Determining the Range of Applicability of Analytical Methods for Belleville Springs and Novel Approach of Calculating Quasi-Progressive Spring Stacks

Abstract

1. Introduction

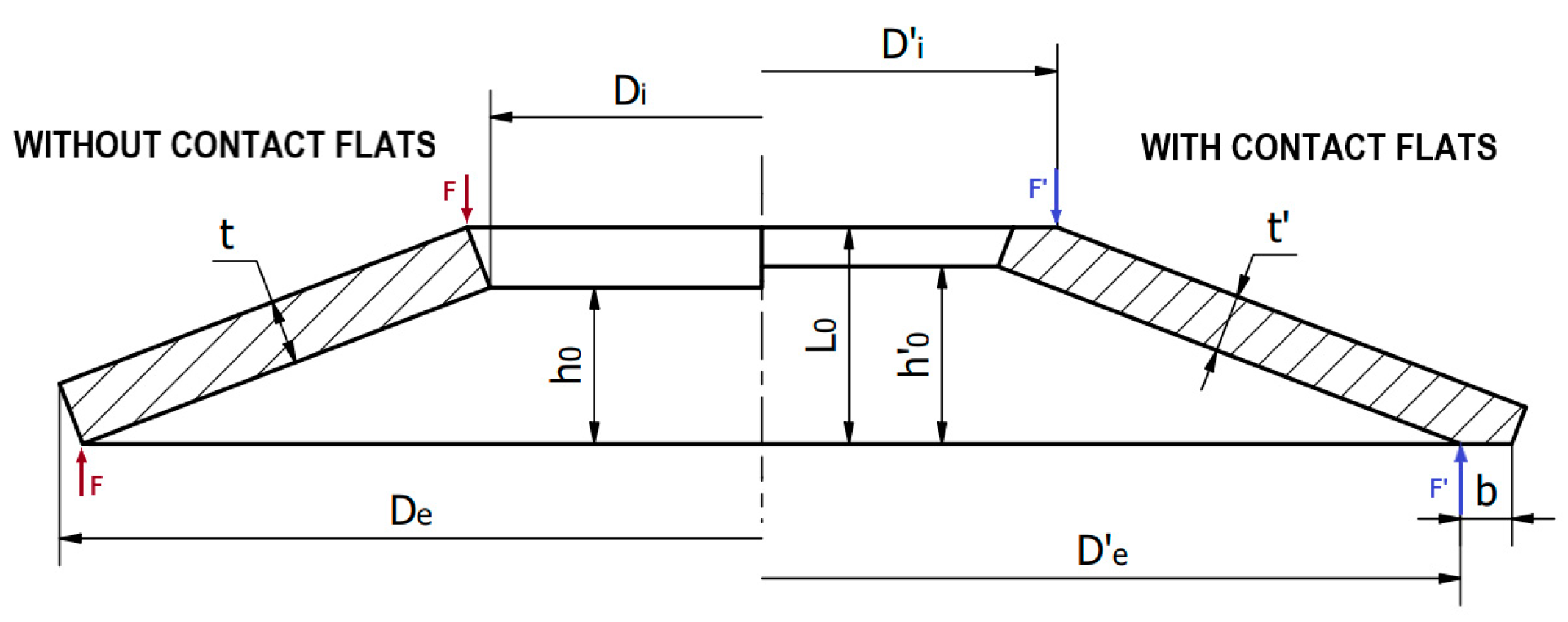

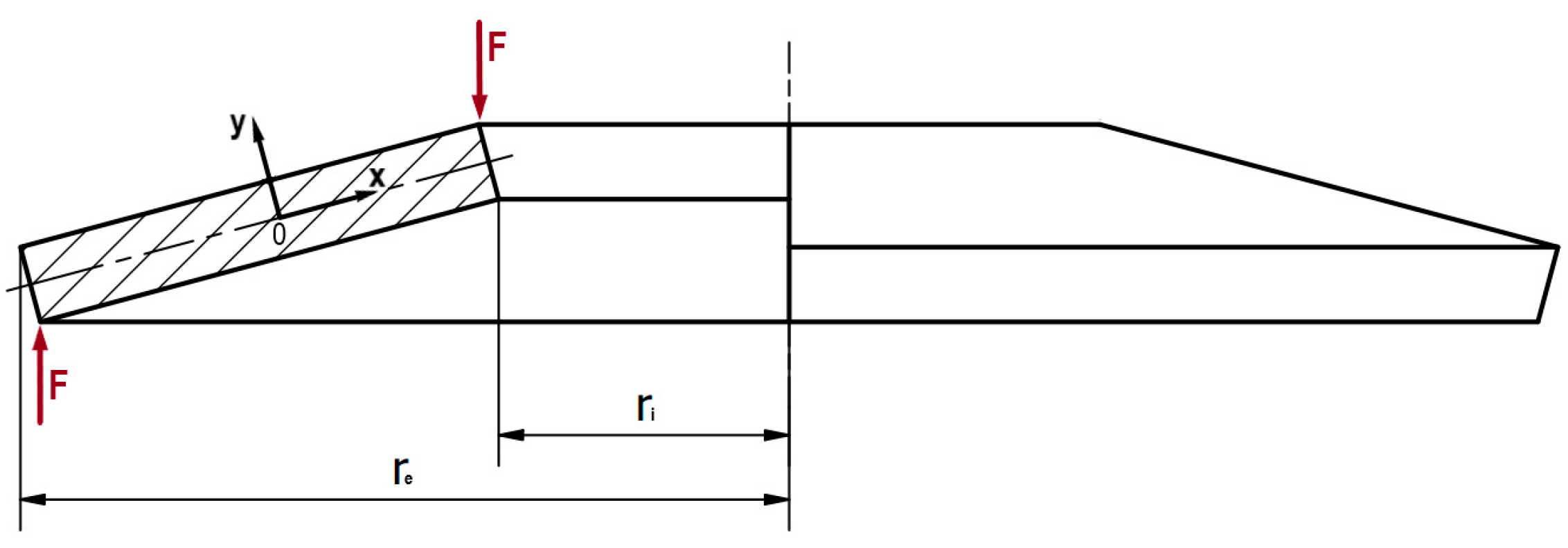

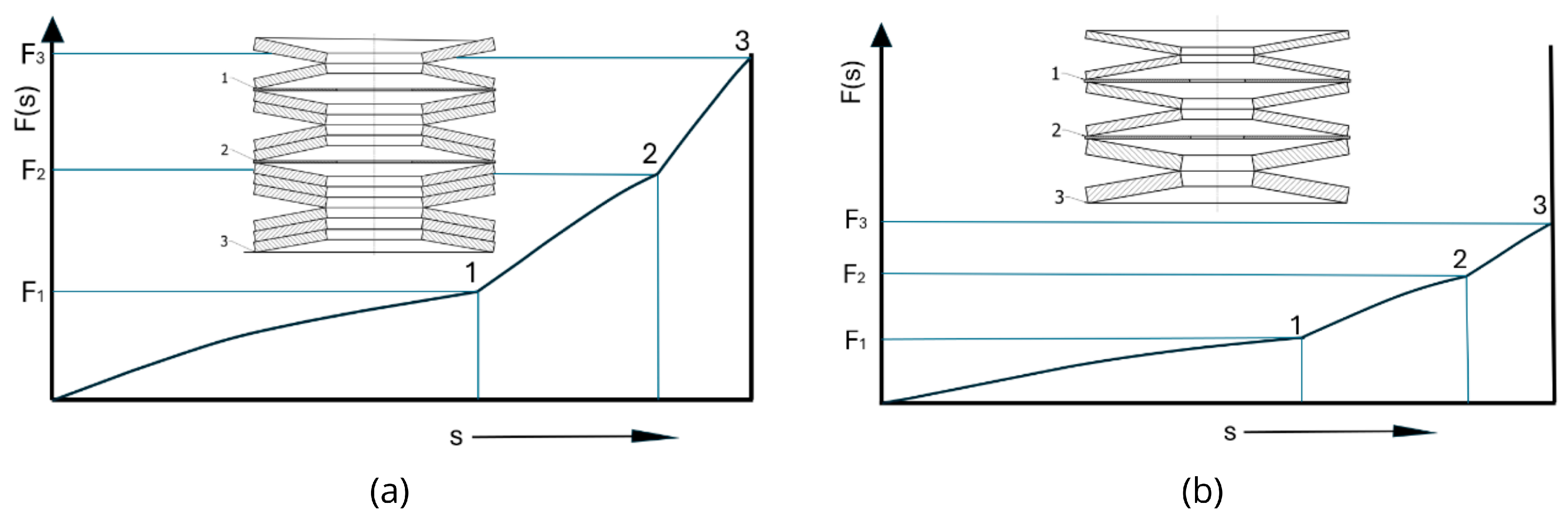

2. Structures and Characteristics of Belleville Springs

