Design of an Articulated Neck to Assess Impact Head-Neck Injuries

Abstract

:1. Introduction

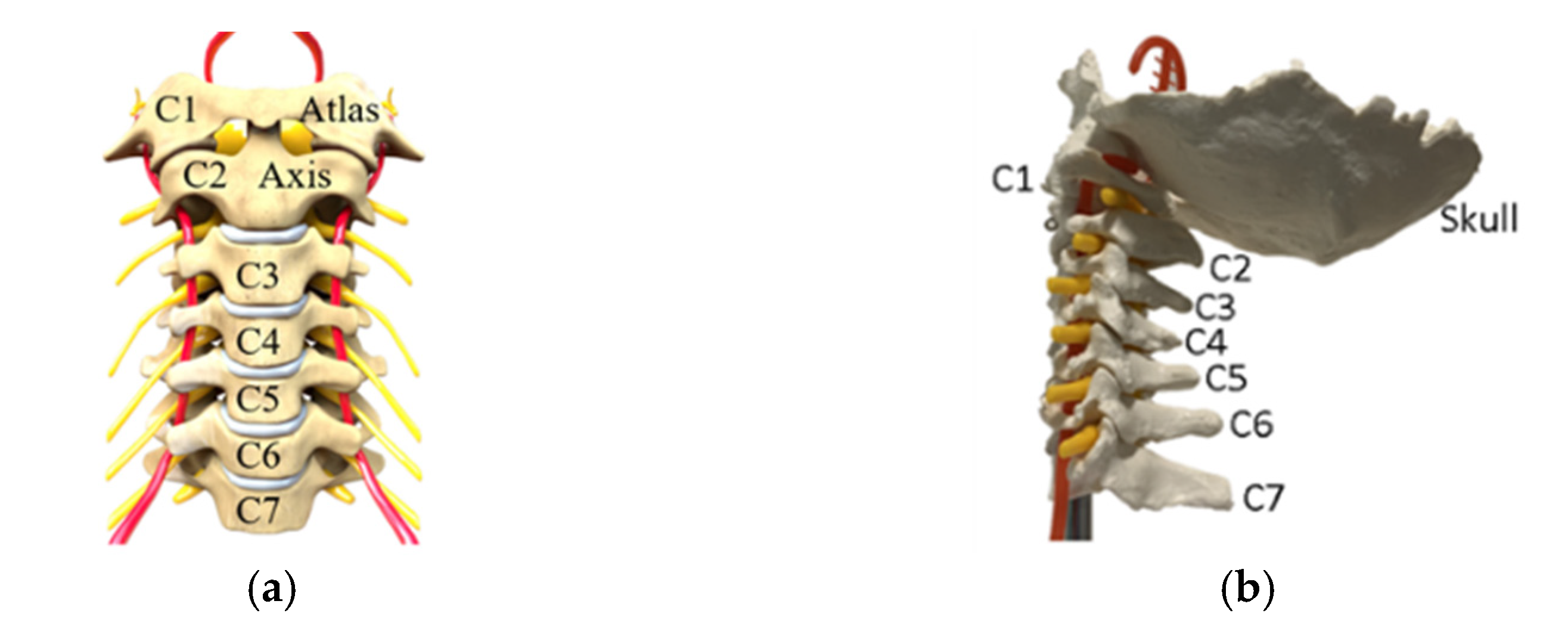

2. Problems and Requirements

- An articulated neck structure able to realistically simulate head impact events.

- A model of an articulated neck can consist of at least three cervical vertebrae if the neck motion ranges are fully achieved.

- The neck motions are considered in terms of flexion angles from 50° and extension up to 80°; rotation angles 140° (70° to each side) and lateral bending 45° to each side, as shown in Figure 2 for the complete neck motion range.

- A mechanical design should be defined with low-cost solutions for reasonably easy replacement of broken parts after an impact test, which commonly fails the element tested.

