Performance Gain of Collaborative Versus Sequential Motion in Modular Robotic Manipulators for Pick-and-Place Operations

Abstract

1. Introduction

- The potential time gain when using collaborative motion compared to sequential motion is quantified using realistic multi-body motion simulations.

- Experimental validation of this time gain is provided on a linear track + 6-DOF robotic arm system with a pick-and-place use case.

- The corresponding gain in energy savings is quantified and validated.

- A software architecture for control and perception is presented, based on open-source components, which enables collaborative motion in modular mechatronic systems.

2. Control and Sensing Architecture

2.1. World Model

2.2. Optimal Trajectory Planner

- The combined kinematic model of the top sliding platform and robot arm;

- Position, velocity, acceleration, and jerk limits of the top platform and robot joints;

- Collision avoidance based on capsule–capsule distances;

- A boundary constraint for the initial configuration q and its derivative of the robot and top platform;

- Boundary constraints of all joint accelerations and jerks being zero at the start and end of the planning horizon.

- 6.

- Boundary constraint matching the target’s extrapolated position and orientation with that of the gripper at the end of the planning horizon.

2.3. Low-Level Controller

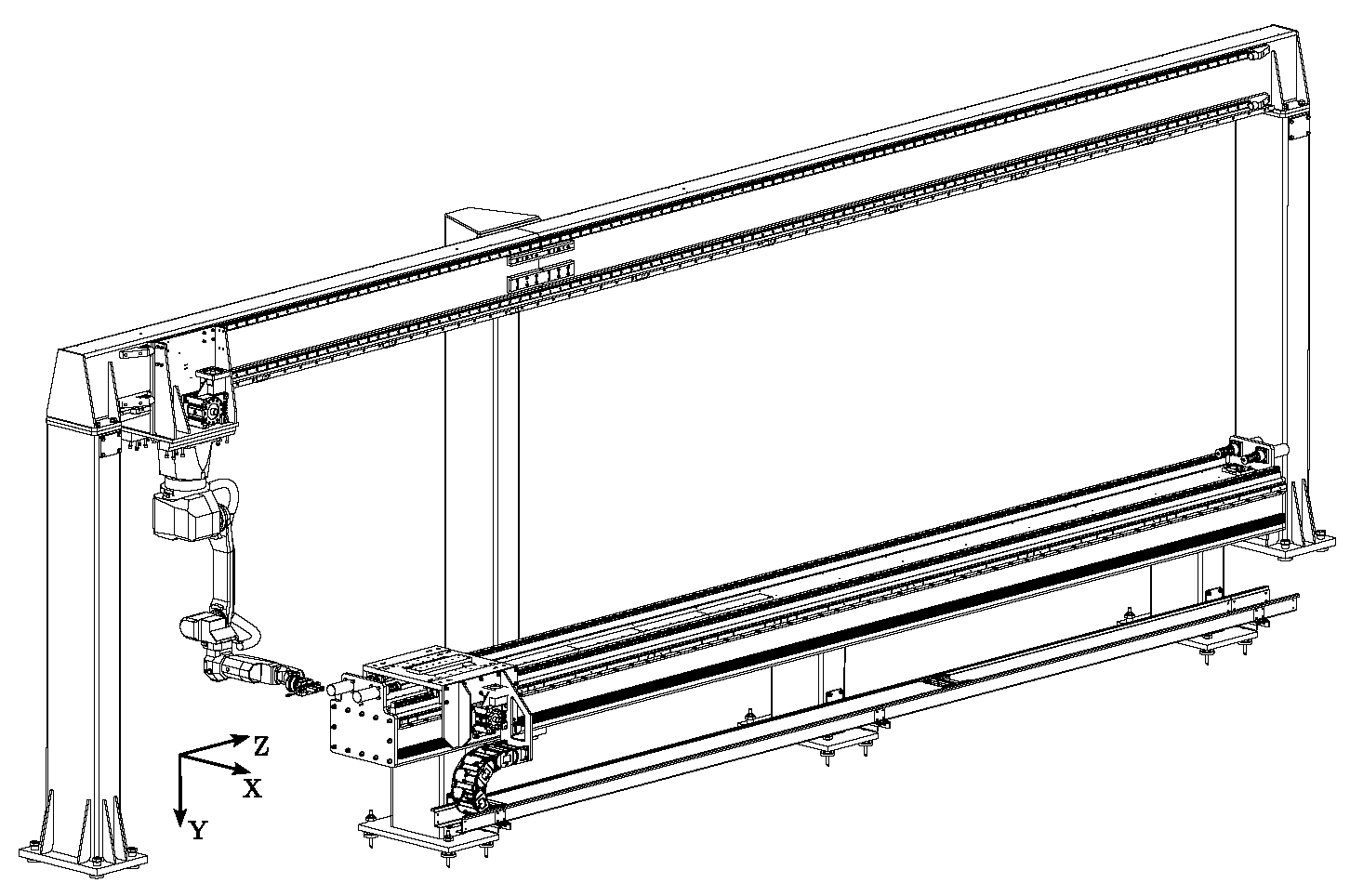

