A Review of the Industry 4.0 to 5.0 Transition: Exploring the Intersection, Challenges, and Opportunities of Technology and Human–Machine Collaboration

Abstract

1. Introduction

2. Methods

3. Technological Foundation of IR4.0

3.1. IoT

3.2. Big Data

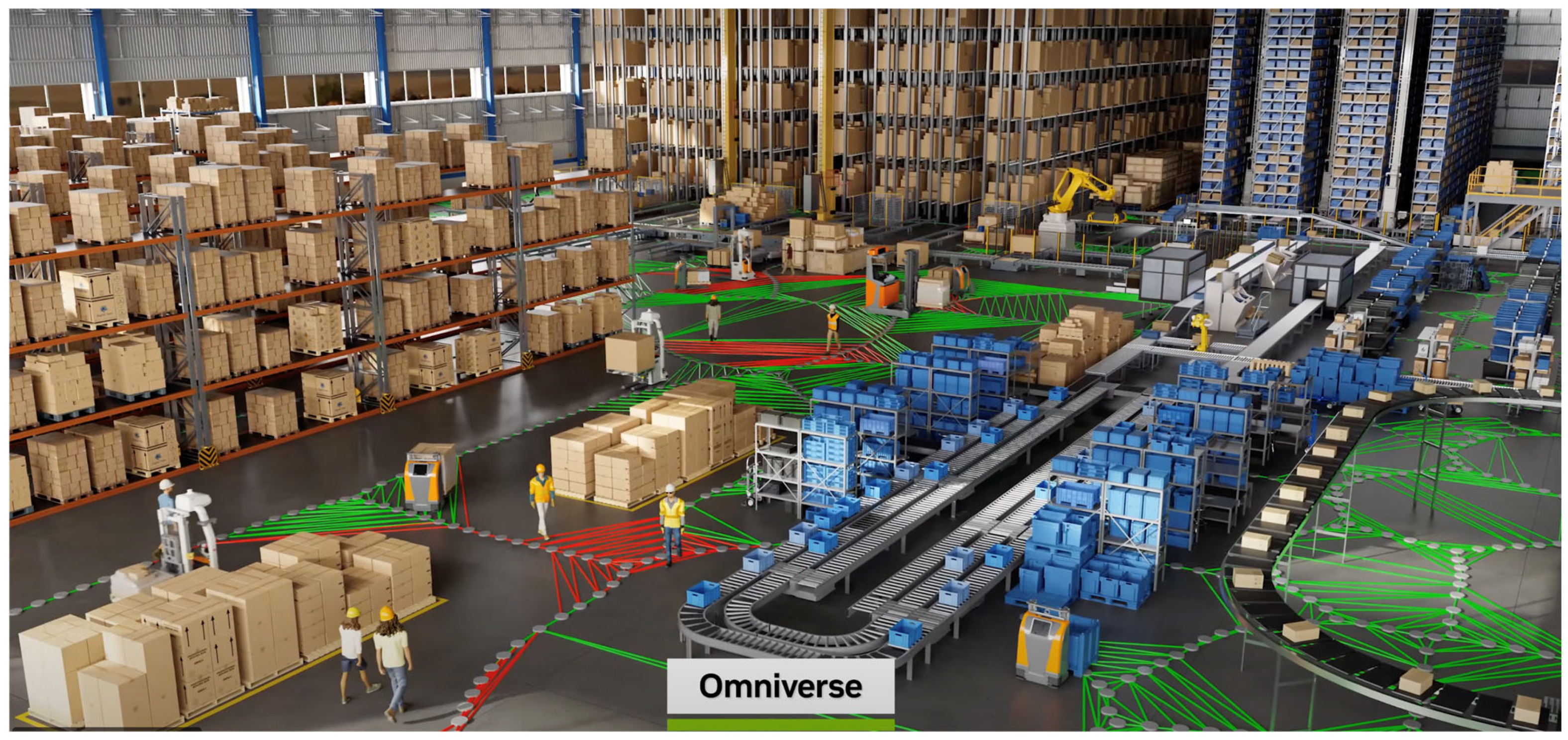

3.3. Digital Twin of Industrial Processes

3.4. Physics-Informed Machine Learning (PIML)

3.5. Additive Manufacturing

3.6. Robotic Systems

3.7. Immersive Technologies

4. Emergence of IR 5.0

4.1. Symbiosis of Human and Machine Intelligence

4.2. Emotional Intelligence

4.3. Environment, Sustainability, and Circular Economy

4.4. The AI Revolution

5. Socioeconomic Implications of IR4.0 to IR5.0 Transition

5.1. Workforce Upskilling

5.2. Ergonomics

6. Tools and Techniques

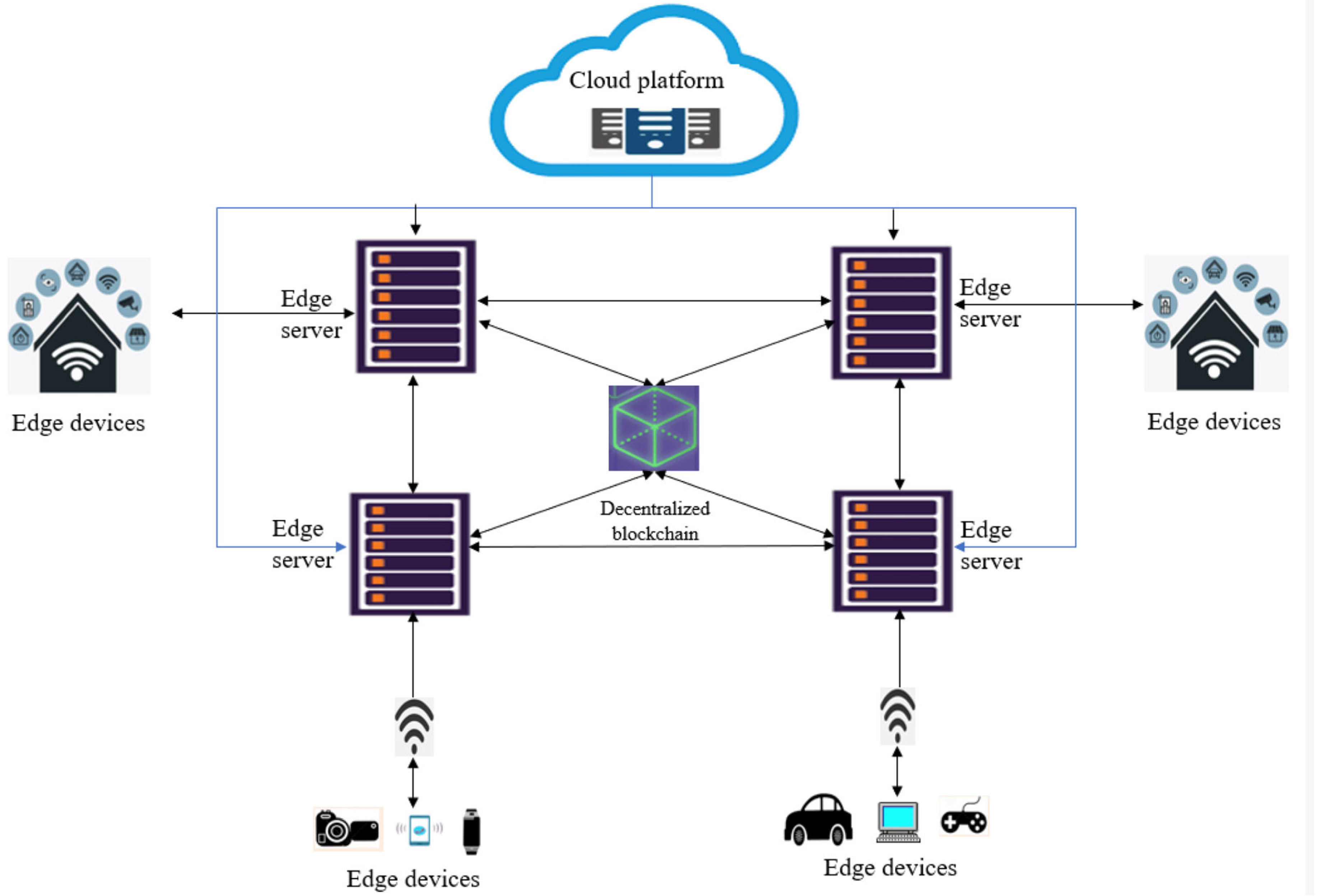

6.1. Data Decentralization

- Edge Computing

- Blockchain

6.2. Human–Machine Collaboration

- Collaborative Robots (Co-bots) and Humanoids

6.3. Wearable and Immersive Technologies

- Wearable Devices

- Immersive Technologies

6.4. Generative AI

6.5. Advanced Wireless Network

7. Applications and Opportunities

7.1. Manufacturing and Production

7.2. Consumer and Retail

7.3. Biotech and Healthcare

7.4. Service Industry

7.5. Infrastructure and Utilities

8. Challenges and Future Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Britannica. Industrial Revolution|Definition, History, Dates, Summary, & Facts|Britannica. Encyclopedia Britannica—Isomerism. Available online: https://www.britannica.com/event/Industrial-Revolution (accessed on 8 November 2024).

- Roy, M. Asia’s Role in the Four Industrial Revolutions. 2018. Available online: https://www.asianstudies.org/publications/eaa/archives/asias-role-in-the-four-industrial-revolutions/ (accessed on 8 November 2024).

- Tech-Labs. The Evolution of Industry 1.0 to 4.0 and Beyond. Technical Laboratory Systems, Inc. Available online: https://tech-labs.com/blog/evolution-industry-10-40-and-beyond (accessed on 14 September 2024).

- Levi, O. Industrial Revolution: From Industry 1.0 to Industry 5.0. Available online: https://www.coretigo.com/industrial-revolution-from-industry-1-0-to-industry-5-0/ (accessed on 14 September 2024).

- Jha, A. The Evolution of Industry: From 1.0 to 6.0. LinkedIn. Available online: https://www.linkedin.com/pulse/evolution-industry-from-10-60-arnav-jha/ (accessed on 9 September 2024).

- Preuveneers, D.; Ilie-Zudor, E. The intelligent industry of the future: A survey on emerging trends, research challenges and opportunities in Industry 4.0. J. Ambient. Intell. Smart Environ. 2017, 9, 287–298. [Google Scholar] [CrossRef]

- Bhuiyan, A.B.; Ali, J.; Zulkifli, N.; Kumarasamy, M.M. Industry 4.0: Challenges, Opportunities, and Strategic Solutions for Bangladesh. Int. J. Bus. Manag. Futur. 2020, 4, 41–56. [Google Scholar] [CrossRef]

- Tatipala, S.; Larsson, T.; Johansson, C.; Wall, J. The Influence of Industry 4.0 on Product Design and Development: Conceptual Foundations and Literature Review. In Design for Tomorrow; Smart Innovation, Systems and Technologies; Springer: Singapore, 2021; pp. 757–768. [Google Scholar] [CrossRef]

- Rosário, A.T.; Dias, J.C. How Industry 4.0 and Sensors Can Leverage Product Design: Opportunities and Challenges. Sensors 2023, 23, 1165. [Google Scholar] [CrossRef]

- Herceg, I.V.; Kuč, V.; Mijušković, V.M.; Herceg, T. Challenges and Driving Forces for Industry 4.0 Implementation. Sustainability 2020, 12, 4208. [Google Scholar] [CrossRef]