3. Analytical Models

3.1. Almen and László Method

3.2. Zheng Method

3.3. DIN 2092 Method

3.4. Giammarco Ferrari Method

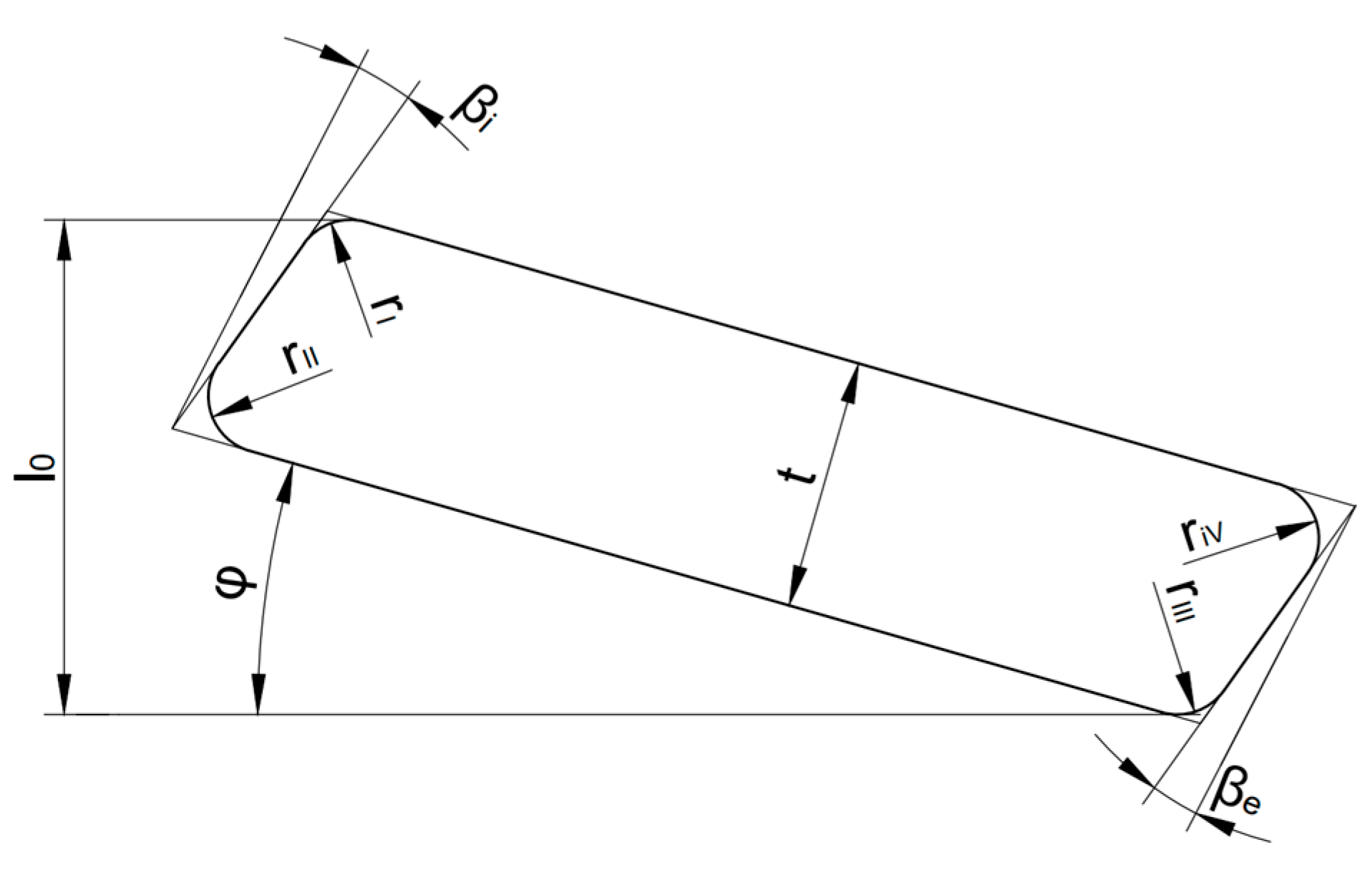

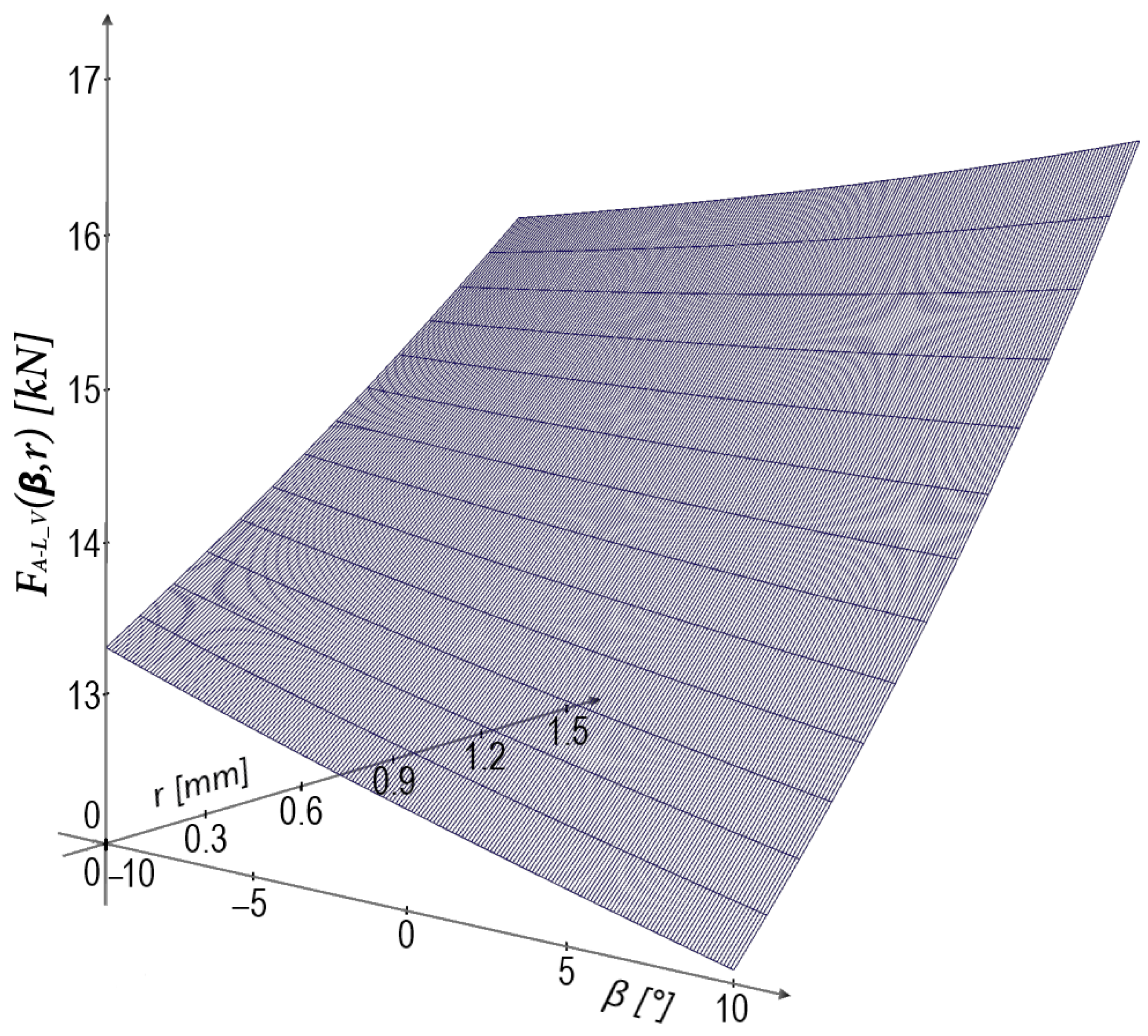

3.5. Leininger Method

3.6. Stacking Belleville Springs

3.7. Stacking Belleville Springs to Obtain Progressive Characteristics

