is less than 0.01 after convergence, and the root mean square errors of joint control were reduced to 0.069 and 0.093, respectively.

In addition, combining neural networks with feedforward control can significantly improve the response time of the control system on the premise of reducing tracking errors. Yuan et al. [120] proposed an integral sliding mode control and feedforward control that combines PID and RBFNN to achieve adaptive trajectory tracking. The integral sliding mode control can improve tracking performance and reduce chattering phenomena. The feedforward controller uses an inverse dynamic model to reduce the response time.

Dan et al. [121] proposed an adaptive control strategy based on the adaptive radial basis function network (ARBFN) and feedforward control for exoskeleton robot tracking control. The controller predicts and compensates for uncertain parameters in the dynamic model, and the feedforward controller quickly compensates for input torque, effectively improving the system’s tracking accuracy and performance for gait trajectories.

In the field of exoskeleton control, the traditional computed torque control (CTC) is a common method. Due to its global asymptotic stability, it is an effective method for exoskeleton motion control. However, it has certain limitations under conditions where the model parameters are unknown, it is difficult to obtain the model of the human–exoskeleton coupling system, and the external disturbances are complex. Therefore, Narayan et al. [122] proposed an adaptive RBF neural network computed torque control scheme, an RBFNN-compensated CTC, where the adaptation of network weights depends on the Gaussian function and Lyapunov equation. An experimental study was conducted on a 12-year-old child subject, and the tracking effect was 40% higher than that of traditional CTC. This also brings new inspiration to the torque control of upper limb exoskeleton robots. Compared with traditional time delay estimation (TDE), the extended state observer (ESO), nonlinear disturbance observer (NDO), etc., CTC can better achieve the specified transient response on the premise of ensuring accuracy and provide better torque control and human–robot interaction effects.

The above-mentioned neural network methods are mainly used to compensate for the errors of the exoskeleton model and continuously approximate the nonlinear characteristics of the system. Taking advantage of the predictive ability of neural networks, Souza et al. [123] proposed a neural network method directly based on long short-term memory (LSTM). By using simulation data to predict the torque output of joint motors, better results were obtained compared with CTC. The exoskeleton torque command can be predicted within a range of 100 milliseconds, with a relative error of less than 5%. However, this method is only data-driven and directly predicts the torque without considering the quality of the exoskeleton model and the interaction between humans and the exoskeleton.

Neural networks can approximate internal disturbances in nonlinear systems, but they struggle to approximate external disturbances, especially those of the mismatched type, and complex controller schemes are unable to suppress them. Therefore, Yang et al. [124] proposed a novel high-performance multilayer neural controller that can simultaneously suppress matched and unmatched disturbances, compensate for disturbances in advance, and has a simple control scheme. This provides a new solution for the suppression of external disturbances. Subsequently, he proposed a new state-filtered disturbance rejection control architecture for the problem of matched and unmatched disturbances [125], introducing a set of state filters for feedforward compensation, using command filters to avoid the adverse effects of “explosion of complexity” and employing an auxiliary system to reduce the errors of all filters.

4.3.2. Intelligent Control of Assist as Needed

During the application of neural networks, there is no theoretical basis for the selection of membership functions and the proportion of each layer. It is often chosen based on the experience of the designers. With the continuous improvement of patients’ rehabilitation levels, patients’ muscles are already able to provide a certain amount of strength on their own to support daily movements. The exoskeleton only needs to offer assistance, that is, assist as needed (AAN), which maximally imitates the role of human therapists in rehabilitation exercises and can adaptively provide assistance intensity according to different stages of patients’ rehabilitation.