- Alqoud, A.; Schaefer, D.; Milisavljevic-Syed, J. Industry 4.0: Challenges and Opportunities of Digitalisation Manufacturing Systems. In Proceedings of the 19th International Conference on Manufacturing Research, Incorporating the 36th National Conference on Manufacturing Research, Derby, UK, 6–8 September 2022. [Google Scholar] [CrossRef]

- Jayashree, S.; Malarvizhi, C.A.; Reza, M.N.H. The Challenges and Opportunities of Industry 4.0—A Review. Asia Proc. Soc. Sci. 2019, 5, 173–178. [Google Scholar] [CrossRef]

- Abu-Rumman, A.; AlSha’ar, H.; Alqhaiwi, L.A.; Al Shraah, A. Exploring the Challenges and Opportunities of Implementing Industry 4.0 in Jordan: Public Shareholding Manufacturing Companies Perspective. Wirel. Pers. Commun. 2023. preprint. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Silva, H.R.O.; Terra da Silva, M.; Gonçalves, R.F.; Sacomano, J.B. Industry 4.0 and Sustainability Implications: A Scenario-Based Analysis of the Impacts and Challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Fuertes, G.; Zamorano, J.; Alfaro, M.; Vargas, M.; Sabattin, J.; Duran, C.; Ternero, R.; Rivera, R. Opportunities of the Technological Trends Linked to Industry 4.0 for Achieve Sustainable Manufacturing Objectives. Sustainability 2022, 14, 11118. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0—Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Rijwani, T.; Kumari, S.; Srinivas, R.; Abhishek, K.; Iyer, G.; Vara, H.; Dubey, S.; Revathi, V.; Gupta, M. Industry 5.0: A review of emerging trends and transformative technologies in the next industrial revolution. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 19, 667–679. [Google Scholar] [CrossRef]

- Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud Comput. 2022, 11, 40. [Google Scholar] [CrossRef]

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11, 193. [Google Scholar] [CrossRef]

- Crnobrnja, J.; Stefanovic, D.; Romero, D.; Softic, S.; Marjanovic, U. Digital Transformation Towards Industry 5.0: A Systematic Literature Review. In Advances in Production Management Systems. Production Management Systems for Responsible Manufacturing, Service, and Logistics Futures; Springer: Cham, Switzerland, 2023; pp. 269–281. [Google Scholar] [CrossRef]

- Santosh, I.; Shukla, P.; Sahoo, M.K.; Ramya, B. Industry 5.0—The Road to Sustainability-Review. In Anticipating Future Business Trends: Navigating Artificial Intelligence Innovations; Springer: Cham, Switzerland, 2024; pp. 241–250. [Google Scholar] [CrossRef]

- Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R.Y. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 2, 951643. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Pradeep, A. Integration of IoT and Industry 4.0: Revolutionizing Industrial Processes. In Advanced Communication and Intelligent Systems; Communications in Computer and Information Science; Springer: Cham, Switzerland, 2023; pp. 85–96. [Google Scholar] [CrossRef]

- Yang, C.; Shen, W.; Wang, X. The Internet of Things in Manufacturing: Key Issues and Potential Applications. IEEE Syst. Man Cybern. Mag. 2018, 4, 6–15. [Google Scholar] [CrossRef]

- Chowdhury, B.D.B.; Islam, M.T.; Son, Y.J.; Tronstad, R. Optimal deployment of indoor sensors for a real-time location tracking system. In Proceedings of the IISE Annual Conference and Expo 2021, Online, 22–25 May 2021. [Google Scholar]

- Khan, M.A.; Salah, K. IoT security: Review, blockchain solutions, and open challenges. Futur. Gener. Comput. Syst. 2018, 82, 395–411. [Google Scholar] [CrossRef]

- Parkins, D. The World’s Most Valuable Resource Is No Longer Oil, but Data. The Economist, 6 May 2017. Available online: https://www.economist.com/leaders/2017/05/06/the-worlds-most-valuable-resource-is-no-longer-oil-but-data (accessed on 24 November 2024).