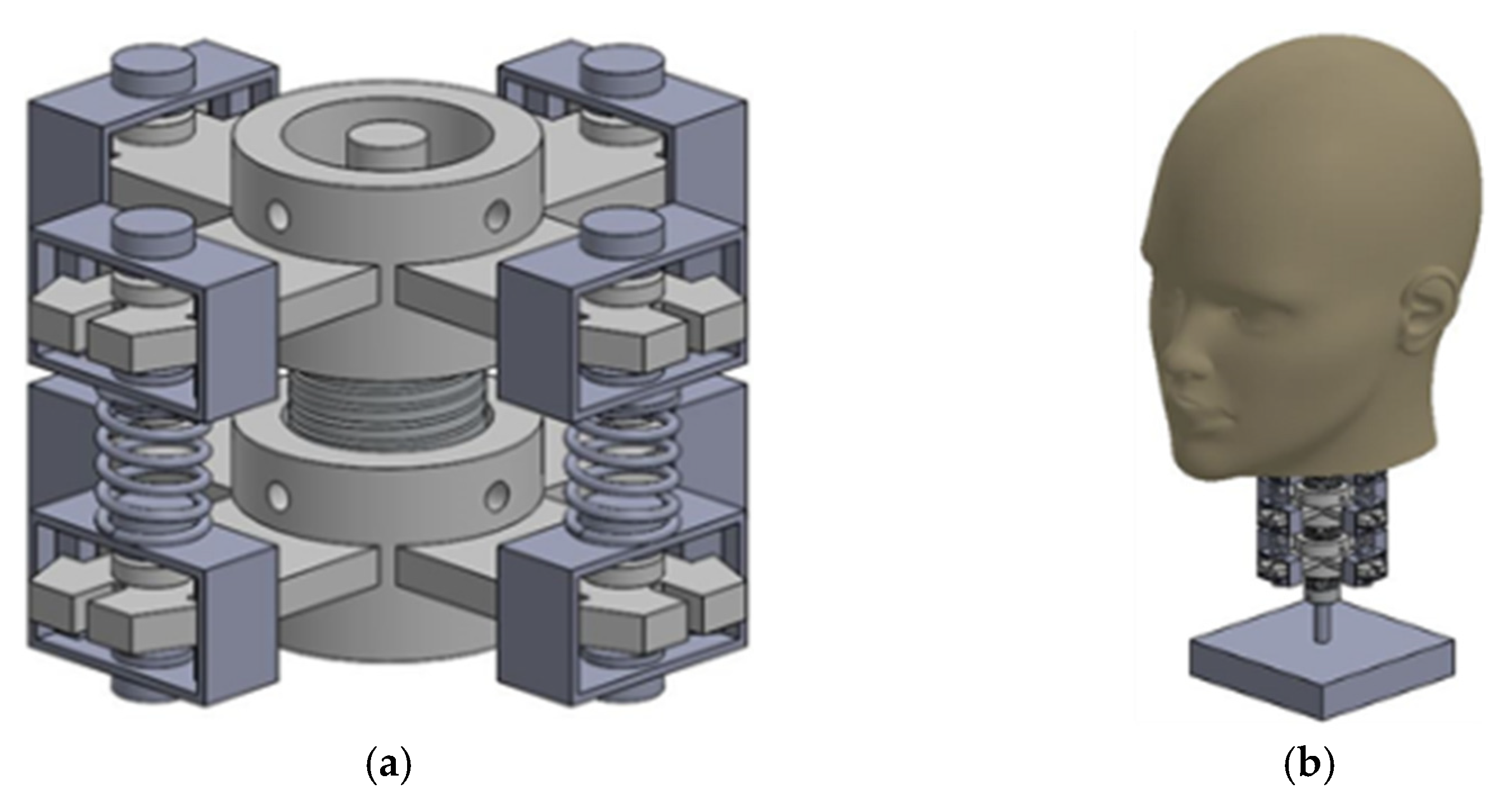

3. Modelling and Construction of the Articulated Neck

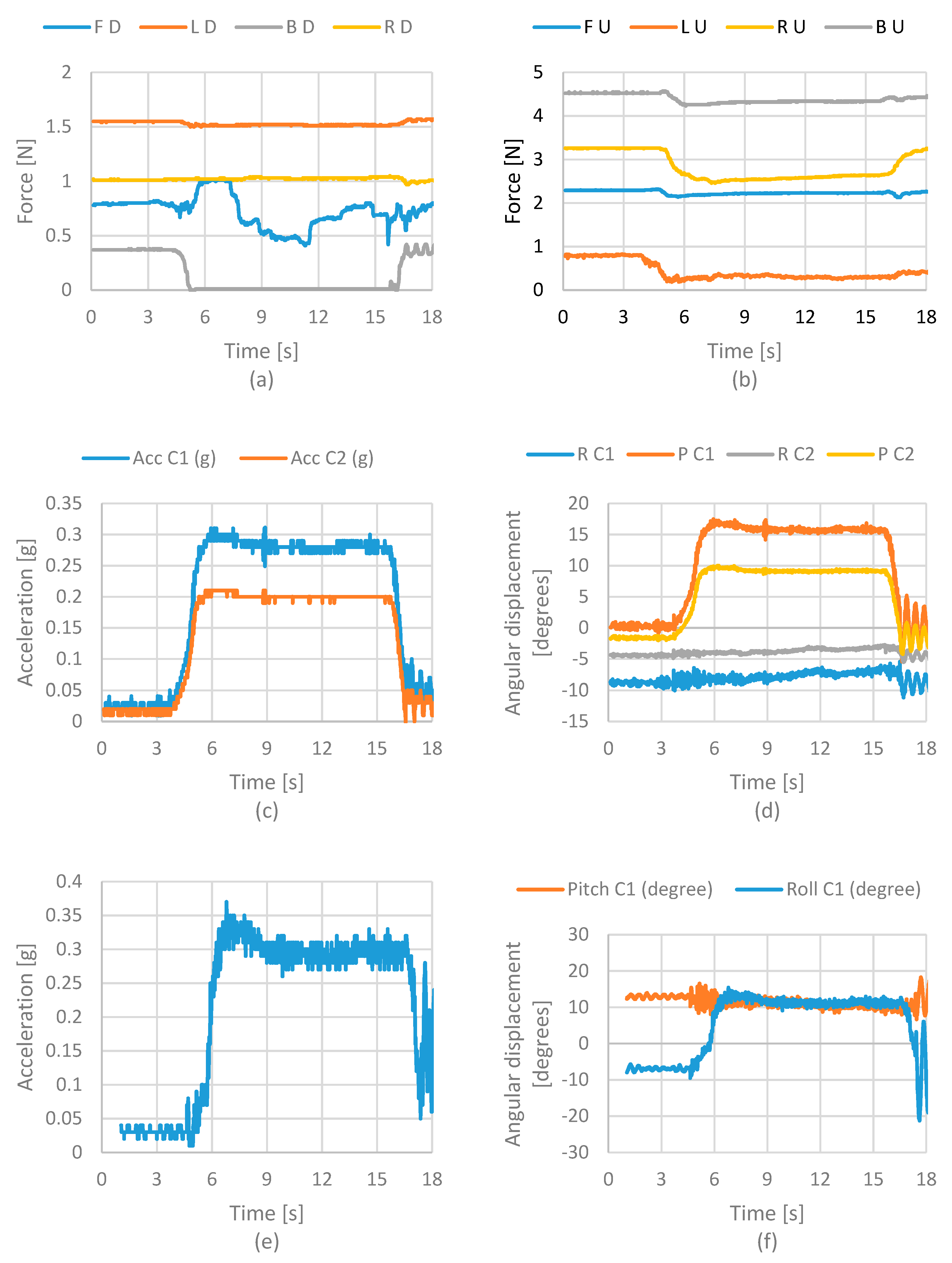

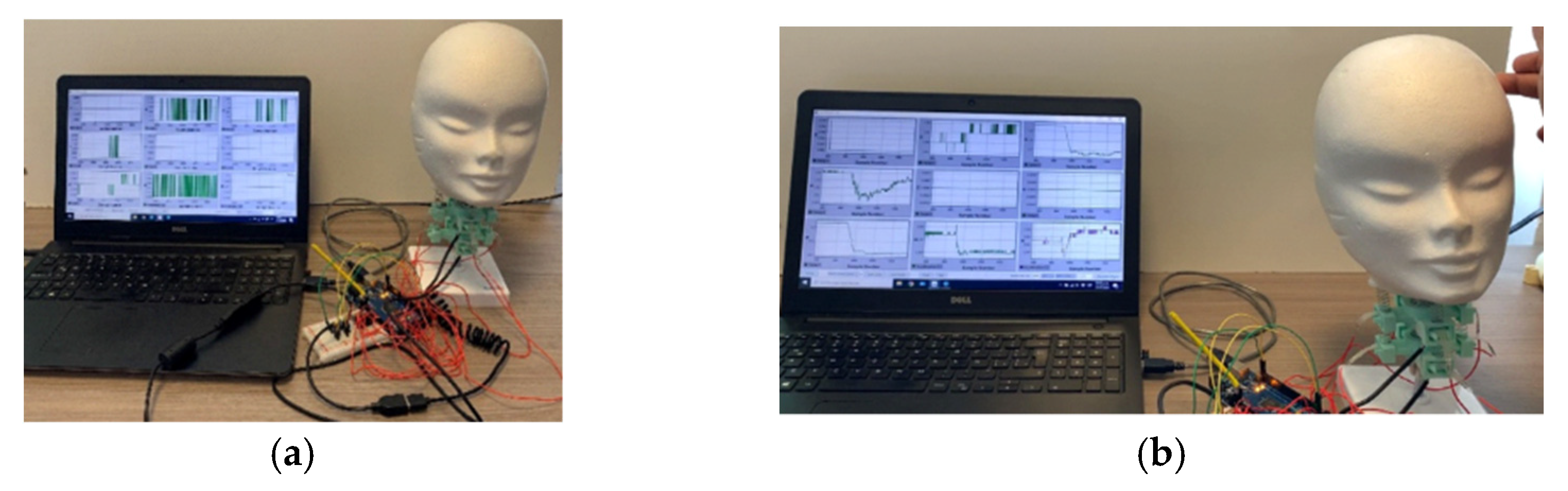

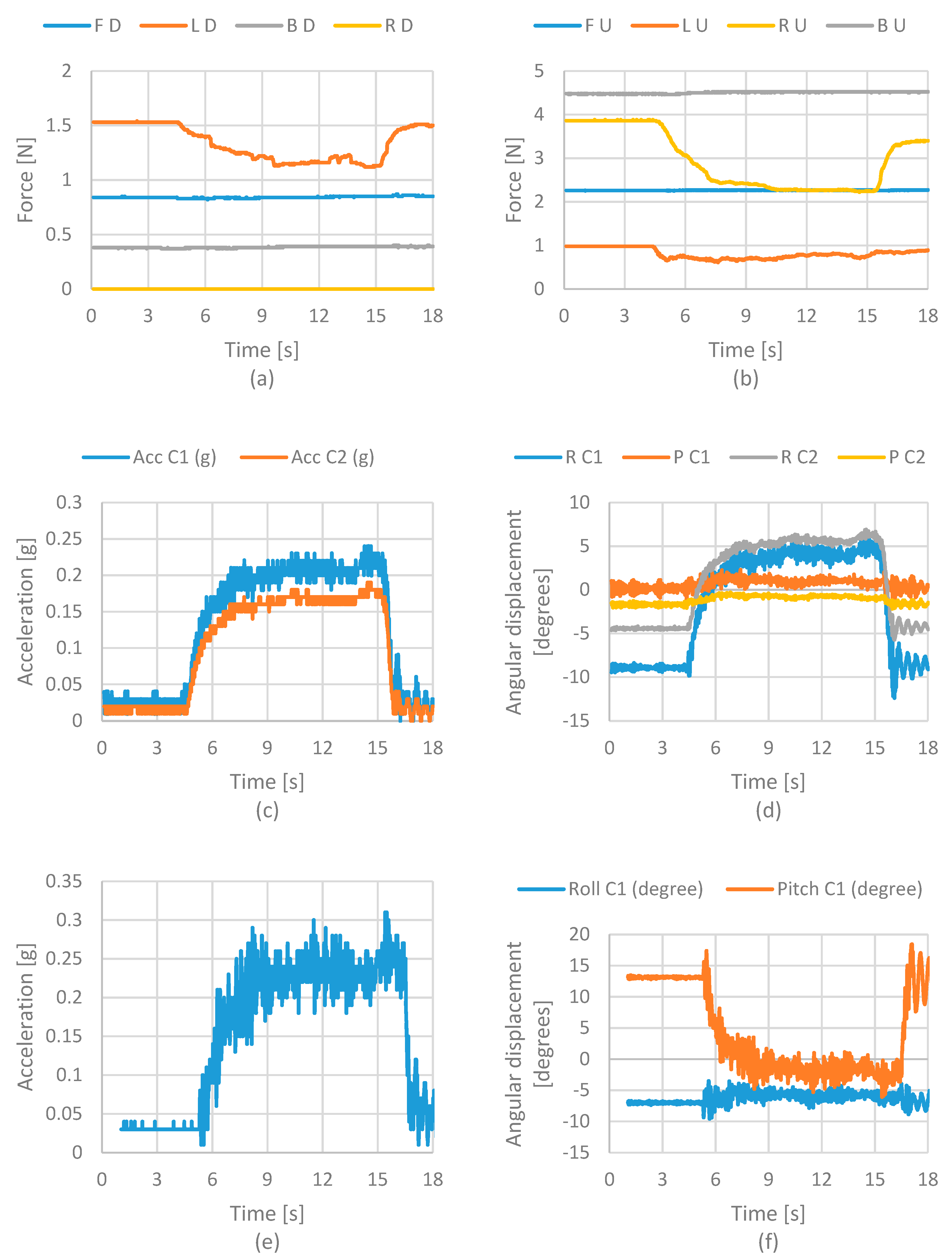

4. Test Modes and Results

5. Discussion

6. Conclusions

7. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, R.; Lim, J.; Mekary, R.A.; Rattani, A.; Dewan, M.C.; Sharif, S.Y.; Osorio-Fonseca, E.; Park, K.B. Traumatic Spinal Injury: Global Epidemiology and Worldwide Volume. World Neurosurg. 2018, 113, 345–363. [Google Scholar] [CrossRef]

- O’Connor, R.J.; Murray, P.C. Review of spinal cord injuries in Ireland. Spinal Cord. 2006, 44, 445–448. [Google Scholar] [CrossRef] [Green Version]

- Pickett, G.E.; Campos-Benitez, M.; Keller, J.L.; Duggal, N. Epidemiology of Traumatic Spinal Cord Injury in Canada. Spine 2006, 31, 799–805. [Google Scholar] [CrossRef] [PubMed]