3.8. Friction in Belleville Springs

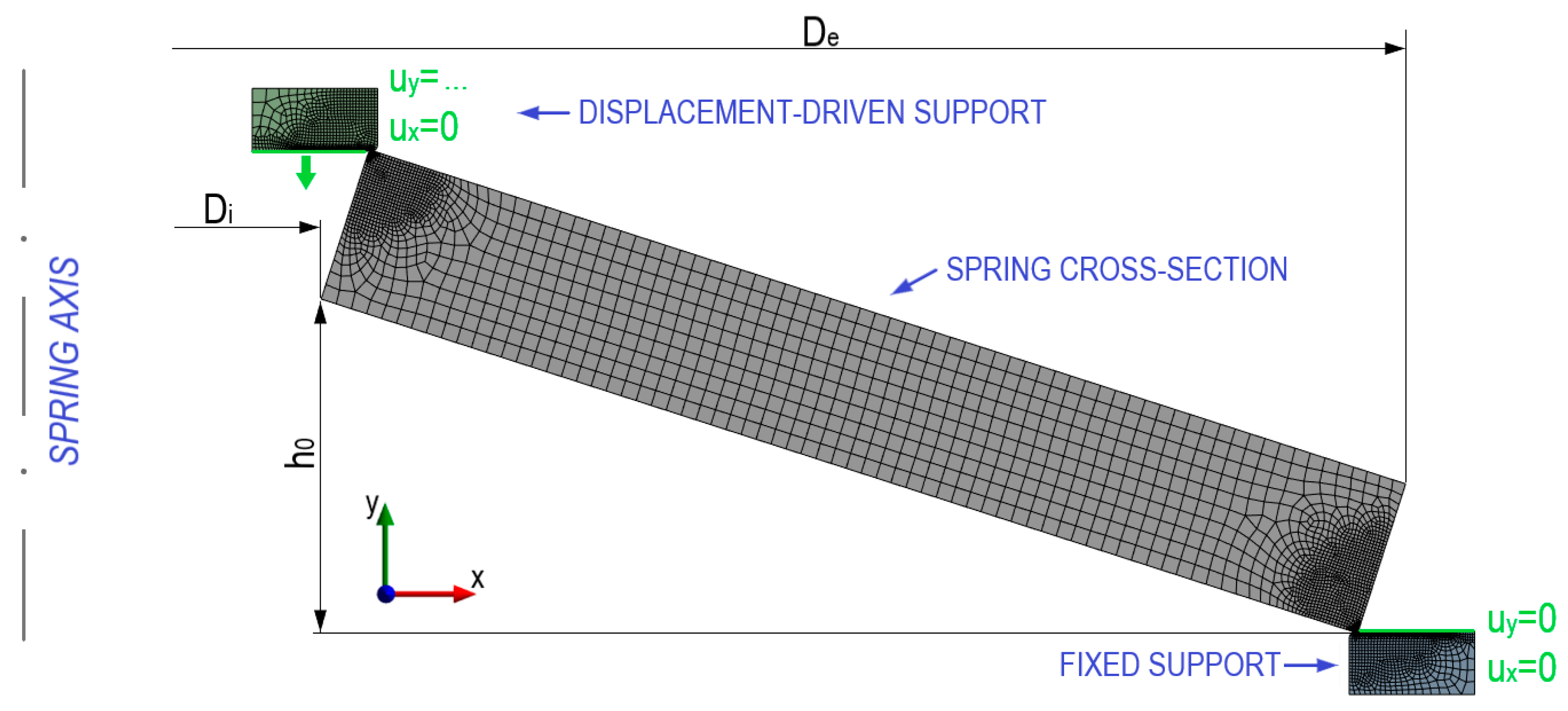

4. FEA Verification

Mesh Independence Study

5. Results

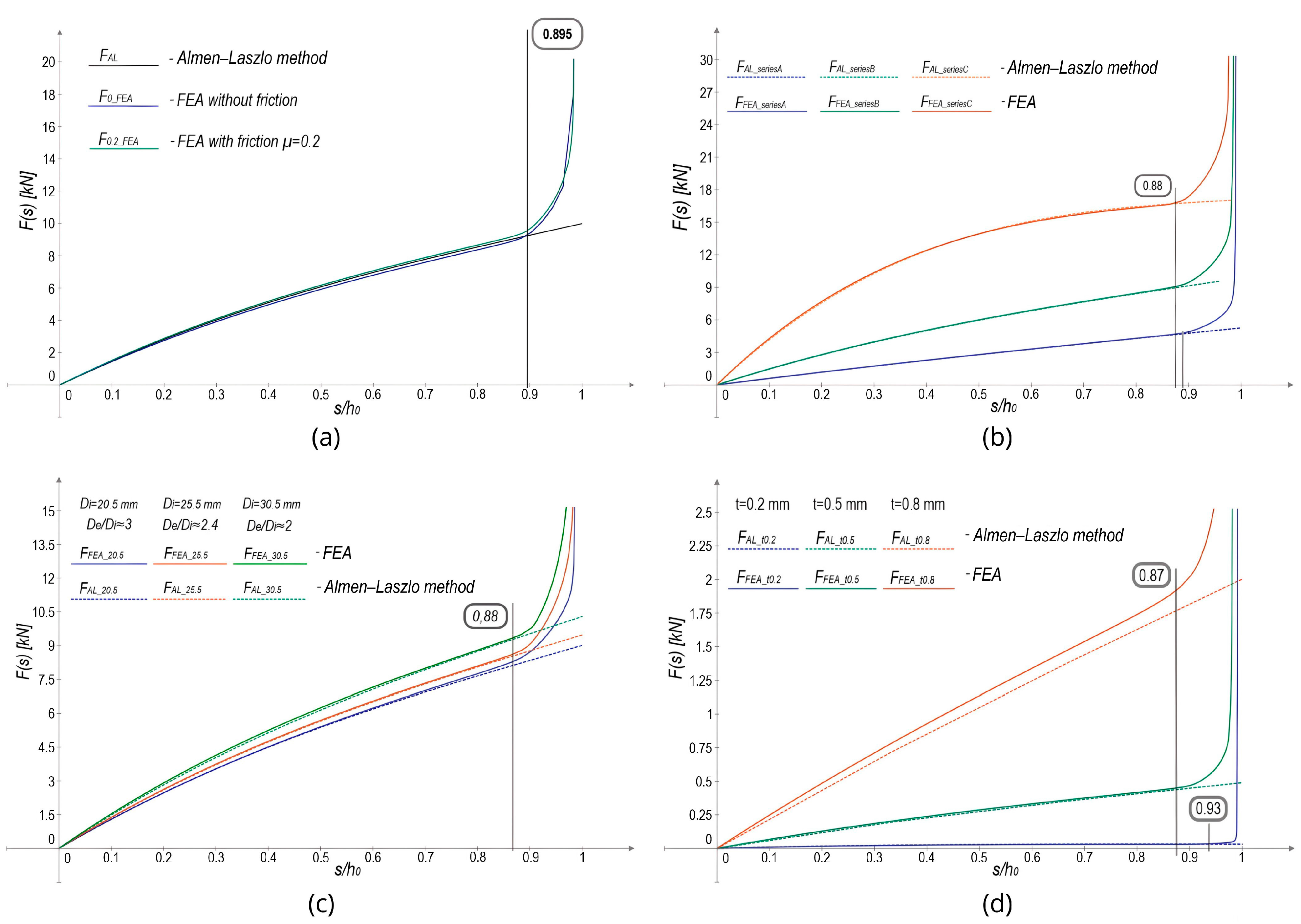

5.1. Analysis of the Applicability Range of Belleville Springs

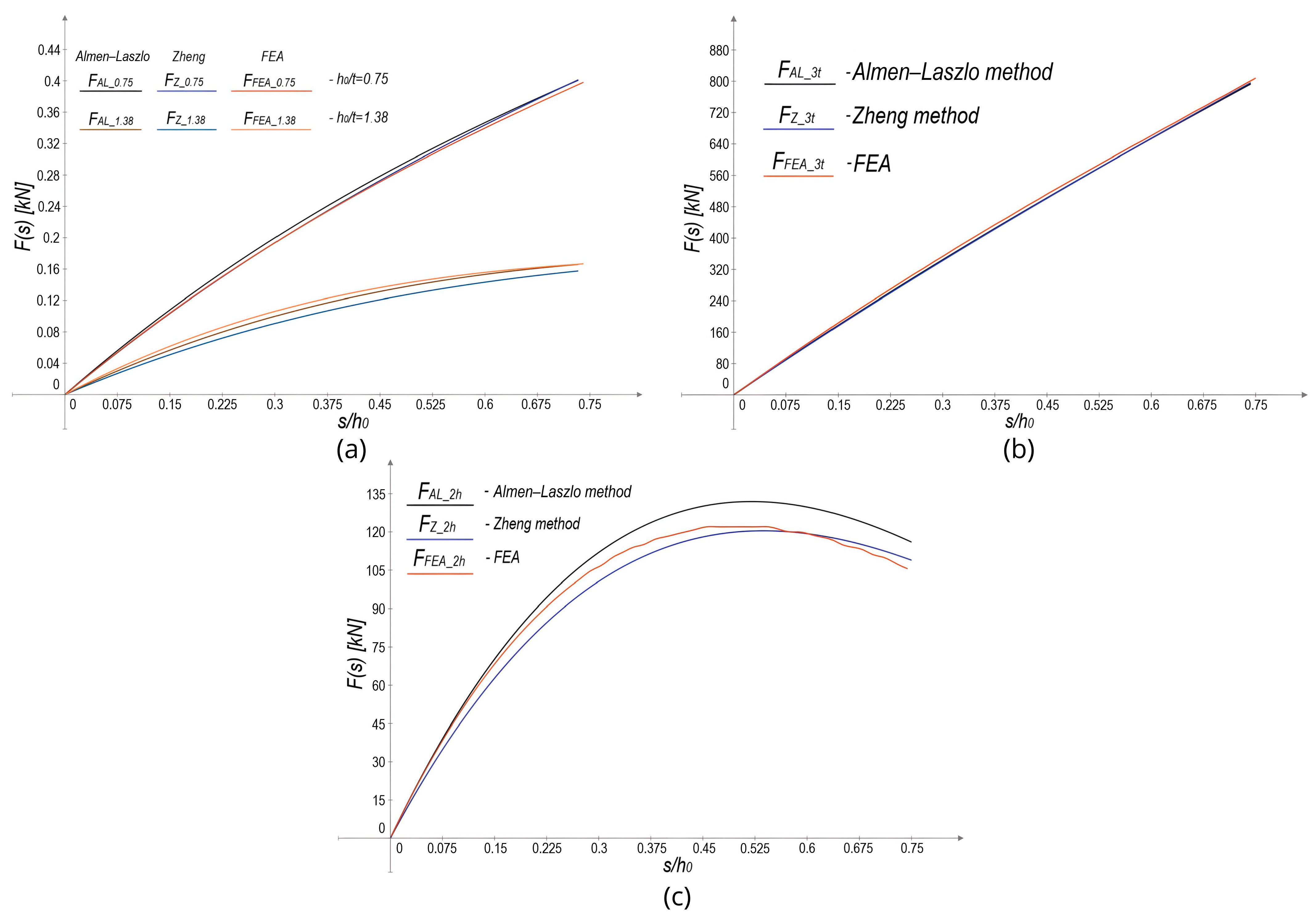