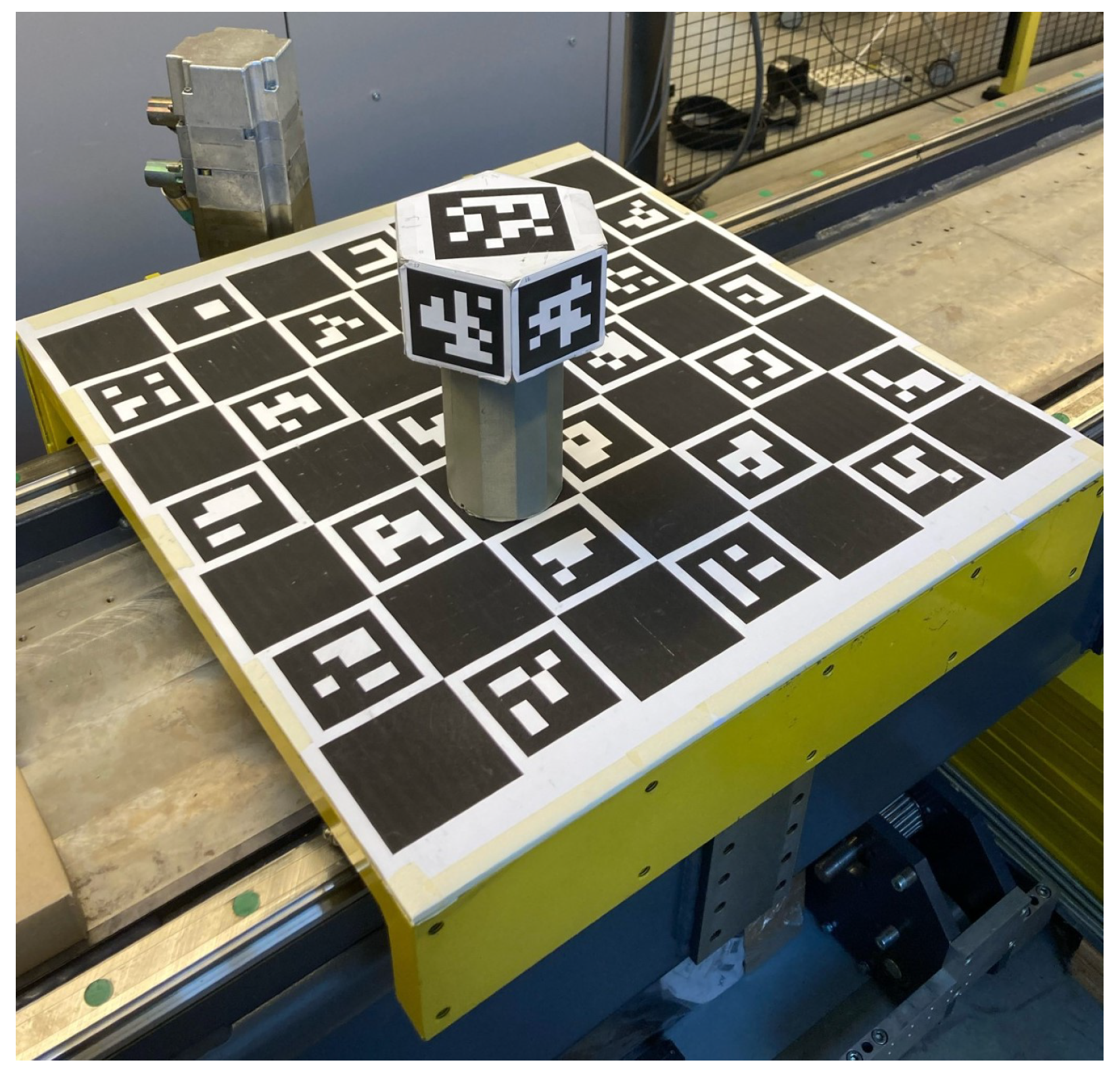

3. Setup Description

3.1. Simulation Model

3.2. Experimental Setup

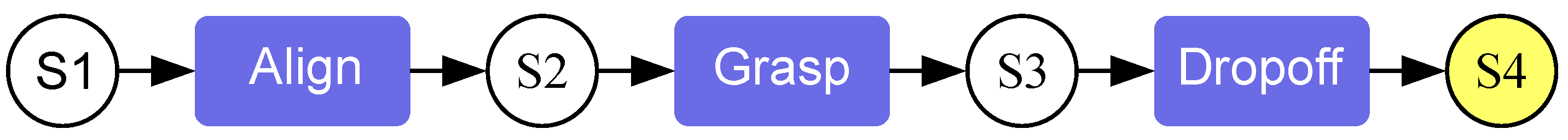

4. Use-Case Description

5. Results and Discussion

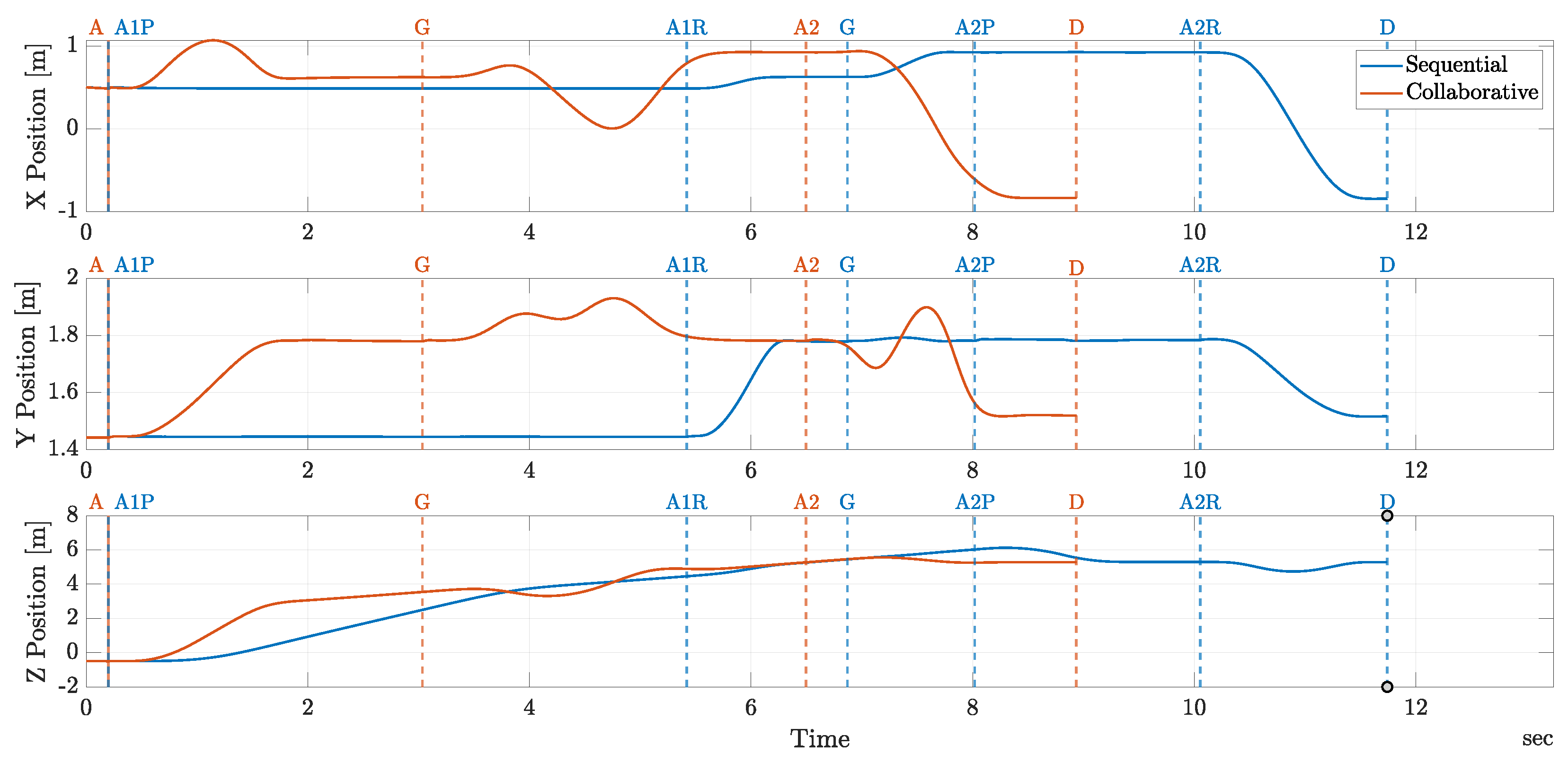

5.1. Simulation Results

5.1.1. Singular Case Study

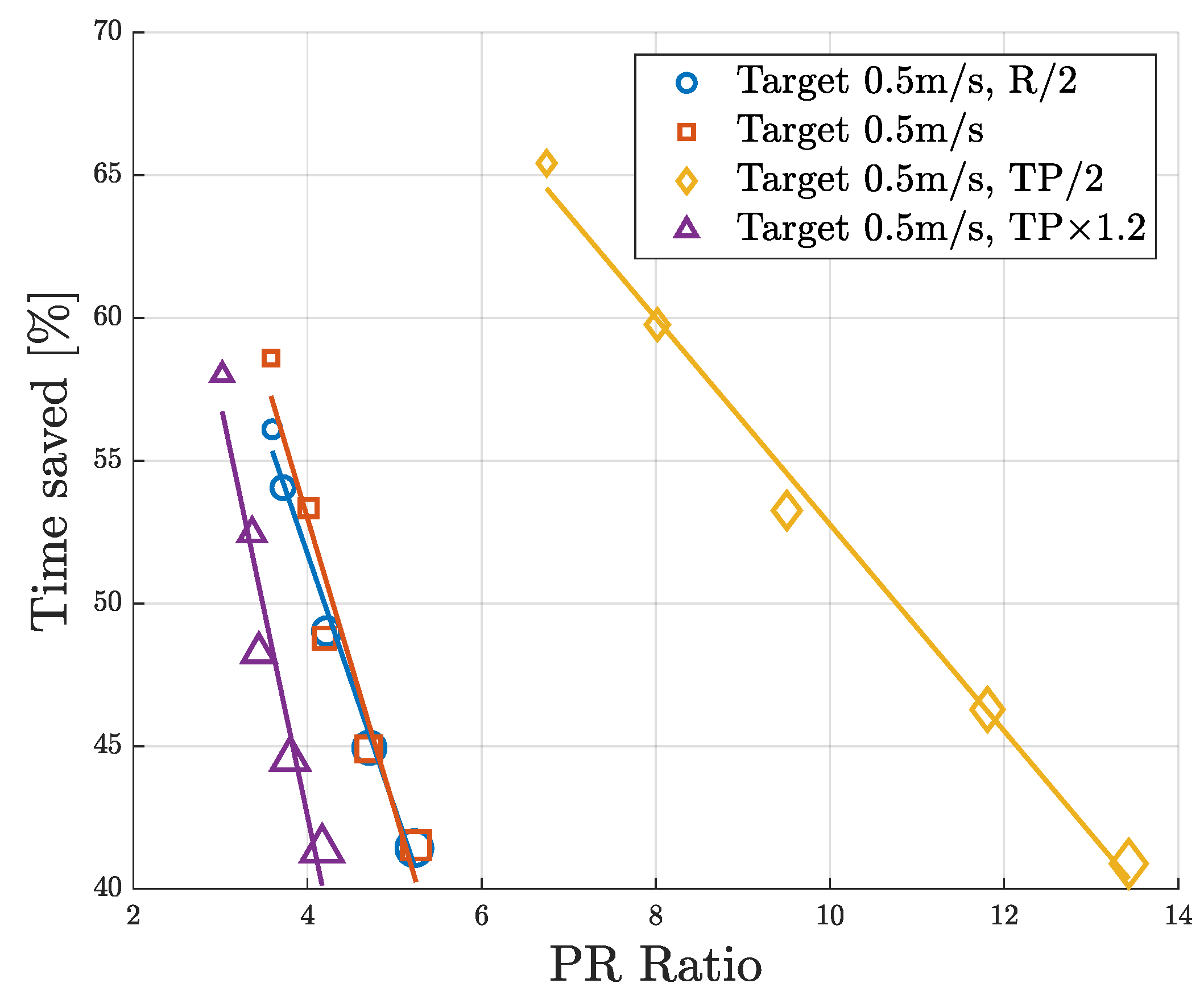

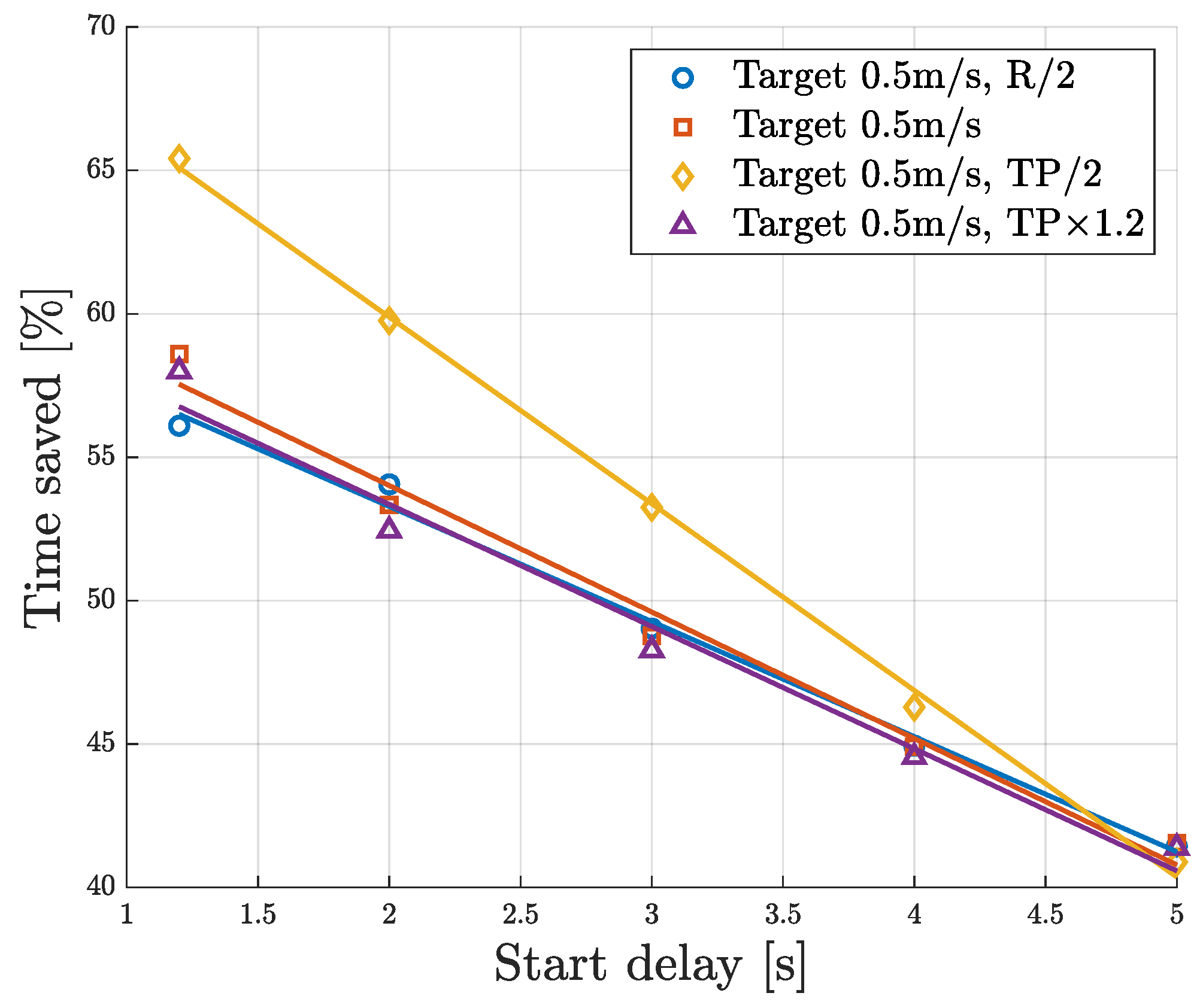