- Manyika, J.; Chui, M.; Brown, B.; Bughin, J.; Dobbs, R.; Roxburgh, C.; Hung Byers, A. Big Data: The Next Frontier for Innovation, Competition and Productivity; McKinsey Global Institute: New York, NY, USA, 2011. [Google Scholar]

- Jagatheesaperumal, S.K.; Rahouti, M.; Ahmad, K.; Al-Fuqaha, A.; Guizani, M. The Duo of Artificial Intelligence and Big Data for Industry 4.0: Applications, Techniques, Challenges, and Future Research Directions. IEEE Internet Things J. 2022, 9, 12861–12885. [Google Scholar] [CrossRef]

- Khan, M.; Wu, X.; Xu, X.; Dou, W. Big data challenges and opportunities in the hype of Industry 4.0. In Proceedings of the 2017 IEEE International Conference on Communications (ICC), Paris, France, 21–25 May 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Pires, F.; Cachada, A.; Barbosa, J.; Moreira, A.P.; Leitao, P. Digital twin in industry 4.0: Technologies, applications and challenges. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Suman, R. Digital Twin applications toward Industry 4.0: A Review. Cogn. Robot. 2023, 3, 71–92. [Google Scholar] [CrossRef]

- Huang, M. NVIDIA Unveils ‘Mega’ Omniverse Blueprint for Building Industrial Robot Fleet Digital Twins. 2025. Available online: https://blogs.nvidia.com/blog/mega-omniverse-blueprint/ (accessed on 8 February 2025).

- Quinlivan, J. How Amazon Deploys Collaborative Robots in Its Operations to Benefit Employees and Customers. 2023. Available online: https://www.aboutamazon.com/news/operations/how-amazon-deploys-robots-in-its-operations-facilities (accessed on 8 February 2025).

- Uhlemann, T.H.-J.; Schock, C.; Lehmann, C.; Freiberger, S.; Steinhilper, R. The Digital Twin: Demonstrating the Potential of Real Time Data Acquisition in Production Systems. Procedia Manuf. 2017, 9, 113–120. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Karniadakis, G.E.; Kevrekidis, I.G.; Lu, L.; Perdikaris, P.; Wang, S.; Yang, L. Physics-informed machine learning. Nat. Rev. Phys. 2021, 3, 422–440. [Google Scholar] [CrossRef]

- Shukla, K.; Xu, M.; Trask, N.; Karniadakis, G.E. Scalable algorithms for physics-informed neural and graph networks. Data-Centric Eng. 2022, 3, e24. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Tu, H.; Moura, S.; Wang, Y.; Fang, H. Integrating physics-based modeling with machine learning for lithium-ion batteries. Appl. Energy 2023, 329, 120289. [Google Scholar] [CrossRef]

- Zhu, Q.; Liu, Z.; Yan, J. Machine learning for metal additive manufacturing: Predicting temperature and melt pool fluid dynamics using physics-informed neural networks. Comput. Mech. 2021, 67, 619–635. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, Q.; Michaleris, P. A Physics-Informed Two-Level Machine-Learning Model for Predicting Melt-Pool Size in Laser Powder Bed Fusion. J. Dyn. Syst. Meas. Control. 2021, 143, 121006. [Google Scholar] [CrossRef]

- Kashinath, K.; Mustafa, M.; Albert, A.; Wu, J.-L.; Jiang, C.; Esmaeilzadeh, S.; Azizzadenesheli, K.; Wang, R.; Chattopadhyay, A.; Singh, A.; et al. Physics-informed machine learning: Case studies for weather and climate modelling. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2021, 379, 20200093. [Google Scholar] [CrossRef]

- Deng, W.; Nguyen, K.T.; Medjaher, K.; Gogu, C.; Morio, J. Physics-informed machine learning in prognostics and health management: State of the art and challenges. Appl. Math. Model. 2023, 124, 325–352. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Lopez, H.; Martinez, E.; Machado, B.I.; Hernandez, D.H.; Martinez, L.; Lopez, M.I.; Wicker, R.B.; et al. Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 1999–2032. [Google Scholar] [CrossRef]

- Tsai, S.; Wang, Q.; Wang, Y.; King, W.P.; Tawfick, S. Miniature soft jumping robots made by additive manufacturing. Smart Mater. Struct. 2023, 32, 105022. [Google Scholar] [CrossRef]

- Kariuki, L.W.; Ikua, B.W.; Karanja, S.K.; Ng’Ang’A, S.P. A Digital and Additive Manufacturing Approach for the Fabrication of Custom Orthoses. In Proceedings of the 2023 IEEE AFRICON, Nairobi, Kenya, 20–22 September 2023. [Google Scholar] [CrossRef]

- Abdalla, H.; Fattah, K.P.; Abdallah, M.; Tamimi, A.K. Environmental footprint and economics of a full-scale 3d-printed house. Sustainability 2021, 13, 11978. [Google Scholar] [CrossRef]

- Goel, R.; Gupta, P. Robotics and Industry 4.0. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Advances in Science, Technology and Innovation; Springer: Cham, Switzerland, 2020; pp. 157–169. [Google Scholar] [CrossRef]

- Shneier, M.; Bostelman, R. Literature Review of Mobile Robots for Manufacturing; National Institute of Standards and Technology, US Department of Commerce: Washington, DC, USA, 2015; Report Number 8022.

- Edwards, M. Robots in industry: An overview. Appl. Ergon. 1984, 15, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Substantial capabilities of robotics in enhancing industry 4.0 implementation. Cogn. Robot. 2021, 1, 58–75. [Google Scholar] [CrossRef]

- Moon, H.; Freidouny, M.; Rajabi, M.S.; Bozorgmehrian, S.; Sangwan, A.; Jeon, M. The Influence of Olfactory and Visual Stimuli on Students’ Performance and Mood in Virtual Reality Environment. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2023, 67, 2441–2446. [Google Scholar] [CrossRef]

- Huang, T.-L.; Liao, S.-L. Creating e-shopping multisensory flow experience through augmented-reality interactive technology. Internet Res. 2017, 27, 449–475. [Google Scholar] [CrossRef]

- Arino, J.-J.; Juan, M.-C.; Gil-Gómez, J.-A.; Mollá, R. A comparative study using an autostereoscopic display with augmented and virtual reality. Behav. Inf. Technol. 2014, 33, 646–655. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Ong, S.K.; Nee, A.Y.C. An Augmented Reality-Assisted Therapeutic Healthcare Exercise System Based on Bare-Hand Interaction. Int. J. Hum. Comput. Interact. 2016, 32, 708–721. [Google Scholar] [CrossRef]

- Estejab, H.; Bayramzadeh, S. The Application of Augmented Reality in Simulation-Based Design Evaluations of Trauma Rooms. HERD Health Environ. Res. Des. J. 2025, 18, 70–85. [Google Scholar] [CrossRef]

- Maydanchi, M.; Ziaei, M.; Mohammadi, M.; Ziaei, A.; Basiry, M.; Haji, F.; Gharibi, K. A Comparative Analysis of the Machine Learning Methods for Predicting Diabetes. J. Oper. Intell. 2024, 2, 230–251. [Google Scholar] [CrossRef]

- Novák, J.Š.; Masner, J.; Benda, P.; Šimek, P.; Merunka, V. Eye Tracking, Usability, and User Experience: A Systematic Review. Int. J. Hum. Comput. Interact. 2024, 40, 4484–4500. [Google Scholar] [CrossRef]

- Daugherty, P.R.; Wilson, H.J. Human + Machine: Reimagining Work in the Age of AI; Harvard Business Press: Brighton, MA, USA, 2018. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Kaplan, A.; Haenlein, M. Rulers of the world, unite! The challenges and opportunities of artificial intelligence. Bus. Horizons 2020, 63, 37–50. [Google Scholar] [CrossRef]

- Landry, L. Why Emotional Intelligence Is Important in Leadership. 2019. Available online: https://online.hbs.edu/blog/post/emotional-intelligence-in-leadership (accessed on 8 December 2024).