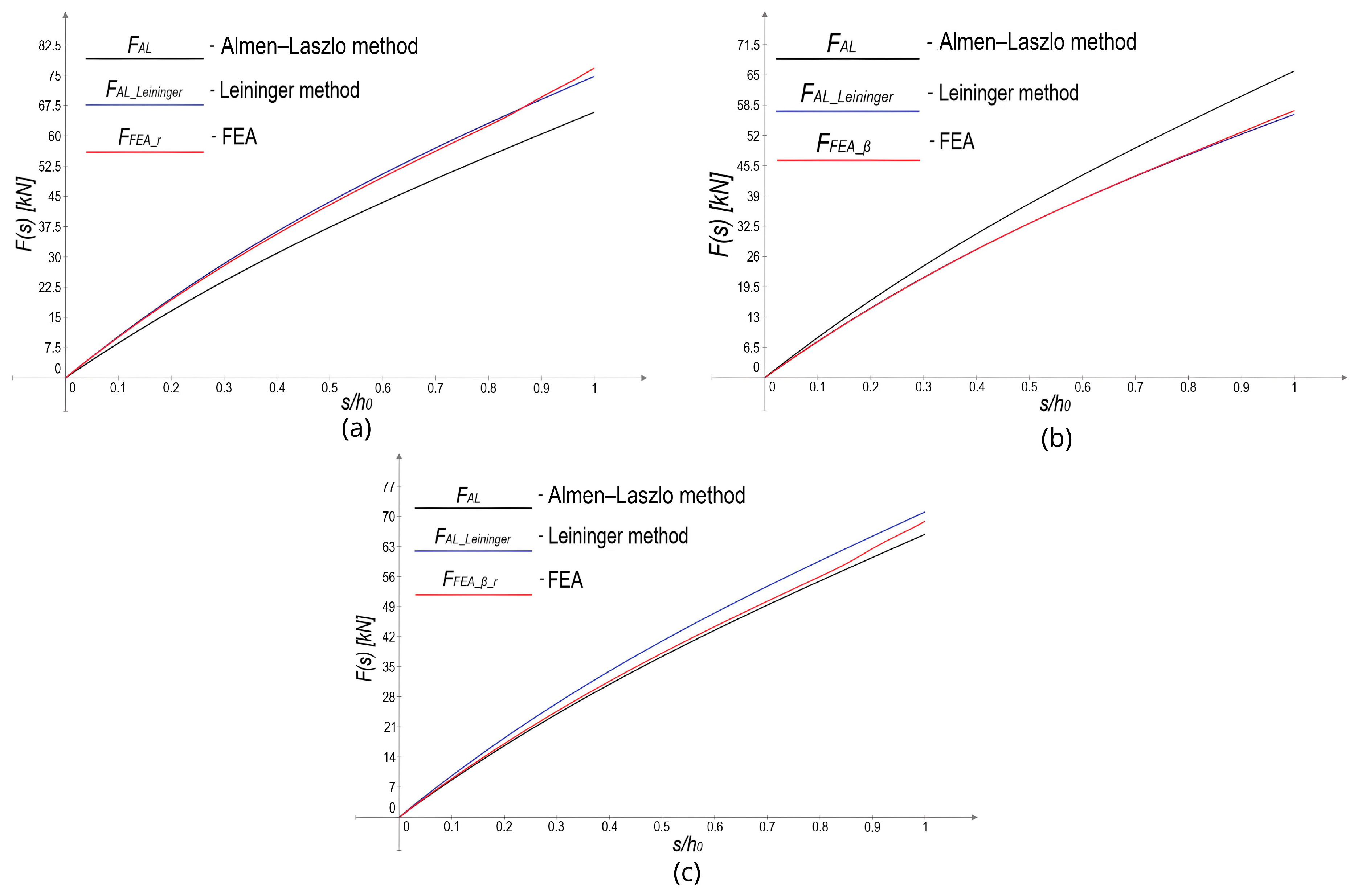

5.2. Comparative Analysis of the Zheng Method and the Almen–Laszlo Method

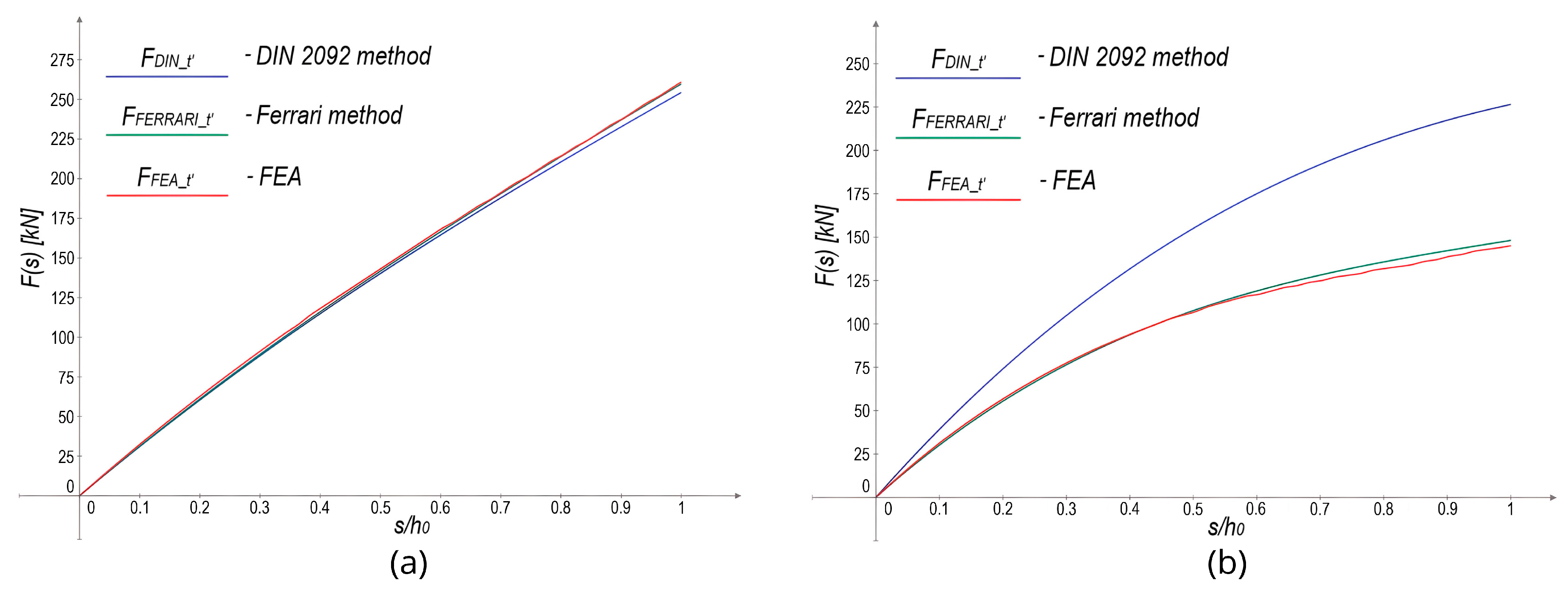

5.3. Verification of Ferrari’s Method for Belleville Springs with Contact Flats

5.4. Verification of Leininger’s Method

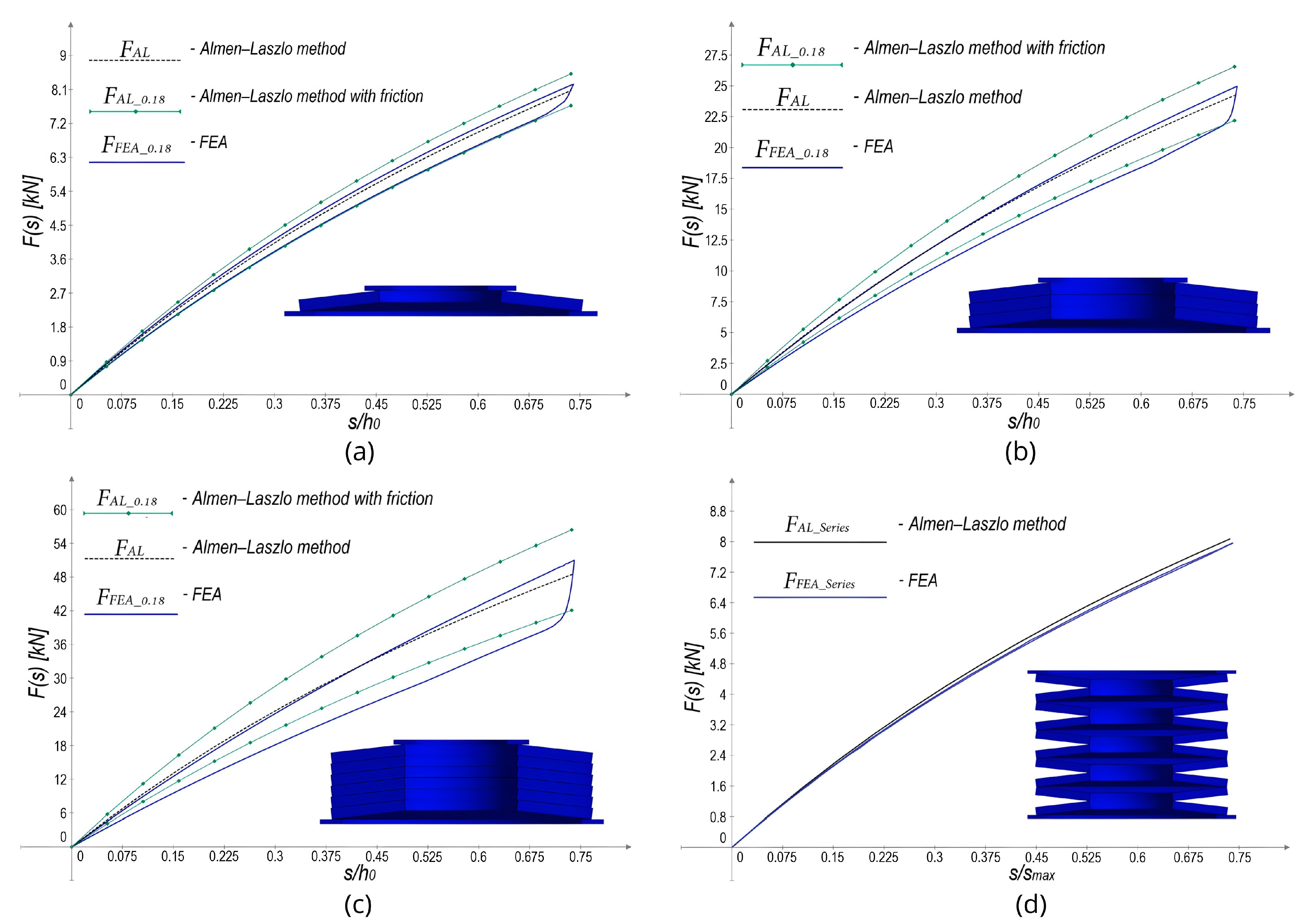

5.5. Effect of Friction on Disc Springs

6. Discussion

7. Algorithm for Selecting the Calculation Method for a Belleville Spring

Summary Description of the Methods and the Scope of Their Applicability

- (I)

- Almen–Laszlo Method

- Description: A widely used analytical method for calculating the force-deformation characteristics of Belleville springs.