- Löfvenmark, I.; Norrbrink, C.; Nilsson-Wikmar, L.; Hultling, C.; Chakandinakira, S.; Hasselberg, M. Traumatic spinal cord injury in Botswana: Characteristics, aetiology and mortality. Spinal Cord 2015, 53, 150–154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sabre, L.; Remmer, S.; Adams, A.; Vali, M.; Rekand, T.; Asser, T.; Kõrv, J. Impact of fatal cases on the epidemiology of traumatic spinal cord injury in Estonia. Eur. J. Neurol. 2015, 22, 768–772. [Google Scholar] [CrossRef] [PubMed]

- Kang, Y.; Ding, H.; Zhou, H.; Wei, Z.; Liu, L.; Pan, D.; Feng, S. Epidemiology of worldwide spinal cord injury: A literature review. J. Neurorestoratol. 2017, 6, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Albers, A.; Brudniok, S.; Ottnad, J.; Sauter, C.; Sedchaicharn, K. Upper body of a new Humanoid Robot—The Design of AMAR III. In Proceedings of the 6th IEEE-RAS International Conference on Humanoid Robots, Genova, Italy, 4–6 December 2006; pp. 308–313. [Google Scholar]

- Beira, R.; Lopes, M.; Praca, M.; Santos-Victor, J.; Bernardino, A.; Metta, G.; Becchi, F.; Saltaren, R. Design of the robot-cub (iCub) head. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, 2006 ICRA, Orlando, FL, USA, 15–19 May 2006; pp. 94–100. [Google Scholar]

- Gao, B.; Zhu, Z.; Zhao, J.; Jiang, L. Inverse Kinematics and Workspace Analysis of a 3 DOF Flexible Parallel Humanoid Neck Robot. J. Intell. Robot. Syst. 2017, 87, 211–229. [Google Scholar] [CrossRef]

- Bruneau, D.; Cronin, D.; Panzer, M.; Giudice, S.; Kent, R. Comparison of the Hybrid III Head and Neck to a Detailed Head and Neck Finite Element Model with Active Musculature, in a Football Impact Scenario. In Proceedings of the International Research Council on Biomechanics of Injury 2018 (IRCOBI 2018), Athens, Greece, 12–14 September 2018; pp. 322–323. [Google Scholar]

- Cruz-Jaramillo, I.L.; Miguel, C.R.T.S.; Cortes-Vásquez, O.; Martínez-Sáez, L. Numerical Low-Back Booster Analysis on a 6-Year-Old Infant during a Frontal Crash Test. Appl. Bionics Biomech. 2018, 2018, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Martinez, L.; Reed, M.P.; Garcia, A.; De Loma-Ossorio, M.; Torres, C.; Bueno, A. Crash impact dummies adapted to people affected by osteogenesis imperfect. In Proceedings of the IRCOBI Conference Proceedings—International Research Council on the Biomechanics of Injury, Malaga, Spain, 14–16 September 2016; pp. 768–769. [Google Scholar]