Luo [126] proposed a greedy neural network control-based upper limb rehabilitation training program, which improves the patient’s participation in rehabilitation training. This control mode includes a baseline controller and a Gaussian radial basis function network, continuously updating network weights, learning the maximum strength provided by the subject over time, and enhancing the autonomy of rehabilitation. Castiblanco et al. [127] developed a new closed-loop architecture that continuously monitors muscle activity through EMG signals and dynamically adjusts the assistive force of the exoskeleton. The system analyzes the EMG signals of four stroke patients based on the ANN model. According to the measurements of contraction strength, co-activation, and muscle activation, the muscle states are divided into three levels, namely low activity (ANN output 0–0.4, requiring high-level assistance), transitional state (0.4–0.8, with dynamically adjusted assistance), and high activity (0.8–1.0, with minimal assistance). A fuzzy-logic controller adjusts the exoskeleton speed according to the real-time state, increasing the assistive force during low activity and reducing it during high activity to encourage independent movement. Experiments show that the system can smoothly switch the intensity of assistance, with a maximum speed change of 0.7 mm/s and a tracking error of <5%, effectively balancing the need for assistance and movement autonomy. Yin et al. [128] implemented an AAN control based on sliding mode adaptation. On the basis of tracking the ideal target rehabilitation trajectory, a forgetting factor term λ was introduced. By dynamically attenuating the weight of historical errors, the system preferentially utilized the recent trajectory-tracking deviation to estimate the patient’s movement ability. Based on this estimation, the required torque was calculated. When the patient’s active force increased, λ reduced the weight of historical data, enabling the system to adapt to the new state more quickly and achieve on-demand assistance. Experiments were conducted on a single-joint lower limb exoskeleton prototype. Moreover, the idea of introducing a forgetting factor could also be applied to single-joint exoskeleton robots, which could potentially support multi-degree-of-freedom cooperative movement of the upper limb.

The above control methods can automatically adjust the assistance effect. However, with the deepening of research, how to activate patients’ individual motor abilities to the greatest extent and provide the minimum assistance effect rather than providing assistance as needed has become a research hotspot. This plays an important role in improving patients’ muscle motor performance. Pehlivan et al. [129] proposed a minimum assist-as-needed (mAAN) control scheme. The controller uses sensorless force estimation technology, Kalman filtering, and Lyapunov stability analysis to dynamically assess the user’s input ability during the rehabilitation process and calculate the corresponding auxiliary torque. At the same time, by adjusting the ultimate limit of position error, necessary help is provided to ensure that users can receive effective assistance while maintaining a high degree of participation and initiative in upper limb rehabilitation training.

In June 2024, Zarrin et al. [130] proposed the first minimal intervention controller. According to the patient’s motor abilities and movement intentions, it dynamically adjusts the parameters of the virtual model in wrist interaction to achieve minimal intervention control, which is essentially passive impedance control. During the process of leading patients to achieve a fixed trajectory, it continuously adjusts the interaction force to more accurately determine when assistance is needed, thereby enhancing patients’ participation.

Although the AAN strategy has improved patient participation in the short term, further research is still needed on its long-term rehabilitation effects and impact on patients’ functional recovery. Most of the research on AAN has not considered the safety issues caused by errors. For example, when there are large errors in intention recognition, it is prone to incorrect assistance effects, especially when the electromyographic signal test is subject to significant interference. Therefore, the safety mode is an important part of the AAN scheme. It will stop the movement when the deviation between the interaction force and the empirical value is too large, thus improving the safety of the exoskeleton assistance [131]. Dong et al. [132] proposed an AAN controller with adaptive gain. Through the dynamic gain adjustment mechanism, the system can adjust the control force in real time and has a safety protection scheme, effectively avoiding the overshoot and oscillation problems of high-gain adaptation.