- Picard, R.W.; Vyzas, E.; Healey, J. Toward machine emotional intelligence: Analysis of affective physiological state. IEEE Trans. Pattern Anal. Mach. Intell. 2001, 23, 1175–1191. [Google Scholar] [CrossRef]

- Kulke, L.; Feyerabend, D.; Schacht, A. A Comparison of the Affectiva iMotions Facial Expression Analysis Software with EMG for Identifying Facial Expressions of Emotion. Front. Psychol. 2020, 11, 329. [Google Scholar] [CrossRef] [PubMed]

- PAT Research. What Is Affective Computing? Top 15 Affective Computing Companies. PAT Research. 2020. Available online: https://www.predictiveanalyticstoday.com/what-is-affective-computing/ (accessed on 8 December 2024).

- Amores, J.; Hernandez, J.; Dementyev, A.; Wang, X.; Maes, P. BioEssence: A Wearable Olfactory Display that Monitors Cardio-respiratory Information to Support Mental Wellbeing. In Proceedings of the 2018 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Honolulu, HI, USA, 18–21 July 2018. [Google Scholar] [CrossRef]

- International Energy Agency. EV Battery Supply Chain Sustainability. 2024. Available online: www.iea.org (accessed on 15 January 2025).

- Lepre, N.; Burget, S.; Gabriel, N.U.S. Investments in Electric Vehicle Manufacturing 2023. 2023. Available online: https://atlaspolicy.com/wp-content/uploads/2023/05/U.S.-Investments-in-Electric-Vehicle-Manufacturing-2023.pdf (accessed on 4 February 2025).

- International Energy Agency. Trends in the Electric Vehicle Industry. 2024. Available online: https://www.iea.org/reports/global-ev-outlook-2024/trends-in-the-electric-vehicle-industry (accessed on 4 February 2025).

- Gohlke, D.; Iyer, R.K.; Kelly, J.; Monthe, A.P.N.; Wu, X.; Barlock, T.A.; Mansour, C. Quantification of Commercially Planned Battery Component Supply in North America Through 2035. 2024. Available online: http://www.osti.gov/ (accessed on 15 January 2025).

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen fuel cell vehicles; Current status and future prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Jensen, H.H. For Manufacturers, the Circular Economy Strengthens Supply Chains. Here’s How. 2024. Available online: https://www.weforum.org/stories/2024/02/how-manufacturers-could-lead-the-way-in-building-the-circular-economy/ (accessed on 4 February 2025).

- Nanayakkara, P.R.; Jayalath, M.M.; Thibbotuwawa, A.; Perera, H.N. A circular reverse logistics framework for handling e-commerce returns. Clean. Logist. Supply Chain 2022, 5, 100080. [Google Scholar] [CrossRef]

- Generes, T.O., Jr. Get Ready for the Product-As-A-Service Revolution. Forbes, 15 October 2020. Available online: https://www.forbes.com/sites/servicenow/2020/10/15/get-ready-for-the-product-as-a-service-revolution/ (accessed on 15 January 2025).

- Zhang, Y. Analysis of Battery Swapping Technology for Electric Vehicles—Using NIO’s Battery Swapping Technology as an Example. SHS Web Conf. 2022, 144, 02015. [Google Scholar] [CrossRef]

- European Commission. EU Climate Action and the European Green Deal; EU Action; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- U.S Environmental Protection Agency. Summary of Inflation Reduction Act Provisions Related to Renewable Energy. 2025. Available online: https://www.epa.gov/green-power-markets/summary-inflation-reduction-act-provisions-related-renewable-energy (accessed on 4 February 2025).

- Fonseca, L.M.; Domingues, J.P.; Dima, A.M. Mapping the sustainable development goals relationships. Sustainability 2020, 12, 3359. [Google Scholar] [CrossRef]

- Copeland, B.J. Early AI in Britain: Turing et al. IEEE Ann. Hist. Comput. 2023, 45, 19–31. [Google Scholar] [CrossRef]

- Gugerty, L. Newell and Simon’s logic theorist: Historical background and impact on cognitive modeling. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2006, 50, 880–884. [Google Scholar] [CrossRef]

- Lillicrap, T.P.; Santoro, A.; Marris, L.; Akerman, C.J.; Hinton, G. Backpropagation and the brain. Nat. Rev. Neurosci. 2020, 21, 335–346. [Google Scholar] [CrossRef] [PubMed]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Ferrucci, D.A. Introduction to “This is Watson”. IBM J. Res. Dev. 2012, 56, 1:1–1:15. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. In Advances in Neural Information Processing Systems; Curran Associates, Inc.: Red Hook, NY, USA, 2012. [Google Scholar]

- Chen, R.H.; Chen, C. AlphaGo. In Artificial Intelligence; Chapman and Hall/CRC: Boca Raton, FL, USA, 2024. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Łukasz, K.; Polosukhin, I. Attention is all you need. In Advances in Neural Information Processing Systems; Curran Associates, Inc.: Red Hook, NY, USA, 2017. [Google Scholar]

- OpenAI. Introducing Operator. 2025. Available online: https://openai.com/index/introducing-operator/ (accessed on 8 February 2025).

- Fei, N.; Lu, Z.; Gao, Y.; Yang, G.; Huo, Y.; Wen, J.; Lu, H.; Song, R.; Gao, X.; Xiang, T.; et al. Towards artificial general intelligence via a multimodal foundation model. Nat. Commun. 2022, 13, 3094. [Google Scholar] [CrossRef]

- European Commission. The Impact of Artificial Intelligence on the Future of Workforces in the European Union and the United States of America. December 2022. Available online: https://digital.library.unt.edu/ark:/67531/metadc2288721/m1/1/ (accessed on 9 January 2025).

- World Economic Forum. Future of Jobs Report 2025. 2025. Available online: https://reports.weforum.org/docs/WEF_Future_of_Jobs_Report_2025.pdf (accessed on 8 February 2025).

- Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Xu, M.; David, J.M.; Kim, S.H. The fourth industrial revolution: Opportunities and challenges. Int. J. Financ. Res. 2018, 9, 90. [Google Scholar] [CrossRef]

- Lutln, L. Superlearning: Reskilling the Workforce. Deloitte Insights, Belgium. 29 June 2020. Available online: https://www2.deloitte.com/us/en/insights/focus/technology-and-the-future-of-work/reskilling-the-workforce.html (accessed on 9 January 2025).

- Ozkan-Ozen, Y.D.; Kazancoglu, Y. Analysing workforce development challenges in the Industry 4.0. Int. J. Manpow. 2022, 43, 310–333. [Google Scholar] [CrossRef]

- Caesar, L.D. Emerging Dynamics of Training, Recruiting and Retaining a Sustainable Maritime Workforce: A Skill Resilience Framework. Sustainability 2023, 16, 239. [Google Scholar] [CrossRef]

- PwC. Workforce. Available online: https://www.pwc.com/gx/en/services/workforce.html (accessed on 9 January 2025).