- Cruz-Jaramillo, I.L.; Torres-SanMiguel, C.R.; Leal-Naranjo, J.A.; Martínez-Sáez, L. Numerical child restraint system analysis in 6 years old infant during a dolly rollover test. Int. J. Crashworthiness 2020, 26, 404–412. [Google Scholar] [CrossRef]

- Cruz-Jaramillo, I.L.; Miguel, C.R.T.-S.; Martínez-Sáez, L.; Ramírez-Vela, V.; Urriologoitia-Calderón, G.M. Numerical Low-Back Booster Analysis in a 6-Year-Old Infant during a Dolly Rollover Test. J. Adv. Transp. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- Ramírez, O.; Torres-SanMiguel, C.R.; Cuautle-Estrada, A.; Rivera-Hernández, M.A. Design of a test bench for a sternum prosthesis. J. Phys. Conf. Ser. 2021, 1723, 012056. [Google Scholar] [CrossRef]

- Ramirez, O.; Ceccarelli, M.; Russo, M.; Torres-San-Miguel, C.R.; Urriolagoitia-Calderon, G. Experimental Dynamic Tests of RIB Implants. Springer: Dordrecht, The Netherlands, 2019; Volume 68. [Google Scholar]

- Ramirez, O.; Torres-San-Miguel, C.R.; Ceccarelli, M.; Urriolagoitia-Calderon, G. Experimental characterization of an osteosynthesis implant. Adv. Mech. Mach. Sci. 2019, 73, 53–62. [Google Scholar]

- Cuautle-Estrada, A.; Torres-SanMiguel, C.R.; Urriolagoitia-Sosa, G.; Martínez-Sáez, L.; Romero-Ángeles, B.; Urriolagoitia-Manuel, G.M. Simplified Test Bench Used to Reproduce Child Facial Damage During a Frontal Collision. In Engineering Design Applications III: Structures, Materials and Processe; Öchsner, A., Altenbach, H., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 23–29. [Google Scholar] [CrossRef]

- Arreguín, J.L.R.; Miguel, C.R.T.S.; Ceccarelli, M.; Vela, V.R.; Calderón, G.M.U. Design of a Test Bench to Simulate Cranial Sudden Impact. In New Trends in Medical and Service Robotics; Springer: Cham, Switzerland, 2019; pp. 225–234. [Google Scholar] [CrossRef]

- Yoganandan, N.; Pintar, F.A.; Moore, J.; Maiman, D.J. Sensitivity of THOR and Hybrid III Dummy Lower Neck Loads to Belt Systems in Frontal Impact. Traffic Inj. Prev. 2011, 12, 88–95. [Google Scholar] [CrossRef] [PubMed]

- Dibb, A.T.; Nightingale, R.W.; Chancey, V.C.; Fronheiser, L.E.; Tran, L.; Ottaviano, D.; Myers, B.S. Comparative Structural Neck Response of THOR-NT, Hybrid III, and Human in Combined Tension-Bending and Pure Bending. Stapp Car Crash J. 2006, 50, 567–581. [Google Scholar] [PubMed]

- Albert, D.L.; Beeman, S.M.; Kemper, A.R. Evaluation of Hybrid III and THOR-M neck kinetics and injury risk under various restraint conditions during full-scale frontal sled tests. Traffic Inj. Prev. 2018, 19, S40–S47. [Google Scholar] [CrossRef] [PubMed]

- Ludwinek, K.; Jurecki, R.; Jaskiewicz, M.; Szumska, E.; Sulowicz, M. A test stand for the experimental analysis of physical quantities during crash test at low speeds. In Proceedings of the XI International Science-Technical Conference Automotive Safety, Casta, Slovakia, 18–20 April 2018; pp. 1–7. [Google Scholar]

- Patton, K.T.; Thibodeau, G.A. Mosby’s Handbook of Anatomy & Physiology, 2nd ed.; Elsevier Health Sciences: Maryland Heights, MO, USA, 2014; pp. 119–124. [Google Scholar]