4.3.3. Intelligent Control of Reinforcement Learning

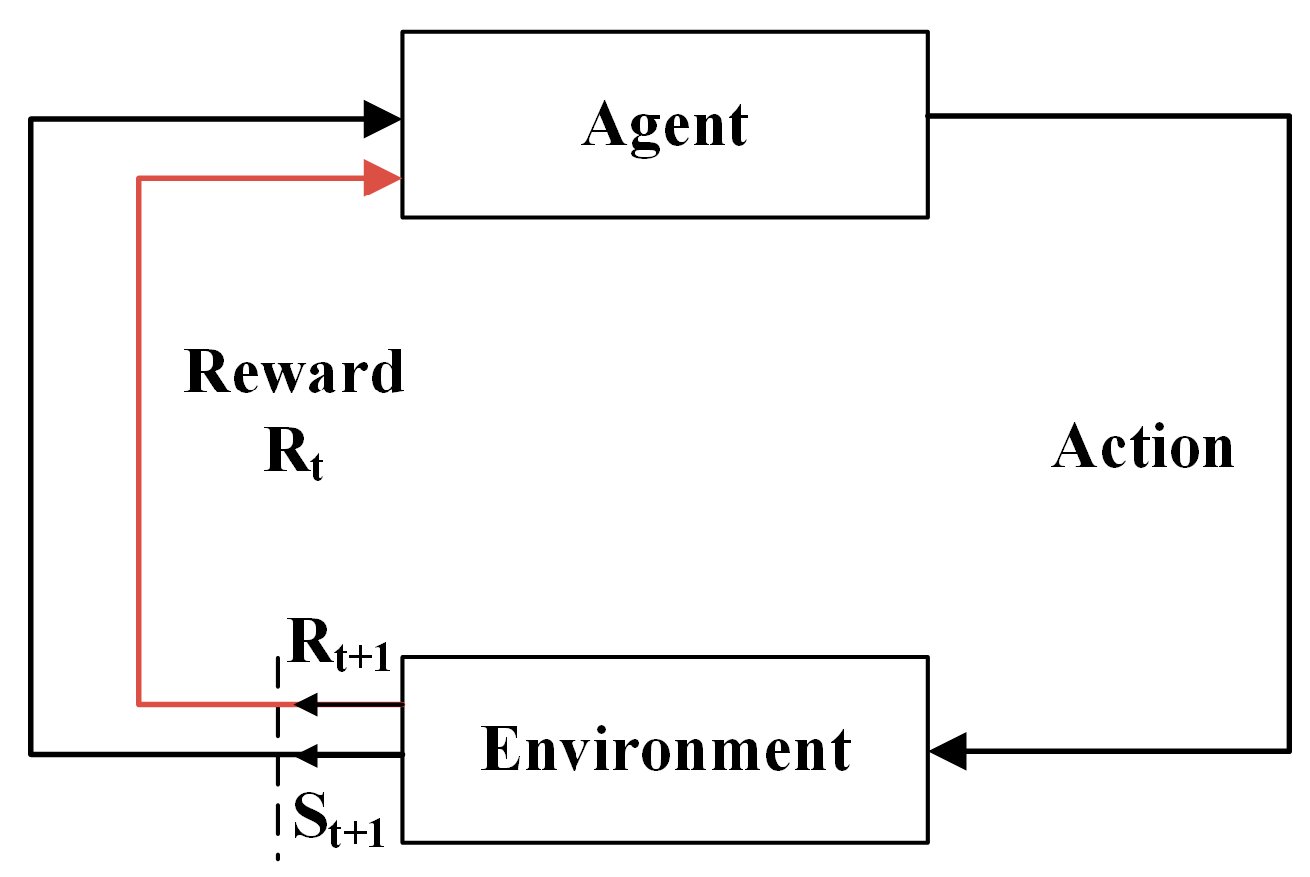

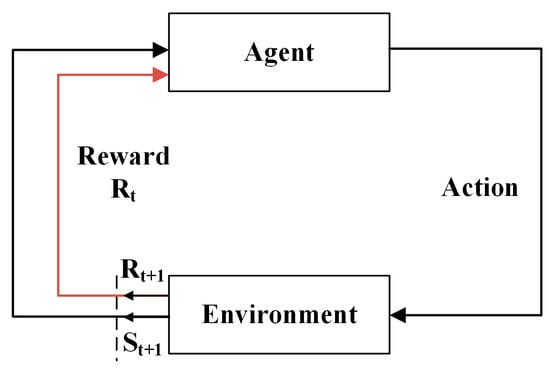

With the continuous development of computing power and reinforcement learning algorithms, reinforcement learning methods have been gradually applied to the search for control strategies or the optimization of controller parameters for upper limb exoskeletons. However, it is still in its infancy.