- Kadir, B.A.; Broberg, O.; da Conceição, C.S. Current research and future perspectives on human factors and ergonomics in Industry 4.0. Comput. Ind. Eng. 2019, 137, 106004. [Google Scholar] [CrossRef]

- Botti, L.; Mora, C.; Regattieri, A. Integrating ergonomics and lean manufacturing principles in a hybrid assembly line. Comput. Ind. Eng. 2017, 111, 481–491. [Google Scholar] [CrossRef]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Emerging research fields in safety and ergonomics in industrial collaborative robotics: A systematic literature review. Robot. Comput. Integr. Manuf. 2021, 67, 101998. [Google Scholar] [CrossRef]

- Antonaci, F.G.; Olivetti, E.C.; Marcolin, F.; Jimenez, I.A.C.; Eynard, B.; Vezzetti, E.; Moos, S. Workplace Well-Being in Industry 5.0: A Worker-Centered Systematic Review. Sensors 2024, 24, 5473. [Google Scholar] [CrossRef] [PubMed]

- Malik, A.A.; Bilberg, A. Complexity-based task allocation in human-robot collaborative assembly. Ind. Robot. Int. J. Robot. Res. Appl. 2019, 46, 471–480. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Sharma, M.; Tomar, A.; Hazra, A. Edge Computing for Industry 5.0: Fundamental, Applications, and Research Challenges. IEEE Internet Things J. 2024, 11, 19070–19093. [Google Scholar] [CrossRef]

- Dmitrieva, E.; Thakur, G.; Prabhakar, P.K.; Prakash, A.; Vyas, A.; Prasanna, Y.L. Edge Computing and AI: Advancements in Industry 5.0- An Experimental Assessment. BIO Web Conf. 2024, 86, 01096. [Google Scholar] [CrossRef]

- Roy, D.G. BlockEdge: A Privacy-Aware Secured Edge Computing Framework Using Blockchain for Industry 4.0. Sensors 2023, 23, 2502. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; da Cruz, A.M.R.; Lopes, S.I. An Overview of Blockchain for Industry 5.0: Towards Human-Centric, Sustainable and Resilient Applications. IEEE Access 2024, 12, 116162–116201. [Google Scholar] [CrossRef]

- Manditereza, K. Powering Industrial AI Use Cases with the Unified Namespace. HiveMQ. Available online: https://www.hivemq.com/blog/powering-industrial-ai-use-cases-with-unified-namespace-uns/ (accessed on 9 January 2025).

- Oliveira, M.; Chauhan, S.; Pereira, F.; Felgueiras, C.; Carvalho, D. Blockchain Protocols and Edge Computing Targeting Industry 5.0 Needs. Sensors 2023, 23, 9174. [Google Scholar] [CrossRef]

- Schillmoeller, S. Innovative Human-Robot Cooperation in BMW Group Production. BMW Group. Available online: https://www.press.bmwgroup.com/global/article/detail/T0209722EN/innovative-human-robot-cooperation-in-bmw-group-production?language=en (accessed on 6 January 2025).

- Industrial Decarbonization Network. 3 Examples of Cobots at Work. Available online: https://www.industrialdecarbonizationnetwork.com/digital-transformation-1/case-studies/3-examples-of-cobots-at-work (accessed on 9 January 2025).

- Darvish, K.; Penco, L.; Ramos, J.; Cisneros, R.; Pratt, J.; Yoshida, E.; Ivaldi, S.; Pucci, D. Teleoperation of Humanoid Robots: A Survey. IEEE Trans. Robot. 2023, 39, 1706–1727. [Google Scholar] [CrossRef]

- Stellarix. Wear It Well: The Rise of Industrial Wearables. LinkedIn. Available online: https://www.linkedin.com/pulse/wear-well-rise-industrial-wearables-stellarix-ewjyf/ (accessed on 7 January 2025).

- Universal Robots. Cobots Transferring Operators from Repetition to Reward. Available online: https://www.universal-robots.com/case-stories/sanofi/ (accessed on 6 January 2025).

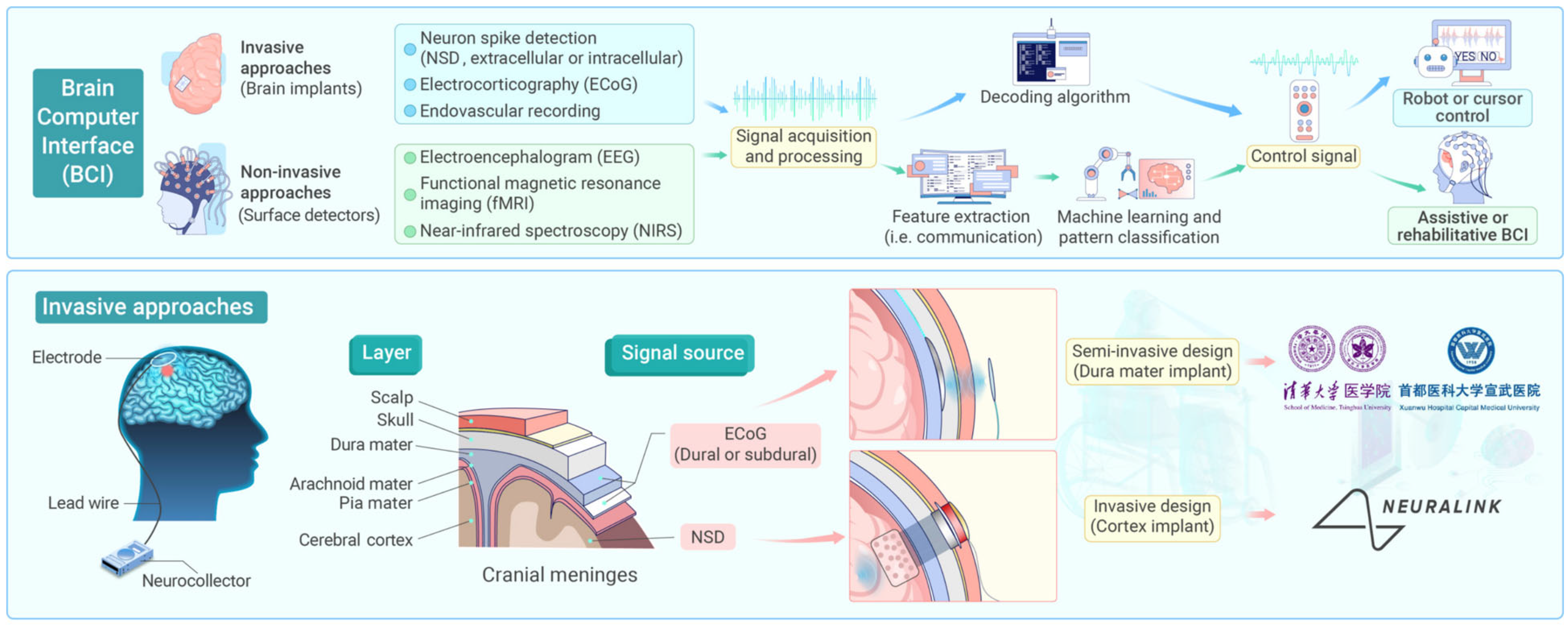

- Pang, W.; Yuan, C.; Zheng, Y.; Zhong, T.; Lai, P. Applications over the horizon—Advancements and challenges in brain-computer interfaces. Innov. Life 2024, 2, 100058. [Google Scholar] [CrossRef]

- Drew, L. Elon Musk’s Neuralink brain chip: What scientists think of first human trial. Nature 2024. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Dai, J. Fully implantable wireless brain-computer interface for humans: Advancing toward the future. Innovation 2024, 5, 100595. [Google Scholar] [CrossRef]

- Wolpaw, J.R.; Wolpaw, E.W. Brain–Computer Interfaces: Something New under the Sun. In Brain-Computer Interfaces: Principles and Practice; Wolpaw, J.R., Wolpaw, E.W., Eds.; Oxford University Press: Oxford, UK, 2012; pp. 3–12. [Google Scholar] [CrossRef]