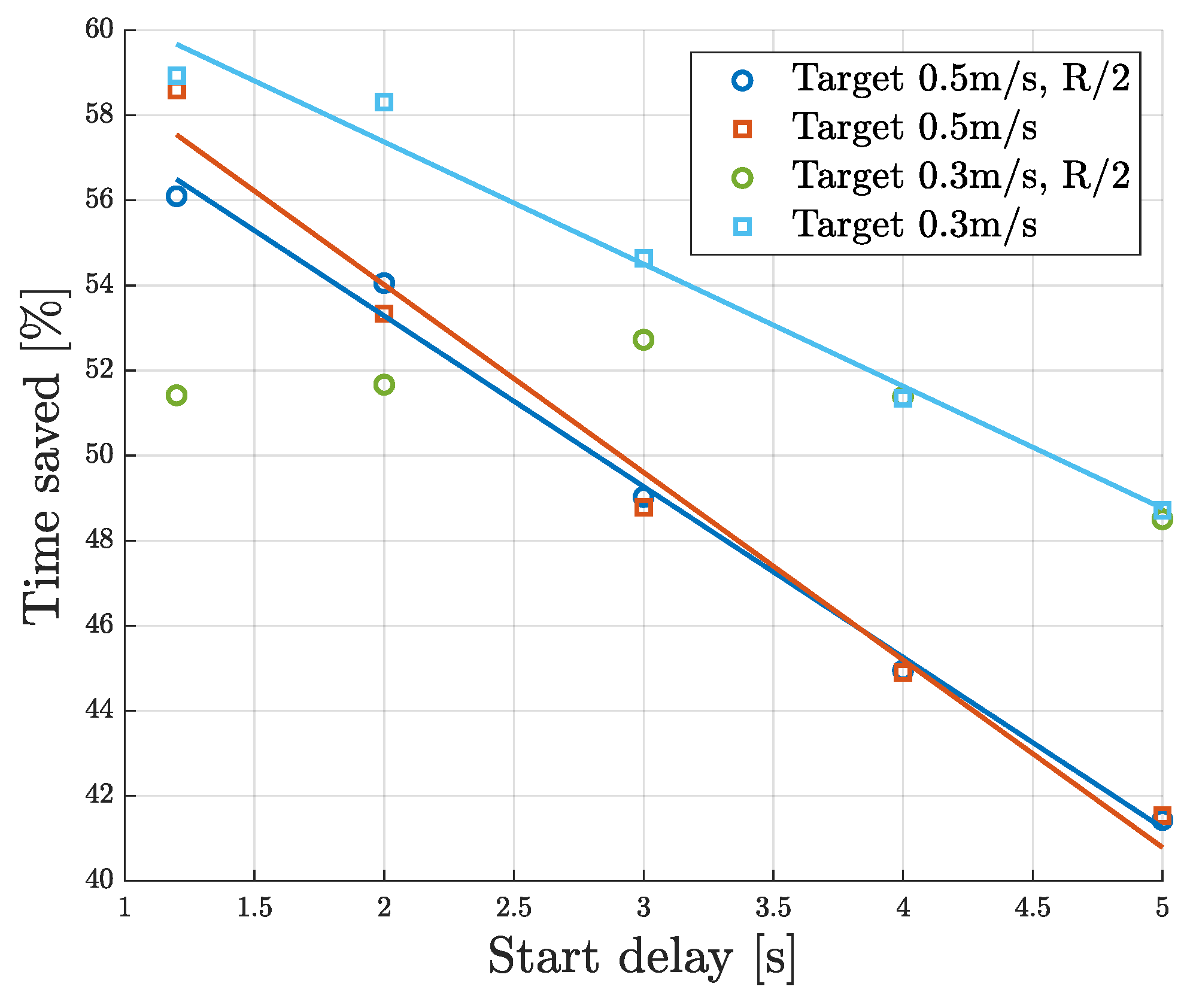

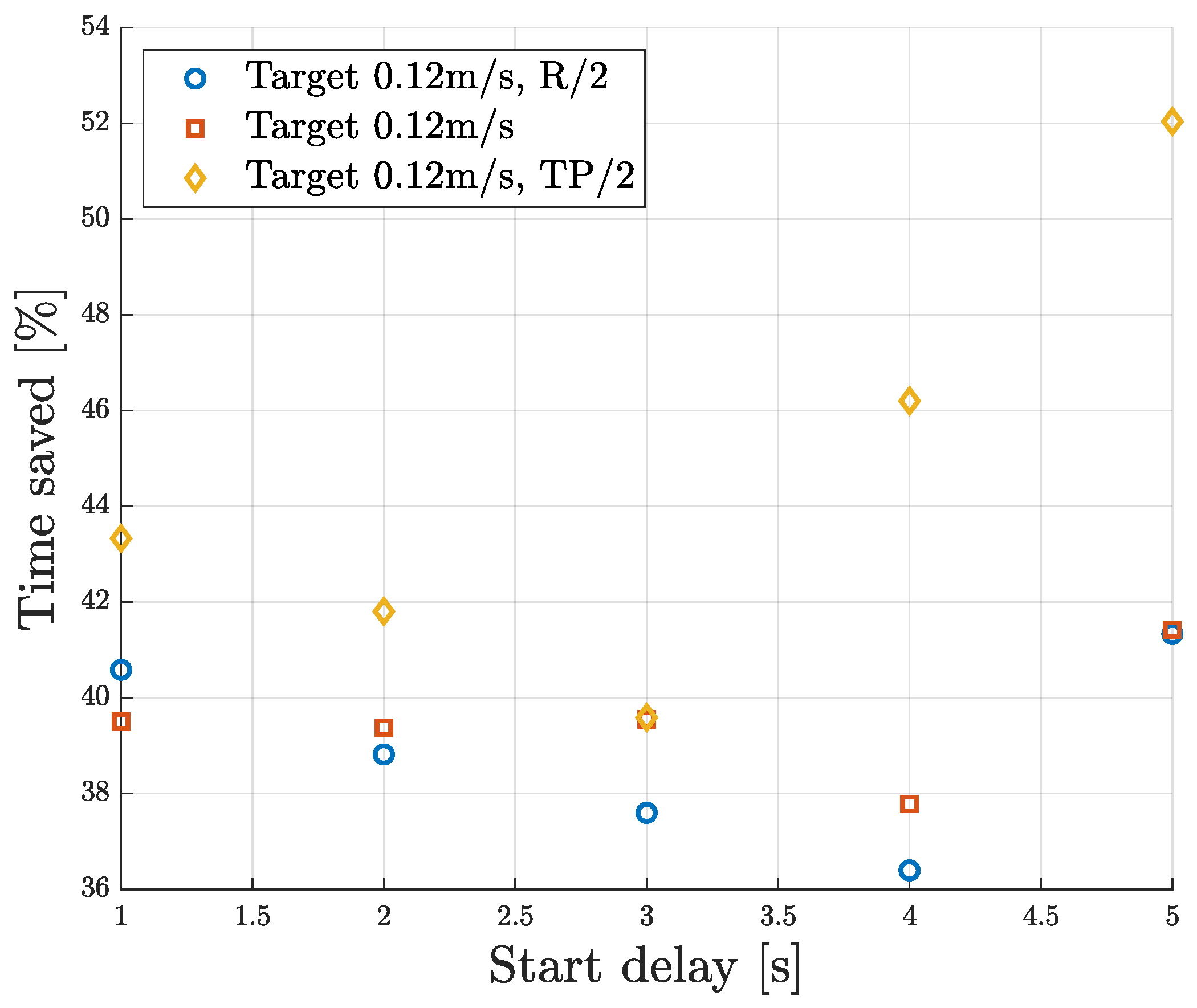

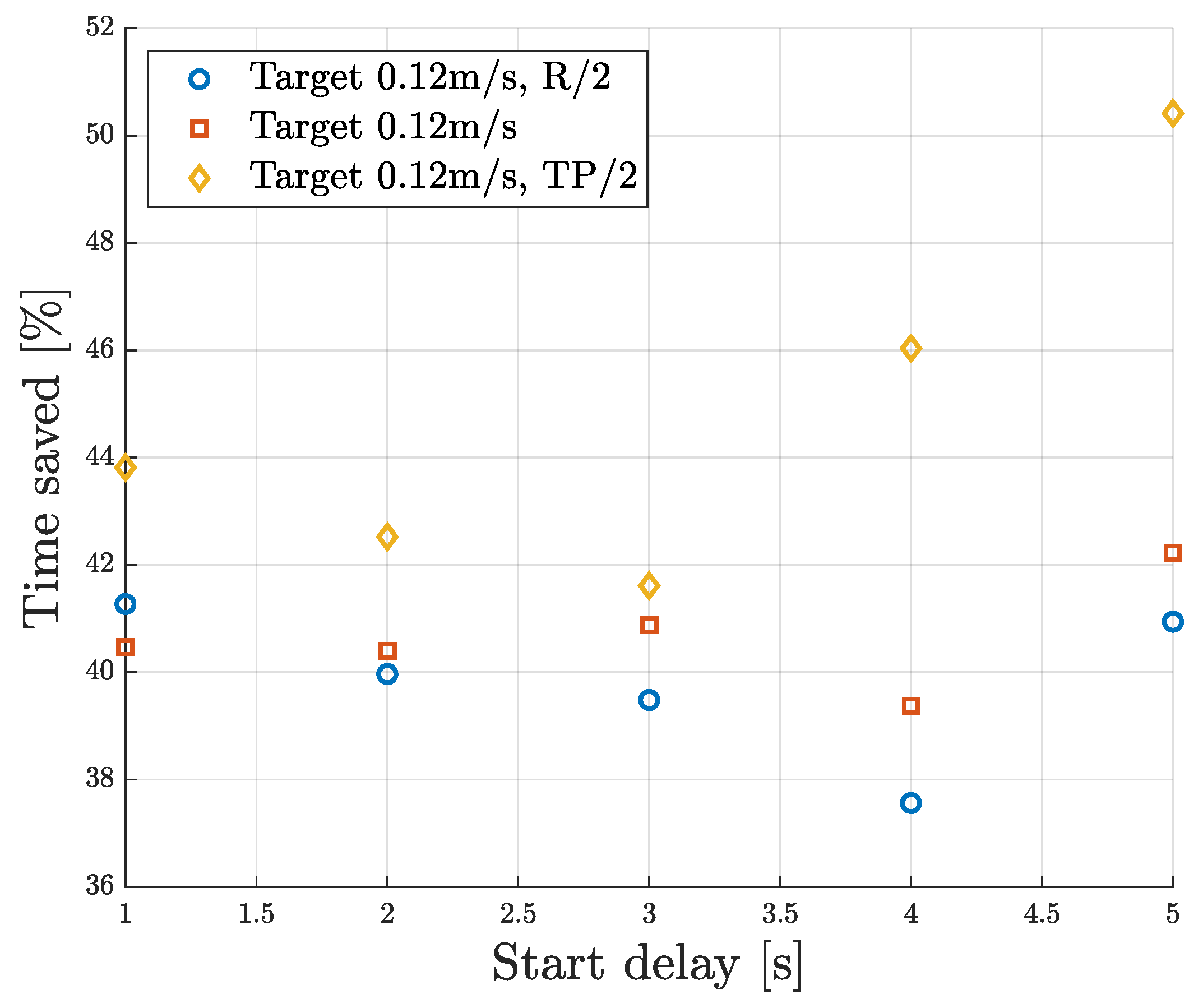

5.1.2. Sensitivity Analysis on Time Savings

5.2. Experimental Results

5.2.1. Analysis of Task Execution Time

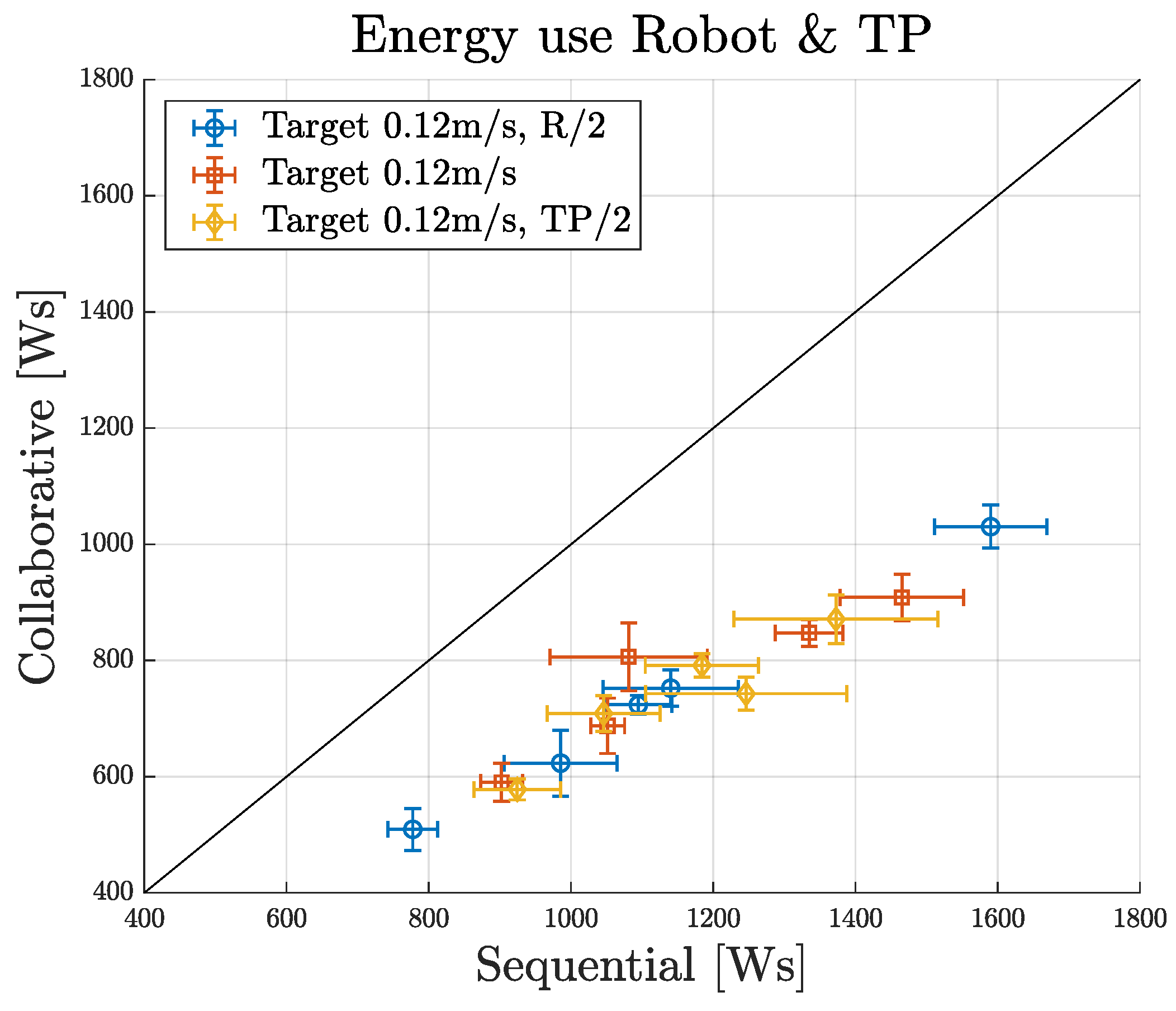

5.2.2. Energy Sustainability Study

- is the simulation timestep;