As a subset of autonomous learning, reinforcement learning (RL) aims to simplify the control strategy and system identification process by learning the optimal strategy through interactions with the environment. RL can automatically discover control strategies without the need for predefined rules or precise system models. However, RL relies on a reward function set based on engineering knowledge. At the same time, RL usually requires extensive interaction with the system, which may be impractical in exoskeleton control due to time constraints. In response to this, Deisenroth et al. [133] proposed methods to accelerate learning by extracting more information from data and proposed the Probabilistic Inference for Learning COntrol (PILCO) algorithm, which is a probability-based, non-parametric model. By explicitly incorporating model uncertainty into long-term planning and controller learning, the algorithm reduces the impact of model errors and has strong application capabilities in real robot control tasks.

Hamaya et al. [134] utilized the PILCO algorithm to minimize the intensity of EMG signals as the objective. They learned assistance strategies from the interactions between the users and the robots. They managed to learn and find the appropriate assistance strategies within only 60 s of interaction. With the assistance of the exoskeleton robots, the intensity of the users’ electromyographic signals was significantly reduced.

In addition, reinforcement learning can also be used for the online parameter tuning of controllers and actuators in control systems. The principle is to find a suitable strategy that maximizes the reward function generated by the agent during its interaction with the environment through the trial-and-error search for strategies. Introducing reinforcement learning control methods can reduce the expert knowledge, prior knowledge, precise training samples, and teaching information required for system design. It can also gradually optimize the system’s control performance through interaction with the controlled object. Huang et al. proposed an adaptive impedance control using reinforcement learning [135]. This method aims to minimize motion tracking errors and human energy consumption. It obtains the optimal impedance model based on linear quadratic regulation and solves the design problem through integral reinforcement learning (IRL) without the need for information about the human dynamic model. The proposed controller is effective in tracking the desired trajectories. However, it is limited by specific models.

Therefore, applying reinforcement learning to robot control can improve control performance and provide a new path for optimizing decisions for complex systems with unknown models. The basic framework of reinforcement learning is shown in Figure 17. Among them, S represents the environmental state and R is the reward function.

Figure 17.

Reinforcement learning basic framework.

In the myriad of reinforcement learning algorithms, the actor–critic algorithm combines the ideas of value iteration and policy gradient methods, enabling it to not only learn a good policy but also evaluate the performance of this policy. This allows the algorithm to more effectively balance exploration (the process of trying new actions to discover their effects) and exploitation (making decisions using currently known information to obtain the highest rewards), and its application in the field of exoskeletons can significantly improve the device’s adaptability. Bayiz et al. [136] used the actor–critic reinforcement learning algorithm to optimize control performance, suitable for reference tracking tasks with nonlinear disturbances. This method was applied to a one-DOF robotic arm’s reference tracking problem affected by gravitational disturbances, significantly improving control performance. Pane et al. [137] used the actor–critic method to establish input compensation and reference compensation methods, aiming to enhance the performance of nominal tracking controllers. Each joint of a six-DOF robotic arm was equipped with an actor–critic compensator, reducing the number of learning parameters and simplifying the model of the learning algorithm.

Hfaiedh et al. [138] proposed a sliding mode control of upper limb exoskeletons based on reinforcement learning using the actor–critic algorithm. The designed actor network learns the policy and the critic evaluates the quality of the actions chosen by the actor. Meanwhile, it was also pointed out that this method has superiority in terms of the position tracking error compared with the standard nonsingular terminal sliding mode control and CTC.

Meng et al. [139] proposed an adaptive inverse optimal hybrid control (AHC) algorithm, combining inverse optimal control and actor–critic learning to provide global asymptotic tracking for unknown nonlinear robots with uncertain human dynamics.

Reinforcement learning can also be used in impedance control to automatically learn and adjust the impedance magnitude, that is, online parameter adjustment. This enables passive impedance control to possess the ability of active learning as well. Li et al. [140] proposed a variable impedance controller based on a model-based reinforcement learning algorithm. Different from the simple regional variable impedance control, this method enables the robot to effectively learn parameters in unstructured environments and accurately control the contact force.