- Applicability: Suitable for standard disc springs with a rectangular cross-section without contact flats and when the spring geometry adheres to typical industrial standards (e.g., DIN 2092, DIN 2093).

- (II)

- Zheng Method

- Description: An alternative analytical method that improves the accuracy for springs without contact flats with a higher ratio of cone height to thickness .

- Applicability: Best for non-standard disc springs, those exhibiting higher non-linearity and greater ratio, which exceeds the ratio for the springs from series C according to DIN 2093 (.

- (III)

- Leininger Method

- Description: A method introducing reduced values to the Almen–Laszlo or Zheng method to account for curved edges and non-rectangular cross-sectional shape. For Belleville springs without contact flats.

- Applicability: Most accurate for springs with highly non-rectangular cross-sections. For small values of the radius and the angle of deviation , this method proved to yield less accurate results compared to the Almen–Laszlo method. Therefore, its use is recommended only for high values of and , such as and .

- (IV)

- DIN 2092 Method for Springs with Contact Flats

- Description: The modified Almen–Laszlo method enabling the determination of the characteristic for standard Belleville springs with contact flats, where the ratio adheres to the specifications outlined in the DIN 2093 standard.

- Applicability: This method yields inaccurate results for Belleville springs with a non-standard ratio , with deviations increasing as the difference from this ratio becomes larger.

- (V)

- Giammarco Ferrari Method

- Description: A method for calculating Belleville springs with contact flats, where the accuracy is not dependent on the ratio.

- Applicability: The method provides accurate force calculations for non-standard ratios, with the results closely matching the DIN 2092 method for .

8. Development of a Calculation Method for Belleville Spring Assemblies with a Quasi-Progressive Characteristic

8.1. General Formula for the Characteristic of a Belleville Spring Assembly Consisting of Identical Springs Arranged in Segments Separated by Limiters

- (Ia)

- Analytical method (as shown in Appendix A.1)

- (Ib)

- The method with parameters corrected based on the FEM model (as shown in Appendix A.2)

- (II)

- Substituting the determined coefficients into the general formula for force in the stack