- Dmytriyev, Y.; Zaki, A.M.A.; Carnevale, M.; Insero, F.; Giberti, H. Brain computer interface for human-cobot interaction in industrial applications. In Proceedings of the 2021 3rd International Congress on Human-Computer Interaction, Optimization and Robotic Applications (HORA), Ankara, Turkey, 11–13 June 2021. [Google Scholar] [CrossRef]

- Douibi, K.; Le Bars, S.; Lemontey, A.; Nag, L.; Balp, R.; Breda, G. Toward EEG-Based BCI Applications for Industry 4.0: Challenges and Possible Applications. Front. Hum. Neurosci. 2021, 15, 705064. [Google Scholar] [CrossRef]

- Asgher, U.; Ayaz, Y.; Taiar, R. Editorial: Advances in artificial intelligence (AI) in brain computer interface (BCI) and Industry 4.0 for human machine interaction (HMI). Front. Hum. Neurosci. 2023, 17, 1320536. [Google Scholar] [CrossRef]

- Yenduri, G.; Maddikunta, P.K.R.; Gadekallu, T.R.; Jhaveri, R.H.; Bandi, A.; Chen, J.; Wang, W.; Shirawalmath, A.A.; Ravishankar, R.; Wang, W. Spatial Computing: Concept, Applications, Challenges and Future Directions. arXiv 2024, arXiv:2402.07912. [Google Scholar]

- Balakrishnan, S.; Hameed, M.S.; Venkatesan, K.; Aswin, G. Interaction of Spatial Computing in Augmented Reality. In Proceedings of the 2021 7th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 19–20 March 2021. [Google Scholar] [CrossRef]

- Sepanloo, K.; Gharehtoragh, M.A.; Duffy, V.G. Transforming User Experience Through Extended Reality and Conversational AI: A Systematic Review. In HCI International 2024—Late Breaking Papers; Springer: Cham, Switzerland, 2025; pp. 183–194. [Google Scholar] [CrossRef]

- Wang, X.; Dunston, P.S. Comparative Effectiveness of Mixed Reality-Based Virtual Environments in Collaborative Design. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2011, 41, 284–296. [Google Scholar] [CrossRef]

- EC Electronics. Introducing Wearable Technology in Factories. Available online: https://ecelectronics.com/news/introducing-wearable-technology-in-factories (accessed on 9 January 2025).

- Azumuta. Generative AI in Manufacturing: 5 Industry-Transforming Use Cases. Available online: https://www.azumuta.com/blog/generative-ai-in-manufacturing-5-industry-transforming-use-cases/ (accessed on 9 January 2025).

- Bordukova, M.; Makarov, N.; Rodriguez-Esteban, R.; Schmich, F.; Menden, M.P. Generative artificial intelligence empowers digital twins in drug discovery and clinical trials. Expert Opin. Drug Discov. 2023, 19, 33–42. [Google Scholar] [CrossRef]

- Jumper, J.; Evans, R.; Pritzel, A.; Green, T.; Figurnov, M.; Ronneberger, O.; Tunyasuvunakool, K.; Bates, R.; Žídek, A.; Potapenko, A.; et al. Highly accurate protein structure prediction with AlphaFold. Nature 2021, 596, 583–589. [Google Scholar] [CrossRef]

- Sai, S.; Sai, R.; Chamola, V. Generative AI for Industry 5.0: Analyzing the impact of ChatGPT, DALLE, and Other Models. IEEE Open J. Commun. Soc. 2024. [Google Scholar] [CrossRef]

- Loucks, J.; Sarer, B.; Crossan, G.; Widener, C. Autonomous Generative AI Agents: Under Development. Deloitte Insights. Available online: https://www2.deloitte.com/us/en/insights/industry/technology/technology-media-and-telecom-predictions/2025/autonomous-generative-ai-agents-still-under-development.html (accessed on 6 January 2025).

- Devi, M.K.; Priya, M.P. Evolution of Next Generation Networks and Its Contribution Towards Industry 5.0. In Resource Management in Advanced Wireless Networks; Wiley: Hoboken, NJ, USA, 2023; pp. 45–80. [Google Scholar] [CrossRef]

- Alsharif, M.H.; Jahid, A.; Kannadasan, R.; Kim, M.-K. Unleashing the potential of sixth generation (6G) wireless networks in smart energy grid management: A comprehensive review. Energy Rep. 2024, 11, 1376–1398. [Google Scholar] [CrossRef]

- Chen, X.; Tan, J.; Kang, L.; Tang, F.; Zhao, M.; Kato, N. Frequency Selective Surface Toward 6G Communication Systems: A Contemporary Survey. IEEE Commun. Surv. Tutor. 2024, 26, 1635–1675. [Google Scholar] [CrossRef]

- Strinati, E.C.; Barbarossa, S. 6G Networks: Beyond Shannon Towards Semantic and Goal-Oriented Communications. arXiv 2020, arXiv:2011.14844. [Google Scholar]

- Akyildiz, I.F.; Kak, A.; Nie, S. 6G and Beyond: The Future of Wireless Communications Systems. IEEE Access 2020, 8, 133995–134030. [Google Scholar] [CrossRef]

- Liu, F.; Cui, Y.; Masouros, C.; Xu, J.; Han, T.X.; Eldar, Y.C.; Buzzi, S. Integrated Sensing and Communications: Towards Dual-functional Wireless Networks for 6G and Beyond. arXiv 2021, arXiv:2108.07165. [Google Scholar] [CrossRef]

- Dong, R. Research on the Digital Transformation Business Model of the Automobile Manufacturing Industry. Adv. Econ. Manag. Politi.-Sci. 2023, 33, 113–120. [Google Scholar] [CrossRef]

- Moghrabi, I.A.R.; Bhat, S.A.; Szczuko, P.; AlKhaled, R.A.; Dar, M.A. Digital Transformation and Its Influence on Sustainable Manufacturing and Business Practices. Sustainability 2023, 15, 3010. [Google Scholar] [CrossRef]

- Hu, B.; Lv, J.; Yang, K. Cost-Benefit Models on Integrating Information Technology Services in Automotive Production Management. Sci. Program. 2020, 2020, 8877780. [Google Scholar] [CrossRef]

- Alhamadah, A.; Mamun, M.; Harms, H.; Redondo, M.; Lin, Y.-Z.; Pacheco, J.; Salehi, S.; Satam, P. Photogrammetry for Digital Twinning Industry 4.0 (I4) Systems. In Proceedings of the 2024 IEEE/ACS 21st International Conference on Computer Systems and Applications (AICCSA), Sousse, Tunisia, 22–26 October 2024. [Google Scholar]

- Nugroho, E.A.; Setiawan, J.D.; Munadi, M. Handling Four DOF Robot to Move Objects Based on Color and Weight using Fuzzy Logic Control. J. Robot. Control (JRC) 2023, 4, 769–779. [Google Scholar] [CrossRef]

- Wang, H. The Application of Big Data Analysis in the Hierarchical Management of Automobile Customers. In Proceedings of the 2022 2nd International Conference on Economic Development and Business Culture (ICEDBC 2022); Atlantis Press International BV: Dordrecht, The Netherlands, 2022; pp. 1770–1774. [Google Scholar] [CrossRef]

- Cao, Y.; You, J.; Shi, Y.; Hu, W. The obstacles of China’s intelligent automobile manufacturing industry development. Chin. Manag. Stud. 2020, 14, 159–183. [Google Scholar] [CrossRef]