- ;

- N is the number of timesteps for a sub-task.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rikalovic, A.; Suzic, N.; Bajic, B.; Piuri, V. Industry 4.0 Implementation Challenges and Opportunities: A Technological Perspective. IEEE Syst. J. 2022, 16, 2797–2810. [Google Scholar] [CrossRef]

- Zou, Y.; Kim, D.; Norman, P.; Espinosa, J.; Wang, J.C.; Virk, G.S. Towards robot modularity—A review of international modularity standardization for service robots. Robot. Auton. Syst. 2022, 148, 103943. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Narwane, V.S.; Narkhede, B.E. Applications of industry 4.0 to overcome the COVID-19 operational challenges. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 1283–1289. [Google Scholar] [CrossRef]

- Sundarkumar, V.; Wang, W.; Mills, M.; Oh, S.W.; Nagy, Z.; Reklaitis, G. Developing a Modular Continuous Drug Product Manufacturing System with Real Time Quality Assurance for Producing Pharmaceutical Mini-Tablets. J. Pharm. Sci. 2024, 113, 937–947. [Google Scholar] [CrossRef] [PubMed]

- Riesener, M.; Kuhn, M.; Boßmann, C.; Schuh, G. Methodology for the Design of Interdisciplinary Modules for Mechatronic Modular Product Platforms. Procedia CIRP 2023, 119, 675–680. [Google Scholar] [CrossRef]

- Janssen, L.A.L.; Fey, R.H.B.; Besselink, B.; Wouw, N.v. Modular redesign of mechatronic systems: Formulation of module specifications guaranteeing system dynamics specifications. Mechatronics 2024, 103, 103236. [Google Scholar] [CrossRef]

- Seidenberg, T.; Disselkamp, J.-P.; Jürgenhake, C.; Grobbel, D.; Dumitrescu, R.; Papanikolaou, A. Development of a modular architecture for complex mechatronic systems. In Proceedings of the 33rd CIRP Design Conference, Sydney, Australia, 17–19 March 2023. [Google Scholar]

- Grosz, E.A.; Borzan, M. Modular Robotics Configurator: A MATLAB Model-Based Development Approach. Appl. Syst. Innov. 2024, 8, 21. [Google Scholar] [CrossRef]

- Choi, L.; Choi, M.; Kwon, S.; Youn, D.; Song, G. Modular production of small ship models using 3D printing for model tests. Ocean. Eng. 2024, 302, 117685. [Google Scholar] [CrossRef]

- Kern, W.; Rusitschka, F.; Bauernhansl, T. Planning of Workstations in a Modular Automotive Assembly System. Procedia CIRP 2016, 57, 327–332. [Google Scholar] [CrossRef]

- Hossain, M.S.; Chakrabortty, R.K.; Elsawah, S.; Ryan, M.J. Hierarchical joint optimization of modular product family and supply chain architectures considering sustainability. Sustain. Prod. Consum. 2023, 43, 15–33. [Google Scholar] [CrossRef]

- Wang, X.; Liu, W.; Wu, Q.; Li, S. A Modular Optimal Formation Control Scheme of Multiagent Systems With Application to Multiple Mobile Robots. IEEE Trans. Ind. Electron. 2023, 69, 9331–9341. [Google Scholar] [CrossRef]

- Mo, F.; Rehman, H.U.; Monetti, F.M.; Chaplin, J.C.; Sanderson, D.; Popov, A.; Maffei, A.; Ratchev, S. A framework for manufacturing system reconfiguration and optimisation utilising digital twins and modular artificial intelligence. Robot. Comput. Integr. Manuf. 2023, 82, 102524. [Google Scholar] [CrossRef]

- Gros, J.; Zatyagov, D.; Papa, M.; Colloseus, C.; Ludwig, S.; Aschenbrenner, D. Unlocking the Benefits of Mobile Manipulators for Small and Medium-Sized Enterprises: A Comprehensive Study. Procedia CIRP 2023, 120, 1339–1344. [Google Scholar] [CrossRef]

- Amertet, S.; Gebresenbet, G.; Alwan, H.M. Optimizing the performance of a wheeled mobile robots for use in agriculture using a linear-quadratic regulator. Robot. Auton. Syst. 2024, 174, 104642. [Google Scholar] [CrossRef]

- Sayar, E.; Gao, X.; Hu, Y.; Chen, G.; Knoll, A. Toward coordinated planning and hierarchical optimization control for highly redundant mobile manipulator. ISA Trans. 2024, 146, 16–28. [Google Scholar] [CrossRef] [PubMed]

- Ye, L.; Wu, F.; Zou, X.; Li, J. Path planning for mobile robots in unstructured orchard environments: An improved kinematically constrained bi-directional RRT approach. Comput. Electron. Agric. 2023, 215, 108453. [Google Scholar] [CrossRef]

- Ristevski, S.; Cakmakci, M. Planar motion controller design for a modular mechatronic device with heading compensation. Mechatronics 2019, 62, 102257. [Google Scholar] [CrossRef]

- Jiang, Z.; Chen, Z.; Xu, K.; Shi, L. Distributed collaborative control to pose tracking for six-DOF parallel mechanism under multi-cylinder communication. ISA Trans. 2025, 159, 312–325. [Google Scholar] [CrossRef]

- Sekban, H.T.; Basci, A. Designing New Model-Based Adaptive Sliding Mode Controllers for Trajectory Tracking Control of an Unmanned Ground Vehicle. IEEE Access 2023, 11, 101387–101397. [Google Scholar] [CrossRef]

- Liu, W.; Liu, C.; Liang, X.; Zheng, M. A hybrid task-constrained motion planning for collaborative robots in intelligent remanufacturing. Mechatronics 2024, 102, 103222. [Google Scholar] [CrossRef]

- Saeed, M.; Demasure, T.; El-Houssaine, A.; Cottyn, J. Optimization-based estimation of the execution time of a robotic assembly task sequence. Int. J. Adv. Manuf. Technol. 2024, 130, 5315–5328. [Google Scholar] [CrossRef]