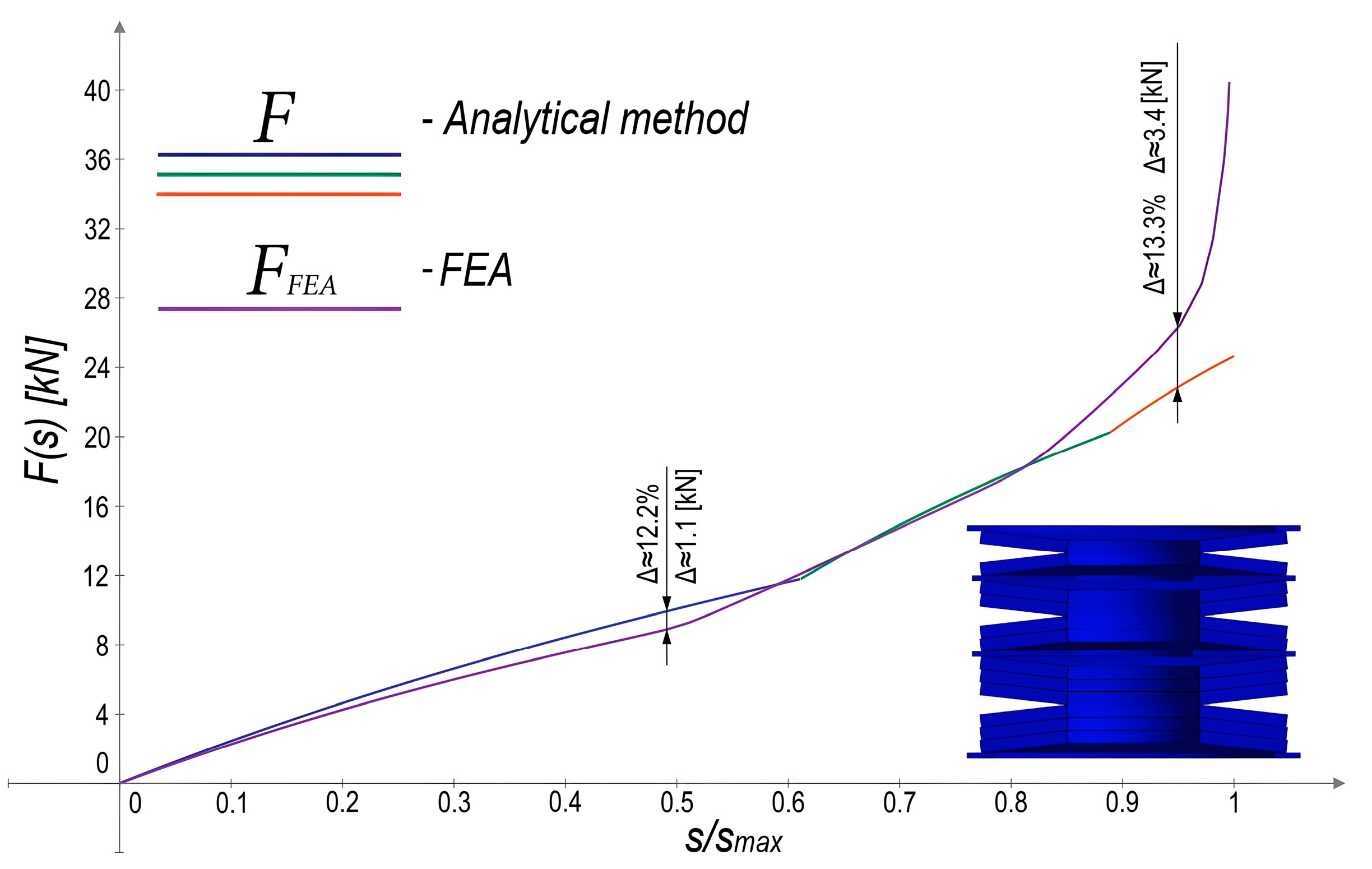

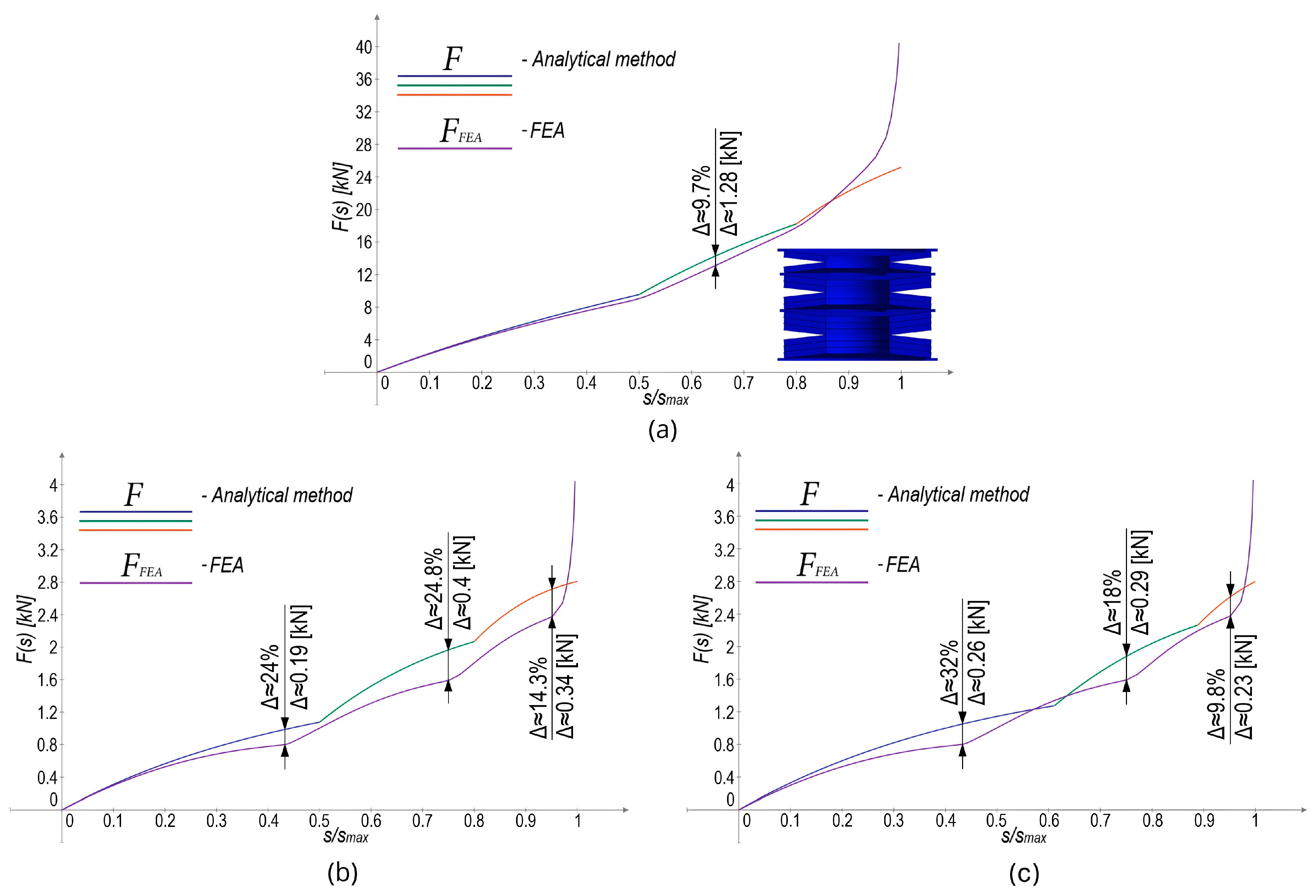

8.2. Comparison of the Developed Analytical Method with the FEA Results

8.3. Adjustment of Parameters for the Developed Analytical Method Based on the Obtained FEA Results

8.4. Conclusions Regarding the Developed Method for Calculating Belleville Spring Assemblies with a Quasi-Progressive Characteristic

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Outside diameter | [mm] | |

| Reduced outside diameter | [mm] | |

| Inside diameter | [mm] | |

| Reduced inside diameter | [mm] | |

| Disc thickness | [mm] | |

| Reduced disc thickness | [mm] | |

| Initial cone height | [mm] | |

| Reduced initial cone height | [mm] | |

| Free overall height of spring in its initial position | [mm] | |

| Reduced free overall height of spring in its initial position | [mm] | |

| Spring deflection | [mm] | |

| Spring cone angle | [°] | |

| Young’s modulus | [MPa] | |

| Poisson’s ratio | [-] | |

| Ratio of the outside diameter to the inside diameter of the spring | [-] | |

| Number of springs in parallel | [-] | |

| Number of springs in series | [-] | |

| Friction coefficient between the conical surfaces of the springs | [-] | |

| Friction coefficient on the contact surface | [-] | |

| Modified outside diameter according to Leininger’s method [33] | [mm] | |

| Modified initial cone height according to Leininger’s method [33] | [mm] | |

| Modified coefficient according to Leininger’s method [33] | [-] | |

| Modified radius of a spring according to Leininger’s method [33] | [mm] | |

| Deflection-dependent lever arm according to Leininger’s method [33] | [mm] | |

| Nomenclature specific for the developed method | ||

| Number of all segments | [-] | |

| Segment number | [-] | |

| Number of active segments undergoing deformation | [-] | |

| Maximum deflection in a given deflection range | [mm] | |

| Maximum real deflection of the stack | [mm] | |

| Maximum calculated deflection of the stack | [mm] | |

| Parameter defining the deflection as a fraction of the maximum deflection at each stage | [-] | |

| Deflection of individual segments at each stage | [mm] | |

| Parameter defining the deflection as a fraction of the maximum deflection of a given segment at each stage | [-] | |

| Deflection range | [mm] | |

| Basic Equations | ||

| [-] | ||

| [-] | ||

| [-] | ||

| [-] | ||

| [-] | ||

| [-] | ||

| [-] | ||

| [-] | ||

| [mm] | ||

| [mm] | ||

| [-] | ||

| Basic equations specific for the developed method | ||

| [-] | ||

| [mm] | ||

| [mm] | ||

| [mm] | ||

Appendix A. The Process of Developing a New Computational Method for Belleville Spring Assemblies with a Quasi-Progressive Characteristic

Appendix A.1. Development of an Analytical Method

- (I)

- , ,

- (II)

- ,

- (III)

- ,

Appendix A.2. Adjustment of the Parameters for the Developed Analytical Method Based on the Obtained FEA Results

| Parameter | Calculated Analytically | Determined from the FEA Model | |

|---|---|---|---|

| Flattening of the first segment | |||

| Flattening of the second segment | |||

| Stage I (until the flattening of the first segment) | Deflection of the first segment | ||

| Deflection of the second segment | |||

| Deflection of the third segment | |||

| Stage II (until the flattening of the second segment) | Deflection of the second segment | ||

| Deflection of the third segment | |||

| Deflection of the third stage (to the final deflection of the stack) | |||

- (I)

- , , ,

- (II)

- , ,

- (III)

- ,

References

- Howell, L.L.; Magleby, S.P.; Olsen, B.M. Handbook of Compliant Mechanisms; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2013; ISBN 9781118516515. [Google Scholar]

- Mott, R.L.; Vavrek, E.M.; Wang, J. Machine Elements in Mechanical Design; Pearson: London, UK, 2018; ISBN 0134441184. [Google Scholar]

- Wahl, A.M. Mechanical Springs, 1st ed.; Penton Publishing Company: New York, NY, USA, 1944. [Google Scholar]

- Yamada, Y. Materials for Springs; Scholars Portal; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 9783540738114. [Google Scholar]

- Canale, L.C.F.; Penha, R.N.; Totten, G.E.; Canale, A.C.; Gasparini, M.R. Overview of Factors Contributing to Steel Spring Performance and Failure. Int. J. Microstruct. Mater. Prop. 2007, 2, 262. [Google Scholar] [CrossRef]

- Bayoumi, M.R.; Abdellatif, A.K. Effect of Surface Finish on Fatigue Strength. Eng. Fract. Mech. 1995, 51, 861–870. [Google Scholar] [CrossRef]

- Avilés, R.; Albizuri, J.; Lamikiz, A.; Ukar, E.; Avilés, A. Influence of Laser Polishing on the High Cycle Fatigue Strength of Medium Carbon AISI 1045 Steel. Int. J. Fatigue 2011, 33, 1477–1489. [Google Scholar] [CrossRef]

- Beretta, S. Fatigue Strength and Surface Quality of Eutectoid Steel Wires. Int. J. Fatigue 1999, 21, 329–335. [Google Scholar] [CrossRef]

- Nishimura, Y.; Endo, M.; Yanase, K.; Ikeda, Y.; Miyakawa, S.; Miyamoto, N. High Cycle Fatigue Strength of Spring Steel with Small Scratches. In Advances in Structural Integrity; Springer: Singapore, 2018; pp. 541–548. [Google Scholar]

- SEA Spring Committee Spring Design Manual; Society of Automotive Engineers: Warrendale, PA, USA, 1995.

- Zhao, F.; Zhang, C.L.; Liu, Y.Z. Ferrite Decarburization of High Silicon Spring Steel in Three Temperature Ranges. Arch. Metall. Mater. 2016, 61, 1715–1722. [Google Scholar] [CrossRef]

- ASTM A232; Standard Specification for Chromium-Vanadium Alloy Steel Valve Spring Quality Wire. ASTM International: West Conshohocken, PA, USA, 2024.

- JIS G 3565; Specification for Chromium-Vanadium Alloy Steel Spring Wire. Japanese Industrial Standards Committee: Tokyo, Japan, 1994.