- Lin, Y.-Z.; Alhamadah, A.H.J.; Redondo, M.W.; Patel, K.H.; Ghimire, S.; Latibari, B.S.; Salehi, S.; Satam, P. Transforming Engineering Education Using Generative AI and Digital Twin Technologies. arXiv 2024, arXiv:2411.14433. [Google Scholar]

- Yadav, S.; Kopare, A.; Manjunath, H.R.; Mishra, A. Effects of the industrial 4.0 transition on consumer behavior: A systematic overview. Multidiscip. Rev. 2024, 6, 2023ss066. [Google Scholar] [CrossRef]

- Lumivalo, J.; Clements, K.; Hannuksela, E.-S. Harnessing Digital Services for Co-creating Sustainability Value in the Retail Servicescape. In Proceedings of the Hawaii International Conference on System Sciences, Maui, HI, USA, 4–7 January 2022. [Google Scholar] [CrossRef]

- Raj, A.; Nakul, P. Customizing AI Assistants for Industry-Specific Operational Excellence: Case Studies and Empirical Evaluation. Int. Res. J. Mod. Eng. Technol. Sci. 2024, 6, 2767–2780. [Google Scholar] [CrossRef]

- Castillo, J. How interactions influence customer empowerment and satisfaction in the retail industry. J. Bus. Retail. Manag. Res. 2018, 12. [Google Scholar] [CrossRef]

- Lu, Z.; Zhu, L.; Li, X.; Li, Z. The Impact of the COVID-19 Pandemic on Consumer Behavior—Evidence from China’s Stock Market. Front. Public Health 2022, 10, 865470. [Google Scholar] [CrossRef]

- Butu, A.; Brumă, I.S.; Tanasă, L.; Rodino, S.; Vasiliu, C.D.; Doboș, S.; Butu, M. The Impact of COVID-19 Crisis upon the Consumer Buying Behavior of Fresh Vegetables Directly from Local Producers. Case Study: The Quarantined Area of Suceava County, Romania. Int. J. Environ. Res. Public Health 2020, 17, 5485. [Google Scholar] [CrossRef] [PubMed]

- Ernawati, H.; Rudiyanto, A. Unveiling the Path to Sustainable Behavior in Tourism through a Systematic Literature Review. Asian J. Educ. Soc. Stud. 2023, 49, 498–514. [Google Scholar] [CrossRef]

- Das, D.; Sarkar, A.; Debroy, A. Impact of COVID-19 on changing consumer behaviour: Lessons from an emerging economy. Int. J. Consum. Stud. 2022, 46, 692–715. [Google Scholar] [CrossRef]

- Briedis, H.; Kronschnabl, A.; Rodriguez, A.; Ungerman, K. (2020, May 14). Adapting to the Next Normal in Retail: The Customer Experience Imperative. McKinsey & Company. Available online: https://www.mckinsey.com/industries/retail/our-insights/adapting-to-the-next-normal-in-retail-the-customer-experience-imperative (accessed on 15 January 2025).

- Maydanchi, M.; Ziaei, A.; Basiri, M.; Azad, A.N.; Pouya, S.; Ziaei, M.; Haji, F.; Sargolzaei, S. Comparative Study of Decision Tree, AdaBoost, Random Forest, Naïve Bayes, KNN, and Perceptron for Heart Disease Prediction. In Proceedings of the SoutheastCon 2023, Orlando, FL, USA, 1–16 April 2023; pp. 204–208. [Google Scholar] [CrossRef]

- Massabni, A.C.; Da Silva, G.J. Biotechnology and Industry 4.0: The professionals of the future. Int. J. Adv. Med. Biotechnol. IJAMB 2019, 2, 45–53. [Google Scholar] [CrossRef]

- Saraei, M.; Liu, S. Attention-based Deep Learning Approaches in Brain Tumor Image Analysis: A Mini Review. Front. Health Inform. 2023, 12, 164. [Google Scholar] [CrossRef]

- Oliveira, A.F.; Pessoa, A.C.S.N.; Bastos, R.G.; de la Torre, L.G. Microfluidic tools toward industrial biotechnology. Biotechnol. Prog. 2016, 32, 1372–1389. [Google Scholar] [CrossRef] [PubMed]

- Pervez, N.; Titus, A.J. Integrating MLSecOps in the Biotechnology Industry 5.0. In The Role of Cybersecurity in the Industry 5.0 Era; IntechOpen: London, UK, 2024. [Google Scholar] [CrossRef]

- Kang, H.S.; Exworthy, M. Wearing the Future—Wearables to Empower Users to Take Greater Responsibility for Their Health and Care: Scoping Review. JMIR mHealth uHealth 2022, 10, e35684. [Google Scholar] [CrossRef] [PubMed]

- Devi, U.A.; Venkateshwarlu, M.; Parvathi, D.; Ugandhar, T. Significance of Biotechnology in Promoting Energy and Food Industries: Exploring the Potential of Bio-based Products. Int. J. Multidiscip. Res. 2023, 5. [Google Scholar] [CrossRef]

- Meyer, V.; Basenko, E.Y.; Benz, J.P.; Braus, G.H.; Caddick, M.X.; Csukai, M.; De Vries, R.P.; Endy, D.; Frisvad, J.C.; Gunde-Cimerman, N.; et al. Growing a circular economy with fungal biotechnology: A white paper. Fungal Biol. Biotechnol. 2020, 7, 5. [Google Scholar] [CrossRef] [PubMed]

- Chazhaev, M. Economic potential of biotechnologies: Challenges and windows of opportunity. BIO Web Conf. 2023, 76, 10002. [Google Scholar] [CrossRef]

- Saraei, M.; Rahmani, S.; Rajebi, S.; Danishvar, S. A Different Traditional Approach for Automatic Comparative Machine Learning in Multimodality Covid-19 Severity Recognition. Int. J. Innov. Eng. 2023, 3, 1–12. [Google Scholar] [CrossRef]

- Ciao, B. Business founding in biotech industry: Process and features. Manag. Res. Rev. 2020, 43, 1183–1219. [Google Scholar] [CrossRef]

- Mahmood, S.S.; Sharma, P. Iot Based Industrial Automation using Zigbee Communication Standard. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 379–383. [Google Scholar] [CrossRef]

- Umma, N.I.; Utomo, Y. Development of Generator Set Product Services Using Quality Function Deployment at PT X. J. Sist. Tek. Ind. 2023, 25, 298–311. [Google Scholar] [CrossRef]

- Mbelekani, N.Y.; Bengler, K. Balancing Automation: Evaluating the Impacts of Landborne and Airborne Automation in Industry. In Proceedings of the 2023 International Conference on Electrical, Computer and Energy Technologies (ICECET), Cape Town, South Africa, 16–17 November 2023. [Google Scholar] [CrossRef]

- Dissanayake, N.; Xia, B.; Wu, P. Measuring Sustainability Performance Within the Australian Energy Industry. In Proceedings of the 19th International Symposium on Advancement of Construction Management and Real Estate; Springer: Berlin/Heidelberg, Germany, 2015; pp. 135–143. [Google Scholar] [CrossRef]

- Parekh, N.; Kurian, J.; Patil, R.; Gautam, R. A review on techno managerial approaches to energy optimization in chemical process industries. Front. Energy Res. 2023, 10, 1107912. [Google Scholar] [CrossRef]

- Woo, S.H.; Choi, M.S.; Duffy, V.G. Artificial Intelligence and Transportations on Road Safety: A Bibliometric Review. In HCI International 2023—Late Breaking Papers; Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Ehigiamusoe, K.U.; Ramakrishnan, S.; Lean, H.H.; Somasundram, S. Role of Energy Consumption on the Environmental Impact of Sectoral Growth in Malaysia. SAGE Open 2023, 13. [Google Scholar] [CrossRef]