- Peta, K.; Wiśniewski, M.; Kotarski, M.; Ciszak, O. Comparison of Single-Arm and Dual-Arm Collaborative Robots in Precision Assembly. Appl. Sci. 2025, 15, 2976. [Google Scholar] [CrossRef]

- Angleraud, A.; Mehman Sefat, A.; Netzev, M.; Pieters, R. Coordinating Shared Tasks in Human-Robot Collaboration by Commands. Front. Robot. AI 2021, 8, 734548. [Google Scholar] [CrossRef] [PubMed]

- Calvo, R.; Gil, P. Evaluation of Collaborative Robot Sustainable Integration in Manufacturing Assembly by Using Process Time Savings. Materials 2022, 15, 611. [Google Scholar] [CrossRef]

- Papanastasiou, S.; Kousi, N.; Karagiannis, P.; Gkournelos, C.; Papavasileiou, A.; Dimoulas, K.; Baris, K.; Koukas, S.; Michalos, G.; Makris, S. Towards seamless human robot collaboration: Integrating multimodal interaction. Int. J. Adv. Manuf. Technol. 2019, 105, 3881–3897. [Google Scholar] [CrossRef]

- Polonara, M.; Romagnoli, A.; Biancini, G.; Carbonari, L. Introduction of Collaborative Robotics in the Production of Automotive Parts: A Case Study. Machines 2024, 12, 196. [Google Scholar] [CrossRef]

- Polonara, M.; Carbonari, L.; Romagnoli, A.; Biancini, G. Collaborative Mobile Robotics for SMEs: A Case Study. In Proceedings of the 2024 20th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Genova, Italy, 2–4 September 2024. [Google Scholar]

- Faccio, M.; Bottin, M.; Rosati, G. Collaborative and traditional robotic assembly: A comparison model. Int. J. Adv. Manuf. Technol. 2019, 102, 1355–1372. [Google Scholar] [CrossRef]

- Carlier, R.; Gillis, J.; Rademakers, E.; Borghesan, G.; Clercq, P.D.; Ganseman, C.; Stockman, K.; Kooning, J.D.M.D. A Digital Twin Framework for Virtual Re-Commissioning of Work-Drive Systems Using CAD-based Motion Co-Simulation. In Proceedings of the 2023 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Seattle, WA, USA, 28–30 June 2023. [Google Scholar]

- Gillis, J.; Vandewal, B.; Pipeleers, G.; Swevers, J. Effortless modeling of optimal control problems with rockit. In Proceedings of the 39th Benelux Meeting on Systems and Control, Elspeet, The Netherlands, 10–12 March 2020. [Google Scholar]

- Andersson, J.A.E.; Gillis, J.; Horn, G.; Rawlings, J.B.; Diehl, M. CasADi–A software framework for nonlinear optimization and optimal control. Math. Program. Comput. 2019, 11, 1–36. [Google Scholar] [CrossRef]

- Gillis, J.; Pipeleers, G.; Swevers, J. Effortless modeling of optimal control problems with rockit. In Proceedings of the 41st Benelux Meeting on Systems and Control, Brussels, Belgium, 5–7 December 2020. [Google Scholar]

- Wächter, A.; Biegler, L.T. On the implementation of an interior-point filter line-search algorithm for large-scale nonlinear programming. Math. Program. 2006, 106, 25–57. [Google Scholar] [CrossRef]

| DOF | Gearbox Ratio | Max Torque [N m] | Max Speed [°/s] |

|---|---|---|---|

| Robot | 118 | 230 | |

| 135 | 225 | ||

| 131 | 230 | ||

| 14 | 430 | ||

| 54 | 430 | ||

| 41 | 630 | ||

| Gearbox Ratio | Max Torque [N m] | Max Speed [m/s] | |

| TP |

| Environment | Case | BP [m/s] | TP Start [s] | Robot | TP |

|---|---|---|---|---|---|

| Sim. | 1–5 | 1.2–5 | 1 | ||

| 6–10 | 1.2–5 | 1 | 1 | ||

| 11–15 | 1.2–5 | 1 | |||

| 16–20 | 1.2–5 | 1 | |||

| 21–25 | 1.2–5 | 1 | |||

| 26–30 | 1.2–5 | 1 | 1 | ||

| Exp. | 1–5 | 1–5 | 1 | 1 | |

| 6–10 | 1–5 | 1 | |||

| 11–15 | 1–5 | 1 |

| Task | Mean [s] | [s] | [%] |

|---|---|---|---|

| Align 1 | |||

| Grip | |||

| Align 2 | |||

| Total | |||

| Task | Mean [s] | [s] | [%] |

| Align 1P | |||

| Align 1R | |||

| Grip | |||

| Align 2P | |||

| Align 2R | |||

| Total |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carlier, R.; Gillis, J.; De Clercq, P.; Borghesan, G.; Stockman, K.; De Kooning, J.D.M. Performance Gain of Collaborative Versus Sequential Motion in Modular Robotic Manipulators for Pick-and-Place Operations. Machines 2025, 13, 348. https://doi.org/10.3390/machines13050348

Carlier R, Gillis J, De Clercq P, Borghesan G, Stockman K, De Kooning JDM. Performance Gain of Collaborative Versus Sequential Motion in Modular Robotic Manipulators for Pick-and-Place Operations. Machines. 2025; 13(5):348. https://doi.org/10.3390/machines13050348

Chicago/Turabian StyleCarlier, Remy, Joris Gillis, Pieter De Clercq, Gianni Borghesan, Kurt Stockman, and Jeroen D. M. De Kooning. 2025. "Performance Gain of Collaborative Versus Sequential Motion in Modular Robotic Manipulators for Pick-and-Place Operations" Machines 13, no. 5: 348. https://doi.org/10.3390/machines13050348

APA StyleCarlier, R., Gillis, J., De Clercq, P., Borghesan, G., Stockman, K., & De Kooning, J. D. M. (2025). Performance Gain of Collaborative Versus Sequential Motion in Modular Robotic Manipulators for Pick-and-Place Operations. Machines, 13(5), 348. https://doi.org/10.3390/machines13050348