- GB/T 1222; Spring Steels. Standardization Administration of China: Beijing, China, 2016.

- Kotous, J.; Salvetr, P.; Procházka, R. New Approach to Heat Treatment of Spring Steel. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1178, 012031. [Google Scholar] [CrossRef]

- Hauserova, D.; Dlouhy, J.; Novy, Z. Microstructure and Properties of Hardened 100CrMnSi6-4 Bearing Steel After Accelerated Carbide Spheroidization and Long-Duration Annealing. In Bearing Steel Technologies: 10th Volume, Advances in Steel Technologies for Rolling Bearings; ASTM International: West Conshohocken, PA, USA, 2015; pp. 389–409. [Google Scholar]

- Saha, A.; Mondal, D.K.; Biswas, K.; Maity, J. Development of High Strength Ductile Hypereutectoid Steel by Cyclic Heat Treatment Process. Mater. Sci. Eng. A 2012, 541, 204–215. [Google Scholar] [CrossRef]

- Zhuang, M.; Wang, M.; Zhao, Y.; Zheng, B.; Guo, A.; Liu, J. Fabrication and High-Temperature Properties of Y-TZP Ceramic Helical Springs by a Gel-Casting Process. Ceram. Int. 2015, 41, 5421–5428. [Google Scholar] [CrossRef]

- Khader, I.; Koplin, C.; Schröder, C.; Stockmann, J.; Beckert, W.; Kunz, W.; Kailer, A. Characterization of a Silicon Nitride Ceramic Material for Ceramic Springs. J. Eur. Ceram. Soc. 2020, 40, 3541–3554. [Google Scholar] [CrossRef]

- Collins, J.A.; Busby, H.; Staab, G. Mechanical Design of Machine Elements and Machines, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; ISBN 978-0-470-41303-6. [Google Scholar]

- DIN 2092:1992-01; Design of Conical Disc Springs. German Institute for Standardization: Berlin, Germany, 1992.

- DIN 2093:1992-01; Disc Springs—Quality Specifications—Dimensions. German Institute for Standardization: Berlin, Germany, 1992.

- Almen, J.O.; Laszlo, A. The Uniform-Section Disk Spring. Trans. Am. Soc. Mech. Eng. 1936, 58, 305–314. [Google Scholar] [CrossRef]

- UNI ISO 8737:1991; Coned-Disc (or Belville) Springs. International Organization for Standardization: Geneva, Switzerland, 1991.

- Timoshenko, S. Strength of Materials, 2nd ed.; D. Van Nostrand Company, Inc.: New York, NY, USA, 1940; Volume 1, ISBN 10.0898746213. [Google Scholar]

- Boivin, M.; Bahuaud, J. Calcul Des Ressorts Diaphragmes. Mecanique 1974, 298, 24–31. [Google Scholar]

- Curti, G.; Orlando, M. A New Calculation of Coned Annular Disk Spring. In Proceedings of the ASME Winter Annual Meeting, New York, NY, USA, 5–10 December 1976. [Google Scholar]

- Hübner, W. Deformationen Und Spannungen Bei Tellerfedern. Konstruction 1982, 34, 387–392. [Google Scholar]

- Hübner, W. Axialsymmetrsche Große Defromationen Einer Elastischen Kegelschale. ZAMM 1982, 62, 408–411. [Google Scholar] [CrossRef]

- Muhr, K.H.; Niepage, P. Zur Berechnung von Tellerfedern Mit Rechteckigem Querschnitt Und Auflageflächen. Konstruktion 1966, 18, 24–27. [Google Scholar]

- Ferrari, G. A New Calculation Method for Belleville Disc Springs with Contact Flats and Reduced Thickness. Int. J. Manuf. Mater. Mech. Eng. 2013, 3, 63–73. [Google Scholar] [CrossRef][Green Version]

- Zheng, E.; Jia, F.; Zhou, X. Energy-Based Method for Nonlinear Characteristics Analysis of Belleville Springs. Thin-Walled Struct. 2014, 79, 52–61. [Google Scholar] [CrossRef]

- Leininger, D.S.; Geilen, M.B.; Klein, M.; Oechsner, M. A New Method for the Calculation of Characteristics of Disc Springs with Trapezoidal Cross-Sections and Rounded Edges. Materials 2022, 15, 1954. [Google Scholar] [CrossRef]

- Dubey, H.K.; Bhope, D.V.; Tahilyani, S.; Singh, K. Effects of Slots on Deflection and Stresses in Belleville Spring. Int. J. Eng. Sci. (IJES) 2013, 2, 43–48. [Google Scholar]

- Kiran, C.H.R.; Reddy, G.C.M.; Krishna, V.S.R.; Hussain, S. Effect of Diphenylamine Nano Additive with Pine Oil Biodiesel on Performance and Emission Characteristics of CI Engine. AIP Conf. Proc. 2021, 2317, 020041. [Google Scholar]

- Curti, G.; Montanini, R. On the Influence of Friction in the Calculation of Conical Disk Springs. Trans. ASME 1999, 121, 622–627. [Google Scholar] [CrossRef]

- Ozaki, S.; Tsuda, K.; Tominaga, J. Analyses of Static and Dynamic Behavior of Coned Disk Springs: Effects of Friction Boundaries. Thin-Walled Struct. 2012, 59, 132–143. [Google Scholar] [CrossRef]

- Maharjan, D.; Shah, S.; Abugharara, A.; Butt, S. Calculating Frictional Losses in Belleville Springs by Linear Interpolation. In Progress in Canadian Mechanical Engineering, Proceedings of the Canadian Society for Mechanical Engineering International Congress 2020, Charlottetown, PE, Canada, 21–24 June 2020; University of Prince Edward Island. Robertson Library: Charlottetown, PE, Canada, 2020; Volume 3. [Google Scholar]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 10th ed.; McGraw-Hill Education: New York, NY, USA, 2015; ISBN 978-0-07-339820-4. [Google Scholar]

- Paredes, M.; Daidié, A. Optimal Catalogue Selection and Custom Design of Belleville Spring Arrangements. Int. J. Interact. Des. Manuf. (IJIDeM) 2010, 4, 51–59. [Google Scholar] [CrossRef]

| Equation | Description | Unit |

|---|---|---|

| -Deflection range (corresponding to each deflection stage) | [mm] | |

| - Maximum calculated deflection | [mm] | |

| -Maximum deflection in a given deflection range | [mm] | |

| -A parameter defining deflection as a fraction of the maximum deflection at various stages | [-] | |

| -Deflection of individual segments in a given deflection range | [mm] | |

| -A parameter defining deflection as a fraction of the maximum deflection of a given segment at various stages | [-] |

| The Arrangement of a Belleville Spring Stack | Parameter | Determined from FEA Models |

|---|---|---|

| ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koralewski, J.; Wodtke, M. Determining the Range of Applicability of Analytical Methods for Belleville Springs and Novel Approach of Calculating Quasi-Progressive Spring Stacks. Machines 2025, 13, 349. https://doi.org/10.3390/machines13050349

Koralewski J, Wodtke M. Determining the Range of Applicability of Analytical Methods for Belleville Springs and Novel Approach of Calculating Quasi-Progressive Spring Stacks. Machines. 2025; 13(5):349. https://doi.org/10.3390/machines13050349

Chicago/Turabian StyleKoralewski, Jędrzej, and Michał Wodtke. 2025. "Determining the Range of Applicability of Analytical Methods for Belleville Springs and Novel Approach of Calculating Quasi-Progressive Spring Stacks" Machines 13, no. 5: 349. https://doi.org/10.3390/machines13050349

APA StyleKoralewski, J., & Wodtke, M. (2025). Determining the Range of Applicability of Analytical Methods for Belleville Springs and Novel Approach of Calculating Quasi-Progressive Spring Stacks. Machines, 13(5), 349. https://doi.org/10.3390/machines13050349