- Cucchi, M.; Volpi, L.; Ferrari, A.M.; García-Muiña, F.E.; Settembre-Blundo, D. Industry 4.0 real-world testing of dynamic organizational life cycle assessment (O-LCA) of a ceramic tile manufacturer. Environ. Sci. Pollut. Res. 2022, 30, 124546–124565. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; He, R.; Wu, Q. A Novel Efficiency Measure Model for Industrial Land Use Based on Subvector Data Envelope Analysis and Spatial Analysis Method. Complexity 2017, 2017, 9516267. [Google Scholar] [CrossRef]

- Oke, J.A.; Abuel-Naga, H. Assessment of a Non-Destructive Testing Method Using Ultrasonic Pulse Velocity to Determine the Compressive Strength of Rubberized Bricks Produced with Lime Kiln Dust Waste. Geotechnics 2023, 3, 1294–1308. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable Construction Materials Using Agro-Wastes. Materials 2020, 13, 262. [Google Scholar] [CrossRef]

- Putra, R.D.; Dizaji, H.B.; Kulshresth, D.; Zeng, T.; Overmann, S.; Vollpracht, A. Characterisation of Bottom Ashes from Non-Woody Biomass Combustion for Application as Sustainable Supplementary Cementitious Material. Energies 2024, 17, 468. [Google Scholar] [CrossRef]

- Klinsrisuk, R.; Pechdin, W. Evidence from Thailand on Easing COVID-19’s International Travel Restrictions: An Impact on Economic Production, Household Income, and Sustainable Tourism Development. Sustainability 2022, 14, 3423. [Google Scholar] [CrossRef]

- Borges, R.J.; Carrera, L.A.I.; Bastida, E.J.L.; García-Martínez, J.R.; Carrillo-Serrano, R.V.; Rodríguez-Reséndiz, J. Energy Sustainability Indicators for the Use of Biomass as Fuel for the Sugar Industry. Technologies 2024, 12, 36. [Google Scholar] [CrossRef]

- Kumar, S.; Mallipeddi, R.R. Impact of cybersecurity on operations and supply chain management: Emerging trends and future research directions. Prod. Oper. Manag. 2022, 31, 4488–4500. [Google Scholar] [CrossRef]

- Kseniia, N.; Minbaleev, A. Legal support of cybersecurity in the field of application of artificial intelligence technology. In Proceedings of the 2020 International Conference Quality Management, Transport and Information Security, Information Technologies (IT&QM&IS), Yaroslavl, Russia, 7–11 September 2020; pp. 59–62. [Google Scholar] [CrossRef]

- Singh, T.; Johnston, A.C.; D’Arcy, J.; Harms, P.D. Stress in the cybersecurity profession: A systematic review of related literature and opportunities for future research. Organ. Cybersecur. J. Pract. Process People 2023, 3, 100–126. [Google Scholar] [CrossRef]

- Zohuri, B. AI Revolution: Safeguarding Tomorrow’s Frontiers—Transforming Cybersecurity Across Industries (A Short Approach). Curr. Trends Eng. Sci. (CTES) 2024, 4, 1057. [Google Scholar] [CrossRef]

- Ekechukwu, D.E.; Simpa, P. The importance of cybersecurity in protecting renewable energy investment: A strategic analysis of threats and solutions. Eng. Sci. Technol. J. 2024, 5, 1845–1883. [Google Scholar] [CrossRef]

- Obasi, S.C.; Solomon, N.O.; Adenekan, O.A.; Simpa, P. Cybersecurity’s Role in Environmental Protection and Sustainable Development: Bridging Technology and Sustainability Goals. Comput. Sci. IT Res. J. 2024, 5, 1145–1177. [Google Scholar] [CrossRef]

- Layode, O.; Naiho, H.N.N.; Labake, T.T.; Adeleke, G.S.; Udeh, E.O.; Johnson, E. Addressing Cybersecurity Challenges in Sustainable Supply Chain Management: A Review of Current Practices and Future Directions. Int. J. Manag. Entrep. Res. 2024, 6, 1954–1981. [Google Scholar] [CrossRef]

- Khan, M.; Ahmad, A.; Sobieczky, F.; Pichler, M.; Moser, B.A.; Bukovsky, I. A Systematic Mapping Study of Predictive Maintenance in SMEs. IEEE Access 2022, 10, 88738–88749. [Google Scholar] [CrossRef]

- Malomane, R.; Musonda, I.; Okoro, C.S. The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety. Int. J. Environ. Res. Public Health 2022, 19, 846. [Google Scholar] [CrossRef]

- Wichienrat, W.; Surisaeng, T.; Sa-Ard-Iam, N.; Chanamuangkon, T.; Mahanonda, R.; Wisitrasameewong, W. Alveolar Bone Loss in a Ligature-Induced Periodontitis Model in Rat Using Different Ligature Sizes. Eur. J. Dent. 2024, 18, 933–941. [Google Scholar] [CrossRef]

- Kihara, Y.; Takeda, Y.; Ohmura, Y.; Katsura, Y.; Shinke, G.; Kinoshita, M.; Aoyama, S.; Yanagisawa, K.; Katsuyama, S.; Ikeshima, R.; et al. Minimally invasive liver resection for cholangiolocellular carcinoma: A single-institution experience. Asian J. Endosc. Surg. 2024, 17, e13272. [Google Scholar] [CrossRef]

- Muwanguzi, E.; Oboi, J.E.; Nabbamba, A.; Wanyama, R. Treatment outcome and associated factors for severely malnourished children (1–5 years) admitted to Lacor Hospital and Gulu Regional Referral Hospital in Uganda. J. Nutr. Sci. 2021, 10, e33. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Truong, Q.T.T.; Valčo, M.; Khvatova, M.A.; Tyazhelnikov, A.A. Christian Theological Views on Industrial Revolutions and Related Ethical Challenges: A Western (And a Global) Perspective. Bogosl. Vestnik 2020, 80, 177–190. [Google Scholar] [CrossRef]

- Denuwara, N.; Kim, A.; Atree, V.; Newenhisen, P.; Gibson, C.; Schork, D.; Hakovirta, M. Corporate economic performance and sustainability indices: A study based on the Dow Jones Sustainability Index. SN Bus. Econ. 2022, 2, 77. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, M.T.; Sepanloo, K.; Woo, S.; Woo, S.H.; Son, Y.-J. A Review of the Industry 4.0 to 5.0 Transition: Exploring the Intersection, Challenges, and Opportunities of Technology and Human–Machine Collaboration. Machines 2025, 13, 267. https://doi.org/10.3390/machines13040267

Islam MT, Sepanloo K, Woo S, Woo SH, Son Y-J. A Review of the Industry 4.0 to 5.0 Transition: Exploring the Intersection, Challenges, and Opportunities of Technology and Human–Machine Collaboration. Machines. 2025; 13(4):267. https://doi.org/10.3390/machines13040267

Chicago/Turabian StyleIslam, Md Tariqul, Kamelia Sepanloo, Seonho Woo, Seung Ho Woo, and Young-Jun Son. 2025. "A Review of the Industry 4.0 to 5.0 Transition: Exploring the Intersection, Challenges, and Opportunities of Technology and Human–Machine Collaboration" Machines 13, no. 4: 267. https://doi.org/10.3390/machines13040267

APA StyleIslam, M. T., Sepanloo, K., Woo, S., Woo, S. H., & Son, Y.-J. (2025). A Review of the Industry 4.0 to 5.0 Transition: Exploring the Intersection, Challenges, and Opportunities of Technology and Human–Machine Collaboration. Machines, 13(4), 267. https://doi.org/10.3390/machines13040267