- Nieto, N.J.; Vinciguerra, A.; Brach del Prever, E.; Ceccarelli, M. Estimate of Torsional Stiffness and Shear Moduli of Human Cervical Spine Discs. Anales de Ingenierìa Mecànica Associazione Spagnola di Ingegneria Meccanica Murcia 1987, 5, 193–197. [Google Scholar]

- White, A.A.; Panjabi, M.M. Clinical Biomechanics of the Spine, 2nd ed.; Lippincott, Williams & Wilkins: Baltimore, MD, USA, 1999. [Google Scholar]

- Arosio, B.; Mongiardini, M.; Mattos, G.A. Comparison of hybrid III and human body model in head injury encountered in pendulum impact and inverted drop tests. In First International Roadside Safety Conference; EEUU: San Francisco, CA, USA, 2017. [Google Scholar]

- Humanetics©, Hybrid III 50th Male Dummy Parts Catalog, Humanetics Innivative Solutions, Inc. Available online: https://humanetics.humaneticsgroup.com/products/anthropomorphic-test-devices/frontal-impact/hybrid-iii-50th-male/hybrid-iii-50th-male (accessed on 15 January 2022).

- Ceccarelli, M.; Rueda Arreguin, J.L.; Torres San Miguel, C.R. Articulated Neck for Head Mannequin. 102020000005596, (Submitted on 28 May 2020).

- Rueda-Arreguin, J.L.; Ceccarelli, M.; Miguel, C.R.T.S. Design of an Articulated Neck for Testbed Mannequin. In Advances in Italian Mechanism Science; IFToMM ITALY; Springer: Cham, Switzerland, 2020; pp. 94–101. [Google Scholar]

- Parr, M.J.C.; Miller, M.E.; Bridges, N.R.; Buhrman, J.R.; Perry, C.E.; Wright, N.L. Evaluation of the Nij Neck 416 Injury Criteria with Human Response Data for Use in Future Research on Helmet Mounted Display Mass Properties. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, Boston, MA, USA, 22 October 2012; Volume 56, pp. 2070–2074. [Google Scholar]

- Kleinberger, M.; Sun, E.; Eppinger, R.; Kuppa, S.; Saul, R. Development of improved injury criteria for the assessment of advanced automotive restraint systems. NHTSA Docket 1998, 4405, 12–17. [Google Scholar]

- Rueda Arreguín, J.L.; Ceccarelli, M.; Torres-San-Miguel, C.R.; Morales Cruz, C. Lab Experiences on Impact Biomechanics of Human Head. In Mechanisms and Machine Science; MESROB 2020; Springer: Cham, Switzerland, 2020; Volume 93, pp. 229–237. [Google Scholar]

- Rueda Arreguín, J.L.; Ceccarelli, M.; Torres-San-Miguel, C.R. Design and Simulation of a Parallel-Mechanism Testbed for Head Impact. In Mechanisms and Machine Science; RAAD 2020; Springer: Cham, Switzerland, 2020; Volume 84, pp. 400–407. [Google Scholar]

- Fernandes, F.A.; de Sousa, R.A. Head injury predictors in sports trauma—A state-of-the-art review. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2015, 229, 592–608. [Google Scholar] [CrossRef] [PubMed]

| Impact Test | HIC Value |

|---|---|

| 1 | 0.298 |

| 2 | 0.311 |

| 3 | 0.294 |

| 4 | 0.305 |

| 5 | 0.302 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rueda-Arreguín, J.L.; Ceccarelli, M.; Torres-SanMiguel, C.R. Design of an Articulated Neck to Assess Impact Head-Neck Injuries. Life 2022, 12, 313. https://doi.org/10.3390/life12020313

Rueda-Arreguín JL, Ceccarelli M, Torres-SanMiguel CR. Design of an Articulated Neck to Assess Impact Head-Neck Injuries. Life. 2022; 12(2):313. https://doi.org/10.3390/life12020313

Chicago/Turabian StyleRueda-Arreguín, José Luis, Marco Ceccarelli, and Christopher René Torres-SanMiguel. 2022. "Design of an Articulated Neck to Assess Impact Head-Neck Injuries" Life 12, no. 2: 313. https://doi.org/10.3390/life12020313

APA StyleRueda-Arreguín, J. L., Ceccarelli, M., & Torres-SanMiguel, C. R. (2022). Design of an Articulated Neck to Assess Impact Head-Neck Injuries. Life, 12(2), 313. https://doi.org/10.3390/life12020313